Page 1

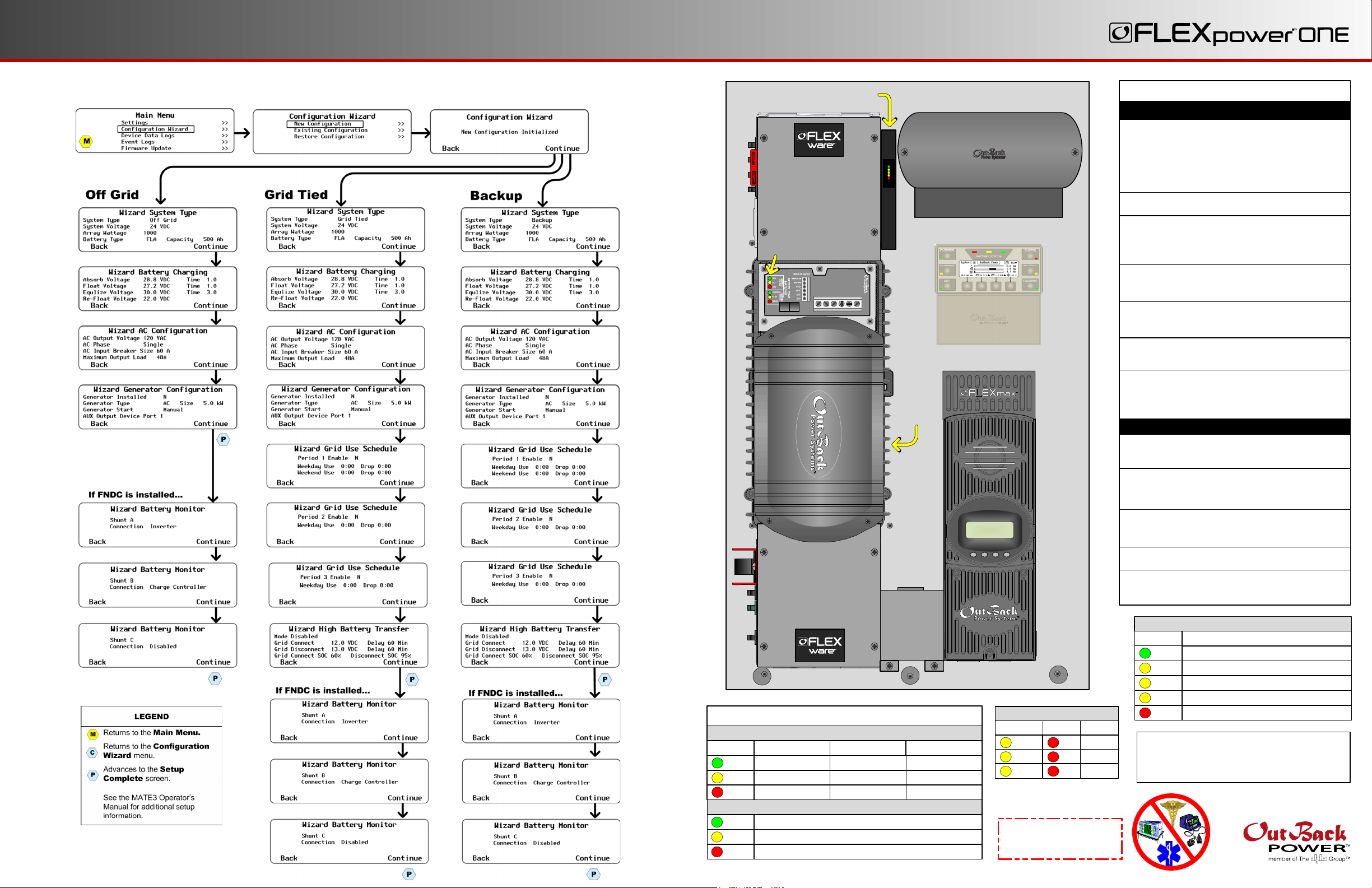

MATE3 Programming

IMPORTANT:

Programming should be done by a qualified installer who is trained on programming inverter power systems. Failure to program accurate parameters for the

system could potentially cause equipment damage. Damage caused by inaccurate programming is not covered by the limited warranty for the system.

