Page 1

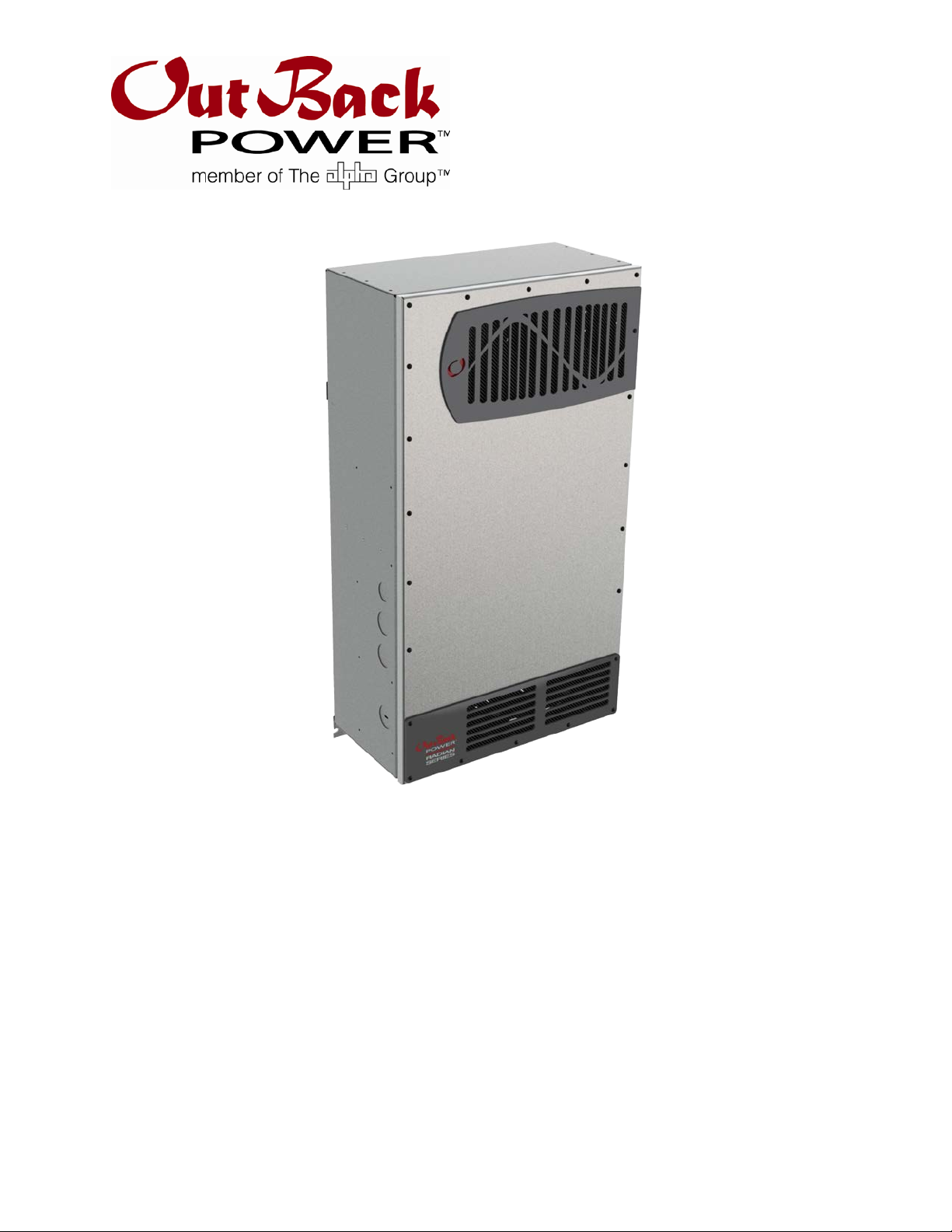

Radian Series Inverter/Charger

GS8048

Installation Manual

Page 2

Address:

Corporate Headquarters

Arlington, WA 98223 USA

European Office

Schwabach, Germany

Telephone:

+1.360.435.6030

+1.360.435.6019 (Fax)

+49.9122.79889.0

Email:

Support@outbackpower.com

Website:

http://www.outbackpower.com

About OutBack Power Technologies

OutBack Power Technologies is a leader in advanced energy conversion technology. OutBack products include

true sine wave inverter/chargers, maximum power point tracking charge controllers, and system communication

components, as well as circuit breakers, accessories, and assembled systems.

Contact Information

17825 – 59th Avenue N.E.

Suite B

+1.360.618.4363 (Technical Support)

Hansastrasse 8

D-91126

+49.9122.79889.21 (Fax)

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER TECHNOLOGIES:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF

ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Warranty Summary

OutBack Power Technologies Inc. warrants that the products it manufactures will be free from defects in

materials and workmanship for a period of five (5) years subject to the conditions set forth in the warranty detail,

found in the Radian Series Inverter/Charger Operator’s Manual.

OutBack Power Technologies cannot be responsible for system failure, damages, or injury resulting from

improper installation of their products.

Notice of Copyright

Radian Series Inverter/Charger Installation Manual © 2011 by OutBack Power Technologies. All Rights Reserved.

Trademarks

OutBack Power and the OutBack Power logo are trademarks owned and used by OutBack Power Technologies,

Inc. The ALPHA logo and the phrase “member of the Alpha Group” are trademarks owned and used by Alpha

Technologies Inc. These trademarks may be registered in the United States and other countries.

Date and Revision

October 2013, Revision B

Part Number

900-0021-01-00 Rev B

Page 3

Important Safety Instructions

Symbol

Description

Ground

AC Current

DC Current

Sine Wave

WARNING: Hazard to Human Life

This type of notation indicates that the hazard could be harmful to human life.

CAUTION: Hazard to Equipment

This type of notation indicates that the hazard may cause damage to the equipment.

IMPORTANT:

equipment warranty.

READ AND SAVE THESE INSTRUCTIONS!

This manual contains important safety instructions for the Radian Series Inverter/Charger. Read all

instructions and cautionary markings on the inverter and on any accessories or additional equipment

included in the installation. Failure to adhere to these instructions could result in severe shock or

possible electrocution. Exercise extreme caution at all times to prevent accidents.

Audience

These instructions are for use by qualified personnel who meet all local and governmental code

requirements for licensing and training for the installation of electrical power systems with AC and DC

voltage up to 600 volts.

Symbols Used

This type of notation indicates that the information provided is important to

the installation, operation and/or maintenance of the equipment. Failure to

follow the recommendations in such a notation could result in voiding the

900-0021-01-00 Rev B 1

Page 4

Important Safety Instructions

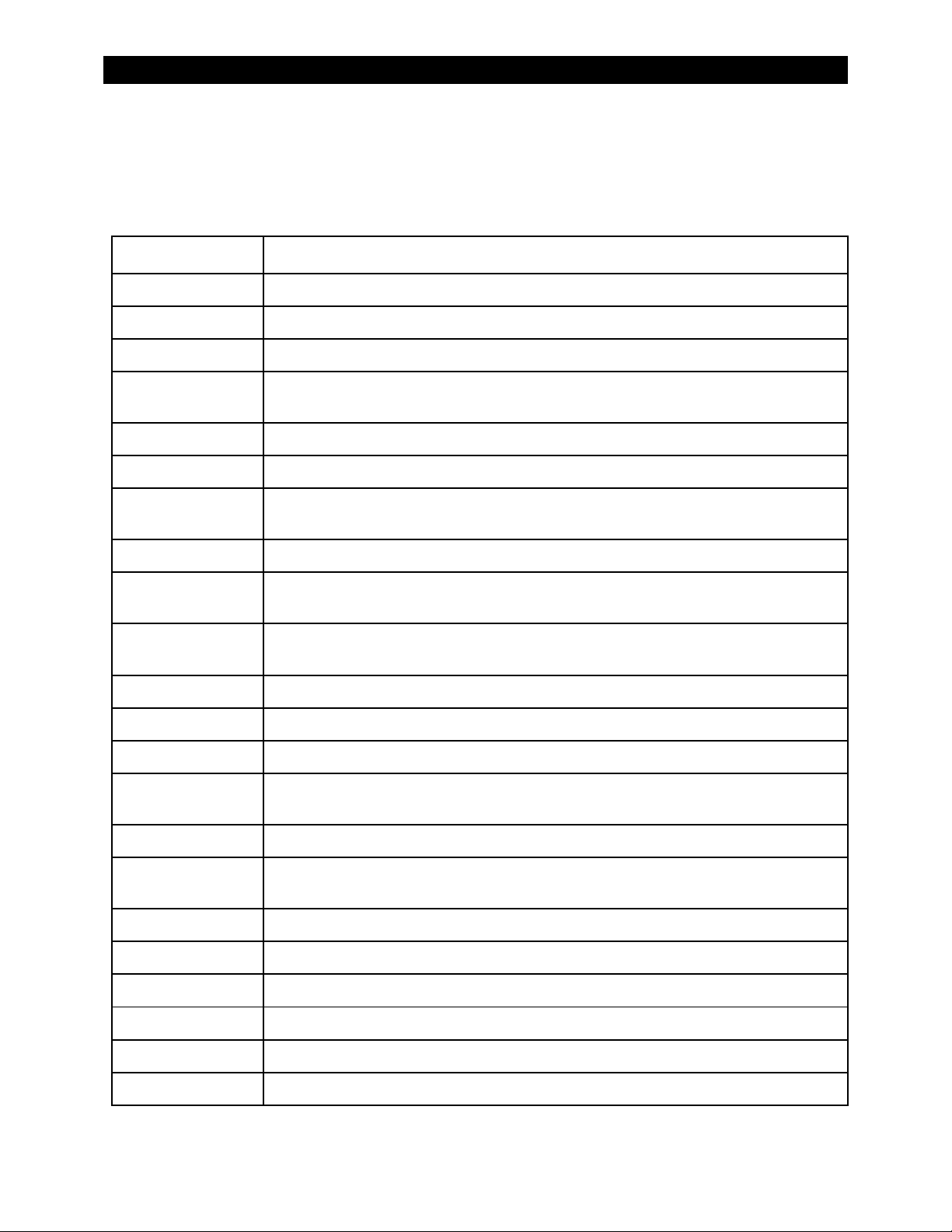

Table 1 Terms and Definitions

Term

Definition

12V AUX

Auxiliary connection that supplies 12 Vdc to control external devices.

