Page 1

INSTALLATION AND OPERATION MANUAL

Heat Recovery Unit OXYGEN X-Air C200

Rev 1.6 2019.06

Page 2

1

Page 3

CONTENTS

1. TRANSPORTATION AND STORAGE OF EQUIPEMENT .......................................................................................3

2. UNIT PACKAGE ..................................................................................................................................................4

3. SAFETY REQUIREMENTS ...................................................................................................................................5

4. EU DECLARATION OF CONFORMITY .................................................................................................................6

5. TECHNICAL DATA ..............................................................................................................................................7

5.1. Performance characteristics .................................................................................................................8

5.2. Performance and power consumption .................................................................................................8

5.3. Sound characteristics ............................................................................................................................9

5.4. Dimensions and weight ..................................................................................................................... 10

6. FUNCTIONALITY ............................................................................................................................................. 11

7. INSTALLATION OF THE UNIT .......................................................................................................................... 12

7.1. Selecting the mounting location ........................................................................................................ 12

7.2. Installation incline ............................................................................................................................. 12

7.3. Connecting ducts ............................................................................................................................... 13

7.4. Installing the maintenance and servicing hatch ................................................................................ 14

7.5. Connecting the condensate drain ..................................................................................................... 15

8. CONNECTION OF THE UNIT ........................................................................................................................... 16

8.1. Connecting electric circuit ................................................................................................................. 16

8.2. Connecting the control panel ............................................................................................................ 17

8.3. Connector of comfort functions ........................................................................................................ 18

8.4. Control board electrical wiring diagram ............................................................................................ 19

8.5. Description of control board contacts ............................................................................................... 20

9. OPERATION OF THE UNIT .............................................................................................................................. 21

9.1. Control panel with a knob ................................................................................................................. 21

9.1.1. Operating state indicator .............................................................................................................. 21

9.1.2. Air filter replacing / anti-frost protection indicator ...................................................................... 21

9.1.3. Failure indicator ............................................................................................................................. 22

9.1.4. Additional system settings............................................................................................................. 23

9.2. Control panel with touchscreen display ............................................................................................ 25

9.2.1. Standby mode ................................................................................................................................ 25

9.2.2. Main screen ................................................................................................................................... 26

9.2.3. Settings menu ................................................................................................................................ 27

9.2.4. Setting up weekly operation program ........................................................................................... 27

9.2.5. Failure indication ........................................................................................................................... 28

9.3. Replacing of air filters ........................................................................................................................ 29

10. MAINTEINANCE AND WARRANTY ................................................................................................................. 31

11. CONTACTS ...................................................................................................................................................... 32

2

Page 4

1. TRANSPORTATION AND STORAGE OF EQUIPEMENT

Heat Recovery Unit (hereinafter – the Unit) is prepared for transportation and storage. Packaging

materials ensure protection against exposure to environment, dust and humidity. The Unit must be

properly secured during transportation to protect it against possible housing deformation or other

mechanical damage.

Transportation conditions:

Long-term storage conditions:

IMPORTANT! Sender does not assume any obligations towards damage or loss of the Unit or its part, if

there is no a corresponding record in the consignment document!

CONSIGNMENT ACCEPTANCE:

Carefully check the received consignment – make sure that the number of packages matches with

the consignment documentation. Upon noticing any non-conformity or damage of the package

(tears, dents or compressed box, detached or reattached packaging tape), inform the courier

immediately and indicate the disrepancies or damages in the consignment document.

Verify if the right product was delivered. Upon noticing any non-conformity, inform the Sender

immediately.

Verify if all the supplementary parts listed were delivered. In case of any doubt, contact the Sender

-20oC - +40oC.

+5oC - +40oC, relative air humidity <= 60%.

immediately.

Do not attempt to repair the Unit, damaged during the transportation by yourself!

3

Page 5

2. UNIT PACKAGE

Heat Recovery Unit Oxygen X-Air C200 1 pc.

Control panel 1 pc.

Contol panel connection cable, 10m 1 pc.

Fastening elements:

L-shaped horizontal installation bracket 4 pcs.

Bolt (type M5), 8 mm 8 pcs.

Spring washer (type M5) 8 pcs.

Condensate drain nozzle, Ø32 1 pc.

Condensate drain gasket, Ø20 1 pc.

Installation manual 1 pc.

4

Page 6

3. SAFETY REQUIREMENTS

Carefully read and follow safety requirements provided below before installing and while operating the

Unit:

Do not discard the Installation and operation manual, keep it for future reference.

The Unit should be installed and operated in compliance with this Installation and operation

manual, following the requirements of effective legislation and standards.

When connecting the Unit to mains supply, grounding must be installed in compliance with

requirements of effective legislation and standards.

To prevent accidents and potential damage to the Unit, it should be installed, connected,

maintained and repaired only by qualified technician. Never attempt to do this by yourself!

Turn off the Unit by using Control panel and wait for fans to stop completely before replacing air

filters.

Turn off the Unit by using Control panel, wait for fans to stop completely and disconnect the Unit

from mains supply before performing any maintenance.

