Page 1

TM

power ONE

Installation Manual

Page 2

About OutBack Power Systems

OutBack Power Systems is a leader in advanced energy conversion technology. Our products include

true sine wave inverter/chargers, maximum power point charge controllers, system communication

components, as well as breaker panels, breakers, accessories, and assembled systems.

Contact Information

Telephone: +1.360.435.6030 (North America)

+1.360.618.4363 (Technical Support)

+1.360.435.6019 (Fax)

Address: North America

19009 62nd Avenue NE

Arlington, WA USA

E-mail: Support@outbackpower.com

Web Site: www.outbackpower.com

+34.93.654.9568 (Barcelona, Spain)

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER SYSTEMS:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL

OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Warranty Summary

OutBack Power Systems Inc. warrants that the products it manufactures will be free from defects in

materials and workmanship for a period of five (5) years subject to the conditions set forth in the

warranty detail found inside the back cover of this manual.

OutBack Power Systems cannot be responsible for system failure, damages, or injury resulting from

improper installation of their products.

Notice of Copyright

FLEXpower ONE™ Installation Manual ©October 2009 by OutBack Power Systems. All Rights Reserved.

Trademarks

FLEXpower ONE is a registered trademark of OutBack Power Systems. OutBack Power is a registered

trademark of OutBack Power Systems.

Date and Revision

October 2009, Revision A

Part Number

900-0095-01-00 Rev A

Page 3

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS!

This manual contains important safety instructions for the FLEXpower ONE. Read all instructions and

cautionary markings on the FLEXpower ONE and on any accessories or additional equipment included

in the installation. Failure to adhere to these instructions could result in severe shock or possible

electrocution. Exercise extreme caution at all times to prevent accidents.

Symbols Used

Symbol Description

Ground

AC Current

DC Current

Single-Phase

∅

Sine Wave

WARNING: Hazard to Human Life

This type of notation indicates that the hazard could be harmful to human life.

CAUTION: Hazard to Equipment

This type of notation indicates that the hazard may cause damage to

the equipment.

IMPORTANT:

This type of notation indicates that the information provided is important to

the installation, operation and/or maintenance of the equipment. Failure to

follow the recommendations in such a notation could result in voiding the

equipment warranty.

Audience

These instructions are for use by qualified personnel who meet all local and governmental code

requirements for licensing and training for the installation of electrical power systems with AC and DC

voltage up to 240 Vac and 150 Vdc.

900-0095-01-00 Rev A 1

Page 4

Important Safety Instructions

Definitions

Off-Grid

On-Grid

utility grid.

Grid-tie, Grid-interactive, Grid-intertie

capable of returning (selling) electricity back to the utility grid.

Table 1 Acronyms

Acronym Definition

AC Alternating Current

ANSI American National Standards Institute

DC Direct Current

FCC Federal Communications Commission (North America)

GND Ground

IEEE Institute of Electrical and Electronics Engineers

– Utility Grid Power

– Utility Grid power is available for use. Does not imply the ability to sell power back to the

available for use.

is not

– Utility Grid Power is available for use and the system is

N AC Neutral

NEC National Electric Code (North America)

NFPA National Fire Protection Association

OSHA Occupational Safety and Health Association

PV Photovoltaic

RE Renewable Energy

UL Underwriters Laboratory

General Safety

WARNING: Limitations on Use

This equipment is NOT intended for use with life support equipment or other

medical equipment or devices.

CAUTION: Equipment Damage

Only use components or accessories recommended or sold by OutBack Power

Systems or its authorized agents.

IMPORTANT:

Do not attempt to install this equipment if it appears to be damaged in any

way. See the Troubleshooting Section for instructions on how to return the

equipment if you know, or suspect, it is damaged.

2 900-0095-01-00 Rev A

Page 5

Personal Safety

WARNING: Personal Injury

This equipment weighs approximately 98 lbs (44.5 kg). Use safe lifting

techniques when lifting this equipment as prescribed by the Occupational

Safety and Health Association (OSHA) or other local codes.

Use standard safety equipment such as safety glasses, ear protection, steeltoed safety boots, safety hard hats, etc. as prescribed by the Occupational

Safety and Health Association (or other local codes) when working on this

equipment.

Use standard safety practices when working with electrical equipment

(e.g., remove all jewelry, use insulated tools, wear cotton clothing, etc.)

Never work alone when installing or servicing this equipment. Have

someone nearby that can come to your aid if necessary.

FLEXpower ONE System Safety

WARNING: Lethal Voltage

Review the system configuration to identify all possible sources of energy.

Ensure ALL sources of power are disconnected before performing any

installation or maintenance on this equipment. Confirm that the terminals

are de-energized using a validated voltmeter (rated for a minimum

1000 Vac and 1000 Vdc) to verify the de-energized condition.

Do not perform any servicing other than that specified in the installation

instructions unless qualified to do so or as instructed to do so by OutBack

Power Systems Technical Support personnel.

Important Safety Instructions

900-0095-01-00 Rev A

WARNING: Burn Hazard

Internal parts can become hot during operation. Do not remove the cover

during operation or touch any internal parts. Be sure to allow them sufficient

time to cool down before attempting to perform any maintenance.

WARNING: Fire Hazard

In residential installations: check for multi-wire branch circuit wiring at the

location for the installation. A possible fire hazard can exist if 120 Vac only

sources (such as inverters and generators) are wired incorrectly into

120/240 Vac panels containing multi-wire branch circuits. Consult the local

electric code for assistance.

Do not place combustible or flammable materials within 12 feet (3.7 m) of

the equipment.

Use only the recommended cable sizes (or greater) for AC and DC

conductors in compliance with local codes. Ensure all conductors and

connections are in good condition. Do not operate the unit with damaged

or substandard cabling.

3

Page 6

PV Safety

Important Safety Instructions

CAUTION: Equipment Damage

When connecting cables from the inverter to the battery terminals, ensure

the proper polarity is observed. Connecting the cables incorrectly can

damage or destroy the equipment.

Thoroughly inspect the equipment prior to energizing. Verify that no tools

or equipment have been inadvertently left behind.

Ensure clearance requirements are strictly enforced and that all vents are

clear of obstructions that can prevent proper air flow around or through

the unit.

Sensitive electronics inside the equipment can be destroyed by static

electricity. Be sure to discharge any static electricity built up before

touching the equipment and wear appropriate protective gear.

WARNING: Shock Hazard

Photovoltaic (PV) arrays can be energized with minimal ambient light available.

Therefore to ensure a safe disconnect from the system, be sure to install a PV

disconnect, breaker, or accessible fuse box (depending on local code

requirements).

CAUTION: Equipment Damage

PV Arrays must be wired with correct polarity (positive-to-positive, negative-tonegative). Connecting the cables incorrectly can damage or destroy the

equipment.

Battery Safety

WARNING: Electrocution Hazard

Use the battery types recommended by OutBack Power Systems. Follow

the battery manufacturer’s recommendations for installation and

maintenance.

Ensure clearance requirements are strictly enforced around batteries.

Ensure the area around the batteries is well ventilated and clean of debris.

Always use insulated tools. Avoid dropping tools onto batteries or other

electrical parts.

Keep plenty of fresh water and soap nearby in case battery acid contacts

skin, clothing, or eyes.

If you need to remove a battery, always remove the ground terminal from

the battery first. Make sure all accessories are turned off so you don’t cause

a spark.

If a remote or automatic generator control system is used, disable the

automatic starting circuit and/or disconnect the generator from its starting

battery while performing maintenance to prevent accidental starting.

4 900-0095-01-00 Rev A

Page 7

Important Safety Instructions

WARNING: Fire or Burn Hazard

Ensure the cables are properly sized. Failure to size the cables properly can

result in a Fire Hazard.

Wear complete eye protection and clothing protection when working with

batteries. Avoid touching your eyes while working near batteries.

If battery acid contacts skin or clothing, wash immediately with soap and

water. If acid enters the eye, immediately flood it with running cold water

for at least 20 minutes and get medical attention immediately.

Never smoke or allow a spark or flame near the batteries.

Keep plenty of fresh water and soap nearby in case battery acid contacts

skin, clothing, or eyes.

WARNING: Explosion Hazard

Never charge a frozen battery. A flooded battery discharged to 40% SOC (stateof-charge) can freeze at or below -8.9° C (16° F).

CAUTION: Equipment Damage

When connecting cables from the DC input breaker to the battery terminals,

ensure proper polarity is observed (positive-to-positive, negative-to-negative).

Connecting the cables incorrectly can damage or destroy the equipment.

IMPORTANT:

Baking Soda neutralizes lead-acid battery electrolyte.

Vinegar neutralizes NiCad and NiFe battery electrolyte.

Have a supply of either substance readily available if using these types

of batteries.

Regulatory References

National Electric Code (NEC) Article 690, (current edition)

Canadian Electrical Code, Part I (CSA 107.1)

UL 1741-2005 Static Inverter and Charge Controllers for Use in Photovoltaic Power Systems

American National Standards Institute/National Fire Protection Agency (ANSI/NFPA) 70

Recycling Information

IMPORTANT: Recycle Electronics and Batteries

Batteries are considered hazardous waste and must be recycled according to

local jurisdiction. Inverters and other electronics contain metals and plastics

that can (and should) be recycled. The following are some websites and phone

numbers that provide information and “how” and “where” to recycle batteries

and other electronic equipment.

900-0095-01-00 Rev A

OutBack Power Systems strongly encourages you to learn about recycling and

to dispose of recyclable items accordingly. The Earth, and OutBack Power

Systems, thanks you for that effort.

5

Page 8

Earth 911

Web site: www.Earth911.com

Address: 14646 N. Kierland Blvd., Suite 100

Scottsdale, AZ 85254

Phone: +1.480.337.3025 (direct)

Environmental Protection Agency, USA

Web site: www.epa.gov/recyclecity/

Phone: +1.415.947.8000

(Monday –Friday 8:00 AM to 12:00 PM and 1:00 PM to 4:00 PM PST)

Email: r9.recyclecity@epa.gov

Keep America Beautiful, USA

Web site: www.kab.org/

Address: 1010 Washington Boulevard

Stamford, CT 06901

Phone: +1.203.659.3000 (Main number)

Fax: +1.203.659.3001

Email: info@kab.org

Important Safety Instructions

Office of Waste Management, Canada

Address: Office of Waste Management

Conservation and Protection

Environment Canada

Ottawa, Ontaro K1A 0H3

Phone: +1. 819.997.2800

Web site: http://www.portaec.net/library/recycling/recycling_in_canada.html

National Institute of Recyclers, Mexico

Web site: http://www.inare.org.mx/

Email: a57841279@prodigy.net.mx, margarita@inare.org.mx

Phone: 55.57.85.9160

Fax:

55.57.84.1279

EuroRecycle.net

The following website provides general information about Recycling in Europe. It also provides a list

of companies and organizations that provide recycling information or assistance.

