Page 1

250

TM

User’s Guide

Includes Mounting, Installation, and

Product Registration

Page 2

Page 3

About OutBack Power Systems

OutBack Power Systems is a leader in advanced energy conversion technology. Our products

include true sine wave inverter/chargers, maximum power point charge controllers, system

communication components, as well as breaker panels, breakers, accessories, and assembled

systems.

Notice of Copyright

FLEXware

TM

250 User’s Guide© 2007 All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER SYSTEMS:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

April, 2008 REV A

Contact Information

OutBack Power Systems

19009 62nd Ave. NE, Arlington, WA 98223

Phone (360)435-6030

Fax (360)435-6019

www.outbackpower.com

1

Page 4

Warranty Introduction

Dear OutBack Customer,

Thank you for your purchase of OutBack products. We make every eort to assure our power

conversion products will give you long and reliable service for your renewable energy system.

As with any manufactured device, repairs might be needed due to damage, inappropriate use,

or unintentional defect. Please note the following guidelines regarding warranty service of

OutBack products:

• Any and all warranty repairs must conform to the terms of the warranty.

• All OutBack equipment must be installed according to their accompanying instructions and

manuals with specied over-current protection in order to maintain their warranties.

• The customer must return the component(s) to OutBack, securely packaged, properly

addressed, and shipping paid. We recommend insuring your package when shipping.

Packages that are not securely packaged can sustain additional damage not covered by the

warranty or can void warranty repairs.

• There is no allowance or reimbursement for an installer’s or user’s labor or travel time

required to disconnect, service, or reinstall the damaged component(s).

• OutBack will ship the repaired or replacement component(s) prepaid to addresses in the

continental United States, where applicable. Shipments outside the U.S. will be sent freight

collect.

• In the event of a product malfunction, OutBack cannot bear any responsibility for

consequential losses, expenses, or damage to other components.

Please read the full warranty at the end of this manual for more information.