AC

Alternating Current; refers to voltage produced by the inverter, utility grid, or generator

AGS

Advanced Generator Start

CSA

Canadian Standards Association; establishes Canadian national standards and the

Canadian Electrical Code, including C22.1 and C22.2

DC

Direct Current; refers to voltage produced by the batteries or renewable source

DVM

Digital Voltmeter

ETL

Electrical Testing Laboratories; short for the company ETL Semko; refers to a certification

issued by ETL to OutBack products indicating that they meet certain UL standards

GFDI

Ground Fault Detector Interruptor; a safety device for PV systems

GND

Ground; a permanent conductive connection to earth for safety reasons; also known as

Chassis Ground, Protective Earth, PE, Grounding Electrode Conductor, and GEC

Grid-interactive,

grid-intertie, grid-tie

Utility grid power is available for use and the inverter is a model capable of returning

(selling) electricity back to the utility grid

GSLC

GS Load Center; the wiring box for the Radian (GS) inverter

HBX

High Battery Transfer; a function of the MATE3

HUB

A line of OutBack communications manager products

IEEE

Institute of Electrical and Electronics Engineers; refers to a series of standards and

practices for the testing of electrical products

LBCO

Low Battery Cut-Out; set point at which the inverter shuts down due to low voltage

MATE3

An OutBack system display, used for monitoring, programming and communicating

with the inverter

NEC

National Electric Code

NEU

AC Neutral; also known as Common

Off-grid

Utility grid power

is not

available for use

PV

Photovoltaic

RELAY AUX

Auxiliary connection that uses switch (relay) contacts to control external devices.

RTS

Remote Temperature Sensor; accessory that measures battery temperature for charging

Definitions

The following is a list of initials, terms, and definitions used with this product.

2 900-0021-01-00 Rev B

Page 5

Important Safety Instructions

Table 1 Terms and Definitions

Term

Definition

Split-phase

A type of utility electrical system with 2 “hot” lines that are 120 Vac with respect to

neutral and 240 Vac between the “hot” lines; common in North America

System display

Remote interface device (such as the MATE3), used for monitoring, programming and

communicating with the inverter; also called “remote system display”

UL

Underwriters Laboratories; refers to a set of safety standards governing electrical

products

Utility grid

The electrical service and infrastructure supported by the electrical or utility company;

also called “mains”, “utility service”, or “grid”

WARNING: Limitations on Use

equipment or devices.

CAUTION: Equipment Damage

Technologies or its authorized agents.

IMPORTANT:

the Warranty section for instructions on returning the equipment.

WARNING: Personal Injury

General Safety

This equipment is NOT intended for use with life support equipment or other medical

Personal Safety

Only use components or accessories recommended or sold by OutBack Power

Do not attempt to install this equipment if it appears to be damaged in any way. See

This equipment weighs in excess of 125

when lifting this equipment as prescribed by the Occupational Safety and Health

Association (OSHA) or other local codes.

Use standard safety equipment such as safety glasses, ear protection, steel-toed

safety boots, safety hard hats, etc., as prescribed by the Occupational Safety and

Health Association (or other local codes) when working on this equipment.

Use standard safety practices when working with electrical equipment (e.g., remove

all jewelry, use insulated tools, wear cotton clothing, etc.).

Never work alone when installing or servicing this equipment. Have someone

nearby that can assist if necessary.

57 kg). Use safe lifting techniques

lbs (

900-0021-01-00 Rev B 3

Page 6

Important Safety Instructions

Inverter Safety

WARNING: Lethal Voltage

WARNING: Burn Hazard

to cool down before attempting to perform any maintenance.

WARNING: Fire Hazard

CAUTION: Equipment Damage

equipment and void the product warranty.

CAUTION: Equipment Damage

Review the system configuration to identify all possible sources of energy. Ensure

ALL sources of power are disconnected before performing any installation or

maintenance on this equipment. Confirm that the terminals are de-energized using

a validated voltmeter (rated for a minimum 1000 Vac and 1000 Vdc) to verify the deenergized condition.

Do not perform any servicing other than that specified in the installation

instructions unless qualified to do so, or have been instructed to do so by OutBack

Power Technologies Technical Support personnel.

Internal parts can become hot during operation. Do not remove the cover during

operation or touch any internal parts. Be sure to allow sufficient time for internal parts

Do not place combustible or flammable materials within 12 feet (3.7 m) of

the equipment.

This product contains relays with moving parts and is not ignition-protected.

Ensure AC, DC, and ground cable sizes conform to local codes. See pages 24

through 26 for minimum size requirements. Ensure all conductors are in good

condition. Do not operate the unit with damaged or substandard cabling.

When connecting cables from the inverter to the battery terminals, ensure the proper

polarity is observed. Connecting the cables incorrectly can damage or destroy the

Thoroughly inspect the equipment prior to energizing. Verify that no tools or

equipment have been inadvertently left behind.

Ensure clearance requirements are strictly enforced. Keep all vents clear of

obstructions that can prevent proper air flow around, or through, the unit.

Sensitive electronics inside the equipment can be destroyed by static electricity. Be

sure to discharge any static electricity before touching the equipment and wear

appropriate protective gear.

4 900-0021-01-00 Rev B

Page 7

Important Safety Instructions

WARNING: Explosion, Electrocution, or Fire Hazard

IMPORTANT:

Have a supply of either substance readily available if using these types of batteries.

Battery Safety

Use the battery types recommended by OutBack Power Technologies. Follow the

battery manufacturer’s recommendations for installation and maintenance.

Ensure the cables are properly sized. Failure to size the cables properly can result in

a fire hazard.

Ensure clearance requirements are strictly enforced around the batteries.

Ensure the area around the batteries is well ventilated and clean of debris.

Never smoke near, or allow a spark or flame near, the batteries.

Always use insulated tools. Avoid dropping tools onto batteries or other

electrical parts.

Keep plenty of fresh water and soap nearby in case battery acid contacts skin,

clothing, or eyes.

Wear complete eye and clothing protection when working with batteries. Avoid

touching bare skin or eyes while working near batteries.

If battery acid contacts skin or clothing, wash immediately with soap and water. If

acid enters the eye, immediately flood it with running cold water for at least

20 minutes and get medical attention as soon as possible.

Never charge a frozen battery.

Insulate batteries as appropriate against freezing temperatures. A discharged

battery will freeze more easily than a charged one.

If a battery must be removed, always remove the grounded terminal from the

battery first. Make sure all devices are de-energized or disconnected to avoid

causing a spark.

If a remote or automatic generator control system is used, disable the starting

circuit and/or disconnect the generator from its starting battery while performing

maintenance to prevent accidental starting.

Baking Soda neutralizes lead-acid battery electrolyte.

Vinegar neutralizes NiCad and NiFe battery electrolyte.

900-0021-01-00 Rev B 5

Page 8

Additional Information

Regulatory Specifications

See the Radian Series Inverter/Charger Operator’s Manual for all specifications and regulatory

information, including certifications.

Required Resources

This product is required to be installed according to pertinent safety codes and standards. If installed

in the United States, wiring practices must meet the requirements of the National Electrical Code

(NEC). If installed in Canada, wiring practices must meet the requirements of the Canadian

Electrical Code.

National Electrical Code (NEC)/NFPA 70, Current Edition

Canadian Electrical Code, C22.1, Current Edition

Additional Resources

The following are references which may be used when installing this equipment. Depending on the

nature of the installation, it may be highly recommended to consult any or all of these resources.

National Electrical Code (NEC)/NFPA 70 Handbook, Current Edition

UL 1741, Current Edition, Static Inverter and Charge Controllers for Use in Photovoltaic Power Systems

International Building Code (IBC), Current Edition

Photovoltaic Power Systems and the 2005 National Electrical Code: Suggested Practices

6 900-0021-01-00 Rev B

Page 9

Additional Information

IMPORTANT: Recycle Electronics and Batteries

provide additional information for recycling electronic products and batteries.

