Page 1

LAC#3

ABRASIVE GUNS

OPERATING INSTRUCTIONS & REPLACEMENT PARTS

APPLICATIONS:

The LA Abrasive Gun has almost unlimited uses as an etching

tool for directory panels, directional signs and name plates; for

applying designs to plate glass and glassware, colored and

transparent plastics, stone, silver and other metals.

INSTRUCTIONS AND PARTS LIST LAC-8/31/21011

Supersedes Instructions & Parts list LAC-6/16/2010

WARNING: Read instructions for proper care in

handling and operation. Always wear a Respirator and

Goggles when using the LAC#3 Abrasive Gun. Use in

Well Ventilated Area to remove dust. Always read and

follow, Cautions and Warnings on materials being

sprayed. M a x i m u m A i r P r e ss u r e 1 00 P. S. I .

The application of such design on glass and metal, which is now

being used for wall surfaces, opens a new field for the decorator

equipped with an LA Abrasive Gun.

Stencils for production purposes may be rubber or metal. For a

single stenciling operation, stencil paper fastened with rubber

cement will prove adequate. Paint and art supply stores carry

necessary materials.

INSTRUCTIONS:

1. Abrasive guns can direct a limited amount of abrasive or a

strong blast when treating larger surfaces.

a. Trigger controls volume of air.

b. The nozzle can be adjusted and locked for material

control.

2. To operate: Fill polyethylene bottle 3/4 full of selected

abrasive. Use Aluminum Oxide, Pumice, Starch or other

abrasive that will pass through 30 to 100 mesh screen,

depending on etching speed and surface effect desired.

3. To adjust abrasive feed turn LAC-3 Aircap clockwise for

less feed, counter clockwise for more feed. Lock position

of aircap by tightening D-60 Locknut.

4. Air pressure of 30 to 100 lbs. is used depending upon

speed, texture and result desired.

5. With stencil design or mask properly placed on glass,

metal or other material to be treated, point LA Abrasive

Gun at the surface 2" to 6" from and directly above the

stencil. Pull trigger and spread abrasive evenly over the

part to be etched or blasted.

a. For a sharper line move gun closer to working surface.

b. Greater depth can also be obtained by continued

coverage of the part to be blasted, or by using sharper

abrasive.

6. For faster deeper cutting, or greater production, increase

air pressure and abrasive feed.

LAC#3 is suitable

for heavier spray

r e q u i r e m e n t s .

LAC#3 Abrasive

Gun has a steel tip

with Carbide insert

for longer life.

SBB-4 SANDBLAST BOOTH- (31" Shelf Height Above Floor,

3'6" x 2' Inside Dimensions) Abrasive material is confined within

the booth and falls through an expanded metal shelf to the bottom

where it is recovered. The tilting glass eye shield permits full view

of work area. The booth is constructed of 18 gauge galvanized

sheet steel, and can accommodate top or back exhaust. It is

available in standard sizes or can be manufactured to fit your

special requirements. SBB- Booth is furnished without an

exhaust system allowing the purchaser to furnish their own “Dust

Collection System” if desired. SBBV- Booth is furnished with a

Ventilating Unit to pull air and abrasive into the booth. Regulator

Moisture Condenser Unit and Abrasive Gun are optional

equipment, please specify your requirements.

AIR CONNECTIONS:

Air connections are 1/4" Standard Pipe Thread.

1. Attach air hose to outlet of compressor and blow out airline

to remove all foreign particles before connecting to

Abrasive Gun.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

Printed in the U.S.A.

