Page 1

AB (Fine Art) Airbrush

Customer Note: New “AB” Airbrushes are factory inspected for

immediate use.

The “A B ” A i rbru s h m aint e nance an d r e p lace m ent part s

instructions are for Airbrushes that have been used extensively

and require refurbishing.

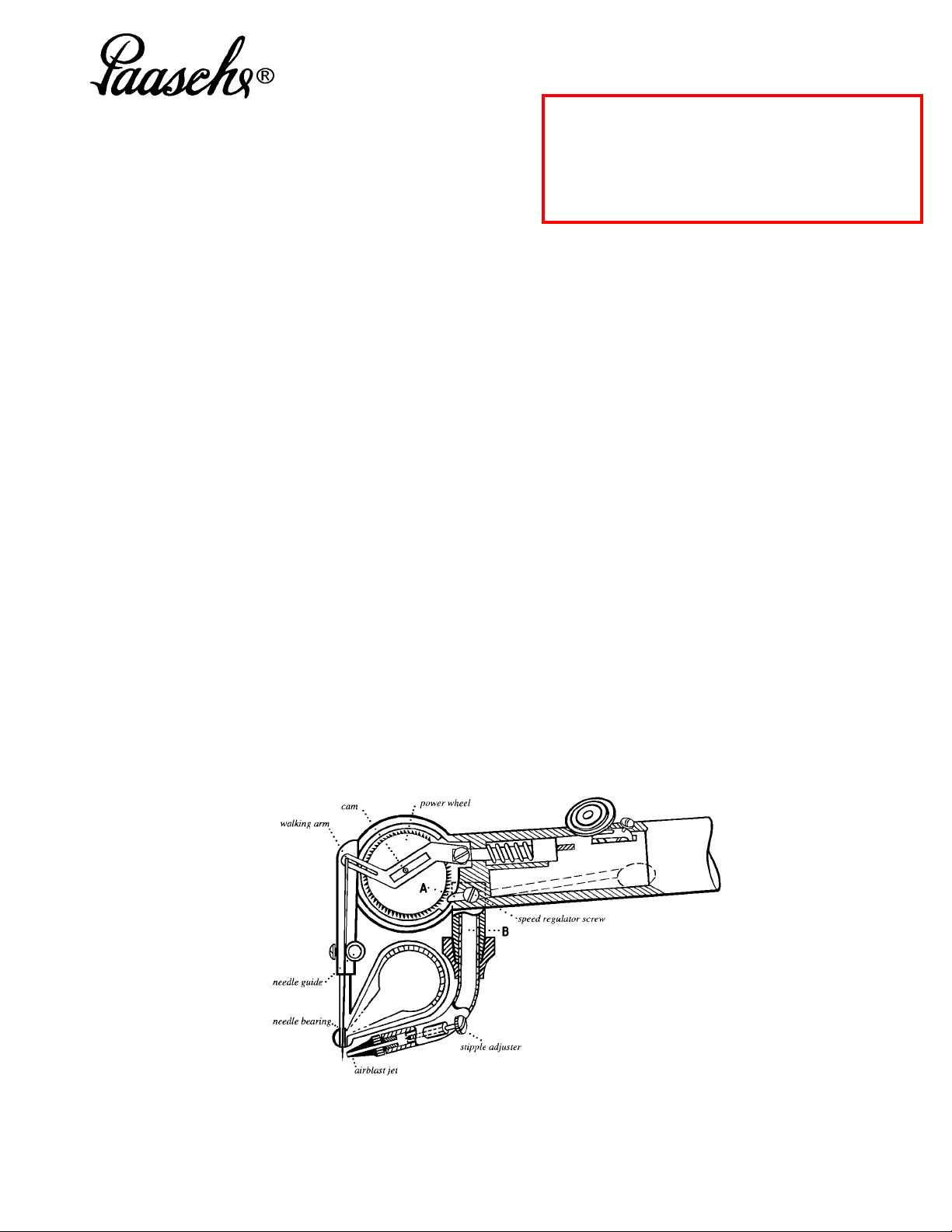

HOW THE AB WORKS:

The illustration below gives you an idea what is going

on inside your AB. As the finger lever is pressed down, air

from your compressor is channeled from the air valve

through the body of the airbrush. The airstream then

splits, and part of the air is pushed across the edge of the

power wheel ( A ) while the rest goes through the airblast

tube ( B ). The edge of the power wheel is serrated, so

that the air pushing against it causes the power wheel to

spin. You will notice that the shaft on which the power

wheel rotates passes through a slot in the walking arm.

