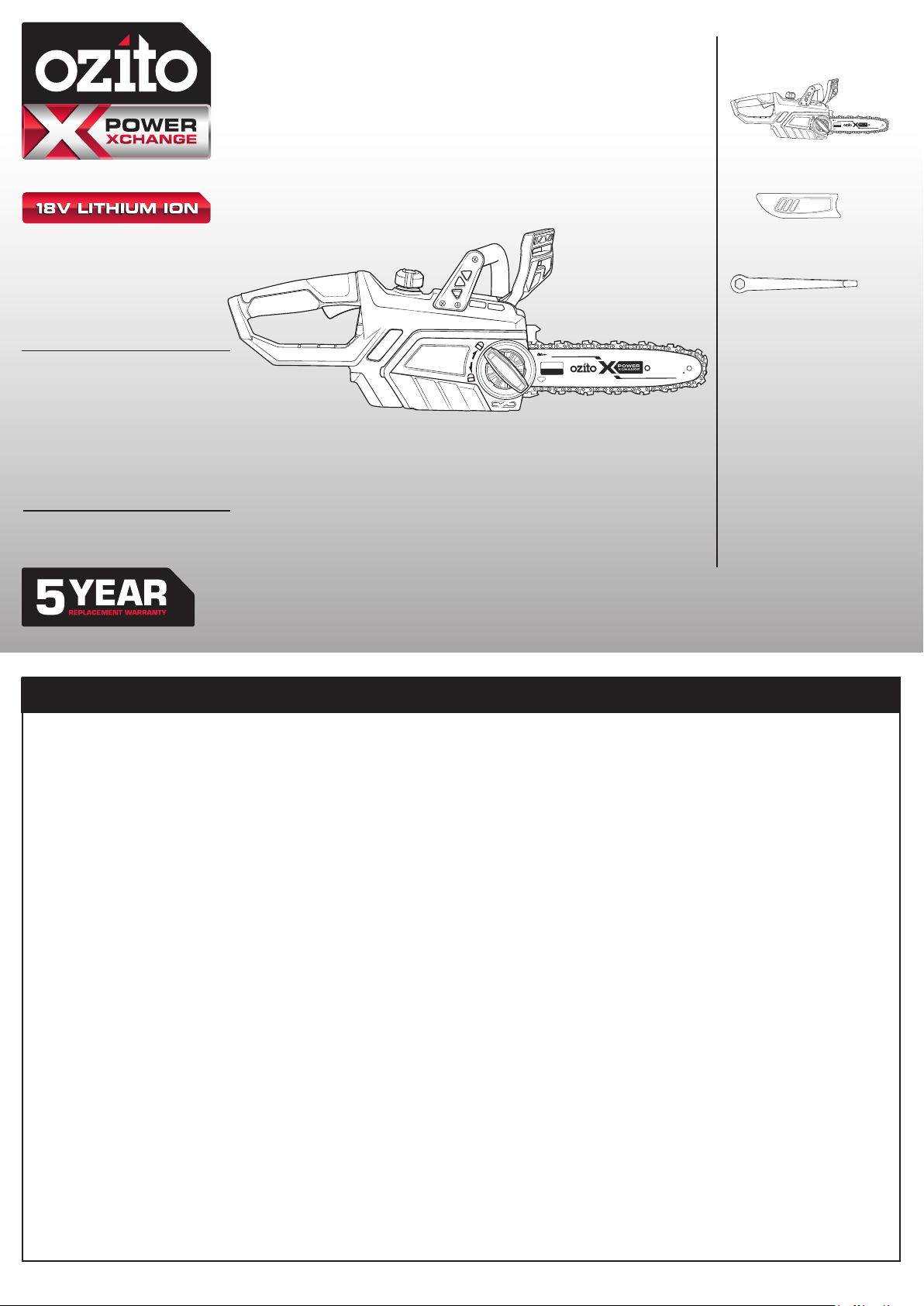

Ozito PXCCSS-018 User Manual

CORDLESS

10

in

250

mm

3/8” LP

40

STANDARD EQUIPMENT

10

in

mm

250

40

3/8” LP

Chainsaw

Guide Bar Cover

CHAINSAW

INSTRUCTION MANUAL

SPECIFICATIONS

Input: 18V

Bar Length: 250mm (10”)

Cutting Length Max.: 230mm

Chain Speed: 4.3m/s

Chain Pitch: 9.53mm (3/8”)

Chain Gauge: 1.1mm (.043”)

Oil Tank Capacity: 200ml

Weight: 3.0kg

ozito.com.au

WARRANTY

IN ORDER TO MAKE A CLAIM UNDER THIS WARRANTY YOU

MUST RETURN THE PRODUCT TO YOUR NEAREST BUNNINGS

WAREHOUSE WITH YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY PLEASE TELEPHONE

OUR CUSTOMER SERVICE HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

Screwdriver

PXCCSS-018

The benets provided under this warranty are in addition to other rights and

remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded at law. You are entitled to

a replacement or refund for a major failure and for compensation for any other

reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

Generally you will be responsible for all costs associated with a claim under this

warranty, however, where you have suffered any additional direct loss as a result of

a defective product you may be able to claim such expenses by contacting our

customer service helpline above.

