Page 1

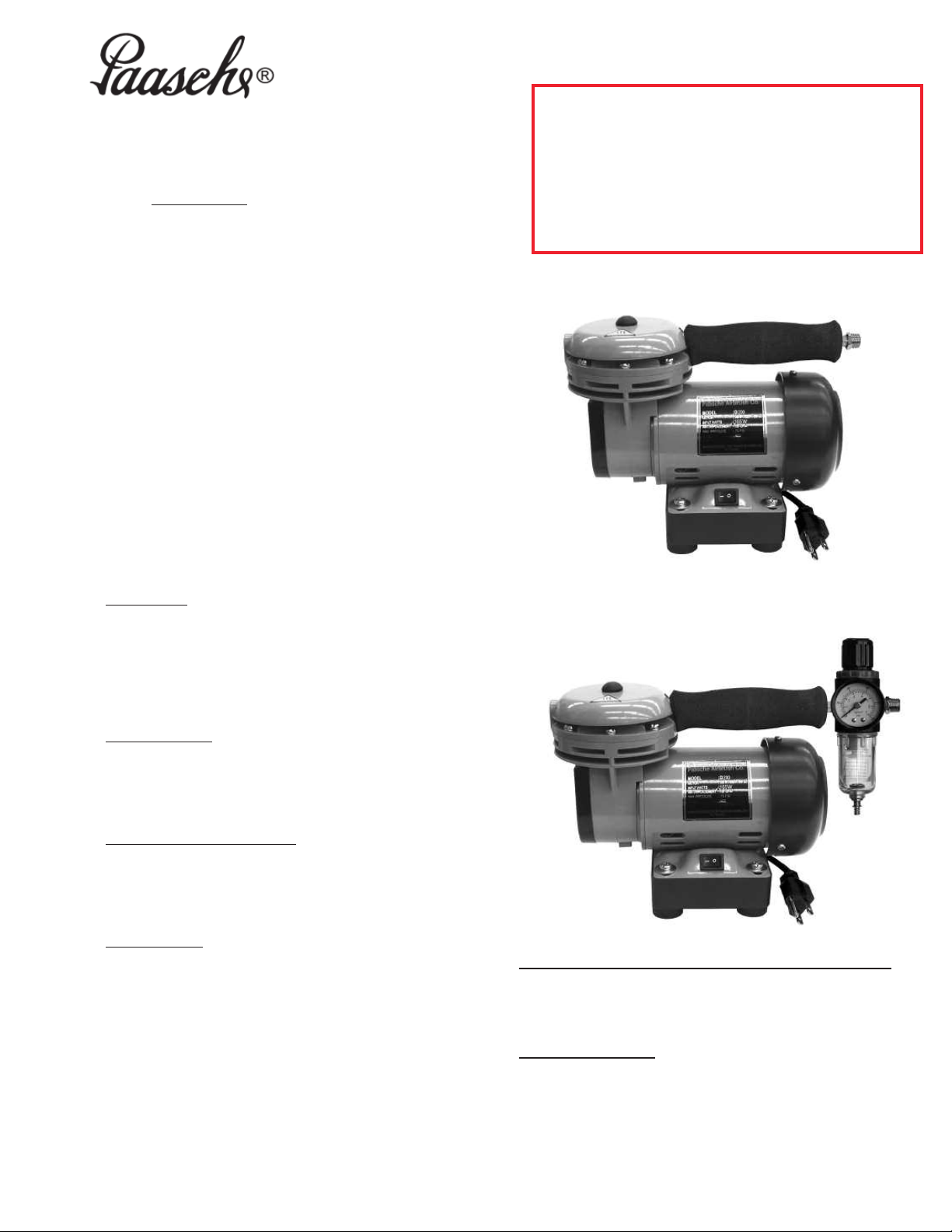

D200 & D200R

Air Compressor

1/6 HP, 110V, 60Hz, 1.5 AMP, .7 CFM @ 20 PSI,

70 PSI, Shipping Weight: 5.2 kgs (11.6 lbs.)

OPERATION: OI LLESS - NEEDS NO LUBRICATI ON

The compressor is maintenance free. To avoid mal-functions and

premature wear and tear, the following points should be

observed.

1. WARNING: Plug the power cord into a 110V.-60Hz Cycle

grounded outlet. Do not use an adapter to by-pass the

grounding feature. Do not operate compressor in a wet area.

2. Place compressor on a level surface, preferably on the floor.

3. Carrying compressor while operating is not advisable.

4. Do not let the compressor run unnecessarily, i.e. the unit

should be switched off when the airbrush is not being used.

5. Always remove the power cord from the electric outlet when

making adjustment or changing parts.

6. Always provide plenty of ventilation while spraying.

7. Never smoke or eat while spraying.

8. Wear a respirator and eye protection when spraying.

INSTRUCTION AND PARTS LIST D200 & D200R, 8/31/2011

Supercedes Instructions & Parts List D200 & D200-50, 8/28/2008

WARNING: When a flammable liquid is sprayed, there may

be danger of fire or explosion especially in a closed room:

keep compressor at least 20 feet away from areas where

hazardous concentrations of flammable vapors are likely to

occur. Disconnect power before servicing.

ATTENTION: Lorsqu'un liquide inflammable est pulverise, il

peut y avoir danger d'incendie ou d'explosion, specialement

dans une piece fermee; garder le compresseur a au moins

20 pieds des endroits ou des concentrations dangereuses de

vapeurs inflammables sont susceptibles de se produire.

Debrancher avant toute maintenance.

D200 Air Compressor, 110V.,60Hz.

TROUBLE-SHOOTING:

1. Low air flow

Possible causes: What to do:

-Reed valve (#33) -Change the defective air

or air valve (#38) valve plate or air valve

damaged

-Diaphragm (#31) damaged -Change the diaphragm

-6 screws (#42) are too loose -Tighten the screws

-Air hose leaking -Check seal, or change

2. Noisy operation

Possible causes: What to do:

-6 screws (#42) are too tight - Loosen the screws, and

then tighten them equally.

Do not over tighten.

-Bearing fault -Return to Factory.

3. Humming but does not work

Possible causes: What to do:

-6 screws (#42) are too tight -Loosen the screws, and

then tighten them equally.

Do not over tighten.

-Armature fault -Return to the Factory.

4. Does not work

Possible causes: What to do:

-Armature fault -Return to the Factory.

NOTICE:

If you need to disassemble the compressor, take care to note the

position and orientation of the parts to assure the correct reassembly.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

D200R Air Compressor, 110V.,60Hz., with

R-75 Air Filter Regulator

D200 & D200R AIR COMPRESSOR PARTS

D200-28 Diaphragm

D200-60 Switch

D200-62 Rubber Feet

Optional Items:

R-75 Filter Regulator

HFM-2-1/4 Air Manifold

Manufactured in Taiwan for Paasche

Loading...

Loading...