Page 1

F88P-2-0-6

DUAL FLUID SPRAY GUN

OPERATING INSTRUCTIONS AND REPLACEMENT PARTS

INTRODUCTION:

This Manual Spray Gun requires clean dry air regulated

from 6 to 8 C.F.M. at 60 to 80 lbs. air pressure depending

on the size of atomizing heads to be used. Paasche

Regulator & Condenser Units are recommended for

attaching to air supply line to remove water, oil, rust or

scale and help insure a quality finish of coating.

AIR AND FLUID CONNECTIONS:

1. Air Connection: To remove any accumulated foreign

matter blow out all hoses before using.

a. Air supply to Spray Gun must be turned off

before attaching fittings to the Air Inlet.

b. Attach HT-1/4 Air Hose to the Air Outlet on the

Air Regulator and Air Inlet on the bottom of the

handle on the Spray Gun.

2. Fluid Hose Connection: HPT-1/4 PVC Fluid Hose

with Stainless Steel Couplings should be long enough

to form a loop below the Spray Gun at all times when

using fluid hose to feed material to the Spray Gun

(two required).

a. Attach NS-3/8 Nut and HNS-1/4-3/8 Nipple,

Stainless Fittings, to the fluid inlets of the two

Fluid Bodies.

b. Attach opposite ends, NS-3/8 Nut and HNS-1/4-

3/8 Nipple, Stainless Fittings, to containers of

respective materials being sprayed.

3. Fluid Container Connection: When using USP-QT

(QT./.946 l) Plastic Bottle Assemblies, make sure

Screw Covers are tightened securely so fluid will not

leak at Bottle connections.

4. Tighten all Air and Fluid connections securely.

OPERATION:

1. After hose connections have been made, regulate the

air pressure to about 40 lbs. and then pull trigger back

slowly.

a. The first 1/4" of trigger stroke opens the Air

Valve which operates both the cylinders.

b. Continued pull on the trigger opens both of the

atomizing Spray Heads for spraying.

INSTRUCTIONS AND PARTS LIST, F88P-8/31/2011

Supersedes Instruction & Parts List F88P-11/13/2009

WARNING: Spray materials may be harmful if inhaled or allowed

to come into contact with skin or eyes. Consult the product label and

Material Safety Data Sheet supplied for the spray material. Follow

all safety precautions. CAUTION: Well Ventilated Area

Required to remove fumes, dust or overspray. Check

co mpat ibili ty of mate r ials used with Poly e thyl e ne

container and PVC Fluid Hose. Secure airhose and fluid

hose wrench tight for safety and to prevent leaks.

M a x i m u m A i r P r e s s u r e 8 0 P . S . I .

M a x i m u m F l u i d P r e s s u r e 4 5 P . S . I .

2. The U-1460 Adjusting Nut (part 39) can be used to

regulate desired amount of fluid to the automatic

Spray Head.

3. Dual Fluid Spray Guns are designed to atomize and

mix fluid materials outside the atomizing aircaps. This

prevents materials from hardening inside the spray

gun.

4. The U-28-12 Packing Washers (part 6) should be

replaced periodically.

a. Fill packing cavity with 3 new U-28-12 Packing

Washers and replace U-29 Packing Gland (part

7), DU-30 Spring (part 8) and U-31 Spring Seat

(part 9) in position.

b. A few drops of oil should occasionally be

applied to the U-2506 Piston Leather (part Z) to

keep it pliable.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

Printed in the U.S.A.