Actually, the portion of the shaft which rides in the slot is

offset from center, so that with a cam like action the

spinning of the power wheel causes the walking arm (and

thus the needle) to oscillate back and forth. The speed

regulator screw controls the speed of the power wheel

(and thus the walking arm and needle) by regulating the

volume of air pushing against the power wheel.

When you press down on the finger lever, you let air

into the airbrush and start the needle moving back and

forth. Then as you pull back on the finger lever, the

walking arm is pushed forward, and in turn the oscillating

needle is pushed into the stream of air coming from the

airblast tube. Thousands of times per minute, the needle

retracts into the needle bearing, picks up a coating of color

and then moves forward, drawing the color out of the

bearing and into the airstream, where the color is blown off

the needle and onto the surface you are painting. The

needle is tapered, so that as you pull back farther on the

finger lever, a thicker portion of the needle is exposed to

the airstream and a wider band of color is formed.

A line is thus formed by the action of the needle passing

back and forth in front of the stream of air coming from the

airblast jet, and you control the thickness of that line with

the finger lever. But the quality of that line and the ease

with which you can control it are affected by three other

INSTRUCTIONS AND PARTS LIST AB-8/31/2011

Supersedes Instructions & Parts List AB-10/29/2008

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray m aterial. Follow all safety precautions.

CAUTION: We ll Ventil at ed Area Required to rem ove

fumes, dust or overspray. Secu re ai rhose to A irbrush

with V-62 Wrench for safety a nd to prevent air leaks.

M a x i m u m A i r P r e s s u r e 5 0 P . S . I .

controls, all of which regulate the volume or the pressure

of the air passing through the airbrush.

METHODS OF CONTROL:

As menti o ned b efore , the speed regul a tor s crew

controls the volume of air hitting the power wheel, and so

controls the speed of the needle. The faster the needle

moves, the more color is being blown onto the surface you

are painting during a given length of time. If you want to

form a thin line, you can do so by having the needle

moving at a high speed and sweeping the airbrush very

quickly over your work, or by having the needle oscillating

much s lower and movi ng t he a irbru sh more slowl y.

Obviously the second method offers the most control and

is a major advantage of using the Paasche AB.

There is another method of controlling the speed of the

needle, however, and that is by adjusting the pressure of

the air coming into the airbrush. In this case, if you have

the speed regulator screw turned wide open (counterclockwise) with low air pressure (8-15 P.S.I.) from your air

source, the power wheel and needle will move slowly. But

the needle will also move slowly using a high air pressure

(25-35 P.S.I.) with the speed screw turned almost closed

(clockwise).

A comparable situation exists for the flow of air through

the airblast tube. The stipple adjuster screw restricts the

airflow through the airblast jet and across the needle.

When the air is almost closed off, a grainy or stippling

effect is created. But the same effect happens with the

stipple adjuster wide open using a very low air pressure.

As you can see, there are many different combinations

of settings for these three controls (the speed regulator,

the stipple a d juster, a n d the air p r e s s u r e ) e a c h

combination producing a characteristic effect, both in spray

pattern and handling of the airbrush.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: info@paascheairbrush.com

