User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 1 of 28

User & Superuser Manual

Touch screen Controller

intelliControl Siemens

Manufacturer:

OXYMAT – Slovakia, s.r.o.

Vaďovce 87

916 13 Vaďovce

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 2 of 28

Siemens SIMATIC HMI TP700 comfort – for

standard functionality + remote control and view

Siemens SIMATIC HMI KTP700 basic for

standard functionality

Valid for:

intelliControl Siemens X1-X2

Software version: ≥ 1.09

SIMATIC KTP700 BASIC

SIMATIC TP700 COMFORT

COPYRIGHT NOTICE

Any unauthorized use or copying of the contents or any part thereof is prohibited.

This applies in particular to trademarks, model & functionality names, and pictures.

Siemens, Siemens Logo and Simatic is a registered trademark of Siemens AG

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 3 of 28

Contents

1. Safety and responsibility ......................................................................................................................................... 4

1.1. Specified & Improper use ..................................................................................................................................................... 4

1.2. Safety precautions ................................................................................................................................................................ 4

2. Design and function ................................................................................................................................................. 5

2.1. Main components ................................................................................................................................................................. 5

2.2. Function ................................................................................................................................................................................ 5

3. Home ......................................................................................................................................................................... 6

3.1. System status ....................................................................................................................................................................... 7

3.2. Purge status ......................................................................................................................................................................... 7

4. Operation .................................................................................................................................................................. 8

4.1. PSA generator Start & Stop ................................................................................................................................................. 9

4.2. Start & Stop in service mode ............................................................................................................................................... 9

5. Process ................................................................................................................................................................... 10

6. Settings ................................................................................................................................................................... 11

6.1. General settings ................................................................................................................................................................. 11

6.2. Process settings ................................................................................................................................................................. 12

6.3. Measure 1 settings ............................................................................................................................................................. 13

6.4. Measure 2 settings ............................................................................................................................................................. 13

6.5. Advanced settings .............................................................................................................................................................. 14

6.6. Alarm settings page 1 & 2 .................................................................................................................................................. 15

6.7. Smart delivery .................................................................................................................................................................... 16

6.8. PID Flowcontrol .................................................................................................................................................................. 17

6.9. SMS setting ........................................................................................................................................................................ 18

7. Trends ..................................................................................................................................................................... 19

8. Service ..................................................................................................................................................................... 20

9. Alarm ....................................................................................................................................................................... 21

9.1. Alarm history ...................................................................................................................................................................... 21

9.2. Alarm List & philosophy ..................................................................................................................................................... 22

10. Access levels .......................................................................................................................................................... 23

11. HMI desktop and Start center ................................................................................................................................ 24

11.1. Remote view ....................................................................................................................................................................... 24

11.2. IP address change ............................................................................................................................................................. 26

12. Logging ................................................................................................................................................................... 27

13. Loading program from SD card ............................................................................................................................ 28

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 4 of 28

1. Safety and responsibility

IntelliControl is manufactured to the latest engineering standards and acknowledged safety regulations. The

safety regulations of the PSA Generator manufactured by Oxymat-Slovakia in which Intellicontrol is installed

apply.

1.1. Specified & Improper use

IntelliControl is intended for the control of machines in which is factory-installed. Any other use is considered

incorrect. The manufacturer is not liable for any damages that may result from incorrect use. The operator alone

is liable for any risks incurred. Improper usage can cause damage to property and/or (severe) injuries to operator

or other personnel.

1.2. Safety precautions

Warning:

Use IntelliControl only as intended.

Warning:

Do not use IntelliControl to control other machines for which is not intended.

Warning:

The screen can be damaged if you press to hard or if you strike it with a hard or pointed object.

Warning:

The operating temperature shall be between 0°C to +50°C and humidity must not exceed 85%

RH (relative humidity). Otherwise, the screen may malfunction, or operating life shortens.

Warning:

Do not use in areas with large temperature fluctuations. This can cause condensation inside the

screen.

Warning:

Do not let water, other liquids, metal or charged particles enter into the screen. This can create

an electrical shock.

Warning:

Do not use the screen in direct sunlight. The UV rays can cause damage to the screen. Nor in

very dusty/dirty environments.

Warning:

To avoid impreciseness, keep the screen away from large shocks and excessive vibration.

Warning:

Do not use paint thinner or organic solvents to clean the screen.

Warning:

Temperature higher or lower than recommended can cause irreversible damage to data.

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 5 of 28

2. Design and function

IntelliControl controls, regulates, monitors, and protects the PSA Generator.

All parameters and settings needed to operate Oxymat PSA Generator can be set and displayed

using the IntelliControl. Various customer dependent password mechanisms protect the parameters.

2.1. Main components

IntelliControl has the following components:

• Enclosure

• Siemens PLC – industrial PC

• Siemens HMI – user interface

2.2. Function

The control and regulating functionality allows:

Control of the PSA Generator by HMI Touch screen

Setting parameters of process, e.g. pressure

Automatic stand by mode.

The monitoring functionality allows:

Monitoring of PSA process parameters, e.g. pressure, purity and temperature

Displaying warning alarms

The protective functionality allows:

