Page 1

GS Load Center

Installation Manual

Page 2

Address:

Corporate Headquarters

Arlington, WA 98223 USA

European Office

Schwabach, Germany

Telephone:

+1.360.435.6030

+1.360.435.6019 (Fax)

+49.9122.79889.0

Email:

Support@outbackpower.com

Website:

http://www.outbackpower.com

About OutBack Power Technologies

OutBack Power Technologies is a leader in advanced energy conversion technology. OutBack products include true sine

wave inverter/chargers, maximum power point tracking charge controllers, and system communication components, as well

as circuit breakers, batteries, accessories, and assembled systems.

Grid/Hybrid™

As a leader in off-grid energy systems designed around energy storage, OutBack Power is an innovator in Grid/Hybrid system

technology, providing the best of both worlds: grid-tied system savings during normal or daylight operation, and off-grid

independence during peak energy times or in the event of a power outage or an emergency. Grid/Hybrid systems have the

intelligence, agility and interoperability to operate in multiple energy modes quickly, efficiently, and seamlessly, in order to

deliver clean, continuous and reliable power to residential and commercial users while maintaining grid stability.

Contact Information

17825 – 59th Avenue N.E.

Suite B

+1.360.618.4363 (Technical Support)

Hansastrasse 8

D-91126

+49.9122.79889.21 (Fax)

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER TECHNOLOGIES:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

OutBack Power Technologies cannot be responsible for system failure, damages, or injury resulting from improper

installation of their products.

Information included in this manual is subject to change without notice.

Notice of Copyright

GS Load Center Installation Manual © 2012 by OutBack Power Technologies. All Rights Reserved.

Trademarks

OutBack Power, the OutBack Power logo, FLEXpower ONE, and Grid/Hybrid are trademarks owned and used by OutBack

Power Technologies, Inc. The ALPHA logo and the phrase “member of the Alpha Group” are trademarks owned and used by

Alpha Technologies Inc. These trademarks may be registered in the United States and other countries.

Date and Revision

February 2014, Revision C

Part Number

900-0123-01-00 Rev C

Page 3

Table of Contents

Introduction ......................................................................................................... 5

Welcome to OutBack Power Technologies ................................................................................................................. 5

GSLC – Components ........................................................................................................................................................... 7

GSLC175-120/240 – Components .................................................................................................................................. 8

GSLC175-230 – Components ........................................................................................................................................... 9

GSLC175-PV-120/240 – Components ........................................................................................................................ 10

GSLC175-PV-230 – Components ................................................................................................................................. 11

GSLC175PV1-120/240 – Components ....................................................................................................................... 12

GSLC175PV1-230 – Components ................................................................................................................................ 13

Planning ............................................................................................................ 15

Tools Required .................................................................................................................................................................... 15

Materials Required ............................................................................................................................................................ 15

Location/Environmental Requirements .................................................................................................................... 15

Installation ......................................................................................................... 17

Hardware Options ............................................................................................................................................................. 17

Remove Top Cover ............................................................................................................................................................ 18

Remove Front Door .......................................................................................................................................................... 18

Remove Interior Cover ..................................................................................................................................................... 19

Installing the Internal Hardware .................................................................................................................................. 19

Assembling DC Positive (+) Cable Plate (Bus Bar) .................................................................................................................. 20

Installing Inverter Positive Bus Bars ............................................................................................................................................. 21

Installing Inverter Main DC Disconnects ................................................................................................................................... 22

Installing DC Shunts .......................................................................................................................................................................... 23

Installing PV and AC Circuit Breakers and GFDI ...................................................................................................................... 24

Mounting on the Inverter .......................................................................................................................................................................... 25

Mounting FLEXmax Charge Controller ...................................................................................................................................... 27

Mounting the HUB Communications Manager ...................................................................................................................... 28

Wiring .................................................................................................................................................................................... 29

Grounding ............................................................................................................................................................................................. 29

Bonding ........................................................................................................................................................................................................... 30

DC Wiring ............................................................................................................................................................................................... 31

Inverter Wiring .............................................................................................................................................................................................. 31

Battery Wiring ............................................................................................................................................................................................... 31

Installing the FLEXnet DC .......................................................................................................................................................................... 33

DC Devices ..................................................................................................................................................................................................... 34

PV and Charge Controller Wiring ............................................................................................................................................................ 34

AC Wiring ............................................................................................................................................................................................... 37

Split-Phase Wiring ........................................................................................................................................................................................ 37

Single-Phase Wiring .................................................................................................................................................................................... 39

Wiring the AC Bypass Assembly .............................................................................................................................................................. 41

Multiple-Inverter Installations (Stacking Inverters) ........................................................................................................................... 42

Bypass Switches ............................................................................................................................................................................................ 42

Wiring Diagrams ................................................................................................................................................................................. 45

900-0123-01-00 Rev C 1

Page 4

Table of Contents

Specifications ..................................................................................................... 51

Electrical Specifications ................................................................................................................................................... 51

Mechanical Specifications .............................................................................................................................................. 51

Regulatory Specifications ............................................................................................................................................... 51

Definitions ............................................................................................................................................................................ 52

Index ................................................................................................................. 53

List of Tables

Table 1 Size and Torque Requirements for Circuit Breakers and Bus Bars .................................... 19

Table 2 Terminal Bus Bar (TBB) Wire Size and Torque Requirements ............................................. 29

Table 3 Electrical Specifications ................................................................................................................... 51

Table 4 Mechanical Specifications .............................................................................................................. 51

Table 5 Terms and Definitions ..................................................................................................................... 52

List of Figures

Figure 1 GS Load Center (GSLC) ................................................................................................................. 5

Figure 2 GS Load Center with Devices ..................................................................................................... 6

Figure 3 GSLC Components ......................................................................................................................... 7

Figure 4 GSLC175-120/240 Components ................................................................................................ 8

Figure 5 GSLC175-230 Components ......................................................................................................... 9

Figure 6 GSLC175-PV-120/240 Components ....................................................................................... 10

Figure 7 GSLC175-PV-230 Components ................................................................................................ 11

Figure 8 GSLC175PV1-120/240 Components ...................................................................................... 12

Figure 9 GSLC175PV1-230 Components ............................................................................................... 13

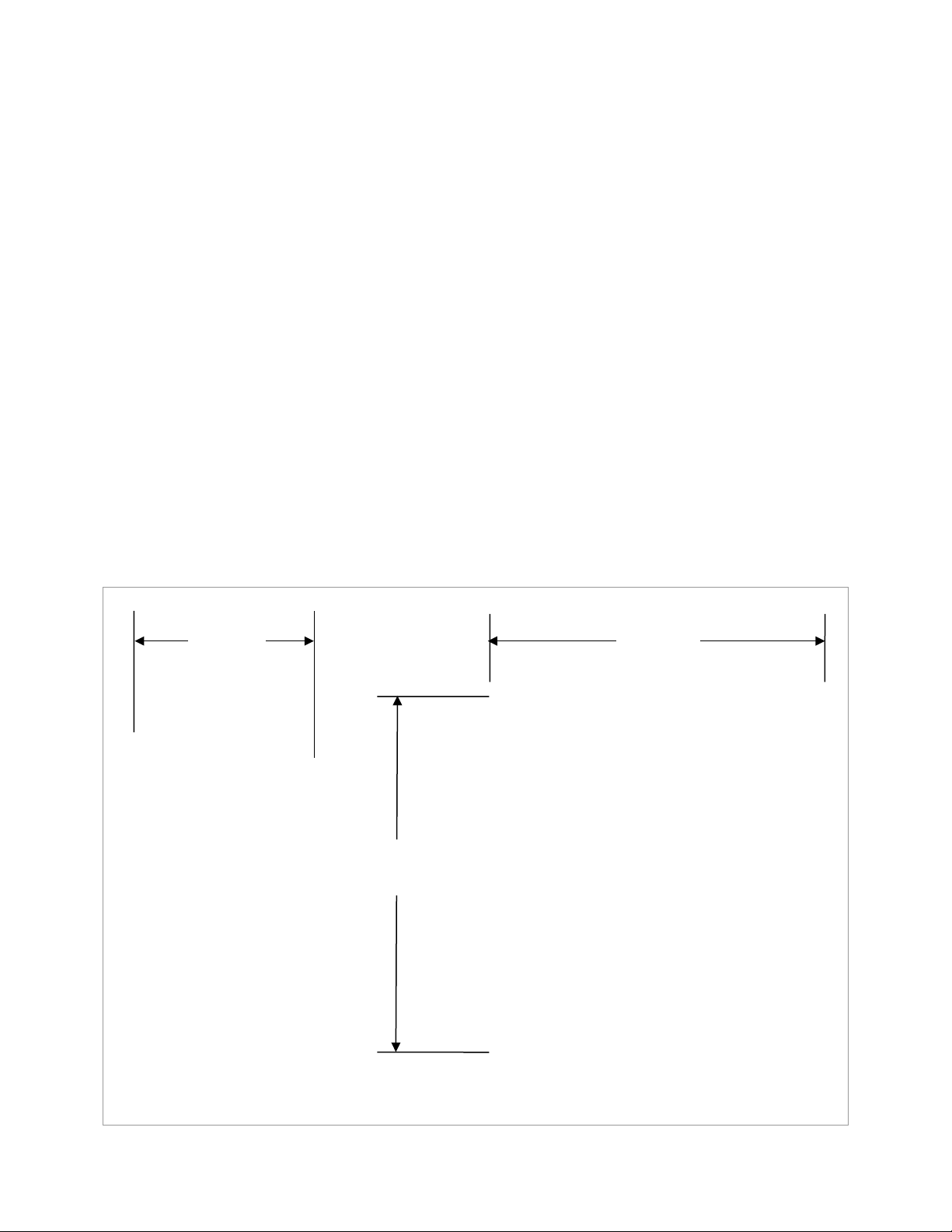

Figure 10 Dimensions ..................................................................................................................................... 15