Before connecting the Unit make sure that no items will get sucked into the its air intake openings!

Children may only use the Unit under adult supervision.

The Unit is not intended to be used by persons (including children) with reduced physical, sensory

or mental capabilities, unless they have been instructed to use of the Unit and under constant

supervision of person held responsible for their safety.

Only original supplementary parts and consumables, certified by manufacturer should be used.

The Unit package (cardboard, plastic, foam polystyrene) can pose hazard to children. Dispose of

or recycle the package elements!

Disused Unit should be disposed of in accordance with requirements of legislation on handling

of waste electrical and electronic equipment.

IT IS PROHIBITED to operate the Unit with damaged mains supply cable! Switch off the power

circuit-breaker to disconnect mains supply and contact a qualified technician or manufacturer

service centre immediately upon noticing such damage.

IT IS PROHIBITED to attempt the repair of the damaged Unit or its part, to open its cover! Contact

a qualified technician or manufacturer service centre.

5

Page 7

4. EU DECLARATION OF CONFORMITY

We, undersigned below, representing the manufacturer of ventilation equipment:

Sviezias oras, JSC

Birzelio 23-osios g. 23G

50220 Kaunas

LITHUANIA

confirm, that heat recovery ventilation device Oxygen X-Air C200 conforms to Europe Union standarts,

directives and regulations:

2009/125/EC – eco-design requirements for energy-related products

ES 1253/2014

2010/30/EU – labelling and standard product information of the consumption of energy and other

resources by energy-related products

ES 1254/2014

2011/65/EU – restriction of the use of certain hazardous substances in electrical and electronic

equipment (RoHS)

EN 50581(2012)

2014/35/EU – harmonization of the laws of the Member States relating to the making available on the

market of electrical equipment designed for use within certain voltage limits

LST EN 60335-1:2012 (EN 60335-1:2012)