Automatic shutdown on alarms that may lead to damage to the machine,

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 6 of 28

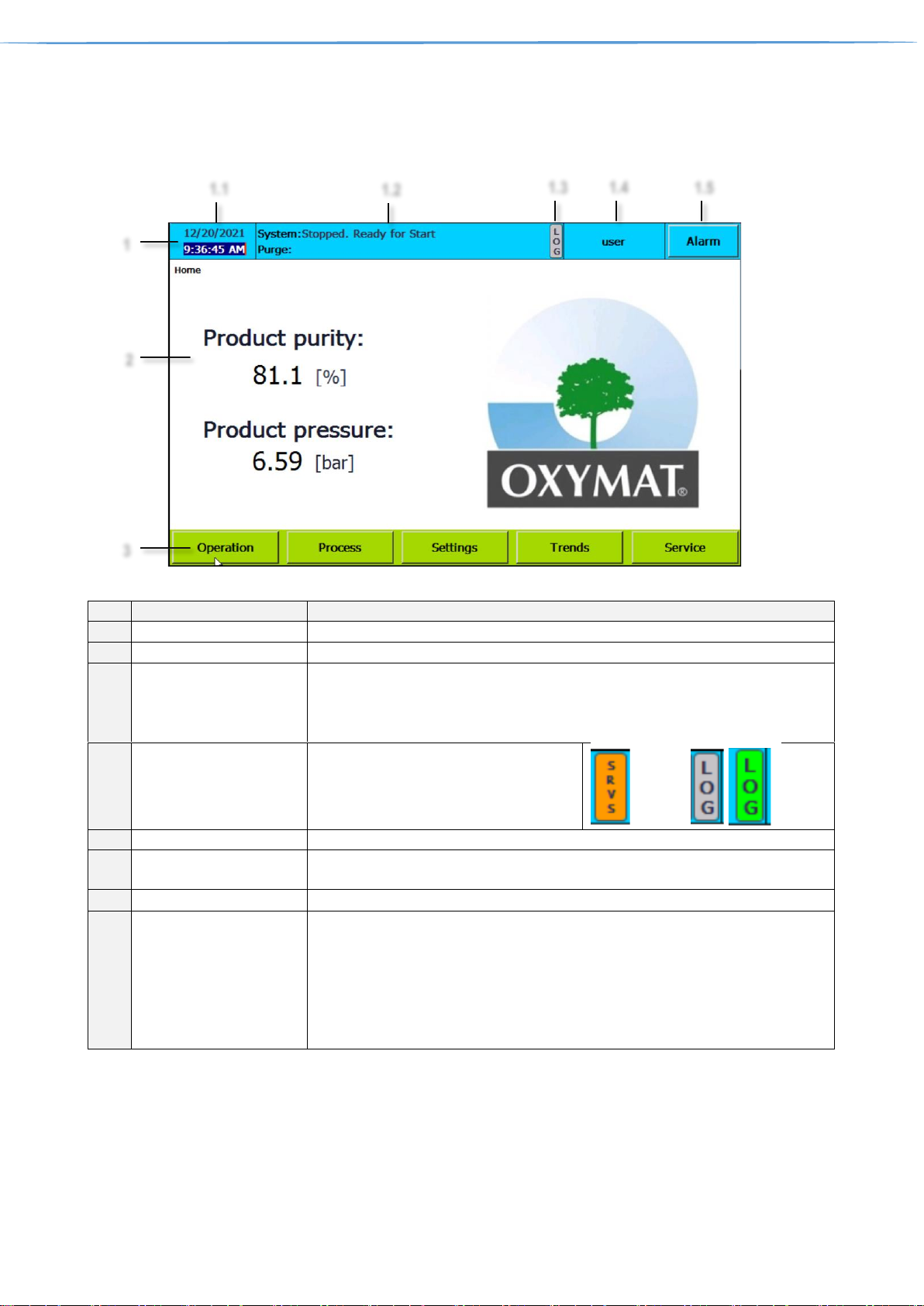

3. Home

The home screen is the screen that is shown automatically when the PSA Generator is powered up.

Ref.

Designation

Function

1

Information bar

1.1

Date & Time information

Shows screen time. Can be tapped to change time and date.

1.2

PSA status

PSA System and purge status information

PSA status information. It is divided into two sections, System and Purge, (Purge

is available only when Purity control addon is purchased)

See chapter 3.1 & 3.2

1.3

LOG/SRVS

Indicates when

Logging is inactive when grey

Logging is active when bright green

Service mode is active SRVS displayed

1.4

Log-in information

Shows information about user and can be tapped to change user.

1.5

PSA Alarm information

Blue = no active alarms, Flashing red = active alarm present,

Can be tapped to see active alarms and alarm history. See chapter 9. Alarms

2

Screen specific content

Specific for each screen, Home screen shows Product purity & pressure

3

Buttons bar

Accessible touch buttons (black text on green background),

Can be tapped to view specific screen.