2

Page 5

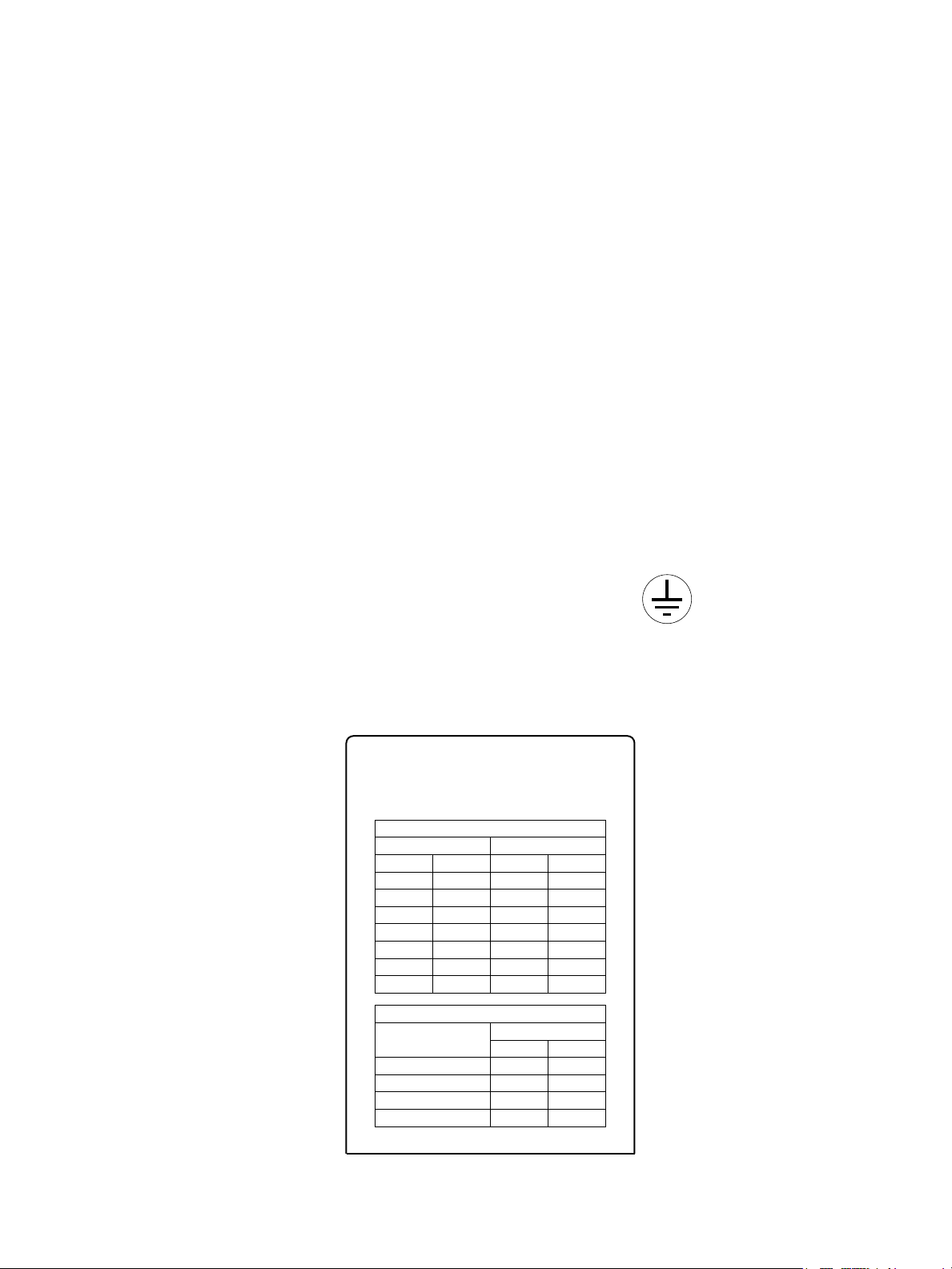

IMPORTANT SAFETY INSTRUCTIONS

USE ONLY WITH COPPER

CONDUCTORS RATED

75° C MINIMUM

TORQUE DATA FOR SCREWDRIVER LUGS

mm²

AWG

WIRE SIZE TORQUE

In Lbs

Nm

TORQUE DATA FOR BREAKER LUGS

BREAKER STUD

TORQUE

In Lbs

Nm

14 - 10

8

6 - 4

3

2

1

1 / 0

2.1 - 5.3

8.4

13.3 - 21.2

26.7

33.6

42.4

53.5

20

25

35

35

40

50

50

2.3

2.8

4.0

4.0

4.5

5.7

5.7

20 2.3

35 4.0

50 5.7

225 25.5

1/4 - 20

M8

5/16 - 18

3/8 - 16

DIN RAIL MOUNTED BREAKER TERMINALS - 22 In Lbs

This manual contains important instructions for the FLEXware 250 that must be followed

during its installation and future maintenance for your safety and the integrity of the product.

SAVE THESE INSTRUCTIONS!

Requirements and Warnings

The OutBack Power Systems FLEXware 250 is listed by ETL as an accessory enclosure for

OutBack FX, GTFX, GVFX, and VFX Series Inverter/Chargers to UL standard UL 1741.

This enclosure is intended for battery circuits congured for 12 to 48 volts nominal.

Grounding Instructions – The frame of this enclosure should be connected to a grounded,

permanent wiring system. The AC and DC circuits are not bonded to the FLEXware 250

chassis. System grounding, when required by sections 690.41, 690.42, and 690.43 of the

National Electric Code, ANSI/NFPA 70, is the responsibility of the installer. For most installations,

the negative battery conductor should be bonded to the grounding system at one (and only

one) point in the DC system. All installations should comply with all national and local codes

and ordinances.

The equipment ground on FLEXware 250 is marked with this symbol:

FLEXware is designed for indoor mounting only with appropriate fasteners and a secure

mounting surface that can handle the full weight of an assembled system.

3

Page 6

Welcome to OutBack Power Systems’ FLEXware 250

FLEXware is a convenient all-aluminum power system oering simple, code-compliant

installation of OutBack power electronics components. Three versions of FLEXware are

available:

• FLEXware 250 for single FX Series Inverter/Charger installations along with the desired AC

and DC disconnects

• FLEXware 500, which supports up to two FXs and two OutBack Series Charge Controllers,

accommodating both split-phase and/or higher power output as needed

• FLEXware 1000 accommodates up to four FXs and four OutBack Series Charge Controllers

Note: Both the FLEXware 500 and the FLEXware 1000 power systems provide locations for

FW-X240 Auto-Transformers, multiple DC shunts and other essential components required in

higher kW systems.

FLEXware 250 Parts List

The FLEXware 250 consists of an aluminum enclosure which can be used for either the AC or

DC side of an FX Series Inverter/Charger. Each FLEXware 250 includes:

• Installed ground bus bar

• Breaker Guard (for DC installations)

• Hardware Kits for mounting to an FX and for securing AC and DC breakers (refer to the

hardware bag label for a complete listing of parts)

• Cover Plate

• Breaker Label Kit

The chassis itself features conduit knockouts (see Figures 2-5) and knockouts for AC breakers

and DC breakers.

