Page 1

net DC

User’s Guide

Includes Mounting and Installation

TM

Page 2

Warranty

Dear OutBack Customer,

Thank you for your purchase of OutBack products. We make every e ort to assure our power

conversion products will give you long and reliable service for your renewable energy system.

As with any manufactured device, repairs might be needed due to damage, inappropriate use, or

unintentional defect. Please note the following guidelines regarding warranty service of OutBack

products:

• Any and all warranty repairs must conform to the terms of the warranty.

• All OutBack equipment must be installed according to their accompanying instructions and

manuals with speci ed over-current protection in order to maintain their warranties.

• The customer must return the component(s) to OutBack, securely packaged, properly addressed,

and shipping paid. We recommend insuring your package when shipping. Packages that are not

securely packaged can sustain additional damage not covered by the warranty or can void warranty

repairs.

• There is no allowance or reimbursement for an installer’s or user’s labor or travel time required to

disconnect, service, or reinstall the damaged component(s).

• OutBack will ship the repaired or replacement component(s) prepaid to addresses in the continental

United States, where applicable. Shipments outside the U.S. will be sent freight collect.

• In the event of a product malfunction, OutBack cannot bear any responsibility for consequential

losses, expenses, or damage to other components.

• Please read the full warranty at the end of this manual for more information.

About OutBack Power Systems

OutBack Power Systems is a leader in advanced energy conversion technology. Our products

include true sine wave inverter/chargers, maximum power point tracking charge controllers, system

communication components, as well as breaker panels, breakers, accessories, and assembled systems.

Notice of Copyright

FLEXnet DC User’s Guide © 2007 All rights reserved.

1

Page 3

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER SYSTEMS:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

January, 2008

Contact Information

OutBack Power Systems

19009 62nd Ave. NE

Arlington, WA 98223

Phone (360)435-6030

Fax (360)435-6019

outbackpower.com

2

Page 4

TABLE OF CONTENTS

Warranty Summary..................................................................................................................................................................... 1

Introduction .................................................................................................................................................................................... 4

System Overview ......................................................................................................................................................................... 5

Reading the FLEXnet DC ......................................................................................................................................................... 6

FLEXnet DC Package ................................................................................................................................................................. 7

Installing the FLEXnet DC ................................................................................................................................................7-10

FLEXnet DC Measurements ................................................................................................................................................11

Logged Data .................................................................................................................................................................................12

User Adjustable Set Points ...................................................................................................................................................12

Programming and Using the MATE for FLEXnet Operations..........................................................................13

FLEXnet DC Modes ...................................................................................................................................................................14

Programming the Auxiliary Relay ....................................................................................................................................16

MATE Screens ....................................................................................................................................................................... 17-28

Technical Notes...........................................................................................................................................................................29

Warranty ..................................................................................................................................................................................30-31

Warrranty Registration ............................................................................................................................................................32

3

Page 5

Introduction

The OutBack Power Systems FLEXnet DC

The FLEXNet DC collects, monitors and records time-based battery amp, watt and volt data for display

on the OutBack MATE series of products, allowing for more accurate set point adjustments and precise

battery recharging. Five LEDs on the FLEXnet DC act as a state-of-charge indicator bar for a quick status

display.

The FLEXnet DC also o ers an auxiliary (AUX) relay that acts like a switch to turn on or o a

user-installed light, alarm, or similar low voltage DC device. It can also be set up as a two-wire auto

generator starter.

The FLEXNet DC works in conjunction with up to three input current shunts (either a FW-SHUNT250 or

FW-SHUNT500, each rated 500A/50mV) also available from OutBack.

Only a single FLEXNet DC is needed for any system using OutBack components.

The FLEXnet DC is not intended to be used with the MATE2M. It is designed to work with the MATE or

the MATE2.

NOTE: • One shunt is included as standard equipment with each OutBack FW500-DC and FW1000-AC

enclosures.

• The shunt(s) cannot be connected to a positive (+) ground system.