Operation is described in Chapter 4

Process is described in Chapter 5

Settings is described in Chapter 6

Trends is described in Chapter 7

Service is described in Chapter 8

1

2 3 1.1

1.2

1.3

1.4

1.5

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 7 of 28

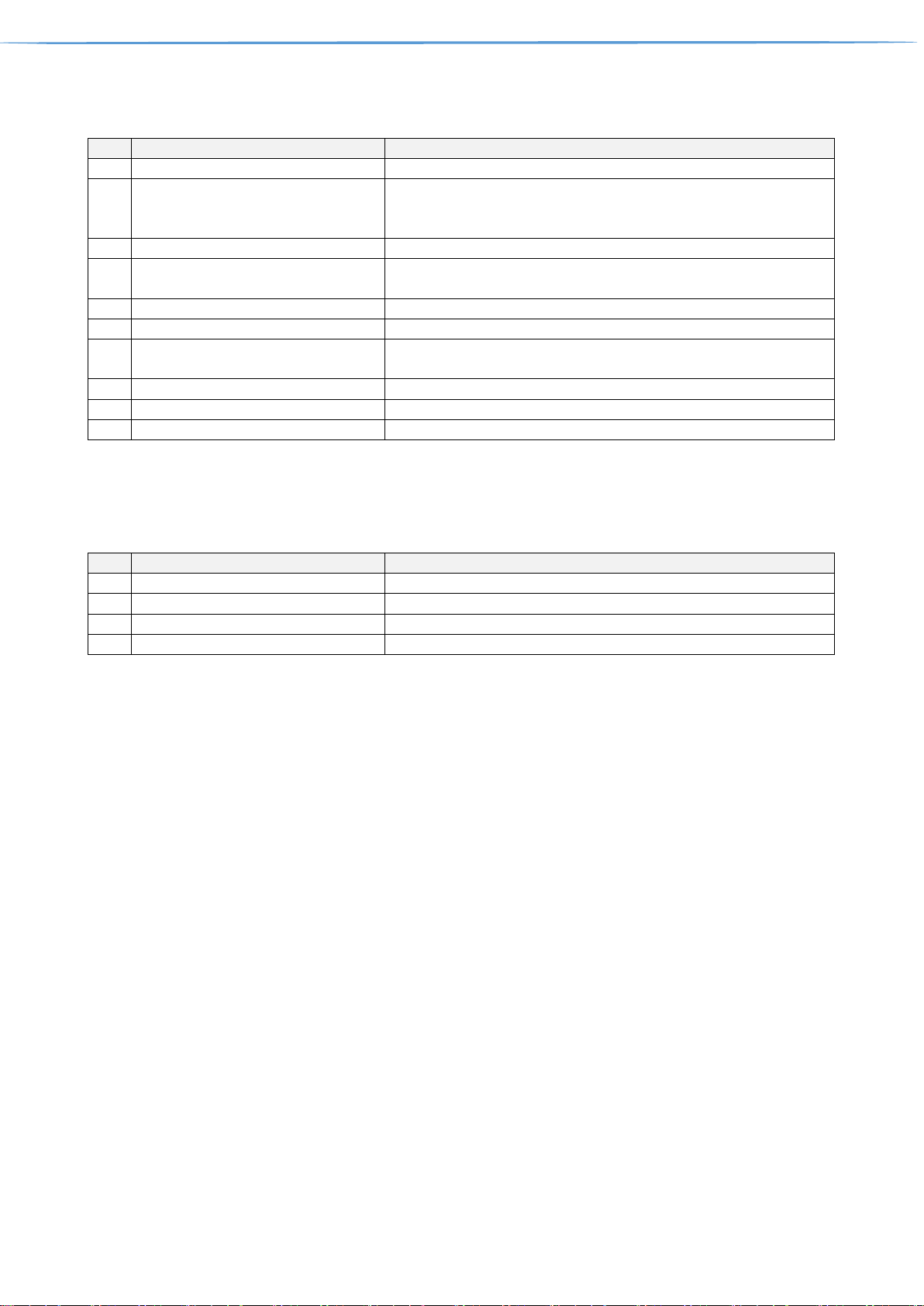

3.1. System status

Ref.

Status

Function

1

Stopped. Ready for start

Default state when PSA Generator is turned off and is ready for start

2

Stopped. Cannot Start

Default state when PSA Generator is turned off and cannot be started

because alarm (A and C alarm type) is present. See chapter Alarm 9.

For more details

3

Starting air pack

Air pack starting See chapter Process settings 6.2 Air pack control

4

Filling air tank

When PSA Generator is started compressor is filling air tank, when

setpoint is reached, starting sequence continues with ref. 5

5

Equalizing PSA columns

Equalizing pressure in PSA Generator columns

6

Running normally

PSA Generator running normally

7

Standby mode

PSA Generator is in standby mode. See chapter Advanced settings 6.5

Standby mode

8

Remote started – Running normally

PSA Generator running normally – started by remote digital input

9

Remote started – Standby mode

PSA Generator is in stand by mode – started by remote digital input

10

Stopping after PSA sequence

Stopping PSA Generator, manual stop or by Alarm (type C)

3.2. Purge status

For details about Purity control settings, see chapter 6.5 Advanced settings

Ref.

Status

Function

1

Purging

Purge valve is opened, delivery valve is closed.

2

Delivering

Delivery valve is opened, Purge valve is closed.

3

Waiting for min. pressure

Purity control is waiting for minimum pressure in product tank.

4

(No text)