• DC installations include a slot for either a 175 or 250 amp OBDC breaker and slots for four

load breakers.

• AC installations allow for the optional 120/230 VAC Input/Output/Bypass Assembly

(IOB) kit.

Optional Parts:

• FW-IOB (Input/Output/Bypass Assembly) Kit for 120/230 VAC.

4

Page 7

Getting to Know FLEXware 250

When mounting the FLEXware 250, the various breaker

slots must be in a vertical (forward facing) position

and cannot face downward or upward. Otherwise, the

breakers can malfunction.

The FLEXware 250 also accommodates a shelf

or at surface mounting as long as no breaker

slots are facing downward or upward.

FLEXware 250 mounted

as an AC enclosure

DC Breaker Guard

Figure 1: FLEXware 250

FLEXware 250 mounted

as a DC enclosure (shown

with cover plate)

5

Page 8

DC side

Figure 2: FW250 Enclosure

AC side

Unthreaded standos for attaching to FX

Unthreaded standos insert

into the AC or DC end of the FX

Inverter/Charger’s top casting

mounting holes.

Bottom 2” knockout

Ground Bus Bar

Figure 3: FLEXware 250 top view

6

Page 9

DC input breaker slot

and Breaker Guard

mounting holes

Unthreaded standos

½” conduit knockouts

Figure 4: FLEXware 250 DC side

DC breaker

slots

2” conduit

knockout

AC breaker slots

Bypass Slide Plate

mounting holes

2” conduit knockout

Figure 5: FLEXware 250

AC side

AC receptacle

knocko

(o-grid

systems only)

Unthreaded

standos

3/4” counduit

knockout

1” conduit

knockout

7

Page 10

AC side

screw holes

DC side

screw holes

Remove these

screws to install

the FLEXware 250

on the AC side of

the FX (unthreaded

standos insert

into screw holes).

Figure 6: FLEXware 250 AC and DC chassis mounting locations

Unthreaded stando

Remove these

screws to install

the FLEXware 250

on the DC side of

the FX (unthreaded

standos insert into

screw holes).

Screw hole

Figure 7: Side view of FLEXware 250 tting onto AC side of an FX Series Inverter/Charger

8

Page 11

Installing the FLEXware 250

With the FX secured to a surface (see FX Series Inverter/Charger Installation Manual for details),

the FLEXware 250 installs on either the DC or the AC side of the FX.

To install the FLEXware 250:

• Remove the cover plate screws and cover plate.

• Verify which knockouts will be removed for the installation and remove those knockouts.

• Remove only the two M5 X 12mm screws that secure the FX’s upper and lower casing

halves on whichever side (AC or DC) you rst install the FLEXware 250.

• Insert the unthreaded standos into the holes on the FX and then insert two M5 X 25mm

screws, included with the FLEXware 250, into the standos and tighten.

• After all wiring has been completed, install the DCC and securing with four M5 X 12mm

screws (included with the DCC).

• Install each FLEXware 250 top cover plate and secure the #10 X 3/8” sheet metal screws.

For AC wiring instructions for the FLEXware 250, please see the schematics in the individual

AC Input/Output/Bypass Assembly (IOB) kits.

