Page 1

PV 8 Combiner

TM

PV 12 Combiner

User’s Guide

Includes Mounting and Installation Instructions

Page 2

2

Page 3

About OutBack Power Systems

OutBack Power Systems is a leader in advanced energy conversion technology. Our products include

true sine wave inverter/chargers, a maximum power point charge controller, system communication

components, as well as breaker panels, breakers, accessories, and assembled systems.

Notice of Copyright

FLEXware PV 8 Combiner FLEXware PV 12 Combiner Manual Copyright © 2008 All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER SYSTEMS:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Revision

March 2008

Contact Information

OutBack Power Systems

19009 62nd Ave. NE

Arlington, WA 98223

Phone (360) 435-6030

Fax (360) 435-6019

www.outbackpower.com

1

Page 4

TABLE OF CONTENTS

Warrranty Introduction ....................................................................................................................................................................3

Safety Instructions .............................................................................................................................................................................4

Requirements.........................................................................................................................................................................................5

FWPV-8 Combiner Features ..........................................................................................................................................................7

Sample FW-CBUS-8 (Bus Bar) Installations ...........................................................................................................................8

FWPV-8 Combiner ...............................................................................................................................................................................9

FWPV-8 Knockouts and Dimensions ....................................................................................................................................10

FLEXware PV-8 Combiner Wiring Sample (Circuit Breakers) .................................................................................11

Wiring Diagram ........................................................................................................................................................................12

FLEXware PV-8 Combiner Wiring Sample (Fuses) ........................................................................................................13

Wiring Diagram ........................................................................................................................................................................13

Fuse Holder Installation ................................................................................................................................................................14

FWPV-12 Combiner Features ....................................................................................................................................................16

Sample FW-CBUS-12 (Bus Bar) Installations .....................................................................................................................17

FLEXware PV-12 Combiner .........................................................................................................................................................18

FWPV-12 Knockouts and Dimensions .................................................................................................................................19

FLEXware PV-12 Combiner Wiring Sample (Circuit Breakers) ..............................................................................20

Wiring Diagram ........................................................................................................................................................................21

FLEXware PV-12 Combiner Wiring Sample (Fuses) .....................................................................................................22

Wiring Diagram ........................................................................................................................................................................23

Product Registration..................................................................................................................................... ..................................24

2

Page 5

Warranty Introduction

Dear OutBack Customer,

Thank you for your purchase of OutBack products. We make every e ort to assure our power

conversion products will give you long and reliable service for your renewable energy system.

As with any manufactured device, repairs might be needed due to damage, inappropriate use, or

unintentional defect. Please note the following guidelines regarding warranty service of OutBack

products:

• Any and all warranty repairs must conform to the terms of the warranty.

• All OutBack equipment must be installed according to their accompanying instructions and

manuals with speci ed over-current protection in order to maintain their warranties.

• The customer must return the component(s) to OutBack, securely packaged, properly addressed,

and shipping paid. We recommend insuring your package when shipping. Packages that are

not securely packaged can sustain additional damage not covered by the warranty or can void

warranty repairs.

• There is no allowance or reimbursement for an installer’s or user’s labor or travel time required to

disconnect, service, or reinstall the damaged component(s).

• OutBack will ship the repaired or replacement component(s) prepaid to addresses in the

continental United States, where applicable. Shipments outside the U.S. will be sent freight

collect.

• In the event of a product malfunction, OutBack cannot bear any responsibility for consequential

losses, expenses, or damage to other components.

Please read the full warranty at the end of this manual for more information.

3

Page 6

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

The OutBack FLEXware PV-8 and PV-12 Combiners are listed by ETL as PV Combiners under the follow-

ing standards:

• UL 67, 11th Edition

• UL 1741, First Edition

• CSA C22.2, No.29-M1989

These enclosures meet Type 3R rainproof requirements when mounted vertically or leaning back to 14

degrees (3/12 pitch).