Purity control addon is not purchased

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 8 of 28

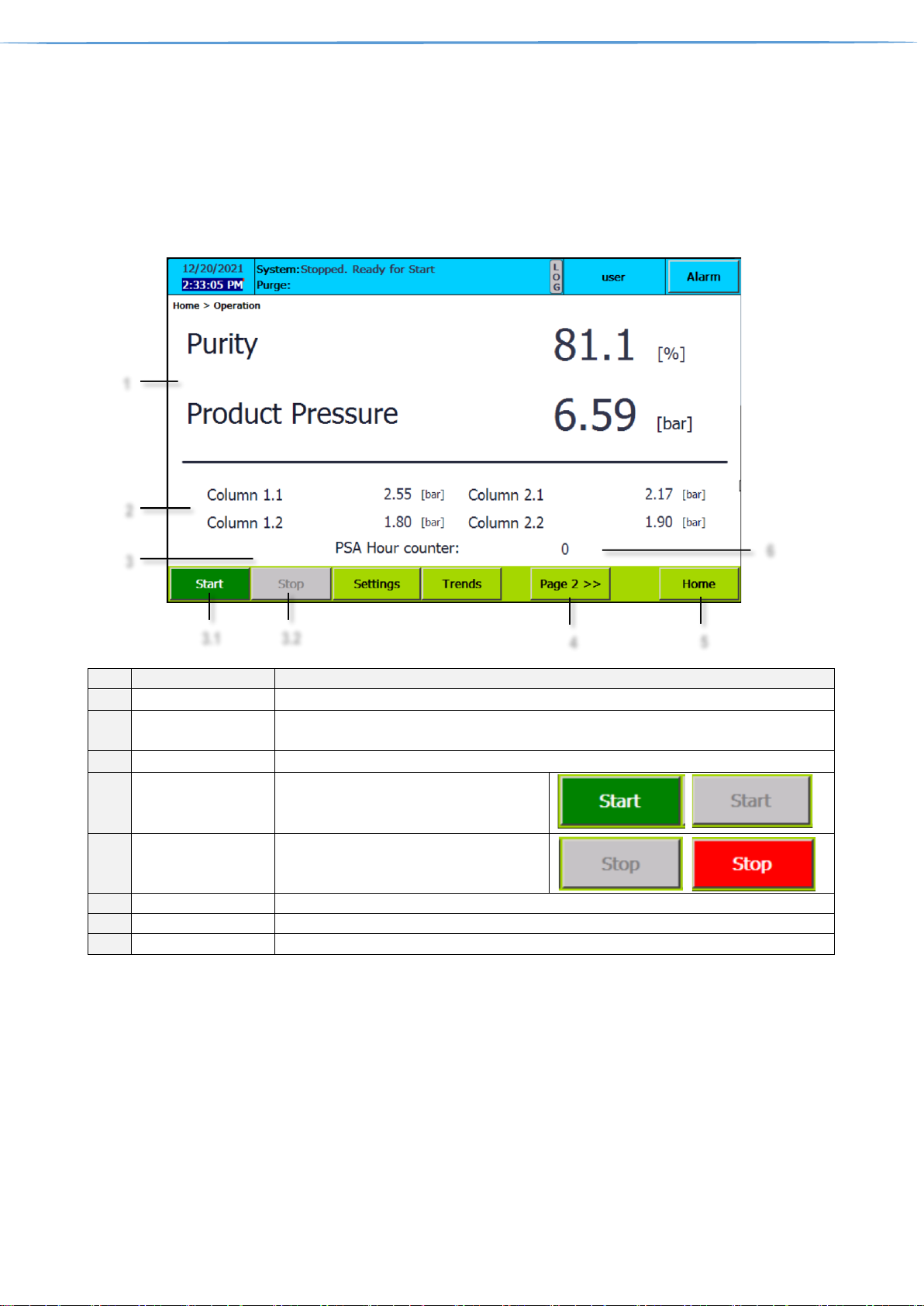

4. Operation

Tapping the operation button on home screen leads to operation where PSA starting and stopping is operated

When the PSA is powered up the first time or if there has been a power failure, the oxygen, nitrogen sensor will

need to heat up to measure correct. As long they are doing that, the readings can be incorrect (several seconds).

Ref.

Designation

Function

1

Product parameters

Shows information about purity & pressure in product tank

2

Column pressures

Shows information about pressure in both PSA generator columns. Respectively in four

if PSA Generator is X2 version.

3

PSA Start & Stop

Start & Stop of the PSA Generator

3.1

Start

Green when PSA is not running

Grey when PSA is running

Can be tapped to start

3.2

Stop

Grey when PSA is not running.

Red when PSA is running

Can be tapped to stop

4

Log-in information

Can be tapped to move to page 2 of Operation screen

5

Home

Can be tapped to return to Home screen

6

PSA Hour counter

PSA running hours counter

1

2

3.1 4 5

3.2

3

6

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 9 of 28

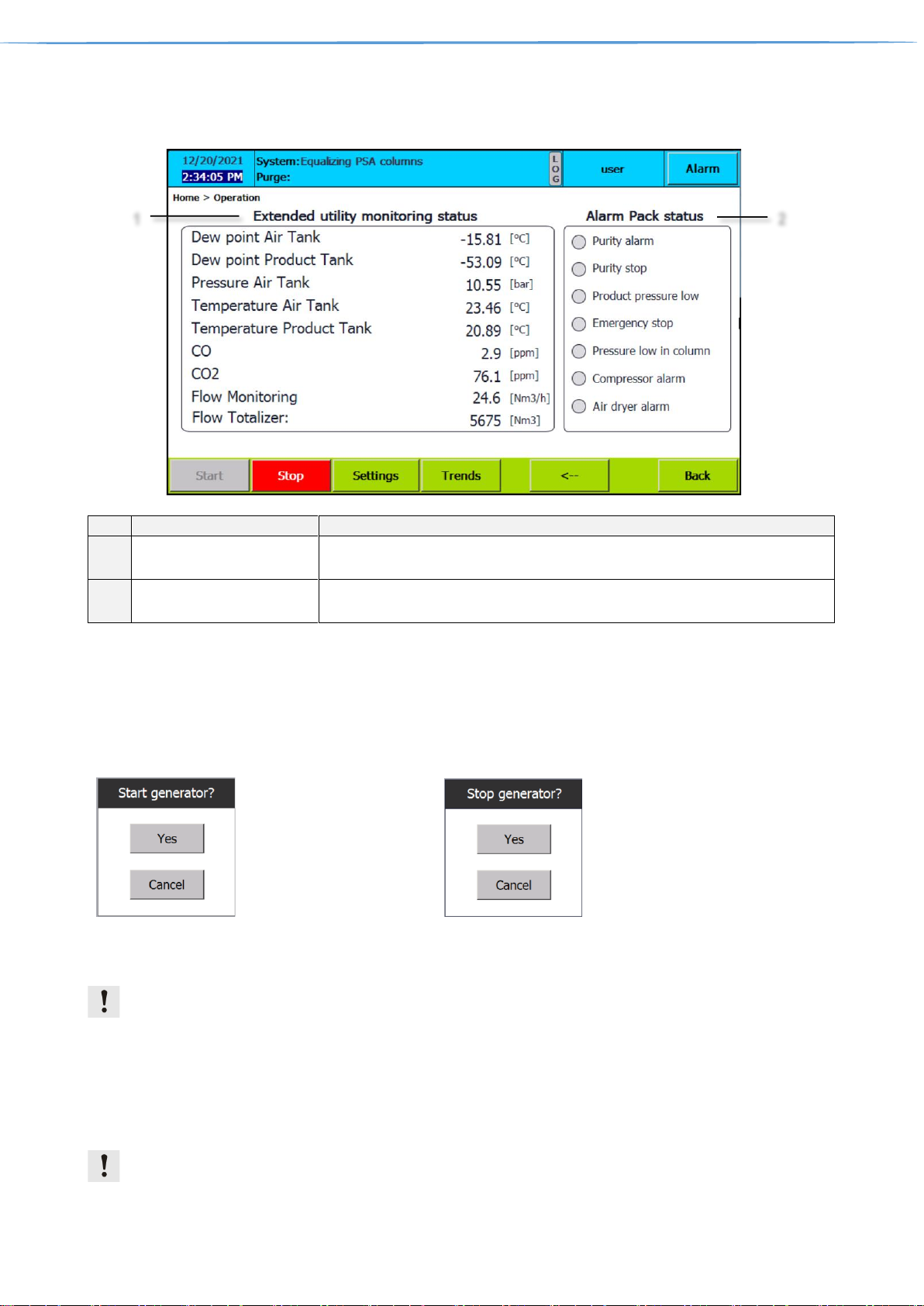

Page 2

Ref.