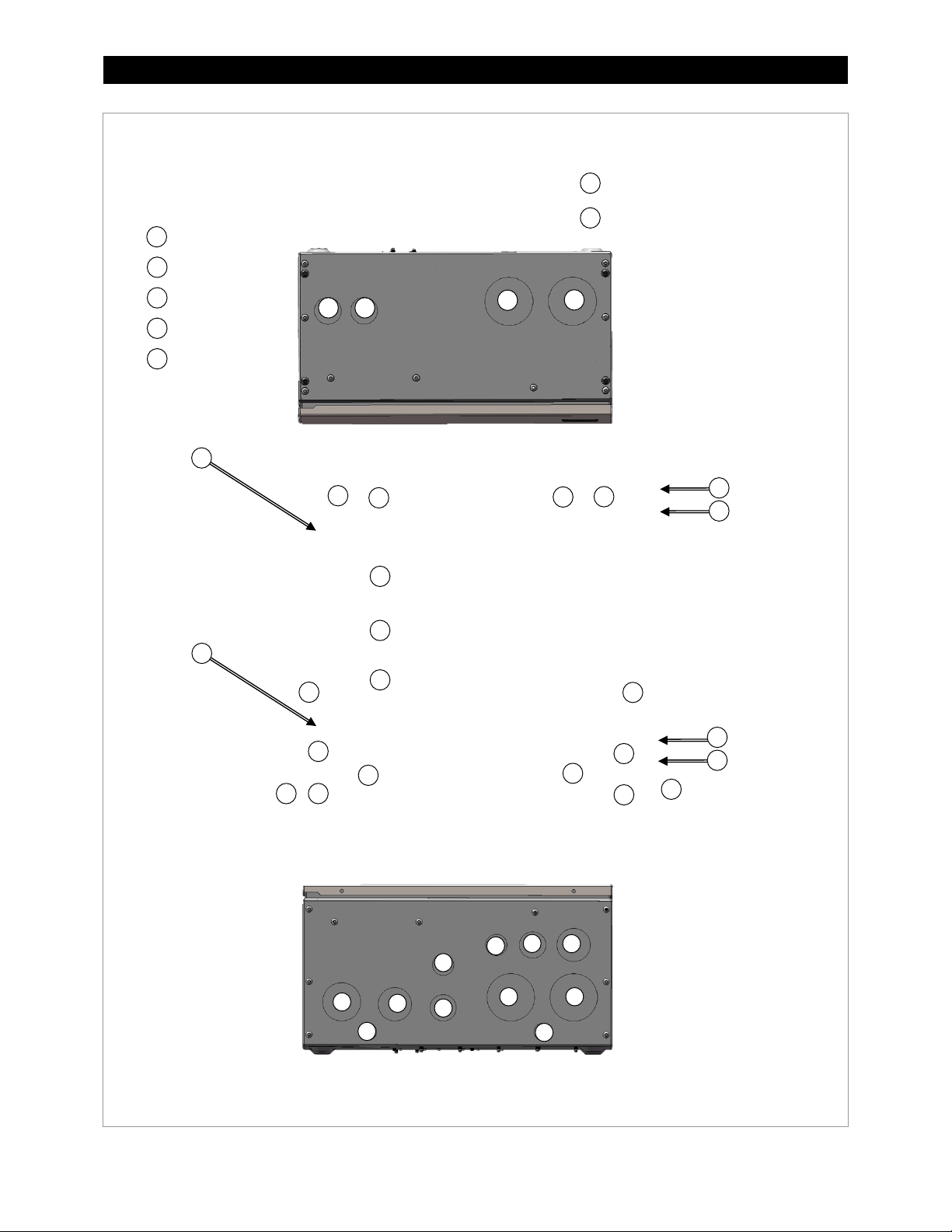

Figure 11 Knockouts and Mounting Holesfor Devices ....................................................................... 16

Figure 12 GSLC – Additional Components .............................................................................................. 17

Figure 13 GSLC175-120/240 and GSLC175-230 – Additional Components ................................ 17

Figure 14 Removing the Top Cover from the GSLC ............................................................................. 18

Figure 15 Removing the Front Door from the GSLC ............................................................................ 18

Figure 16 Removing the Interior Cover from the GSLC ...................................................................... 19

Figure 17 DC Positive Cable Plate (FW-BBUS) ........................................................................................ 19

Figure 18 Assembling the DC Positive (+) Cable Plate ........................................................................ 20

Figure 19 Inverter Bus Bars ........................................................................................................................... 21

Figure 20 Inverter Main DC Disconnects .................................................................................................. 22

Figure 21 DC Shunts ....................................................................................................................................... 23

Figure 22 Circuit Breakers ............................................................................................................................. 24

Figure 23 Mounting the GSLC ..................................................................................................................... 25

Figure 24 Mounting the Charge Controller to the GSLC Enclosure ................................................ 27

Figure 25 Mounting the HUB Product to the GSLC Enclosure .......................................................... 28

Figure 26 Grounding....................................................................................................................................... 29

Figure 27 Removing Bonding Connections ............................................................................................ 30

Figure 28 Battery Connections .................................................................................................................... 32

2 900-0123-01-00 Rev C

Page 5

Table of Contents

Figure 29 FN-DC and Wiring Block ............................................................................................................. 33

Figure 30 Installing the FLEXnet DC .......................................................................................................... 33

Figure 31 PV Connections in the GSLC ..................................................................................................... 35

Figure 32 PV Connections in the FLEXmax Charge Controller ......................................................... 35

Figure 33 AC Terminal Bus Bars (split-phase) ......................................................................................... 37

Figure 34 Inverter AC Connections (split-phase) .................................................................................. 38

Figure 35 AC Terminal Bus Bars (single-phase) ...................................................................................... 39

Figure 36 Inverter AC Connections (single-phase) ............................................................................... 40

Figure 37 Maintenance Bypass Wiring (split-phase) ............................................................................ 41

Figure 38 Maintenance Bypass Wiring (single-phase)......................................................................... 42

Figure 39 Bypass Switches ............................................................................................................................ 43

Figure 40 OutBack Bypass (split-phase) ................................................................................................... 43

Figure 41 Bypass Switching for Multiple Inverters (split-phase) ...................................................... 44

Figure 42 Wiring Diagram – GSLC175-120/240 ..................................................................................... 45

Figure 43 Wiring Diagram – GSLC175-PV-120/240 with FNDC ........................................................ 46

Figure 44 Wiring Diagram – GSLC175PV1-120/240 with FNDC ....................................................... 47

Figure 45 Wiring Diagram – GSLC175-230 .............................................................................................. 48

Figure 46 Wiring Diagram – GSLC175-PV-230 with FNDC ................................................................. 49

Figure 47 Wiring Diagram – GSLC175PV1-230 with FNDC ................................................................ 50

900-0123-01-00 Rev C 3

Page 6

Table of Contents

This page intentionally left blank.

4 900-0123-01-00 Rev C

Page 7

Introduction

Welcome to OutBack Power Technologies

Thank you for purchasing a GS Load Center (GSLC) from OutBack Power Technologies. The GSLC is

part of an OutBack Grid/Hybrid™ system. It is a balance-of-systems enclosure intended to work with

Radian Series (GS) inverter/chargers, FLEXmax Charge Controllers, and an OutBack HUB

Communications Manager.

The removable front cover allows for opening from either side of the enclosure.

Figure 1 GS Load Center (GSLC)

The product is designed in the following configurations:

900-0123-01-00 Rev C 5

– GS Load Center for Radian Series. Recommended for custom-built systems. Recommended for use

GSLC

with multiple Radian inverters (one GSLC per inverter). Can be used with other inverter models. The term

“GSLC” is also used to refer generically to the product line.

Intended for any Radian model.

∼

GSLC175-120/240

inverter circuit breakers, dual AC inputs, and 120/240 Vac maintenance bypass assembly. Recommended for

systems which have a single Radian inverter and an AC source, but can be customized in other ways.

Intended for Radian models GS8048 and GS8048A.

∼

GSLC175-230

inverter circuit breakers, dual AC inputs, and 230 Vac maintenance bypass assembly. Recommended for

systems which have a single Radian inverter and an AC source, but can be customized in other ways.

Intended for Radian model GS7048E.

∼

– GS Load Center for AC applications (split-phase). Factory-prepared with dual 175 Adc

– GS Load Center for AC applications (single-phase). Factory-prepared with dual 175 Adc

Page 8

Introduction

The enclosure provides mounting holes for the HUB Communications Manager on the left.

Manual for more information.

GSLC175-PV-120/240

– GS Load Center for PV and AC applications (split-phase). Factory-prepared with

dual 175 Adc inverter circuit breakers, dual AC inputs, 120/240 Vac maintenance bypass assembly, PV GFDI,

and two PV array inputs, FLEXnet DC battery monitor and three shunts. Intended as a “plug-and-play”

solution for systems with a single inverter, two FLEXmax charge controllers, and battery monitoring.

Intended for Radian models GS8048 and GS8048A.

∼

GSLC175-PV-230

inverter circuit breakers, dual AC inputs, 230 Vac maintenance bypass assembly, PV GFDI, two PV array inputs, FLEXnet

DC battery monitor, and three shunts. Intended as a “plug-and-play” solution for systems with a single inverter, two

FLEXmax charge controllers, and battery monitoring.