This enclosure is rated for up to 150VDC circuit breakers and up to 600VDC fuses.

Grounding Instructions – Each enclosure should be connected to a grounded, permanent wiring

system. For most installations, the negative battery conductor should be bonded to the grounding

system at one (and only one) point in the DC system. All installations must comply with all national

and local codes and ordinances. System grounding as required by the National Electric Code, ANSI

/NFPA 70-1996, or other appropriate codes is the responsibility of the system installer.

The equipment ground on FLEXware PV Combiner is marked with this symbol:

NOTE: Solar panels produce electrical current when light is present, even during overcast

weather. Do not wire from the array to the PV-8 or the PV-12 Combiner. Complete all

connections inside the combiner rst and then connect at the array.

OutBack Power Systems’ FLEXware

FLEXware is a convenient system of all-aluminum, powder-coated modular enclosures with associated

mounting hardware and stainless steel fasteners for housing OutBack power components. Our

indoor-rated enclosures and mounting plates o er secure and centralized installations for various

combinations of FX Series Inverter/Chargers, OutBack Charge Controllers, the OutBack HUB, MATE, and

Auto-Transformer, as well as breakers, bus bars, and balance-of-system components.

General Wiring and Installation Instructions

• Remove any necessary knockouts before securing the combiner to its mounting surface.

• Mount the combiner, securing it appropriately.*

• Slide the circuit breakers or fuse holders onto the DIN rail and lock in place.

• Secure the box lugs to the Combiner Bus Bar.

• Install the Combiner Bus Bar and secure it to either the fuse holders or the circuit breakers.

• Connect all wires to the fuse holders or circuit breakers and the box lugs, securing them

according to the listed torque values.

• Connect the wires to the solar array.

*FLEXware PV-8 and PV-12 Combiners are designed for weather-resistant outdoor installation when appropriate

fasteners and secure mounting surfaces are used. The back of each combiner has knockouts to accommodate

fasteners, U-bolts, or other hardware for secure attachment to a solid surface, including pole mounting. Both the

surface and the fastening hardware must be su cient to support the weight of the combiner.

4

Page 7

Requirements

• Use minimum 75

• Use only code-approved, appropriately listed circuit breakers, fuse holders, and fuses.

