Output Floor Stacker Owner's Manual

LaserMatrix

®®®®

LaserMatrix

LaserMatrixLaserMatrix

Floor Model Stacker

Floor Model Stacker

Floor Model StackerFloor Model Stacker

(Full Capacity Models LM1000A115 & LM2400A100)

Operator’s Guide

Operator’s Guide

Operator’s GuideOperator’s Guide

Part No: 066-00452-02

January 23, 1998 — Rev. G

COPYRIGHT

COPYRIGHT 1994, OUTPUT TECHNO

COPYRIGHT COPYRIGHT

All rights reserved under the Berne Convention.

TRADEMARKS

TRADEMARKS

TRADEMARKSTRADEMARKS

LaserMatrix is a registered trademark of Output Technology

Corporation.

PARTS AND SERVICE

PARTS AND SERVICE

PARTS AND SERVICEPARTS AND SERVICE

Contact Output Technology Corporation for parts and service. Have the

serial number of your printer and LaserMatrix Stacker handy so that we

can serve you more quickly.

We suggest you use genuine Output Technology Corporation supplies

and authorized service centers. Contact us at —

1994, OUTPUT TECHNOLOGY CORPORATION

1994, OUTPUT TECHNO 1994, OUTPUT TECHNO

(509) 536-0468 (Voice) or (509) 533-1280 (Fax)

LOGY CORPORATION

LOGY CORPORATIONLOGY CORPORATION

Output Technology maintains a Bulletin Board System (BBS) service.

In the U.S.A., call (509) 533-1217 to access our BBS service for the

very latest drivers, firmware, pricing, maintenance and troubleshooting

aids, and application information. Also, you can contact us at —

FTP: ftp.output.com/public/output

WWW: http://www.output.com

CONTENTS

CONTENTS

CONTENTSCONTENTS

Introduction.......................................1 Setup.................................17

Paper & Label Requirements............2 Operation..........................20

Floor Model Stacker Specifications..3 Maintenance .....................25

Unpacking & Installation..................4 Troubleshooting................26

Assembly...........................................7 Parts & Accessories..........27

INTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

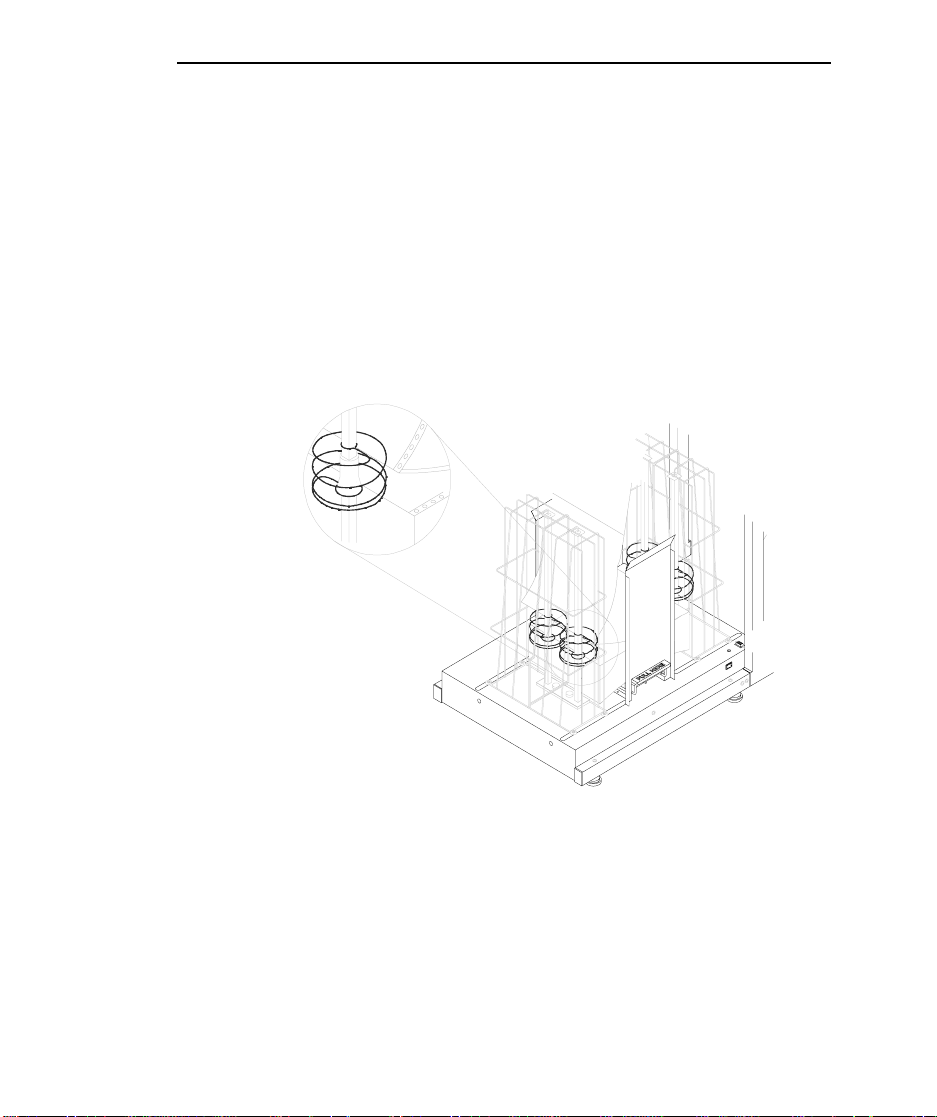

The LaserMatrix® Floor Model Stacker (Models

LM1000A115 & LM2400A100) will stack up to one full box of

printed forms from a LaserMatrix printer.

In the automatic mode, the stacker is controlled by the

printer. When the printer prints, the stacker turns two pairs of

floating helical coils which “refold” and then stack the fanfolded

paper. The coils float up with the paper as the stack grows in

height.

LaserMatrix Floor Model Stacker 1

LB0-B1

The LaserMatrix Stacker solves a problem common to

continuous form laser printers. The problem arises when a laser

printer fuses toner to the paper. In the process, heat and pressure

from the fuser iron out the perforations in the forms. The

“ironed-out” forms are more difficult to refold and stack.

2 LaserMatrix Floor Model Stacker

The LaserMatrix Floor Model Stacker allows you to

reliably print large jobs unattended — up to one full box of

paper. The stacker handles most grades of fanfolded paper and

label stock made for a laser printer.

NOTE: Due to variations in manufacturing process, quality,

and composition of forms, Output Technology cannot guarantee

satisfactory performance with all forms. Forms should be tested

to verify satisfactory performance prior to purchasing forms.

The stacker also includes a convenient and stable platform

for the printer itself.

PAPER &

PAPER & LABEL REQUIREMENTS

PAPER &PAPER &

LABEL REQUIREMENTS

LABEL REQUIREMENTS LABEL REQUIREMENTS

Paper Type: fanfold, single-part paper with a bond

weight of 18 to 24 lb (65 to 90 g/m

and a caliper thickness of 3.2 to 4.5 mil

(0.081 to 0.114 mm). Prefer 24 lb paper

without

Label Type: fanfold labels with a caliper (thickness)

not to exceed 7.5 mil (0.190 mm)

Sheet Lengths: variable from 6 to 14 in. (approx. 152 to

355 mm), perf to perf

Sheet Widths: variable from 4 to 10 in. (approx. 101 to

254 mm), including

laser (clear perf) perforations

1

/2 in. tractor strips

2

)

LaserMatrix Floor Model Stacker 3

Stack Limit: up to 15 in. (approx. 380 mm) in height

or about 2000 sheets of 24 lb bond

paper

FLOOR MODEL STACKER

FLOOR MODEL STACKER SPECIFICATIONS

FLOOR MODEL STACKER FLOOR MODEL STACKER

Width: 20 in. (approx. 508 mm)

Length: 37 in. (approx. 940 mm)

Height: 30 in. (approx. 762 mm)

Weight: 43 lb (approx. 20 kg)

Shipping Dimensions: 22 x 26 x 33 in. (approx. 560 x 660 x

Shipping Weight: 55 lb (approx. 25 kg)

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

840 mm)

Power Supply: 12 vdc at 800 ma. One of two power

supplies is shipped with the stacker:

either a UL/CSA, 120 vac, 60Hz, plugin power supply, or a 230 vac, 50Hz, inline power supply with a TÜV power

cord

Power Consumption: not more than 10 w

4 LaserMatrix Floor Model Stacker

UNPACKING & INSTALLA

UNPACKING & INSTALLATION

UNPACKING & INSTALLAUNPACKING & INSTALLA

You will need a utility knife for unpacking the container

and a small, flat-blade screwdriver to fasten cable connectors.

1. Inspect shipping container for damage. Report damage to

carrier immediately.

2. Stand shipping container upright.

3. Use a utility knife to remove one side of the container.

4. See Caution below, then move contents to installation site.

! CAUTION !

If you use a lift truck, only lift along bottom rails of the

stacker. Do not use a lift truck after plastic strap has

been removed.

