Page 1

LFC

Flock Gun

with Quart Aluminum Cup

OPERATING INSTRUCTIONS & REPLACEMENT PARTS

(NEW) INSTRUCTIONS AND PARTS LIST LFC-8/31/2011

Supersedes Instructions & Parts List LFC-8/19/2009

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult the

product label and Material Safety Data Sheet supplied for the

spray materials being used. Follow all safety precautions. Use

equipment in Well Ventilated Area to remove flammable or

explosive fumes, dust or overspray. Regular maintenance

checks for material residue must be performed to remove any

fire or explosion hazard. Exhaust fans should be checked for

build-up and kept clean. Filters must be changed frequently

and disposed of properly. Never use glass containers.

M A X I M U M A I R P R E S S U R E 7 5 P . S . I .

FLOCK GUN USES:

Flock is being used for decorative purposes and functional

applications. New uses are being discovered daily in

utilizing this finishing material.

When flock is applied to toys, novelties, printed matter,

scenic backgrounds and window displays, the velour finish

is attractive and lasting.

Flock is employed for sound-deadening, as a build-up for

shock absorption, for felt like non-mar surface protection

and for gasket seal.

Flock is cotton, wool, rayon or other natural or synthetic

fibers cut to the lengths of 1/64", 1/32" or 1/16". Longer

fibers are not recommended for the LFC Flock Gun. The

binder or adhesive is a silk screen process color or a

special adhesive. Both flock and binder are obtainable at

leading paint supply stores. Binder colors vary from the

deepest black to delicate pastel shades. For good matches

binder colors should be the same shade as flock used. By

varying binder shades, novel tones can be obtained.

DIRECTIONS . . .

1. Before connecting air hose from air supply to air inlet of

flock gun, blow out airline to remove any moisture and

other foreign matter. For art, display and small production

flocking for which the LFC Flock Gun is designed, use

Paasche’s D Air Compressor W/Switch. For high speed

work, a larger Air Compressor is required.

2. Fill cup three-quarters full with dry flock. Be sure it is

dry; damp flock will nest and may cause clogging of the

gun. For satisfactory operation of gun it is essential that

air be dry. To assure clean, dry air, a Paasche R2-1/4M

Regulator & Condenser Unit with manual drain is

recommended.

3. Screw cup onto gun. Make sure gasket is in position

and screw cover is on tight.

4. Adjust LF-61 Fan Guard for round or fan spray.

5. Start Air Compressor, open air line valve, pull trigger.

6. For spray adjustment, the LF-72 DIAL controls the

amount of air blowing flock through the multiplehead,

and the ajitator tube. Turn the dial all the way down until

it stops, then turn it counterclockwise until desired flow

is achieved.

7. When applying the flock, direct the spray at several

different angles to obtain good coverage. Release trigger

at end of each stroke to save material and assure uniform

coverage.

OPERATION SUGGESTIONS . . .

Binder may be applied with models AUFB and BUFB

Spray Guns or L Sprayer. They assure uniform

application of material.

For economic, sanitary and safety reasons, a CB or FB

Ventilating Flock Reclaiming Booth should be used for

recovering unused flock and removing dust and fumes as

illustrated in Paasche’s Industrial Catalog.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

Printed in the U.S.A.

