OXLEY Inter Connect User Manual

Oxley Interconnect Catalogue

Introduction

Introduction

Oxley is an established design and manufacturer of quality electronic

components.

We meet customer requirements with a complete range of standard electrical

components for interconnection, as well as offering clients custom design

and manufacturing facilities for non-standard solutions.

We offer a wide range of surface mount and through hole interconnect

products off-the-shelf for use in electronic applications:

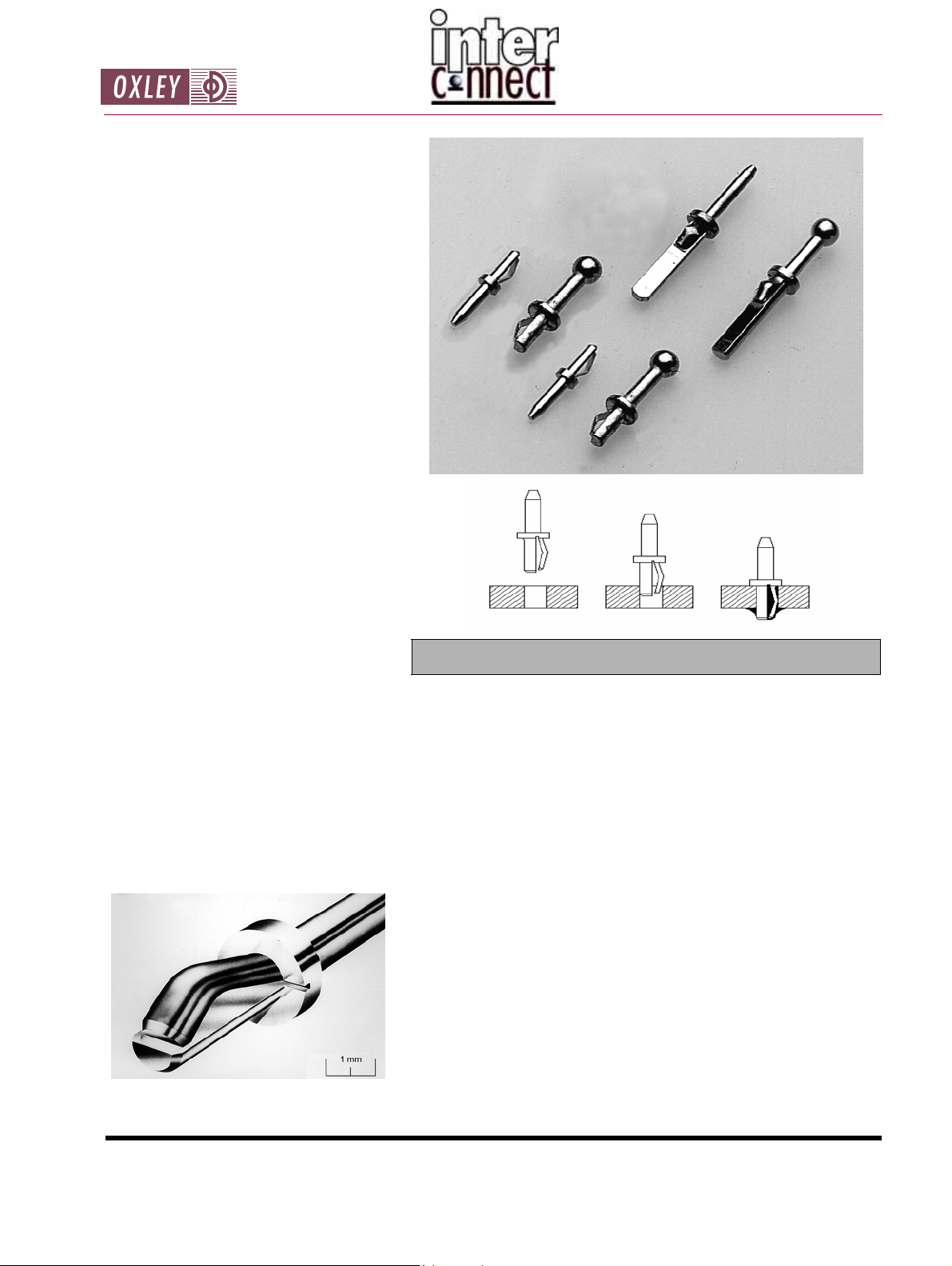

• Surface Mount PCB Test Points

• Through Hole PCB Test Points

• Through Hole PCB Connectors

• Chassis Mounted Insulated Terminals and Feedthroughs

• Chassis Mounted and In Line Insulated Plugs and Sockets

• Custom Interconnection

In addition, we offer a sub contract precision machining service to produce

tight toleranced turned parts including those made from speciality materials

such as Alumel and Chromel. Parts can be supplied in a wide variety of

plating finishes to various standards.

In terms of design, production and Quality Assurance procedures, the Oxley

high standard has been recognised by National Approvals for manufacture

and research to BS EN ISO 9001: 2000, BS9000 and IECQ-CECC.