Maximum Fuse Rating 15 AMP , 600VDC

Maximum Circuit Breaker Rating 15 AMP, 150VDC

Total Maximum Current Rating PV8—120 AMPS DC PV12—180 Amps DC

Maximum Fuse Short Circuit Current 10kA

Maximum Breaker Short Circuit Current 10kA for 80V; 100A for 150V

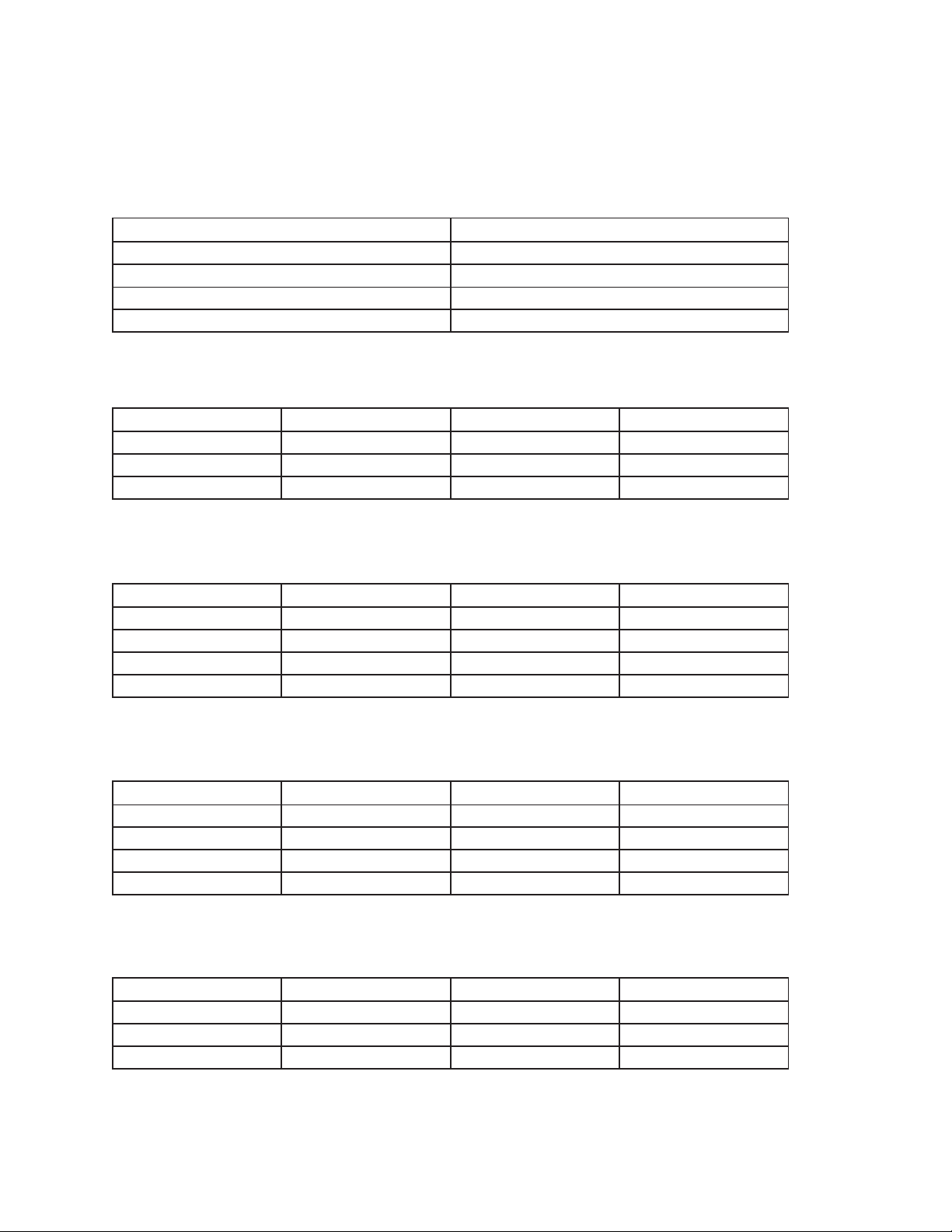

Torque Data* for DC Negative Bus Bar Small Holes

0

C copper conductors.

WIRE SIZE TORQUE

AWG mm

14-10 2.1-5.3 20 2.3

8 8.4 25 2.8

6 13.3-21.2 35 4.0

2

in lbs Nm

Torque Data* for Box Lug

WIRE SIZE TORQUE

AWG mm

14-10 2.1-5.3 35 4.0

8 8.4 40 4.5

6-4 13.3-21.2 45 5.1

2/0-3 13.3-21.2 50 5.7

2

in lbs Nm

Torque Data* for DC Negative Bus Bar Large Holes

WIRE SIZE TORQUE

AWG mm

14-10 2.1-5.3 35 4.0

8 8.4 40 4.5

6-4 13.3-21.2 45 5.1

2/0-3 13.3-21.2 50 5.7

2

in lbs Nm

Torque Data* for Ground Bus Bar

WIRE SIZE TORQUE

AWG mm

14-10 2.1-5.3 20 2.3

8 8.4 25 2.8

6-4 13.3-21.2 35 4.o

2

in lbs Nm

DIN Rail Mounted Breaker and Fuse Holder Terminals are torqued 22 in lbs/2.5 Nm

*Data is also listed on the product label attached to the combiner box.