TO ENSURE A SPEEDY RESPONSE PLEASE HAVE THE MODEL

NUMBER AND DATE OF PURCHASE AVAILABLE. A CUSTOMER

SERVICE REPRESENTATIVE WILL TAKE YOUR CALL AND

ANSWER ANY QUESTIONS YOU MAY HAVE RELATING TO THE

WARRANTY POLICY OR PROCEDURE.

5 YEAR REPLACEMENT WARRANTY

Your Product is guaranteed for a period of 60 months from the original date of

purchase and is intended for DIY (Do It Yourself) use only. If a product is defective it

will be replaced in accordance with the terms of this warranty. Lithium Ion

batteries and chargers are covered by a 36 month

warranty Warranty excludes consumable parts, for example: guide bar, chain

and included accessories.

WARNING

The following actions will result in the warranty being

void.

• If the tool has been operated on a supply voltage other

than that specied on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the instruction manual.

• If the tool is disassembled or tampered with in any way.

• Professional, industrial or high frequency use.

OZITO Australia/New Zealand (Head Ofce) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

0718

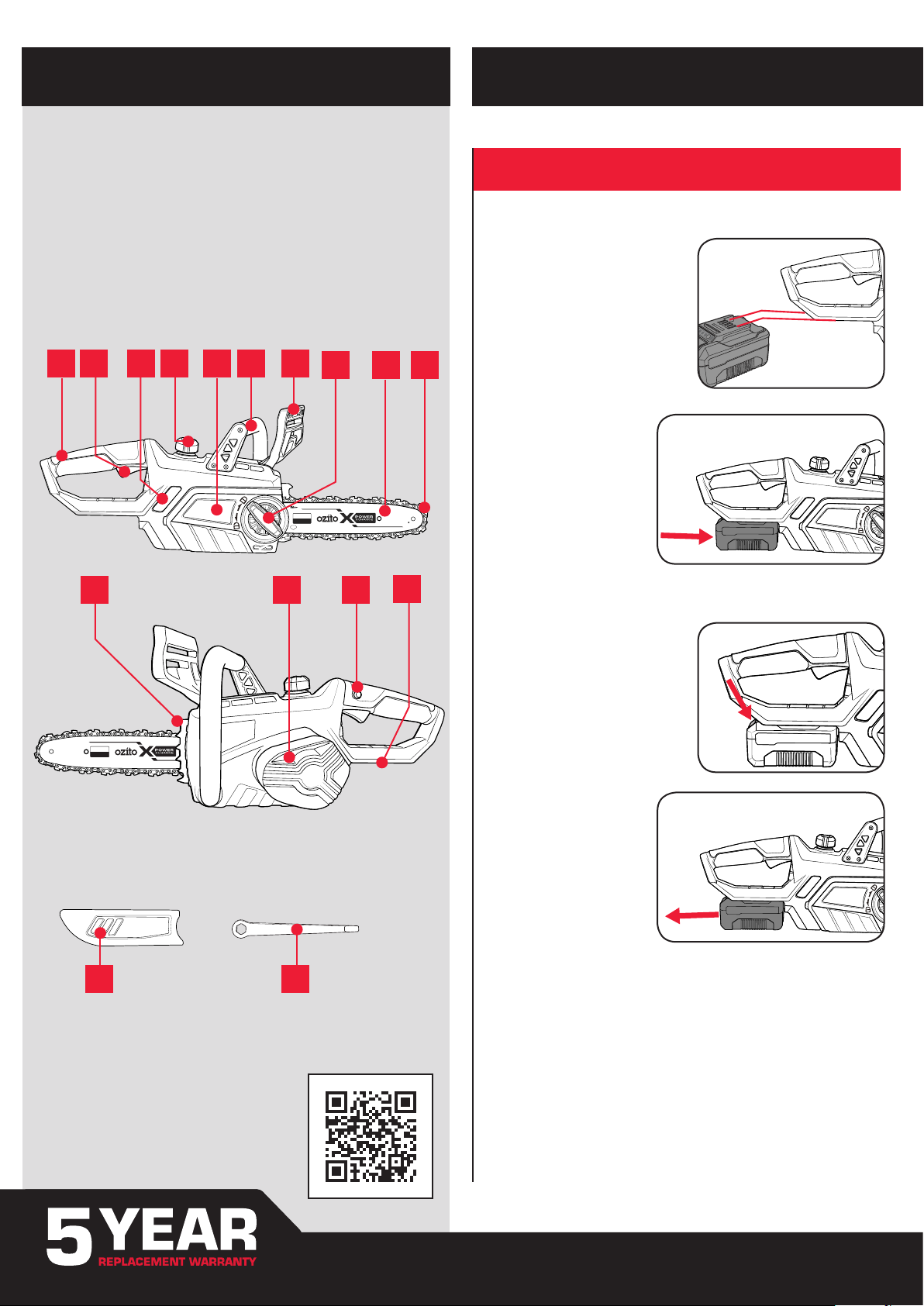

KNOW YOUR PRODUCT

SETUP & PREPARATION

CORDLESS CHAINSAW

1. Rear Handle

2. Trigger Switch

3. Oil Level Window

4. Chain Oil Tank Cap

5. Side Cover

6. Front Handle

7. Chain Brake

8. Guide Bar Locking Knob

9. Guide Bar

10. Chain

11. Bucking Spikes

12. Motor Cover

13. Lock-Off Button

14. Battery Seating

1 2 3 4 5 6 7

10

250

40

3/8” LP

11 12 13

1. INSERTING & REMOVING BATTERY

Installing a Battery into the Chainsaw

1. Align the ribs of the battery with

the recess below the handle

8

in

mm

9

14

10

2. Slide the battery in so

that it clicks into place.

Removing a Battery from the Chainsaw

10

in

mm

250

ACCESSORIES

15 Guide Bar Cover 16 Screwdriver

15 16

BATTERY & CHARGER

This tool is compatible with all battery and chargers from the Ozito

Power X Change Range.

1. Press and hold the battery

release tab to release the

battery.

2. Slide the battery out.

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to the

online manual.