Web site: http://euro.recycle.net/assn/index.html

E-mail: http://euro.recycle.net/cgi-bin/feedback1.cgi?w=27

(This is an on

line form providing a means to contact

the owners of the website.)

6 900-0095-01-00 Rev A

Page 9

Table of Contents

Important Safety Instructions ...................................................................1

Symbols Used ........................................................................................................................................................................1

Audience .................................................................................................................................................................................1

Definitions...............................................................................................................................................................................2

General Safety .......................................................................................................................................................................2

Personal Safety......................................................................................................................................................................3

FLEXpower ONE System Safety.......................................................................................................................................3

PV Safety..................................................................................................................................................................................4

Battery Safety.........................................................................................................................................................................4

Regulatory References........................................................................................................................................................5

Recycling Information ........................................................................................................................................................5

Earth 911 .............................................................................................................................................................................................6

Environmental Protection Agency, USA...................................................................................................................................6

Keep America Beautiful, USA .......................................................................................................................................................6

Office of Waste Management, Canada .....................................................................................................................................6

National Institute of Recyclers, Mexico..................................................................................................................................... 6

EuroRecycle.net................................................................................................................................................................................6

Introduction.............................................................................................11

Components .......................................................................................................................................................................12

Applications ........................................................................................................................................................................ 13

On-Grid Applications ....................................................................................................................................................................13

Off-Grid Applications....................................................................................................................................................................14

Grid-Interactive Applications.....................................................................................................................................................14

PV Array Planning ..........................................................................................................................................................................15

Battery Bank Planning..................................................................................................................................................................15

Generator Requirements................................................................................................................................................ 16

Preparation.......................................................................................................................................................................... 17

Tools Required ................................................................................................................................................................................17

Materials Required.........................................................................................................................................................................17

Accessories.......................................................................................................................................................................................17

Location.............................................................................................................................................................................................17

Environmental.................................................................................................................................................................................17

Clearance and Access Requirements .........................................................................................................................18

Dimensions..........................................................................................................................................................................19

Conduit and Knockout Preparation............................................................................................................................ 20

Mounting.............................................................................................................................................................................. 21

Removing the Covers....................................................................................................................................................... 24

Accessing the Wiring Compartments ........................................................................................................................ 25

Wiring ....................................................................................................................................................................................26

Grounding ........................................................................................................................................................................................26

DC Connections..............................................................................................................................................................................27

900-0095-01-00 Rev A 7

Page 10

Table of Contents

AC Connections ..............................................................................................................................................................................31

Functional Test/Commissioning..................................................................................................................................33

Pre-startup Procedures ................................................................................................................................................................33

Energize/Startup ............................................................................................................................................................................33

Reassembling the Enclosures .......................................................................................................................................35

Operation.................................................................................................39

Setting Basic Parameters ................................................................................................................................................ 39

MATE2 Settings...............................................................................................................................................................................39

Charger Settings.............................................................................................................................................................................39

Setting Time, Date & Display on the MATE2.........................................................................................................................40

Selecting the AC Source and AC Input Limit on the Inverter..........................................................................................42

Accessing the Advanced Menu.................................................................................................................................................43

Setting Battery Amp-Hours and Return Amps using the FLEXnet DC Monitor ........................................................44

Setting Charging Parameters.....................................................................................................................................................45

De-energize/Shutdown ...............................................................................................................................................................46

Specifications...........................................................................................49

Feature Matrix .................................................................................................................................................................... 49

Electrical Specifications, 120 Vac/60 Hz Models .................................................................................................... 50

Mechanical Specifications, 120 Vac/60 Hz Models................................................................................................ 50

Electrical Specifications, 230 Vac/50 Hz Models .................................................................................................... 51

Mechanical Specifications, 230 Vac/50 Hz Models................................................................................................ 51

Surge Protector.................................................................................................................................................................. 52

LEDs ....................................................................................................................................................................................................52

Renewable Energy Input & Storage............................................................................................................................53

PV Sizing............................................................................................................................................................................................53

Battery Bank Sizing........................................................................................................................................................................53

Amp-Hour Requirements............................................................................................................................................................53

Wiring Configurations .............................................................................59

FLEXpower ONE with FLEXnet DC Monitor and GFDI.......................................................................................... 61

FLEXpower ONE with FLEXnet DC Monitor Only (no GFDI)............................................................................... 62

FLEXpower ONE with GFDI Only (no FLEXnet DC Monitor)...............................................................................63

FLEXpower ONE (no FLEXnet DC Monitor or GFDI) .............................................................................................. 64

Warranty ..................................................................................................65

How to Arrange for Warranty Service ........................................................................................................................ 66

Return Material Authorization (RMA)......................................................................................................................................66

Returning Product to OutBack ..................................................................................................................................................66

Index ........................................................................................................67

8 900-0095-01-00 Rev A

Page 11

Table of Contents

List of Tables

Table 1 Acronyms.............................................................................................................................................................................. 2

Table 2 Basic Components of a FLEXpower ONE System..................................................................................................12

Table 3 Ground Conductor Size and Torque Requirements.............................................................................................26

Table 4 DC Conductor Size and Torque Requirements......................................................................................................27

Table 5 AC Conductor Size and Torque Requirements......................................................................................................31

Table 6 Feature Matrix...................................................................................................................................................................49

Table 7

Table 8 Worksheet

Worksheet for Determining Average Daily Load in Amp-hours

for Determining Battery Bank Size

.................................................................................................57