4

Page 6

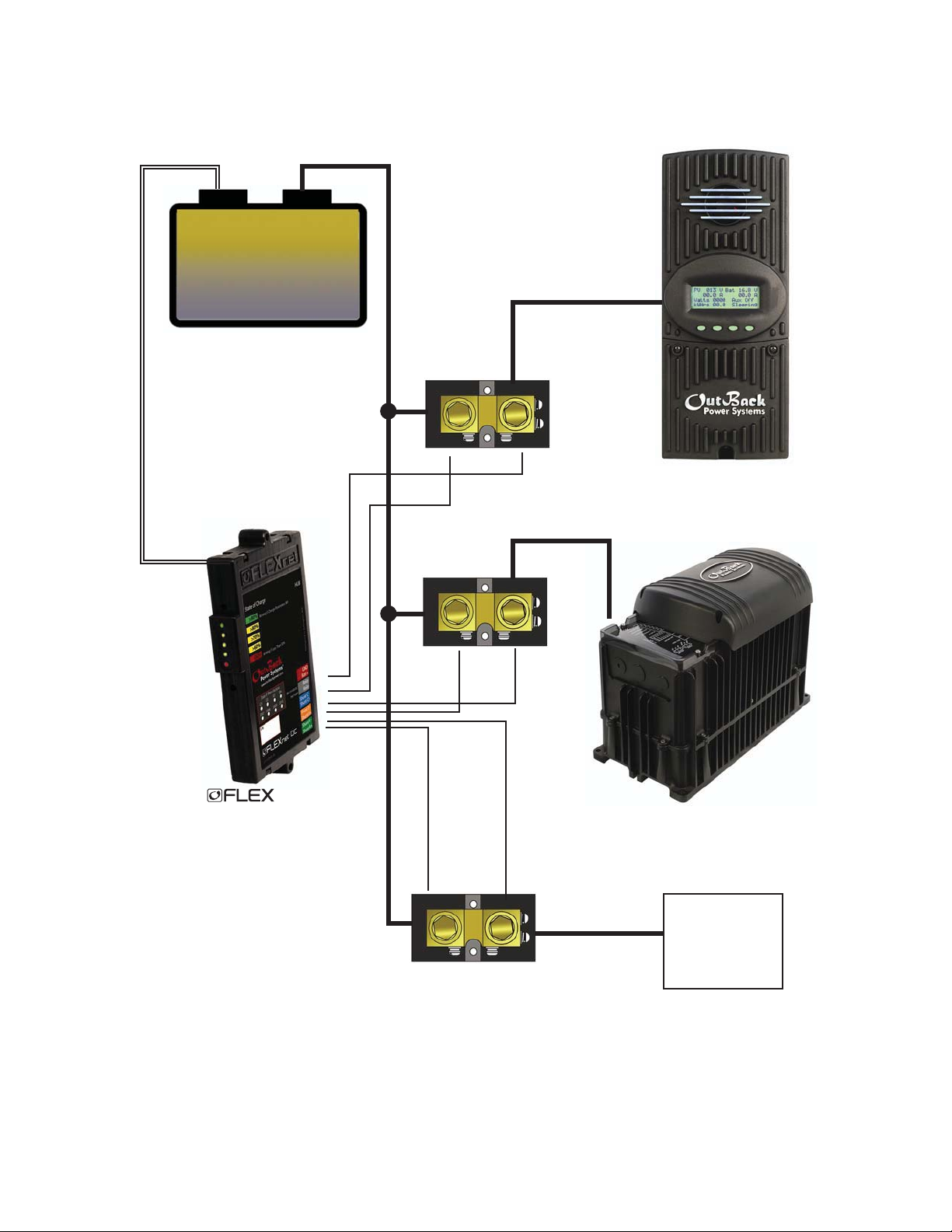

SYSTEM OVERVIEW

BAT + BAT -

CHARGE CONTROLLER BATTERY -

SHUNT C

CHARGE CONTROLLER

FX BATTERY -

SHUNT B

C DEVICE

C BAT (-)

TM

net DC

B DEVICE

A BAT (-)

B BAT (-)

A DEVICE

FX INVERTER/CHARGER

BATTERY -

OTHER DC

SOURCE OR

SHUNT A

Think of the input shunts as breaks or junctions in the DC (-) conductor. The current is conducted

as though it were a continuous conductor, but the shunts allow the user to monitor the current,

providing information for more accurate battery recharging.

