Ozito ACP-2420 Instruction Manual

OILED AIR

COMPRESSOR

24L 2.0HP

INSTRUCTION MANUAL

SPECIFICATIONS

Power supply: 220–240V ~ 50Hz

Motor: 1500W (S2 15min), 2.0HP

Tank Capacity: 24L

No Load Speed: 2,850/min

Max. Pressure: 8bar (116psi)

Max. Flow Rate: 165L/min

Free Air Delivery: 54.4L/min

IP Rating: IP20

Weight: 22kg

ozito.com.au

STANDARD EQUIPMENT

100

150

50

200

0

225

100

150

50

200

0

225

Air Compressor

WARRANTY

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE WITH

YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY

PLEASE TELEPHONE OUR CUSTOMER SERVICE

HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL

AND ANSWER ANY QUESTIONS YOU MAY

HAVE RELATING TO THE WARRANTY POLICY

OR PROCEDURE.

ACP-2420

The benefits provided under this warranty are in addition

to other rights and remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded

at law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Generally you will be responsible for all costs associated with

a claim under this warranty, however, where you have suffered

any additional direct loss as a result of a defective product you

may be able to claim such expenses by contacting our customer

service helpline above.

3 YEAR REPLACEMENT WARRANTY

Your product is guaranteed for a period of 36 months from

the original date of purchase. If a product is defective it will

be replaced in accordance with the terms of this warranty.

Warranty excludes consumable parts, for example: valve adapters

and accessories.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage other

than that specified on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the

instruction manual.

• If the tool is disassembled or tampered with in any way.

• Professional, industrial or high frequency use.

