Page 1

CU-

MANUAL SPRAY GUN

OPERATING INSTRUCTIONS & REPLACEMENT PARTS

INSTRUCTIONS & PARTS LIST CU-8/31/2011

Supersedes Instructions & Parts List CU-6/2008

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray material. Follow all safety precautions.

CAUTION: Well Vent ilat ed Area Requ ired t o rem o ve

fume s , dust o r overspray. S e c ure ai r h o s e and f l u i d

hose wrench tight for safety and to prevent leaks.

M a x i m u m A i r P r e s s u r e 1 0 0 P . S . I .

M a x i m u m F l u i d P r e s s u r e 4 5 P. S . I .

DESCRIPTION:

CU- Manual Spray Guns are for use from Low to Medium Pressure

with Light to Heavy Fluids. They will cover a range of materials to

include heavy Abrasives, Enamels, Latex, and Lacquers etc. See

page 2 for different styles of Srpay Head Components and page 4

for information on available Fluid Bodies. These Models require 3

to 24 C.F.M. at 30 to 50 lbs. Air Pressure depending on Spray

Head selected and Material being sprayed.

CONNECTIONS:

Spray Guns have the following threaded connections: Air inlet

1/4" N.P.T. (Male) and Fluid inlet 3/8" N.P.T. (Male).

MATERIAL:

Mixture should be to the consistency recommended by the

manufacturer. Strain through cloth or fine mesh wire prior to

using material. This will insure that all foreign particles are

removed.

OPERATION:

1. Blow out all airline hoses before connecting to the

Spray Gun to remove foreign particles.

2. Connect HT-1/4 or 5/16 Air Hose to air inlet fitting.

3. Connect HA-1/4 or 3/8 Fluid Hose to fluid inlet.

4. Tighten all hose connections securely.

5. Adjust air pressure to required amount at the

Regulator & Moisture Condenser Unit.

6. Adjust fluid volume on the CUF- Model by turning the

200-17 Fluid Knob.

7. The Fan pattern is controlled by turning the U-2065

Fan Control Screw on the CUF- Model.

8. Test spray on some cardboard or news paper for final

adjustment before spraying your project.

MAINTENANCE:

The specially treated leather packings (U-28) should be replaced

at least once a month. Old U-28 Packing Washers can cause

leakage of air and fluid. PTFE Packings (59-28 Packing

Assembly) are self-lubricating.

TROUBLE SHOOTING SPRAY PATTERNS:

A. A ROUGH OR STIPPLE FINISH is due to low or restricted

flow of air pressure or heavy materials being applied with the

spray gun too close to surface.

B. A WET OR SAGGING FINISH is due to low air pressure or

restricted flow of air, material being too thin or applied too

close to the surface.

C. A SPUTTERING SPRAY is caused by air leaking into fluid

line or can be caused by a loose fluid tip, a broken or split tip,

lumpy material, a clogged vent hole in cover of material cup,

air leak at fluid pipe attached to inside of tank cover, or a

clogged paint strainer.

TO CORRECT: Tighten tip securely or replace. Strain

material and clean strainer. Sputtering might also be caused

by worn packing washers, or worn or scored needle.

D. AN ARCHED FAN SPRAY PATTERN is caused by dried

material accumulated in one fan port of the fan aircap,

distorting the pattern.

TO CORRECT: Dissolve material inside fan port with

suitable water/solvent applied with a small brush.

Never use wire or sharp instruments to clean fan ports

as permanent damage to the air ports will result in

altering uniformity of the fan spray pattern.

E. UNBALANCED FAN SPRAY PATTERN, heavy on one side,

may be caused by material collecting around outside of the

fluid tip and aircap, or by a loose aircap.

TO CORRECT: Remove aircap and clean fluid tip and aircap

with water/solvent, dry with air pressure. Always be sure fan

aircap and aircap body is tightened securely.

F. A HEAVY CENTER in a fan pattern is caused by insufficient

air pressure at the fan port. Rough or shady edges are also

caused by low air pressure.

TO CORRECT: Increase air line pressure.

G A SPLIT FAN SPRAY PATTERN, heavy on each end and

light in the center, is caused by excessive air pressure.

TO CORRECT: Reduce air pressure.

CLEANING:

After each use flush clean solvent through the fluid passages of the

Spray Gun and wipe off the outside with clean solvent. Never leave

the entire Spray Gun immersed in solvent. Dirty Aircaps and Tips

should be cleaned by soaking in solvent and then blown clean with

air. Personal Safety Equipment should be used at all times.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

Printed in the U.S.A.