www.oxleygroup.com/interconnect

ODCSM:40566/4/2007

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Developments Company Ltd

Email: sales@oxley.co.uk

Tel: +44 (0)1229 840519

1

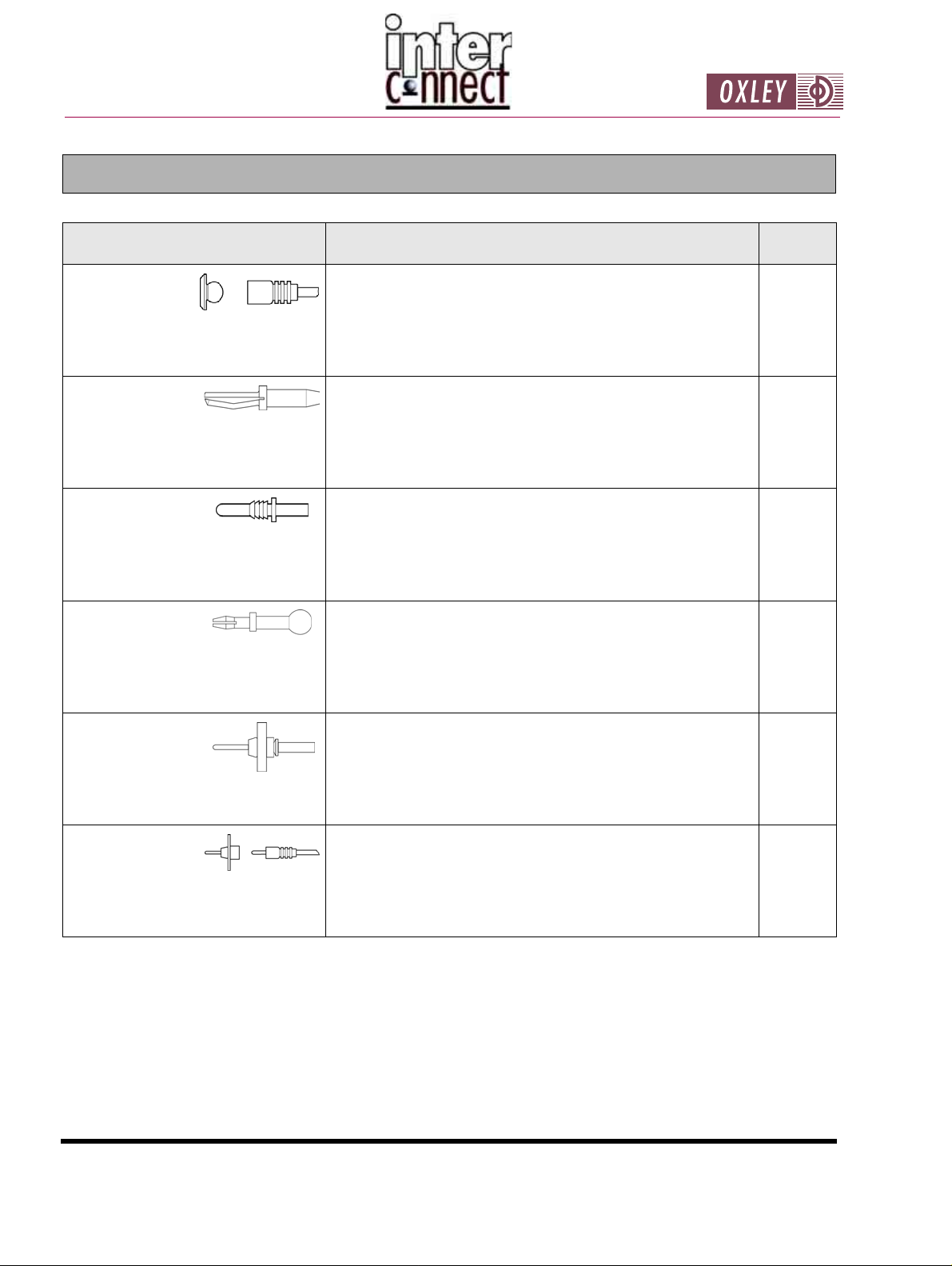

PCB/Panel Mounting

Interconnection Products

Types Features Page

SMOX

Surface Mount

Test points

KINKY PIN PTH

Connectors

Snale

Printed Circuit

Connectors

PCB/Panel Mounting Interconnection Products

Selection Guide

• available either loose or taped and reeled.

• requires minimum pad size of only 2 mm diameter.

• unique retention mechanism prevents damage to

PCB during connection/disconnection of socket.

• designed for plated through hole applications.

• insertion tools available for hand and semi-automatic insertion.

• custom styles available.

• self-retention mechanism provides high retention and rigidity.

• custom styles available.

• Snaplox, holed and test-point styles available.

3

7

12

SNAPLOX

Printed Circuit

Test Point

BARBCONE

LOCK

PTFE Insulated

Terminals

BARBCONE

LOCK

Plugs and

Sockets

• award winning design allows rapid connection/

disconnection.

• self-retaining and straight shank designs available.

• suitable for chassis, PCB and ceramic hybrids.

• insulated terminal designed for mounting on

chassis/frameworks.

• hermetically sealed versions available as standard.

• hand assembly tools available for ease of insertion.

• PCB Edge Mounted Variants available for card-rack systems.

• Colour options for PTFE Bush.

• in-line and stackable styles to reduce real estate.

• ease of assembly to increase production.

16

23

33

Oxley Developments Company Ltd

2

Email:sales@oxley.co.uk

Tel: +44 (0)1229 840607

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

www.oxleygroup.com/interconnect

ODCSM:40566/4/2006

Features

• Unique retention mechanism enhances

reliability through low stress

connections.

• Minimum contact resistance (less than

2 mΩ) through 8 points of contact.

• Chamfer design allows excellent solder

fillets to be formed.

• Available loose or taped and reeled.

• Award winning kinematic design allows

rapid connection/disconnection.

• Proven application through Snaplox

range of test points.

• Hand or automatic assembly.

SMOX® Surface Mount Test

Surface Mount Applications

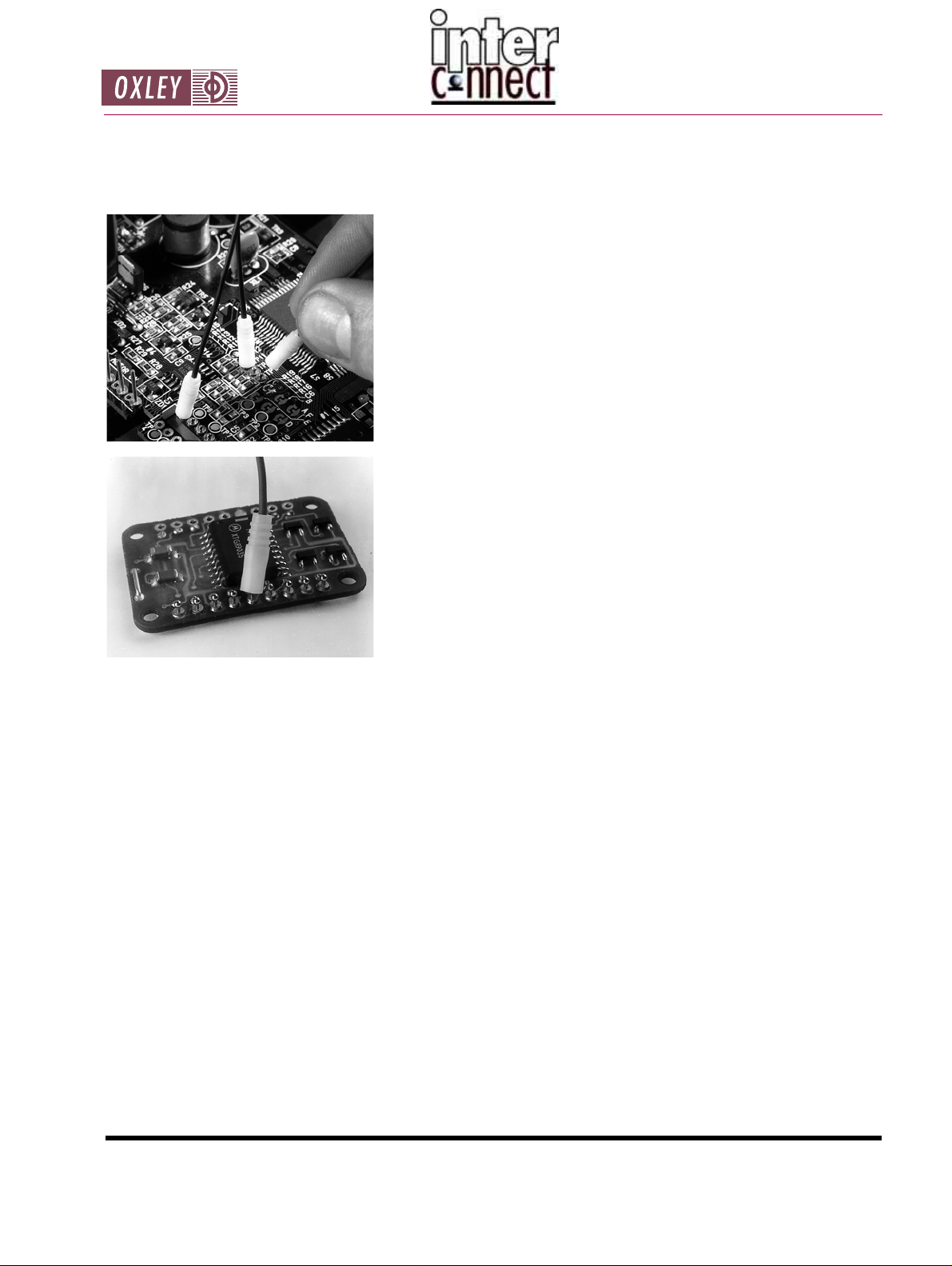

Surface-Mount Oxley (SMOX) Test-Point is available Taped and Reeled,

with a compatible mating socket and is suitable for a range of applications.