5

Page 8

6

Page 9

FWPV-8 Combiner Features

Removable front cover

• Accommodates circuit breakers or fuse holders using a

reversible* combiner bus bar

• Two output set screw lugs for parallel positive strings

capable of accepting 2/0 AWG/67.4 mm

2

output wires

• Comes with one ground bus bar and one negative bus bar

• 1” EKO bottom knockout punchable to 2” EKO

• 1” back knockout punchable to 1.5”

• Can be mounted on a 3”, 4” or 6” pole**

• Roof mountable at an angle down to 3-in-12 pitch (14

0

)

*NOTE: A combiner can use either circuit breakers or fuses

depending on the installation requirements, but it cannot use

both at the same time.

Each FWPV-8 comes with appropriate hardware for

securing either circuit breakers or fuses and their conductors.

Please see the separate FW-CBUS-8 Instructions for further

information.

**Requires fasteners not available from OutBack Power Systems

7

Page 10

Sample FW-CBUS-8 (Bus Bar) Installations

Circuit breaker installation using included bus

bar hardware

Bus bar hardware installed

Fuse holder installation

Optional DIN Rail

End Clamp

(FW-EC-DIN)

8

Page 11

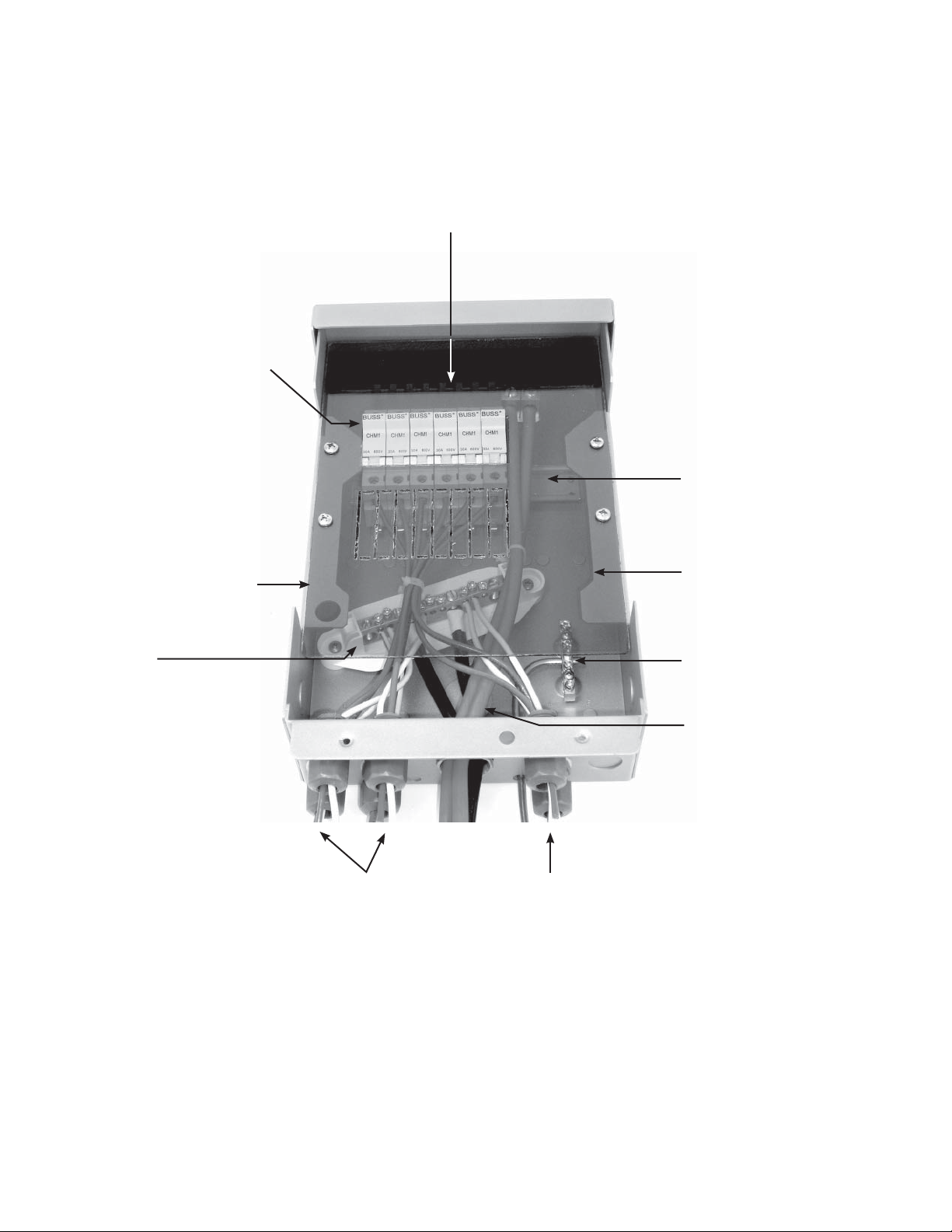

FWPV-8 Combiner

Two #12 sheet metal screws*

secure the combiner’s front cover.

A 7/16” lock hole accepts a

padlock to secure the cover.

Houses up to:

• Six “touch safe” OBFH fuse holders and knockouts for six input strings

• Eight DIN mount OBB circuit breakers

• Electrical knockouts capable of accommodating copper wire sizes from 2/0 to 14 AWG (67.4

2

mm

to 2.08 mm2)

Circuit Breaker

Optional circuit

Knockouts

breakers

Reversible, tinted

Fuse Knockouts

polycarbonate dead

front with breaker

and fuse knockouts is

secured with four #12

sheet metal screws*.

