Page 1

D3 0 0 0R Co m p re s s or & Ta n k

1/8 HP, 110-120Volts, 60Hz, .30 CFM @ 30 PSI

Operating Pressure 20-40 Depending on airbrush

P.S.I., Shipping Weight: 5.6 kgs (12.2 lbs.),

ETL Listed.

OPERATION INSTRUCTIONS

Unpacking Instructions

When you unpack your unit, check carefully for damage that might have

occurred in transit.

Electrical Requirements:

This unit must only be used at the listed voltage. Low voltage will cause

the motor to overheat. Low voltage is recognized when the following

conditions exist:

1. Motor does not develop full power or speed.

2. A fuse blow out occurs at starting or when load is applied.

3. Lights dim when motor starts and remains dim.

Avoid excessive voltage drop by keeping extension cords as short as

possible. If it is necessary to use an extension cord, do not use less

than16 gauge for 25 feet, 14 gauge for 50 feet, or 12 gauge for 100 feet

or more.

GENERAL INFORMATION

The maximum pressure of the compressor is 50 PSI (4.3 Bar). The

maximun operating pressure while spraying will vary depending on size of

fluid tip, needle and/or aircap, etc.

THERMAL PROTECTOR

The motor of this compressor has a thermal overload protector. If the

motor should overheat, the overload protector will shut off the motor. If this

should occur, unplug the compressor and allow the motor to cool (approx.

5 minutes), remove excess load and restart compressor. If the

compressor fails to start, check for blown fuses. The compressor may

need to cool further before attempting to restart. If the overload protector

shuts off the motor frequently you may have a low voltage situation. Low

voltage can also be suspected when:

1. The motor does not get up to full power or speed.

2. Fuses or circuit breakers activate when starting compressor.

3. Lights dim or remain dim when compressor is started.

4. Other motor operated appliances fail to operate properly. Too many

motor operated appliances on same circuit.

SEALING OF AIR HOSE

When attaching the female pipe thread fitting from your air hose to the

compressor, it may be necessary to use a quality pipe thread sealant or

PTFE pipe thread tape on the threaded air outlet of the compressor.

Failure to do so may cause an air leak and your compressor will not shut

off as it should. NOTE: This unit does not require any lubricants or oil.

Applying oil to any part could result in damage to the compressor. All

bearings, including those in the motor, are grease packed. In case of

motor failure, return to authorized motor service station in your area.

AUTOMATIC SHUT-OFF FEATURE

This compressor has a built-in pressure switch that automatically shutsoff the compressor when the airbrush is not in use once the maximum

tank pressure is reached. It will immediately start again as soon as the air

is allowed to flow through the airbrush bleeding off tank pressure.