LST EN 60335-1:2012/A11:2014

CEO Zilvinas Salialionis

10.05.2018, Vilnius

6

Page 8

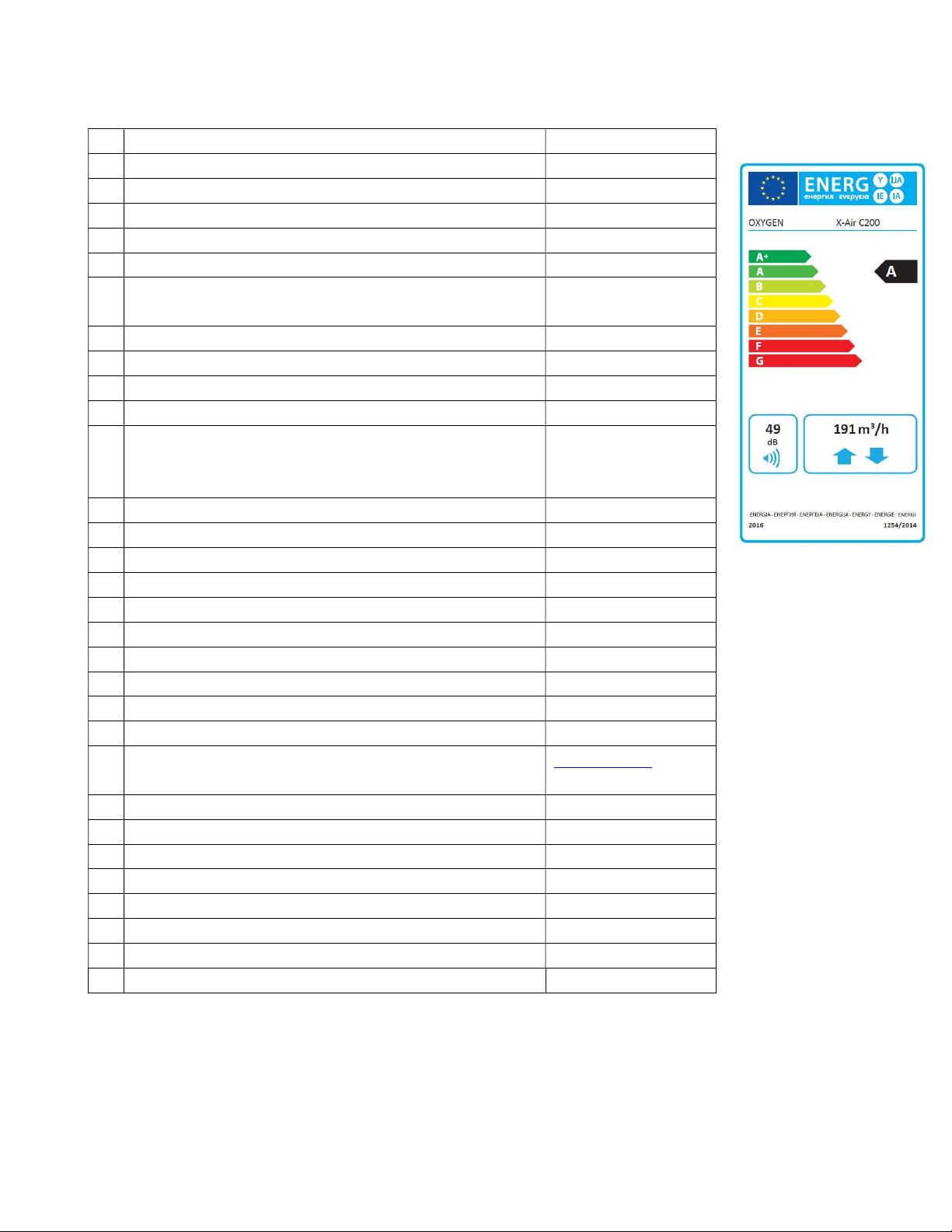

5. TECHNICAL DATA

a) Supplier's name or trade mark OXYGEN

b) Model identifier X-Air C200

c) Specific energy consumption (SEC), SEC class A

Warm climate kWh/m2.a -15.7

Average climate kWh/m2.a -40.0

Cold climate kWh/m2.a -77.7

d) Declared typology Bi-directional,

residential ventilation

e) Type of drive installed or intended to be installed Variable speed drive

f) Type of heat recovery system Recuperative

g) Thermal efficiency of heat recovery % 81

h) Maximum flow rate m3/h 191

i) Electric power input of the fan drive, including

any motor control equipment, at maximum flow

rate

j) Sound power level (LWA) 49

k) Reference flow rate m3/s 0.0378

l) Reference pressure difference Pa 50

m) Specific power input (SPI) W/(m3/h) 0.353

n) Control factor 0.65

Control typology Local demand control

o) Declared maximum leakage rate:

internal % 2.31

external % 1.16

q) Position and description of visual filter warning See user’s manual

s) Internet address for pre-/dis-assembly

instructions

v) The annual electricity consumption (AEC)

Warm climate kWh/m2.a 1.9

Average climate kWh/m2.a 2.3

Cold climate kWh/m2.a 7.7

w) The annual heating saved (AHS)