Intended for Radian model GS7048E.

∼

GSLC175PV1-120/240

inverter circuit breaker, dual AC inputs, 120/240 Vac maintenance bypass assembly, PV GFDI, one PV array input,

FLEXnet DC battery monitor, and two shunts. Intended as a “plug-and-play” solution for systems with a single inverter,

one FLEXmax charge controller, and battery monitoring.

Intended for Radian model GS4048A.

∼

GSLC175PV1-230

inverter circuit breakers, dual AC inputs, 230 Vac maintenance bypass assembly, PV GFDI, one PV array input, FLEXnet DC

battery monitor, and two shunts. Intended as a “plug-and-play” solution for systems with a single inverter, one FLEXmax

charge controller, and battery monitoring.

Intended for Radian model GS3548E.

– GS Load Center for PV and AC applications (single-phase). Factory-prepared with dual 175 Adc

— GS Load Center for PV and AC applications (split-phase). Factory-prepared with one 175 Adc

— GS Load Center for PV and AC applications (single-phase). Factory-prepared with one 175 Adc

On the right, the enclosure has mounting holes for brackets to mount up to two FLEXmax charge controllers.

NOTE: OutBack FLEXmax Extreme charge controllers do not mount directly to the GSLC and do not require

additional mounting brackets. They are mounted beside the inverter or the GSLC. See the Radian Series Installation

Figure 2 GS Load Center with Devices

6 900-0123-01-00 Rev C

Page 9

Introduction

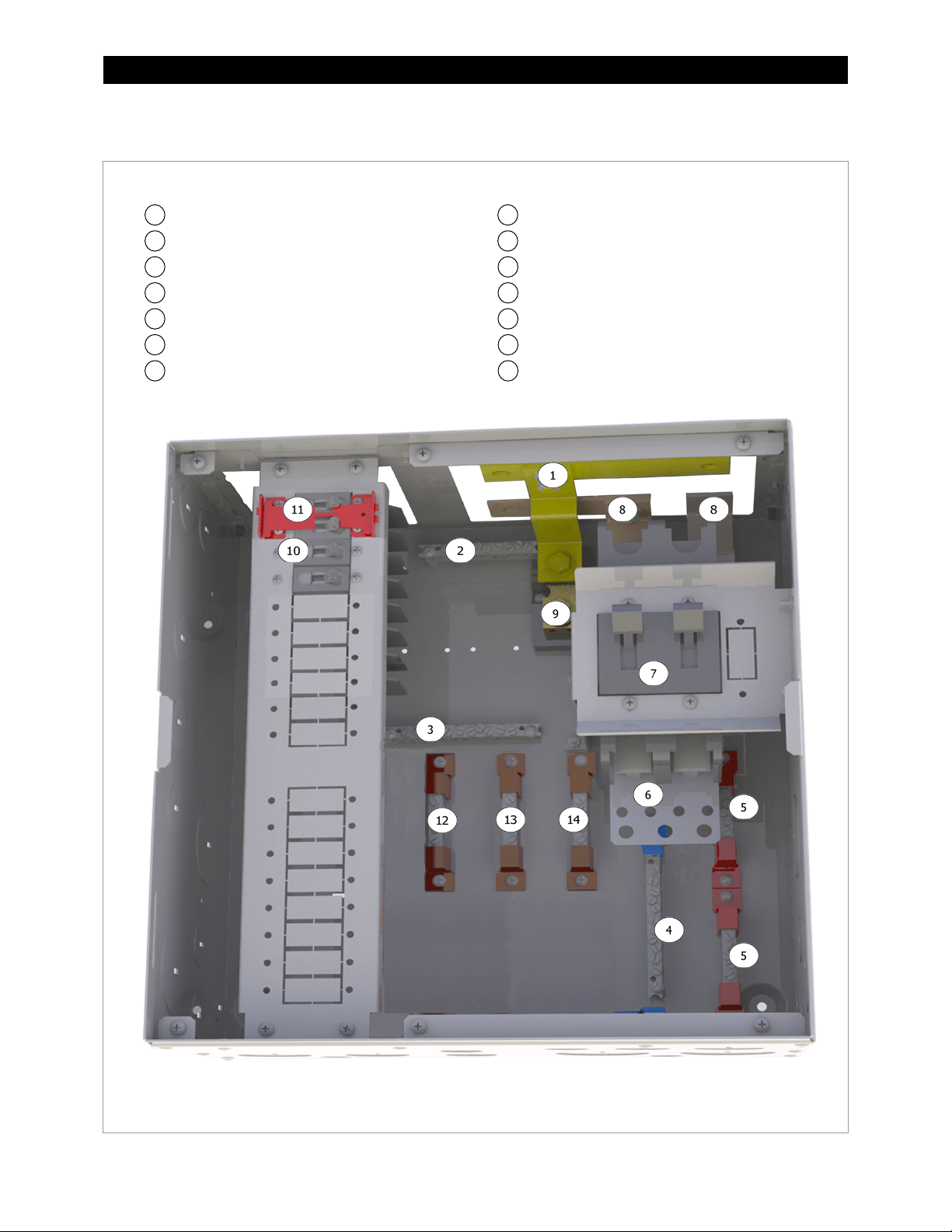

GSLC – Components

Inverter Negative (–) DC Bus Bars

NOTE: The installed Neutral TBB has white insulators

Legend

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-WHITE)

PV Positive (+) TBB (TBB-RED)

Shunt (FW-SHUNT500)

(TBB-WHITE). A set of blue insulators (TBB -BLUE) is included

in the kit for locations where blue is standard.

The DC Positive (+) Bus Plate (FW-BBUS) and the other

inverter positive (+) DC bus bars are also included in the kit.

900-0123-01-00 Rev C 7

Figure 3 GSLC Components

Page 10

Introduction

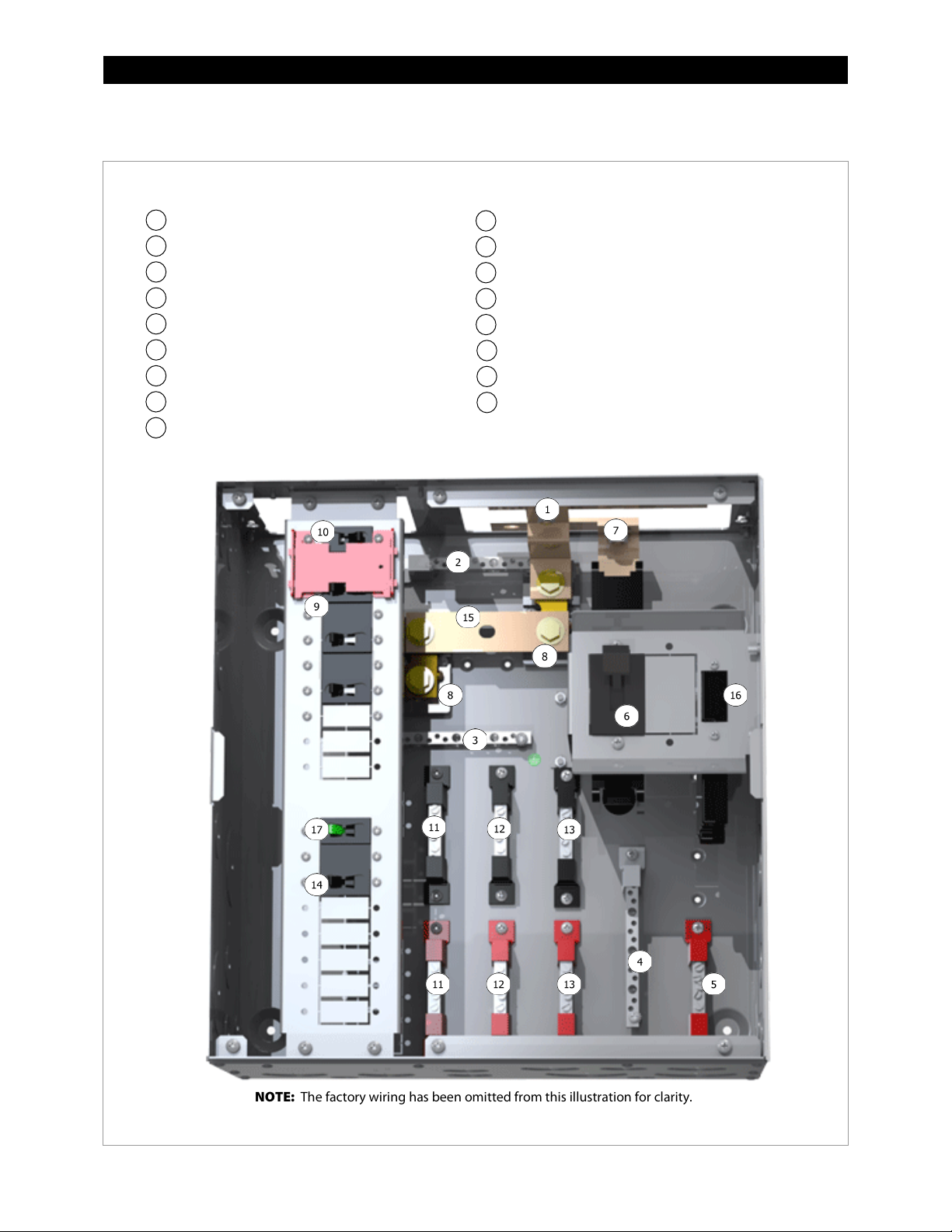

GSLC175-120/240 – Components

Inverter Negative (–) DC Bus Bar

Inverter Positive (+) DC Bus Bar

Legend

12

11

1

2

3 4 5 6 7

8

9

101413

NOTE: The factory wiring has been omitted from this illustration for clarity.