Recycling Information

Batteries are considered hazardous waste and must be recycled according to

local jurisdiction. Inverters and other electronics contain metals and plastics

that should also be recycled. The following web sites and phone numbers

Earth 911, USA

Web site: www.Earth911.com

Address: 14646 N. Kierland Blvd., Suite 100

Scottsdale, AZ 85254

Phone: +1.480.337.3025 (direct)

Environmental Protection Agency, USA

Web site: www.epa.gov/recyclecity/

Email: r9.recyclecity@epa.gov

Phone: +1.415.947.8000

(Monday –Friday 8:00 AM to 12:00 PM and 1:00 PM to 4:00 PM PST)

Keep America Beautiful, USA

Web site: www.kab.org/

Email: info@kab.org

Address: 1010 Washington Boulevard

Stamford, CT 06901

Phone: +1.203.659.3000 (Main number)

Fax: +1.203.659.3001

OurEarth.org, USA

There is a place on the website for contacting OurEarth.org using email. No direct email address

is provided.

Web site: http://www.ourearth.org

Address: P.O. Box 62133

Durham, NC 27715

Phone: +1.410.878.6485

National Institute of Recyclers, Mexico

Web site: http://www.inare.org.mx/

Email: a57841279@prodigy.net.mx, margarita@inare.org.mx

Phone: +1.55.57.85.9160

Fax: +1.55.57.84.1279

900-0021-01-00 Rev B 7

Page 10

Additional Information

Natural Resources Canada

Address: 580 Booth, Ottawa, ON K1A 0E8

Web site: http://www.nrcan-rncan.gc.ca/mms-smm/busi-indu/rec-rec-eng.htm

Phone: +1.613.995.0947

TTY: +1.613.996.4397

(Phone and TTY: Monday to Friday, 8:30 a.m. to 4:30 p.m. ET)

Office of Waste Management, Canada

Web site: http://www.portaec.net/library/recycling/recycling_in_canada.html

Address: Office of Waste Management

Conservation and Protection

Environment Canada

Ottawa, Ontaro K1A 0H3

Phone: +1.819.997.2800

EuroRecycle.net, Europe

The following website provides general information about recycling in Europe. It also provides a list of

companies and organizations that provide recycling information or assistance.

Web site: http://euro.recycle.net

E-mail: http://euro.recycle.net/cgi-bin/feedback1.cgi?w=27

(This is an online form providing a means to contact the owners of the website.)

8 900-0021-01-00 Rev B

Page 11

Table of Contents

Important Safety Instructions ........................................................................ 1

Audience ................................................................................................................................................................................. 1

Symbols Used ........................................................................................................................................................................ 1

Definitions ............................................................................................................................................................................... 2

General Safety ....................................................................................................................................................................... 3

Personal Safety ...................................................................................................................................................................... 3

Inverter Safety ....................................................................................................................................................................... 4

Battery Safety ......................................................................................................................................................................... 5

Regulatory Specifications .................................................................................................................................................. 6

Required Resources ............................................................................................................................................................. 6

Additional Resources .......................................................................................................................................................... 6

Recycling Information ........................................................................................................................................................ 7

Introduction ............................................................................................... 11

Welcome to OutBack Power Technologies .............................................................................................................. 11

Components and Accessories ...................................................................................................................................... 12

Planning .................................................................................................... 13

Applications ........................................................................................................................................................................ 13

Renewable Energy ............................................................................................................................................................ 14

Battery Bank ........................................................................................................................................................................ 14

Generator ............................................................................................................................................................................. 15

Maintenance Bypass Switching ................................................................................................................................... 16

Installation ................................................................................................. 17

Location and Environmental Requirements ............................................................................................................ 17

Dimensions .......................................................................................................................................................................... 17

Tools Required .................................................................................................................................................................... 18

Mounting .............................................................................................................................................................................. 18

Accessory Mounting .......................................................................................................................................................................... 20

Removing Front Cover .................................................................................................................................................... 21

Terminals and Ports .......................................................................................................................................................... 22

Grounding ............................................................................................................................................................................ 24

DC Wiring ............................................................................................................................................................................. 25

AC Wiring.............................................................................................................................................................................. 26

AC Sources ............................................................................................................................................................................................. 27

Accessory Wiring ............................................................................................................................................................... 28

AUX Wiring .......................................................................................................................................................................... 29

Generator Control) ............................................................................................................................................................................. 31

Single-Inverter AC Installations .................................................................................................................................... 34

Multiple-Inverter AC Installations (Stacking) ........................................................................................................... 35

Functional Test ................................................................................................................................................................... 38

Index ......................................................................................................... 39

900-0021-01-00 Rev B 9

Page 12

Table of Contents

List of Tables

Table 1 Terms and Definitions ................................................................................................................... 2

Table 2 Components and Accessories .................................................................................................. 12

Table 3 Ground Conductor Size and Torque Requirements .......................................................... 24

Table 4 DC Conductor Size and Torque Requirements ................................................................... 25

List of Figures

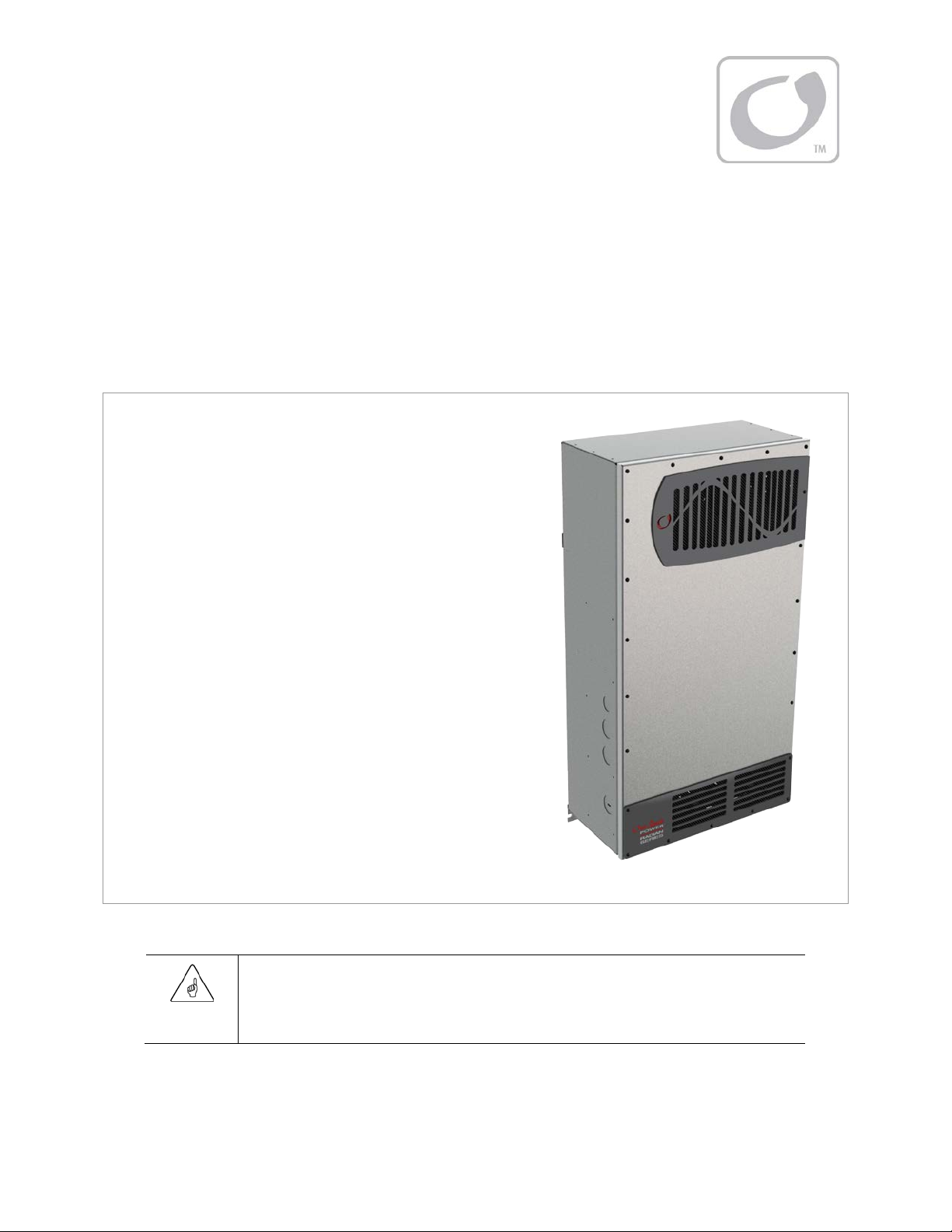

Figure 1 GS8048 Inverter/Charger ........................................................................................................... 11

Figure 2 Radian Inverter and Accessories ............................................................................................. 12

Figure 3 Applications (Example) ............................................................................................................... 13

Figure 4 Bypass Switching .......................................................................................................................... 16

Figure 5 Bypass Switching for Multiple Inverters ............................................................................... 16

Figure 6 Dimensions ..................................................................................................................................... 17

Figure 7 Installing the Mounting Plate ................................................................................................... 18

Figure 8 Mounting the Inverter ................................................................................................................ 19

Figure 9 Mounting for System Components ........................................................................................ 20