Designation

Function

1

Extended utility monitoring

status

Addon that extends monitoring to additional instruments

Visible only when extended utility monitoring addon is purchased

2

Alarm pack status

Addon that indicates alarms for customer

Visible only when alarm pack addon is purchased

4.1. PSA generator Start & Stop

It is possible to start the PSA when no critical or high level alarms are active. tap “Start” button to start PSA.

Small box appears with confirmation statement: „Start generator? “

To stop generator tap stop button. Again small box appears with confirmation statement: „ Stop generator? “. It

is not possible to restart during the stopping sequence. The text “Stopping” is shown on the Information bar.

Pop up screen when

starting PSA generator

Pop up screen when

stopping PSA generator

4.2. Start & Stop in service mode

Service mode is dedicated for service personnel & troubleshooting only.

It is possible to start the PSA in service mode when no critical alarms are active. Go to Settings/Advanced

(Chapter 6.5) and press “Service mode” ON.

To stop service mode, press button OFF. Than start/stop generator as is described above (Start generator).

It is not possible to restart during the stopping sequence (the text “Stopping”) is shown on the Information bar. It

is possible to switch service mode during running generator. To start service mode the operator must log in

as superuser.

Pressure stop/restart function, high and low alarms are bypassed in service mode.

1

2

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 10 of 28

5. Process

Tapping the Process button on home screen leads to Process screen where Process overview can be observed

including basic debugging information.

Ref.

Designation

Function

1

Debug information

Shows information about currently running process times

2

Reset totalizer

Can be tapped to reset flow totalizer

3

Test Drain

Can be tapped to test drain valve functionality located in the air tank

4

PSA Process information

Shows PSA1 column pressures and indicates opened valve with green dot

If PSA generator is X2 version, shows also PSA2

5

Product tank process information

Shows Product tank pressure

6

Back

Can be tapped to return back

1

2 3 6

5

4

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 11 of 28

6. Settings

Settings is the place where PSA Generator can be configured. It has lot of sub-screens, tapping the Settings

button on home screen leads to sub screen visited previously.

6.1. General settings

Ref.

Designation

Function

1

PSA Generator factory

information

Shows information about PSA Generator factory info such as model and serial

number, software version.

2

PLC Time information

Green Online indicates, that connection is established,

Offline button can be tapped to disconnect.

Red Offline indicates, that connection is not established.

Online button can be tapped to connect.

SET_PLC_time can be tapped to set PLC time to current

display time. To see more about screen time please refer

to Home screen.

3

Current PLC time/date

information

Shows information about current PLC time and date,

Note: PLC time/date can be different compared to screen time/date

1

2

3

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 12 of 28

6.2. Process settings

Ref.

Designation

Function

1

Process times Settings

The process time values are controlling the basic functionality of the PSA. Process

settings are pre-set during test generator by test engineer and only with permission

from Oxymat can be changed.

2

Air pack control

Shows information about Air pack. Can be tapped to enable/disable Air dryer or

compressor. (remote stop/start, run/alarm signal). Devices must be connected.

OFF- device is disabled

ON- device is enabled

2.1

Air pack delay

Shows information, about start delays for each device of Air pack. Can be tapped to

change start delay of Air compressor or Air dryer

3

Drain Settings

Shows drain valve settings, Can be tapped and changed.

4

Drain in Stop mode

Enable disable draining during Stop mode, Intervals can be chnaged

This example uses the drain valve operation with 3 min interval and 5 sec open time for drain valve.

The drain function always starts with an open period.

1

2

2.1

4

3

Drain open

Drain closed

Drain valve

5 s.

3 min

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 13 of 28

6.3. Measure 1 settings

Ref.

Designation

Function

1

Measurements

Shows list of basic measurements. Column 2.1 & 2.2 is only available for X2

PSA generator

2

Measurements range

Can be tapped to change Low and High range

3

Actual values

Shows actual value of the measurements

6.4. Measure 2 settings

Ref.

Designation

Function

1

Utility monitoring

Measurements

Shows List of measurements available only with utility monitoring addon.

Square can be tapped to disable measurement

Enabled measurement

Disabled measurement

2

Measurements range

Can be tapped to change Low and High range

3

Actual values

Shows actual value of the measurements

1

3

2

1 3 2

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 14 of 28

6.5. Advanced settings

Ref.

Designation

Function

1

Standby settings

Shows information about PSA Generator factory stand by settings. Can be tapped to

change stand by pressure, restart pressure and minimum cycles required before going

into standby.

When the pressure reaches the pressure stop level, then the PSA goes into stand-by

mode and wait for the pressure to drop below the pressure restart level. Then the PSA

will start again automatically. The standby mode will be cancelled if purge valve is opened.

2

Temporary

password

Temporary password can be inserted. With temporary password superuser is able to

enable purity control functionality (Ref. 3) or Enable/disable one of the PSA generators

X2 version only (Ref. 4). Contact Oxymat service for password.

Purity control

temporary enabler

Purity control is an addon and enable when

purchased. In case of purchase after delivery it can

be activated by temporary password. Upon inserting

temporary password, enabler is displayed

3

Purity control

settings

Can be tapped to change thresholds of purity control and minimum pressure required for

purity control functionality

PSA Oxygen generator

If the purity reading drops below the “Purge start” value and the pressure in the product

tank is above “Min Purge Pressure” then the purge function opens the purge valve and

closes the delivery valve.

The system automatically calculates the purity and pressure levels where the delivery

valve is opened again.

PSA Nitrogen generator

1

5

3

2

6

4

7

Time

Stop level

Restart level

Pressure in product vessel (P)

PSA running

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 15 of 28

If the purity reading exceeds the “Purge start” value and the pressure in the product tank

is above “Min Purge Pressure” then the purge function opens the purge valve and closes

the delivery valve.