OPERATION

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

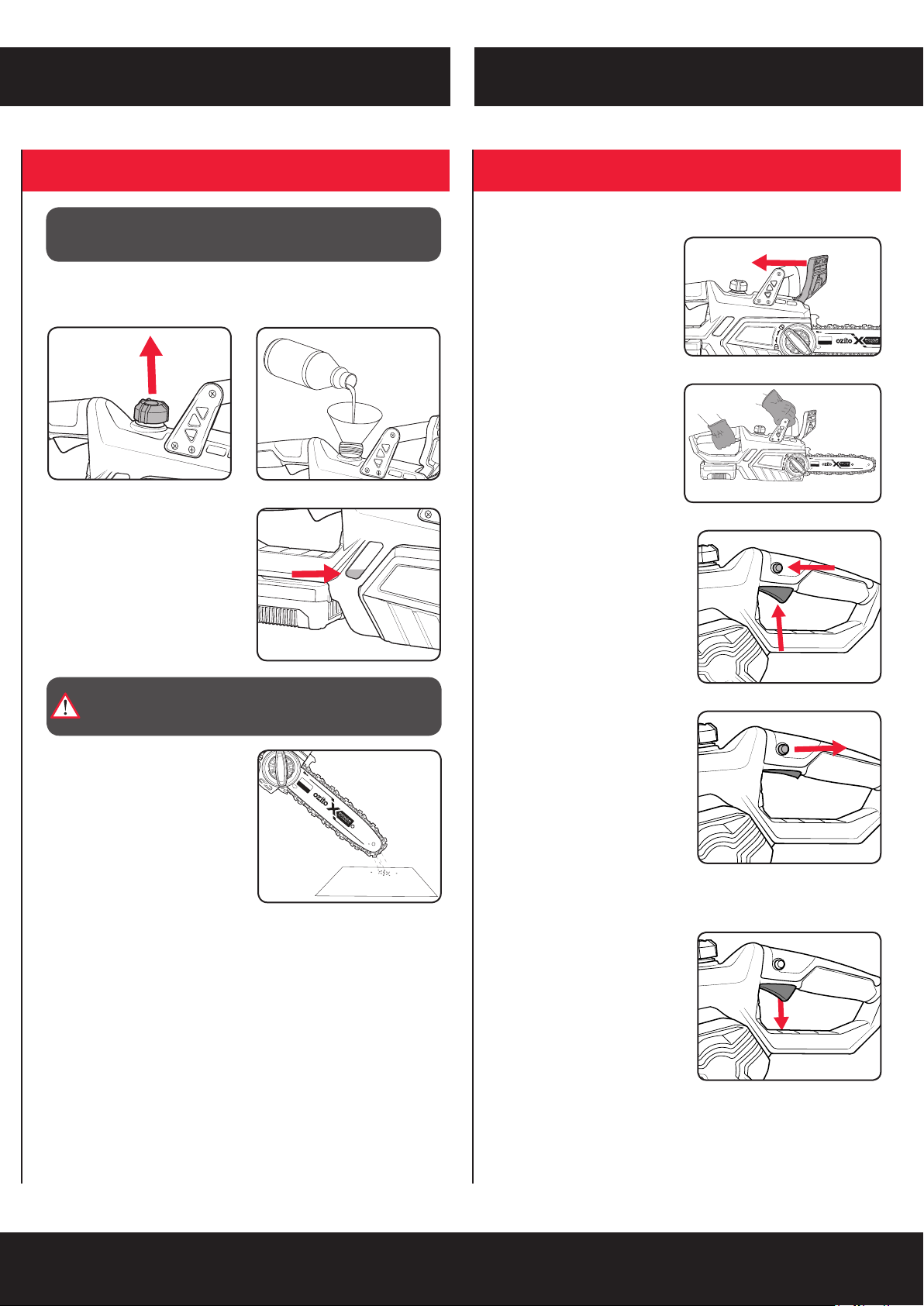

2. OIL 3. SWITCHING ON/OFF

IMPORTANT: ONLY USE OIL THAT IS EXPRESSLY LABELLED

“CHAIN BAR OIL”.

1. Remove the chain bar oil cap.

2. Fill the tank with chain bar oil.

The capacity of the chain oil

tank is 220ml. Do not over ll.

3. Ret cap and clean any oil

spillage.

4. Always ll the oil tank when the

oil level is below the minimum

mark on the oil level window.

Switching ON

1. Pull the hand guard/chain brake

towards you.

2. Hold the front handle with your

left hand and the rear handle

with your right hand.

3. Press the lock-off button with

your thumb, then squeeze the

trigger switch. The chainsaw

starts after a short delay.

WARNING!: NEVER START WORK UNLESS THE

CHAIN AND BAR ARE LUBRICATED

5. To check the lubricating system,

switch on the chainsaw and hold it

with the guide bar and chain above

some light coloured paper such as

newspaper. A steadily increasing

stain caused by oil spray shows

the lubricating system is working.

Note: Chain bar oil may leak if the tool is left for long periods. This is

normal. If the tool is to be left unused for an extended time, drain the oil from

the tool. Rell before use.

4. The chain will now be running,

ready to make a cut. Release

the lock-off switch.

Switching OFF

1. Release the trigger switch, the

chain and motor will quickly stop.

Running in the Chain

Prior to operation, a new chain should be run in for 2–3 minutes and then its

tension should be checked and adjusted as detailed in “MAINTENANCE”.