Warm climate kWh/a 20.4

Average climate kWh/a 45.0

Cold climate kWh/a 88.0

W 106

www.oxygen.lt

According to commission delegated regulation (EU) No. 1254/2014

7

Page 9

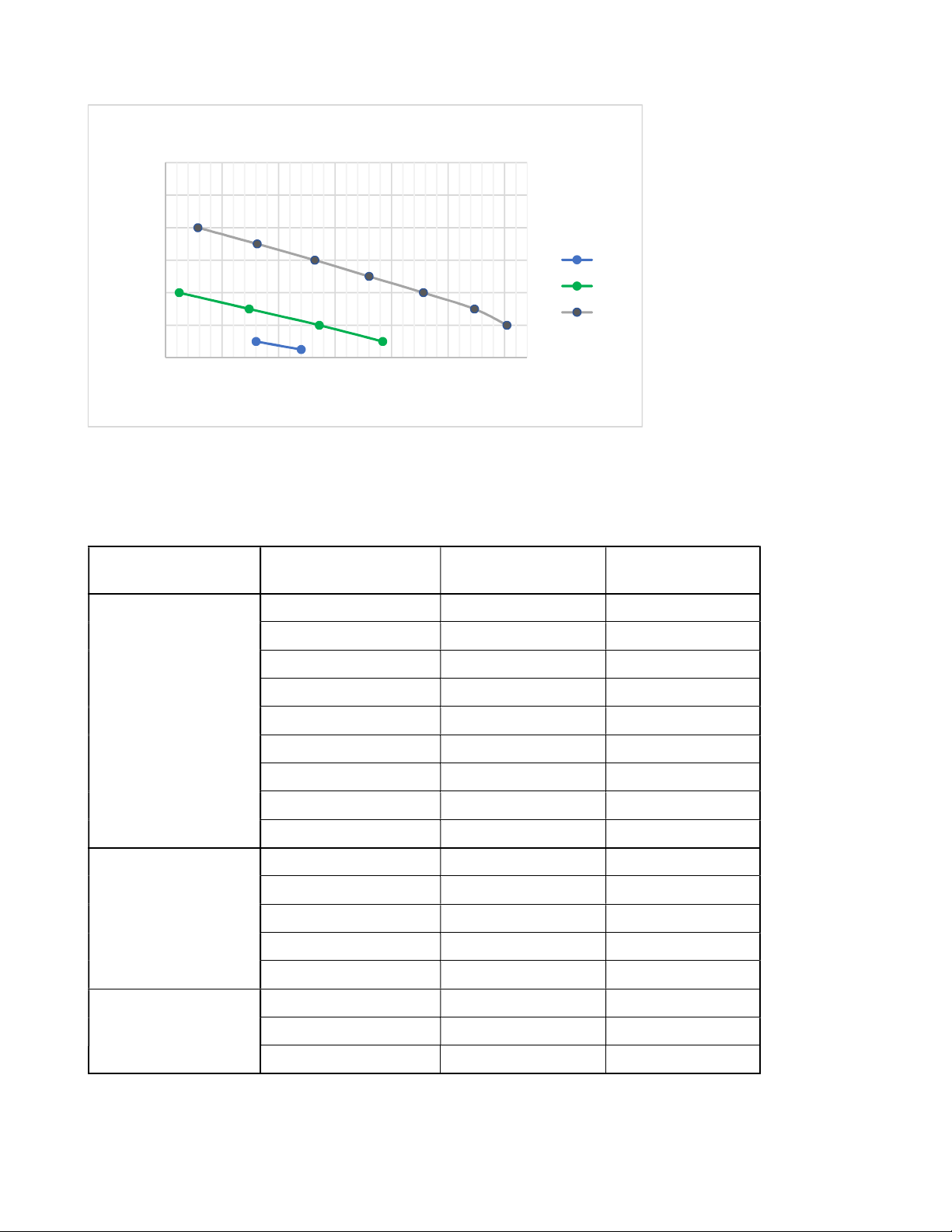

5.1. Performance characteristics

Performance curves

600

500

400

300

200

Pasipriešinimas, Pa

100

0

40 65 90 115 140 165 190

50%

70%

100%

Air flow, m3/h

Graph. 1. Ventilation power dependence on the resistance of the installed ventilation system

5.2. Performance and power consumption

Power setting Resistance, Pa Air flow, m3/h El. outlay, W

100 191 101

150 189 99

200 184 98

250 172 100

100%

300 154 98

350 136 96

400 110 97

450 91 97

490 75 98

50 140 46

100 130 46

70%

150 114 44

200 85 44

250 61 41

25 100 24

50%

75 80 24

115 50 22

According to EN13141-7, with G4 class filters installed.