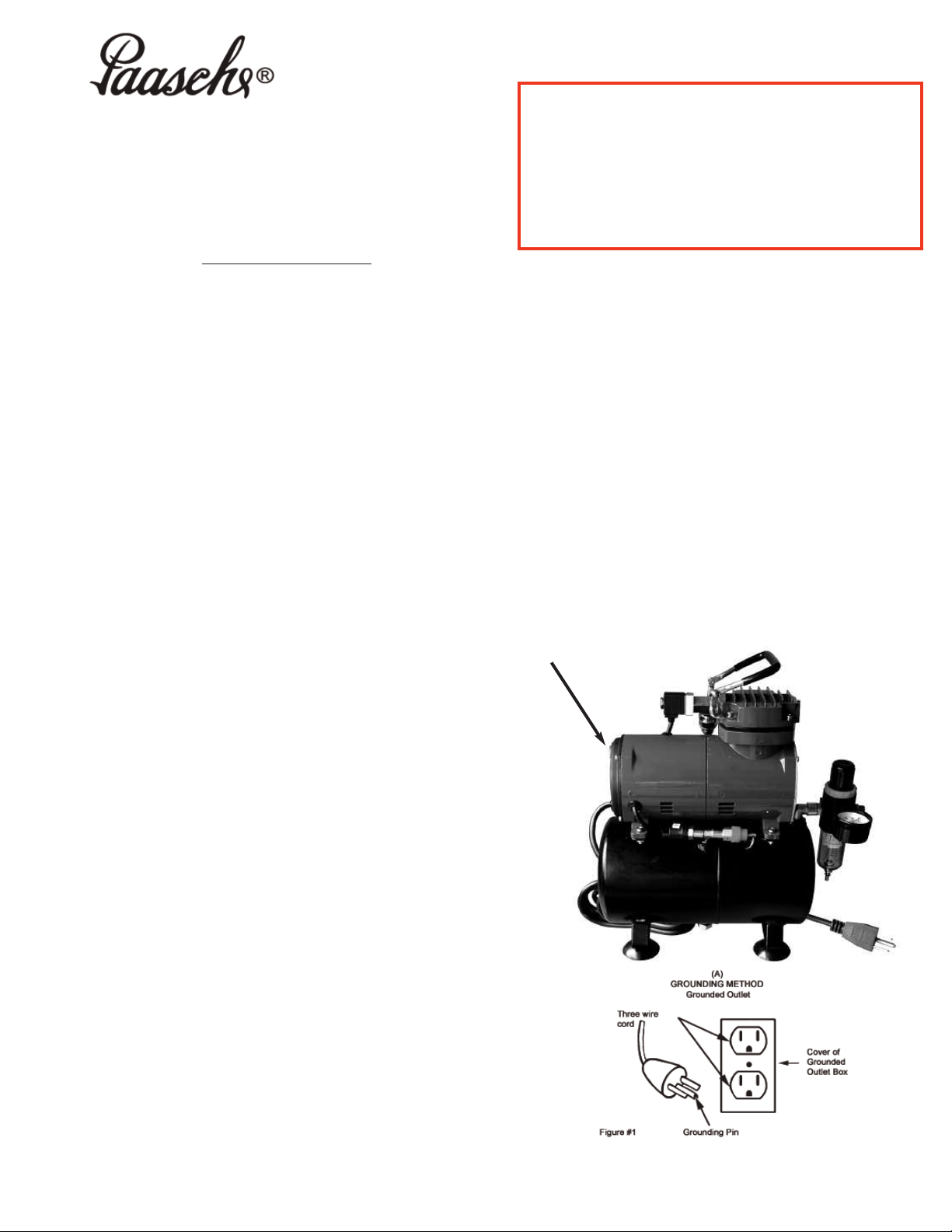

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire

for the electric current. This product is equipped with a cord having a

grounding wire with a grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

INSTRUCTION AND PARTS LIST D3000R-8/31/2011

Supersedes Instruction & Parts List D3000-11/04/09

WARNING: When a flammable liquid is sprayed, there may be

danger of fire or explosion especially in a closed room: keep

compressor at least 20 feet away from areas where hazardous

concentrations of flammable vapors are likely to occur. Disconnect

power before servicing.

ATTENTION: Lorsqu'un liquide inflammable est pulverise, il

peut y avoir danger d'incendie ou d'explosion, specialement

dans une piece fermee; garder le compresseur a au moins 20

pieds des endroits ou des concentrations dangereuses de

vapeurs inflammables sont susceptibles de se produire.

Debrancher avant toute maintenance.

DANGER– Improper installation of the grounding plug can result in a risk

of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect

the grounding wire to either flat blade terminal. The wire with insulation,

having an outer surface that is green with or without yellow stripes, is the

grounding wire. Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood or if in doubt as to

whether the product is properly connected.

Do not modify the plug provided; if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

DANGER– Do not use temporary adapter plugs with this compressor.

EXTENSION CORDS – If it is necessary to use an extension cord, use a

3-wire extension cord that has a 3-blade grounding plug and a 3-slot

receptacle that will accept the plug on the product. Make certain your

extension cord is in good condition. Make certain your extension cord

wire is not less than 16 gauge for 25 feet, 14 gauge for 50 feet and 12

gauge for 100 feet. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

SWITCH WITH SINGLE AND DOUBLE LINES CONTROLS THE WAY

COMPRESSOR SHUTS OFF. SET TO ONE LINE AND THE MOTOR

RUNS UNTIL PRESSURE IS AT TANK MAXIMUM - SET AT TWO

LINES AND THE MOTOR WILL RUN CONTINUOUSLY EVEN THOUGH

THE TANK IS FULL.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

Manufactured for Paasche in China

Loading...

Loading...