4

X2 PSA Generator

temporary selector

Can be tapped to enable PSA1 or PSA2

5

AutoStart after

power failure

This feature allows the control to start automatically after power failure. When the power

is recovered, then a special “recover” sequence is started and the control will try to start

again.

6

Service mode

When no critical alarms are active, is possible to start the PSA in service mode. Consider

that the pressure stop/restart function, high and low alarms are bypassed in service mode

7

Stop runtime

Can be tapped to stop runtime and access Desktop and Start Center of the Siemens HMI.

It is used to access IP settings of the HMI or configuration of Remote control view. See

chapter 11 for more details

6.6. Alarm settings page 1 & 2

Ref.

Designation

Function

1

Alarm delay

At every startup alarms are not active for preset period of time. Can be tapped to

change.

2

Changeable Alarms

Complete list of changeable alarms is divided into two pages.

3

Alarm setpoints

Alarm setpoints are factory preset. Can be tapped to change these settings.

1

2

3

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 16 of 28

6.7. Smart delivery

Smart delivery is applicable only for PSA Oxygen Generators

Ref.

Designation

Function

1

Smart delivery settings

Smart delivery settings are preset by Oxymat. Adjustment is not possible.

The actual delivery clip time is calculated based on the actual pressure in the product

vessel. When the pressure is 0 (zero), then the minimum clip value is used.

When the pressure reaches the reference pressure (or above), then the maximum

value is used. In between 0 (zero) and the reference pressure, then the clip time is

calculated based on the linear function shown below.

2

Temporary password

When Logged as superuser and temporary password provided by Oxymat, smart

delivery can be disabled and altered. (Diagnostic purpose only)

1

2

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 17 of 28

6.8. PID Flowcontrol

Ref.

Designation

Function

1

PID controller status

Shows status of the PID controller. Automatic or Manual.

In Automatic mode, controller works according to the Flow setpoint with PID

parameters active

In Manual mode, the valve % open must be manually set. (See Ref. 3)

2

Flow setpoint

Shows setpoint of the Flow, can be tapped to change (Automatic mode only). Shows

also Flow input and % valve open.

3

PID parameters

proportional, integral, and derivative settings of the controller, Can be tapped to

change.

4

Manual mode

Can be tapped to switch between Manual and Automatic mode.

the valve % open can be set

5

PID reset

Reset Controller- clears error code

Restart Controller- restart of automatic mode for specific time

6

Error code

Diagnostic tool

1 3 4

5

2

6

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 18 of 28

6.9. SMS setting

Ref.

Designation

Function

1

SMS centre

SMS centre number of your provider, Can be tapped to insert

2

Alarm broadcast

Shows for how many numbers alarms are sent. Can be tapped to modify

3

Accepted SMS settings

Every change of the settings must be applied with this button.

4

Name/Phone

Shows information about names and phones. Can be tapped to insert up to 5 names

with numbers. recipients in the list can send SMS commands to intelliControl Siemens.

5

Test/Delete

Test –send test SMS to recipient

Delete – delete name/number

6

Send SMS status

sending text message

text message send

text message sending error

Before first using insert unlocked SIM card.

It is possible sends a text message containing alarm information to any cell phones, but extended with SMS

control. System can receive a text message containing control information.

Users in the user list are able to send SMS commands to intelliControl – Siemens:

Command

Explanation

#status#

The response from intelliControl – Siemens will be:

Product purity: xx.x

Product pressure: yy.y

System: zzzzzzzzzzzzzzzzzzzzzzzzz

xx.x will show actual O2 level

yy.y will show actual pressure in product vessel

zzzzzzzz shows the status text ex. Reast for start.

#start#

This command will try to start the system. Response will be “#start command executed”.

#stop#

This command will try to stop the system. Response will be “stop command executed”.

#reset#

This command will reset alarms. Response will be “#reset command executed”.

Example:. #status#(sender phone number)

1

2

3

5

4

6

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 19 of 28

7. Trends

Trends is the place where PSA Generator recent history parameters development can be viewed. It is divided

into six sub-screens. Availability of trends is limited to purchased instruments

Column pressure –pressure measurements in the PSA generator columns

Pressure inlet/Outlet – pressure measurements in the Air tank and Product tank

Purity – Oxygen content measurement in the Product tank

Temperature – temperature measurements in the Air tank and Product tank

Dew point - moisture measurements in the Air tank and Product tank

Flow - flow measurement of product

Ref.

Designation

Function

1

Auto changeable limits

for trend (Axis Y)

Units are according to the measurements screen. See chapters 6.3 & 6.4

2

Trend view

Can be tapped to stop trend curve view forward & backward or zoom in & out

3

Trend name

Trend(s) name and color designation

4

Actual trend

Actual trend view

5

Time (Axis X)

Time & date in actual view

1

2 3 5

4

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 20 of 28

8. Service

Service is the place where PSA Generator service inspection intervals can be viewed and reset

Ref.

Designation

Function

1

PSA service counter

Counter of running hours for PSA Generator maintenance

2

Filter service counter

Counter of running hours for Filter cartridge maintenance

3

Pre-set running hours

8000 hours for PSA Generator and 4000 hours for Filter is factory pre-set. Can be

tapped to change this value

4

Reset counter

Can be tapped to reset current service counters

Both service counters are descending from pre-set value to 0, and when it is reached, service maintenance is

required.