............................................................56

900-0095-01-00 Rev A 9

Page 12

Table of Contents

List of Figures

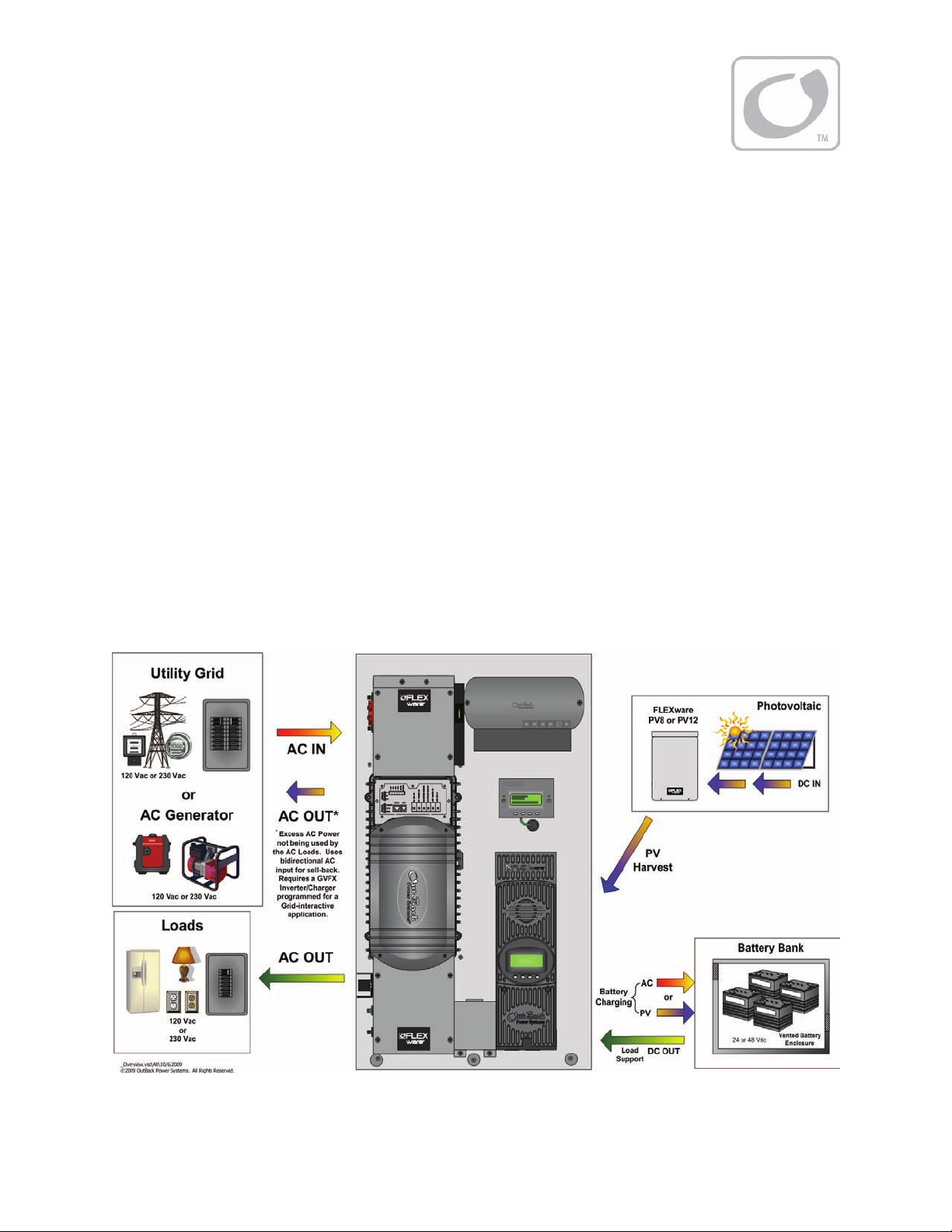

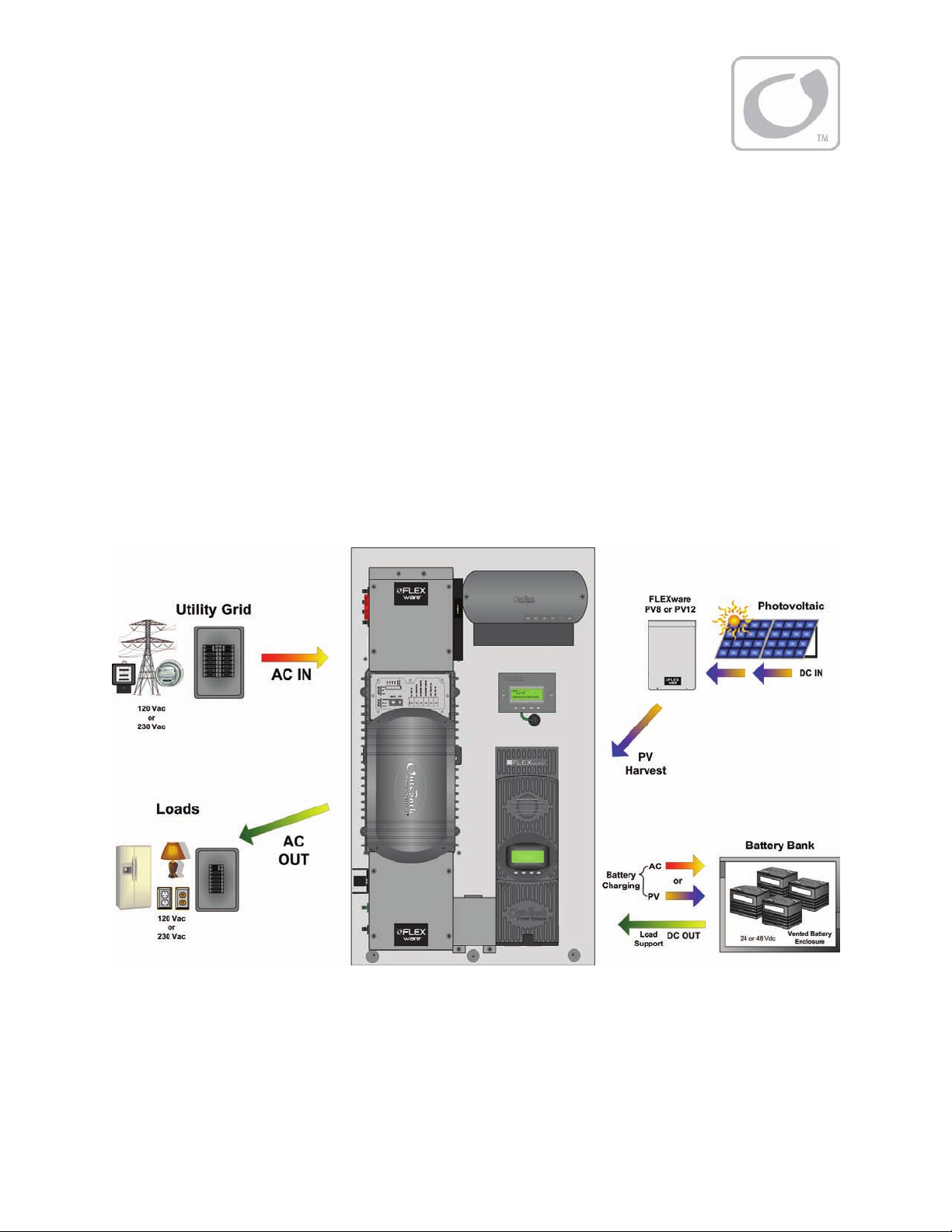

Figure 1 FLEXpower ONE System Overview............................................................................................................................11

Figure 2 Basic Components of a FLEXpower ONE System..................................................................................................12

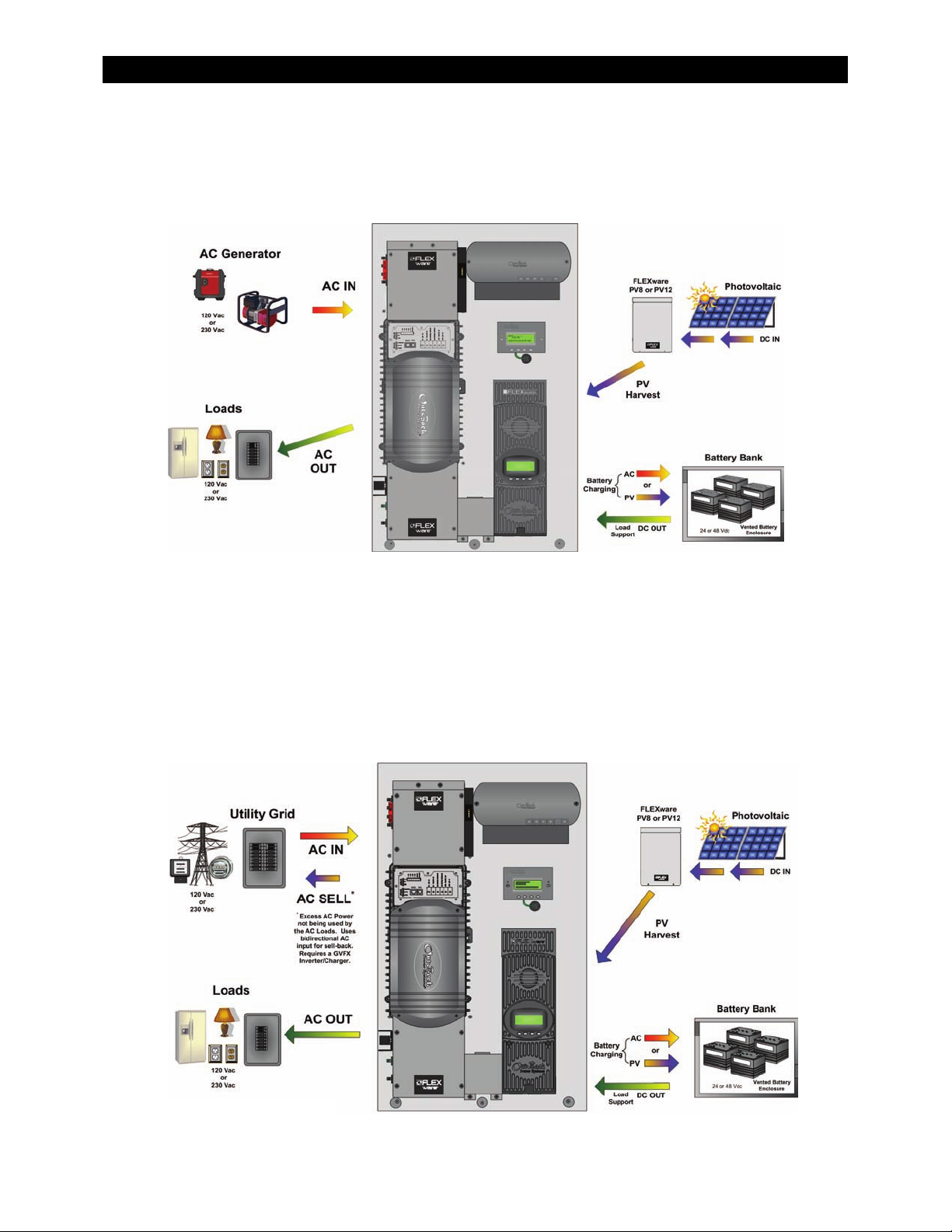

Figure 3 On-Grid Applications (Example).................................................................................................................................13

Figure 4 Off-Grid Applications (Example).................................................................................................................................14

Figure 5 Grid-Interactive Applications (Example)..................................................................................................................14

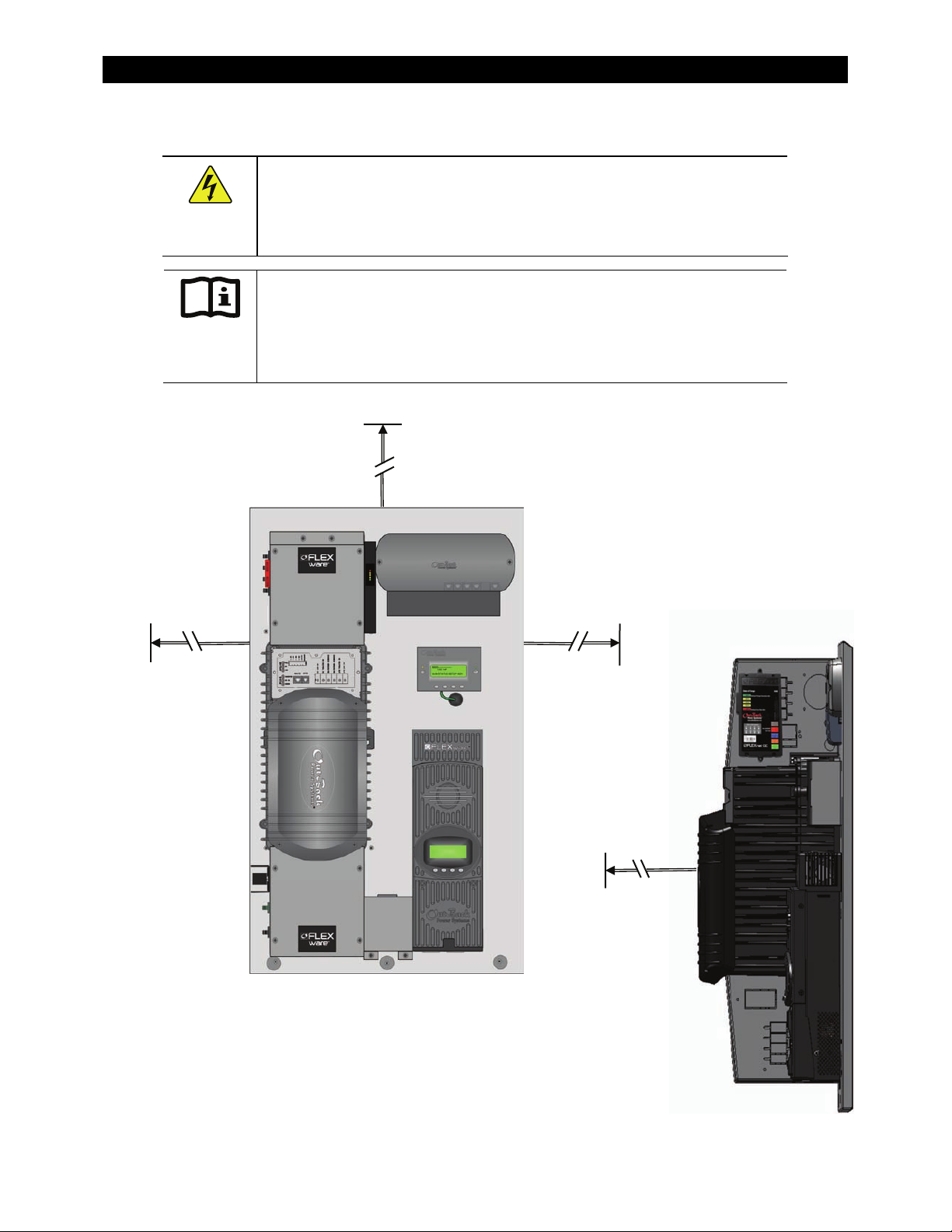

Figure 6 Clearance and Access Requirements........................................................................................................................18