Figure 8: FLEXware 250 Dimensions

9

Page 12

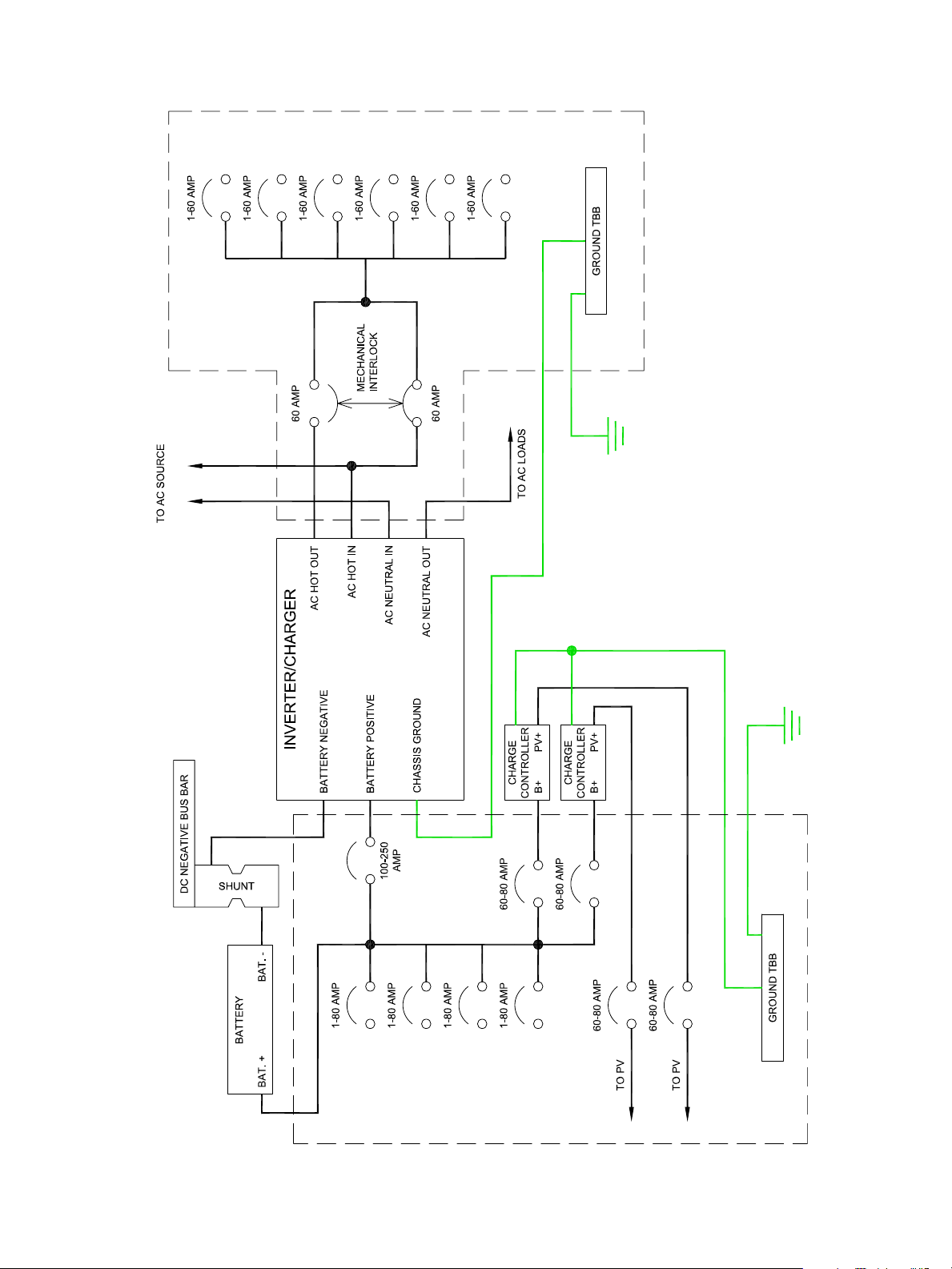

The dashed lines represent the FLEXware 250 enclosure. This drawing

shows two units—one for an AC application and one for a DC application.

10

Figure 9: FLEXware 250-DC Wiring Diagram

Page 13

11

Page 14

250

Product Registration

Please take a moment to register and provide

us with some important information in order to

improve our products.

Complete this form and return it to:

Outback Power Systems Inc.

19009 62nd Avenue NE

Arlington, WA 98223

Note: Complete one form for all installed FLEXware products.

FLEXware 250 Product Registration

System Owner

Name: _______________________________ Address: ______________________________

City, State, Zip Code: ____________________ Country: ______________________________

Telephone Number: _____________________ E-mail: ________________________________

Installer

Company: ____________________________ Contractor Number:______________________

Installer Address: _______________________ Installer City, State, Zip: ___________________

Installer E-mail: _________________________

System

System Install/Commission Date: __________

Please circle type of application:

O-Grid Grid-Interactive AC Coupled Backup Mobile

Enclosure Model Number(s): ______________ OB Kit Model Number: ___________________

Sold by: ______________________________ Purchase Date: ________________________

The system is equipped with (circle one):

FW-X240 PSX-240 PSX-240-Relay

Please circle the three most important factors aecting your purchase decision:

Price Product Reputation Product Features Reputation of OutBack Power Systems Value

I am interested in receiving information concerning OutBack Power Systems products and events

(circle one):

Yes No

12

Revision.2007-11-12

Page 15

13

Page 16

Corporate Oce

19009 62nd Avenue NE

Arlington, WA 98223 USA

360-435-6030

European Sales Oce

C/ Castelló, 17

08830 - Sant Boi de Llobregat

BARCELONA, España

+34.93.654.9568

www.outbackpower.com

900-0088-01-00 REV A

Loading...

Loading...