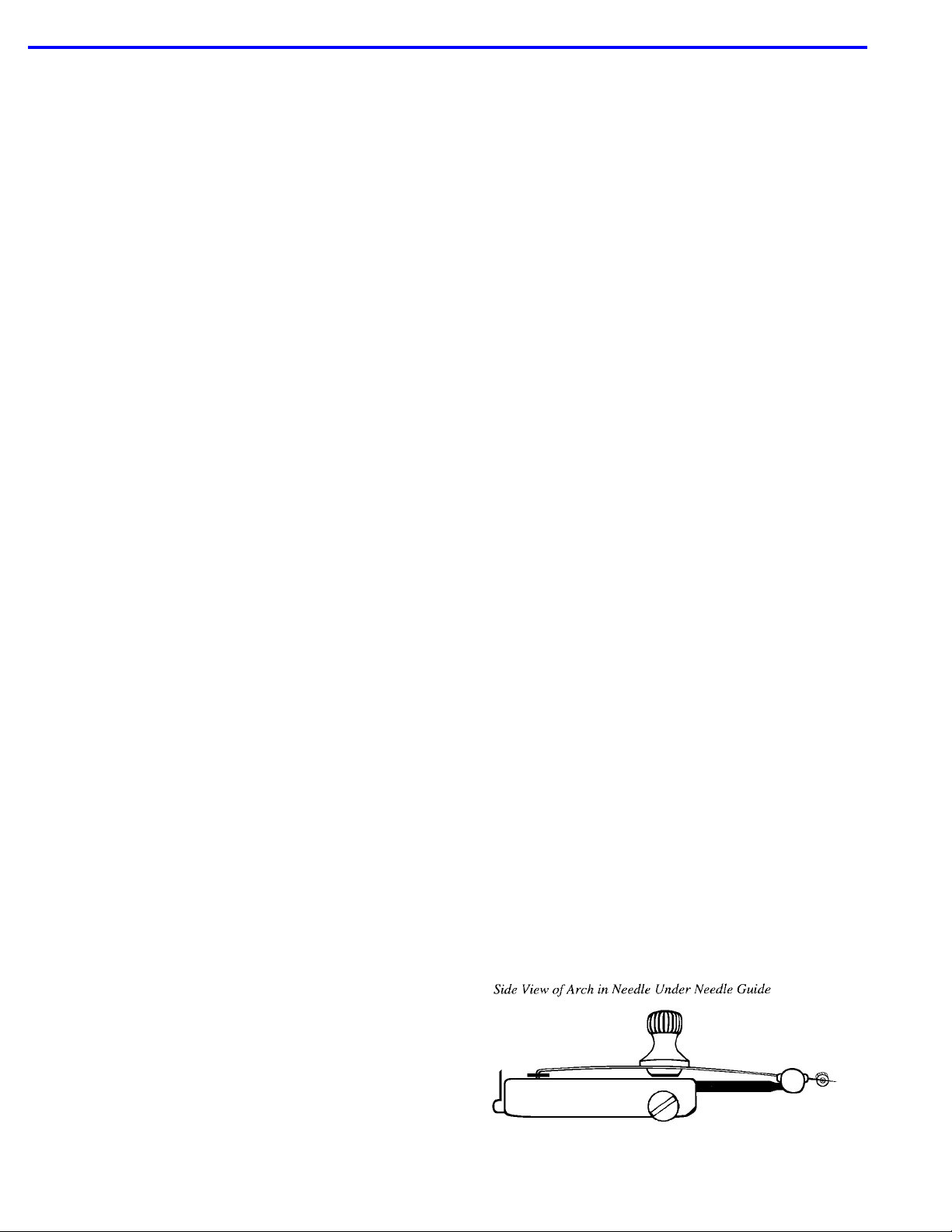

All AB needles should have a bow in them in

order t o be held securely by the needle

guide and enter the needle bearing properly.

Printed in the U.S.A.

Page 2

Page 2 Paasche AB (Fine Art) Airbrush Instructions and Parts List

BASIC PRECAUTIONS:

Before starting any adjustments or parts replacements,

a couple of precautions should be observed. The fine tip of

the needle is very delicate, and once damaged it is difficult

to straighten again. Remove the needle before beginning a

repair, or if necessary use an old needle. Secondly, most

of the threaded parts are made of brass, and the threads

are easily stripped. Do not force the parts to do what they

don’t want to do.

(See section “Speed Regulator Screw” for specific

example of this problem.)

