Ozito MCS-2355 Instruction Manual

METAL

STANDARD EQUIPMENT

CUT-OFF SAW

2300W

INSTRUCTION MANUAL

SPECIFICATIONS

Motor: 2300W

Input: 230

No Load Speed: 4,400/min

Cut-off Wheel

Max. Diameter: 356 x 3mm (14” x 1/8’’)

Arbour Size: 25.4mm

Cutting Angle Capacity: 0

Max. Cutting Capacities @90°: Round steel 130mm

Square steel 120mm

Rectangle steel 120x130mm

Angle steel 140x140mm

@45°: 90x100mm

Weight: 16.8kg

ozito.com.au

–

240V~50Hz

–

45º Left, 0 – 15º Right

Metal Cut-off Saw

Cut-off Wheel (Fitted)

Hex Key

MCS-2355

WARRANTY

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE WITH

YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY

PLEASE TELEPHONE OUR CUSTOMER SERVICE

HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL

AND ANSWER ANY QUESTIONS YOU MAY

HAVE RELATING TO THE WARRANTY POLICY

OR PROCEDURE.

The benefits provided under this warranty are in addition

to other rights and remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded

at law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Generally you will be responsible for all costs associated with

a claim under this warranty, however, where you have suffered

any additional direct loss as a result of a defective product you

may be able to claim such expenses by contacting our customer

service helpline above.

3 YEAR REPLACEMENT WARRANTY

Your product is guaranteed for a period of 36 months from

the original date of purchase. If a product is defective it will

be replaced in accordance with the terms of this warranty.

Warranty excludes consumable parts, for example: carbon brushes,

spanners, cutting disc, accessories.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage other

than that specified on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the

instruction manual.

• If the tool is disassembled or tampered with in any way.

• Professional, industrial or high frequency use.