OZITO

Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

1118

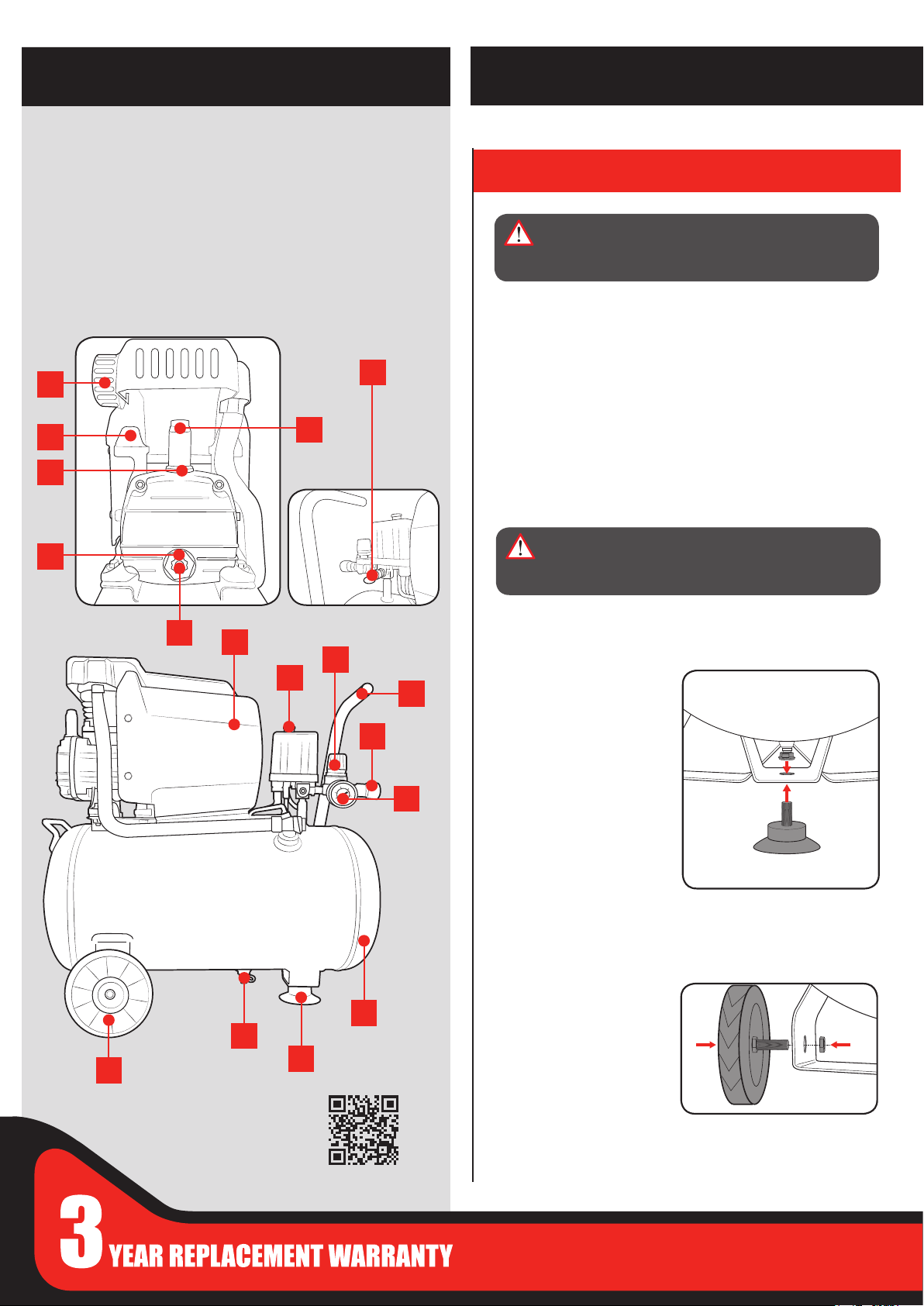

KNOW YOUR PRODUCT

AIR COMPRESSOR

1. Safety Relief Valve

2. Oil Sealing Plug

3. Intake Air Filter

4. Overload Reset Switch

5. Oil Filler Opening

6. Oil Drainage Screw

7. Oil Level Window

8. Motor Housing

9. On/O Button

3

4

5

10. Pressure Regulator

11. Transport Handle

12. Regulated Pressure Outlet

13. Regulated Pressure Gauge

14. Pressure Tank

15. Support Foot

16. Drain Valve

17. Wheels

2

SETUP & PREPARATION

1. ASSEMBLY

WARNING! ENSURE THE TOOL IS TURNED OFF

AND DISCONNECTED FROM THE POWER SUPPLY

BEFORE PERFORMING ANY OF THE FOLLOWING

OPERATIONS.

Pre-Setup Checks

• Examine the machine for signs of transit damage. If damaged, do

not use, return to place of purchase

1

• The compressor should be set up near to the user.

• Avoid long air lines and long supply lines (extensions).

• Make sure the intake air is dry and dust-free.

• Do not set up the compressor in damp or wet rooms. The

compressor is designed to be used in dry rooms. It is prohibited

to use the compressor in areas where work is conducted with

sprayed water.

• Before you use the machine, make sure that the mains voltage

complies with the specications on the rating plate.

WARNING! ALWAYS KEEP THE COMPRESSOR

6

7

8

10

9

11

12

100

150

50

200

0

225

13

UPRIGHT. TIPPING THE COMPRESSOR ON ITS SIDE

MAY CAUSE THE OIL IN THE MOTOR TO LEAK OUT

AND DAMAGE THE UNIT.

Attaching The Support

Foot

1. Insert the support foot bolt

through the hole in the frame

for the support foot and

secure it in place with a Nyloc

nut.

Attaching The Wheels

1. Place the bolt on a wheel

assembly through the hole in

the wheel bracket and fasten

it in position with a Nyloc nut.

17

14

16

15

ONLINE MANUAL

Scan this QR Code with

your mobile device to take

you to the online manual.

2. Repeat step 1 to t the second wheel on the opposite side of the

tank.

OPERATION

Max.

Min.