Figure 10 Cover Screws .................................................................................................................................. 21

Figure 11 DC Terminals, Ribbon Cables, and Auxiliary Terminals ................................................... 22

Figure 12 AC Terminals, Ports, and Ground Bus .................................................................................... 23

Figure 13 Chassis Ground TBB ..................................................................................................................... 24

Figure 14 DC Cable Hardware (underside of inverter) ........................................................................ 25

Figure 15 AC Terminals .................................................................................................................................. 26

Figure 16 AC Sources ...................................................................................................................................... 27

Figure 17 Accessory Connections .............................................................................................................. 28

Figure 18 ON/OFF Jumper and Connections.......................................................................................... 28

Figure 19 AUX Connections for Vent Fan (Example)............................................................................ 29

Figure 20 AUX Connections for Diversion (Example) .......................................................................... 30

Figure 21 Two-Wire Generator Start (RELAY AUX)................................................................................ 31

Figure 22 Two-Wire Generator Start (12V AUX) ..................................................................................... 32

Figure 23 Three-Wire Generator Start (Example) .................................................................................. 33

Figure 24 Single-Inverter Wiring ................................................................................................................. 34

Figure 25 OutBack HUB4 and MATE3 ....................................................................................................... 35

Figure 26 Example of Parallel Stacking Arrangement (Three Inverters)........................................ 36

Figure 27 Parallel Wiring ................................................................................................................................ 37

10 900-0021-01-00 Rev B

Page 13

Introduction

IMPORTANT:

Controller. Use of these products is not supported with the Radian Series.

Mounts easily with supplied mounting plate.

Welcome to OutBack Power Technologies

Thank you for purchasing the OutBack Radian Series Inverter/Charger. This product offers a complete

power conversion system between batteries and AC power. It can provide backup power, sell power

back to the utility grid, or provide complete stand-alone off-grid service.

All terminals exit at the bottom of the inverter.

This allows the installer to use a single distribution

box. The GS Load Center (GSLC) is specifically

designed for this purpose and is sold separately.

Uses spring-based AC terminals instead of

screw-based terminals. This eliminates torque

requirements and periodic re-tightening.

Uses the MATE3 System Display and Controller

(sold separately) for user interface.

Features versatile mounting locations for the

MATE3, HUB, and FLEXmax products, as well as

the GSLC.

The venting on the cover allows mounting of

multiple Radian inverter/chargers side by side

with zero clearance required between them.

Up to 10 Radian Series Inverter/Chargers can be

stacked together.

This product is not compatible with the OutBack MATE or MATE2 System Display and

Figure 1 GS8048 Inverter/Charger

900-0021-01-00 Rev B 11

Page 14

Introduction

Radian Series Installation Manual

RTS (Remote Temperature Sensor)

Radian Series Operator’s Manual

Hardware Kit

Mounting Bracket

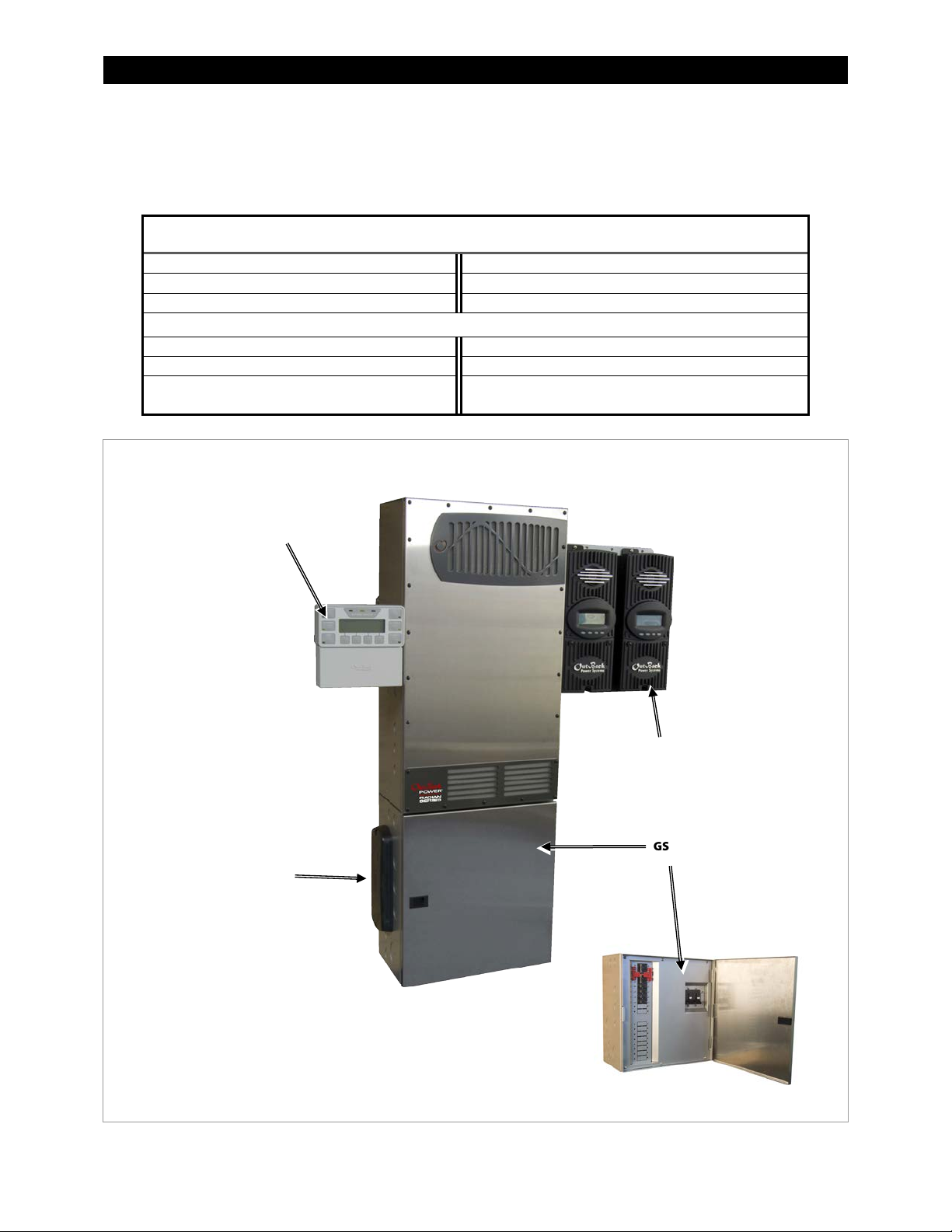

Optional Components for Attachment to Radian Inverter

MATE3 System Display and Controller

FLEXmax 60 or FLEXmax 80 Charge Controller

FW-MB3 (MATE3 bracket)

FW-CCB or FW-CCB2 (charge controller brackets)

GSLC, GSLC175-120/240, or GSLC-PV-120-/240

(GS Load Centers)

GSLC

MATE3

HUB

FLEXmax

Charge Controllers

Components and Accessories

Table 2 Components and Accessories

Included in Box

OutBack HUB4 or HUB10

12 900-0021-01-00 Rev B

Figure 2 Radian Inverter and Accessories

Page 15

Planning

Applications

The Radian Series Inverter/Charger is intended for both grid-interactive and off-grid applications.

These inverters are designed to use a battery bank to store energy. They can work in conjunction with

photovoltaic (PV) panels to harvest solar energy, as well as wind turbines and other renewable

sources. These sources charge the battery, which in turn is used by the inverter.

Figure 3 Applications (Example)

The Radian inverter has six modes of operation. Each mode has functions and priorities that are

intended for a designated application. Each of the Radian’s two AC inputs can be set to a different

operating mode, so that different applications can be supported.

: See the Radian Series Inverter/Charger Operator’s Manual for additional information on these

NOTE

modes, including the benefits of using each mode.

Generator

imperfect AC waveform. The Radian will charge from the generator even when the generator is undersized

or substandard.

Support

other limitations may require temporary assistance to run very large loads. The Radian adds inverter and

battery power to the AC source to ensure that the loads receive the power they require.

Grid Tied

batteries above a selected “target” voltage, the Radian inverter will send the excess energy to any loads. If

the loads do not use all the excess energy, then the Radian will return that energy to the utility grid.

UPS

power to the loads without any interruption during a transfer to, or from, the AC input. The speed of

900-0021-01-00 Rev B 13

: This mode is intended for a wide range of AC sources, including generators with a rough or

: This mode is intended for systems that use the utility grid or a generator. AC source size, wiring, or

: This mode is intended for grid-interactive systems. When renewable energy sources charge the

(Uninterruptible Power Supply): This mode is intended for systems whose main focus is to maintain

Page 16

Planning

response in this mode has been increased so that if the AC input power is disconnected or a scheduled

disconnect occurs the response time will be minimized.

Backup

the Radian inverter to power the loads unless utility power is lost. If utility grid power is lost, then the Radian

inverter will supply energy to the loads from the battery bank until the power is back online.

Minigrid

renewable energy production. The system will run off the renewable energy production until the battery

voltage falls to a specified low level. When this occurs, the Radian inverter will connect to the utility grid,

which will power the loads. The Radian inverter will disconnect from the utility grid when the batteries are

sufficiently recharged.