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-WHITE)

PV Positive (+) TBB (TBB-RED)

DC Positive (+) Cable Plate (FW-BBUS)

Main Inverter Disconnect(s) (PNL-175-DC)

Shunt (FW-SHUNT500)

AC Input Circuit Breakers (PNL-50D-AC-120/240V)

Maintenance Bypass Interlock

AC TBB (Inverter Output) L1, L2 (STBB-RED or BLACK)

AC TBB (Grid) L1, L2 (STBB-RED or BLACK)

AC TBB (Generator) L1, L2 (STBB-RED or BLACK)

8 900-0123-01-00 Rev C

Figure 4 GSLC175-120/240 Components

Page 11

Introduction

GSLC175-230 – Components

Inverter Negative (–) DC Bus Bar

Main Inverter Disconnect(s) (PNL-175-DC)

Inverter Positive (+) DC Bus Bar

Legend

12

11

1

2 3 4

5 6 7 8 9

10

14

13

NOTE:

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-BLUE)

PV Positive (+) TBB (TBB-RED)

DC Positive (+) Cable Plate (FW-BBUS)

Shunt (FW-SHUNT500)

AC Input Circuit Breakers (PNL-50-AC-230V)

Maintenance Bypass Interlock

AC TBB (Inverter Output) (TBB-BROWN)

AC TBB (Grid) (TBB-BROWN)

AC TBB (Generator) (TBB-BROWN)

900-0123-01-00 Rev C 9

The factory wiring has been omitted from this illustration for clarity.

Figure 5 GSLC175-230 Components

Page 12

Introduction

GSLC175-PV-120/240 – Components

Inverter Negative (–) DC Bus Bar

Legend

NOTE:

1 2 3

4

5 6 7

8

9

AC Input Circuit Breakers (PNL-50D-AC-120/240V)

12111014131615

18

17

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-WHITE)

PV Positive (+) TBB (TBB-RED)

DC Positive (+) Cable Plate (FW-BBUS)

Main Inverter Disconnect(s) (PNL-175-DC)

Inverter Positive (+) DC Bus Bar

Shunt (FW-SHUNT500)

Maintenance Bypass Interlock

AC TBB (Inverter Output) L1, L2 (STBB-RED or BLACK)

AC TBB (Grid) L1, L2 (STBB-RED or BLACK)

AC TBB (Generator) L1, L2 (STBB-RED or BLACK)

PV Input Disconnects (PNL-80-DC)

Shunt Bus (GS-SBUS)

Battery Monitor (FN-DC)

PV Ground Fault Detector/Interrupter

(PNL-GFDI-80D)

Figure 6 GSLC175-PV-120/240 Components

10 900-0123-01-00 Rev C

The factory wiring has been omitted from this illustration for clarity.

Page 13

Introduction

GSLC175-PV-230 – Components

Inverter Negative (–) DC Bus Bar

Legend

NOTE:

1 2 3 4 5

6 7 8

9

AC Input Circuit Breakers (PNL-50-AC-230V)

(PNL-GFDI-80D)

121110

141316

15

18

17

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-BLUE)

PV Positive (+) TBB (TBB-RED)

DC Positive (+) Cable Plate (FW-BBUS)

Main Inverter Disconnect(s) (PNL-175-DC)

Inverter Positive (+) DC Bus Bar

Shunt (FW-SHUNT500)

Maintenance Bypass Interlock

AC TBB (Inverter Output) (TBB-BROWN)

AC TBB (Grid) (TBB-BROWN)

AC TBB (Generator) (TBB-BROWN)

PV Input Disconnects (PNL-80-DC)

Shunt Bus (GS-SBUS)

Battery Monitor (FN-DC)

PV Ground Fault Detector/Interrupter

900-0123-01-00 Rev C 11

The factory wiring has been omitted from this illustration for clarity.

Figure 7 GSLC175-PV-230 Components

Page 14

Introduction

GSLC175PV1-120/240 – Components

Inverter Negative (–) DC Bus Bar

Legend

NOTE:

1 2 3

4

5 6 7

8

9

Maintenance Bypass Interlock

12111014131615

17

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-WHITE)

PV Positive (+) TBB (TBB-RED)

Main Inverter Disconnect (PNL-175-DC)

Inverter Positive (+) DC Bus Bar

Shunt (FW-SHUNT500)

AC Input Circuit Breakers (PNL-50D-AC-120/240V)

AC TBB (Inverter Output) L1, L2 (STBB-RED or BLACK)

AC TBB (Grid) L1, L2 (STBB-RED or BLACK)

AC TBB (Generator) L1, L2 (STBB-RED or BLACK)

PV Input Disconnect (PNL-80-DC)

Shunt Bus (GS-SBUS)

Battery Monitor (FN-DC)

PV Ground Fault Detector/Interrupter

(PNL-GFDI-80)

12 900-0123-01-00 Rev C

The factory wiring has been omitted from this illustration for clarity.

Figure 8 GSLC175PV1-120/240 Components

Page 15

Introduction

GSLC175PV1-230 – Components

Inverter Negative (–) DC Bus Bar

Legend

NOTE:

1 2 3

4

5 6 7

8

9

Maintenance Bypass Interlock

12111014131615

17

Negative (–) Terminal Bus Bar (TBB-WHITE)

Ground TBB (TBB-GROUND)

Neutral TBB (TBB-WHITE)

PV Positive (+) TBB (TBB-RED)

Main Inverter Disconnect (PNL-175-DC)

Inverter Positive (+) DC Bus Bar

Shunt (FW-SHUNT500)

AC Input Circuit Breakers (PNL-50-AC-230V)

AC TBB (Inverter Output) (TBB-BROWN)

AC TBB (Grid) (TBB-BROWN)

AC TBB (Generator) (TBB-BROWN)

PV Input Disconnect (PNL-80-DC)

Shunt Bus (GS-SBUS)

Battery Monitor (FN-DC)

PV Ground Fault Detector/Interrupter

(PNL-GFDI-80D)

900-0123-01-00 Rev C 13

The factory wiring has been omitted from this illustration for clarity.

Figure 9 GSLC175PV1-230 Components

Page 16

Introduction

This page intentionally left blank.

14 900-0123-01-00 Rev C

Page 17

Planning

8½" (21.6 cm) deep

Side View

17"

high

16" (40.6 cm) wide

Front View

Tools Required

Open-ended wrenches (9/16" and13 mm)

Wire cutters/strippers

Torque wrenches

Assorted insulated screwdrivers

Digital Voltmeter (DVM) or regular voltmeter

Materials Required

Conductors for wiring

Conduits

Location/Environmental Requirements

Indoor mount only

(43.2 cm)

Figure 10 Dimensions

900-0123-01-00 Rev C 15

Page 18

Planning

Legend

Mounting holes for FW-CCB

and FW-CCB2 brackets

2” or 63 mm

1¼” or 40 mm

½” or 20 mm

1½” or 50 mm

1” or 32 mm

1

2 3 4

5

Top View

1

1

4 4 7

8

Cable Knockouts

Mounting holes for HUB product

Side View

4

4 7 4

Side View

4

4

8 8 4 4 1 5 7

4

4

1 4 4 5 1

8 8 1

Bottom View

4 4 1 1 2 3 3

4

3 5 5

(U.S. Trade Size or Metric Trade Size)

16 900-0123-01-00 Rev C

Figure 11 Knockouts and Mounting Holesfor Devices

Page 19

Installation

The following components are sold separately

The following components are sold separately for the GSLC:

Hardware Options

The seven versions of the GSLC come with different components already installed.

, the “basic” or “empty” version, requires almost all components to be installed if they are needed.

GSLC

Instructions for this product begin on page 19.

GSLC175-120/240

and GS7048E. They have hardware for Radian inverter AC and DC connections. Battery monitoring or PV

capability must be installed as needed. Installation for these items begins with the DC shunts on page 23.

GSLC175-PV-120/240

GS8048A, and GS7048E. They have all options already present and need only to have external wiring and

devices added. Users with either of these versions can skip to the wiring section on page 29.

GSLC175PV1-120/240

and GS3548E. They have all options already present and need only to have external wiring and devices

added. Users with either of these versions can skip to the wiring section on page 29.

and

GSLC175-230

and

and

GSLC175-PV-230

GSLC175PV1-230

are the “inverter only” versions for Radian models GS8048, GS8048A,

are the “fully-loaded” versions for Radian models GS8048,

are the “fully-loaded” versions for Radian models GS4048A

Additional AC and DC circuit breakers are available for installation on all models.

The following pages describe the installation of individual items, including the removal of the GSLC

covers. Page 19 lists the hardware requirements for these items.

Instructions for Radian inverter mounting (along with other devices) begin on page 25.

Instructions for installing the FLEXnet DC battery monitor begin on page 33.

Instructions for installing the AC input-output bypass (IOB) assembly begin on page 42.

Inverter Main Disconnects (required for inverter installations)

AC Maintenance Bypass Assembly

AC Terminal Bus Bars (TBB)

PV Ground Fault Detector-Interrupter (GFDI)

FLEXnet DC Battery Monitor (FN-DC); see page 32

Additional DC shunts and GS-SBUS

PV Disconnect 80-amp circuit breaker (PNL-80-DC)

Figure 12 GSLC – Additional Components

for the GSLC175-120/240 and GSLC175-230:

PV Ground Fault Detector-Interrupter (GFDI)

FLEXnet DC Battery Monitor (FN-DC);

see page 32

Additional DC shunts and GS-SBUS

PV Disconnect 80-amp circuit breaker

(PNL-80-DC)

Figure 13 GSLC175-120/240 and GSLC175-230 – Additional Components

900-0123-01-00 Rev C 17

Page 20

Installation

Remove Top Cover

To Remove the Top Cover:

Enclosure with

Top Removed

Lift up to remove.