RUN

BRAKE ON

BRAKE OFF

STOP

10

in

250

mm

3/8” LP

40

4. CHAIN BRAKE

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

10

in

250

mm

3/8” LP

40

LEFT HAND

STRAIGHT

ARM

POSITION

CHAIN

LINE

30°

30°

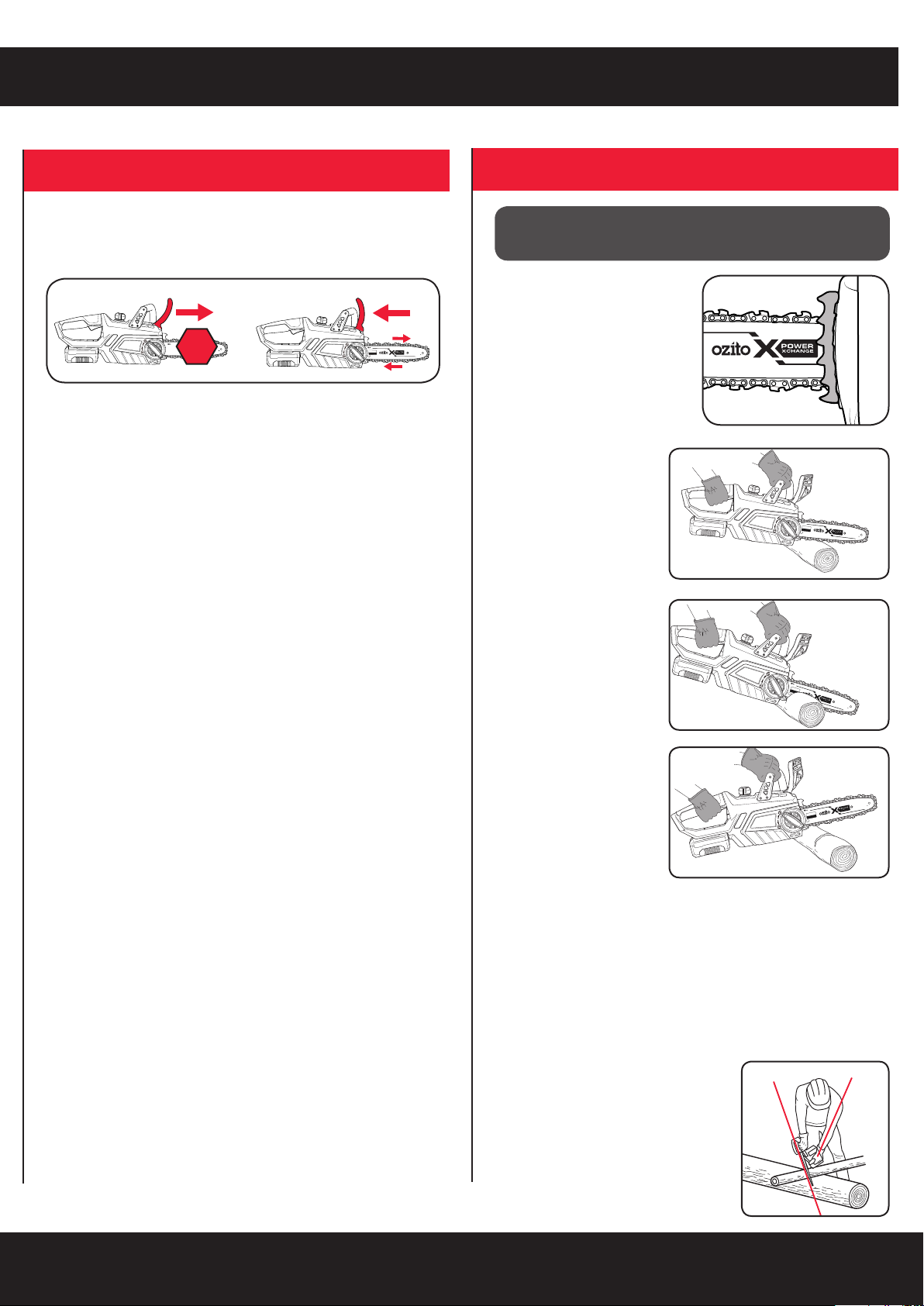

5. CUTTING

The chain brake operates automatically in the event of kick back.

The chainsaw is tted with a hand guard/chain brake which when operated

brings the chain to a stop within a tenth of a second.

The chain brake can be operated manually by pushing it forward or

automatically as a result of kickback.

Kickback occurs if the chain catches on the wood being cut and the chainsaw

recoils back suddenly.

In the event of kickback, your hand (which is on the front handle during

operation) jerks forward causing the back on your hand to push the guard

forward, engaging the chain brake and quickly stopping the chain.

CAUTION: FIRST TIME USERS SHOULD, AS A MINIMUM

PRACTISE, CUT LOGS ON A SAW-HORSE OR CRADLE

1. Press the bucking spikes against

the timber ensuring the chain

is not making contact with the

material being cut.

2. Start cutting by holding the

chainsaw by the front handle

and raising the rear handle.

3. If you cannot cut the timber

in a single stroke, apply

light pressure to the front

handle and continue sawing,

draw the chainsaw back a

little then apply the bucking

spikes a little lower and

nish the cut by raising the

rear handle.

4. Withdraw the chainsaw from

the cut while the chain is still

running.

Hints and Tips

• Do not force the saw into the cut. Apply only light pressure whilst running

the chain.

• If the saw chain gets caught in the cut, do not try to remove it by twisting

the guide bar or pulling forcibly. Use a lever or wedge to open up the cut

so that the saw chain is freed.

• Keep your left arm with elbow locked in a “straight arm” position to

withstand any kickback force.

• While cutting, always:

– Run the chainsaw motor at full speed. This makes the job safer, as there

is less chance of pull-in or kick-back.

– Position your body to the left of

the chainsaw so if it kicks back

uncontrollably, it goes over your right

shoulder, never stand in the cutting line

of the saw.

– Keep a rm grip with your left hand

on the front handle, with your thumb

securely below the handle.