Page 2

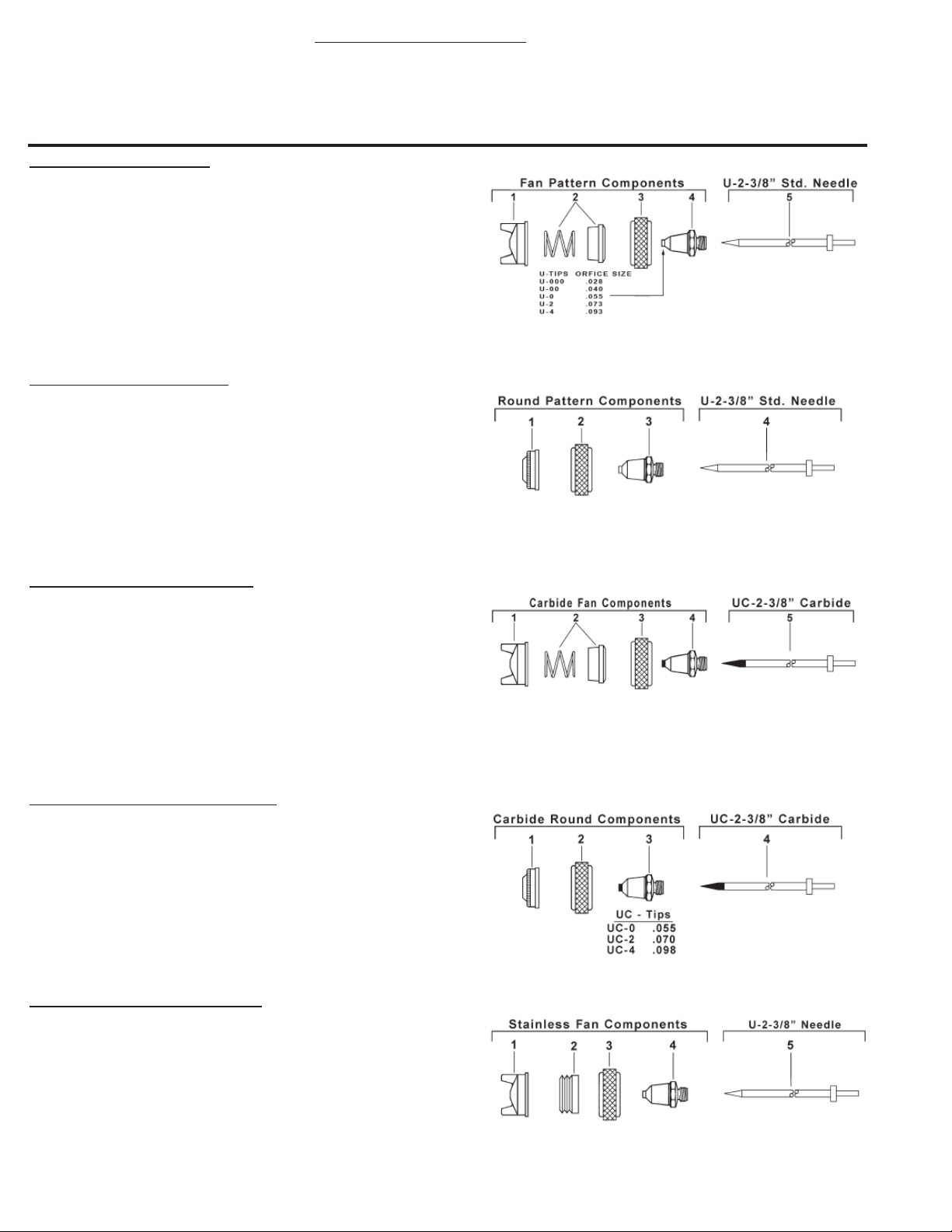

SPRAY HEAD COMPONENTS

Page 2

Spr ay Heads for CU- Manual Spray Gu ns are availa ble in severa l different styles, some of whic h are

avail able with Stain less Steel components. The C.F.M. requirements range from 3 to 24 C. F.M. @ 40 to 50

lbs. air pres sure. NOTE: Whe n eith er flu id Tip or fluid Needle is worn and requires replacemen t, it is

recom mended that both items be changed for best res ults. All Tips and Need les are made using 303

Stainless Steel. Carbide Tips & N eedles are a vailable fo r use with abrasive m aterials.

EXTERNAL- FAN PATTERN

• Application: Broad coverage - High Production.

• Sizes: 000-3, 00-4, 00-4-6, 06, 0-9, 2-8, 4-10, 4-15.

• Fluid Viscosity: Light to Heavy (3 to 24 C.F.M.@ 40 or 50 P.S.I.)

1. 56FA- Aircap Body (Select Size above)

2. U-2639S Sleeve & Spring

4. U-1649 Aircap Nut

5. U- Stainless Tip (Select Size 000,00,0,2,4)

6. U-2-3/8 Stainless Needle

INTERNAL- ROUND PATTERN

• Application: Narrow trim, inside crevice, dot, line, High Production.

• Sizes: 2-5, 4-6.