8

Page 10

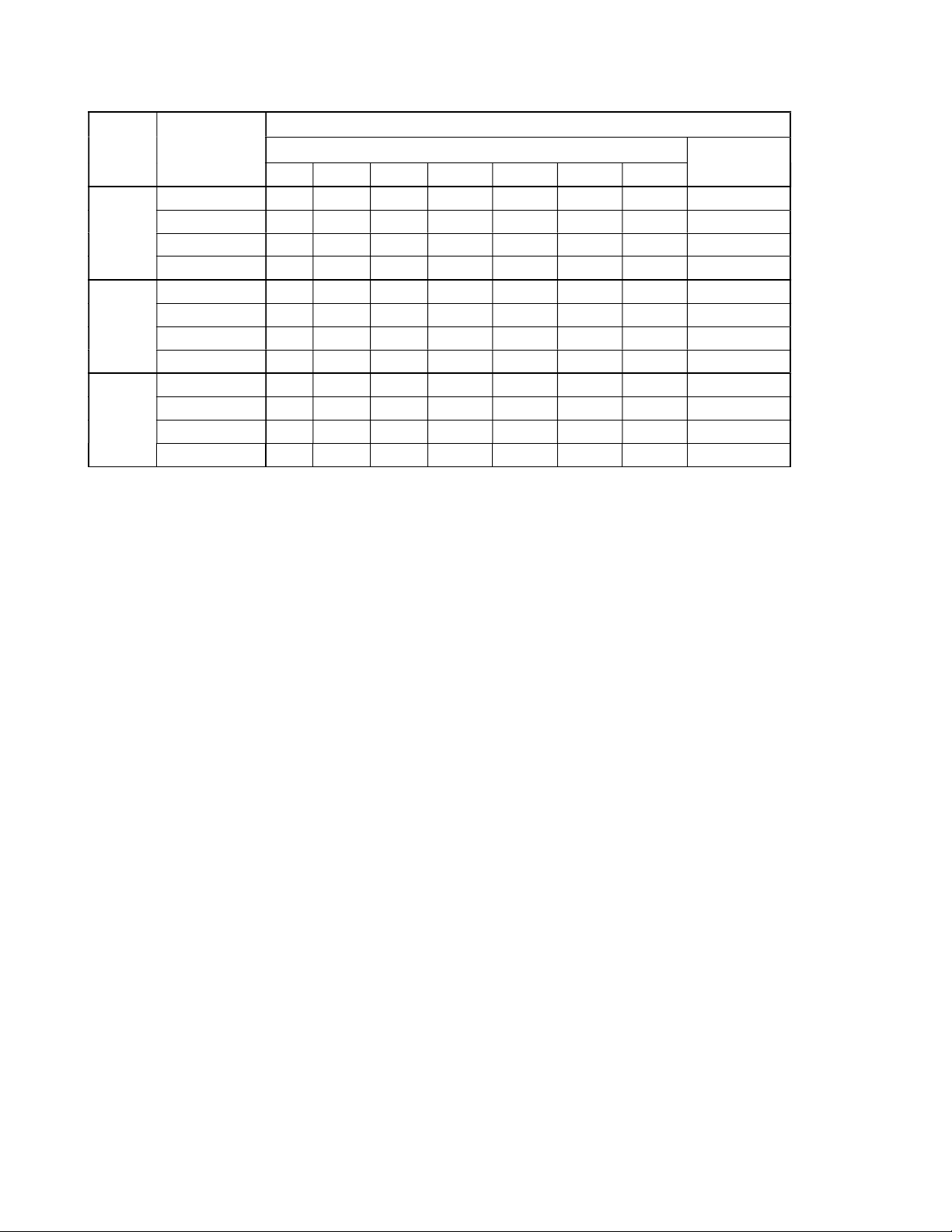

5.3. Sound characteristics

Power

Air duct

setting

125 250 500 1000 2000 4000 8000

Suppply 34.1 42.8 42.2 41.7 40.9 30.6 17.5 48.2

50%

Extract 13.3 35.6 35 26.8 22.4 14.8 12.6 38.8

Outside 15.1 36.7 32.1 26.9 21.8 14.4 12.6 38.5

Exhaust 28.9 39.7 42 40.7 38.5 28.6 16 46.6

Suppply 39 51.1 51.8 51.2 49.9 43.8 30.4 57.3

70%

Extract 21.5 45.2 44.5 36.6 33.2 22.5 14.2 48.4

Outside 22 44.6 42.8 36.1 33.1 21.7 13.7 47.3

Exhaust 35.4 51.1 51.6 50.4 48.4 41.8 28.7 56.8

Suppply 43 56.1 63.3 58.5 58.7 53.6 41.3 66.3

100%

Extract 30.1 47.7 55.3 46.5 42.4 32.1 21.6 56.7

Outside 29.7 48.1 54.3 45.7 42.4 30.7 20.7 55.9

Exhaust 41.2 53.3 62 58.4 57.6 52.7 40 65.2

According to LST EN13141-7.

Sound power level (LWA)

Octave band, Hz

Total

9

Page 11

5.4. Dimensions and weight

OXYGEN X

-

Air C200

–

left-side version

OXYGEN

X-Air C200

–

right

-

side version

Figure 1. Unit dimensions

Body dimensions and weight Length, mm Width, mm Height, mm Weight, kg

OXYGEN X-Air C200 1010 500 254 23

10

Page 12

6. FUNCTIONALITY

Function Control

panel with

a rotary

Ventilation

Silent and efficient EC fans

Stepless power setting adjustment 30-100%

Power setting at 5% steps within 30-100% range

Weekly operation program, up to 4 different modes for every week day

Ventilation boost activation by control panel button

System balancing by adjusting power of each fan

Constant air pressure maintenance

Display of outdoor, supply, extract and exhaust air temperatures

Display of relative air humidity indoors

Display of date and time

Stepless increase of preheater power

„WC boost″ activation by turning the light switch on

„Away″ - reduced ventilation power, when the security system is active

Adjustment of ventilation power according to CO2 level indoors *

Adjustment of ventilation power according to humidity level indoors *

Summer time ventilation – heat exchanger bypass device

Filtration

G4 class filter (average deposition of synthetic dust <90%)

M5 class filter (efficiency to filter 0.4 µm diameter particles 40-60%)

F7 class filter (efficiency to filter 0.4 µm diameter particles 80-90%)

Visual warning of the necessity to replace the filters

Filter lifetime metering

Filter fouling metering

Protection functions

Overheat protection

Anti-frost protection

Ventilation shutdown function upon activation of fire alarm

Visual warning of the Unit failure

Additional functions / features

Possibility to install according to the layout of outdoor ventilation openings

(right / left versions)

switch

Control

panel with

a LCD

*

*

* sensors for pressure maintenance and determination of indoor air quality are optional.

11

Page 13

7. INSTALLATION OF THE UNIT

7.1. Selecting the mounting location

It is recommended to install the Unit in a heated room such as bath, storage room, boiler room or an

attic. Make sure, that there is sufficient space to install not only the Unit itself, but also auxiliary ventilation

system components – noise silencers or air distribution boxes. Make sure that there is a possibility to

connect the condensate drain pipe of the Unit to the internal or external sewerage system.

Operating conditions:

The Unit should be installed horizontally, with servicing cover looking downwards. 4 L-shape fastening

brackets (provided) should be used to fasten Unit to the ceiling. Use ceiling pins or locking sleeves (not

included), depending on installation surface. It is essential to use vibroinsulation gaskets (not included)

to ensure that Unit vibration will not be transferred to the mounting surface.

+10oC - +30oC, relative air humidity <= 60%.

7.2. Installation incline

IMPORTANT! After Unit installation, make sure that the condensate drain corner is positioned lower than

remaining Unit corners (refer to Figure 2). This will ensure smooth removal of accumulated condensate.

Corresponding distances must be maintained from ceiling plane, when installing the Unit:

No. Distance from horizontal plane

1 20 mm

2 10 mm

3 0 mm

4 10 mm

12

Page 14

OXYGEN X

-

Air C200

–

left-side version

OXYGEN X

-

Air C200

–

right

-

side version

Figure 2. Horizontal installation diagram

7.3. Connecting ducts

It is recommended to install outside air supply and exhaust ducts as far as possible from each other to

prevent the ingress of contaminated air back to premises. Please refer to local construction regulations.

Make sure that outdoor humidity or precipitation will not get into the Unit, when connecting outside air

supply and exhaust ducts. Make sure that openings in the outside wall are installed lower than the Unit

itself. The air intake opening in the outside wall should be protected against precipitation ingress to

ventilation duct by grille or roof, with mesh to prevent ingress of insects and other small objects.