Negative Terminal

Fuse Knockouts

Bus Bar

Ground Bus Bar

Circuit Breaker

Knockouts

*Finish torque to 14 in-lbs

Dead front ips over

to accommodate fuse

holders or breakers

9

Page 12

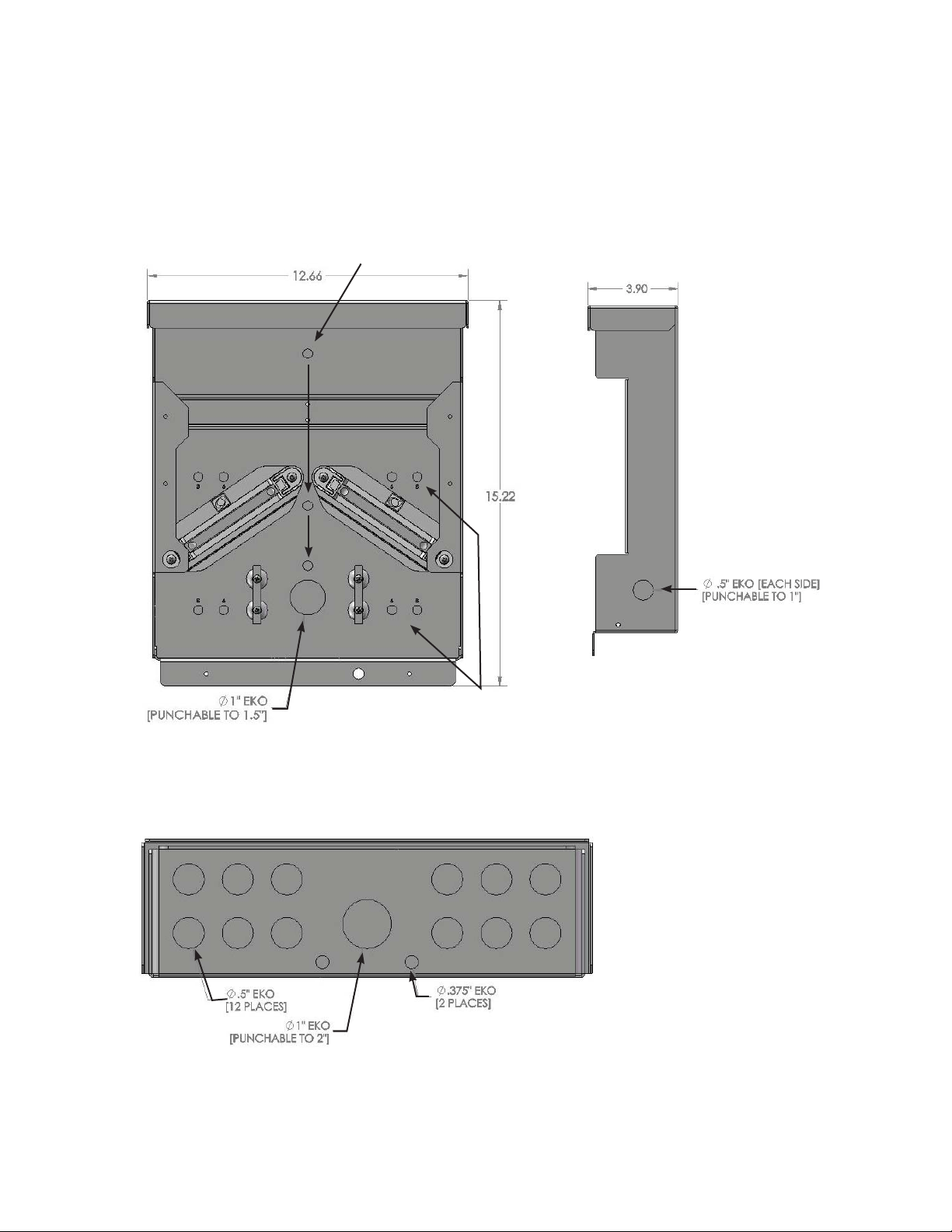

Knockouts and Dimensions

FWPV-8 Combiner

Knockouts for at surface installation

10

Front View

Front View

Bottom View

Knockouts for 3”, 4” , and 6” U-bolts (pole mount installation)

Side View

Page 13

FLEXware PV-8 Combiner Wiring Sample (Circuit Breakers)

COMB(iner) Bus—combines all the PV array output “strings” or wiring at one

bus which connects to the OutBack Charge Controller(s); lugs can accept

cable sizes ranging from 2/0 to 14 AWG (67.4 mm2 to 2.08 mm2) copper wires.

Individual PV circuit

breakers (up to 15

amp/150 VDC) are

available from

OutBack.

Circuit breakers must

be secured to the

DIN rail and installed

ush against the

dead front mounting

ange.

Dead front mounting

ange.

DIN rail

Dead front

Negative Terminal

Bus Bar

Back chassis knockout

Individual array wiring enters through the bottom knockouts to stay weather resistant.

Ground Bus Bar

11

Page 14

BREAKERS

UP TO DUAL 2/0 AWG OUTPUT WIRES

POSITIVE COMBINATION BUS

TO CHARGE CONTROLLER OR INVERTER

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

GROUND BUS

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

GROUNDING ELECTRODE

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

PV NEGATIVE TBB

12

FWPV-8 with circuit breakers

Page 15

FLEXware PV-8 Combiner Wiring Sample (Fuses)

COMB(iner) Bus—combines all the PV array output “strings” or wiring at one

bus which connects to the OutBack Charge Controller(s); lugs can accept cable

sizes ranging from 2/0 to 14 AWG (67.4 mm2 to 2.08 mm2) copper wires.

Individual PV array fuses

and fuse holders (up to

15 amp/600 VDC) are

available from OutBack.

Fuse holders must be

secured to the DIN

rail and installed ush

against the dead front

mounting ange

DIN rail

Dead front mounting

ange

Negative Terminal Bus

Bar

Individual array wiring enters through the bottom knockouts to stay weather resistant.