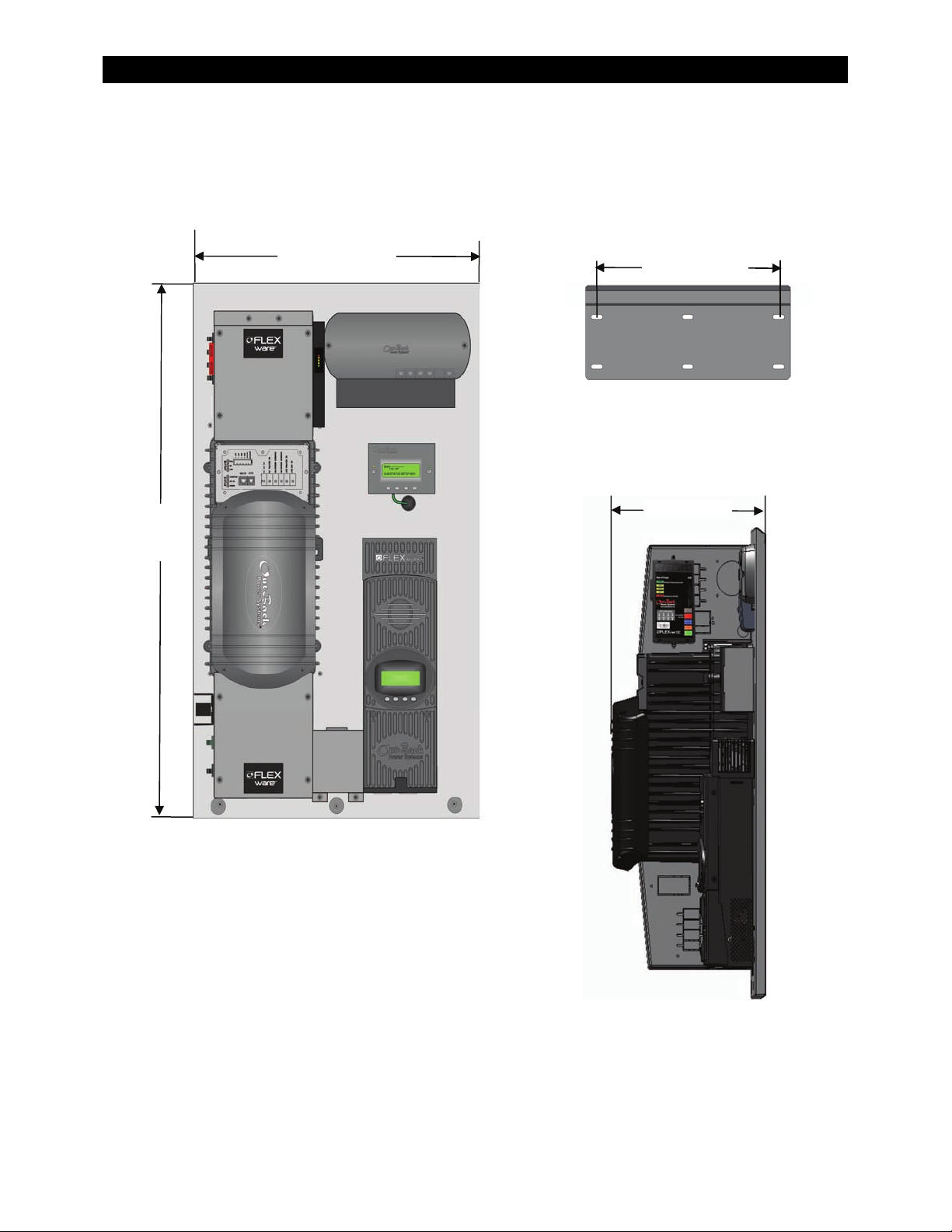

Figure 7 Dimensions........................................................................................................................................................................19

Figure 8 Conduit and Knockout Preparation...........................................................................................................................20

Figure 9 Installing the Mounting Bracket .................................................................................................................................22

Figure 10 Attaching the Mounting Plate to the Mounting Bracket ...................................................................................23

Figure 11 Removing the Covers.....................................................................................................................................................24

Figure 12 Wiring and Breaker Compartment.............................................................................................................................25

Figure 13 Ground Connections......................................................................................................................................................27

Figure 14 Battery Connections with the FLEXnet DC Monitor.............................................................................................28

Figure 15 Battery Connections without the FLEXnet DC.......................................................................................................29

Figure 16 PV Connections with a FLEXnet DC Monitor..........................................................................................................30

Figure 17 AC IN Connections...........................................................................................................................................................31

Figure 18 AC OUT Connections......................................................................................................................................................32

Figure 19 Energize Procedures.......................................................................................................................................................33

Figure 20 Functional Test Procedures for Initial Startup........................................................................................................34

Figure 21 Replacing the Raceway and FLEXmax 80 Front Cover........................................................................................35

Figure 22 Replacing the Inverter’s AC Terminal Access Cover.............................................................................................35

Figure 23 Replacing the AC Enclosure Front Cover.................................................................................................................36

Figure 24 Replacing the AC Enclosure Top Cover....................................................................................................................36

Figure 25 Replacing the DC Enclosure Front Cover.................................................................................................................37

Figure 26 Replacing the DC Cover.................................................................................................................................................37

Figure 27 MATE2 Setup Screen (Page 1) .....................................................................................................................................40

Figure 28 MATE2 Setup Screen (Page 2 and 3) .........................................................................................................................41

Figure 29 Inverter Setup Screen – Selecting AC Source.........................................................................................................42

Figure 30 Accessing the Advanced Menus.................................................................................................................................43

Figure 31 Setting Battery Amp-hours and Return Amps.......................................................................................................44

Figure 32 Setting Input Source and Current Limit...................................................................................................................45

Figure 33 Shutdown Procedures....................................................................................................................................................46

Figure 34 Functional Test Procedures to Confirm the Unit is De-energized...................................................................47

Figure 35 FLEXpower ONE with FLEXnet DC Monitor and GFDI.........................................................................................61

Figure 36 FLEXpower ONE with FLEXnet DC Monitor Only (No GFDI)..............................................................................62

Figure 37 FLEXpower ONE with GFDI Only (no FLEXnet DC Monitor)..............................................................................63

Figure 38 FLEXpower ONE (no FLEXnet DC Monitor or GFDI).............................................................................................64

10 900-0095-01-00 Rev A

Page 13

Introduction

Thank you for choosing a FLEXpower ONE System from OutBack Power Systems. FLEXpower ONE is

an integrated power system solution designed to be quick to install and easy to use.

The FLEXpower ONE System is intended for off-grid and on-grid applications up to 3.6 kW. It is

intended for use with photovoltaic (PV) modules for harvesting energy and a battery bank for energy

storage. FLEXpower ONE can also be configured as “Grid-interactive” meaning that excess energy

(energy that exceeds usage) will be returned to the Grid (Sell Mode).

The FLEXpower ONE System is designed with the following features:

3.5 kW and 3.6 kW units.

120 Vac/60 Hz configurations and 230/50 Hz configurations

Rated for Indoor Installations

Includes mounting bracket for wall-mounting

Charge controller uses MPPT technology to maximize the harvest from solar modules

Grid-interactive capable (requires a configuration that features a GVFX Inverter)

Battery status monitor takes independent shunt measurements of PV and inverter power

Includes OutBack’s Surge Protector for additional protection against damaging power surges

Figure 1 FLEXpower ONE System Overview

900-0095-01-00 Rev A 11

Page 14

Introduction

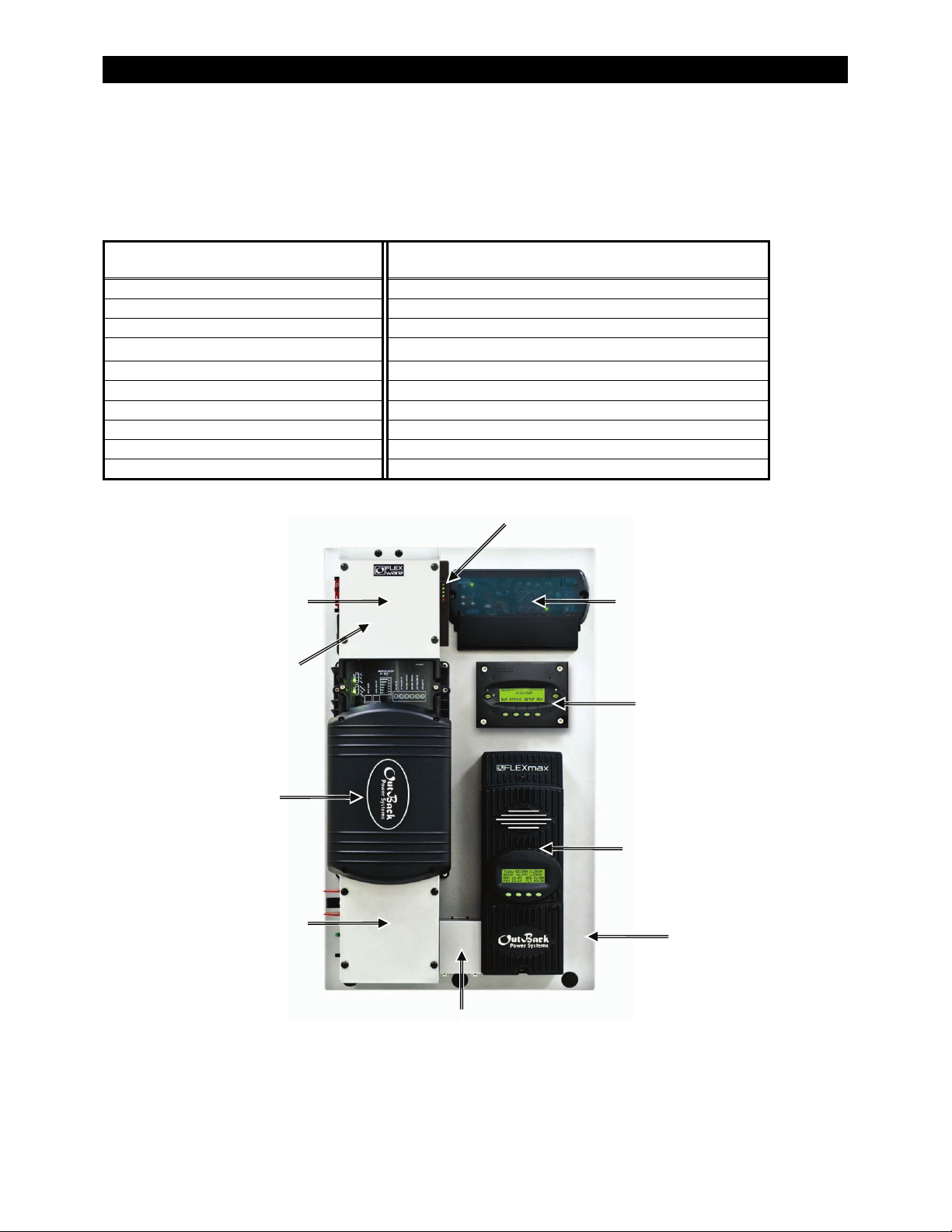

Components

A complete FLEXpower ONE is composed of the following components. See page 49 for details on

specific configurations.