0

50

100

150

200

225

ON

OFF

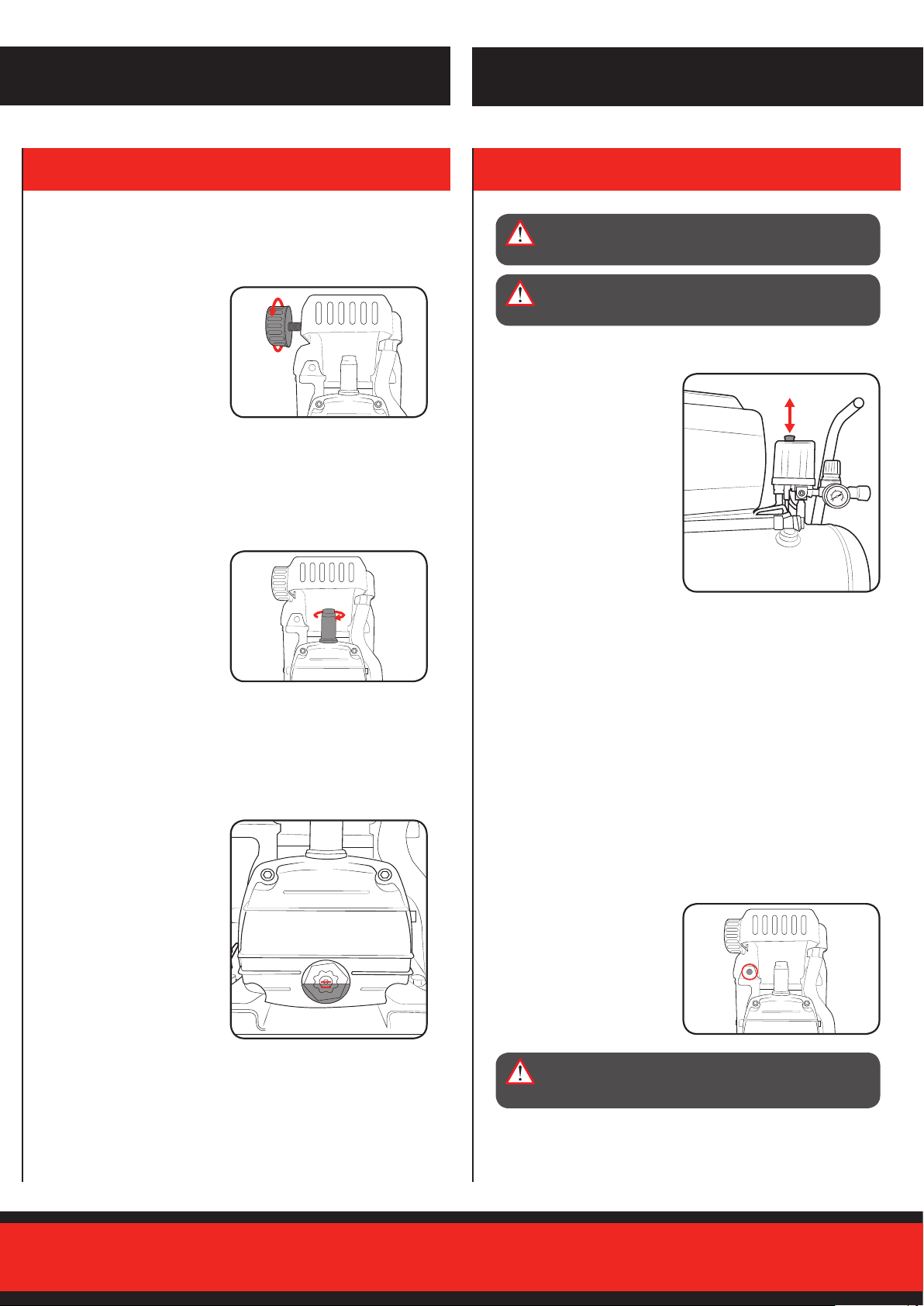

2. CONTROLS

Fitting The Air Filter

1. Remove the transportation cover from the air lter connection with

a screwdriver.

2. Attach the supplied air lter by

screwing it in clockwise.

Fitting The Oil Sealing Plug

1. Remove the transportation cover from the oil ller opening with a

athead screwdriver.

2. Insert the oil sealing plug into

the oil ller opening.

WARNING! THE AIR COMPRESSOR MUST BE USED

WITH A RESIDUAL CURRENT DEVICE WITH A

RATED RESIDUAL CURRENT OF 30MA OR LESS.

WARNING! DO NOT LEAVE THE AIR COMPRESSOR

UNATTENDED WHILE THE ON/OFF SWITCH IS IN

THE ‘ON’ POSITION.

Switching The Compressor On/O

1. To switch the compressor on,

press the on/o switch to the

‘I’ position. Allow the motor to

run and the tank to ll up.

The compressor will automatically cut o when the tank

Note:

pressure reaches 8bar and will automatically start up again when the

tank pressure drops to 5.5bar.

Checking The Oil Level

1. Place the compressor on a level surface.

2. Check that the oil level is

between the the ‘MAX’ and

‘MIN’ marks on the oil level

window.

3. If the oil level is below the ‘MIN’ mark, refer to the Maintenance

section - Changing The Oil and follow the directions for relling the

oil in the compressor.

2. To switch the compressor o, press the on/o switch to the ‘0’

position.

Restarting The Compressor If It Overloads & Shuts O

The motor is tted with an overload switch which turns o the

equipment automatically to protect the compressor from overheating.

1. If the overload switch triggers, switch o the compressor using the

On/O Switch and wait until the compressor cools down.

2. Press the Overload Reset

Switch and restart the

compressor.

WARNING! DO NOT CONTINUE USE OF THE

UNIT IF THE OVERLOAD SWITCH TRIPS AGAIN

IMMEDIATELY AFTER THE RESET.

Loading...

Loading...