LOAD

5

Page 7

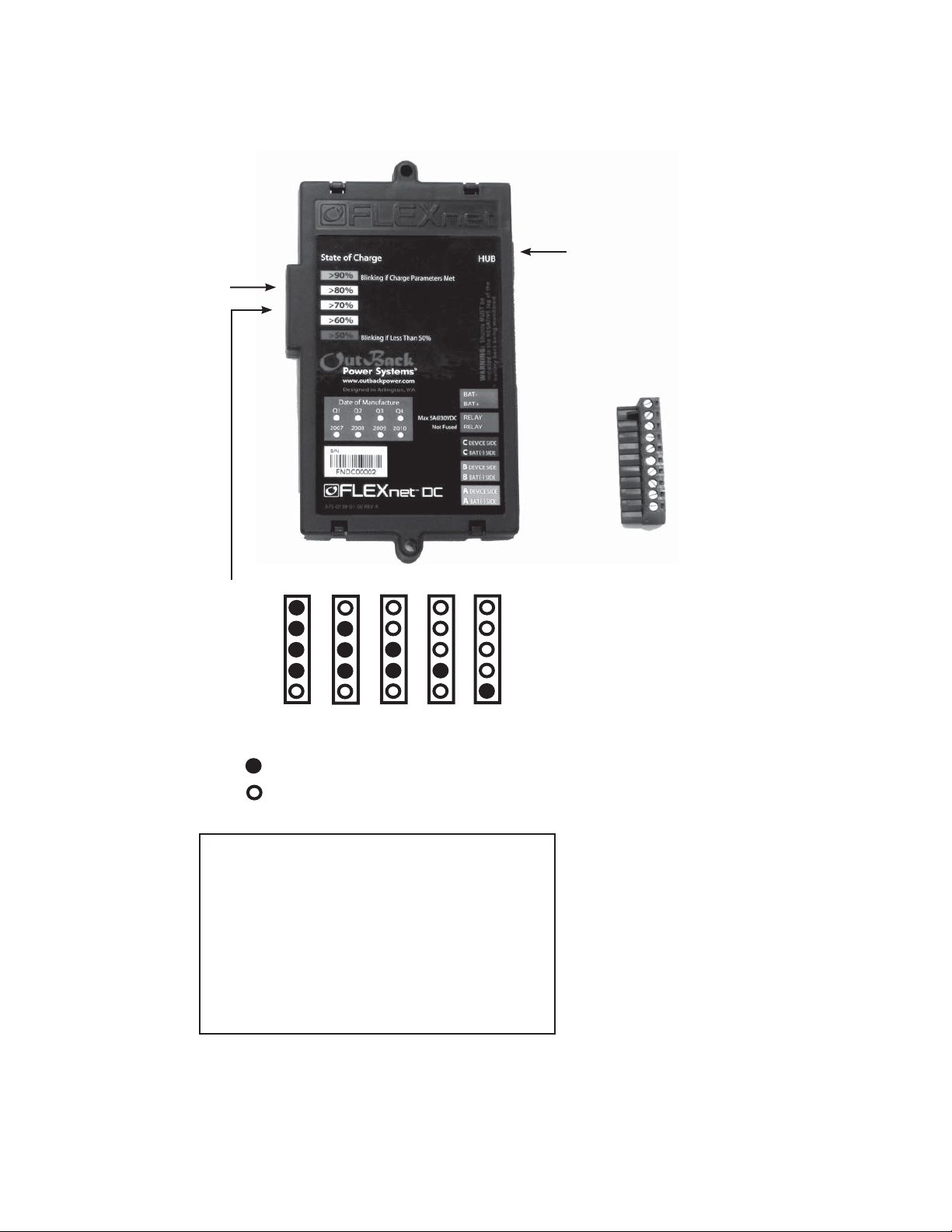

Reading the FLEXnet DC

LEDs*

RJ45 jack connects to

Port 2 or higher in HUB

1

2

3

4

5

6

7

8

9

10

(GREEN)

( Y E L L O W )

(YELLOW)

(YELLOW)

(RED)

SOC >90% 80-89% 70-79% 60-69% 50-59%

ON

OFF

• Blinking green LED: Charge parameters met

• Solid green LED: SOC** is above 90%

• Solid red LED: SOC is greater than 49% but less

than 60%

• O red LED: SOC is above 59%

• Blinking red LED: SOC is less than 50%

*See page 15

**State of Charge

10-postion wiring block

1: BAT 2: BAT+

3. Relay

4. Relay

5: C DEVICE SIDE

6: C BAT (-) SIDE

7: B DEVICE SIDE

8: B BAT (-) SIDE

9: A DEVICE SIDE

10: A BAT (-) SIDE

• BAT+/- must connect

directly to battery

terminals of the bank being

monitored.

• Proper polarity must be

observed on all connections.