: This mode is intended for systems that have the utility grid available. This source will flow through

: This mode is intended for systems that have the utility grid as an input and a sizable amount of

Renewable Energy

The Radian Series Inverter/Charger cannot connect directly to photovoltaic arrays, wind turbines, or

other renewable sources. The batteries are the primary source of power. However, if these sources

are used to charge the batteries, the inverter can use their energy by drawing it from the batteries.

The renewable source is always treated as a battery charger, even if all of its power is used

immediately. The renewable source must have a charge controller or some way to prevent

overcharging. OutBack Power’s FLEXmax family of charge controllers can be used for this purpose, as

can other products.

The GSLC will receive the mechanical and electrical connections for up to two FLEXmax charge

controllers. It can receive the electrical connections for two FLEXmax Extreme charge controllers.

Battery Bank

When planning a battery bank, consider the following:

Cables:

will determine the placement of the battery bank. Other local codes or regulations may apply and may take

priority over OutBack recommendations.

Battery Type:

discharge. These include batteries for marine, golf-cart, and forklift applications. They also include gel-cell

batteries and absorbed glass-mat (AGM) batteries. OutBack Power recommends the use of batteries

designed specifically for renewable energy applications. Automotive batteries are strongly discouraged and

will have a short life if used in inverter applications. Nickel-based batteries are discouraged due to

limitations in the Radian charger. Lithium-based batteries and other advanced battery technologies may

require special considerations. Please contact OutBack Technical Support at

implementing advanced battery technologies.

The Radian inverter/charger is designed to work with a 48-volt battery bank. Before constructing a battery

bank, confirm the nominal voltage of individual batteries.

Bank Size:

expected loads and run time.

~ To prevent the inverter’s charger from overcharging, the minimum recommended battery bank size is

~ If other charging devices are present, the minimum bank size should be determined by adding the

Systems intended to bridge short-term outages can use smaller battery banks. In these cases, the bank can

be as low as 200 amp-hours per inverter. However, the charge rate must be decreased to half the inverter’s

maximum using the MATE3. (See the MATE3 manual.) One of the following conditions must also be true.

~ The system is equipped with a backup generator that is programmed for automatic start, or

Recommendations for battery cable size and length are shown on page 25. The maximum length

The Radian inverter/charger works best with lead-chemistry batteries intended for deep

+1.360.618.4363

In backup or off- grid applications, the battery bank size should be calculated based on

350 amp-hours for every Radian inverter/charger installed on the system.

inverter(s) charge rate to any other chargers and multiplying the result by five. Example: If the system’s

combined charge rate was 160 Adc, the minimum battery bank size should be 800 amp-hours.

before

14 900-0021-01-00 Rev B

Page 17

Planning

~ Typical grid loss is 30 minutes or less, or

IMPORTANT:

factory default settings, may cause the batteries to be undercharged or overcharged.

CAUTION: Hazard to Equipment

product warranty. (Sealed batteries may be an exception.)

~ The loads are less than 2 kW.

NOTE: If support time or load size are disproportionate to the bank size, they will cause inverter shutdown

due to low battery voltage after a short time. These conditions could be detrimental to the life of a small

battery bank. If this is true, the recommendations from the previous page apply instead.

Charger Settings and Maintenance:

code and is recommended in most cases for safety reasons. It may be necessary to use a fan to ventilate the

battery enclosure. (See the Operator’s Manual for vent fan applications.)

Batteries must be regularly maintained according to the instructions of the battery manufacturer.

A vented enclosure for the battery bank may be required by electric

Battery charger settings need to be correct for a given battery type. Always follow

battery manufacturer recommendations. Making incorrect settings, or leaving them at

Batteries can emit vapors which are corrosive over long periods of time. Installing the

inverter in the battery compartment may cause corrosion which is not covered by the

Generator

The Radian inverter/charger has specific connections for a “split-phase” generator. It can work with

any generator that delivers clean 120/240 Vac at 60 Hz. This product cannot work with a single-phase

or three-phase generator.

The Radian inverter/charger can provide a start signal to control an automatic start generator. If automatic

generator starting is required, the generator must be an electric-start model with automatic choke and

two-wire start capability. (See page 30.) For other configurations, additional equipment may be required.

In all cases, the inverter may need to be programmed using the MATE3 according to the specifications of the

generator and the requirements of the system. (See the Radian Series Inverter/Charger Operator’s Manual

and the MATE3 Owner’s Manual.) Parameters to be programmed may include generator size, automatic

starting requirements, and potential fluctuations in generator AC voltage.

Generator Sizing

A generator should be sized to provide enough power for all the loads and the battery charger.

Available generator power may be limited by ratings for circuit breakers and/or generator connectors. The

maximum allowed AC circuit breaker size is 50 Aac per Radian inverter/charger.

The generator must be able to provide current to all inverters. Minimum generator wattage

recommended to be twice the wattage of the inverter system. Many generators may not be able to

maintain AC voltage or frequency for long periods of time if they are loaded more than 80% of rated

capacity.

A generator that is to be installed in a building should not have a bond between the neutral and ground

connections. Installations in North America are expected to bond the neutral and ground at the main

electrical panel.

1

is usually

1

This is the wattage value after de-ratings for peak versus continuous power, for load power factor considerations, for fuel

type, for altitude, and for ambient temperature.

900-0021-01-00 Rev B 15

Page 18

Planning

WARNING: Shock Hazard or Equipment Damage

equipment.

AC Source

AC Loads

GSLC Bypass

Inoperative

Inverter

Input Wiring

Output Wiring

AC Source

AC Loads

Output Wiring

Inactive Radian Inverters

Input Wiring

GSLC Bypass Devices

(not to be used)

External Bypass Device

Maintenance Bypass Switching

Inverter systems are often equipped with AC maintenance bypass switches or interlocks. If the

inverter system ever needs to be shut down or removed, the AC sources and loads must be

disconnected. A bypass device allows the AC source to deliver power directly to the loads, bypassing

the inverter. This can minimize disruption to the system and avoids the need for extensive rewiring.

Radian

Figure 4 Bypass Switching

The GSLC (see page 12) can be equipped with bypass circuit breakers for this purpose. However, if

multiple Radian inverters are stacked in a single system, then the bypass function must be

simultaneous for all inverters. The GSLC bypass kits operate independently, not simultaneously, and

should not be installed in this kind of application. Both manual and automatic double-pole,

double-throw bypass switches are commonly available in a range of sizes and options. These are

highly recommended for systems with more than a single inverter.

Using independent bypass devices on multiple inverters can result in power being routed

to inappropriate places. This could create an electric shock hazard or damage the

Figure 5 Bypass Switching for Multiple Inverters

16 900-0021-01-00 Rev B

Page 19

Installation

Enclosure Height

28” (71.1 cm)

Width 16” (40.6 cm)

Depth

Enclosure

Height with

Flange

29.13”

(7

Location and Environmental Requirements

Radian Series Inverter/Chargers must be located in a weather-proof enclosure or enclosed area. These

inverters are not designed for exposure to water or excessive wind-blown dust and debris.

The Radian inverter must be wall-mounted in an upright position. The inverter is not approved for

mounting in any other position or orientation.

Recommended minimum clearance is 2 to 4 inches (5 to 10 cm) for the front and top of the inverter.

The sides and bottom may be enclosed or obscured with no restriction when mounting accessory devices or

one other Radian Series Inverter/Charger. If more than two Radian inverters are installed side by side with

the GSLC, the inverters should be separated by at least 0.9 inches (2.3 cm) to accommodate the GSLC doors.

The Radian inverter will function best if operated in a temperature range of 32°F to 77°F (–20°C to 25°C). At

temperatures up to 122°F (50°C), all inverter components meet their specifications, but the inverter’s power

is derated. It can function in environments as cold as –40°F (–40°C) and as warm as 140°F (60°C), but it may

not meet all component specifications. This temperature range also applies to storage.

The specifications are listed in the Radian Series Inverter/Charger Operator’s Manual.

Dimensions

Figure 6 Dimensions

8.75” (22 cm)

4 cm)

900-0021-01-00 Rev B 17

Page 20

Installation

IMPORTANT:

The Radian inverter is mounted using these

Continued on the next page…

16.0” (40.6 cm)

Mounting Plate

4.1”

5.0”

(12.7 cm)

Long-nose pliers

a #2 Phillips screwdriver 15-16” long

Tools Required

The following tools may be required for this installation:

Wire cutters/strippers

Wrench and socket sets; should include torque and ratchet

wrenches; also reversible (stubby) wrenches for narrow access

DVM or Voltmeter

Insulated screwdriver set; should include

Mounting

Two or more people may be needed to install the Radian inverter/charger due to its weight.

Mount and secure each component before attaching any wiring. The bottom of the inverter must be

enclosed to meet NEC requirements. The GS Load Center was specifically designed for this purpose.

Avoid large air gaps behind the Radian inverter/charger and its mounting plate. These can result in louder

mechanical noise during heavy inverting or charging. Mount the plate on a flat, solid mounting surface.

Use correct fasteners to secure the mounting plate and the Radian inverter/charger to the

mounting surface. OutBack cannot be responsible for damage to the product if it is attached

with inadequate fasteners.