Table 2 Basic Components of a FLEXpower ONE System

Components Documentation

FX Series Inverter/Charger

Mounting Plate

(with mounting bracket)

(VFX or GVFX)

FLEXpower ONE Installation Manual

(this book)

MATE Remote Control and Display

AC Enclosure

DC Enclosure

(120 V-NA or 230 V-EU)

(125, 175, or 250A)

MATE Installation and User’s Manual

Additional Reference Documents

FLEXnet DC Battery Monitor FLEXnet DC Monitor

FLEXmax 80 Charge Controller FX or Grid-Interactive Programming Manual

Raceway FLEXmax 80 User’s Manual

HUB4 Communication Manager HUB4 Communication Manager User’s Manual

FLEXware Surge Protector

FLEXnet DC Battery Monitor

FW250-AC-120V-NA

Or

FW250-AC-230V EU

FLE

e Surge Protector

Xwar

(mounted under AC cover)

HUB4 Communication Manager

MATE2 Remote Control

FX Series

Inverter/Charger

FLEXmax 80 Charge Controller

FW250-DC-125,

FW250-DC-150,

or

FW250-DC 250

Raceway

Mounting Plate

Figure 2 Basic Components of a FLEXpower ONE System

12 900-0095-01-00 Rev A

Page 15

Planning

Applications

The FLEXpower ONE is intended for on-grid, off-grid, and grid-interactive applications. It is

designed to use photovoltaic (PV) panels to harvest solar energy and a battery bank to store the

harvested energy.

On-Grid Applications

In on-grid applications, the FLEXpower ONE can use the grid power as the primary power source or as

the backup source of power. If the FLEXpower ONE is used as backup to the grid, the FLEXpower ONE

will take over when the grid fails. If the FLEXpower ONE is used as the primary source, the grid power

will be used when the batteries have been drained. In this situation, the AC power or PV harvest can

be used to recharge the battery bank.

Figure 3 On-Grid Applications (Example)

900-0095-01-00 Rev A 13

Page 16

Planning

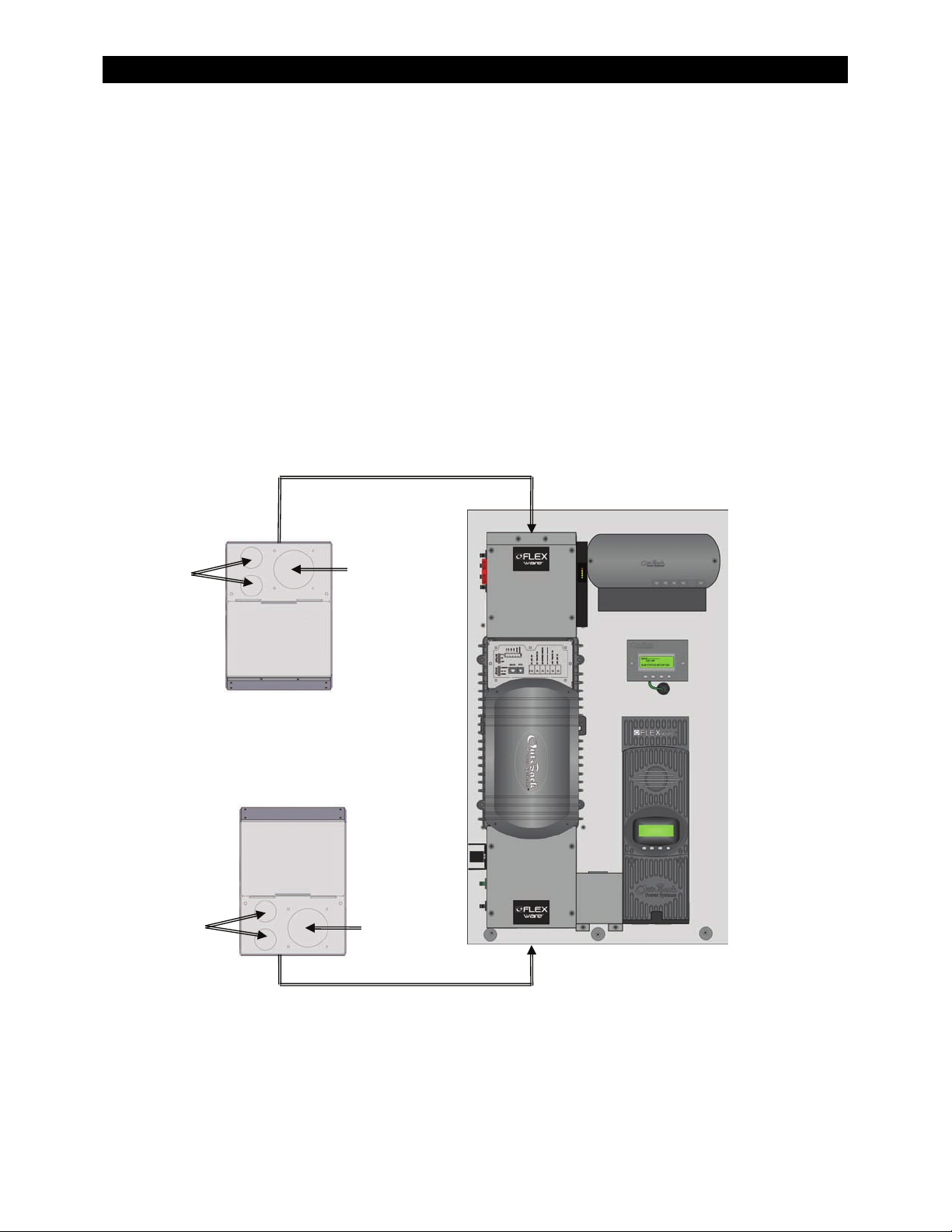

Off-Grid Applications

In off-grid applications, the FLEXpower ONE can use the harvested energy from the battery bank as

the primary power source. An AC generator can also be connected to support the system

when required.

Figure 4 Off-Grid Applications (Example)

Grid-Interactive Applications

In grid-interactive applications, grid power is used to run the loads. When excess PV is available from

the batteries, the FLEXpower ONE supports those loads with the PV. When the PV exceeds the load

requirements, the FLEXpower ONE sells that excess power back through its input, to the utility grid.

When the utility grid is not available, the FLEXpower ONE takes over to run the loads with PV and

energy stored in the battery bank.

Figure 5 Grid-Interactive Applications (Example)

14 900-0095-01-00 Rev A

Page 17

Planning

PV Array Planning

The FLEXpower ONE is designed to use PV input to charge the battery bank. The FLEXmax 80 charge

controller(s) integrated into the FLEXpower ONE System uses Maximum Power Point Tracking (MPPT)

technology to maximize the PV harvest. A PV Combiner box (not included) may be required for

multiple PV strings. PV Combiner Boxes are available from OutBack Power Systems for 8 to 12

PV strings.

FLEXpower ONE includes one FLEXmax 80 Charge Controller. The charge controller allows input from

a single PV array. The PV input can support the following PV configuration.

4,000 W

150 V

64 A I

on 48 Vdc system, 2,000 W

STC

including local temperature correction factor per NEC 690.7

OC

maximum PV array current per NEC 690.8

SC

on 24 Vdc system

STC

For a PV Planning Tool, see the following website.

http://outbackpower.com/resources/string_sizing_tool/

Battery Bank Planning

Types of Batteries

The FLEXpower ONE System supports a 24 or 48 Vdc battery bank, depending on the inverter that

is featured in the configuration. Before constructing a battery bank, check the model number on

the side of the inverter to confirm the nominal battery voltage.

A vented enclosure for the battery bank may be required by electric code.

Bank Sizing

In general, the size of the loads (watts) and the required backup period (hours) will determine best size

for the battery bank. To calculate this, use the information provided on page 53 through page 57.

Worksheets are provided

for assistance.

900-0095-01-00 Rev A

15

Page 18

Generator Requirements

IMPORTANT:

All connections must comply with local electric code.

Generator grounding and neutral-to-ground bonding should be

provided in accordance with specific system configuration and

national/local code requirements.

Follow the manufacturer’s recommendations for fuel type and

maintenance.

Planning

The following are general requirements for using a generator with the FLEXpower ONE

Electrical Requirements

.

~ North American Applications: 120 Vac / 60 Hz

~ European Applications: 230 Vac / 50 Hz

Minimum available generator power* should be equal to or greater than nominal inverter rating

(*after de-ratings for peak verses continuous power, for load power factor considerations, for

altitude, and for ambient temperature).

~ A generator with a de-rated power specification smaller than that of the inverter may not be

able to handle all downstream AC loads and/or the built-in battery charger.

~ A generator with a de-rated power specification larger that that of the inverter may be

required to handle the built-in battery charger as well as all downstream AC loads.

~ Available power from the generator may be further limited by ratings for circuit breakers

and/or generator output connectors. “Full” generator output power may not be available

from a single generator connector.

~ Generator sizing may be affected by start-up surge current requirements of 3X to 6X normal

operating current for some loads (i.e., motors with large loads).

~ The inverter and/or downstream loads may have difficulty operating from poorly-regulated

generators (voltage, frequency, load).