6

Page 8

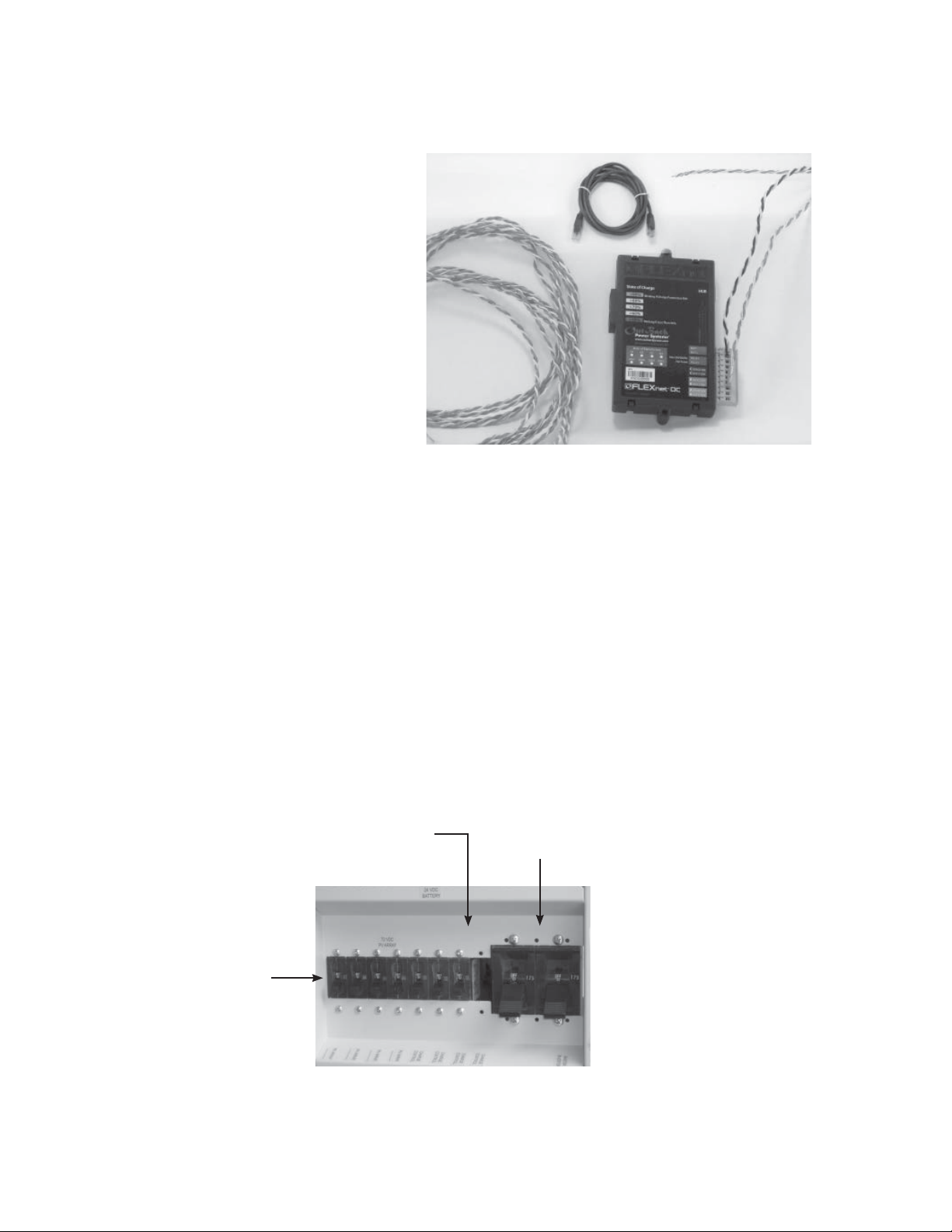

The FLEXNet DC package includes:

A. FLEXnet DC

B. Ten-pin wiring plug for shunt, relay

and battery connections

C. Six feet of CAT5 cable for HUB connection

D. Ten-foot color-coded twisted pair

(TP) cable connects to the battery

E. Three six-foot, color-coded,

twisted pair cables for shunt connections

F. Two #6-32 X 3/8” panhead

machine screws

G. Colored labels identifying shunts

C

D

E

A

E

B

Installing the FLEXnet DC

The FLEXnet DC mounts in a 3/4” DC breaker slot in an OutBack DC breaker bracket installed inside

a FLEXware enclosure or previous model OutBack enclosure. To mount the FLEXnet DC inside an

OutBack enclosure:

1.

2.

3.

4.

5.

6.