ADJUSTING STIPPLE ADJUSTER & AIRBLAST JET:

The stipple adjuster is the screw at the elbow of the

airblast tube. It controls the airflow through the airblast

tube. By turning this screw in (clockwise), you restrict the

volume of air blown out the airblast jet and across the

needle. When the air is almost shut off you create a grainy,

stippling effect.

The threads of the stipple screw can become so loose

that it will not hold its position in the airblast tube and will

gradually turn out as you use the airbrush. As a preventive

measure, we suggest you avoid excessive turning in and

out of this screw. From the fully closed position, you only

need to turn the screw two full turns to fully open this little

valve.

If the screw is too loose, you can tighten the threads’ fit

by pressing a dab of beeswax onto the threads and rolling

the screw between your thumb and forefinger to work the

beeswax into the threads. Only a thin coating is needed.

Then pass the screw very briefly over a match flame,

melting the beeswax into the threads. The wax will adhere

better as you insert the screw back into the airblast tube.

SPEED REGULATOR SCREW:

This s crew w o r k s much the same as the s tipple

adjuster. It controls airflow and thus the speed of the

power wheel and the needle. Again, all the adjustments

happen within a range of two turns of the screw. As noted

before, do not try to force the screw tighter than it wants to

go. You can shear the head of the screw right off, leaving

the screw firmly embedded in the body of the airbrush,

impossible to remove.

POWER WHEEL TOP SHAFT BEARING ADJUSTING:

Adjusting shaft bearings is a procedure that should be

done only if the power wheel is sluggish, is intermittently

binding, or is completely stuck. To check this, remove the

needle, then try to operate the power wheel and walking

arm, pressing down the finger lever and moving it back

and forth. If the power wheel runs smoothly now, the

problem i s with your needle, not with the bearing

adjustments. If the problem continues, however, you will

need to adjust the bearings. If the power wheel is sluggish

or will not move at all, it could be that you simply need to

loosen the top bearing a little. Remove the top grease cap,

exposing the top shaft bearing. You will find the bearing

covered with grease, which you may want to remove in

order to see the slot in the top of the bearing better. To

adjust the bearing, use a screwdriver with a blade as wide

as the ope ning int o wh ich the bearing fits . A larg er

screwdriver can be filed down to fit exactly the slot in the

bearing. While pressing down on the finger lever for air,

slowly loosen the top bearing (turn counter-clockwise). If

the power wheel frees itself and begins to run smoothly,

yo u hav e fo und the prob lem. To adjus t th e bea ring

accurately, tighten it again until the power wheel stops,

then loosen it just until the power wheel runs smoothly.

This is a matter of 1/16 to 1/8 turn, never more than 1/4

turn. Do not loosen the bearing beyond the point where the

power wheel frees itself and runs smoothly. Beyond this

point the power wheel will begin to vibrate in the bearing. It

will appear to be running smoothly but then will suddenly

bog down. If this happens, tighten the bearing a little. You

will find the power wheel returns to normal speed.

If you find that the power wheel runs smoothly for a

while then freezes up ag ain, the problem is that the

threads in the power wheel cover have become too worn

to hold the bearing snugly in place. The power wheel

happens to spin in the same direction needed to tighten

the top shaft bearing. If the bearing does not fit snugly in

the power wheel cover, the power wheel will actually drag

the bearing until it stops the power wheel! The remedy for

this situation is the same as for the loose stipple adjuster

or speed control—work beeswax into the threads of the

bearing. Over a long time period, the beeswax will wear

out and this repair will have to be done again.

FINGER LEVER ADJUSTING SCREW:

This screw is located at the back of the finger lever, in

the lever fork, and adjusts the “rest position” of the finger

lever. When you turn the adjusting screw in, the walking

arm is pushed farther into the stream of air from the

airblast jet. By adjusting this screw you set the width of the

line created when the finger lever is simply depressed, but

not pulled back (the “rest position” spray width.) Note: In

the “farthest forward rest position” you get no spray if the

color cup is properly positioned.

Be careful with the two extremes of this adjustment. If

you t u r n t he adjusting s c r e w t o o far out ( c o u n t e r clockwise), the needle moves to the very end of the slot in

the walking arm, and the needle binds between this slot

and the slot in the color cup support. Always check that the

needle is at least a “hair’s breadth” from the very end of

the walking arm slot.