1

2

1

2

APPLICATIONS

1

2

1

2

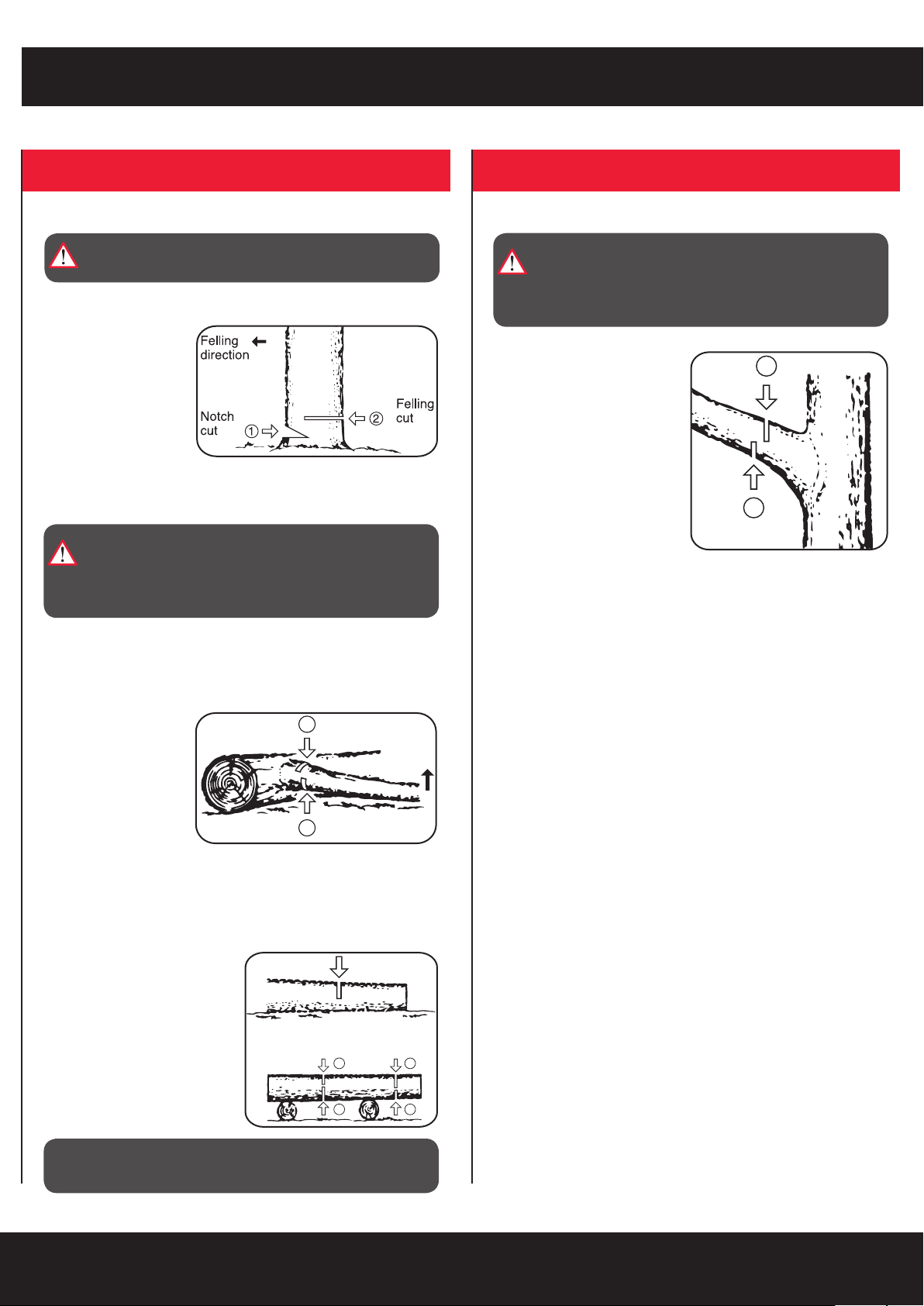

Felling a Tree

WARNING!: FELLING A TREE SHOULD ONLY BE

DONE BY TRAINED OPERATORS.

Decide the direction in which you wish the tree to fall, taking into account

the direction of the wind, the position of branches, lean of the tree, ease

of subsequent limbing and

bucking and other factors

prevalent at the time.

Limbing

WARNING!: FELLING ALWAYS KEEP A BALANCED

STANCE. DO NOT STAND ON THE LOG. BE ALERT TO

THE FACT THAT THE LOG MAY ROLL OVER. WHEN

WORKING ON A SLOPE, ALWAYS STAND ON THE UP HILL

SIDE OF THE LOG.

Limbing is the process of removing the branches from a fallen tree. Check

the direction in which a branch will bend before cutting it. Always cut on the

opposite side to the bending direction so that the guide bar is not pinched in

the cut. For large limbs that cannot be removed in one cut, make an initial cut

from the bent side and nish

by sawing from the opposite

direction. Do not remove

limbs that are supporting the

fallen tree on the ground until

the tree has been cut into

lengths.