Put the system into bypass mode

Shut o all AC input to inverters

Shut o all PV and DC breakers

Disconnect the battery cables at the battery

Remove the breaker bracket from its enclosure by removing the four corner screws

Remove a DC breaker knockout

FLEXnet DC mounts in a DC breaker

slot after removing the breaker

knockout

DC breakers o

PV breakers o

7

Page 9

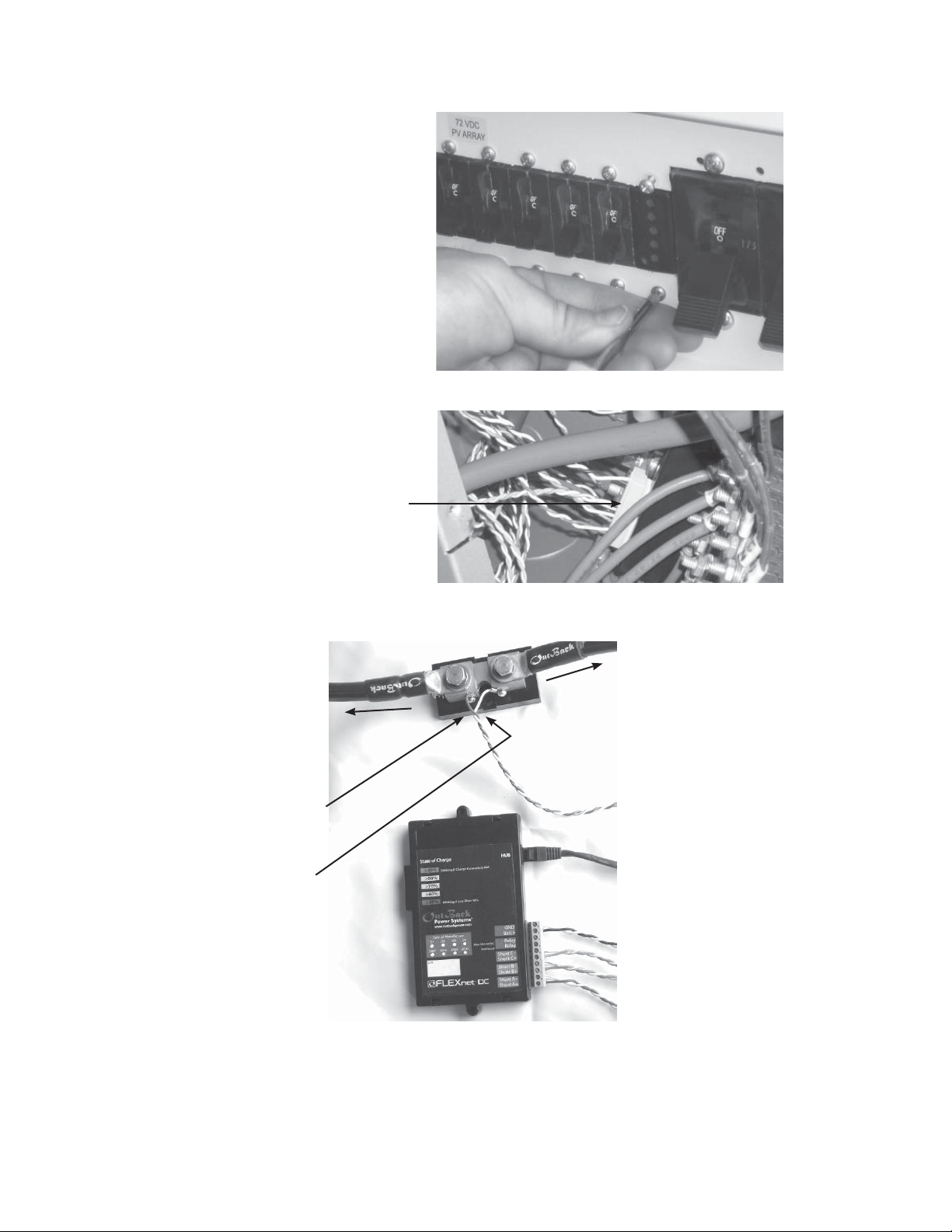

• Insert the FLEXNet DC inside the DC

breaker box and through the back side

of the breaker bracket; secure with two

#6-32 X 3/8 panhead machine screws

(included) torqued at 5 to 8 inch-pounds

• Connect all wires to the ten-pin wiring

connector. Do not leave any loose wires!

• Connect each twisted pair to a shunt.

Source/Load Negative

Battery Negative

Example:

• Battery side (green wire in

twisted pair) connects to the

battery negative side of the

shunt

• Device side (white wire in

twisted pair) connects to the

source/load (negative) side of

the shunt

NOTE: Color of wiring jacket

can vary

NOTE: The FLEXNet DC shunts must be connected in the negative (low) side of whatever they monitor.

Otherwise, the unit can be damaged.

8

Page 10

• Black/White twisted pair connects directly to the battery bank being monitored:

White to BAT (-)

Black to BAT (+)

An appropriate fuse—with a rating of 5 amps

or less and greater than 100 volts

DC—may be placed in the black conductor

BLACK/WHITE TWISTED PAIR

Wiring Block Connections

Color-coded twisted pair 18 AWG connects the wiring block and shunt(s) or battery. The wiring must

be installed with the proper polarity to avoid corrupting the data.

The wires connected to the wiring block should match the color-coded label where the wiring block

inserts into the FLEXnet DC.

• Green and White/Green

• Orange and White/Orange

• Blue and White/Blue

• Black and White

6’ twisted pair wires with #8 forked spade

terminals connected to the shunts

10’ twisted pair wire with 5/16” ring

terminals connected to the battery bank

The wiring block can accommodate #12 AWG to #26 AWG (2.5 mm2 to .20 mm2) wire with a strip

length of 1/4” (6 mm).

Torque Values

• Five inch-pound maximum torque on each terminal block screw

• 4-5 inch-pound torque is recommended if using the supplied 18 AWG stranded twisted pair wire

9

Page 11

(Installing the FLEXnet DC continued)

• Insert the 10-pin connector to the wiring block on

the back of the FLEXnet DC.

• Install the CAT5 cable into the RJ45 jack in the back

of the FLEXNet DC. Connect the other end of the

cable to the HUB using Port #2 or higher.

FLEXnet DC removed from the breaker

bracket for clarity.

• Replace the breaker bracket and secure with its

four corner fasteners.

• With all FLEXnet DC wires connected, reinstall the

DC enclosure cover and secure its four Phillips

screws.

• After the cover is installed, reconnect the battery

cables at the battery, turn on all the breakers, and

power up the system.

10

Page 12

FLEXNet DC Measurements

The FLEXNet DC can measure and record:

• Volts for one battery bank*

• Amps**

• KiloWatts

• kWhrs removed from the batteries

• kWhrs returned to the batteries

• Amp hours removed from the batteries

• Amp hours returned to the batteries

• Battery bank state-of-charge

• Lifetime kiloamp hours removed from the batteries***

• Days since charge parameters last met

• Lowest battery state-of-charge reached

• Minimum battery voltage***

• Maximum battery voltage***

• Maximum amp charged***

• Maximum amp discharged***

• Maximum kWhrs charged***

• Maximum kWhrs discharged***

For each channel

For each amps channel

* Battery volt input: 0-80 VDC in .1 volt resolution

** 2000 amp DC span (+/- 1000 amps DC—net amps are charging, net amps

are discharging), .1 amp resolution

*** The user can manually reset these data. At any given time, the values

displayed are the most recent since the values were last displayed

11

Page 13

Logged Data*

The previous 128 days of data are accessible with the MATE. The data is logged each night at

midnight. Be sure the MATE’s clock is set to the correct local time (refer to your MATE manual).