The Radian inverter/charger comes equipped with a mounting plate, as shown in Figure 7.

steps.

1. The mounting plate is to be screwed or

bolted directly to a solid mounting surface

such as wall studs. (See Figure 7.) Lag

screws are provided for this purpose.

~ The plate is designed to mount on wall

studs with a spacing of 16” (40.6 cm).

If the studs have a different spacing,

plywood or similar material should be

installed over the studs. This material

should be1/2” size or thicker. The

mounting plate can be installed on the

plywood surface.

~ If multiple Radian inverter/chargers are

being installed, all mounting plates

should be installed first. The inverters

can be mounted and secured one at a

time when this is done.

(10.4 cm)

6.0” (15.2 cm)

8.0” (20.3 cm)

18 900-0021-01-00 Rev B

Figure 7 Installing the Mounting Plate

Page 21

Installation

GS Inverter

Mounting Plate

3. Align the left edge of the inverter with the left edge of the

2. Place the Radian inverter against the wall and slide it directly

over the upper lip of the mounting plate. The inverter’s

WARNING: Shock Hazard

chassis may involve metal-to-metal contact, or separate ground wires.

…continued from the previous page…

mounting flange should come to rest within the lip so that it

hangs securely.

To assist in alignment, dimples have been placed on the side of

the unit to mark the lower edge of the flange. In the picture to

the left, the two X symbols show the location of the dimples.

mounting plate. This will expose the right edge of the plate,

allowing easy installation of another Radian inverter/charger in

the future. All additional inverters are mounted to the right of

the existing unit.

The unit shown to the right is not aligned with the mounting

plate, as the plate is still visible. In this example, it should slide

to the left so that the plate is entirely covered.

NOTE: If the GSLC is used with the Radian inverter, the

following step should be omitted.

4. Once aligned, secure the Radian inverter to the stud using a lag

screw (provided) in the left corner of the inverter’s bottom

flange. Securing the inverter this way will prevent it from

dislodging from the mounting plate in the event of an

earthquake or similar event.

NOTE: The left corner is used for securing the inverter to a stud.

If the Radian inverter is mounted on plywood or a similar

wide-area mounting surface as shown, any of the slots in the

mounting flange may be used.

When the inverter is used with other metal chassis, make sure that all chassis are

grounded appropriately. (See the grounding instructions on page 23.) Grounding other

Figure 8 Mounting the Inverter

900-0021-01-00 Rev B 19

Page 22

Installation

For the FLEXmax charge controller:

For the MATE3:

To fit on the Radian inverter’s

left side, the MATE3 requires

the FW

bracket. Holes are provided on

the upper and lowe

to attach the FW

more information, see the

FW

For the HUB:

To fit on the Radian inverter’s left side,

the HUB uses two mounting holes and

three knockouts.

The top of the GS Load Center (GSLC) connects to the bottom of

NOTE: The OutBack FLEXmax Extreme should be installed on the wall to either side of the GSLC

for direct wiring access and does not require additional brackets.

Accessory Mounting

the Radian inverter using four keyhole slots. The keyhole slots fit

over four screws on the bottom of the inverter that will secure

the GSLC to the inverter when they are tightened.

(The long screwdriver recommended on page

18 may

be needed to reach these screws.) The GSLC should be

secured to the wall using screws or wall anchors. The

GSLC also makes a mechanical connection to the Radian

using bus bars that bolt to the inverter’s DC terminals. Other

connections are wired as necessary. For more information on

these connections, see the GS Load Center Installation Manual.

Several system components can mount directly onto the Radian

inverter or the GSLC. The MATE3 System Display and the HUB

Communications Manager can easily be mounted on the left side

of the system. Up to two FLEXmax 60 or 80 charge controllers can

be mounted on its right side.

: The FLEXmax controller requires mounting brackets

NOTE

(see below). The conduit provided with these brackets is long

enough to wire the FLEXmax directly to the GSLC. Additional

conduit may be necessary when mounting on the inverter. The

image on the right shows GSLC mounting. See Figure 2 on page

12 for other configurations.

-MB3 mounting

r left side

-MB3. For

-MB3 instruction sheet.

20 900-0021-01-00 Rev B

Figure 9 Mounting for System Components

To fit on the Radian inverter’s right side, the FLEXmax

charge controllers require the FW-CCB or FW-CCB2

mounting brackets. To accommodate many possible

mounting requirements, four sets of mounting holes

have been provided for the brackets.

Page 23

Installation

Removing Front Cover

Screws

The front cover must be removed in order to access the Radian inverter’s AC terminals and other

connections. These include the “Remote” and “Batt Temp” ports, as well as several sets of auxiliary

terminals.

Twenty-two machine screws are located around the perimeter. Remove these screws with a Phillips

screwdriver. Once they are removed, the cover can be lifted off.

Figure 10 Cover Screws

NOTE:

initial installation. The remaining screws are included in the hardware kit.

900-0021-01-00 Rev B 21

The Radian inverter may ship with only a few screws installed to make it easier to perform the

Page 24

Installation

WARNING: Shock Hazard and Equipment Damage

the Radian service manual.) The cables must never be removed until all power has been disconnected from

handling. This damage is not covered under the unit’s warranty.

RIBBON CABLES

:

Connect the Radian’s power

modules and control

12V AUX: Delivers 12 Vdc up to

0.7

be switched on and off for many

function

See the MATE3 manual for

programming instructions.

SWITCH INV

: R

eceives wires for a manual

on/off

page

NOTE:

overrides these terminals when installed.

(See above.)

RELAY AUX: Relay contacts with no

voltage (

The relay can be switche

many functions.

See the MATE3 manual for programming

instructions.

ON/OFF INV JUMPER (J3): Overrides the

DC TERMINALS

:

Connect to battery cables and DC system. There are two DC

positive and two DC negative terminals. Each DC positive terminal requires

separate cables and separate overcurrent protecti

instructions.

Terminals and Ports

on. See page 25 for

board. See Warning below.

SWITCH INV terminals when installed. When

installed, the inverter is ON. The ON or OFF

states can then only be controlled by the MATE3.

NOTE: J3 is installed to the ON position during

manufacture, but the Radian inverter is given an

external OFF command at the same time. Its

10 amps at 250 Vac or 30 Vdc).

d on and off for

See page 29 for details.

amps (8.4 watts). The output can

s. See page 29 for details.

initial state will be OFF.

switch to control the inverter. See

28 for instructions.

The ON/OFF INV jumper (J3)

Figure 11 DC Terminals, Ribbon Cables, and Auxiliary Terminals

It may be necessary to remove the ribbon cables in the course of servicing the Radian. (This is detailed in

the Radian for a minimum of one minute. If the cables are removed prematurely, the Radian’s capacitors

22 900-0021-01-00 Rev B

will retain a sizable charge, which can cause electrical shock or severe equipment damage during normal

Page 25

Installation

WARNING: Shock Hazard

Manual for the shutdown procedure before removing the covers.

REMOTE and BATTERY TEMP

AC TERMINAL BLOCK

:

Receives AC

CONTROL WIRING TERMINAL BLOCK:

Receives control wires for a variety of

functions

, including generator control.

S

GROUND BUS

:

Receives ground

ee facing page for terminal descriptions.

JACKS: Receive the RJ45 and RJ11

plugs from the MATE3 system display

and Remote Temp Sensor. See page

28 for instructions.

input wires for two input sources (L1, L2

and neutral for each). Also receives AC

output wires (L1, L2, and neutral). All

neutral wires are electrically common.

See page

26 for instructions.

wires from multiple locations.

See page

24 for instructions.

Figure 12 AC Terminals, Ports, and Ground Bus

900-0021-01-00 Rev B 23

After installation, do not remove the covers while the inverter has any source of power. See the Operator’s

Page 26

Installation

WARNING: Shock Hazard

equipped with its own bond, which may need to be removed.)

WARNING: Shock Hazard

GSLC is also equipped with its own bond, which may need to be removed.)

IMPORTANT:

www.outbackpower.com/forum/

, where this subject has been discussed extensively.

The inverter’s ground terminal bus bar (TBB) is used for

Grounding

Table 3 Ground Conductor Size and Torque Requirements

Terminal Location Minimum Conductor Size Torque Requirements

The unit must be connected to a grounded, permanent wiring system. If a bond is made

between neutral and ground, make sure only one bond is present in the AC system at any

time. Some codes require the bond to be made at the main panel only. (The GSLC is

For all installations, the negative battery conductor should be bonded to the grounding

system at only one point. If the OutBack GFDI is present, it can provide the bond. (The

OutBack products are not designed for use in a positive-grounded system. If it is

necessary to build this system with OutBack products, contact OutBack Technical Support

at

+1.360.618.4363

before proceeding. Additionally, consult the online forum at

Ground TBB

#8 AWG (0.013 in²) or 10 mm² 25 in-lbs/2.8 Nm

making all ground connections to other parts of the

system. Examples include inverter equipment grounding,

generator grounding, load panel grounding, and main

earth ground wire.

This TBB accepts up to #4 AWG (0.033 in²) or 25 mm²wire.