To Remove the Front Door:

Open to 90 degrees

1. Remove the four screws; one in each corner.

2. Lift the top off the enclosure.

Figure 14 Removing the Top Cover from the GSLC

Remove Front Door

1. Open the door to about 90 degrees.

2. Lift the hinges out of the slots at the

inside edge.

18 900-0123-01-00 Rev C

(shown partly open)

Figure 15 Removing the Front Door from the GSLC

Page 21

Assembly

Remove Interior Cover

Item

Terminal/Bolt Size

Torque Requirements

To Remove the Interior Cover:

Remove (x3)

Remove (x3)

Interior

Cover

Top Holes

Bottom Holes

0.5" (12.7 mm)

0.31" (8 mm)

0.4" (10 mm)

NOTE: The DC Positive (+) Cable

cannot be used with these models.

In order to make any wiring connections or to install components, the interior cover must be removed

to expose the interior of the enclosure. (This cover is sometimes called the “dead front.”)

1. Remove the three screws along the top of the enclosure

(with one star washer).

2. Remove the three screws along the bottom of the

enclosure (with one star washer).

3. Lift the front cover off the enclosure.

Figure 16 Removing the Interior Cover from the GSLC

Installing the Internal Hardware

Table 1 Size and Torque Requirements for Circuit Breakers and Bus Bars

Inverter Positive (+) Bus Bars M8 60 in-lb (6.8 Nm)

Shunt Bolts 3/8" 60 in-lb (6.8 Nm)

DC Positive (+) Cable Plate Top Holes (x3) 60 in-lb (6.8 Nm)

Bottom Holes (x7) 50 in-lb (5.7 Nm)

Circuit Breaker Studs M8 20 in-lb (2.3 Nm)

1/4" 35 in-lb (4.0 Nm)

5/16" 50 in-lb (5.7 Nm)

3/8" 225 in-lb (25.5 Nm)

900-0123-01-00 Rev C 19

Plate (FW-BBUS) is not included

with model GSLC175PV1-120/240

or model GSLC175PV1-230. It

Figure 17 DC Positive Cable Plate (FW-BBUS)

Page 22

Installation

Assembling DC Positive (+) Cable Plate (Bus Bar)

The bottom of each DC disconnect

: These instructions are not used with model GSLCPV1-120/240 and models GSLC175PV1-230.

NOTE

If using either of these models, proceed to page 21 or the next appropriate instruction.

(circuit breaker) is bolted to a metal

plate (bus bar) which receives the

inverter’s positive (+) battery cables.

To assemble the DC Positive Plate:

1. Remove the nuts and other hardware

(washer, lock washer, hex nut) from the

bottom terminal in the back of each DC

disconnect.

2. Place the two DC disconnects side

by side.

3. Orient the DC positive plate so that the

three largest holes are at the top. These

holes have a diameter of 0.50" (1.3 cm).

Insert the studs on each disconnect

through the first and third holes.

4. Replace the disconnect hardware

(washer, lock washer, hex nut). Tighten

the nuts to the values shown in Table 1

on page 19. The plate will hold the two

circuit breakers together as a set.

20 900-0123-01-00 Rev C

Figure 18 Assembling the DC Positive (+) Cable Plate

Page 23

Assembly

Installing Inverter Positive Bus Bars

A

B

To assemble the Inverter Positive (+) Bus Bars:

B

A

Top Bar

A

The GSLC parts kit contains two bus bars, A and B, which attach

to the tops of the DC disconnects. These bus bars make the

connections with the Radian inverter’s positive DC terminals.

Although they have similar shapes, the bus bars are not

interchangeable.

:

NOTE

model GSLC175PV1-230. When these models are in use, begin

the instructions with step 2.

1. Attach bus bar B to the top terminal of the

DC disconnect on the right, using the stud and

hardware on the back of the DC disconnect.

Tighten the nuts to the values shown in

Table 1 on page 19.

is not included with model GSLC175PV1-120/240 or

B

3. Mount bus bar A and the top bar to the top

terminal of the DC disconnect on the left.

Tighten to the value shown in Table 1 on page 19.

900-0123-01-00 Rev C 21

2. The GSLC’s hardware kit contains a top bar which attaches

to bus bar A. Attach these two bars together using a 5/16"

flat washer, a 5/16" lock washer, and an M8 nut (included in

hardware kit). Tighten to the value shown in

page 19.

Figure 19 Inverter Bus Bars

Table 1 on

Page 24

Installation

Installing Inverter Main DC Disconnects

To mount the inverter main DC disconnects:

in Table 1 on page 19.

These instructions assume that the GSLC has not yet been mounted to the Radian

Premounted bracket

Negative Top Bar

1. If the negative top bar is installed, loosen or remove it.

2. Slide the disconnect assembly through the opening in the

top of the GSLC and place it behind the premounted

bracket. Center the disconnect assembly so that the raised

area around the switch protrudes through the bracket. It

may be necessary to hold the assembly in place by hand.

3. Take the mounting screws provided with the circuit

breaker and insert them from the outside into the GSLC

bracket.

4. Tighten until secure, but do not over-tighten.

5. Reattach the negative top bar. Tighten to the value shown

inverter and that the top is open. If the GSLC’s top is closed or inaccessible, remove the

premounted bracket. Attach the disconnect assembly to it. Finally, re-install the bracket.

Figure 20 Inverter Main DC Disconnects

22 900-0123-01-00 Rev C

Page 25

Assembly

Installing DC Shunts

A single 500 Adc/50 mV shunt is included

Mounting Holes for

Pre-installed Shunt

Additional Shunt Placement

with the GSLC. Up to two more shunts

can be installed as needed. These shunts

are used in conjunction with the FLEXnet

DC battery monitor. See page

more instructions on wiring.

To mount DC Shunts:

1. Four mounting holes are located to the

lower left of the first shunt. Center each

shunt across one pair of mounting holes.

These should line up with the mounting

holes built into each shunt.

2. Using the screws included with the shunt,

attach each shunt to the GSLC enclosure.

3. Tighten the screws until secure, but do

not over-tighten.

31 for

Additional Shunts

NOTE: The GS-SBUS can be purchased

and installed to connect the

three shunts together. See

Figure 30 on page 33.

Figure 21 DC Shunts

900-0123-01-00 Rev C 23

Page 26

Installation

Installing PV and AC Circuit Breakers and GFDI

To mount circuit breakers:

NOTES

1. It may be necessary to remove the knockout

from the location where the circuit breaker is

to be placed to make room for the circuit

breaker to be installed. Be sure to remove

any debris that may occur from removing the

knockout.

2. Place each circuit breaker behind the

premounted rail. Center the device so that

the raised area around the switch protrudes

through the bracket. It may be necessary to

hold the device in place by hand.

2. When the circuit breaker is in place, insert the

screws included with each breaker through

the holes in the mounting rail.

3. Tighten the screws until secure, but do not

over-tighten.

Although there are no specific designations, the upper end of the mounting rail is generally used for AC

A PV ground-fault device may be required. The OutBack GFDI is pre-installed on some models. With other

Some installations may require an AC maintenance bypass. This is referred to as the Input-Output Bypass

24 900-0123-01-00 Rev C

devices (including the maintenance bypass). The lower end is generally used for DC devices, including the

GFDI. The preassembled GSLC models follow this convention.

models it can be purchased separately for manual installation. (See page 17.) The GFDI mounts the same

way as other circuit breakers. Once mounted, see page 34 and the GFDI manual for wiring instructions.

(Note that the GFCI usually requires multiple rail slots.)

or IOB. The bypass comes prewired for a single Radian inverter in some GSLC versions. It can also be

purchased separately. See page 37 and the GS-IOB manual for mounting and wiring instructions.

Figure 22 Circuit Breakers

Page 27

Assembly

Mounting on the Inverter

IMPORTANT:

strengthen the wall surface if required.

To mount the GSLC to the Radian inverter:

Bottom Screws

Mounting Feet

Holes (x4)

14"

12.5"

Continued on the next page....

Keyhole Slots

Keyhole Slots

The Radian inverter and GSLC are intended for indoor use only. Ensure that the

mounting surface is strong enough to support the full weight of the Radian

inverter/charger and the GSLC. Use a minimum 3/4" (19 mm) sheet of plywood to

1. Install the Radian inverter on the mounting bracket.

Remove knockouts from the bottom of the Radian inverter

if necessary and install bushings.

2. Back out bottom screw(s) approximately 1/4" (0.6 cm) to

3/16" (0.5 cm).

3. Remove the front and interior covers from the GSLC if

necessary (as described on page 18).

4. Align the GSLC along the bottom of the inverter and slide

the bottom screws into the keyhole slots.

5. Hanging the GSLC from the screws and holding it flush

against the bottom of the inverter, mark the spots for the

holes for the mounting feet. These are located in the rear

of the GSLC and are marked below.

6. If using wall anchors (included): Remove the GSLC. Using a

3/8" (10 mm) drill bit, drill leader holes for the hardware to

be used to secure the GSLC to the surface. Install the wall

anchors. If mounting on a solid surface like plywood, this

step can be skipped.

900-0123-01-00 Rev C 25

(35.6 cm)

Figure 23 Mounting the GSLC

Page 28

Installation

7. Realign the GSLC along the bottom of the inverter and slide the mounting screws into the keyhole slots.

Bottom Screws

Keyhole Slots

Keyhole Slots

...continued from the previous page.