Due to the unique nature of the SMOX Connection System, it represents the

only Surface Mount Test Point available on the market with a specially

designed socket for easy low contact resistance and gentle detachment; the

applications and potential uses are limitless.

Requiring a minimum pad size of only two millimetres (0.080”), and being a

singlepole device, the SMOX can be placed accurately by any Pick and

Place machine in even the most congested designs. The socket is normally

used with the recommended PTFE Insulated Sleeve, (diameter 3.2 mm/

0.128”), but for those very close pitch designers, this can be replaced with

alternative insulation techniques.

Detecting and localising board faults is an obvious application, where the

ability to quickly and individually identify faulty components, cracked solder

joints or short circuits can save time of testing via an edge mounted

connector, or under a microscope.

On thick multilayered boards, where complex track designs can lead to very

expensive PCB’s, the benefits of quickly and effectively identifying and

repairing any faulty populated PCB can be easily recognised.

The ability to monitor waveform characteristics and determine the

performance of a circuit with variable components is vital, and not just in a

test laboratory. Where exact frequency output is required, a certain

waveform is needed or the ability to manually set the characteristics of each

production board manufactured; the inclusion of SMOX Test Points fulfils

that requirement.

www.oxleygroup.com/interconnect

ODCSM:40566/4/2007

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Developments Company Ltd

Email: sales@oxley.co.uk

Tel: +44 (0)1229 840519

3

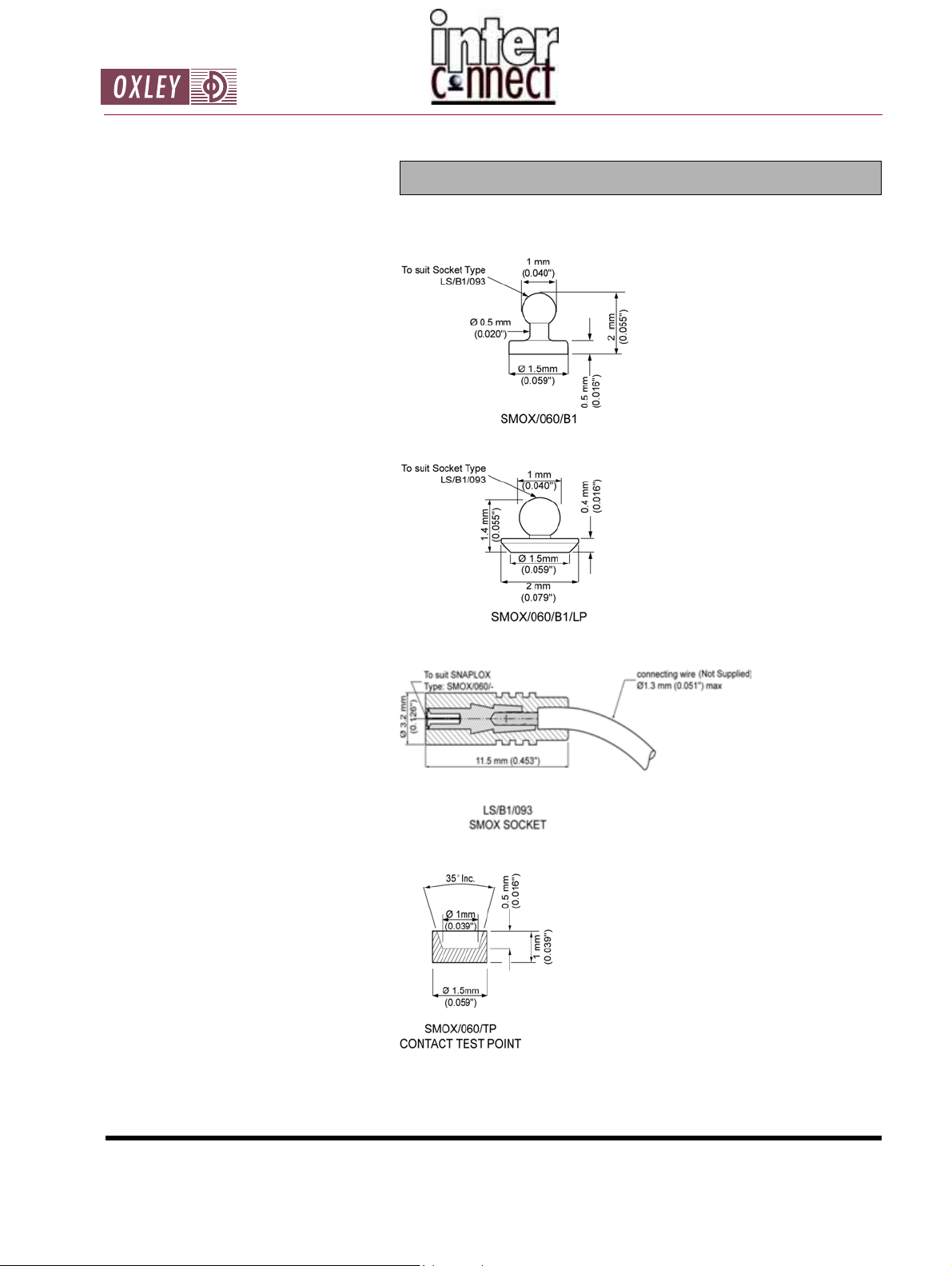

SMOX® Surface Mount Test

Key Characteristics

Gold plated SMOX Test Point for low contact resistance and durability.

SMOX Connector Systems to reduce the risk of accidental damage to the

PCB. Can be used on any Pick and Place machine using vacuum nozzles.

Square or round solder pads can be used, with a minimum pad size of 2 mm

diameter.

Sockets are gently

detached when moved

beyond an angle of 30°

from vertical.

Packaging

The SMOX/060/B1LP.R3K Test Point is available on Tape and Reel, to

enable placement on to PCB’s by a variety of pick and Place machines. The

plastic reels are an industry standard 7” diameter and the R3K extension

denotes 3,000 components in a specially designed carrier tape.

The SMOX/060/B1-R2K test point is available on Tape and Reel, to enable

placement on to PCB’s by a variety of pick and Place machines. The plastic

reels are an industry standard 7” diameter and the .R2K extension denotes

2,000 components in a specially designed carrier tape.

The solid flat bottomed pocket ensures the component is in the correct

vertical position when the heat sealing backing tape is peeled off. 100%

visual inspection by camera during population of the tape ensures no

components are heat sealed in place in the wrong position, or that empty

pockets can be sealed.

For customers requiring the SMOX Socket to be supplied assembled, a

standard product is available on 15” of cable, with differing lengths possible

where demand exists.