Grid-interactive inverters typically require inverter-type generators.

Split-phase generators (i.e., 120/240 Vac / 60 Hz) can be adapted to a single-phase inverter using

an autotransformer such as the X-240. For additional information, see…

~ PSX-240 Manual: http://www.outbackpower.com/pdf/manuals/PSX-240_Installation

Manual.pdf

~ X-240 Manual: http://www.outbackpower.com/pdf/manuals/

The OutBack MATE can be used to program an inverter’s AUX output to start and stop a generator.

fw-x240.pdf

This 12 V output can often control a two-wire-start generator directly. Three-wire-start generators

require an interface such as an Atkinson module. For additional information, see…

~ OutBack Power Systems AGS Brochure:

http://www.outbackpower.com/pdf/brochures/Automatic_Generator_Start.pdf

~ OutBack Power Systems MATE Manual:

http://www.outbackpower.com/pdf/manuals/mate.pdf

~ Atkinson Electronics: http://atkinsonelectronics.com/

16 900-0095-01-00 Rev A

Page 19

Preparation

Tools Required

Planning

The following tools may be required for installing this equipment.

Wire cutters/strippers Drill and drill-bits

Torque wrenches Ratchet drives

Assorted insulated screw-drivers

Digital Voltmeter

Materials Required

The following materials may be required for installing this equipment.

Conductors for wiring

Conduits, bushings

Anchor Bolts (x4) or Dry-wall (x6) screws for mounting

Plywood (optional, for additional wall support)

Accessories

The following accessories are available for purchase.

PV8/PV12 Combiner Box

See the OutBack catalog for a complete list of other parts and components that are available.

Location

FLEXpower ONE is rated for indoor installations.

In areas where seismic activity is a concern, consult local code for seismic safety requirements.

Environmental

This unit is performance rated at 25°C (77°F). Exposure to extreme hot temperatures can reduce

the unit’s performance. When used in an outdoor installation, use a shading structure to avoid

direct exposure to sunlight.

The mounting surface should be vertical, smooth, and able to support three (3) times the weight

of the enclosure (98 lb, or 44.5 kg. This may require additional support for wall-mounted

installations.

900-0095-01-00 Rev A

17

Page 20

Clearance and Access Requirements

WARNING: Fire/Explosion Hazard

Do not place combustible or flammable materials within 12 feet (3.7 m) of

the equipment. This unit employs mechanical relays and is not ignitionprotected. Fumes or spills from flammable materials could be ignited by sparks.

IMPORTANT:

Clearance and access requirements may vary by location. Maintaining a 36”

(0.91 cm) clear space in front of the system for access is recommended.

Consult local electric code to confirm clearance and access requirements for

the specific location.

Planning

12” (30.5 cm)

(Minimum)

12” (30.5 cm)

(Minimum)

Minimum recommended

clearance above and on sides.

12” (30.5 cm)

(Minimum)

Side View

36” (91.4 cm)

(Minimum)

Minimum recommended

clearance in front.

Figure 6 Clearance and Access Requirements

18 900-0095-01-00 Rev A

Page 21

Dimensions

Planning

33½”

(851 cm)

19¾” (481 cm)

16” (41 cm)

Mounting Bracket

≈13” (33 cm)

Figure 7 Dimensions

900-0095-01-00 Rev A

19

Side View

Page 22

Planning

T

Conduit and Knockout Preparation

Knockouts (two 1”, one 2”) are provided on the ends of the AC and DC enclosures for routing cable

into the enclosures. Conduit and bushings are recommended to prevent damage to conductors from

sharp edges along knockout holes.

1. Remove the 2” knockout on the DC end to accommodate the larger battery cables and Remote

Temperature Sensor cable.

2. Remove the 1” knockout(s) on the AC end to accommodate the AC cabling.

3. Install conduit and bushings to protect the cable from damage from the sharp edges of the hole.

4. Ensure no debris or metal shavings have fallen into the enclosures.

AC End

1”

1”

op View

Front Side

Front Side

Bottom View

2”

2”

DC End

Figure 8 Conduit and Knockout Preparation

20 900-0095-01-00 Rev A

Page 23

Installation

The FLEXpower ONE system is designed for flexibility and easy installation. The system comes

attached to a mounting plate with the selected components pre-installed and wired. The Mounting

Plate attaches to a mounting bracket that attaches to a wall.

WARNING: Personal Injury

This equipment weighs 98 lbs (44.5 kg). Use safe lifting techniques when

lifting this equipment as prescribed by the Occupational Safety and Health

Association (OSHA) or other local codes.

Use standard safety equipment such as safety glasses, ear protection, steeltoed safety boots, safety hard hats, etc. as prescribed by the Occupational

Safety and Health Association (or other local codes) when working on this

equipment.

Use standard safety practices when working with electrical equipment

(e.g., remove all jewelry, use insulated tools, wear cotton clothing, etc.)

Never work alone when installing or servicing this equipment. Have

someone nearby that can come to your aid if necessary.

Mounting

The FLEXpower ONE is designed to be wall-mounted, indoors. The mounting bracket has six holes in

it with the outside holes measuring 16” center-to-center. This allows the mounting bracket to be

secured to wall studs 16” apart. If the wall studs are 24” apart, the center mounting holes should be

used to secure the bracket to the wall stud and the outside holes should be used for extra stability.

IMPORTANT:

The mounting surface should be able to hold three times the combined weight

of all the components. A sheet of ¾” plywood may be required to meet this

requirement. Check with local code to ensure regulatory compliance for

stability and cabling.

To install the Mounting Bracket:

1. Note the height of the Mounting Plate as indicated in Figure 7.

2. Place the Mounting Bracket at the desired height

recommended to hang at about eye level.

3. Secure the Mounting Bracket to the wall as shown in Figure 9. Use all six mounting slots provided

on the bracket, if possible.

4. Lift the Mounting Plate above the Mounting Bracket. Slip the top of the Mounting Plate over the

the Mounting Bracket. See Figure 10 on page 23.

angled lip

5. Secure the lower back flange of the Mounting Plate to the wall (with appropriate hardware), using

the rear flange slots

6. Insert all three 1” nylon hole plug

900-0095-01-00 Rev A 21

of

as shown in Figure 10 on page 23.

s into the rear slot access holes.

for the panel. The bottom of the bracket is

Page 24

Mounting the bracket to

wall studs 16” apart.

Mounting the bracket to

wall studs 24” apart.

Installation

Mounting the bracket

to plywood.

Figure 9 Installing the Mounting Bracket

900-0095-01-00 Rev A

22

Page 25

Installation

Lift the Mounting Plate

above the wall bracket.

Slip the top of the

Mounting Plate over

the angled lip of the

wall bracket.

Secure the Mounting Plate to the wall

at the 3 locations shown here.

Secure the Mounting Plate to the

wall at the 3 locations shown

below.

Figure 10 Attaching the Mounting Plate to the Mounting Bracket

900-0095-01-00 Rev A

23

Page 26

Removing the Covers

T

Remove the screws in

the AC Enclosure’s

Front Cover (x4).

Gently pull the Front

Cover away from the

chassis being careful

not to disconnect or

damage the wiring for

the Surge Protector.

The Front Cover cannot

be completely removed

due to the Surge

Protector wiring

(see page 52).

Remove the screws on

the Inverter Terminal

Access Cover (x2).

Remove the screws on the

AC Access Cover (x2).

Installation

Note: The AC Enclosure has two covers: the access cover

and the front cover. Both covers need to be opened to

make conductor connections. Once connections are

made, the access cover can be used for visual inspection,

so that the wiring will not be disturbed when inspected

by the local electrical authority.

Remove the screws

on the Inverter DC

Cover (x4).

Remove the screws on

the DC Enclosure

Front Cover (x4).

1

Remove the screws on

the Raceway (x2).

1

he Raceway and front cover on the FLEXmax 80 Charge

Controller only need to be removed if the FLEXnet DC

Monitor is included in the configuration.

1

Remove the screws on

the FLEXMax 80

Charge Controller

(x3).

Figure 11 Removing the Covers

24 900-0095-01-00 Rev A

Page 27

Accessing the Wiring Compartments

k

T

Installation

Internal components may vary from model to model.

Factory wiring is not shown.

FLEXnet DC Monitor

erminal Bus Bar for

Neutral Connections

AC Input, Output, & Bypass

Breakers (x3)

(120-NA: 60 A)

(230 EU : 30 A)

Mechanical Interloc

Breaker for AC Outlet (X1)

120-NA: 20 A

23-EU: 16 A

AC Outlet (X1)

AC Ground Bar

Battery Positive (+)

Battery Negative (–)

Inverter Terminal Enlargement

(If installed)

1

Shunt A

DC Ground Bar

Battery Disconnect

(125, 175, or 250 Adc)

Breaker for FNDC (1 A)

PV Disconnect (80 Adc)

1

Required by FLEXnet DC Monitor. Shunt A monitors inverter input and output

current. Shunt B monitors PV input current. Shunts are not present if the

FLEXnet DC Monitor is not part of the configuration. Shunt B is not present if the

FLEXmax 80 Charge Controller is not part of the configuration.

(if installed)

GFDI Breaker (1 Adc)

Shunt B

1

FLEXmax 80

Terminal Block

Enlargement

Figure 12 Wiring and Breaker Compartments

900-0095-01-00 Rev A

25

Page 28

Wiring

IMPORTANT:

All connections must comply with local electric code. Local code may

require sizes other than those recommended in this manual. For all wiring,

use copper conductors rated at 75°C minimum.

If the installation involves grid-tie activities such as selling power back to

the grid, per NEC 690, ensure the total value of the breakers installed in

either the main AC distribution panel or the AC sub-panel does not exceed

the total rating on the terminal distribution bus in the distribution panel. In

other words, if the main terminal distribution bus in the panel is rated for

100 amps, then the total value of all the breakers installed can not exceed

100 amps.

The size of the breaker installed to support the inverter should not exceed

60 A maximum.

When smaller AC sources are used, smaller AC wiring may be used (down to

the minimum sizes indicated in Tables 4 and 6). The external AC breakers

must be sized accordingly to protect smaller wires.

Installation

Grounding

IMPORTANT:

System grounding is the responsibility of the installer.

Grounding requirements may vary by location depending on the local

electric code. In North America, inverter systems are considered two

separate electrical systems and, therefore, are required by code to have

each system (AC and DC) connected to a ground electrode conductor (also

known as a primary system ground).

