Page 1

K R G & K R S

Manual Spray Guns

OPERATING INSTRUCTIONS AND REPLACEMENT PARTS

INSTRUCTIONS AND PARTS LIST KRG & KRS-8/31/2011

Supersedes Instructions & Parts List KRG & KRS-9/16/2010

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray material. Follow all safety precautions.

CAUTION: Well Vent ila ted Ar ea Required to re mov e

fumes, dus t or overspray. Secu re air hos e and fluid

hose wrench tight for safety and t o pr eve nt l eak s.

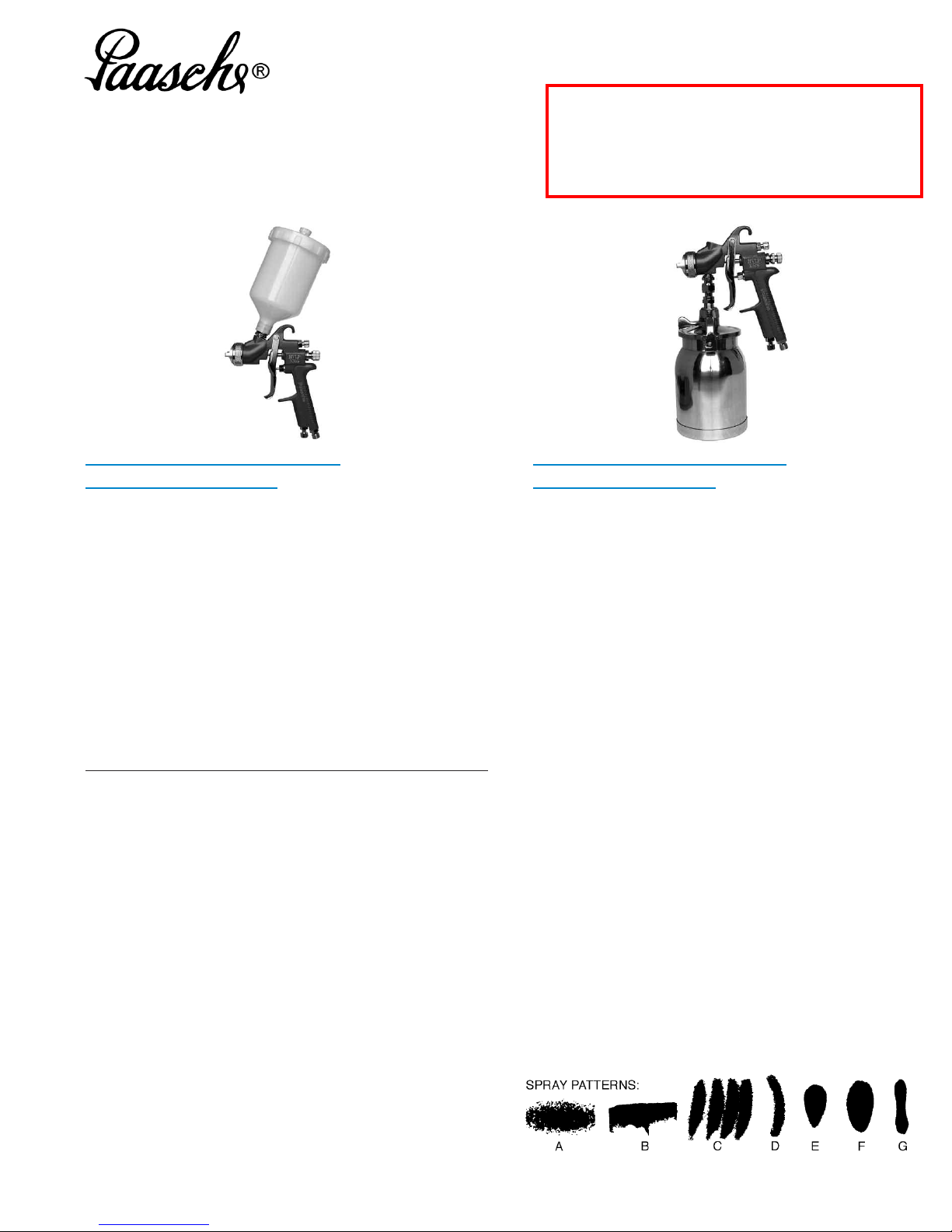

KRG MANUAL SPRAY GUNS

GRAVITY FEED HVLP

1.4 mm Fluid Nozzle and Needle. 20.29 oz.

nondrip plastic cup. Adjustable Fluid, Air and Fan

controls. 10.5 CFM @ 50 P.S.I.