On some ABs, if you turn the adjusting screw too far in

(clockwise), the walking arm will be pushed too far forward

and will hit the front of the opening in the power wheel

cover through which it extends.

SHAPING THE NEEDLE:

In general an AB needle should be curved in two

directions. Viewed from the side the needle should have a

slight arch, so that the needle guide can hold it firmly in the

slot in the needle bearing. Viewed from the top, the needle

should curve underneath the lip of the needle guide screw.

Both arch and curve should be gradual bends along the

length of the needle, with no sudden bends or angles.

About 3/8 inch at the tip of the needle—that portion which

rides in and out of the needle bearing—should be left

straight. In fact, try not to touch the tip at all as you are

arching and curving the needle, for fear of distorting the

needle. Remember that you are shaping the needle to fit

your particular airbrush.

The arch (side view) of the needle does not need to be

too great—just enough to give a little tension when the

needle guide is screwed all the way down. With a more

extreme arch the tip of the needle rides in the bearing at

too great an angle. In addition, the motion of the needle is

not as smooth, because the crest of the arch is passing in

and out from under the needle guide.

Continued on page 3

Page 3

Paasche AB (Fine Art) Airbrush Instructions and Parts List Page 3

AIR VALVE PARTS REPLACEMENT:

Th is is rare ly necessary, but the se part s c an be

replaced fairly simply. Unscrew the valve nut and remove

the spring plunger, and washer in that order. Use a small

stiff wire with a slight hook bent into the end of it to fish

out the washer. Then place a new washer on the plunger

and insert the plunger and washer together. To avoid

compressing the springs too far, screw the valve nut in

only until it is slightly below the level of the air valve

casing.

ADJUSTING THE AIRBLAST TUBE:

Check that the color cup is properly positioned as

described above. With pliers loosen the locknut where the

airblast tube attaches to the body of the airbrush. Now

rotate the airblast tube, screwing it in (counter-clockwise)

or out (clockwise) until the airblast jet is about 1/64 inch

from the end of the needle bearing. Now with the air

turned off pull back the finger lever so that the needle is

pushed out in front of the airblast jet. The distance from

SHAPING THE NEEDLE (Continued from page 2):

The other curve of the needle (top view) is the one that

varies most from airbrush to airbrush. Again, there should

be a gradual curve, with a straight section at the tip of the

needle. The idea is to curve the needle completely under

the lip of the needle guide (if the needle rides at the edge

of the lip, the needle will not stay in place as it oscillates),

and at the same time for the tip of the needle to ride

nearly parallel with the edges of the slot in the needle

bearing. It is normal for the tip of the needle to sit at a

slight angle in the needle bearing—with the curve in the

ne edle, you can ’t help it. But this angl e sh ould be

minimized, to keep the needle from binding in the needle

bearing.

ADJUSTING THE COLOR CUP:

The color cup is clamped into the color cup support by

tightening the screw on the front side of the support. To

the needle to the tip of the jet should be about 1/64 inch.

Very carefully you may bend, if necessary, the airblast

tube where it enters the locknut and arches to the body of

the airbrush to accomplish this second adjustment. Do

not bend at the elbow of the airbrush tube or in front of

the elbow for two reasons: (1) curved tubing such as the

elbow in the airblast tube is inherently more brittle and

tends to crack if leverage is applied to it, and (2) there is a

soldered joint where the stipple adjuster is attached to the

elbow, which may break if pressure is applied.

Finally set the airblast tube so that the needle, when

extend ed, passes through the center of the airstream

from the airblast jet—that is, as you sight down the hole in

the airblast jet, the needle should cross the center of that

hole. If the needle is off center, you will get a stippling

effect, and for some applications you may wish to set the

airblast tube in this way purposely.

determine how far the color cup should project from the

support, first run the Finger Lever Adjusting Screw out

(counter-clockwise) until there is just a “hair’s breadth”

remaining between the butt end of the needle and the end

of the slot in the walking arm. This finger lever position is

called the “farthest forward rest position.”