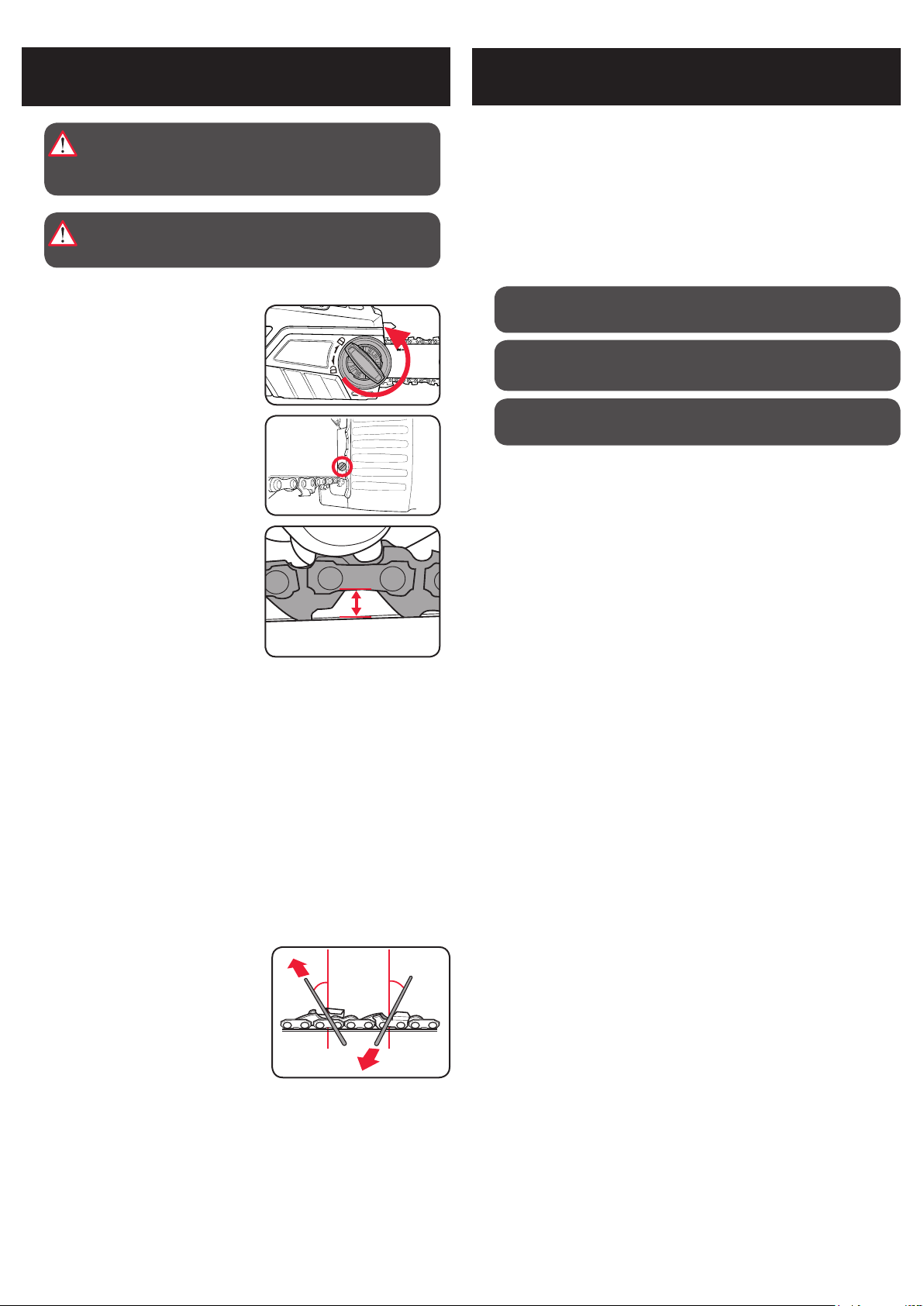

Pruning

WARNING!: DO NOT USE AN UNSTABLE FOOTHOLD

OR LADDER. DO NOT OVERREACH. DO NOT SAW

ABOVE SHOULDER HEIGHT. ALWAYS USE BOTH

HANDS TO HOLD THE SAW. FIRST CUT UP FROM THE

BOTTOM AND FINISH DOWN FROM THE TOP.

Pruning is the removal of a limb or

branch from a standing tree.

Bucking

Bucking is cutting a log into lengths for easier handling. To saw a log lying

on the ground, rst saw halfway, then roll the log over and cut from the

opposite side. To saw the end of a log

supported off the ground, rst saw up

from the bottom one-third through the

log then nish by sawing down from

the top. To saw a log in the middle

of two supports holding it off the

ground, rst saw down from the top

one-third through the log then nish

by sawing up from the bottom.