1

2

4

3

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 21 of 28

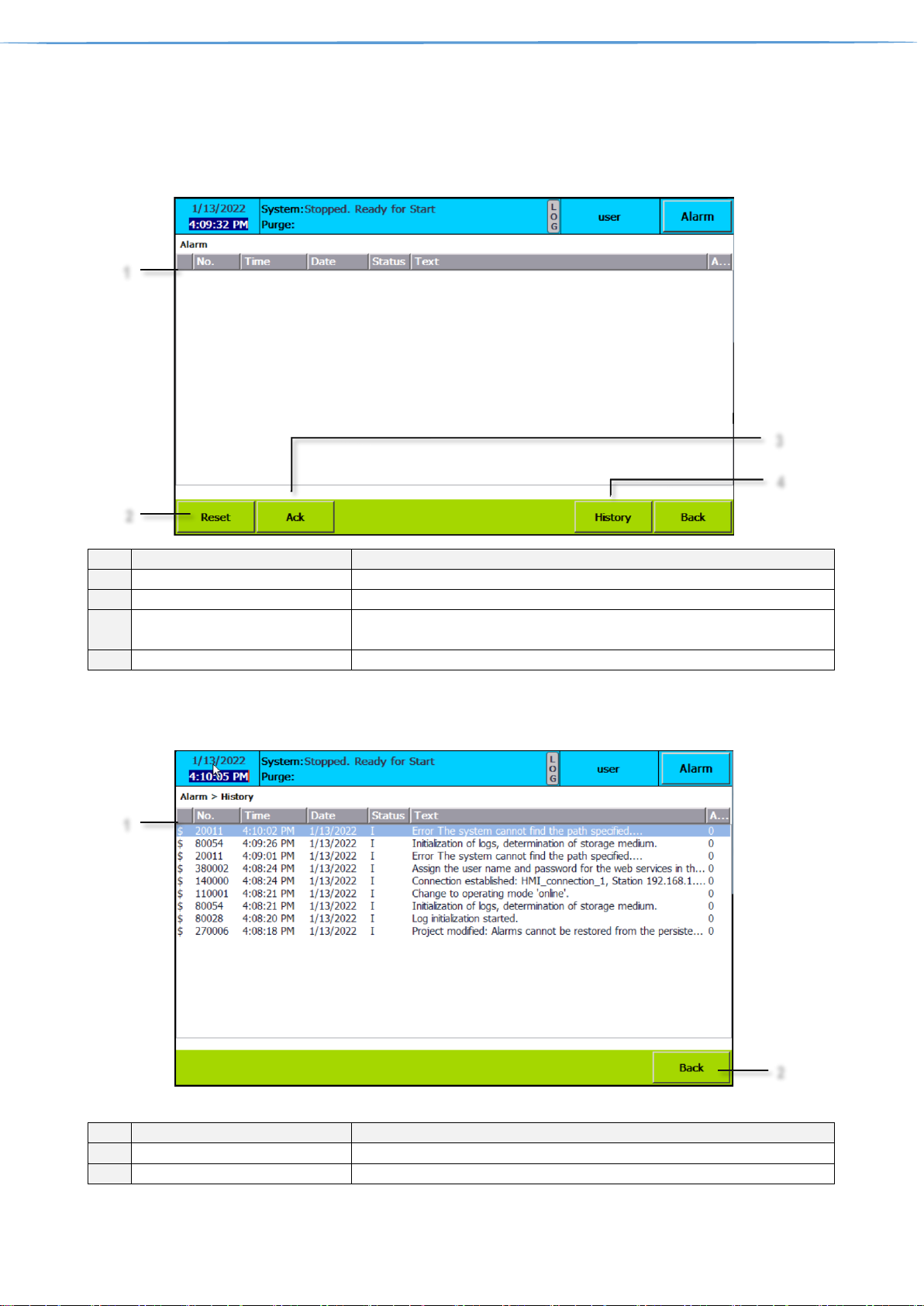

9. Alarm

Tapping the Alarm button on home screen leads to Active Alarms screen, where alarms can be reset,

acknowledged or history can be viewed.

Ref.

Designation

Function

1

List of active alarms

Shows active alarms, when occurred, with short text information

2

Reset

Can be tapped to reset alarm

3

Acknowledgement

Can be tapped to acknowledge alarm for which is acknowledgement needed

before reset

4

Alarm History

Can be tapped to see Alarm history screen (chapter 9.1)

9.1. Alarm history

Ref.

Designation

Function

1

Alarm history list

Shows history of alarms/events occurred

2

Back

Can be tapped to return

1

2

3

4

1

2

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 22 of 28

9.2. Alarm List & philosophy

The alarms are grouped into three categories. Quick stop alarms will stop the PSA immediately.

Delayed stop (with equalization of PSA or after PSA sequence) alarms will perform a controlled stop and

Indicative alarms does not affect the PSA sequence and can be considered as a message.

Alarm type: X,Y

A: Quick stop. (X)

B: Quick stop with equalization of PSA. (X)

C: Stop after PSA sequence. (X)

D: No stops only indicative. (X)

Y=1, Acknowledgment is required to reset the alarm. (Y)

Y=0, Acknowledgment is not required to reset the alarm. (Y)

Digital alarms

Broken Wire Alarms

Alarm Type

Alarm text

Alarm Type

Alarm text

A1

Emergency stop

C1

Product dew Point BWA

D0

Alarm on Compressor

C1

Air Tank dew Point BWA

D0

Alarm on Dryer

C1

Purity BWA

C1

UPS – Running on Battery

C1

CO BWA

D1

UPS - Alarm

C1

CO2 BWA

D0

PSA Filter Service required

C1

Product Pressure BWA

D0

PSA Filter Service Warning 1

C1

Flow Control BWA

D0

PSA Filter Service Warning 2

D1

Column 1.1 pressure BWA

D0

PSA Service required

D1

Column 1.2 pressure BWA

D0

PSA Service Warning 1

D1

Column 2.1 pressure BWA

D0

PSA Service Warning 2

D1

Column 2.2 pressure BWA

D0

Alarm on BEKO drain 1

D1

Air pressure BWA

D0

Not PSA selected in X2 Mode

D1

Air temperature BWA

D1

Start after Power Failure

D1

Product temperature BWA

Analogue Alarms

Alarm Type

Alarm text

Alarm Type

Alarm text

D1

Product Purity Alarm

D1

Air Tank Dew Point Alarm

C1

Product Purity Stop

C1

Air Tank Dew Point Stop

D1

Product Low Pressure Alarm

D1

Product Dew Point Alarm

C1

Product Low Pressure Stop

C1

Product Dew Point Stop

D0

Pressure Low Column 11

D1

Product Temperature Alarm

D0

Pressure Low Column 12

C1

Product Temperature Stop

D0

Pressure Low Column 21

D1

OverFlow

D0

Pressure Low Column 22

D1

CO Alarm

C1

Air Tank Pressure Low

C1

CO Stop

D0

Air Tank Pressure High

D1

CO2 Alarm

D1

Air Tank Temperature Alarm

C1

CO2 Stop

C1

Air Tank Temperature Stop

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 23 of 28

10. Access levels

Operator can log in anytime by tapping user information in information bar (see home screen for details). Or when tapping

a password protected item, a Login screen pops up. The Operator can enter the password.