* Data Logging

User Adjustable Set Points

• Battery charge factor (65-100%) [see page 29]

• Battery bank capacity 0-10000 amp hours

• Shunt A, B, C—enabled or disabled

• Absorb volts (0-80.0 volts, the maximum voltage the battery can absorb)

• Return amps (0-500.0A, the maximum current amperage going into the battery)

• Parameters met timer (0-240 minutes, the amount of time allowed to recharge)

• AUX Relay Set Points

Manual-On, Auto, Manual-O —allows the user to turn the Aux Relay on and

o like a manual switch or to set it to Auto and have it function when certain

conditions are met

Volts HI—when user determined high voltage value is met, the Aux activates

Volts LO—the Aux activates when a low voltage value is met

SOC (State-of-Charge) HI—a high state-of-charge activates the Aux

SOC (State-of-Charge) LO—a low state-of-charge activates the Aux

HI Delay—the user can adjust the high set point delay time (in minutes)

LO Delay—the user can adjust the low set point delay time (in minutes)

AUX-INVERT LOGIC—the invert logic function can be activated with a YES or

NO command (see page 16)

12

Page 14

Programming and Using the MATE for FLEXNet DC Operations

At initial power up, use the MATE (see pages 17-28) to program:

• Battery Bank 20 Hour Capacity (provided by the manufacturer) in amp hours (from 10010,000 amp-hours in ten amp increments)

• Battery charge parameters

•

Return amps: See the manufacturer recommendations or set to 2% of the battery bank

amp hour capacity (e.g. a 1000 amp hour battery bank would set the return amps to 20.0

amps)

NOTE: Older battery banks might require a higher value if the system end of charge amps does not

drop to the 2% level.

Battery End-of-Charge Voltage: See the manufacturer recommendations or set .2 volts lower

•

than the system absorb voltage for 12/24 volt systems and .4 volts lower for 48 volt or higher

systems

• Battery Charge Factor (BCF)

•

The BCF compensates for recharging ine ciency from gassing and heating losses to

assure the battery state-of-charge (SOC) display is accurate by scaling it; the BCF is

programmable from 65% to 100% (see page 29).

If the SOC percentage displays full before the batteries’ user-determined charge settings

•

are met, decrease the BCF percentage; increase it if the SOC is low.

The default setting is 94%, meaning 94% of the charging current is being used for

•

recharging and 6% is lost. OutBack suggests maintaining the default setting until the

FLEXNet DC has monitored the system through a few charge/discharge cycles.

Setting the BCF to 100% e ectively disables any BCF display changes.

•

• Charge Parameters Met Time

•

During this period, the charge parameters must meet or exceed the user-set charge

parameters before the battery is considered full.

Programmable from 0 to 240 minutes

•

Setting this time to 0 e ectively eliminates any ltering provided by this timer. The rst

•

time the charge parameters are met, the unit will consider the parameters met and

perform accordingly.

The default setting is one minute. Longer or shorter periods may apply to

•

certain sources such as wind generators or hydros.

13

Page 15

FLEXNet DC Modes

- Channel A is enabled by default

- Each input channel is either enabled or disabled.

- A disabled channel will show zero values only.

- All enabled channels will run in parallel.

- An enabled channel monitors and totals all current owing into or out of the battery

bank through its shunt. Any DC loads or sources wired directly to the battery cannot be

accounted for by FLEXNet and will result in inaccurate readings.

- All unused channels should be set to disabled.

NOTE: All shunts must be connected in the negative or low side of the system and operate in parallel.

High side connection may result in erratic operation and/or failure of the FLEXNet DC.

Charge Cycle

At power up, the FLEXNet DC assumes the battery is full regardless of the battery state-of-charge. The

batteries should receive a full charge at this time to meet the user-determined charge parameters

(entered at start up).

Typical charge cycle:

1. The battery bank is charging and charge parameters are satis ed (return amps, battery

voltage, and the parameters met time set point).

2. When the top green LED is blinking, the charge parameters have been

satis ed.

3. When a discharge begins, an internal timer counts for one minute. After one minute of

discharge, a new discharge cycle starts. All LEDs go solid and all amp hours and kilowatt

hours registers return to zero.

The FLEXNet DC is now synchronized to the battery.

4. The charged and removed amp-hours from the battery are monitored according to the

following:

• Amp-hours removed from the battery are counted at 100%.

• Amp-hours returned to the battery are discounted by the Battery Charge Factor.

• The default charge factor is 94% (each amp-hour returned to the battery is accounted for

as 0.94 Amp-Hours).