Page 2

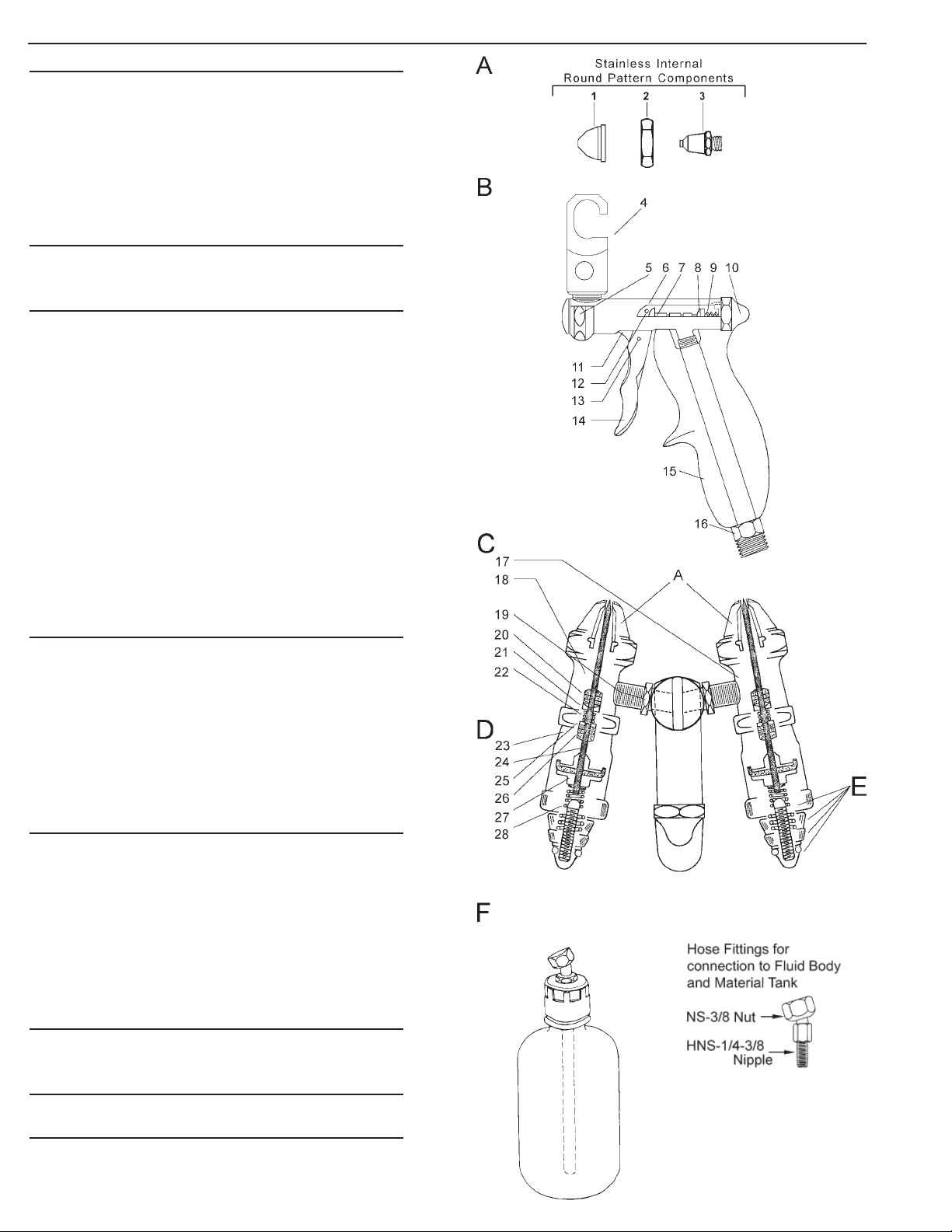

A. Head Assembly Components

1. BSR-15-0 Standard Stainless Aircap(.055)

BSR-15-2 or 4 Optional Aircaps(.073 & .093)

2. BUS-12 Stainless Aircap Nut

3. U-0 Standard Stainless Tip(.055)

U-2 or 4 Optional Tips(.073 & .093)

4. U-3641 Hook & Tee

B. U-1858-1 Handle & Shell Assembly

5. U-755 Link Sleeve

6. P67.1 Shell Assembly

7. U-762 Air Valve Piston

8. U-2520P Air Valve Head

9. U-2500 Spring

10. U-874A Rear Cap

11. P67.4 Link Assembly

12. U-40 Trigger Screw

13. U-35 Trigger Link Screw

14. U-1671 Trigger

15. U-1890P Plastic Handle

16. U-807 Air Inlet Tube

F88P-2-0-6 Page 2

C. Fluid Bodies Right & Left

17. U-3557 St. St. Fluid Body - RIGHT

18. U-3558 St. St. Fluid Body - LEFT

19. U-3399 Locknut (1)

20. U-28-12 Packing Washer (sold per doz.)

21. U-29 Packing Gland (1)

22. DU-30 Spring (1)

D. U-2260 Cylinder Assembies

23. U-2493 Cylinder Shell Assembly

24. A-U-3-1/32 Needle

25. U-203 Packing Gland (1)

26. U-28-12 Packing Washers (sold per doz.)

27. U-2505 Piston Assembly

28. U-2500 Spring

E. U-2264 Rear Cap Assembly

F. USP-QT (QT./.946 l) Plastic Bottle Assembly

NOTE:

U-28-12 Packing Washers sold by the Dozen only.

Loading...

Loading...