Components

FLEXnet DC

Battery Monitor

HUB Communication Manager

(HUB4 or HUB10)

Major Components

FLEXpower System Products

FW250-AC-120V-NA

Surge Protector

(Inside)

Battery Status LEDs

Inverter Status LEDs

CHASSIS GROUND/PE

CHASSIS GROUND/PE

AC NEUTRAL OUT

AC NEUTRAL IN

AC HOT IN

RTS

MATE

MATE

RTS

MATE

RTS

Inverter/Charger

FX Series

VFX Series

GTFX Series

GVFX Series

GFX Series

System Display and Controller

(MATE3)

AC Conduit Box

DC Conduit Box

FW250-AC-120V-NA

FW250-DC-125

FW250-DC-175

FW250-DC-250

AC HOT OUT

AC

IN

MAIN----------------

3:02:14P

SUM STATUS SETUP ADV

INV

System Display and

Controller

Charge Controller

MATE2

MATE3

FLEXmax 60

FLEXmax 80

Charge Controller

(FLEXmax 80)

Communications

Manager

HUB4

HUB10

Remote Temp Sensor RTS

FLEXnet DC Monitor FNDC

Inverter/

Charger

Surge Protector FW-SP-ACA

Customer-Supplied Components

AC Source

Utility Grid, or

AC Generator

900-0132-01-00 Rev A.vsd\Page-1\2013-01-17

©2012 OutBack Power Technologies. All Rights Reserved.

FW250-DC-125

(175 or 250)

LED Indicators on the Inverter

Battery Status LED Indicators

Color

Green

Yellow

Green

Yellow

12 V Inverter 24 V Inverter 48 V Inverter

12.5 Vdc or higher

11.5 to 12.4 Vdc

Red

11.4 Vdc or lower

25.0 Vdc or higher

23.0 to 24.8 Vdc

22.8 Vdc or lower

Inverter Status LED Indicators

Inverter on (solid) or standing by (flash)

AC source in use (solid) or standing by (flash)

Red

Inverter error or warning (see manual)

50.0 Vdc or higher

46.0 to 49.6 Vdc

45.6 Vdc or lower

In 23.2 V 0.0 A

Out 27.6 V 0.0 A

0.000 kW 0.0 kWH

AUX: OFF Sleeping

Surge Protector LEDs

Active Error

Yellow

Yellow

RedYellow

Red

Red

Phase

DC

AC IN

AC OUT

IMPORTANT:

Not intended for use with

life support equipment.

Main Electrical Panel

(or overcurrent device for AC source)

Electrical Distribution Subpanel

(Load Panel)

Battery Bank

Photovoltaic (PV) Array

(with PV Combiner Box [PV8 or PV12])

FNDC LED Indicators

Color

Green

Yellow

Yellow

Yellow

Red

Battery State-of-Charge

> 90% (blinks if charge parameters are met)

≥ 80%

≥ 70%

≥ 60%

≥ 60% off, < 60% solid, < 50% blinks

Contact Technical Support:

Telephone: +1.360.618.4363

Email: Support@outbackpower.com

Website: www.outbackpower.com

Page 2

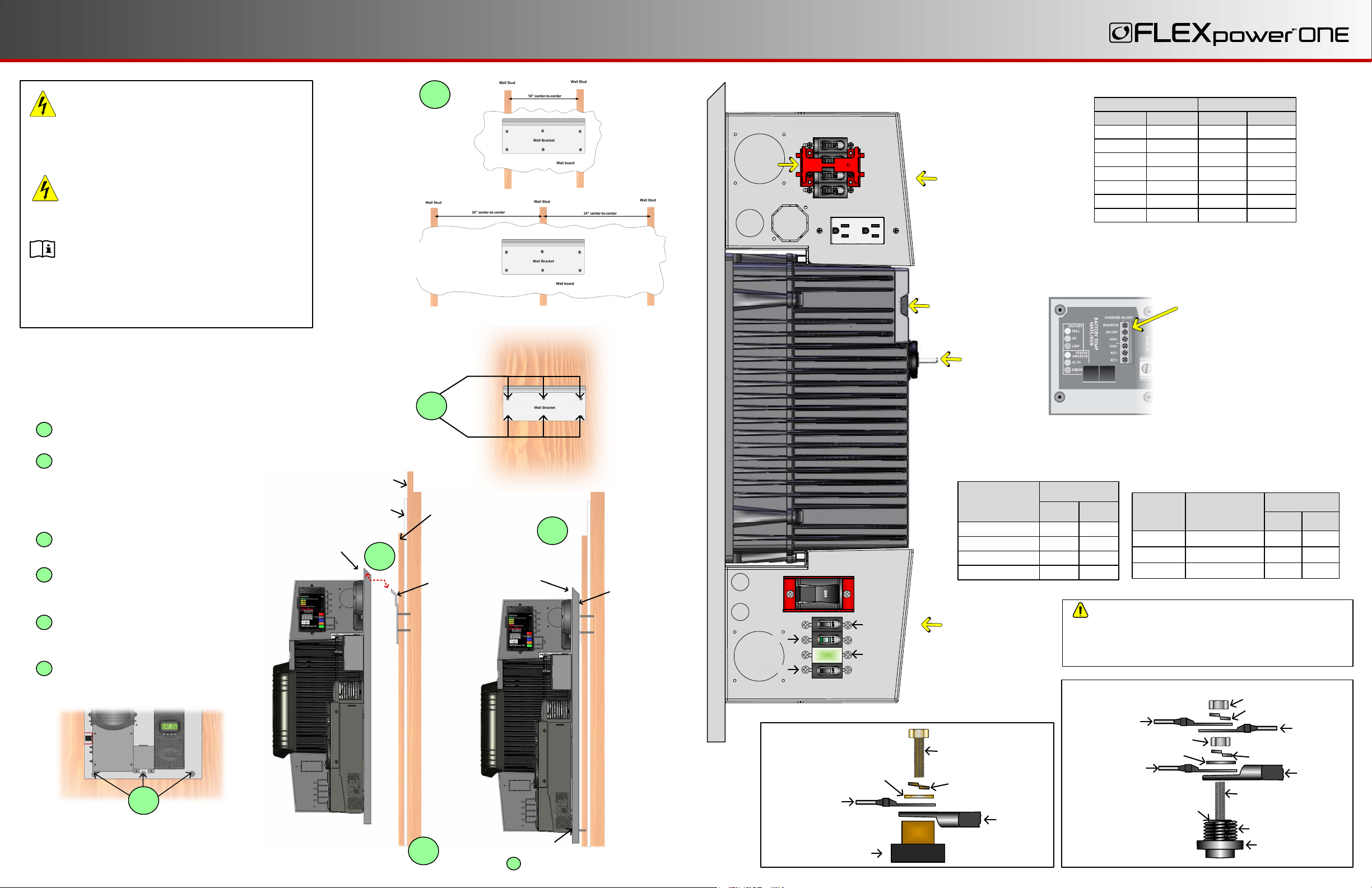

Mounting

Wire Sizes/Torque

Requirements

WARNING: Fire/Explosion Hazard

Do not place combustible or flammable materials

within 12 feet (3.7 m) of the equipment. This unit

employs mechanical relays and is not ignitionprotected. Fumes or spills from flammable materials

could be ignited by sparks.

WARNING: Personal Injury

Use safe lifting techniques and standard safety

equipment when working with this equipment.

IMPORTANT:

Clearance and access requirements may vary by

location. Maintaining a 36” (91.4 cm) clear space in

front of the system for access is recommended.

Consult local electric code to confirm clearance and

access requirements for the specific location.

FP1 Dimensions:

33.5" (85 cm) tall X 19.75" (50 cm) wide

To install the mounting bracket:

1. Place the mounting bracket at the

1

desired height for the panel.

2. Secure the mounting bracket to the

2

surface. Use all six mounting slots

provided on the bracket.

To mount the FP1 panel on the

bracket:

3

3. Lift the mounting plate above the wall

bracket.

4

4. Slip the top of the mounting plate

over the angled lip of the wall

bracket.

5. Secure the lower back flange of the

5

mounting plate to the wall (with

appropriate hardware).

6

6. Insert all three 1-inch nylon hole

plugs into the rear slot access holes.

6

900-0132-01-00 Rev A.vsd\Page-2\2013-01-17

©2012 OutBack Power Technologies. All Rights Reserved.

Wall Stud

Wall Board

FP1

Mounting

Panel

1

Mounting the bracket to

the wall studs 16" apart.

Mounting the bracket to

the wall studs 24" apart.

Mounting the bracket

to plywood

2

Plywood

(if used)

3

Mounting

Bracket

Secure the mounting

plate to the wall at the

5

three locations. See

.