Figure 13 Chassis Ground TBB

24 900-0021-01-00 Rev B

Page 27

Installation

DC Wiring

CAUTION: Equipment Damage

CAUTION: Fire Hazard

conductor to protect the DC system.

IMPORTANT:

The DC terminals must be encased in an enclosure to meet NEC requirements.

Inverter

Nominal DC Amps

(Derated 125%)

Conductor Size

Breaker

GS8048

104

2/0 AWG (0.105 in²) or 70 mm²

175 Adc

Terminal Location

Torque Requirements

Inverter DC Terminals

60 in-lb (6.9 Nm)

Battery Terminals

See battery manufacturer’s recommendations

CAUTION: Fire Hazard

battery cable lug. The decreased surface area can build up heat.

When installing DC cables:

Battery

Flat Washer

M8-1.25 Hex Bolt

Mounting

Surface

Lock Washer

Never reverse the polarity of the battery cables. Always ensure correct polarity.

Always install a circuit breaker or overcurrent device on each DC positive

Table 4 DC Conductor Size and Torque Requirements

Make certain DC circuit breakers are turned to the off position, or fuses are removed, before proceeding.

Battery positive and negative cables should be no longer than 10 feet (3 meters) each, to minimize voltage loss and

other effects.

Note information in Table 4, but refer to NEC or applicable codes for absolute cable size recommendations.

The modular construction of the Radian requires the use of two DC circuit breakers or fuses.

The cables for each overcurrent device must

used if sized to the minimum total ampacity.

The cables listed above are for each inverter in a system. In a system with multiple inverters, each inverter requires

its own cables and overcurrent devices of the size indicated.

Install all overcurrent devices on the positive cable.

Tie, tape, or twist positive and negative cables together to

reduce self-inductance. Run positive and negative cables

through the same knockouts and conduit.

The inverter’s battery terminal is a threaded hole which

accepts a hex bolt (provided). Install battery cable lug,

washers, and bolt in the order illustrated. The battery

cable lug must be the first item installed. It must make

solid contact with the surface. It should have a 5/16 inch

(0.79 cm) diameter hole.

(Minimum, per breaker)

each

(Minimum, per breaker)

be sized appropriately. Alternately, a single cable or bus may be

Size

Cable Lug

Figure 14 DC Cable Hardware (underside of inverter)

Never install extra washers or hardware between the mounting surface and the

900-0021-01-00 Rev B 25

Page 28

Installation

WARNING: Shock Hazard

its own bond, which may need to be removed.

IMPORTANT:

of up to 50 Aac maximum size to meet NEC or other code requirements.

L1 and L2 Out

Neutrals

L1 and L2

Grid

L1 and L2 Generator

AC Wiring

Ensure there is only one AC neutral-ground bond at any time. Some codes

require the bond to be made at the main panel only. The GSLC is equipped with

The AC input and output must be protected with branch-rated circuit breakers

The Radian inverter/charger’s AC terminal block has nine positions for AC wires. The minimum

2

recommended wire size is #8 AWG (0.013 in

specific conditions. The largest size that can be used with the terminals is #6 AWG (0.021 in

2

16 mm

wire.

) or 10 mm2. Larger wire gauges may be required for

2

) or

The inverter makes its AC connections using spring-loaded clamps. It is necessary to strip

approximately ½ inch (1 cm) of insulation from the end of each wire. Other tools are not required.

Figure 15 AC Terminals

The terminals labeled

L1

and

L2 Grid

are used to connect to the two utility grid “hot” wires. The L1

and L2 wires are usually black and red respectively, and read 120 Vac each when measured with

respect to neutral. In a standard service, L1 and L2 are 180 degrees out of phase, and should read 240

Vac when measured from one to the other.

The

L1

and

L2 Gen

terminals are used to connect to the “hot” wires on a 120/240 Vac generator.

All system wiring must comply with national and local codes and regulations.

NOTE:

The terminals are labeled for grid and generator due to common conventions, not because of

inverter requirements. Each input can accept any AC source as long as it meets the requirements of

the Radian inverter and the selected input mode. (See the Operator’s Manual). If necessary, the

terminals can accept grid power. The opposite is also true.

26 900-0021-01-00 Rev B

Gen

Page 29

Installation

The Radian cannot take voltage other than 120/240 Vac. If wires are 120 Vac each, but do not measure

240 Vac from one to the next (such as two legs of a 3-phase source), it will not accept the power.

The AC source(s) can power both battery charger and loads if sized correctly. Use the source

amperage to determine actual maximum draw. Size input circuit breakers accordingly.

The terminals labeled

These terminals also transfer power from an input source if it is available. They can carry up to 55

amps using the inverter’s transfer relay. Size load circuit breakers accordingly.

Three

to connect to neutral wires from various parts of the system. The most common connections are to

the neutral bus on the main panel or utility grid service, the neutral bus on the output load panel, the

neutral bus in the GSLC, and the neutral wire from a generator.

A Ground TBB is also available if multiple ground connections are needed (see Figure 13 on page 24).

terminals are available. These terminals are electrically common. Any of them can be used

Neu

AC Sources

The inverter’s transfer relay is normally set to provide inverter power to the output. When an AC

source is present and accepted, the transfer relay switches to transfer the AC source power to the

loads. (See the Radian Series Inverter/Charger Operator’s Manual for the inverter’s acceptance criteria.)

The Radian inverter has connections for two AC sources for ease of installation. Each source is

transferred with a separate relay. However, internally it can only connect to one AC source at a time. It

cannot use both utility grid and generator power at the same time. If presented with two sources of

power, its default setting is to accept utility grid. (See the MATE3 manual for instructions on changing

the source priority.)

L1

and

L2 Out

are used to connect the Radian inverter to the load circuits.

Figure 16 AC Sources

The arrow between the output neutral and ground wires indicates that these two wires have been

bonded together, usually at the main electrical panel. Only one bond should be made between

neutral and ground at any time. See page 26. If a generator is present in a building-based installation,

the generator’s neutral and ground should be isolated.

900-0021-01-00 Rev B 27

Page 30

Installation

Accessory Wiring

MATE

port

Additional

Ports

The ON/OFF INV jumper bridges two pins. This jumper (J3) parallels the

When a HUB occupies the inverter’s Remote port, the MATE3

Jumper On

Jumper Off

Once the plastic ON/OFF INV jumper

RTS cable

telephone)

has p

See the Operator’s Manual for more

MATE3 or HUB cable

CAT5 non-crossover)

Remote port

Battery Temp port

The upper board

Remote Temperature Sensor (RTS) and the

MATE3 system display. The system display

port is labeled Remote. The RTS port is labeled

Battery Temp.

If a HUB is in use, it occupies the inverter’s

Remote port.

(RJ11, 4-conductor,

(RJ45, 8-conductor,

Figure 17 Accessory Connections

connects directly to the HUB’s “MATE” port.

Inverters plug into ports 1 and above. Charge controllers and

other devices plug into additional ports after the last inverter is

connected. See Stacking on page 35 for information on

connecting inverters. See the HUB manual for other devices.

orts for both the

information on the RTS.

two Switch INV terminals on the terminal block. If either set of

connections is closed, the inverter is ON. (Although the jumper is

factory-installed to the ON position, the inverter is given an OFF

command before leaving the factory and will initially be OFF.)

Removing the jumper will turn the

inverter OFF if it is not already. To

remove the jumper, use long-nose

pliers or a similar tool.

has been removed, the Switch INV

terminals on the terminal block can

be used to wire a manual on/off

switch.

Figure 18 ON/OFF Jumper and Connections

28 900-0021-01-00 Rev B

Page 31

Installation

CAUTION: Equipment Damage

protection is not covered by the Radian warranty.

In this example, the 12V AUX terminals directly

Fan

AUX Wiring

The Radian inverter has two sets of terminals which can respond to different criteria and control many

functions. These include cooling fans, vent fans, load diversion, fault alarms, and the Advanced

Generator Start (AGS) function.

The 12V AUX terminals are a switched 12 Vdc power supply. They can control any of the Auxiliary

Output functions available in the MATE3.

The 12V AUX terminals can supply up to 0.7 amps at 12 Vdc (8.4 watts). This is sufficient to drive a

small fan or a relay controlling a larger device. The terminals accept wire up to #14 AWG (0.0032 in²) or

2.5 mm². This circuit contains electronic overcurrent protection, which resets after being overloaded.

No additional fuses are required for the 12V AUX terminals.

The RELAY AUX terminals are “dry” relay contacts with no voltage. Their most common function is to

serve as a switch for the start circuit of an automatic generator using the generator control functions.

However, they can be programmed for other Auxiliary functions as well. These terminals can conduct

up to 10 amps at up to 30 Vdc or 250 Vac.

This circuit has no overcurrent protection. A fuse of no larger than 10 amps must

be installed to protect the circuit. Since the internal circuitry of the RELAY AUX

terminals do not incorporate overcurrent protection, it is the responsibility of the

installer to ensure the circuit is protected. Internal failure that results from lack of

Each set of terminals has its own set of programmed criteria.

NOTE: The menus for each set of terminals have identical options available, but can control

independent functions. For example, the RELAY AUX terminals can be used for generator control

while the 12V AUX terminals can simultaneously be used to control a vent fan in the battery box.