The AC and DC circuits are not bonded to the FLEXware enclosure.

The equipment ground is marked with this symbol:

WARNING:

Ensure there is only one Neutral-to-Ground Bond in the system.

FLEXpower ONE comes with a Neutral-to-Ground Bond installed. If a Neutralto-Ground bond exists elsewhere in the system, the Neutral-to-Ground Bond in

the FLEXpower ONE will need to be removed. See Figure 18. Check local code

for sp

ecific re

quirements.

The

Table 3 Ground Conductor Size and Torque Requirements

Terminal

Location

Ground Bar #12 AWG (3.3 mm2) 1/0 AWG (53.5 mm2) 35 in-lb (4 Nm)

Minimum Allowed

Conductor Size

Maximum Conductor

Size

Torque

Requirements

26 900-0095-01-00 Rev A

Page 29

Installation

Figure 13 Ground Connections

DC Connections

Table 4 DC Conductor Size and Torque Requirements

DC Terminal Minimum Allowed

Conductor Size

Battery Positive (+) 2/0 AWG (67.5mm2)

Battery Negative (–)

(Shunt)

PV Positive (+) #4 AWG (21.2 mm2)

PV Negative (–)

Ground Bus Bar #12 AWG (3.3 mm2) 1/0 AWG (53.5 mm2) 35 in-lb (4 Nm) N/A

2/0 AWG (67.5 mm2)

#4 AWG (21.2 mm2)

To make the battery connections in systems that have the FLEXnet DC Monitor, see Figure 14 on

page 28.

To make the battery connections in sys

tems that do not have

15 on page 29.

Maximum

Conductor Size

N/A (ring terminal) 50 in-lb (5.7 Nm) 175 Adc

N/A (ring terminal) 50 in-lb (5.7 Nm) N/A

#2 AWG (33.6 mm2) 35 in-lb (4 Nm) 80 Adc

#2 AWG (33.6 mm2) 35 in-lb (4 Nm) N/A

Torque

Requirements

Breaker

Size

the FLEXnet DC Monitor, see Figure

To make the PV connections, see Figure 16 on page 30.

900-0095-01-00 Rev A

27

Page 30

Installation

To make the battery connections in a system with the FLEXnet DC Monitor:

1. Remove all hardware from the side of Shunt A that is not connected to the Inverter.

2. Place the Inverter Negative (–) cable lug and Charge Controller Negative (–) cable lug onto

Shunt A. Secure in place with the Flat Washer, Lock Washer and Nut. Torque to 50 in-lb (5.7 Nm).

3. Connect the Battery (+) conductor to the DC Breaker lug closest to the Mounting Panel.

Torque to 50 in-lb (5.7 Nm).

4. Attach one end of the Battery Temperature Sensor (RTS) cable to the BATT TEMP port on the

Inverter and the other side to one of the batteries in the middle of the Battery Bank.

Internal components shown may vary from model to model.

Factory wiring is not shown.

See Table 4 on page 27

for recommended

Bolt

conductor sizes and

torque requirements.

Charge

Controller

Battery (–)

Lug

Lock Washer

Flat Washer

Shunt

CAUTION: Equipment Damage

The Battery

the first item installed on Shunt A.

Negative lug must be

CAUTION: Equipment Damage

Ensure

that correct polarity is

observed when connecting

battery cables.

Inverter

Battery (–)

Lug

Figure 14 Battery Connections with the FLEXnet DC Monitor

28 900-0095-01-00 Rev A

Page 31

Installation

Te

ost

g

To make the battery connections in a system without the FLEXnet DC Monitor:

1. Remove all hardware from the inverter’s battery negative (–) terminal post.

2. Place the Inverter Negative (–) cable lug and Charge Controller Negative (–) lug onto the terminal

post. Secure in place with the Flat Washer, Lock Washer and Nut. Torque to 50 in-lb (5.7 Nm).

3. Place the GFDI cable lug and Surge Protector DC Negative (–) cable lug onto the terminal post.

Secure in place with the next Lock Washer and Nut. Torque to 35 in-lb (4 Nm)

4. Connect the Battery (+) conductor to the DC Breaker lug closest to the Mounting Panel.

Torque to 50 in-lb (5.7 Nm).

5. Attach one end of the Battery Temperature Sensor (RTS) cable to the BATT TEMP port on the

Inverter and the other side to one of the batteries in the middle of the Battery Bank.

Internal components shown may vary from model to

GFDI Lu

Inverter

Battery (–)

Lug

model. Factory wiring is not shown.

Surge

Protector

Lug

Charge

Controller

Battery (–)

Lug

See Table 4 on

page 27 for

conductor sizes

and torque

requirements.

Nut

Lock Washer

Nut

Lock Washer

Flat Washer

Inverter

Battery (–)

rminal P

CAUTION: Equipment Damage

The Battery Negati

first item installed on the inverter post.

Figure 15 Battery Connections without the FLEXnet DC

900-0095-01-00 Rev A

29

ve lug must be the

CAUTION: Equipment Damage

Ensure that correct polarity is

observed when connecting

battery cables.

Page 32

Installation

To make the PV connections:

1. Ensure the PV array is properly grounded.

2. Route the PV (–) through the bottom of the DC enclosure and into the wiring compartment of the

FM80 charge controller. Connect the PV (–) conductor to the PV (–) terminal in the FM80 charge

controller. Torque to 35 in-lb (4 Nm).

3. Connect the PV (+) to the top terminal of the PV Disconnect in the DC Enclosure. Torque

to 35 in-lb (4 Nm).

Internal components shown may vary from model to model. Factory wiring is not shown.

Figure 16 PV Connections with a FLEXnet DC Monitor

900-0095-01-00 Rev A

30

Page 33

AC Connections

q

WARNING: Fire Hazard

Multi-wire branch circuits in residential installations can create a potential fire

Table 5 AC Conductor Size and Torque Requirements

hazard with inverter installations. Be sure to check for multi-wire branch circuits

before making any AC connections and make any changes required to remove

the hazard.

Installation

AC Terminal Minimum Allowed

Conductor Size

Maximum

Conductor Size

Torque

Requirements

Breaker

Size

AC IN #14 AWG (2.1 mm2) 1/0 AWG (53.5 mm2) 35 in-lb (4 Nm) 60 Aac

AC OUT #14 AWG (2.1 mm2) 1/0 AWG (53.5 mm2) 35 in-lb (4 Nm) 60 Aac

Neutral Bus Bar #14 AWG (2.1 mm2) 1/0 AWG (53.5 mm2) 35 in-lb (4 Nm) N/A

Internal components shown may vary from model to model.

Neutral-to-Ground

Bond

1

Factory wiring is not shown.

1

See the WARNING on

page 32 for additional

See Table 5 for recommended conductor

sizes and tor

ue requirements.

information.

Figure 17 AC IN Connections

900-0095-01-00 Rev A

31

Page 34

Installation

WARNING: Shock Hazard

Ensure there is only one Neutral-to-Ground Bond in the system.

FLEXpower ONE comes with a Neutral-to-Ground Bond installed. If a Neutralto-Ground bond exists elsewhere in the system (e.g., in the main panel, or a

generator), the Neutral-to-Ground Bond in the FLEXpower ONE AC Enclosure

will need to be removed. See Figure 18. Check local code for specific

reme

requi

nts.

The

AC Enclosure

See Table 5 on page 32 for recommended

conductor sizes and torque requirements.

Factory-installed

Neutral-To-Ground

Bond

The factory-installed

Neutral-to-Ground Bond

must be removed if

another Neutral-toGround Bond exists

elsewhere in the

configuration.

Internal components shown may vary from model to model.

Factory wiring is not shown.

Figure 18 AC OUT Connections

32 900-0095-01-00 Rev A

Page 35

Functional Test/Commissioning

Pre-startup Procedures

1. Double-check all wiring connections.

2. Inspect the enclosure to ensure no tools or debris has been left inside.

Energize/Startup

1. Using a digital volt-meter (DVM), verify 24 or

48 Vdc on the Battery terminals (i.e., place

DVM leads on and

3

5

A

Confirm that the voltage is correct for the

inverter model. Confirm the polarity.

CAUTION

Incorrect battery polarity wil

: Equipment Damage

2. Close the DC Breakers from the battery bank

to the inverter.

1+

2

See Figure 19.

Installation

1-

in Figure 20).

l damage the i

nverter.

Figure 19 Energize Procedures

3. Close the AC Output Breakers.

See Figure 19.

4. Using a digital voltmeter, verify 120 Vac on

the AC Breakers (i.e., place voltmeter leads

4+

on

5. Close the AC Input Breakers.

and

4–

in Figure 20).

5

See Figure 19.

6. Using a digital voltmeter, verify 120 Vac on

the AC Breakers (i.e., place voltmeter leads

6+

on

7. Close the PV input Breakers.

and

6–

in Figure 20).

7

See Figure 19.

2

8. Using a digital voltmeter, verify the voltage

on the PV terminal does not equal zero

(i.e., place voltmeter leads on

8+

and

8–

in Figure 20).

7

9. Connect a small AC load and test for proper

functionality.

A

Outlets are model-dependent.

120 V systems will have a 120V outlet,

230 V Systems will have a 230 V outlet.

900-0095-01-00 Rev A

33

Page 36

4+

4–

Installation

6–

6+

Note: The shunt

may or may not be

installed on your

model. Use the

same test point in

all cases.

1–

1+

8+

8–

Figure 20 Functional Test Points for Energizing Systems

34 900-0095-01-00 Rev A

Page 37

Reassembling the Enclosures

Mounting

Slot

Cabling not shown.

Lip

Raceway

Panel

FM80

Front

Cover

Installation

To Replace the Raceway:

1. Slip the lip on the Raceway into the

slot on the mounting panel.

2. Align the holes on the bottom of

the Raceway with the holes

provided on the mounting panel.

3. Secure the Raceway in place with

the screws provided.

To Replace the FLEXmax 80

Front Cover:

1. Align the holes on the FM80

Front Cover.

2. Secure the FM80 Front Cover in

place with the screws provided.

Figure 21 Replacing the Raceway and FLEXmax 80 Front Cover

To Replace the Inverter’s AC

Terminal Access Cover:

Inverter’s AC T

Access Cover

erminal

1. Align the holes on the sides of the

cover with the holes on the inverter.

2. Secure the cover in place with the

screws provided.

Cabling not shown.