8. Secure the enclosure to the mounting surface using all four mounting feet holes.

9. Using the bolts provided on the Radian inverter’s battery terminals, connect the terminals to the GSLC’s

inverter bus bars. Tighten to the value shown in Table 1 on page 19. For more information on the Radian

terminals, see the Radian Series Inverter/Charger Installation Manual.)

10. Leave the door and interior cover removed until all components have been installed and all wiring is

complete.

Figure 23 Mounting the GSLC (continued)

26 900-0123-01-00 Rev C

Page 29

Assembly

To mount the FLEXmax Charge

Dual Charge

(FW-CCB2)

4. Secure to the bottom bracket.

NOTE: This illustration shows only brackets for a

FW-CCB and FW-CCB2 are similar.

Mounting FLEXmax Charge Controller

The GSLC enclosure accommodates up to two FLEXmax charge controllers and a HUB

Communications Manager.

: The following instructions are for the FLEXmax 60 or FLEXmax 80 only. The FLEXmax Extreme

NOTE

charge controller connects directly to the wall and does not need additional brackets.

controller to the side of the GSLC

enclosure:

1. Align the brackets to the

mounting holes and secure the

brackets to the sides of the

enclosure with the hardware

provided with the brackets.

2. Note the location of knockouts on

both the charge controller and the

GSLC. (See page 16.) The holes

will align when the brackets are

used. Remove knockouts if

necessary and insert bushings.

3. Align the charge controller with

the center hole on each bracket

and secure with the hardware

provided with the brackets.

single charge controller (FW-CCB). Dual

charge controller brackets (FW-CCB2) are also

available. The installation instructions for

Controller Bracket

Figure 24 Mounting the Charge Controller to the GSLC Enclosure

900-0123-01-00 Rev C 27

Page 30

Installation

To mount the HUB Communications Manager to the side of the GSLC enclosure:

Mounting

Screw

Mounting

Screw

Mounting the HUB Communications Manager

The GSLC provides mounting holes to support a HUB Communications Manager.

1. Locate the mounting holes on the side of the GSLC enclosure as shown in Figure 11 on page 16.

2. Remove the knockouts and add bushings.

3. Align the HUB (vertically) over the mounting holes with the HUB product’s ports facing forward.

4. Insert the mounting screws from the outside into the GSLC enclosure. The mounting screws are provided

with the HUB product.

5. Tighten until secure, but do not over-tighten.

6. Install CAT5 cabling as needed.

7. Install the protective shield for the HUB product.

Figure 25 Mounting the HUB Product to the GSLC Enclosure

28 900-0123-01-00 Rev C

Page 31

Wiring

Wiring

WARNING: Shock Hazard

WARNING: Shock Hazard

IMPORTANT:

The GSLC’s grounding terminal bus bar ( TBB), which is

Ground TBB

Table 2 Terminal Bus Bar (TBB) Wire Size and Torque Requirements

Conductor Size Torque Requirements

AWG mm² In-lb Nm

#14 – #10 2.5 – 4 20 2.3

#8 6 – 10 25 2.8

#6– #3 16 – 25 35 4.0

#2 35 40 4.5

#1 – 1/0 50 50 5.7

Grounding

The unit must be connected to a permanent wiring system that is grounded

Make sure that no more than one bond is present in the AC system at any time.

For safety, the neutral and ground conductors should be mechanically bonded.

Some generators have a neutral-ground bond. When establishing a single bond

For all installations, the negative (–) battery conductor should be bonded to the

grounding system at only one point.

ground bond.

can provide the bond. See page 30.

Most OutBack products are not designed for use in a positive-grounded system. If it is

necessary to build a positive-grounded system with OutBack products, contact OutBack

Technical Support at

online forum at

discussed extensively.

according to the IEC 60364 TN standard.

Some codes require the bond to be made at the main panel only.

The GS Load Center (GSLC) is equipped with a neutral-ground bond. If bonding is

required to be in another location, the bond in the GSLC may need to be removed.

elsewhere, it may be necessary to check for a generator bond.

The GSLC comes equipped with a negative-

This bond may need to be disconnected. If the OutBack GFDI is present, it

+1.360.618.4363

www.outbackpower.com/forum/

before proceeding. Additionally, consult the

, where this subject has been

bonded to the GSLC chassis, is located to the lower left of

the main inverter disconnect. It accepts conductor sizes

from 1/0 to #14 AWG (50 mm down to 2.5 mm).

This TBB accepts ground connections from the Radian

inverter, FLEXmax charge controllers, the OutBack GFDI, the

Grounding Electrode Conductor (GEC) or external earth

ground, and other equipment.

See the Radian Series Inverter/Charger Installation Manual for

recommendations on ground conductor sizing. Once the

size is determined, see Table

2 for required torque values.

900-0123-01-00 Rev C 29

Figure 26 Grounding

Page 32

Installation

Bonding

WARNING: Shock Hazard

with the OutBack GFDI do not have a bond between negative and ground.

The GSLC’s neutral bus bar is located in

To remove either of the bond connections:

The GSLC’s negative (–) bus bar is located

NOTES:

Screw

TBB

Mount

TBB

Mount

Neutral-Ground Bond

Negative-Ground Bond

Bottom of GSLC

Standoff

Standoff

Inverter

Negative (

Bus Bar

Top of GSLC

Screw

All GSLC models are equipped with a mechanical bond between AC

neutral

and ground.

All models that do not include the GFDI are also equipped with a mechanical bond between DC

negative

and ground. These can be useful in stand-alone systems where no other bond is provided.

If other bonds are present, or if the GFDI is installed later, the GSLC bonds need to be removed.

If the GFDI is manually installed (see page 24 and the GFDI manual), the negative-ground

bond on the GSLC must be removed. This must also be done if any other PV ground-fault

device is present that establishes its own negative-ground bond. GSLC models purchased

the lower right portion of the GSLC.

The neutral-ground bond is established

at one end of the bar, near the base of

the GSLC.

near the top of the GSLC. It is attached to

the inverter negative (–) bus and its shunt.

–)

1. Using a Phillips screwdriver, remove the screw

shown above.

2. Remove the metal standoff beneath the bus

bar. The screw and bus bar provide the

mechanical bond to the chassis ground.

`

3. Rotate the TBB mount. Insert the bus bar into

the open end of the TBB mount so that the TBB

mount supports the bus bar. It may be

necessary to loosen the TBB mount screw

before rotating it.

4. Retighten the screw to secure the TBB mount.

Figure 27 Removing Bonding Connections

30 900-0123-01-00 Rev C

If the TBB is connected directly to

the enclosure by a screw, then the

bond is connected.

If the TBB is held by the TBB mount

and the TBB mount is secured to the

enclosure, the bond is disconnected.

The installed Neutral TBB has white

insulators. A second Neutral TBB with

blue insulators is included in the kit

for locations where blue is standard.

Page 33

Wiring

WARNING: Shock Hazard

before connecting any wires.

CAUTION: Fire Hazard

loss of contact area for current flow. This may allow dangerous levels of heat to build up.

GSLC175-PV-120/240

GSLC175-PV-230

GSLC175-120/240

DC Wiring

Ensure all circuit breakers or disconnect devices are turned off or disconnected

Never install extra washers or hardware between the mounting surface and the battery

cable lug. When installing multiple ring terminals or lugs, stack them on the mounting

surface so that the largest conductor is in direct contact. Smaller ring terminals should be

placed next in decreasing size order. Stacking the hardware in any order can result in a

Inverter Wiring

The DC disconnects are connected directly to the inverter using bus bars during the process of

mounting. See page 26 for more information.

Battery Wiring

Consult the Radian Series Inverter/Charger Installation Manual for appropriate recommendations for

cable number, sizing, and length. When using these recommendations, some models only require

one set of battery cables while other models require two sets of cables. (A single set of larger

conductors can be used if sized correctly.)

See Table 1 on page 19 for required torque values.

Ensure DC disconnects are turned to the OFF position and

DC sources are disconnected (unbolt the

all

battery end of the wires) before proceeding.

See the inverter’s installation manual for additional information on battery wiring.

Battery Positive (+) Cable

Follow the instructions below when connecting battery positive (+) cables to these models:

GSLC175-230

Connect the positive (+) cables to the DC positive (+) wiring plate. This plate is located directly

beneath the main inverter disconnects. It is intended for several ring lugs to be bolted to it.

The smaller holes have a diameter of 0.31" (8 mm).

∼

The larger holes have a diameter of 0.4" (10 mm).

∼

See item B in Figure 28 for an illustration of hardware installation order on the positive (+) plate.

Follow the instructions below when connecting battery positive (+) cables to these models:

GSLC175PV1-120/240

GSLC175PV1-230

Connect the positive (+) cable directly to the DC disconnect, which uses an M8 stud. See item A in

Figure 28 for an illustration of hardware installation order on the DC disconnect.

Follow the appropriate instructions when connecting to an “empty” GSLC which has been

assembled with similar features to one of the models above.

900-0123-01-00 Rev C 31

Page 34

Installation

Battery Negative (–) Cable

Shunt

Battery

Cable Lug

Flat Washer

Lock Washer

Shunt

Battery

Cable Lug

DC Disconnect

Flat Washer

Lock

Nut

Charge Controller

Battery

Monitor Ring

Shunt Plate

(if present)

3/8” Hex Bolt

Hardware Connection

to DC Disconnect

Flat Washer

Lock Washer

M8 -1.25 Hex Bolt

Flat

Nut

Hardware Connection

to DC Positive (+) Plate

Hardware Connection

to Shunt

DC positive (+)

cable plate (bus bar)

Battery

A

C

B

The battery negative (–) cables connect to the pre-installed shunt. This shunt is located to the upper

left of the main inverter disconnect. It is designed for several ring lugs to be bolted to it, with

openings of 3/8" (10 mm) diameter.