Oxley Developments Company Ltd

4

Email:sales@oxley.co.uk

Tel: +44 (0)1229 840607

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

www.oxleygroup.com/interconnect

ODCSM:40566/4/2006

SMOX® Surface Mount Test

SMOX Surface Mount T es t Points

Wires shown for illustration purposes only.

www.oxleygroup.com/interconnect

ODCSM:40566/4/2007

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Developments Company Ltd

Email: sales@oxley.co.uk

Tel: +44 (0)1229 840519

5

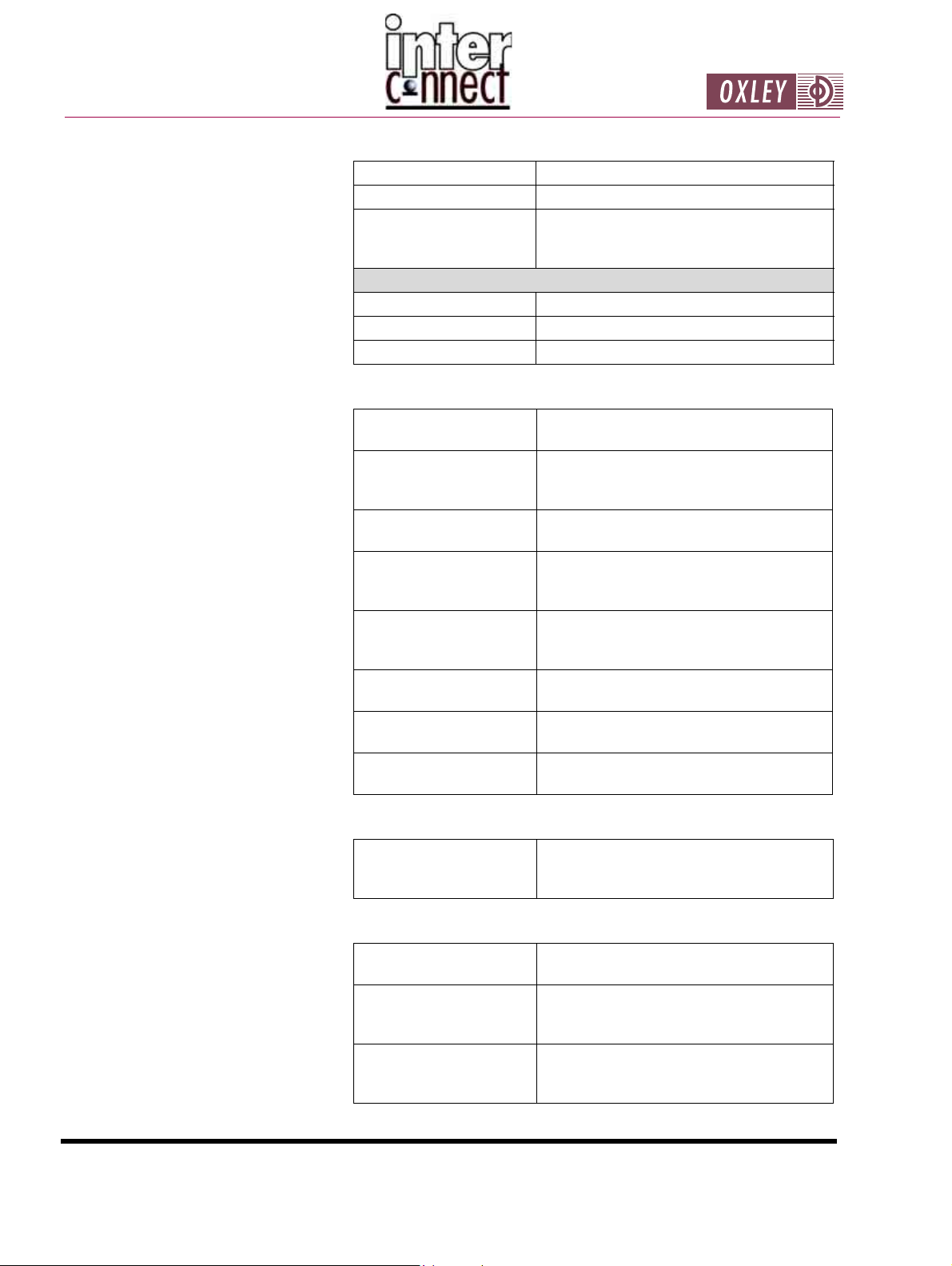

SMOX® Surface Mount Test

Materials

Characteristics

Test Point Copper Alloy

Socket Body Copper Alloy

Insulation High dispersion grade PTFE standard colours

- white, black and red.

Other colours available on request.

Finishes

Standard Gold

Options Palladium, Silver, Nickel or Tin Lead

Socket Silver

Maximum Contact

2 milliOhms

Resistance (with socket)

Maximum Angular

±30º

Movement before

Disconnection

Socket Insulation

10,000 MOhms minimum

Resistance

Typical Retention Force

0.2 kgs

(angles less than 60° or

±30°) off perpendicular

Typical Retention Torque

200 gcm

(angles greater than 30°)

or perpendicular

Current for 10°C Rise

3 A

Above Ambient

Climatic Category -55 to +125 °C, 56 days damp heat

(IEC 68:55/125/56)

Solderability Exceeds Requirements of BS 2011

(IEC 68) Test T

Assembly Tools

Taping and Reeling

Oxley Developments Company Ltd

6

Email:sales@oxley.co.uk

Tel: +44 (0)1229 840607

Tool Numbers Required

for SMOX Sockets (LS/

B1/093) Assembly

Tape 4 mm pitch

Reel Sizes:

SMOX/060/B1/LP.R3K

7 inch 3,000 components

Reel Sizes:

SMOX/060/B1.R2K

7 inch 2,000 components

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

AT1/KP18 and AT1/KP19

8 mm wide

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

www.oxleygroup.com/interconnect

ODCSM:40566/4/2006

Features

• Unique kinked retention mechanism

retains pin in PCB plated through hole

(PTH) prior to soldering.

• Low insertion force avoids damage to

plating of PTH during assemb l y.

• Slotted design enhances solderability

and reliability.

• Family optimised for a wide range of

PTH diameters

0.508 mm (0.020") -

1.524 mm (0.060").

• Capable of hand and semi-automatic

machine insertion.

• Available in a wide range of styles and

finishes for alternative applications.

• Vibratory bowl fed semi-automatic

insertion machines available, details on

request.

KINKY PIN Plated Through

Hole (PTH) Connectors

Application

• Self retaining compliant pin for plated

through holes in multilayer printed

circuit boards.