Figure 3. Air intake duct connection diagram

IMPORTANT! At least 1° ventilation duct incline should be ensured to prevent ingress of outdoor

humidity or precipitation into the Unit.

13

Page 15

IMPORTANT! Both outside air intake and exhaust ducts should be covered with a layer of thermal

insulation of sufficient thickness to prevent condensation of humidity on their walls due to different

outdoor and indoor air temperatures.

7.4. Installing the maintenance and servicing hatch

When installing the Unit ensure enough space for its maintenance. Suspended ceiling in the room should

be installed at least 40 mm from the lowest point of the Unit housing (refer to section 8.2. Installation

incline).

Maintenance and servicing hatch installed in the ceiling should be of suitable size to allow convenient

access to all Unit components. At least 100 mm distance should be ensured from every edge of the Unit.

Figure 4. Installation of maintenance and servicing hatch

IMPORTANT! Owner of the Unit shall ensure the possibility to perform Unit maintenance. If there is not

enough space for Unit maintenance, the manufacturer’s representative is entitled to refuse to perform

maintenance or repairs.

14

Page 16

7.5. Connecting the condensate drain

The Unit condensate drain should be connected to indoor or outdoor wastewater network. If condensate

drain is installed in non-heated premises or directed outdoors, it must be thermally insulated or equipped

with electric heater.

Install a round rubber gasket into the condensate drain socket, then firmly screw the condensate drain

nozzle in by hand.

Figure 5. Installing the condensate drain

IMPORTANT! Do not use pliers or other similar tools, as excess power applied may damage the unit.

The necessary incline of the condensate drain should be ensured during the installation: at least 2° incline

should be ensured in the horizontal part of the system.

Siphon is the obligatory part of the condensate drain system. It is recommended to use HL138 or similar

type, internally or externally mounted siphon with mechanical odor control damper. Siphon should be

installed according to the diagram “Connecting the condensate drain″, ensuring that the manufacturer

instructions on the incline, distances, necessary inspection hatch for the selected siphon model are

observed.

Figure 6. Connecting the condensate drain

15

Page 17

8. CONNECTION OF THE UNIT

- Comfort

f

unctions

c

onnector

(RJ-45) - Mains c

able

(

230V, 3x1.5mm

2

L+N+PE

)

Mains supply, control panel cable and, if necessary, comfort function connector should be connected to

the Unit, according to the following diagram:

- Control panel connector (USB)

Figure 7. Unit connection

IT IS PROHIBITED to connect any cables or devices to the connectors of the control panel and comfort

functions, despite similarity to any standard connectors. External similarity of connectors does not

guarantee compatibility – the connected devices may fail or damage the Unit. The failure of the Unit due

to incompatible supplementary parts connection will void the warranty!

8.1. Connecting electric circuit

WARNING!!!

To prevent accidents and potential damage to the Unit, it can only be connected by a qualified

technician. Do not attempt to do that by yourself!

Mains supply power rating shall comply with the rating indicated in the Unit manual.

Mains supply should be disconnected when connecting the Unit.

The Unit should be connected according to diagram provided in the User Manual.

Only power cable provided with the Unit should be used to connect it to power source.

Grounding should be installed in compliance with the requirements of effective legislation and

standards when connecting the Unit to mains supply.

Electric circuit must be equipped with suitable power circuit-breaker.

16

Page 18

Power supply 230V, 50Hz, 5A

Maximum electric power consumption – fans 106W

Maximum electric power consumption – preheater 500W

IP protection class 20

8.2. Connecting the control panel

It is recommended to install the control panel in residential premises (e.g., corridor or lounge) for

convenient access. It is recommended to install the control panel at 1.5 – 1.6 m height from the floor.

Figure 8. Control panel installation

IT IS PROHIBITED to install control panel in a premises, where relative air humidity exceeds 90%.

17

Page 19

8.3. Connector of comfort functions

The Oxygen X-Air C200 device supports the following external functionality:

Fire alarm – emergency shutdown of the Unit upon activation of fire alarm;

WC boost – ventilation boost activation upon switching on the light in the bathroom;

CO2 sensor – ventilation power increase based on readings of auxiliary CO2 or humidity

sensors connected;

Away – reduction of ventilation power when no one is at home. Requires security system to

be installed in the premises.

Functions can be activated by short circuiting the respective digital contacts of RJ45 function connector.

Conn. contact No. Function of ventilation system

1-2 Fire alarm

3-4 WC boost

5-6 CO2 / humidity sensors

7-8 Away

Figure 9. Contacts of functions connector

IMPORTANT! Only passive jumpers or electric relays should be used to activate the function!

IT IS PROHIBITED to connect the functions connector directly to electrical wiring network!

The optional RJ45 adapter can be used for more convenient connection:

Figure 10. Comfort functions RJ45 connector adapter

18

Page 20

8.4. Control board electrical wiring diagram

Figure 11. Control board electrical wiring diagram

IMPORTANT! Make sure that the Unit is disconnected from mains supply before connecting or

disconnecting system components.

