Page 1

D Air Compressor

1/4 H.P., 115 V., 60 Cyl.

INSTRUCTIONS AND PARTS LIST D-8/2005

Supersedes Instructions & Parts List D-5/2002

Model D Diaphragm Compressor was designed with the

artist in mind, offering quiet dependable service with

sufficient pressure to operate any artist airbrush. Delivers

up to 1/2 C.F.M. at 20 p.s.i. (Maximum 40 p.s.i.) and weighs

20 Ibs. (Shipping Weight 22 lbs.)

INSTRUCTIONS:

BEFORE OPERATING COMPRESSOR, READ AND

FOLLOW DIRECTIONS AS OUTLINED BELOW.

1. The D Compressor is equipped with a 3 wire cord with

On/Off Switch and a 1/4 H.P.,115 V.A.C., 1 Phase, 60

cycle motor. NOTE: Before plugging in, check to make

sure available power is the same as that noted on motor

name plate. Turn off switch and remove plug from wall

outlet when leaving unit unattended.

2. Connect air hose to air outlet on unit.

3. Plug unit into properly wired electrical receptacle.

4. Hold hose and point loose end away from you. Turn on

switch and allow a few moments to blow hose clean of

any foreign particles.

5. Turn switch off.

6. Connect airbrush to hose using V-62 Wrench.

Printed in the U.S.A.

Paasche Airbrush Company

4311 North Normandy

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

CAUTION: When a flammable liquid is sprayed, there may be

danger of fire or explosion especially in a closed room: keep

compressor at least 20 feet away from areas where hazardous

concentrations of flammable vapors are likely to occur.

Compressor may not start when pressure is in the airline. Bleed

air by pressing Air Valve Button on Airbrush. Do Not Start and

Stop Compressor in Rapid Succession–May Burn Out Motor.

ATTENTION: Lorsqu’un liquide inflammable est pulverise, il

peut y avoir danger d’incendie ou d’explosion, specialement

dans une piece fermee; garder le compresseur a au moins 20

pieds des endroits ou des concentrations dangereuses de

vapeurs inflammables sont susceptibles de se produire.

NOTE: Set compressor on floor while operating, to remove

danger of unit falling from an elevated surface, possibly

causing damage to unit or injury. To reduce any noticeable

vibration or movement; suggest placing compressor on a

carpeted surface etc.

Troubleshooting:

1. Motor will not run if:

a. It is not plugged in.

b. The switch is defective or in the off position.

c. There is a blown fuse in house circuit.

d. There is residual pressure in air line:

1. Press finger button on airbrush to release pressure

2. Motor runs but has no air pressure if:

a. The D-77 Screws are loose or missing.

b. D-55, D-54, D-66 are dirty or broken.

c. The D-352 Rod is broken.

d. The D-56 Diaphragm is worn or cracked.

3. Noisy operation occurs when:

a. The D-79 Screw is loose.

b. The D-83 Screw is loose.

c. Connecting Rod Bearing is worn.

d. Puller or Pusher Washer is broken.

e. Inlet Filter is not in place.

NOTE: When reassembling compressor parts, make sure

they are positioned exactly as they were before

disassembly.

SERVICE:

1. Clean intake filter weekly. Replace filter if clogged with

paint overspray.

D Compressor has sufficient air capacity for the

following Paasche Airbrushes, using light fluids:

• Capacity for 2: F#1, V#1, V#2, VJR#1 or VJR#2 Airbrushes.

• Capacity for 2: H#1, H#3, VL#1 or VL#3 Airbrushes.

• Capacity for 1: AB, ABL, H#5, or VL#5 Airbrush.

• Capacity for 1: AUFB-0, AURB-0, or AURB-1 Spray Gun.

• Capacity for 1: 62-1-3 or 62-2-3 (3 oz.) Sprayers.