As default 4 levels are implemented:

Level

login

password

Function

1

Guest / not logged

Monitor

2

user

4021

Monitor & Operate

3

superuser

182087

SuperOperate

4

developer

available only for Oxymat personnel

DeveloperOperate

Accessibility matrix, Some Functions are available only for certain PSA Generators or addons

Screen

Sub-screen

No user

logged in

USER

SUPERUSER

SUPERUSER +

TEMPORARY PASS

Monitor

Monitor

Operate

Super

Operate

Temporary

HOME

full access

full access

full access

N/A

OPERATION

full access

full access

full access

N/A

PROCESS

Test Drain

full access

full access

full access

N/A

Reset totalizer

View only

full access

full access

N/A

SETTINGS

General

Gen.settings

View only

View only

View only

N/A

PLC TIME

View only

View only

Full access

N/A

Process

Drain settings

View only

View only

Full access

N/A

Process times

View only

View only

View only

full access

Advan

ced

StandBy Settings

View only

full access

full access

N/A

Select PSA (X2

MODE)

View only

View only

full access

N/A

Autostart

Powerfailure

View only

full access

full access

N/A

Service Mode

View only

View only

full access

N/A

Purity Control

(Purge Function)

View only

ONLY:

Purge Start/Stop

Min. Purge pressure

Cannot enable/disable Purity control

full access

PILOT_control

View only

View only

full access

N/A

Alarm

View only

ONLY:

Purity Alarms,

Product Pressure

Alarms

full access

N/A

Measure 1

View only

View only

full access

N/A

Measure 2

View only

View only

full access

N/A

PID flow control

View only

View only

full access

N/A

SMS settings

View only

View only

full access

N/A

Smart delivery

View only

View only

View only

full access

SERVICE

View only

View only

full access

N/A

TRENDS

full access

full access

full access

N/A

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 24 of 28

11. HMI desktop and Start center

To access HMI desktop and Start Center runtime must be stopped.

In chapter 6.5 Advanced settings. Is described how to stop runtime.

Ref.

Designation

Function

1

Start

Can be tapped to Start HMI Runtime

2

Settings

Can be tapped to open Settings and configure IP adresses and

WinCC for remote view.

11.1. Remote view

Open “Settings”

Continue to “WinCC Internet Settings”

Proceed to “Remote” and then

1

2

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 25 of 28

Tap “Change settings”

Start automatically after booting must be enabled

Set two security levels:

Password 1 – control – remote control

Password 2 – view – remote view (click on View only)

After setting the passwords, return to the “HMI Desktop and Start center” and run „Runtime“. Having that done, the

application starts at the HMI. Set an identical IP address at your laptop as it was done at the HMI. Now you can start

the application „SmartClient“. A window opens, where a „password“ is required. We set in „settings“ for „Smart Server“

(see pic. 29) two levels:

1. Control

2. View

Choose „control“

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 26 of 28

An application is opened right away that is also running on the HMI. In the „control“ mode, full control of HMI is

enabled. It depends on the logged user_superuser.

In the „view“ mode, only the active screen on HMI is shown. In this mode, control is not enabled, screens cannot be

changed

11.2. IP address change

In case of IP change of the HMI, the IP address of the PLC needs to be altered as well.

Open “Settings”

Continue to “Network and dial-up connection“ and

continue to „PN_X1”

In PN_X1 Settings pop up window, “IP address” of the HMI can be changed, and in the case of having more networks

a “Default Gateway“ can be set as well.

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 27 of 28

12. Logging

Data logging is not availible for KTP700 BASIC HMI. To collect data, standard SD memory card can be used.

To correctly inserd memory card:

• Open the enclosure and refert to backside of the HMI panel.

• Unlock the slot by black slider lock to right side.

• Insert SD card into the DATA X51 slot

• Lock black slider lock to left side

Ref.

Designation

Function

1

HMI backside

N/A

2

Black slider lock

Slide to right to access SD card slot,

Slide to left to lock SD card lock

3

SD card slot

SD memory card can be inserted

2 3 1

User & Superuser Manual intelliControl Siemens v.14.1.2022 Page 28 of 28

13. Loading program from SD card

It is necessary to record parameters of all settings, because after project transfer from SD card all

pre-set parameters will be lost (ranges, alarm setting, Start – Stop pressure values, etc. )

Is available only when software backup is provided from Oxymat. Industrial Siemens SD card

must be used.

Industrial Siemens SD card must not be formatted by standard PC/Laptop

1. With the system switched off you slot the memory card into the memory card slot of the S7-1200 CPU.

2. Switch on the S7-1200 CPU. A flashing sequence between the "RUN/STOP", "ERROR" and "MAINT"

LEDs indicates that the program is currently being transferred to the controller. The end of the transfer is

indicated by the "RUN/STOP" LED lighting orange and the "MAINT" LED flashing at the same time.

3. Switch off the S7-1200 CPU and remove the memory card from the slot.

4. Then switch on the S7-1200 CPU again. The application then starts up automatically ("RUN/STOP" LED

lights green).

5. After restart of CPU please re-enter recorded parameters to system.

Ref.

Designation

Function

1

CPU

CPU identification

2

Cover

Protective cover of terminals and SD card slot. Can be opened to access SD card slot

3

LED indicators

Indicates status of the CPU

4

SD card slot

SD card can be inserted. Accepts only Siemens SD cards

2

3

4

1

Loading...

Loading...