Figure 22 Replacing the Inverter’s AC Terminal Access Cover

900-0095-01-00 Rev A

35

Page 38

Installation

p

The Front Cover of the AC Enclosure will not be

completely removed due to the surge protector

cabling. Work with care not to damage the

surge protector or dislodge the cabling as you

replace the Front Cover.

To Replace the Front of AC Enclosure:

1. Align the holes (x4) in the enclosure front cover

with the holes in the chassis.

2. Replace the screws (x4) removed in the beginning.

Cabling not shown.

Figure 23 Replacing the AC Enclosure Front Cover

Notch

AC To

CoverLip

To Replace the Top of AC Enclosure:

1. Slip the Lip on the AC Top Cover into the notch in

the chassis.

2. Align the holes (x2) in the top cover with the holes

in the front cover.

2. Replace the screws (x2) removed in the beginning.

Cabling not shown.

Figure 24 Replacing the AC Enclosure Top Cover

900-0095-01-00 Rev A

36

Page 39

To Replace the DC Enclosure Front Cover:

1. Align the holes in the DC Enclosure Front cover

2. Replace the screws removed in the beginning.

DC Enclosure

Front Cover

Installation

with the holes in the chassis. Ensure that the

“lip” fits into the notch in the chassis.

Notch

Lip

Figure 25 Replacing the DC Enclosure Front Cover

To Replace the Inverter’s DC Cover:

1. Replace the plastic Battery Terminal Covers.

2. Align the holes in the DC Cover as shown.

3. Replace the screws

DC Cover

Cabling not shown.

removed in the beginning.

Figure 26 Replacing the DC Cover

900-0095-01-00 Rev A

37

Cabling not shown.

Page 40

Installation

38 900-0095-01-00 Rev A

Page 41

Operation

Setting Basic Parameters

IMPORTANT:

This section assumes that the operator is familiar with the basic operation and

navigation of the installed components. Detailed information about component

settings is provided in each of the components respective manuals.

Although some of the programming will be pre-set at the factory (i.e., grid-tie features for gridinteractive units, charging for 24 or 48 Vdc battery banks), the following parameters may need to be

adjusted on-site depending on the configuration of the system.

MATE2 Settings

The MATE2 may need to have basic operational parameters set prior to first use. The time, date, and

display features are available in the Setup Screen for the MATE2. For instructions on setting the time

and date settings, follow the menu maps on page 40 and 41.

Inverter Settings

The VFX/GVFX Series inverter/charger only has one AC input, therefore, the selected input will need to

be identified—Grid or Generator. It will also be necessary to set the AC Input Current Limit for either

the Grid (60 Aac Max) or Generator (60 Aac Max). For instructions for setting the AC Input Current,

follow the menu map on page 42. For instructions on setting other inverter features, see the MATE

Installation an

d User Manual.

Charger Settings

Charging settings include charging current limit and the voltage and time limits for each stage of the

charge cycle (e.g., absorb, float). These parameters will be pre-set at the factory. However, these

settings may still need to be adjusted by individual installer depending on the battery manufacturer’s

recommendations.

Charger settings are located in the FX Advanced Menu and/or the FLEXmax 80 Charge Controller

menu. The configuration will dictate which device will need adjustment.

For instructions on accessing the

FLEXnet DC

If the FLEXnet DC Monitor

For instructions on setting these two parameters, see page 44 in this manual.

FLEXmax 80 Charge

Charging parameters will be dependent on the

array. Basic parameters for either 24 Vdc or 48 Vdc will be pre-set at the factory. Consult the

battery manufacturer for charging recommendations. Refer to the FLEXmax 80 Installation

Manual for additional programming information.

Monitor Settings

is installed, the Battery Amp-hours and Return Amps will need to be set.

Controller Settings

FX Advanced Menu

type and size of batteries and the size of the PV

, see page 43 in this manual.

900-0095-01-00 Rev A 39

Page 42

Setting Time, Date & Display on the MATE2

IMPORTANT:

The following information assumes the installer is familiar with the basic

operation of a MATE2 System Controller and Display. If the installer is not familiar

with basic operation, please refer to the MATE Installation and User Manual for

general information.

Operation

MATE2 Setup

Screen PG 2 and

PG 3 are shown

on page 41

Figure 27 MATE2 Setup Screen (Page 1)

900-0095-01-00 Rev A

40

Page 43

Operation

Continued from page 40.

MATE2 Setup Screen PAGE 2

MATE2 Setup Screen

PAGE 3

Figure 28 MATE2 Setup Screen (Page 2 and 3)

900-0095-01-00 Rev A

41

Page 44

Operation

Selecting the AC Source and AC Input Limit on the Inverter

AC1 GRID Menu:

Adjusts the maximum current the inverter will

draw from the grid for either supporting loads or

battery charging (between 5.0 Aac and 60.0 Aac).

AC2 GEN Menu:

Adjusts the maximum current the inverter will

draw from the generator for either supporting

loads or battery charging (between 2.0 Aac and

60.0 Aac).

INC: Pressing this soft key increases the value.

essing this soft key decreases the value.

DEC: Pr

IMPORTANT:

The AC Input

of the overcurrent protection for the device.

The <Po

ports on the HUB (i.e., between multiple

inverters if installed).

limit should NOT exceed the rating

rt> So

ft Key switches between

Figure 29 Inverter Setup Screen – Selecting AC Source

42 900-0095-01-00 Rev A

Page 45

Operation

Accessing the Advanced Menu

In most cases, the charging parameters set at the factory will work for most systems. However, if

changes are required, these parameters are set using the Advanced Menu system. This includes the

charging input current limit and the voltage and time limit for each stage of charging.

IMPORTANT:

Making changes to the Advanced Settings could adversely affect current

system performance. Only make changes to the factory default settings if

you are qualified to do so.

1

2

3

IMPORTANT:

A password will be required to

access the Advanced Menu

system.

This password cannot be

changed.

The system password is

141

4

5

Figure 30 Accessing the Advanced Menus

900-0095-01-00 Rev A

43

Page 46

Operation

Setting Battery Amp-Hours and Return Amps using the FLEXnet DC Monitor

If a FLEXnet DC Monitor is installed in the configuration, the following parameters will need to be set.

Battery Amp-Hours refers to the total amp-hour capacity of the battery bank (not just amp-hour

rating of the individual batteries within the battery bank).

Return Amps is the low limit to which an absorption current must decrease, while still maintaining

the absorption voltage, before the battery is judged to be full. Use the battery manufacturer’s

specifications or 2% of the battery bank capacity.

IMPORTANT:

Access the Advanced Menu as

instructed on page 43.

To change Battery Amp-hours:

1. Press the <BAT> Soft Key.

2. Press the <INC> or <DEC> Soft

Key to change the parameter.

3. Press <ADV> to return to PG1.

4. Press <PG2> to advance to the

next setup page.

To change Return Amps:

1. Press the <CHARGE> Soft Key.

2. Press the <INC> or <DEC> Soft

Key to change the parameter.

3. Press <TOP> to return to PG2.

4. Press <PG3> to advance to the

next setup page.

5. Press <Main> to return to the

Main Screen.

Figure 31 Setting Battery Amp-hours and Return Amps

44 900-0095-01-00 Rev A

Page 47

Setting Charging Parameters

If changes need to be made to charging parameters, follow the menu map below.

IMPORTANT:

Access the Advanced

Menu as instructed on

page 43.

To Set Charging Limits:

1. Press the <CHGR> Soft Key.

2. Press the <INC> or <DEC> Soft

Key to change the parameter.

3. Press <DOWN> to advance to

the next parameter.

4. Continue p

cycle through all the settings.

ressing <DOWN> to

Operation

IMPORTANT:

Consult the Battery Manufacturer

for exact charging requirements.

WARNING: Explosion Hazard

NEVER equalize a sealed battery.

When the screen reads “Charger Programming Completed”,

press <TOP> to return to the “Choose Category” Screen, or

press <ADV> to return to the “Choose Device” Screen, or

press the <MAIN> s

oft key to return to the

Figure 32 Setting Input Source and Current Limit

900-0095-01-00 Rev A

45

Main page.

Page 48

Operation

De-energize/Shutdown

WARNING: Lethal Voltage

Review the system configuration to identify all possible sources of energy.

Ensure ALL sources of power are disconnected before performing any

installation or maintenance on this equipment. Confirm that the terminals are

de-energized using a validated voltmeter (rated for a minimum 1000 Vac and

1000 Vdc) to verify the de-energized condition.

WARNING: Burn Hazard

Internal parts can become hot during operation. Do not remove the cover

during operation or touch any internal parts. Be sure to allow them sufficient

time to cool down before attempting to perform any maintenance.

1. Open the PV Breakers.

2

2. Open the AC Breakers.

3. Open the DC Breaker for the Battery.

A

4. Using a digital volt-meter, verify 0 Vdc on the

1

2

Battery terminals of the Inverter

(i.e., place voltmeter leads on

and

in

Figure 34 on page 47).

5. Using a digital volt-meter, verify 0 Vdc on the

PV terminal

(i.e., place voltmeter leads on

and

in Figure 34 on page 47).

6. Using a digital volt-meter, verify 0 Vac on the

AC Breakers

(i.e., Place voltmeter leads on

6+

and

6–

in

Figure 34 on page 47).

3

A

Outlets are model-dependent.

120 V systems will have a 120V outlet,

1

230 V Systems will have a 230 V outlet.

Figure 33 Shutdown Procedures

46 900-0095-01-00 Rev A

Page 49

Note: The shunt

may or may not be

installed on your

model. Use the

same test point in

all cases.

Operation

6–

6+

4+

4–

5+

5–

Figure 34 Functional Test Points for De-Energizing Systems

900-0095-01-00 Rev A

47

Page 50

Operation

48 900-0095-01-00 Rev A

Page 51

Specifications

Feature Matrix

The following Matrix shows the FLEXpower ONE models that are described in this manual.

Table 6 Feature Matrix

MODEL

FP1-1

FP1-2

FP1-3

FP1-4

FP1-5

FP1-6

INVERTER

MODEL

VFX3524 X X X X

VFX3648 X X X X

GVFX3524 X X X X

GVFX3648 X X X X

VFX3024E X X X X

VFX3048E X X X X

FM80

FLEXnet DC Monitor AC Enclosure DC Enclosure

FN-DC

SHUNT A

FN-DC

SHUNT B

HUB

Surge

Protector

X