CAUTION: FIRST AVOID CUTTING THE GROUND AS THIS

WILL VERY QUICKLY DULL THE SAW CHAIN.

PXCCSS-018

3 - 4mm gap is

the ideal tension

MAINTENANCE

CUTTERS

RIGHT HAND

CUTTERS

30°

30°

TROUBLESHOOTING

WARNING: BEFORE CLEANING YOUR CHAINSAW OR

CARRYING OUT ANY MAINTENANCE PROCEDURE,

MAKE SURE THE BATTERY REMOVED TO PREVENT

ACCIDENTAL STARTING.

CAUTION: ALWAYS WEAR GLOVES WHEN HANDLING

THE CHAIN AS IT IS VERY SHARP AND CAN CUT YOU

WHEN IT IS NOT MOVING.

Adjusting the Chain Tension

1. Loosen the guide bar locking knob

slightly, by rotating it in an anti

clockwise direction.

2. Adjustment chain tension screw

CLOCKWISE to increase chain tension.

Turning screw COUNTERCLOCKWISE

will decrease amount of tension on

the chain. Adjust the chain tension

screw for the correct tension.

For the correct chain tension, pull up on

the chain from the top and middle of the

exposed guide bar. The bottom tip of the

links should only just stay in the track.

3. After the chain has been accurately

tensioned, lock the guide bar in place

with the guide bar locking knob.

Note: Proper tension of the chain is extremely important and must be

checked before starting, as well as during any cutting operation.

Taking the time to make adjustments to the chain will result in

improved cutting performance and prolonged chain life.

Maintaining the guide bar

1. Remove any sawdust from the guide bar, including the groove.

Oil and sawdust combine and emit a burning smell during operation if the blade is not

regularly cleaned.

2. Make sure that the oil port is not clogged. Grease the nose sprocket at the tip of the

guide bar.

3. Check for oil leakage and loose fastenings, especially those securing the handles and

the guide bar.

4. Reverse the guide bar every 8 working hours to ensure uniform wear. Check the guide

rails frequently and if necessary remove burrs and square up the rails using a at le.

Cleaning and storing

• Keep the handles free of grease so that you can maintain a rm grip.

• Clean the device as required with a damp cloth and, if necessary, mild washing up

liquid.

• If the chainsaw is not to be used for an extended period of time

then you should remove the chain oil from the tank. Briey immerse the chain and

the cutter rail in an oil bath and then wrap them

in oil paper.

• Ensure that the guide bar cover is in place when storing.

CAUTION! ALWAYS DISCONNECT THE BATTERY BEFORE

CLEANING THE CHAINSAW.

CAUTION! NEVER IMMERSE THE UNIT IN WATER OR

OTHER LIQUIDS IN ORDER TO CLEAN IT.

CAUTION! STORE THE CHAINSAW IN A SAFE AND DRY

PLACE OUT OF THE REACH OF CHILDREN.

Battery protection system

The tool is equipped with the battery protection system, which helps to ensure a long service

life.

The output power automatically cuts off during operation when the tool and/or battery are

placed under the following situations:

• When the tool is overloaded:

If this occurs, release the trigger switch and remove causes of overload, then pull the

switch trigger again to restart.

• When the remaining battery capacity becomes low:

Recharge the battery pack.

Note: The battery protection system does not in any way damage the tool.

Note: The indicated capacity may be lower than the actual level during use or immediately

after using the tool.

LED lights do not illuminate on charger

Check the charging adaptor is securely plugged into the wall outlet.

Check the battery is rmly connected to the charging cradle.

Check that the charging jack is securely connected to the charging cradle.

The battery has a short run time

Ensure the battery is properly charged. It will take 4-5 charging cycles before the battery

reaches optimum charge and run time.

Sparking visible through the housing air vents

A small amount of sparking may be visible through the housing vents. This is normal and

does not indicate a problem.

Chain Sharpening

Chain File: 3.96mm (5/32”)

Chain Pitch: 9.53mm (3/8”)

Chain Gauge: 1.1mm (0.043”)

Sharpen the chain regularly to maintain

optimum performance of the saw. Signs of a

dull chain are:

• The sawdust becomes powder-like

• Extra force is required to execute a cut

• The cut does not track in a straight line

• Increased vibration

Sharpen each cutter using a round 3.96mm (5/32”) chain le. Keep the le level with the

top plate of the tooth. Always use outward strokes and maintain a 30° angle between the

chain and le. After sharpening, the cutters must all have the same width and length.

After every 3–4 uses get an authorised repair centre to professionally sharpen your chain.

They have the special tools necessary to ensure the correct cutting angles and depths.

Loading...

Loading...