19

Page 21

8.5. Description of control board contacts

AO1 Exhaust fan control 0-10V

GND Not used

AO0 Supply fan control 0-10V

GND Not used

X13 Exhaust air temperature sensor

X14 Supply air temperature sensor

X15 Outside air temperature sensor

X16 Inside air temperature/ humidity sensor

AI1 DI2 function – „Away″

GND

AI0 DI3 function – „CO2 sensor″

24V Not used

DI1 DI1 function – „WC boost″

GND

DI0 DI0 function – „Fire alarm″

GND

Tach1 Exhaust fan tacho signal

GND

Tach0 Supply fan tacho signal

GND

X20 Control Panel connector

X1 Exthaust air fan L

X3 Exthaust and Supply fans N

X7 Preheater L

X10 Supply fan L

X11 Preheater N

K1 Bypass N

K2 Not used

L Bypass L

L Mains L

N Mains N

N Not used

F1 315mA fuse

20

Page 22

- Ventilation power setting control knob

Operating state

- Air f

ilter replac

ing indicator

- Failure indicator

-

9. OPERATION OF THE UNIT

9.1. Control panel with a knob

Control panel with a knob makes it possible to gradually control the ventilation power. Colored LEDs

indicate status of the Unit.

Figure 12. Control panel with a knob

9.1.1. Operating state indicator

Flashing green led indicates that the Unit is connected to power supply:

flashes 1 time ventilation is off

flashes 2 times ventilation is on

flashes 3 times the Unit is shutting down, shutdown programs are being executed

9.1.2. Air filter replacing / anti-frost protection indicator

Flashing yellow led indicates:

flashing consistently it is necessary to replace filters

yellow and green leds flash in turns anti-frost protection is on

21

Page 23

Control panel will indicate the necessity to replace filters after 6 months of uninterruptable Unit operation

by consistent flashing of yellow led. Disconnection of the Unit from mains supply does not reset the

counter.

IMPORTANT! Filters may need to be replaced more frequently – refer to section 11.1. Replacing of air

filters for more information.

Green and yellow leds flashing in turns indicate that anti-frost protection has been activated – the

preheater is on.

IMPORTANT! Higher than usually power consumption is to be expected when the Unit is operating in

this mode.

9.1.3. Failure indicator

The flashing red led indicates that failure of the Unit component was detected:

flashes 1 time failure of outside air temperature sensor

flashes 2 times failure of exhaust air temperature sensor

flashes 3 times failure of supply air temperature sensor

flashes 4 times failure of extract air temperature sensor

flashes 5 times failure of supply fan motor

flashes 6 times failure of exhaust fan motor

flashes 7 times fire alarm has been activated

flashes 8 times failure of preheater

Unit operation will stop after detecting component failure. You can restart the Unit by following RESET

procedure:

RESET – gently press the hidden button S1 with thin screwdriver (safety-match, toothpick) through the

hole on the side of control panel two times, until all three color leds switch on. Then immediately press

and hold S1 button again for about 3 seconds, until all leds switch off.

22

Page 24

- R

eset button

S1

Figure 13. Reset button

IMPORTANT! If red failure indicator led starts flashing again after the Unit reset procedure has been

performed, contact manufacturer of the Unit or its local representative.

If both red and yellow leds are on (no flashing) – connection between control panel and the Unit was lost,

the Unit is operating in safe mode. Try switching off the power circuit-breaker to disconnect mains supply

and then switch it back again. If the problem persists, contact manufacturer of the Unit or its local

representative.

9.1.4. Additional system settings

Control panel is programmed to maintain 20 °C supply air temperature. Bypass function will be activated,

when there is no need to use heat exchanger, by evaluating outdoor and indoor temperatures.

Controllers for additional settings of ventilation system are installed on the back side of control panel:

P1 boost mode time setting

P2 boost mode power setting

P3 supply fan power adjustment

P4 exhaust fan power adjustment

S1 reset button

S2 not used

23

Page 25

Figure 14. Additional settings for control panel with a knob

You may get access to enhanced Unit functionality, by purchasing control panel with touchscreen display.

24

Page 26

9.2. Control panel with touchscreen display

Control panel with touchscreen display screen makes it possible to use the enhanced Unit functionality.

Figure 15. Control panel with touchscreen display

9.2.1. Standby mode

Touchscreen display of control panel will only display the time of day in standby mode if the Unit is

switched off. If the Unit is in operation, settings of preferred temperature and ventilation power will also

be displayed.