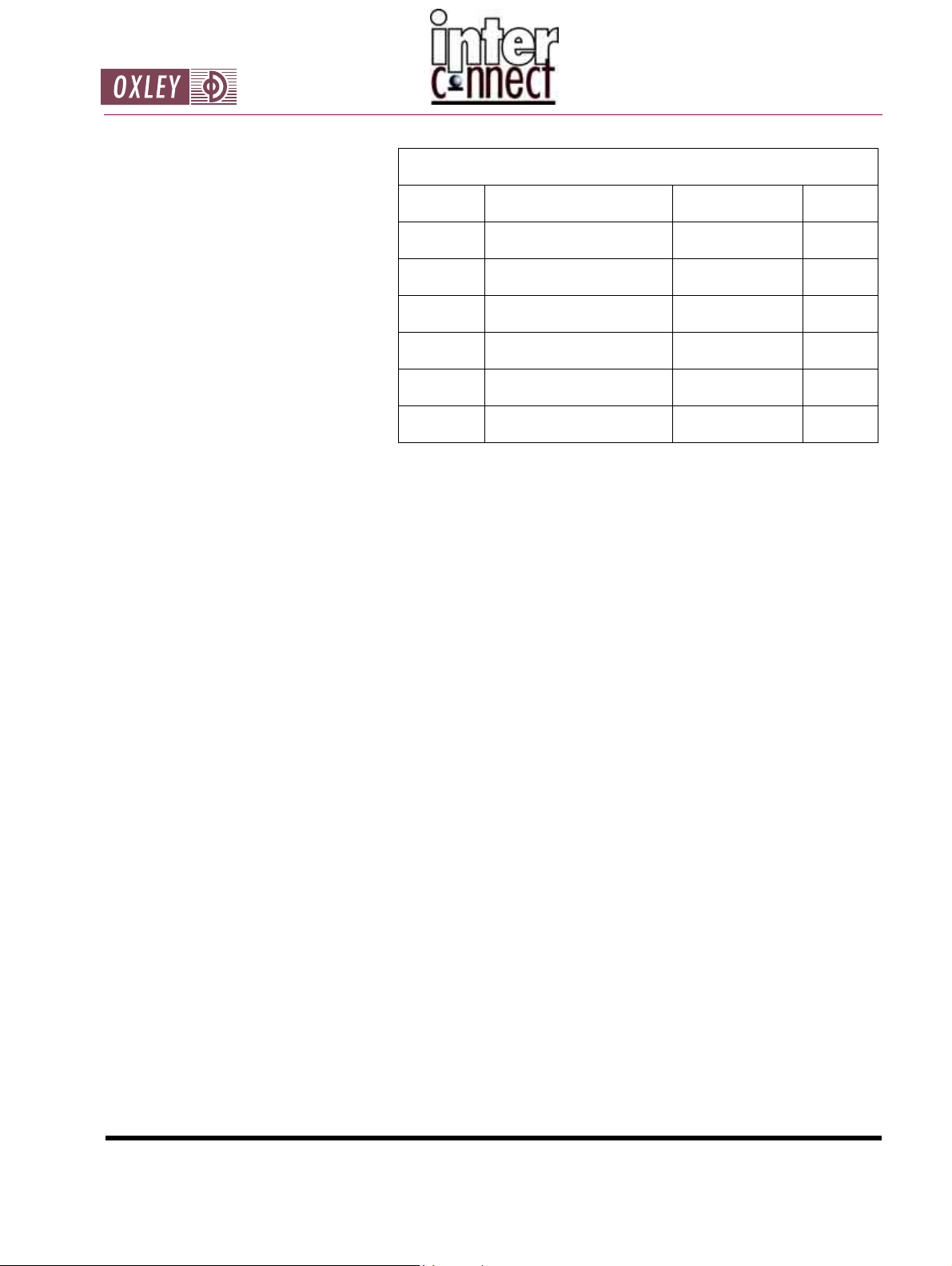

Kinky Pins

Kinky Pins were designed specifically to meet the demands of plated

through hole (PTH) technology introduced in printed circuit boards. They

tend to be used with flexi-circuit termination and as solder terminals,

connectors and in multiway pin arrays.

They use a unique kinked retention mechanism which gives a fit in the PTH

that is unsurpassed. The kinked leg provides a tight non-aggressive spring

loaded fit whilst the straight leg ensures the pin is kept perpendicular to the

PCB prior to soldering.

This Kinky Pin mechanism gives an additional benefit which is a key part

of its operation. The slotted design induces wicking of the solder up into the

kink and up to the flange which means that the solder joint is solid and free

of air pockets. This reduces the possibility of dry joints developing and the

life of the solder joint is therefore increased. In our opinion and that of our

customers, there is no better PTH solder-in terminal!

The Kinky Pin range is comprehensive and our in-house high precision

machining capabilities mean that we have the ability to manufacture

bespoke versions on request. Standard finishes are tin lead and gold;

other finishes are available on request.

www.oxleygroup.com/interconnect

ODCSM:40566/4/2007

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Developments Company Ltd

Email: sales@oxley.co.uk

Tel: +44 (0)1229 840519

7

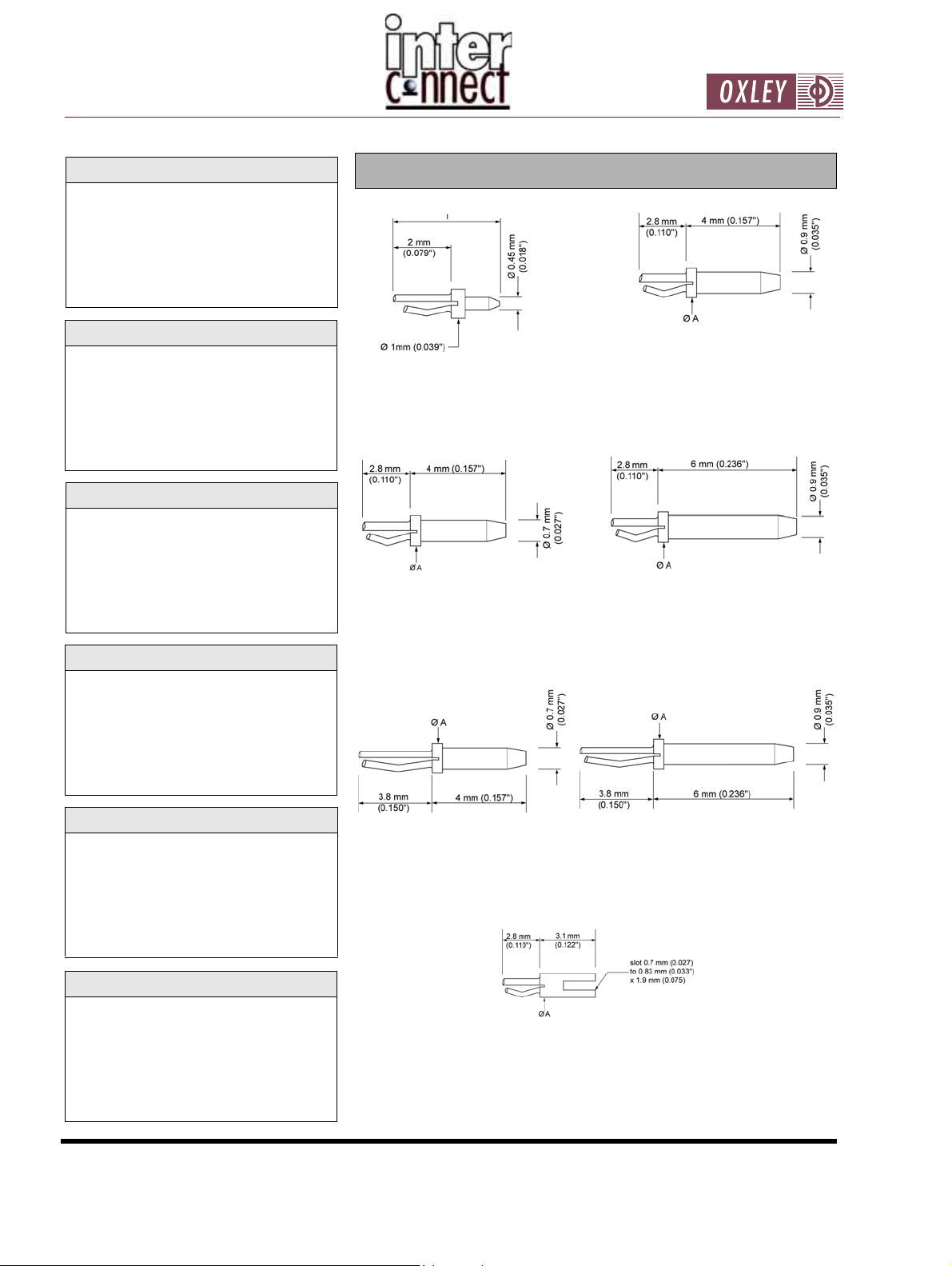

KINKY PIN Plated Through

Hole (PTH) Connectors

Prefix: 020/-

Mounting Hole Diameter:

0.52 mm (0.020") - 0.68 mm (0.027")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.0 mm (0.039")

Prefix: 028/-

Mounting Hole Diameter:

0.68 mm (0.027") - 0.84 mm (0.033")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.6 mm (0.063")

Prefix: 030/-

Mounting Hole Diameter:

0.81 mm (0.032") - 0.96 mm (0.038")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.6 mm (0.063")

Prefix: 040/-

Mounting Hole Diameter:

0.96 mm (0.038") - 1.12 mm (0.044")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.6 mm (0.063")

Kinky Pin Test Points

020/C/KP2 [I = 3.7 mm (0.146")]

020/PT/KP2 [I = 6.1 mm (0.240")]

020/PT/KP2/L [I = 7.3 mm (0.287")]

028/30P/LA/KP2

030/30P/LA/KP2

040/30P/LA/KP2

050/30P/LA/KP2

060/30P/LA/KP2

028/30P/KP2

030/30P/KP2

040/30P/KP2

050/30P/KP2

060/30P/KP2

028/30P/KP2/L

030/30P/KP2/L

040/30P/KP2/L

050/30P/KP2/L

060/30P/KP2/L

Prefix: 050/-

Mounting Hole Diameter:

1.21 mm (0.048") - 1.37 mm (0.054")

Min. Pitch Using Assembly Tool:

3.0 mm (0.118")

Shoulder Diameter A:

2.4 mm (0.094)

Prefix: 060/-

Mounting Hole Diameter:

1.50 mm (0.059") - 1.65 mm (0.065")

Min. Pitch Using Assembly Tool:

3.0 mm (0.118")

Shoulder Diameter A:

2.4 mm (0.094)

Oxley Developments Company Ltd

8

Email:sales@oxley.co.uk

Tel: +44 (0)1229 840607

028/10P/30P/LA/KP2

030/10P/30P/LA/KP2

040/10P/30P/LA/KP2

050/10P/30P/LA/KP2

060/10P/30P/LA/KP2

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

028/T/KP2

030/T/KP2

040/T/KP2

050/T/KP2

060/T/KP2

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

028/10P/30P/KP2/L

030/10P/30P/KP2/L

040/10P/30P/KP2/L

050/10P/30P/KP2/L

060/10P/30P/KP2/L

www.oxleygroup.com/interconnect

ODCSM:40566/4/2006

KINKY PIN Plated Through

Hole (PTH) Connectors

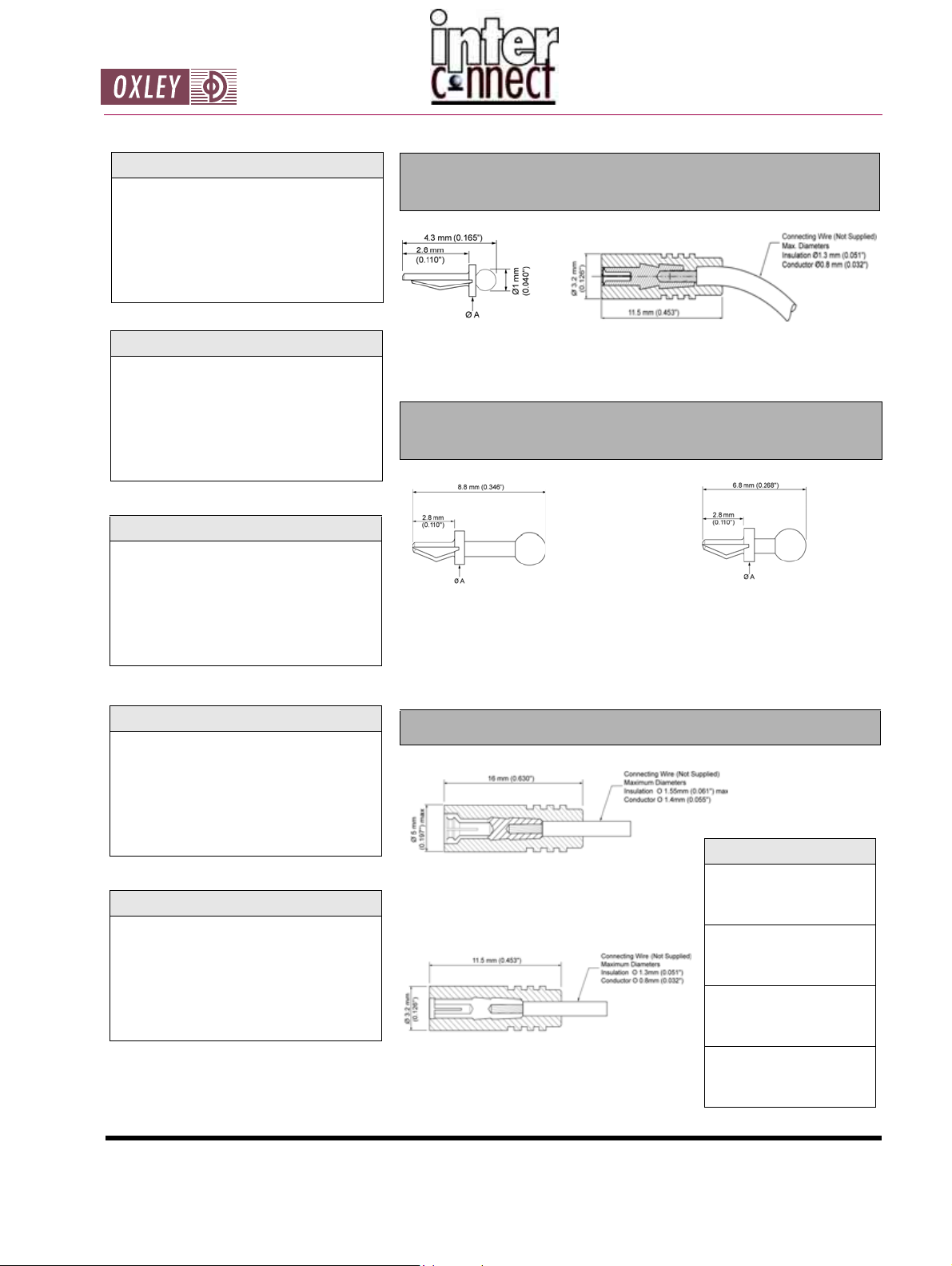

Prefix: 028/-

Mounting Hole Diameter:

0.68 mm (0.027") - 0.84 mm (0.033")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.6 mm (0.063")

Prefix: 030/-

Mounting Hole Diameter:

0.81 mm (0.032") - 0.96 mm (0.038")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.6 mm (0.063")

Prefix: 040/-

Mounting Hole Diameter:

0.96 mm (0.038") - 1.12 mm (0.044")

Min. Pitch Using Assembly Tool:

2.5 mm (0.098")

Shoulder Diameter A:

1.6 mm (0.063")

1 mm Snaplox Kinky-Pins

(To Suit Socket Type Number LS/B1/093)

Wires Shown for illustration purposes only.