OZITO

Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

0919

3

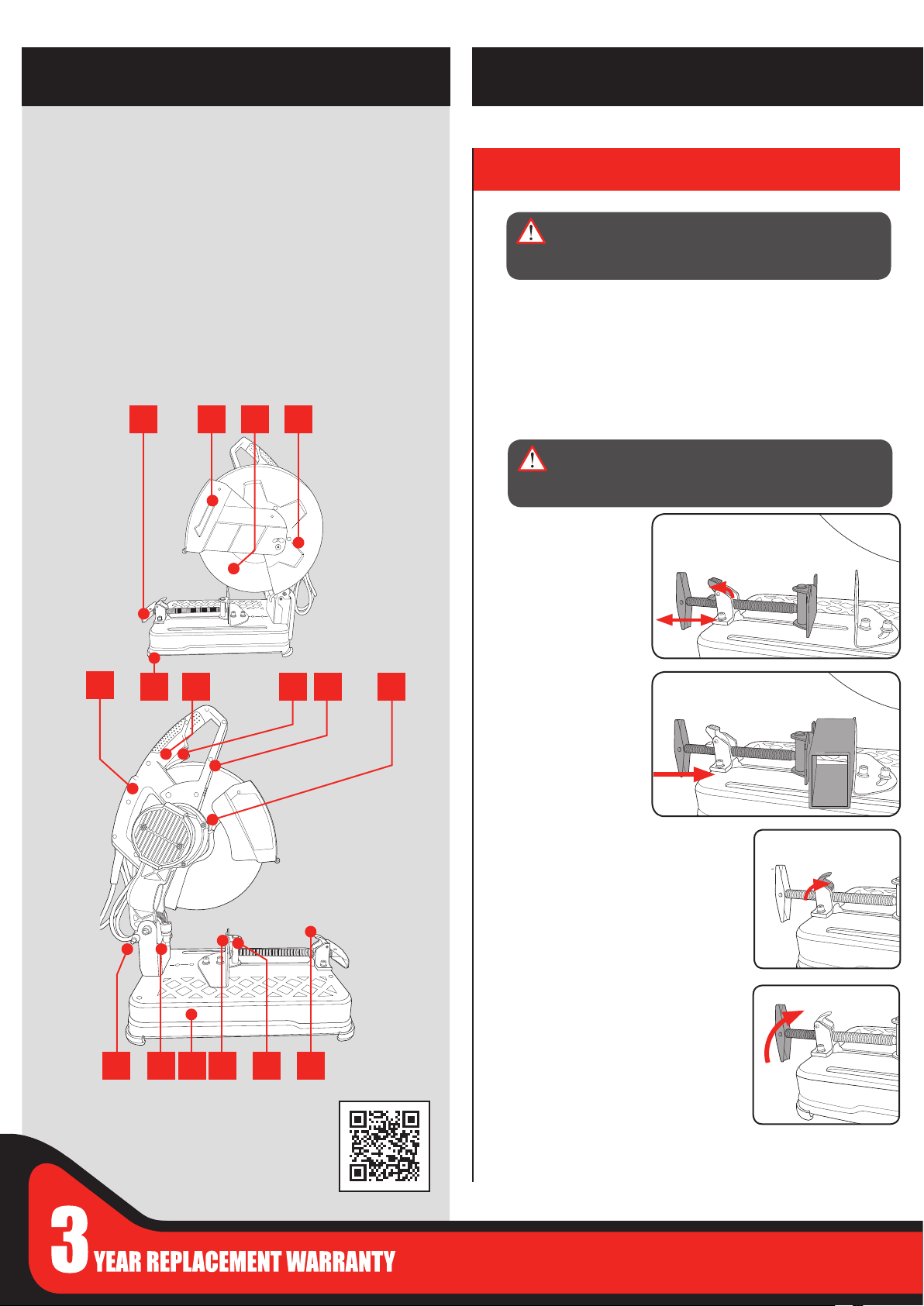

KNOW YOUR PRODUCT

SETUP & PREPARATION

METAL CUT-OFF SAW

1. Vice handle

2. Lower guard

3. Cut-o wheel

4. Upper guard

5. Carry handle

6. Rubber feet

7. Lock-o button

8. Trigger switch

9. Main handle

1

2 3 4

10. Spindle lock button

11. Lock down pin

12. Depth stop

13. Base

14. Fence

15. Vice

16. Quick release vice lock

17. Hex Key Storage

18. Hex Key

1. ADJUSTMENTS

WARNING! ENSURE THAT THE TOOL IS TURNED

OFF AND DISCONNECTED FROM THE POWER

SUPPLY BEFORE PERFORMING ANY OF THE

FOLLOWING OPERATIONS.

Your Metal Cut-O Saw is used for cutting steel such as pipe, box

section, rectangular, angle iron and steel bars. The saw can cut at

angles from 0 to 45º left & 0 to 15º right, it features a three position

fence that permits an extended cutting range. The quick release vice

allows fast adjustment whilst the lock-o button prevents accidental

operation. It is intended for DIY use only.

Adjusting the vice

WARNING! ENSURE THAT THE VICE SECURING

BOLTS AND VICE ARE FIRMLY TIGHTENED BEFORE

USE TO PREVENT THE WORKPIECE MOVING AND

RISK OF PERSONAL INJURY.

The vice can be

adjusted quickly by

lifting the quick release

vice lock and pushing

forward or pulling back

on the vice handle.

5

7 8

6 9 10

11 12 13 14 15 16

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

1. Place your work

piece in between the

fence and vice.

2. Lift the quick release

vice lock and push

the vice forward.

3. Once the vice hits the work piece push

down the quick release vice lock.

4. Rotate the vice handle in a clockwise

direction to secure the work piece in

position.

5. To remove an object from the vice,

rotate the vice handle in an anti-

clockwise direction until the vice jaws

are loose. The work piece can now be

removed.

Note: The quick release vice lock cannot be lifted until the vice jaws

have been loosened.