See item

in Figure 28 for an illustration of hardware installation order on the shunt. The shunt plate

C

(GS-SBUS) may or may not be present.

: Do not install hardware in a different order from the illustrations in Figure 28. In all cases the

NOTE

battery cable lug must be the first item installed. It must make solid contact with the surface.

Ring Terminal

Cable Lug

Figure 28 Battery Connections

32 900-0123-01-00 Rev C

Page 35

Wiring

Installing the FLEXnet DC

HUB port

Wiring block

To install the FN-DC :

When connecting sensing wires: The end of the shunt

FLEXnet DC

GS-SBUS

Shunt

screws

Shunt screws

Mounting

Mounting

The OutBack FLEXnet DC (FN-DC), or a similar battery monitor, may be added to the GSLC for

observing DC current flow and providing battery state-of-charge information.

`

Figure 29 FN-DC and Wiring Block

1. Assemble the FN-DC wiring as shown

in the manual for the FN-DC.

Attach sense wires to FN-DC wiring

block and plug it into the FN-DC.

Plug the CAT5 cable into the port

labeled HUB.

2. Connect FNDC wiring to the GSLC.

The positive (+) and negative (-)

battery voltage sense conductors

should connect directly to the

battery bank.

The shunt sensing wires should

connect to the screws on each

shunt. It may be necessary to

remove the GS-SBUS to reach

the screws.

3. Mount the FN-DC by inserting it into

the opening to the right of the

inverter disconnects. It may be

necessary to hold it in place.

4. Secure the FN-DC with mounting

screws above and below. Tighten

until secure, but do not over-tighten.

`

screws

screws

connected to the GS-SBUS is the negative (–) battery

connection and should be wired accordingly. The other

end of the shunt is the “device” or “load” end and should be

wired accordingly.

See the FLEXnet DC manual for more information on these

connections. See Figure 46 on page 49 for an example of

typical system wiring.

Figure 30 Installing the FLEXnet DC

900-0123-01-00 Rev C 33

Page 36

Installation

DC Devices

In addition to inverter or PV connections, other devices may be connected to the GSLC, such as DC

loads or sources. The wiring on these devices will vary with the application. In most cases the device

will have a separate circuit breaker which is mounted on the rail as shown on page 24. It will be wired

into the battery system using the existing bus bars or shunts. The number and location of these

connections will vary with the options or accessories installed.

PV and Charge Controller Wiring

When wiring the FLEXmax, FLEXmax Extreme, or another charge controller to the GSLC, a number of

elements are involved. These elements include the PV or RE source, the battery connections, the

disconnect circuit breaker, the PV ground-fault device, and the charge controller.

These instructions are written for a PV source which uses the OutBack FLEXmax (or FLEXmax Extreme)

charge controller and the GFDI. Other applications will be similar.

: In GSLC models designated as “PV”, many of the connections below are already provided. The

NOTE

only connections necessary are those for external wiring to the charge controller.

To make PV and charge controller connections:

1. Connect the PV positive wire to the GSLC’s PV positive (+) TBB (see Figure 31).

2. Connect the PV negative wire to the charge controller’s PV negative (–) terminal (see Figure 32).

3. Install a wire from the PV TBB to the PV disconnect circuit breaker (see Figure 31).

4. Install a wire from the PV disconnect to the charge controller’s PV positive (+) terminal.

5. Install a wire from the GSLC’s DC positive (+) cable plate to one pole of the GFDI.

6. Install a wire from the GFDI to the charge controller’s positive (+) battery terminal.

7. Install a wire from the charge controller’s negative (–) battery terminal to the GSLC’s negative TBB.

If the FLEXnet DC or another battery monitor is in use, this wire should connect to the shunt which

monitors that charge controller.

8. Repeat all steps for a second charge controller, if necessary.

NOTES:

Each TBB accepts conductors from 1/0 AWG (70 mm

for required torque values.

For other GSLC required torque values (such as shunts and circuit breakers), see Table 1 on page 19.

For torque values, wire sizes, and other information concerning the FLEXmax charge controller, see the

FLEXmax Series Charge Controllers Owner’s Manual.

For more information on specific wiring of the GFDI, see the GFDI manual.

A diagram that shows typical wiring for a PV system, including the FLEXnet DC, GFDI, and other elements of

the system, is shown on page 49.

A fully-assembled GSLC diagram with the elements mentioned above (as well as the AC system) is shown on

page 49.

2

) to #14 AWG (2.5 mm2) in size. See Table 2 on page 29

34 900-0123-01-00 Rev C

Page 37

Wiring

PV Positive (+) TBB

DC Positive (+) cable

plate (bus bar)

Shunt

PV Disconnect

Negative TBB

GFDI

BAT–

BAT+

PV Negative (–)

Battery Negative (–)

PV Positive (+)

Battery Positive (+)

PV+

PV–

`

Figure 31 PV Connections in the GSLC

`

Figure 32 PV Connections in the FLEXmax Charge Controller

900-0123-01-00 Rev C 35

Page 38

Installation

NOTES:

36 900-0123-01-00 Rev C

Page 39

Wiring

AC Wiring

WARNING: Shock Hazard

before wiring.

AC Output

Grid

Generator

Neutral

To make the external AC connections to the

1 2 3 4 5 6 7

Ensure all circuit breakers or disconnect devices are turned off or disconnected before

wiring. Make certain the inverter and other active devices are turned off or disabled

Split-Phase Wiring

The GSLC can have multiple terminal bus bars for multiple AC connections. Because the Radian

inverter possesses two sets of AC input connections and one set of output connections, up to three

TBB sets are available. Each set of bus bars are paired in red and black, for the 120/240 Vac

connections required by the Radian inverter.

The TBB set on the left is generally used for the inverter’s AC output connections. The central TBB set

is for utility grid connections and the right TBB set is for a generator. The preassembled GSLC models

follow this convention.

Each TBB accepts conductors from 1/0 (70 mm

required torque values.

If steps are inappropriate for a given system (such as instructions for a generator when none is

present), they can be ignored.

2

) to #14 AWG (2.5 mm2). See Table 2 on page 29 for

split-phase GSLC:

1. Connect the L1 wire from the AC load panel

to black TBB 1 (AC OUT - HOT LEG 1).

Connect the L2 wire from the AC load panel

to red TBB 2 (AC OUT - HOT LEG 2).

2. Connect the neutral wire from the AC load

panel to neutral TBB

3. Connect the L1 wire from the utility grid

panel (if present) to black TBB

(GRID IN - HOT LEG 1). Connect the L2 wire

from the utility grid panel to red TBB 5

(GRID IN - HOT LEG 2).

4. Connect the neutral wire from the utility

grid panel (if present) to neutral TBB 3.

5. Connect the L1 wire from the generator

(if present) to black TBB

LEG 1). Connect the L2 wire from the

generator to red TBB

6. Connect the neutral wire from the generator

(if present) to neutral TBB

NOTE: Remove the neutral-ground bond if

necessary. See page 30.

3.

4

6 (GEN IN - HOT

(GEN IN - HOT LEG 2).

7

3.

900-0123-01-00 Rev C 37

Figure 33 AC Terminal Bus Bars (split-phase)

Page 40

Installation

Bypass Assembly

To make the connections to the Radian inverter:

GRID

GEN

AC Output

Disconnects

8 2 3

4

5

6 7 1

Bypass switching can be used when the inverter is shut down for maintenance. This topic is discussed

more beginning on page 42. The GSLC can be equipped with the GS-IOB-120/240VAC bypass

assembly. The instructions on this page are for making external connections to the bypass assembly

after installation. (The installation wiring for the GS-IOB-120/240VAC is described on page 41.)

If no bypass assembly is used, connections should be made directly to each TBB from the circuit

breakers for the inverter, AC sources, and loads. These connections are designated in Figure 33.

Wiring diagrams for an assembled 120/240 Vac system are shown beginning on page 45.

1. Designate the top AC circuit breaker as the

inverter AC output disconnect. Install a wire from

the black AC output TBB (as shown in Figure 33. to

the disconnect marked by

2. Install a wire from the red AC output TBB to the

disconnect marked by

3. Install wires on the left side of the disconnect as

marked by

appropriate L1 and L2 output terminals on

the Radian inverter.

4. Designate the third AC circuit breaker from the

top as the disconnect for one AC source (GRID or

GEN). Install a wire from the black source circuit

TBB (as shown in Figure 33) to the disconnect

marked by 5.

5. Install a wire from the red source circuit TBB to

the disconnect marked by

6. Install wires on the right side of the disconnect

as marked by

appropriate L1 and L2 input terminals on the

Radian inverter (the terminals labeled either GRID

or GEN).

7. If a second AC source is present, repeat steps 4

through 6 using the bottom circuit breaker.

3 and 4. Connect these wires to the

7 and 8. Connect these wires to the

2.

1.

6.

8. Install a wire on the inverter’s NEU terminal and

connect it to the GSLC’s neutral TBB (as shown in

Figure 33). Only one neutral connection is required.

and

inputs

Figure 34 Inverter AC Connections (split-phase)

38 900-0123-01-00 Rev C

Page 41

Wiring

Single-Phase Wiring

AC Output

Grid

Generator

Neutral

To make external AC connections to the

1

2 3 4

The GSLC allows multiple terminal bus bars (TBB) for multiple AC connections. Because the Radian

inverter possesses two sets of AC input connections and one set of output connections, three terminal

bus bars are available for hot connections, as well as one neutral bus bar. The hot bus bars use brown

insulators in 230 Vac models. The neutral bus bar uses blue insulators in 230 vac models.