Note also that the control logic for the terminals is not always located in the same device. The

inverter’s Auxiliary Output functions are located within the inverter itself. Although they require the

system display (MATE3) for programming, they will function even if the MATE3 is removed. However,

the programming for AGS is located within the MATE3 and will not work if the MATE3 is removed.

Other devices may be able to control the inverter’s terminals. See the appropriate manuals for more

information.

For generator control, see page 31. For all other functions, see the MATE3 Owner’s Manual and the

Radian Series Inverter/Charger Operator’s Manual.)

drive a 12-volt vent fan. The + and – wires on the

fan are connected to the AUX terminals.

NOTE: If another device is used, such as a larger

fan, it must not draw more than 0.7 amps.

900-0021-01-00 Rev B 29

Figure 19 AUX Connections for Vent Fan (Example)

Page 32

Installation

In this example, the 12V AUX terminals drive a

relay that diverts wind power. The relay’s coil is

Relay

Element

Turbine

NOTE: Relays and elements shown are examples only

connected to the 12V AUX terminals. When the

AUX function closes the relay (based on battery

voltage), the relay diverts the excess wind power

to a water heating element.

and may vary depending on the installation.

Figure 20 AUX Connections for Diversion (Example)

30 900-0021-01-00 Rev B

Page 33

Installation

CAUTION: Equipment Damage

lack of protection is not covered by the Radian warranty.

Starting Switch

Two-Wire-Start

Generator

Generator Control

The RELAY AUX terminals can most easily perform “two-wire” generator start. A two-wire-start

generator is the simplest type, where the cranking and starting routine is automated. It usually has a

single switch with two positions that is turned ON to start, OFF to stop.

Two-Wire-Start (RELAY AUX Terminals)

The RELAY AUX terminals can be wired in place of the generator’s start switch as shown below. This

method is only advised if the generator’s starting circuit is triggered by continuity. (This circuit must

use fewer than 10 amps.)

This circuit has no overcurrent protection. A fuse of no larger than 10 amps must

be installed to protect the circuit. Since the internal circuitry of the RELAY AUX

terminals does not incorporate overcurrent protection, it is the responsibility of

the installer to ensure the circuit is protected. Internal failure that results from

In other cases, or in the case of a three-wire-start generator, the inverter should use the 12V AUX

terminals instead, in conjunction with a three-to-two wire converter. (See pages 32 and 33.)

Either the MATE3 or the FLEXnet DC battery monitor can be programmed to perform automatic

generator start using these terminals. See the MATE3 or FLEXnet manuals for programming

instructions.

900-0021-01-00 Rev B 31

Figure 21 Two-Wire Generator Start (RELAY AUX)

Page 34

Installation

Two-Wire-Start (12V AUX Terminals)

Starting

Terminals

Generator

Battery

Relay

Relay

Coil

Two-Wire-Start

Generator

1

1

The 12 Vdc signal provided by the 12V AUX terminals can be switched on and off to provide a start

signal. It is not usually recommended to connect the AUX terminals directly to the generator, but to

use the 12V AUX terminals to energize the coil of a 12 Vdc automotive or similar relay.

Depicted is the OutBack FLEXware Relay Assembly, which is sold for this purpose. The relay contacts

can serve in place of the generator’s start switch. The battery shown below is depicted for clarity. In

most cases, it is part of the generator’s internal starting circuit and is not an external component.

The drawing below is one example of a possible arrangement. Specific arrangements, relays, and

other elements depend on the requirements of the installation and of the generator.

Contacts

Figure 22 Two-Wire Generator Start (12V AUX)

32 900-0021-01-00 Rev B

Page 35

Installation

Three-Wire-Start

Atkinson

Three-Wire-Start

Generator

A “three-wire-start” generator has two or more starting circuits. It usually has a separate switch or

position for cranking the generator. A three-wire generator has fewer automated functions than a

two-wire. It usually requires multiple controls for starting, running, or stopping. The inverter

terminals cannot control this type of generator without using a three-wire to two-wire conversion kit.

Atkinson Electronics

(http://atkinsonelectronics.com)

is one company that makes these kits. The

Atkinson GSCM-Mini is intended to work with OutBack inverters.

NOTE:

The conversion kit requires a 12-volt signal which the RELAY AUX terminals cannot provide.

The 12V AUX terminals may be used to operate the conversion kit, as shown in Figure 23 .

If the AUX terminals are being used for another purpose, it may be necessary for the RELAY AUX

terminals to control an external relay and 12-volt source in conjunction with the conversion kit. The

wiring and requirements for this arrangement will depend on the circumstances.

GSCM-Mini

Figure 23 Three-Wire Generator Start (Example)

900-0021-01-00 Rev B 33

Page 36

Installation

Single-Inverter AC Installations

When installing an inverter AC system, the following rules must be observed.

All overcurrent devices in building-based installations must be sized for 50 Aac or less.

All wiring in building-based installations must be sized for 50 Aac or more.

All output circuit breakers must be sized appropriately for loads and inverter wattage.

34 900-0021-01-00 Rev B

Figure 24 Single-Inverter Wiring

Page 37

Installation

IMPORTANT:

Port 1

Additional Ports

MATE3 Port

MATE3

HUB4

Stacking Connections

Stacking requires an

Multiple-Inverter AC Installations (Stacking)

Installing multiple inverters in a single AC system supports larger loads than a single inverter can

handle. This requires stacking. Stacking refers to how the inverters are wired within the system and

then programmed to coordinate activity. Stacking allows all units to work together as a single system.

The Radian Series GS8048 inverter/charger can stack up to ten units in parallel.

OutBack HUB Communications Manager, as well as a MATE3 system display.

A system of four or fewer units may use the HUB4.

A system of up to ten units requires the HUB10 or HUB10.3.

All interconnections between the products are made using CAT5 non-crossover cable.

Each inverter must be assigned a status — “master” or “slave”. The master is the primary and most

heavily used unit. The master inverter’s Remote port must connect to port 1 on the HUB.

Slave inverters provide assistance when the loads are more than the master can handle alone. Slaves

plug into ports 2 and above on the HUB. See the MATE3 manual for other port restrictions pertaining

to stacking. In general, it is always important to keep track of units and ports for programming

purposes.

Programming involves using the MATE3 to assign a status and stacking value to the inverter on each

port. These assignments can be changed at any time as long as the master is plugged into port 1.

900-0021-01-00 Rev B 35

Figure 25 OutBack HUB4 and MATE3

The master inverter must always be connected to port 1 on the HUB. Connecting it

elsewhere, or connecting a slave to port 1, will result in backfeed or output voltage

errors which will shut the system down immediately.

Installing multiple inverters without stacking them (or stacking them incorrectly) will

result in similar errors and shutdown.

Although stacking allows greater capacity, the loads, wiring, and overcurrent devices

must still be sized appropriately. Overloading may cause circuit breakers to open or

the inverters to shut down.

Page 38

Installation

24 kVA

8 kVA

8 kVA

120/240 Vac

8 kVA

Parallel Stacking (Dual-Stack and Larger)

In parallel stacking, two or more inverters are stacked to create a single, common AC bus.

The slave outputs are controlled directly by the master and cannot operate independently.

All inverters share a common input (AC source) and run loads on a common output.

Slave inverters can go into Power Save mode when not in use. The master will activate individual slaves

based on load demand. This reduces idle power consumption and improves system efficiency.

Up to ten inverters may be installed in a parallel arrangement. The example on this page shows three

inverters. The wiring diagram on the next page shows two.

120/240 Vac

120/240 Vac

120/240 Vac

Figure 26 Example of Parallel Stacking Arrangement (Three Inverters)

When installing a parallel system, the following rules must be observed.

Parallel stacking requires the MATE3 system display and a communications manager.

One inverter, and one inverter only, is always the master and is programmed as

setting. (See the MATE3 manual for programming.)

The master must be connected to port 1 of the communications manager. Other inverters must not be

selected as master.

All slave inverters, regardless of number, should be selected as

All overcurrent devices must be sized for 50 Aac or less.

All wiring must be sized for 50 Aac or more.

All output circuit breakers must be sized appropriately for loads and inverter wattage.

The AC input (generator or utility grid) must be 120/240 Vac at 60 Hz (split-phase).

When wiring the AC source to the inverters, local codes may require the inverter circuits to be located at the

opposite end of the panel from the main circuit breaker. This prevents overloading of the AC bus.

during programming.

Slave

. This is the default

Master

36 900-0021-01-00 Rev B

Page 39

Installation

Figure 27 Parallel Wiring

900-0021-01-00 Rev B 37

Page 40

Installation

Functional Test

Once the mounting, wiring, and other installation steps are completed, proceed to the Radian Series

Inverter/Charger Operator’s Manual. The Operator’s Manual has steps for system commissioning. These

include powering up and performing a functional test on the inverter system, as well as powering

down and adding new devices to an existing system.

Refer to the MATE3 Owner’s Manual for programming instructions and menus.

38 900-0021-01-00 Rev B

Page 41

A

AC Wiring ........................................................................ 23, 26

Advanced Generator Start .............................................. 29

Audience ................................................................................... 1