14

Page 16

The FLEXnet DC’s LEDs indicate the SOC by their individual ON/OFF states. Excluding the RED or last

LED, when viewing the remaining four LEDs—GREEN, YELLOW, YELLOW, AND YELLOW— the following

are true:

• All LEDs on = 90-100% SOC

GREEN LED blinking—charge parameters met

Solid GREEN LED—SOC is above 90%

• All but top LED on = 80-89% SOC

• All but top two LEDs on = 70-79% SOC

• Bottom yellow LED on = 60-69% SOC

When viewing the last (RED) LED:

• Bottom RED LED on = 50-59% SOC

• Bottom LED blinking = less than 50% SOC

NOTE: The bottom LED is always o unless the SOC is less than 60%

5. When the SOC is less than 90%, enough of a discharge has taken place that the FLEXnet DC’s data

can be used to determine, among other things, an accurate Battery Charge Factor. A battery amphour charge factor* and the battery kWhr e ciency factor** for the last cycle are calculated using

the stored values from the previous charge cycle (if the SOC is higher than 90%, the values aren’t

reliable enough for these calculations). The battery must cycle at least twice for these values to be

valid.

* Battery amp-hour charge factor = amp-hours removed/amp-hours charged

** Battery kWh e ciency factor= kWhs removed/kWhs charged

(GREEN)

(YELLOW )

(YELLOW)

(YELLOW)

(RED)

ON

> 90% 80-89% 70-79% 60-69% 50-59%

<50%, red LED blinks

OFF

15

Page 17

Programming the Auxiliary Relay

The FLEXNet DC’s unpowered relay is rated 5 amps/30VDC.

NOTE: This relay is not fused and requires appropriate sized wiring and over-current

protection. Damage due to unprotected relay devices is not covered by the warranty.

The relay may be con gured in one of two modes:

1. AUTO activates the relay based on user selected battery voltage, percentage of SOC delay times

and invert logic settings.

2. MANUAL allows direct relay control using the MATE, causing the relay to behave as a switch.

NOTE: When the MATE’s AGS function is active, it will override the AUX set points of whichever component

it has been programmed to control (this should be the AUX connected to the generator). OutBack strongly

recommends using the AGS function of the MATE to control a generator.

AUTO Mode

Six user adjustable set points govern the control logic of AUTO Mode:

1. Vbat Hi (0-99.9Vdc)

2. Vbat Lo (0-99.9Vdc)

3. %SOC Hi (0-100%)

4. %SOC Lo (0-100%)

5. Hi Delay Time in Minutes (0-240 minutes)

6. Lo Delay Time in Minutes (0-240 minutes)

NOTE: Relay logic can be inverted

for these set points

• If the battery voltage set points are not met, then the %SOC set points are evaluated.

• If %SOC set points are not met, then no action is taken.

• If either volts or %SOC set points are met, then the delay timer runs.

• When the set points have been satis ed for a time (either Hi Delay for the Hi set points met or Lo

Delay for the Lo set points met) the relay is actuated.

• Please see pages 26-28 to set the AUX Mode.

Relay Logic:

• Expressed as NO/NC (Normally Open/Normally Closed), basically o /on

• May be controlled via the invert logic selection from the MATE.

• Toggling the relay logic setting changes the logic mode for Hi or Lo set points

Example: The relay’s contacts are closed when the Hi set point is satis ed and open again when the Lo

set point is achieved. However, you want the relay’s contacts to be open under this condition. Toggling

the invert logic set point will accomplish this. The truth table appears as follows:

Invert Logic Hi Set Point Satis ed Lo Set Point Satis ed

Yes Relay Open Relay Closed

No Relay Closed Relay Open

The Hi and Lo delay times are set in minutes.

16

Page 18

MATE Screens

MAIN------------------------------ 11:30:55A

SUM STATUS SETUP ADV

E F

Battery Charging

State of charge 99%

DC NOW 12.5V 99%

In 0.0A 0.000kW

Out 0.5A 0.000kW

Bat -0.5A 0.000kW

From the MAIN MATE menu, press the <SUM> soft key

to view a summary of the system’s operation.

This rst summary screen appears for a few seconds

to display the battery State of Charge. The screen

automatically disappears and a system summary

screen appears.

• Battery voltage

• The current battery state-of-charge (SOC)

• In shows the amount of DC current coming into the

system from all sources

• Out shows DC current from the system

• Bat(tery) displays di erence between the In and Out

values and shows whether the battery is storing or

using current

17

DC Today min/SOC 76%

In 347AH 9.040kWH

Out 331AH 8.510kWH

Bat 16AH 0.530kWH

Press to view

previous days’ history

Press to move

forward one day

Press the second soft key to view the next SUM screen

(the screens will also scroll automatically after a userdetermined period of time programmed in the MATE).