The TBB on the left is generally used for the inverter’s AC output connections. The central TBB is for

utility grid connections and the right TBB is for a generator. The preassembled GSLC models follow

this convention.

2

Each TBB accepts conductors from 70 mm

for required torque values.

If steps are inappropriate for a given system (such as instructions for a generator when none is

present), they can be ignored.

single-phase GSLC:

1. Connect the hot wire from the AC load

panel to brown TBB 1 (AC Output).

(1/0 AWG) to 2.5 mm2 (#14 AWG). See Table 2 on page 29

2. Connect the neutral wire from the AC

load panel to neutral TBB

3. Connect the hot wire from the utility grid

panel (if present) to brown TBB 3 (Grid).

4. Connect the neutral wire from the utility

grid panel (if present) to neutral TBB 2.

5. Connect the hot wire from the generator

(if present) to brown TBB 4 (Generator).

6. Connect the neutral wire from the

generator (if present) to neutral TBB 2.

NOTE: Remove the neutral-ground bond

if necessary. See page 30.

The neutral insulator in Figure 35 is in the

position which opens the bond.

2.

Figure 35 AC Terminal Bus Bars (single-phase)

900-0123-01-00 Rev C 39

Page 42

Installation

Bypass Assembly

To make the connections to the

GRID and GEN inputs

AC output

Disconnects

2

4

1

3

Bypass switching can be used when the inverter is shut down for maintenance. This topic is discussed

more beginning on page 42. The GSLC can be equipped with the GS-IOB-230VAC bypass assembly.

The instructions on this page are for making external connections to the bypass assembly after

installation. (The installation wiring for the GS-IOB-230VAC is described on page 42.)

If the GSLC has no bypass assembly, connections should be made directly to each TBB from the circuit

breakers for the inverter, AC sources, and loads. These connections are designated in Figure 35.

Wiring diagrams for an assembled 230 Vac system are shown beginning on page 48.

Radian inverter:

1. Designate the topmost AC circuit breaker

as the inverter AC output disconnect.

Install a wire from the AC output circuit TBB

(as shown in Figure 35) to that disconnect

as marked by 1.

2. Install a wire on the left side of the

disconnect as marked by

wire to the appropriate output terminals on

the Radian inverter.

3. Designate the third AC circuit breaker as

the disconnect for one AC source (GRID or

GEN). Install a wire from the TBB of the

appropriate source circuit (as shown in

Figure 35) to the left side of that disconnect

as marked by

3.

2. Connect the

4. Install a wire on the right side of the source

disconnect as marked by

wire to the appropriate input terminal on

the Radian inverter (the terminal labeled

either GRID or GEN).

5. If a second AC source is present, repeat

steps 3 and 4.

6. Install a wire on the inverter’s NEU terminal

and connect it to the GSLC’s neutral TBB

(as shown in Figure 35). Only one neutral

connection is required.

4. Connect the

40 900-0123-01-00 Rev C

Figure 36 Inverter AC Connections (single-phase)

Page 43

Wiring

Wiring the AC Bypass Assembly

To wire the GS-IOB-120/240VAC

Output

Inverter

1 2 4

3

5

6

AC

8

7

All models other than the “empty” GSLC are equipped with a maintenance bypass assembly. As

needed, the GSLC can be equipped with a bypass assembly using the GS-IOB-120/240VAC or GS-IOB230VAC accessory kit as appropriate. The accessory kit should be installed according to its own

instructions. Once installed, it can be wired by following the steps shown in Figure 37 or Figure 38 .

The operation of the bypass assembly is discussed on page 42. A series of GSLC diagrams with the

bypass wiring (as well as the rest of both the AC and DC systems) are shown beginning on page 48.

These drawings show the utility grid circuit connected to the bypass assembly. This is the method

used during factory installation. However, either the grid or the generator circuit may be used. A

prewired assembly may be changed. Remove the first source from the bypass assembly and then wire

the second according to the instructions. Connect the first source directly to the terminals as shown in

the drawings beginning on page 45.

: Only one AC source may be bypassed with this assembly, even if two sources are present.

NOTE

WARNING: Shock Hazard or Equipment Damage

Bypassing multiple sources will usually connect the sources to each other, which may

damage one or both sources. It can otherwise result in power being routed to

inappropriate places.

The internal GSLC bypass assembly cannot be used if multiple inverters are in use.

See page 42.

after installation:

1. On the disconnect for the AC

source that will be used during

bypass, install a wire from the

upper pole as shown by

Connect it to the upper pole of

the inverter bypass switch as

shown by

2. From the same disconnect,

install a wire on the lower pole

as shown by

the lower pole of the inverter

bypass switch as shown by 4.

3. On the right side of the inverter

bypass switch, install a wire on

the lower pole as shown by

Connect it to the right side of

the lower pole on the output

switch

between the upper poles of

each switch as shown by

8.

and

1.

2.

3. Connect it to

5.

6. Install a second wire

7

Bypass

Source

Figure 37 Maintenance Bypass Wiring (split-phase)

900-0123-01-00 Rev C 41

Page 44

Installation

To wire the GS-IOB-230VAC

after installation:

Output

Inverter Bypass

AC Source

1 2 3

4

1. On the disconnect for the AC

source that will be used during

bypass, install a wire from the

left side as shown by

Connect it to the input bypass

switch as shown by 2.

2. Install a wire on the right side of

the input bypass switch as

shown by

right side of the output switch

as shown by 4.

3. Connect it to the

Figure 38 Maintenance Bypass Wiring (single-phase)

1.

Multiple-Inverter Installations (Stacking Inverters)

When multiple Radian inverters are stacked for additional power, the basic wiring is repeated for each

inverter. However, several factors need to be considered.

One GSLC is required for each Radian inverter. A single GSLC cannot be sized to handle the requisite current

for multiple Radian inverters.

If more than two Radian inverters are installed, it is recommended to install a separate distribution panel to

distribute incoming power to each GSLC individually. It may be advisable to install separate AC distribution

panels to distribute input and output power to each GSLC.

The GSLC maintenance bypass assemblies cannot be used when more than one Radian inverter is stacked.

See the next section.

Bypass Switches

Inverter systems are often equipped with maintenance bypass switches or interlocks. If the inverter

system ever needs to be shut down or removed, its AC sources and loads must be disconnected. A

bypass device allows the AC source to “bypass” the inverter and deliver power directly to the loads.

This can minimize disruption to the system and it avoids the need for extensive rewiring.

WARNING: Shock Hazard or Equipment Damage

Bypassing multiple sources will usually connect the sources to each other, which may

damage one or both sources. It can otherwise result in power being routed to

inappropriate places.

The bypass assembly does not disconnect the inverter’s AC input. Even with the

inverter bypassed, any AC input source may be a shock hazard unless disconnected.

42 900-0123-01-00 Rev C

Page 45

Wiring

In Figure 39, when Switch 1 is on (normal operation), the inverter’s output sends power to the loads.

AC Loads

Switch 1

Switch 2

Inverter Output

Bypass AC Source

Switch 1 and Switch 2 are prevented

The inverter may use an AC

AC Source

AC Loads

GSLC Bypass

Disconnected

Input Wiring

Output Wiring

Switch 2 is off, preventing the inverter from sending power back to the AC source (backfeeding).

When Switch 2 is on (bypass operation), the AC source sends power directly to the loads. Switch 1 is

off, removing the inverter’s output from the loads. This also prevents the AC source from backfeeding

the inverter. With the inverter removed from the circuit, maintenance can be performed as necessary.

source which powers the

inverter’s output. The bypass

assembly does not disconnect

the inverter’s input.

from being on at the same time by the

Mechanical Interlock. Although both

switches can be off, only one can be on.

In OutBack bypass assemblies, circuit

breakers are used instead of standard

switches.

Figure 39 Bypass Switches

The GSLC can be ordered with bypass circuit breakers for this purpose, or it has a bypass option (the

GS-IOB-120/240VAC or GS-IOB-230VAC) which can be installed.

Radian

Inverter

Figure 40 OutBack Bypass (split-phase)

In a new system with multiple Radian inverters, the basic GSLC should be used in conjunction with an

external assembly of this kind, as shown in Figure 41. The GS-IOB kits should not be installed, or if

previously installed, should be removed and all wires disconnected.

OutBack does not offer a solution for bypassing multiple inverters. However, electrical suppliers offer

both manual and automatic double-pole, double-throw bypass switches in a range of sizes and

options. These are highly recommended for systems larger than a single inverter.

IMPORTANT:

If multiple Radian inverters are stacked in a single system, then these devices

cannot be used. The bypass function must be simultaneous for all inverters. The

GSLC bypass kits operate independently, not simultaneously.

900-0123-01-00 Rev C 43

WARNING: Shock Hazard or Equipment Damage

Using independent bypass devices on multiple inverters can result in power being routed

to inappropriate places. This could lead to an electric shock or to equipment damage.

Page 46

Installation

AC Source

AC Loads

Output Wiring

Inactive Radian Inverters

Input Wiring

GSLC Bypass Devices

External Bypass Device

111

1

Figure 41 Bypass Switching for Multiple Inverters (split-phase)

(must be removed if

installed previously)

44 900-0123-01-00 Rev C

Page 47

Wiring

Wiring Diagrams

This GSLC model has a neutral-ground bond