Dead front

Ground Bus Bar

Back chassis knockout

13

Page 16

FUSEHOLDERS

WITH FUSES

UP TO DUAL 2/0 AWG OUTPUT WIRES

POSITIVE COMBINATION BUS

TO CHARGE CONTROLLER OR INVERTER

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

GROUND BUS

GROUNDING ELECTRODE

PV

PV

PV

PV

+-+++- - -

PV

PV

PV

PV

+-+++- - -

PV NEGATIVE TBB

14

FWPV-8 with fuses

Page 17

15

Page 18

FWPV-12 Combiner Features

Removable front cover

• Accommodates circuit beakers or fuse holders

using a reversible* combiner bus bar

• Four output set screw lugs for positive parallel

strings capable of accepting 2/0 AWG (67.4

2

mm

) output wires

• Comes with two ground bus bars and two

negative bus bars

• 1” EKO bottom knockout punchable to 2” EKO

• 1” back knockout punchable to 1.5”

• Can be mounted on a 6” or 8” pole

• Roof mountable at an angle down to 3-in-12

pitch (14

0

)

*NOTE: A combiner can use either circuit

breakers or fuses depending on the installation

requirements, but it cannot use both at the same

time. Positive combiner bus bars can be

combined per NEC 2008 standards.

Each FWPV-12 comes with appropriate hardware

for securing either circuit breakers or fuses and

their conductors (see next page).

16

Page 19

Sample FW-CBUS-12 (Bus Bar) Installations

Fuse holder installation using included bus

bar hardware

Circuit breaker installation

Optional DIN Rail End Clamps (FW-EC-DIN)

Bus bar hardware installed

17

Page 20

FLEXware PV-12 Combiner

Two #12 sheet metal screws* secure

the combiner’s front cover.

A 7/16” lock hole accepts a

padlock to secure the cover.

Houses up to:

• Eight “touch safe” OBFH fuse holders and OBF fuses and knockouts for eight input strings

• 12 DIN mount OBB circuit breakers

• Electrical knockouts capable of accommodating copper wire sizes from 2/0 to 14 AWG

(67.4 mm

2

to 2.08 mm2)

Combiner shown with

optional fuse holders

mounted to DIN rail.

Tinted polycarbonate

dead front with breaker

and fuse knockouts

secures with four #12

sheet metal screws*.

Negative Terminal Bus

Bars

Circuit

Breaker

Knockouts

Fuse

Knockouts

Fuse

Knockouts

Circuit

Breaker

Knockouts

*Finish torque to 14 in-lbs

18

Ground bus bars

Dead front ips over

to accommodate fuse

holders or breakers

Page 21

Knockouts and Dimensions

FWPV-12 Combiner

Knockouts for at

surface installation

Front View

Bottom View

Side View

Knockouts for 6” and 8”

U-bolts used in pole mount

installation

19

Page 22

FLEXware PV-12 Combiner Wiring Sample (Circuit Breakers)

COMB(iner) Bus Bars—combine all the PV array output “strings” or wiring at two

bus bars which connect to the OutBack Charge Controller(s); lugs can accept cable

sizes ranging from 2/0 to 14 AWG (67.4 mm2 to 2.08 mm2) copper wires.

Dead front

mounting

ange

DIN rail

Negative Terminal

Bus Bar

Back chassis

knockout

Circuit breakers

must be secured

to the DIN rail

and installed ush

against the dead

front mounting

ange

.

Individual PV

circuit breakers

(up to 15 amp/150

VDC) are available

from OutBack

Dead front

Negative Terminal

Bus Bar

Ground

Bus Bars

Individual array wiring enters through the bottom

knockouts to stay weather resistant.