Page 2

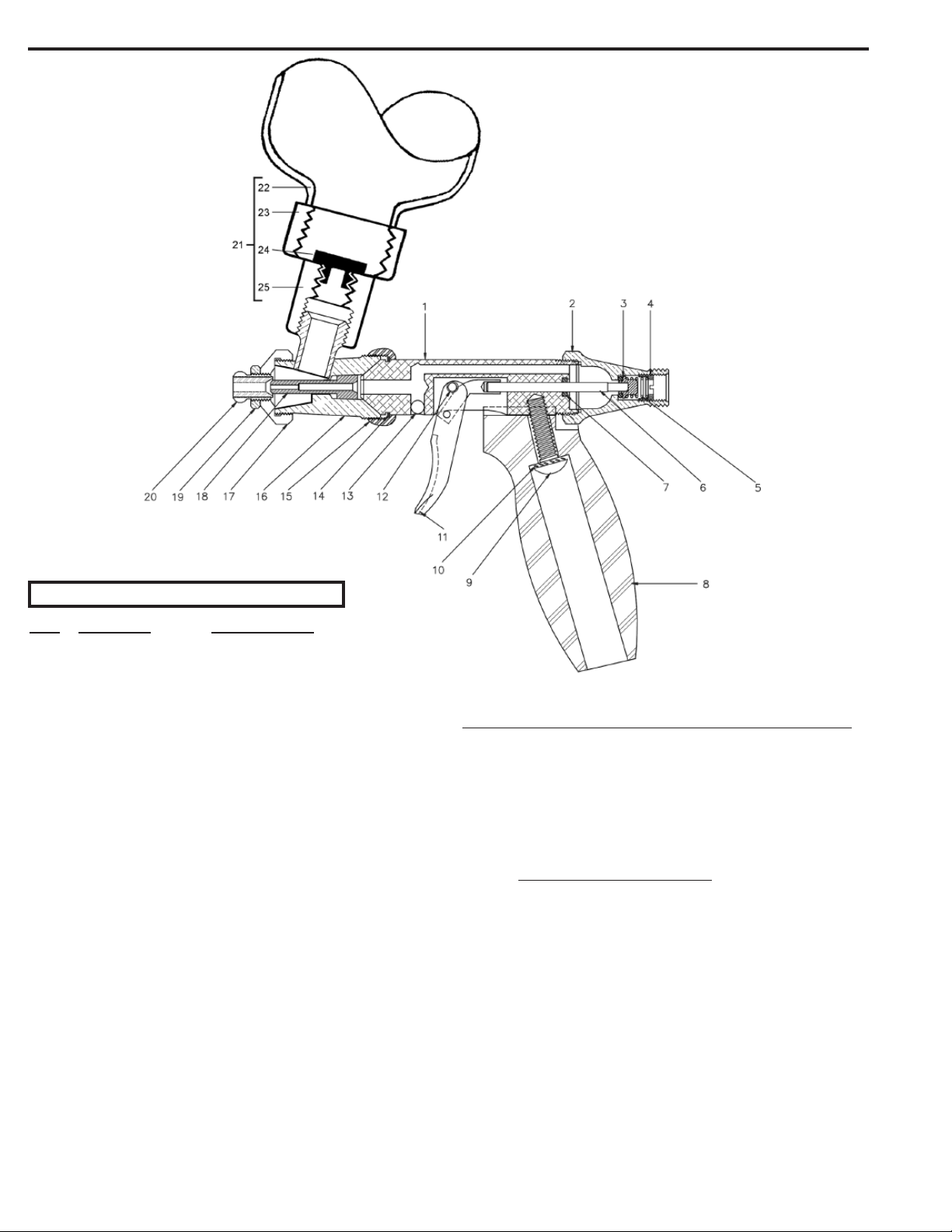

LAC#3 ABRASIVE GUN

LAC#3 Abrasive Gun Components

No. Part No. Description

LAC#3 ABRASIVE GUN W/CARBIDE INSERT TIP

1 LA-7C Shell

2 U-49A Valve Casing

3 U-154P Air Valve Head

4 U-48 Strainer Nut

5 U-1853 Air Valve Spring

6 L-83A Piston Rod

7 H-006 “O” Ring

8 L-86 Handle

9 1/4-20x3/4TR Truss Head Screw

10 1/4ETW External Tooth Lock Washer

11 L-76A Trigger & Rod Assembly

12 U-40 Trigger Screw

13 3/16SBB Ball Bearing Plug

14 U-2153 Retaining Ring

15 U-58 Nut

16 LA-6 Abrasive Body Assembly

17 LA-5 Aircap Nut

18 LA-3N Nozzle

19 D-60 Lock Nut

20 LAC-3 Carbide Insert Aircap

21 LA-27 Bottle Assembly

22 U-3391 Polyethylene Pint Bottle

23 U-3392 Polyethylene Bottle Cover

24 U-3393 Bushing

25 U-3394 Nut

Accessories for Abrasive Guns - not shown

HL-3/16-6 Air Hose with (2) HLC-3/16-1/4 Cplgs.

HF-1/4 Valve Assembly

U-2061 Fluid Control Screw (Old No.15)

U-1702 Valve Spring (Old No.16)

Abrasive Compounds

ALUMINUM OXIDE - Fast Cutting Compound

AEX-25 25 Lbs.

AEX-5 5 Lbs.

AEX-6 6 oz.

PUMICE - Medium Cutting Compound

AE-5 5 Lbs.

AE-6OZ 6 oz.

STARCH - Slow Cutting Compound

SSO-5 5 Lbs.

SSO-6 6 oz.

Page 2

Loading...

Loading...