030/B1/KP2

040/B1/KP2

050/B1/KP2

LS/B1/093

(To suit 1 mm Snaplox)

2 mm Snaplox Kinky-Pins

(To Suit Socket Type Number LS/B2/156)

028/SO/BK2F

030/SO/BK2F

040/SO/BK2F

050/SO/BK2F

060/SO/BK2F

028/SO/BK2P

030/SO/BK2P

040/SO/BK2P

050/SO/BK2P

060/SO/BK2P

Prefix: 050/-

Mounting Hole Diameter:

1.21 mm (0.048") - 1.37 mm (0.054")

Min. Pitch Using Assembly Tool:

3.0 mm (0.118")

Shoulder Diameter A:

2.4 mm (0.094)

Prefix: 060/-

Mounting Hole Diameter:

1.50 mm (0.059") - 1.65 mm (0.065")

Min. Pitch Using Assembly Tool:

3.0 mm (0.118")

Shoulder Diameter A:

2.4 mm (0.094)

www.oxleygroup.com/interconnect

ODCSM:40566/4/2007

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

Socket

Wires Shown for illustration purposes only.

LS/B2/156

(To suit all 2 mm Snaplox)

(To suit -/30P/KP2 AND -/30P/KP2/L))

30/LS/093

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Assembly Tools

-/30P/KP2,

-/30P/KP2/L

AT1/KP1

(028 - 040)/T/KP2,

-/-/BK2F, -/-/BK2P

AT1/KP2

-/10P/30P/KP2/L,

(050 - 060)/T/KP2

AT1/KP3

-/30P/LA/KP2/L,

-/10P/30P/LA/KP2

AT1/KP4

Oxley Developments Company Ltd

Email: sales@oxley.co.uk

Tel: +44 (0)1229 840519

9

KINKY PIN Plated Through

Hole (PTH) Connectors

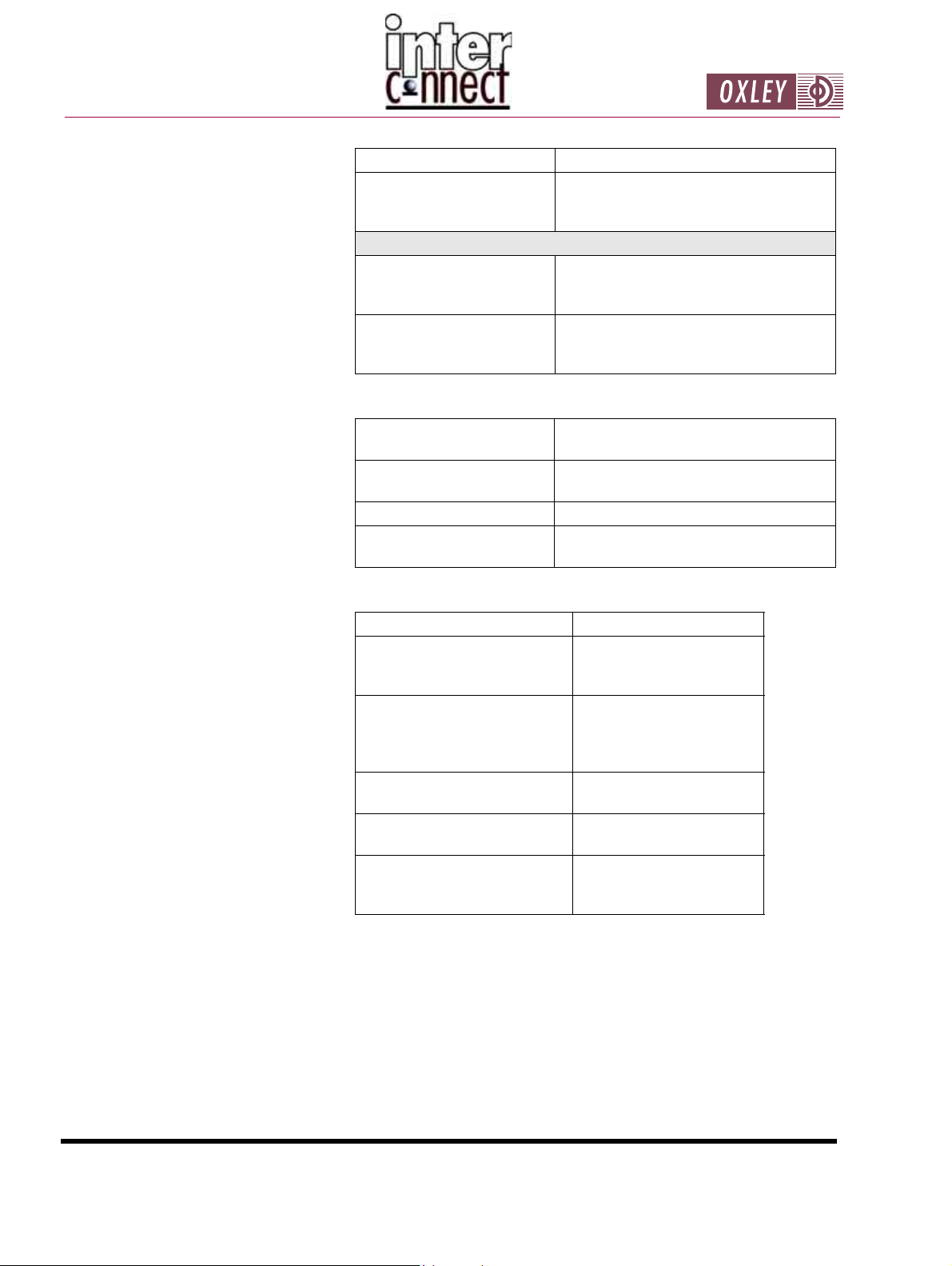

Materials

Characteristics

Pin Copper alloy

Sockets

Contact

Insulation

Brass

High dispersion grade PTFE

Finishes:

Pin

Standard

Options

Tin Lead

Gold (standard on Snaplox Kinky Pins)

Socket

Standard

Options

Contact Resistance

Silver

Gold

less than 5 millohms

(with socket)