paasche

Page 2

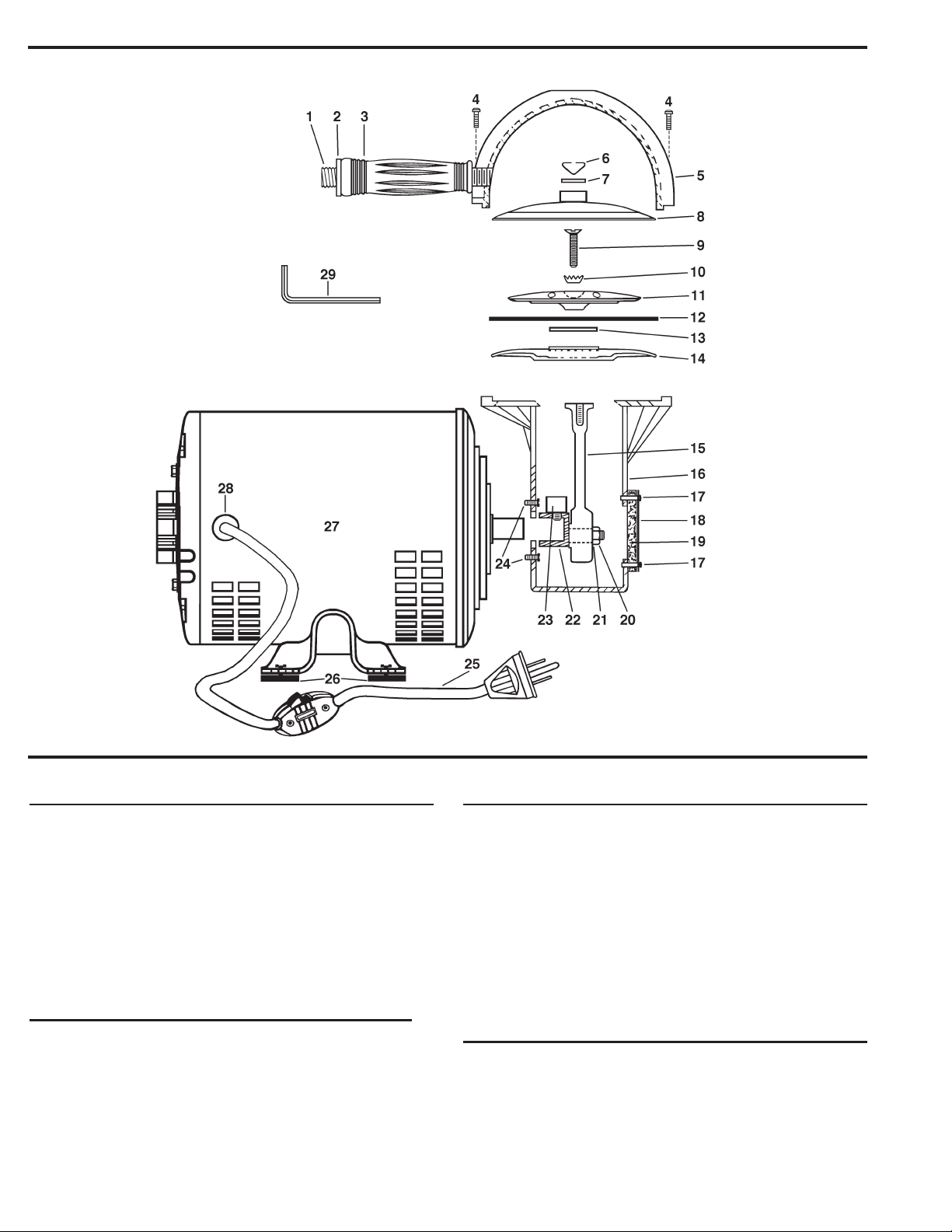

Page 2 Paasche D Air Compressor Parts List

No. Part Description

1. D-49 Handle

2. 1400-50 Retaining Ring

3. D-50 Handle Sleeve

4. D-77 Screw (4)

5. D-48G Reservoir

6. D-106 Retaining Spring

7. D-69N Exhaust Valve Disc

8. D-57 Pressure Head

D-88 Connecting Rod & Diaphragm Assem.

9. D-79 Allen Screw

10. D-103 Lock Washer

11. D-55 Puller Washer

12. D-56 Diaphragm

13. D-66 Intake Valve Disc

14. D-54 Pusher Washer

15. D-352 Connecting Rod & Bearing

No. Part Description

16. D-47G Housing

17. D-343 Nylon Fastener (4)

18. D-341 Nameplate

19. D-342 Inlet Filter

20. D-80 Nut

21. L-70 1/4" Shakeproof Lock Washer

22. D-351 Crank Shaft

23. D-83 Counter Weight & Screw

24. D-346 Screw (4)

Motor Component

s

25. U-2769-6' Cord and Switch

26. D-336 Grommet, Screw & Nut (4)

27. D-159G Motor L/Cord

28. D-357 Cord Strain Relief

29. #532 Allen Wrench

Loading...

Loading...