TION

TIONTION

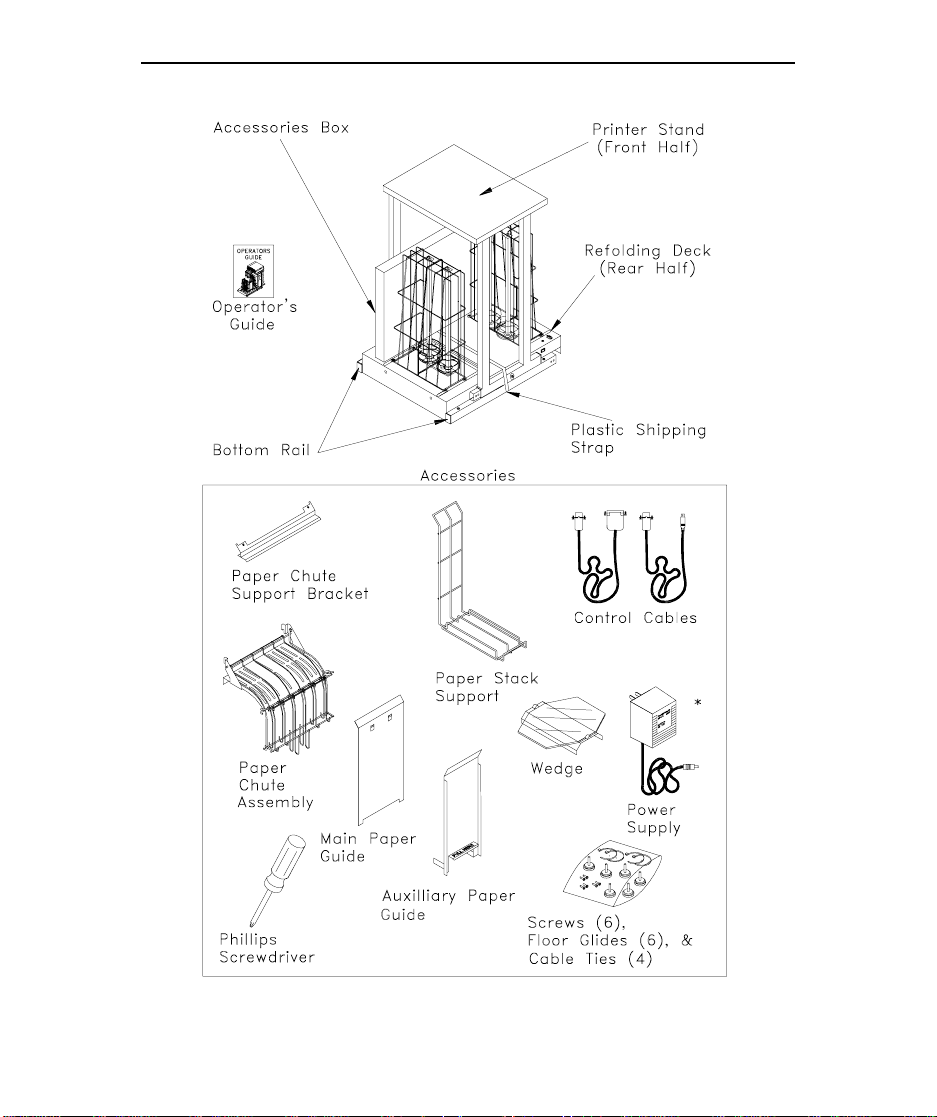

5. Remove plastic stretch wrap.

6. Remove accessories box. Also, remove bubble package

resting on refolding deck. Check contents of box and

package against the following illustration.

7. Cut plastic strap holding cardboard pad to bottom of deck.

8. Use the screwdriver provided to remove two screws (with

nylon washers) holding printer stand to refolding deck.

Lift off stand and then re-install screws and washers to

deck.

LaserMatrix Floor Model Stacker 5

9. Lift refolding deck off cardboard pad. Save all packing

materials.

6 LaserMatrix Floor Model Stacker

LB0-C5

* UL/CSA, 120 vac, plug-in power supply is shown here. A 230 vac, in-line power supply is available.

ASSEMBLY

ASSEMBLY

ASSEMBLYASSEMBLY

1. Move refolding deck and printer stand onto a hard, flat

2. Position U-channels of printer stand rails just opposite

3. Insert channels of printer stand into rails of refolding deck

LaserMatrix Floor Model Stacker 7

surface.

open rails of refolding deck, as shown in the next

illustration.

NOTE: It is possible to install the deck backwards. Make

sure you orient the deck, as shown in the illustration, so

that the corner of the deck with the manual mode switch is

located nearest the printer stand.

so that two pairs of screw holes line up. (It may be

necessary to temporarily loosen the four screws that

secure the refolding deck to its rails.)

4. Secure the two halves of the stacker with the screwdriver

and four,

accessory box.

5. If necessary, retighten screws to resecure deck to its rails.

3

/8-in.-long Phillips screws provided in the

8 LaserMatrix Floor Model Stacker

6. Tilt this assembly and screw in floor glides near the ends

and middle of the rails. Adjust the glides so that the

stacker is stable.

NOTE: An optional set of six casters can be used in place

of the floor glides.

7. Place the stacker in position and then place the printer on

the printer stand. Also, check to see that the front of the

printer is parallel to the front edge of the stand.

LB0-D3

The feet on the printer must rest in the indentations

provided in the stand.

8. Do one of the

following:

• If you have a 24

page per minute

LaserMatrix printer,

proceed to Step 9.

24 Page Per Minute

• If you have a 16

LaserMatrix Printer

paper per minute

PB0-A

Loading...

Loading...