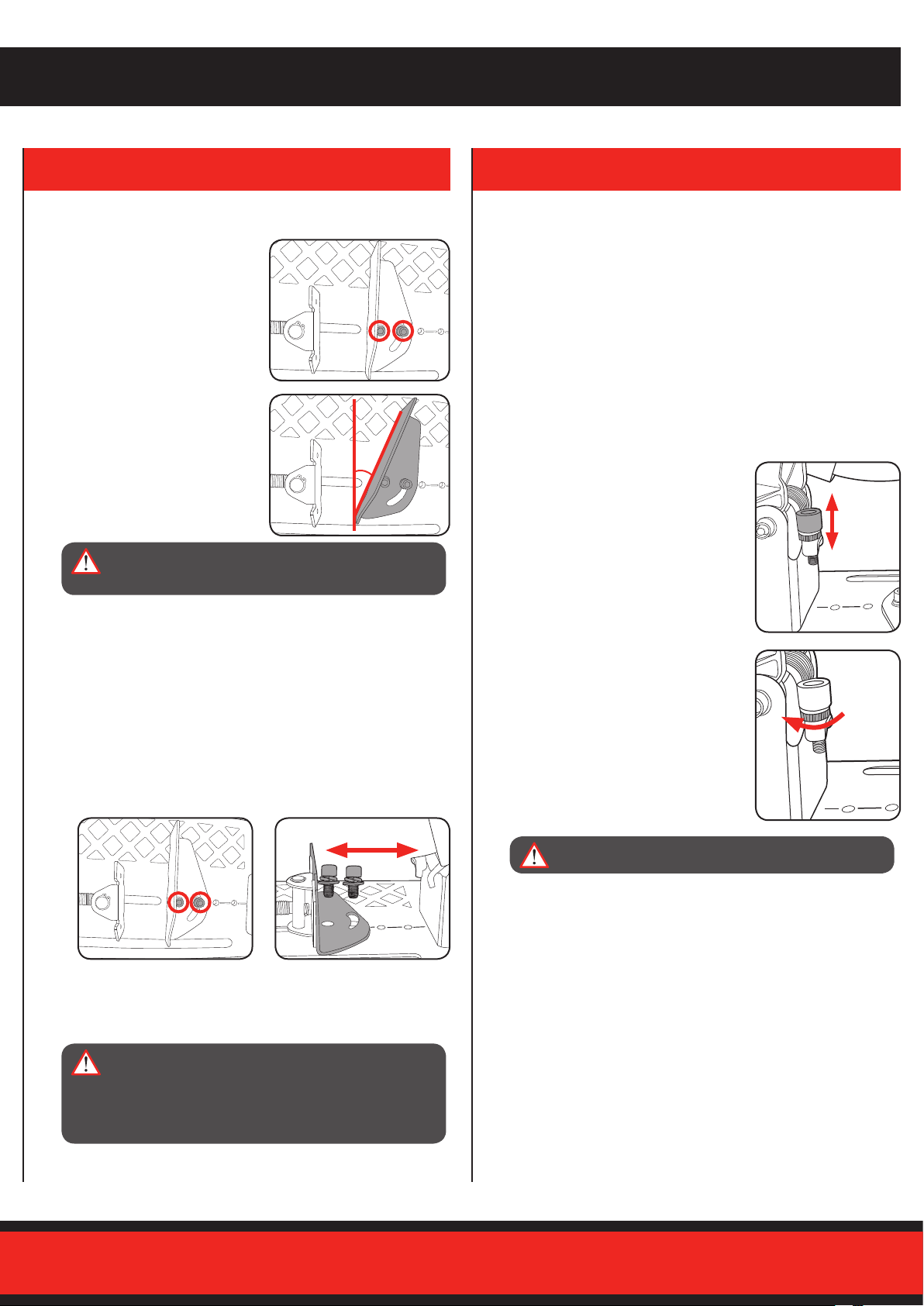

Adjusting the cutting angle

1. To change the cutting angle

loosen the two bolts securing

the fence using the hex key

supplied.

2. Move the rear fence to the

desired angle using the scale

as a guide.

Depth stop

Note: Ensure that the depth stop is adjusted to the correct height

before commencing operation.

The adjustable depth stop is threaded into the base of the machine at

the rear.

The travel of the cut-o wheel can be controlled by raising and lowering

the depth stop bolt.

This feature is particularly useful to prevent contact with the work

bench surface when a new cut-o wheel is tted or to increase cut-o

wheel travel as the cut-o wheel wears.

The depth stop should be checked and adjusted every time

a new cut-o wheel is tted.

3. Tighten the two bolts to secure

the fence in position.

WARNING! ONLY PERFORM ANGLE CUTS WHEN

THE FENCE IS SET AT THE MOST FORWARD

POSITION (REFER TO ADJUSTING THE FENCE).

Note: For accurate cuts, test the cutting angle on some similar scrap

material and adjust the angle to suit your requirements. The scale is

only a guide.

Adjusting the fence

The spacing between the vice and the fence as supplied is 170mm.

When cutting wider materials the rear fence will need to be adjusted to

the rear position. When cutting narrow work pieces the fence should

be positioned in the most forward position.

1. To adjust, loosen and remove the two bolts securing the fence

using the Hex key.

1. Loosen the depth stop with the hex

key supplied.

2. Increase or decrease the height

of the depth stop.

3. Tighten the depth stop knurled lock nut

with your ngers.

WARNING! DO NOT REMOVE OR OPERATE

WITHOUT THE DEPTH STOP!

2. Move the fence backwards or

3. Tighten the two bolts to secure

the fence in position.

WARNING! NARROW WORKPIECES MAY NOT BE

SECURED SAFELY WHEN USING AN INTERVAL

TOO WIDE FOR THE FENCE. ENSURE THAT THE

FENCE IS SET TO THE MOST FORWARDS POSITION

THAT ALLOWS THE WORKPIECE TO BE CLAMPED

SECURELY.

forwards to one of the other

two xing positions.

Loading...

Loading...