Current for 10°C Rise

7 A

Above Ambient

Climatic Category - 55 to +125 °C

Solderability Exceeds Requirements of BS 2011

(IEC 68) Test T

Assembly Tools

Component Type Number Tool Number

-/30P/KP2

AT1/KP1

-/30P/KP2/L

-/LT/30P/KP2/L

(028 - 040) /T/KP2

AT1/KP2

-/LT/T/KP2

-/-/BK2F

-/-/BK2P

-/10P/30P/KP2/L

AT1/KP3

(050 - 060) /T/KP2

-/30P/LA/KP2

AT1/KP4

-/10P/30P/LA/KP2

O20/C/KP2

AT1/KP20

O20/PT/KPT

O20/PT/KP2/L

Oxley Developments Company Ltd

10

Email:sales@oxley.co.uk

Tel: +44 (0)1229 840607

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

www.oxleygroup.com/interconnect

ODCSM:40566/4/2006

KINKY PIN Plated Through

Hole (PTH) Connectors

Mounting Details and

Shoulder Diameter

Mounting Details : Minimum Board Thickness 1.4 mm (0.055")

0.9 mm (0.036") for 020/- and 2.36 mm (0.093") for -/10P

Prefix No Mounting Hole Dia. After

Through Plating

020/- 0.52 mm (0.020") -

Min. Pitch Using

Assembly Tool

2.5 mm (0.098") 1.0 mm

0.68 mm (0.027")

028/- 0.68 mm (0.027") -

2.5 mm (0.098") 1.6 mm

0.84 mm (0.033")

030/- 0.81 mm (0.032") -

2.5 mm (0.098") 1.6 mm

0.96 mm (0.038")

040/- 0.96 mm (0.038") -

2.5 mm (0.098") 1.6 mm

1.12 mm (0.044")

050/- 1.21 mm (0.048") -

3.0 mm (0.118") 2.4 mm

1.37 mm (0.054")

060/- 1.50 mm (0.059") -

3.0 mm (0.118") 2.4 mm

1.65 mm (0.065")

ØA

(0.039")

(0.063")

(0.063")

(0.063")

(0.094")

(0.094")

www.oxleygroup.com/interconnect

ODCSM:40566/4/2007

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Developments Company Ltd

Email: sales@oxley.co.uk

Tel: +44 (0)1229 840519

11

Snale® Printed Circuit

Connectors

Features

• Patented Snale® form provides high

retention and rigidity.

• Low insertion force allows easy hand

assembly.

• Serrated outline inhibits rotation.

• For use with 1.02 mm (0.040") and 1.27

mm (0.050") diameter holes.

• Available in a wide range of styles and

finishes for differing applications.

Application

• Self retaining interference fit pin for

single and double sided printed circuit

boards and chassis.

Oxley Developments Company Ltd

12

Email:sales@oxley.co.uk

Tel: +44 (0)1229 840607

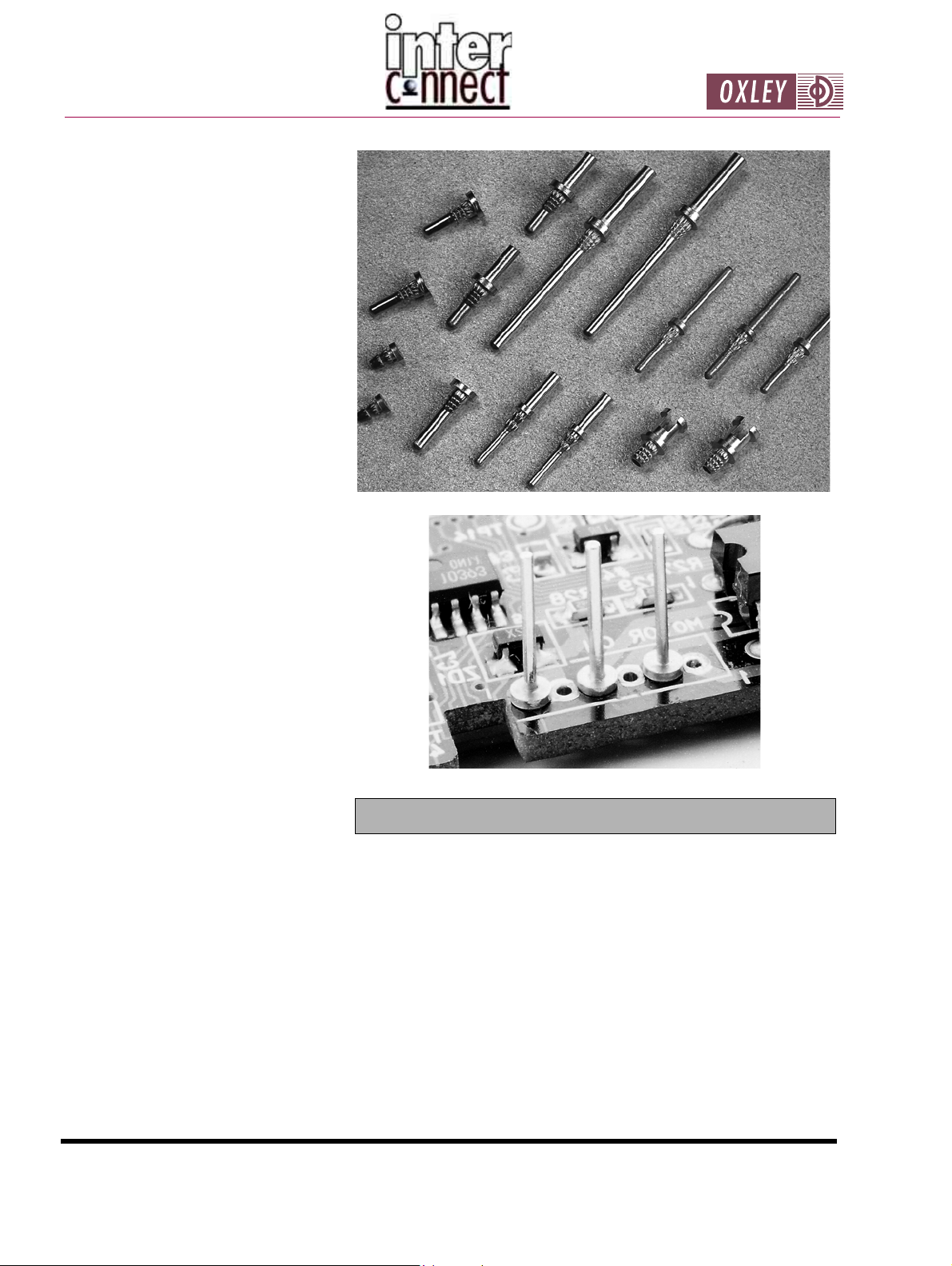

Snale Pins

The use of Snale Pins has been widely established in the commercial and

military electronics market worldwide as the definitive terminal pin for use

with non-plated through hole PCB’s and chassis.

The knurled and barbed retention mechanism gives a low insertion force,

high retention and non-rotation fit ensuring rigidity with ease of assembly.

The snale Pin range is available in a variety of lengths and diameters to suit

applications such as multiway pin headers on aircraft engine control

systems, as pins in connectors and lead-through terminals and solder posts

on flow meters.

They are available in standard Tin Lead and Gold finishes with others

available on request. Bespoke styles are also available due to our in-house

high precision machining capabilities.

Oxley Inc.

Email: sales@oxleyinc.com

Tel: +1 (203) 488 1033

Oxley Group Australia Pty Ltd

Email: sales@oxleygroup.com

Tel +61 (2) 9967 9193

www.oxleygroup.com/interconnect

ODCSM:40566/4/2006

Loading...

Loading...