Now slide the color cup in or out of the support until the

tip of the needle comes to the end of the slot in the

needle bearing but does not project from it. Attach the AB

to your air compressor and start the needle moving with

the finger lever in the “farthest forward rest position”

(push down the lever but do not pull back). Slide the color

cup out unti l the need le d oes not proje ct f rom the

bearing—you now have the correct color cup position for

the “farthest forward rest position.” Note: The rapidly

moving tip is easier to see against a white background.

The color cup can also be partially rotated to allow you

to spray onto a surface more or less horizontally. You will

notice as you rotate the color cup, the position of the

needle bearing changes, necessitating a readjustment of

the airblast tu be an d in a fe w insta n c e s even a

re curv ature o f th e ne edle . F or this rea son you will

probably want to find one position for the color cup which

The “AB” Airbr us h is not suita bl e for use with a lcohol or

lacquer colors. Any water color, opaque or oil can be used with

brilliant results.

See Page 4 for AB Replacement Parts and Parts Numbers.

is comfortable for you and then stick with it. The amount

of tilt is limited, from a position in line with the power

wheel housing to about 30 degrees below this line.

Page 4

Page 4 Paasche AB (Fine Art) Airbrush Instructions and Parts List

If P arts are worn and a forement ioned repa irs a re no t

pro v i ng h elpful , Paa s c he s u ggest s the purch a s e o f

replacement parts listed below. Any Parts not listed MUST

be replaced at the Factory.

* Denotes Part to be Fitted at the Factory.

For further information contact Paasche Service

Department.

NO.

1. A-140 Speed Regulator Screw

2. A-139 Air Blast Tube Locknut

3. A-173 Right Hand Air Blast Tube Assembly

4. *A-138 Right Hand Air Blast Tube

5. A-146 Stipple Adjuster

6. A-101 Air Blast Jet

7. A-179 Right Hand Color Cup Assembly

8. A-177 Right Hand Needle Bearing

9. A-160 Color Cup Screw

10. A-142 Needle Guide

11. A-116 Needles (Dozen)

12. A-107 Walking Arm

13. *A-131 Right Hand Wheel Housing

14. *A-172 Power Wheel & Shaft Assembly

15. A-114 Grease Cup

16. A-106 Walking Arm Shaft (Screw)

17. A-105 Walking Arm Spring

18. A-104 Walking Arm Plunger

19. A-121 Finger Lever and Button

20. A-146 Lever Adjusting Screw (Old# A-60)

21. A-58 Lever Pivot

22. A-14 Lever Fork

23. A-122 Right Hand Shell (Includes A-128)

PART NO. DESCRIPTION

A-173LH Left Hand Air Blast Tube Assembly

*A-138LH Left Hand Air Blast Tube

A-179LH Left Hand Color Cup Assembly

A-177LH Left Hand Needle Bearing

A-116LH Left Hand Needles (Dozen)

*A-131LH Left Hand Wheel Housing

A-122LH Left Hand Shell (Includes A-128)

SPECIAL NOTE: Periodically the

Grease Cup (Item 15) should be

removed and the Bearing checked

for Grease - Apply if necessary.

NO.

24. F-143 Handle (Old Style A-161)

26. A-133 Top Shaft Bearing

27. A-154 Bottom Shaft Bearing

28. A-143 Needle Guide Spring

29. A-52 Valve Washer (Pack of 6)

30. H-21A Valve Plunger

31. A-22 Valve Spring

32. A-23A Air Valve Nut

33. A-128 Valve Casing

PART NO.

A-34 Airbrush Hanger

A-64 Screw Driver

A-117 Tweezers

AB-CASE Case

PART NO.

A-1/8-6 Air Hose W/ Couplings

A-1/8-6MT Air Hose W/ MT Moisture Trap

AC-1/8 -1/4” Coupling

AC-20 1/8”-1/4”-40 Coupling

MT Moisture Trap

HF-1/4 Valve Assembly

PART NO. DESCRIPTION

ACCESSORIES

HOSE & ACCESSORIES

Loading...

Loading...