20

Page 23

UP TO DUAL 2/0 AWG

OUTPUT WIRES

POSITIVE COMBINATION BUS POSITIVE COMBINATION BUS

TO CHARGE CONTROLLER OR INVERTER

BREAKERS

+-+++- - -

PV

PV

PV

PV NEGATIVE TBB

PV

PV

+-+++- - -

PV

PV

PV

PV

PV

+-++

+- - -

+-+++- - -

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

TO CHARGE CONTROLLER OR INVERTER

PV NEGATIVE TBB

PV

PV

PV

PV

PV

PV

PV

GROUND BUS

PV

PV

GROUNDING ELECTRODE

FWPV-12 with circuit breakers

PV

PV

PV

PV

PV

PV

PV

PV

PV

21

Page 24

FLEXware PV-12 Combiner Wiring Sample (Fuses)

COMB(iner) Bus Bars—combine all the PV array output “strings” or wiring at two

bus bars which connect to the OutBack Charge Controller(s); lugs can accept

cable sizes ranging from 2/0 to 14 AWG (67.4 mm2 to 2.08 mm2) copper wires.

Dead front

mounting

ange

DIN rail

Negative

Terminal

Bus Bar

Fuse holders must

be secured to the

DIN rail and installed ush against

the dead front

mounting ange.

Individual PV

array fuses and

fuse holders (up to

15 amp/600 VDC)

are available from

OutBack.

Dead front

Back

chassis

knockout

Individual array wiring enters through the bottom

knockouts to stay weather resistant.

NOTE: Please see page 15 for fuse holder installation information.

Negative

Terminal

Bus Bar

Ground Bus Bars

22

Page 25

UP TO DUAL 2/0 AWG

OUTPUT WIRES

POSITIVE COMBINATIONBUS POSITIVE COMBINATIONBUS

TO CHARGE CONTROLLER OR INVERTER

PV NEGATIVE TBB

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

FUSEHOLDERS

WITH FUSES

PV

PV

PV

PV

PV

+-+++- - -

+-+++- - -

PV

PV

PV

PV

PV

TO CHARGE CONTROLLER OR INVERTER

+-+++- - -

PV NEGATIVE TBB

+-+++- - -

PV

PV

PV

PV

PV

PV

GROUND BUS

GROUNDING ELECTRODE

FWPV-12 with fuses

PV

PV

PV

PV

PV

PV

23

Page 26

TM

Product Registration

us with some important information

Outback Power Systems Inc.

19009 62nd Ave. NE

Arlington, WA 98223

Please take a moment to register and provide

and return it to:

NOTE: Please complete one form for all installed FLEXware product.

FLEXware Product Registration

System Owner

Name: _______________________________________ Address: ________________________________________

City, State, Zip Code: ____________________________ Country: ________________________________________

Telephone Number: _____________________________ E-mail: _________________________________________

Installer

Company: ____________________________________ Contractor Number: _______________________________

Installer Address: _______________________________ Installer City, State, Zip: ____________________________

Installer E-mail: _________________________________

System

System Install/Commission Date: __________________

Sold by: ______________________________________ Purchase Date: ___________________________________

Please circle type of application:

O -Grid Grid-Interactive AC Coupled Backup Mobile

Please circle installed components:

FLEXware Enclosures and Mounting Components IOB Kits

FLEXware 250 FLEXware MP

FLEXware 500 AC FLEXware PV 8

FLEXware 500 DC FLEXware PV 12

FLEXware 1000 AC

FLEXware 1000 DC

The system is equipped with (circle one):

FW-X240 PSX-240 PSX-240-Relay

Please circle the three most important factors a ecting your purchase decision:

• Price • Product Reputation • Product Features • Reputation of OutBack Power Systems • Value

I am interested in receiving information concerning OutBack Power Systems products and

events (circle one):

Yes No

FW-IOB-S-120VAC

FW-IOB-S-230VAC

FW-IOB-D-120/240VAC

FW-IOB-D-120VC

FW-IOB-D-230VAC

FW-IOB-T-120/208VAC

FW-IOB-T-230/400VAC

FW-IOB-Q-120/240VAC

FW-IOB-Q-230VAC

24

Page 27

25

Page 28

19009 62nd Avenue NE

Arlington, WA 98223 USA

(+1) 360.435.6030

European Sales O ce

Barcelona, ESPAÑA

(+34) 600.843.845

www.outbackpower.com

900-0003-01-00 REV A

Loading...

Loading...