FP1

Mounting

Plate

6

4

Mounting

Bracket

AC Conduit Box

AC Circuit Breakers

Mechanical

Interlock

(Bypass)

DC Circuit Breakers

GFDI

PV Array

DC Conduit Box

Battery Cable Connections

with the FNDC

Charge Controller

Battery (–) Lug

GFCI Outlet

Battery Bank

Battery

Status

Monitor

Charge

Controller

Flat Washer

Shunt

Side View

AC

Terminals

Control

Wiring

Terminals

Battery

Terminals

Torque requirements for

Breaker Stud

DC

Terminals

Bolt M8 x 1.25

Lock Washer

*must install upside-down on

units with both Shunt A and

Turbo Kit.

AC Wire Sizes and Torque Values

the conductor lugs

Circuit

M8 20 2.3

¼ - 20 35 4.0

5/16 - 18 50 5.6

3/8 - 16 225 25.4

Inverter

Battery (–) Lug

Torque

In-lb Nm

CAUTION: Equipment Damage

When connecting cables from the inverter to the battery

terminals, ensure the proper polarity is observed.

Connecting the cables incorrectly can damage or destroy

the equipment and void the product warranty.

Battery Cable Connections

without the FNDC

Surge Protector

Charge Controller

Wire Size Torque

AWG In-lb

#14 - 10 20

#8 25

#6 - 4 35

#3 35

#2 40

#1 50

1/0 50

It is recommended that conductors be #6 AWG

THHN copper, or larger, rated to 75°C

(minimum) unless local code requires otherwise.

2

mm

2.5 – 6

10

16 – 25

35

35

50

70

Control Wiring Terminal Block:

The Inverter ON/OFF terminals are

used for connecting an external ON/

OFF switch. To use this feature, the

jumper must be removed. (See

installation manual for details.)

The AUX terminals provide a 12 Vdc

signal. The AUX terminals can be used

to start a generator or to control external

devices.

AUX terminals are also available in the

charge controller and FLEXnet DC. See

the charge controller or FNDC manuals

for details.

Nm

2.3

2.8

4.0

4.0

4.5

5.6

5.6

Minimum DC Cable based on the

DC Circuit Breaker

DC

Circuit

Breaker

125 1/0 (70 mm2)

175 2/0 (70 mm2)

250 4/0 (120 mm2)

Cable Lug

Flat Washer

Battery (–) Lug

Mounting Surface

Cable Size

Nut

In-lb Nm

225 25.4

225 25.4

Nut

Lock Washer

Lock Washer

Bolt M8 x 1.25

Isolator

Inverter Battery (–)

Terminal Post

Torque

50 5.6

GFDI Cable Lug

Inverter

Battery (–) Lug

Page 3

Energize/Startup

De-energize/Shutdown

Procedures

Side View

AC Conduit Box

AC Circuit Breakers

Mechanical

Interlock

(Bypass)

DC Circuit Breakers

GFDI

PV Array

Battery

Bank

Procedures

Pre-startup Procedures:

1. Double-check all wiring connections.

2. Inspect the enclosure to ensure no tools or debris has been left inside.

3. Disconnect all AC loads at the backup (or critical) load panel.

4. Disconnect the AC input feed to the FLEXpower ONE at the source.

To energize or start up the OutBack devices:

1. Using a digital voltmeter (DVM), verify 12, 24, or 48 Vdc on the DC input

5

4

terminals by placing the DVM leads on and . Confirm that the

voltage is correct for the inverter and charge controller models. Confirm

the polarity.

CAUTION: Equipment Damage

!

1a

1b

Incorrect battery polarity will damage the equipment.

2. Turn on (close) the GFDI circuit breaker.

1

3. Verify the voltage on the PV terminal is in the correct range of open-circuit

voltage by placing the DVM leads on and . Confirm the polarity.

4. Turn on (close) the PV input circuit breakers.

5. Turn on (close) the DC circuit breaker from the battery bank to the inverter.

2a 2b

2

3

6. Verify 120 Vac on the AC output circuit breakers by placing the DVM leads

on and .

3+ 3–

7. Turn on (close) the AC output circuit breakers.

4

8. Connect the AC source. Verify 120 Vac on the AC input circuit breakers

by placing the DVM leads on and .