• Fluid Viscosity: Light to Medium (3 to 6 C.F.M. @ 40 P.S.I.)

1. 56RA- Aircap Body (Select Size above)

2. U-1649 Aircap Nut

3. U- Stainless Tip (Select Size 2 or 4)

4. U-2-3/8 Stainless Needle

CARBIDE INSERT- FAN PATTERN

• Application: Abrasive Materials

• Sizes: 0-9, 2-8 or 4-10

• Fluid Viscosity: Light to Medium (4 to 12 C.F.M. @40 or 50 P.S.I.)

1. 56CFA- Aircap Body (Select Size above)

2. U-2639S Sleeve & Spring

3. U-1649 Aircap Nut

4. UC- Carbide Insert Stainless Body Tip (Select Size 0, 2 or 4)

5. UC-2-3/8 Carbide Insert Stainless Needle

CARBIDE INSERT- ROUND PATTERN

• Application: Abrasive Materials

• Sizes: 2-5 & 4-6

• Fluid Viscosity: Light to Medium (3 to 6 C.F.M. @ 40 P.S.I.)

1. 56CRA- Aircap Body (Select Size above)

2. U-1649 Aircap Nut

3. UC- Carbide Insert Stainless Body Tip (Select Size 2 or 4)

4. UC-2-3/8 Carbide Insert Stainless Needle

StainleSS Steel

• Application: Corrosive materials and Latex.

• Sizes: 0-6, 0-9, 2-8, 4-10, 4-20-3.

• Fluid Viscosity: Light to Medium Heavy (4 to 20 C.F.M. @ 40 or 50 P.S.I.)

1. 56SFA- Stainless Aircap Body (Select Size above)

2. U-2639P Poly Sleeve

3. U-1649 Aircap Nut (plated brass)

4. U- Stainless Tip (Select Size 0, 2 or 4)

5. U-2-3/8 Stainless Needle

- FAN PATTERN

Page 3

CU- Spray Gun

CU- Spray Gun Components

No.Part No. Description

1. U-2-3/8 Needle

2. CU-7B Fluid Body

Page 3

U-2072 FAN CONTROL ASSEMBLY

4. AE-43 “O” Ring

5. U-2065 Fan Control Screw

U-3500 PACKING ASSEMBLY

8. U-28-12 Packing Washers (1 Doz.)

9. U-29 Packing Gland (1)

10. DU-30 Spring (1)

11. U-31 Spring Seat (1)

12. U-33 Spring (1)

U-1858-1/4 HANDLE & SHELL ASSEMBLY

13. U-2153 Retaining Ring

14. U-58Nut

15. U-755 Link Sleeve

16. U-828 Hook

17. U-856 Screw

18. U-2154A Shell Assembly

19. U-762 Air Valve Piston

20. U-2520P Air Valve Head

21. U-2500 Spring

U-2106B FLUID CONTROL ASSEMBLY

22. U-2631 Plunger

23. U-2750 Packing Gland

24. AE-43 “O” Ring

25. U-2069B Rear Cap

26. 200-17 Fluid Knob

27. U-1702 Valve Spring

No. Part No. Description

59-28 PTFE PACKING ASSEMBLY

32. U-3353 Packing (PTFE)

33. 59-24 Packing (PTFE) (2)

34. 59-25B Expander Gland

35. DU-30 Spring

OPTIONAL TIPS & NEEDLES

1. URE-00, 0, 2 or 4 Tip (Select Size)

2. URE-1-17/32 Needle

Rear needle seat for Heavy Pigments that would collect

and clog in the cavity of the standard tip.

3. US-0, 2 or 4 Self Cleaning Tip (Select)

(US-0 same as U-0)

4. US-0-2-3/8 Self Cleaning Needle

US-2-2-3/8

US-4-2-3/8

Use to prevent buildup at tip orifice & pressure feed.

28. U-1322A Link Sleeve

29. U-35 Trigger Link Screw

30. U-1671 Trigger

31. U-1890P Durable Plastic Handle

32. U-807 Air Inlet Tube Assembly

Page 4

CU- Spray Gun & Extensions

CAM-LOCK & SCREW COVER CUP ASSEMBLIES

30SC QT. CUP ASSEM.

CL-38 QT. CAM-LOCK &

34SC 1/2 PT. CUP ASSEM.

Page 4

52P QT. CUP ASSEM.

Gun Not Included

CU- FLUID BODIES (See picture below)

1. CU-7B Forged Brass

CUS-7B Stainless Steel

2. CUA-7B Separate Air Atomizing Inlet - Brass

CUSA-7B Separate Air Atomizing Inlet - Stainless St.

3. CUG-7B Circulating Fluid Body - Brass

NOTE: U-28-12 and DU-28-12 Packing Washers only sold by the dozen.

Loading...

Loading...