Page 2

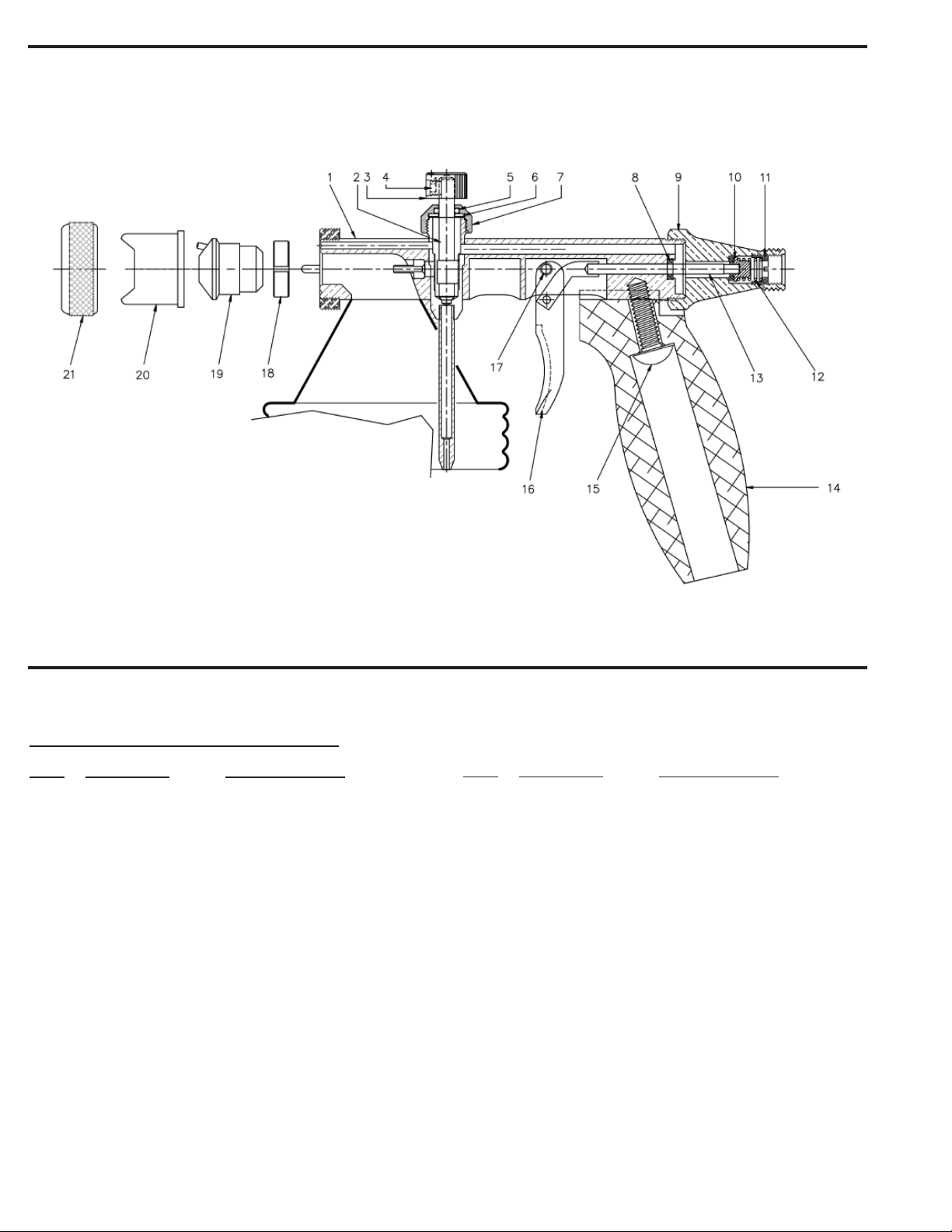

LFC FLOCK GUN Page 2

LFC FLOCK GUN COMPONENTS

No. Part No. Description

1. LF-53C Shell Assembly

2. LF-70 Valve Stem

3. LF-72 Dial

4. 200-11 Set Screw

5. D-339 PTFE “O” Ring

6. LF-73 Gland

7. LF-77 Cap

8. H-006 “O” Ring

9. U-49A Valve Casing

10. U-154P Air Valve Head

11. U-48 Strainer Nut

No. Part No. Description

12. U-1853 Air Valve Spring

13. L-83A Piston Rod

14. L-86 Handle

15. 1/4-20X3/4TR Truss Hd. Phillips Mach.

16. L-76A Trigger & Rod Assembly

17. U-40 Trigger Screw

18. LF-62 Friction Ring

19. LF-60A Aircap Body

20. LF-61 Fan Guard

21. BU-12 Aircap Nut

Loading...

Loading...