Optional sizes available:

1.00 mm, 2.00 mm, 2.4 mm

Shipping Weight: 4 lbs. (1.8 kg)

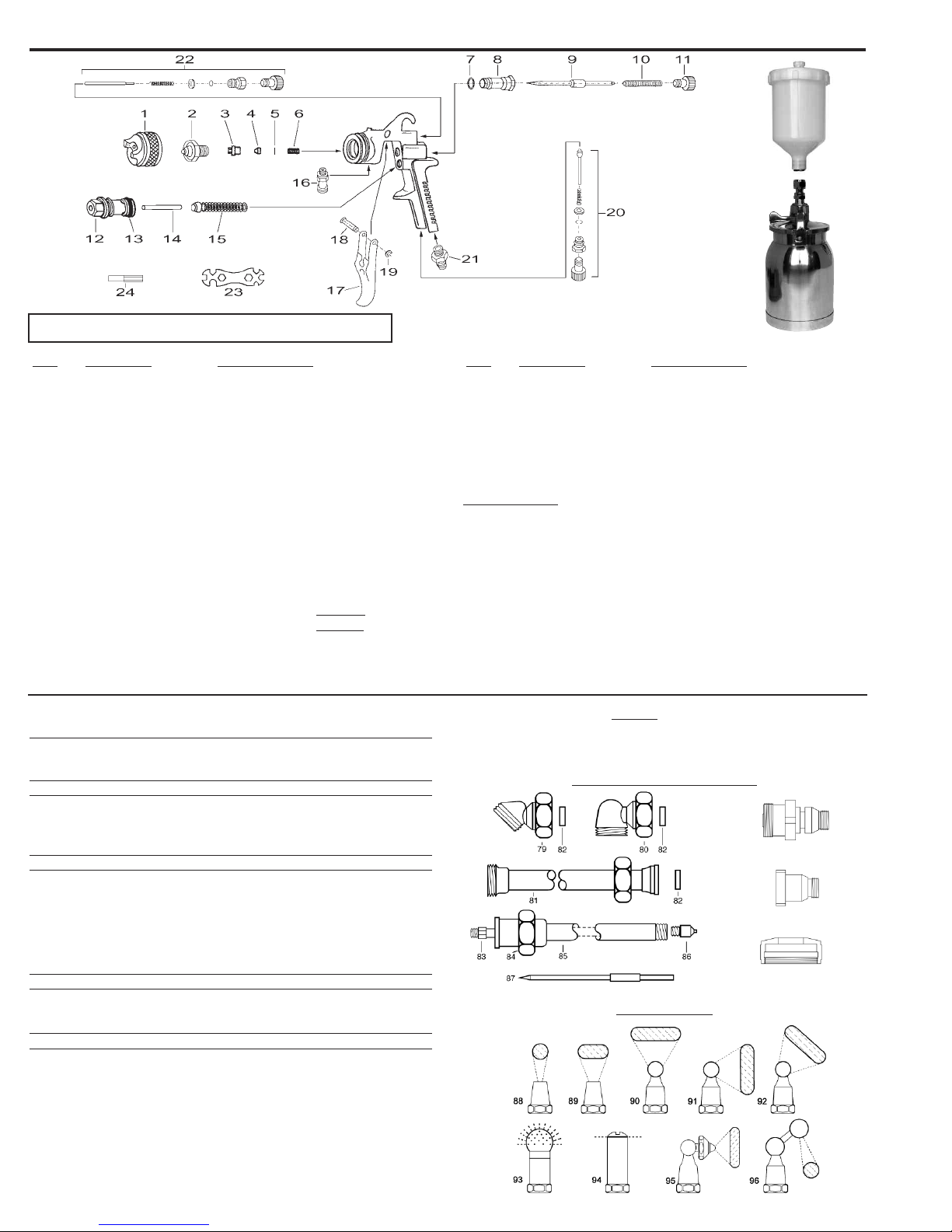

KRS MANUAL SPRAY GUNS

SIPHON FEED HVLP

1.4 mm Fluid Nozzle and Needle. One Quart

Siphon with Clamp Cover. Adjustable Fluid, Air and

Fan controls. 11.5 CFM @ 50 P.S.I.

Optional sizes available:

1.00 mm, 2.00 mm, 2.4 mm

Shipping Weight: 4 lbs. (1.8 kg)

Features: High quality finish. Nozzle and Needle components are made of durable Stainless Steel.

The paint flow regulator and fan regulator allow adjustment of quality fan spray. Ergonomically

designed for your spraying comfort.

TROUBLE SHOOTING SPRAY PATTERNS:

A. A ROUGH OR STIPPLE FINISH is due to low or restricted

flow of air pressure or heavy materials being applied with

the spray gun too close to surface.

B. A WET OR SAGGING FINISH is due to low air pressure or

restricted flow of air, material being too thin or applied too

close to the surface.

C. A SPUTTERING SPRAY is caused by air leaking into fluid

line or can be caused by a loose fluid tip, a broken or split tip,

lumpy material, a clogged vent hole in cover of material cup,

air leak at fluid pipe attached to inside of tank cover, or a

clogged paint strainer.

TO CORRECT: Tighten tip securely or replace. Strain

material and clean strainer. Sputtering might also be caused

by worn packing washers, or worn or scored needle.

D. AN ARCHED FAN SPRAY PATTERN is caused by dried

material accumulated in one fan port of the aircap, distorting

the pattern.

TO CORRECT: Dissolve material inside fan port with

suitable water/solvent applied with a small brush.