9. Turn on (close) the AC input circuit breakers.

4+ 4–

5

10. Turn on the AC disconnects at the load panel and test the loads.

4–

3–

Functional

Test Points

Battery Voltage

Test Points

Battery Negative (–)

1a

Terminal on the Inverter

Circuit Breaker Terminal

connected to the Battery

1b

Positive (+) Cable

Circuit Breaker Terminal

1c

connected to the Inverter

3

1

2

DC Positive (+) Cable

PV Voltage Test Points

PV Negative (–) Terminal

2a

on the Charge Controller

Circuit Breaker terminal

2b

for the PV

PV Positive (+) Terminal

2c

on the Charge Controller

AC OUT Voltage

Test Points

3+ 3–

4+

3+

1a

Side View

AC Conduit Box

Mechanical

Interlock

(Bypass)

GFDI

PV Array

AC Circuit Breakers

DC Circuit Breakers

Battery

Bank

WARNING: Lethal Voltage

Review the system configuration to identify all possible

sources of energy. Ensure ALL sources of power are

disconnected before performing any installation or

maintenance on this equipment. Confirm that the

terminals are de-energized using a validated voltmeter

1

(rated for a minimum 1000 Vac and 1000 Vdc) to verify

the de-energized condition.

1

WARNING: Lethal Voltage

The numbered steps will remove power from the

inverter and charge controller. However, sources of

energy may still be present inside the GSLC and other

locations. To ensure absolute safety, disconnect ALL

power connections at the source.

WARNING: Burn Hazard

Internal parts can become hot during operation. Do not

remove the cover during operation or touch any internal

parts. Be sure to allow them sufficient time to cool

down before attempting to perform any maintenance.

To de-energize or shut down the OutBack devices:

1. Turn off (open) the AC circuit breakers.

2. Turn off (open) the DC circuit breaker for the battery.

3. Turn off (open) the PV circuit breaker.

4. Turn off (open) the GFDI circuit breaker.

1

2

3

4

5. *Verify 0 Vdc on the DC input terminals of the inverter by

placing the voltmeter leads on and .

1a

1c

6. *Verify 0 Vdc on the PV terminal by placing the voltmeter

2

leads on and .

2a

2c

7. *Verify 0 Vac on the AC output circuit breakers by placing

the voltmeter leads on and .

4

3

*See the Functional Test Points key that is included with the

Startup Procedures.

3+ 3–

DC Conduit Box

900-0132-01-00 Rev A.vsd\Page-3\2013-01-17

©2012 OutBack Power Technologies. All Rights Reserved.

AC IN Voltage

Test Points

4+ 4–

2b

1c

1b

2c

DC Conduit Box

2a

Page 4

General Wiring

AC Source

(single)

AC LEGEND

Neutral

HOT L1

Ground

N

L1

AC Distribution

Panel

(or disconnect device)

L1

60 A Circuit

Breaker

(Maximum)

GROUND

L2

NEUTRAL

Input

Output

Bypass

Outlet

MATE RTS

MATE RTS

N

L1

Actual wiring may vary. Factory wiring not shown.

IMPORTANT: Example only.

All configurations must comply with local and national electric codes.

Consult your local electric authority to ensure compliance.

N

IMPORTANT:

Indoor installation only.

L1

CHASSIS GROUND/PE

CHASSIS GROUND/PE

AC NEUTRAL OUT

AC NEUTRAL IN

AC HOT IN

AC HOT OUT

MAIN----------------

AC IN

3:02:14P

SUM STATUS SETUP ADV

INV

If the FLEXnet DC battery monitor

is not installed, the DC shunt will

not be installed.

If the DC shunt is not installed,

connect the DC negative (–) cable

directly to the DC negative (–)

terminal on the inverter.

DC Negative (—)

Terminal on the

Inverter

FLEXware PV8

Photovoltaic Array (PV)

I

OIOIOIOIOIOIO

O

I

Ground Electrode

Conductor

Loads

(120 Vac)

AC Subpanel

HOT

NEUTRAL

N

L1

GROUND

2

DC Negative (—) Cable

2

DC LEGEND

Negative

L1

In 23.2 V 0.0 A

Out 27.6 V 0.0 A

N

0.000 kW 0.0 kWH

AUX: OFF Sleeping

Positive

Ground

1

Battery Status

GFDI

Charge Controller

(RTS)

Battery Bank

900-0132-01-00 Rev A.vsd\Page-4\2013-01-17

©2012 OutBack Power Technologies. All Rights Reserved.

PV Circuit Breaker

Connects to the terminal on the circuit breaker

1

that is opposite the inverter DC cable.

Vented Battery Enclosure

Loading...

Loading...