Figure 16. Control panel with touchscreen display in standby mode: the Unit is switched off, the Unit is in operation

25

Page 27

9.2.2. Main screen

TIme

Date

Outside air temperature

Extract filter lifetime

Supply air temperature

ON / OFF button

Settings menu

Ventilation boost button

Figure 17. Main screen of control panel with touchscreen display

Main screen displays:

Time of day

Date

Temperatures:

Preheater state indicator

Supply air filter lifetime

Exhaust air temperature

Exhaust fan state

Preferred room temperature

Preferred ventilation intensity

Bypass valve state

Extract air temperature and relative humidity

Supply fan state

o Outside air (refer to section on winter mode)

o Extract air (inside)

o Supply air

o Exhaust air

Relative humidity of indoor air

Lifetime of outside and extract air filters

Bypass valve state

Preheater state

This menu enables to:

Activate the “boost” mode by single touch of BOOST button

Access the settings menu

Set the preferred supply air temperature

Select the preferred ventilation intensity

26

Page 28

9.2.3. Settings menu

activation

Language

selection: LT, EN, RU, PL

Desired ventilation intensity

Preferred indoor air temperature

Date and time setting

Figure 18. Settings menu

Control panel settings menu enables to:

Set the system date and time

Select the menu language: English, Russian, Polish, Lithuanian

Set up weekly operation program

Set the duration of boost mode

Reset the filter lifetime counters – after replacing of air filters

9.2.4. Setting up weekly operation program

Weekly program settings, program

Boost mode settings

Filter lifetime counter reset

Up to 4 different ventilation modes can be set for each day of week. After selecting the week day, set:

operating mode start time

selected ventilation intensity

preferred supply air temperature

Day of the week

Operating mode start time

Figure 19. Weekly operating mode settings menu

27

Page 29

Weekly program will be saved by clicking “Back” button.

IMPORTANT! Click on the round button next to schedule button in main menu to activate a weekly

program. Green color of button means the program is active.

9.2.5. Failure indication

In case of Unit component failure, the RESET button will appear in main menu. Failed component will turn

red, the Unit operation will stop.

RESET button

Failed component

Figure 20. Failure indication

Press the RESET button. The Unit will restart and if the failure was resolved, will continue to operate. If

the problem with failed component will persist after the Unit reset procedure has been performed and

RESET button will reappear, contact manufacturer of the Unit or its local representative.

28

Page 30

9.3. Replacing of air filters

OXYGEN X

-

Air C200

–

left-side version

OXYGEN X

-

Air C200

–

right

-

side version

Outside air filter

Extract air filter

Extract air filter

Heat Recovery Unit Oxygen X-Air C200 is equipped with outside and extract air filters.

Outside air filter ensures supply air quality, protects against ingress of outdoor dust and insects

(G4, G4 Carbon, M5, F7 filtering classes);

Extract air filter protects the device against ingress of indoor dust and insects (G4 filtration class).

Figure 21. Locating air filters

Air filter replacing frequency depends on the selected filtering class and environment, where the Unit is

being operated. Dusty operation environment will foul filters faster.

Replacing of air filters:

Shut down the Unit by control panel, make sure that fans have completely stopped

Open the lid of the filter, that you intend to change, marked by „OXYGEN″ by firmly gripping it

and pulling out

Use fabric handle to remove a filter

Insert a new filter, following ventilation flow direction indicated on filter frame – it should point

towards center of the Unit

29

Firmly push the lid of the filter back to its place. Make sure it was tightly inserted into the Unit

housing

Page 31

It is recommended to replace air filters at least:

Filtering class

EN 779:2012

G4 Coarse 65% every 6 months

G4 Carbon ePM

M5 ePM10 55% every 4 months

F7 ePM1 70% every 2 months

Filtering class

ISO 16890

60% every 4 months

2.5

Recommended replacing frequency

IMPORTANT! The fouled air filters can result in ventilation power decrease and higher than usually power

consumption.

IMPORTANT! Only original, manufacturer recommended filters should be used. The use of low quality

third party filters can result in damage to sensitive device components due to excess dust or humidity.

Failure of the Unit caused by the use of non-original components, will void the warranty.

Replacement filters can be ordered at: www.oxygen.lt.

30

Page 32

10. MAINTEINANCE AND WARRANTY

Heat recovery Unit Oxygen X-Air C200 is granted 24 months warranty. Make sure to have the section

below properly filled in to confirm the installation date. Otherwise, have the proof of purchase handy

before contacting service department.

Product Oxygen X-Air C200

Serial No. _________________

Installation date _________________

Contractor (company) _____________________________________________________

_____________________________________________________

(first name, last name, signature, stamp)

IMPORTANT! Before contacting service department, make sure that the failure is persistent – check that:

The Unit is connected to mains supply;

Power circuit-breaker is ON;

If flashing red led of control panel with a knob indicates failure (refer to section 10.1.3. Failure

indicator) or RESET button is being displayed on touchscreen control panel, try rebooting system

first.

IMPORTANT! Flashing green and/or yellow leds of control panel with a knob do not indicate the failure!

(refer to section 10.1.2. Air filter replacing / anti-frost protection indicator).

Contact the service department by sending an e-mail to service@oxygen.lt. The Unit serial number must

be included together with nature of failure. Be as specific as You can when describing the issue.

31

Page 33

11. CONTACTS

UAB “Šviežias oras″

Company code: 304288834

VAT code: LT100010366918

Bank account: LT42 7044 0600 0810 3886

SWIFT: CBVILT2X

AB „SEB″ bank

Address: Birzelio 23-osios g. 23G

50220 Kaunas

Lithuania

Phone No.:

Administration +370 687 81111

Sales +370 627 26666

www.oxygen.lt

Notes:

32

Loading...

Loading...