Never use wire or sharp instruments to clean fan ports

as permanent damage to the air ports will result in

altering uniformity of the fan spray pattern.

E. UNBALANCED FAN SPRAY PATTERN, heavy on one side,

may be caused by material collecting around outside of the

fluid tip and aircap, or by a loose aircap.

TO CORRECT: Remove aircap and clean fluid tip and aircap

with water/solvent, dry with air pressure. Always be sure fan

aircap and aircap body is tightened securely.

F. A HEAVY CENTER in a fan pattern is caused by insufficient

air pressure at the fan port. Rough or shady edges are also

caused by low air pressure.

TO CORRECT: Increase air line pressure.

G. A SPLIT FAN SPRAY PATTERN, heavy on each end and

light in the center, is caused by excessive air pressure.

TO CORRECT: Reduce air pressure.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

Printed in the U.S.A.

Page 2

Page 2 Models KRG & KRS

25

26

Models KRG & KRS - Components

NO. PART NO. DESCRIPTION

1. KR-01-10 *Aircap HVLP (1.0mm)

KR-01-14 *Aircap HVLP (1.4mm)

KR-01-20 *Aircap HVLP (2.0mm)

KR-01-24 *Aircap HVLP (2.4mm)

2. KR-02-10 *Fluid Nozzle HVLP (1.0mm)

KR-02-14 *Fluid Nozzle HVLP (1.4mm)

KR-02-20 *Fluid Nozzle HVLP (2.0mm)

KR-02-24 *Fluid Nozzle HVLP (2.4mm)

7. KR-07 Gasket

8. KR-08 Guide Nut

9. KR-09-10 *Fluid Needle for (1.0mm)

KR-09-14 *Fluid Needle for (1.4mm)

KR-09-20 *Fluid Needle for (2.0mm)

KR-09-24 *Fluid Needle for (2.4mm)

11. KR-11 Fluid Adjusting Knob

16. KRG-16G Fluid Nipple for Gravity

KRS-16S Fluid Nipple for Siphon

17. KR-17 Trigger

18. KR-18 Trigger Pin/Stud

19. KR-19 “E” Stopper

KRG and KRS Models ar e not HVLP

when using E xtensions and Ac cessories

79. AEN-45 45° Elbow 80. AEN-90 90° Elbow

82. AN Nylon Washer 99. KR-41 Aircap Nut for ANFA

AE- Extensions

81. AE- Extension L/Needle (Select Size)

• Sizes: -3" -6" -12" -18" -24" Length

97. KR-42 AE Adapter (Gun to Extension)

99. KR-43 Adapter Nut (Holds Extension to Gun)

AX- Stainless Steel Extensions (AX- Aircaps & Tips Only)

AX- Extensions L/Needle (Select Size)

• Sizes: -3" -6" -12" -18" -24" -36" -48" Length

83. U-2831- St. St. Inner Tube (Select Size)

84. AUF-29 Swivel Nut

85. U-2832- St. St. Outer Tube(Select Size)

98. KR-40 AX Adapter (Gun to Extension)

99. KR-44 Adapter Nut (Holds Extension to Gun)

Stainless Steel Extension Needles for AE- and AX- Extensions

87. KR-30- St. St. Extension Needle (Select Size)

• Sizes: -3" -6" -12" -18" -24" -36" -48" Length

NO. PART NO. DESCRIPTION

20. KR-20 Cheater Valve Assembly

21. KR-21 Air Inlet Nipple

22. KR-22 Spreader Valve Assembly

23. KR-23 Wrench

24. KR-24 Driver Tool for item #3

25. KRG-16 Gravity Container 16 oz.

26. KRS-32 Siphon Container 32 oz.

PACKING SET

KR-100 Packing Set (These items Sold together)

3. Packing Screw for Needle

4. PTFE Seal

5. Washer

6. Spring

10. Needle Spring

13. “O” Ring

15. Spring and Nylon Seat

PTFE Washers (1 ea.) for 20 and 22, (1) Metal Washer for

either 20 or 22.

* NOTE: MATCH AIRCAP, FLUID NOZZLE and FLUID NEEDLE

AE & AX EXTENSIONS require a Pressure Tank to feed material

being sprayed. Always adjust atomizing air pressure higher

than fluid air pressure. AE Extensions use AF or AR Aircaps.

AE and AX EXTENSIONS

97 AE Adapter

98 AX Adapter

99 KR-43 & 44

Hole size varies

AX AIRCAPS

AX- Style Tip and Aircaps (AX- Extension Only)

86. AX-1 Tip

88. AXR Aircap (External Round)

89. AXF Aircap (External Fan)

90. AXIF Aircap (Internal Fan)

91. AXIF-90 Aircap (Internal Fan)

92. AXIF-45 Aircap (Internal Fan)

93. AXIB Aircap (Spherical)

94. AXI-360 Aircap (Radial Dial)

95. AXIF-90A Aircap (Internal Fan)

96. AXIR-15 Aircap (Internal Round)

Loading...

Loading...