• Minimum SOC today (since midnight)

• In: Amp hours and kiloWatt hours from sources

today

• Out: Amp hours and kiloWatt hours output by

system today

• Bat: Di erence of battery in and out amp hours and

kiloWatt hours

Press the second soft key to view the next SUM screen

Page 19

FX Total 12.6V 99%

Inverting 0.000kW

AC Loads 0.000kW

Buying $ 0.000kW

From the MAIN menu, press the <SUM> soft key to view a

summary of the system’s operation. This information is a sum

of all FlexNet DC data. Press the second soft key to view the

next SUM screen

DC BAT 12.5V 99%

Bat -0.6A 0.000kW

Net -4AH 00.7kWH

Days Since Full 4.8

MAIN----------------------------- 11:30:55A

SUM STATUS SETUP ADV

The fourth SUM screen shows:

• Battery voltage

• The current state-of-charge

• Battery readings show the instantaneous amp, amp hour,

kilowatt, and kilowatt hour gures. When comparing the

amp hours reading to “FULL,” the gure is charge factor

compensated.

• The number of days since the battery last met the charge

parameters.

Press the rst soft key to return to the MAIN screen.

Press the <STATUS> soft key to open the STATUS screen to view

the status of either the FX, Charge Controller, or (FLEXnet) DC

18

STATUS

choose device:

FX CC DC MAIN

STATUS/DC/PAGE1 ------------- STATS

METER SHUNT BATT TOP

Press the <DC> soft key to view the status of the (FlexNet) DC

Press the <METER> soft key to view the (FlexNet) DC meter

readings.

Page 20

A: 0.1A 0.000 kW

B: 0.0A 0.000 kW

C: 0.0A 0.000 kW

DOWN STATUS

The rst METER screen shows the amount of instantaneous

current running through each shunt. A positive value

indicates current ow into the battery; a negative value

means a load is being supplied. Press the <DOWN> soft key

to view the AH and kWH (amp hour and watt hour) screen.

A: -1AH 0.100kWH

B: 0AH 0.000kWH

C: 0AH 0.O00kWH

DOWN UP TOP

METER/DC/SHUNT A

removed

12AH 0.030kWH

DOWN UP TOP

METER/DC/SHUNT A

charged

12AH 0.160kWH

DOWN UP TOP

METER/DC/SHUNT B

removed

AH 0kWH

DOWN UP TOP

The second METER screen shows the accumulated amp hours

and kilowatt hours for each shunt. Press the <DOWN> soft

key to view the next METER screen.

This screen shows the number of removed amp hours and

watt hours as measured by SHUNT A. Press the <DOWN>

soft key to view the SHUNT A charged screen.

The fourth meter screen displays the number of charged amp

hours and watt hours as measured by SHUNT A. Press the

<DOWN> soft key to view the rst SHUNT B METER screen.

Pressing the <DOWN> soft key brings up the SHUNT B

charged screen.

19

METER/DC/SHUNT B

charged

AH 0kWH

DOWN UP TOP

Pressing the <DOWN> soft key brings up the rst SHUNT C

METER screen.

Page 21

METER/DC/SHUNT C

removed

AH 0kWH

DOWN UP TOP

Pressing the <DOWN> soft key brings up the SHUNT

C charged screen.

METER/DC/SHUNT C

charged

AH 0kWH

DOWN UP TOP

STATUS/FN/METER

DC fi rmware revision

000.00/040

DOWN UP TOP

STATUS/FN/METER

end of meter menu

UP TOP STATUS

STATUS/FN

STATS

METER SHUNT BATT TOP

Pressing the <DOWN> soft key brings up the FN

rmware screen.

Pressing the <DOWN> soft key leads to the end of

the meter menu

Press the <STATUS> soft key to return to the STATUS

screen.

Press the <SHUNT> soft key to view the amps and

kilowatts removed and charged in each shunt

20

STATUS/DC/SHUNT A

max removed

amps 0.9

DOWN UP RESET TOP

In this example, SHUNT A has detected 0.9 amps

removed. Press the <RESET> soft key to return this

value to 0. Press the <DOWN> soft key to continue

through the menu.

Page 22

STATUS/DC/SHUNT A

max removed

kWatts 0.010

DOWN UP RESET TOP

Displaying the kilowatts removed provides the user

with more precise energy usage information. This

gure can be returned to 0 by pressing the <RESET>

soft key. Press the <DOWN> soft key to view the max

charged screen.

STATUS/DC/SHUNT A

max charged

amps 39.8

DOWN UP RESET TOP

SHUNT A shows a maximum of 39.8 amps charged.

Pressing the <RESET> soft key returns this value to

0. Press the <DOWN> soft key to continue in the

STATUS menu.

STATUS/DC/SHUNT A

max charged

kWatts 0.510

DOWN UP RESET TOP

SHUNT A shows 0.510 kilowatts as the maximum

charged. Pressing the <RESET> soft key returns

this value to 0. Press the <DOWN> soft key to view

SHUNT B and SHUNT C values. Proceed through the

same steps as in SHUNT A. When nished with SHUNT

C, the end of shunt status menu screen appears

CONTINUING TO PRESS THE<DOWN> SOFT KEY LEADS TO max removed amps, max removed

kWatts, max charged amps, and max charged kWatts for SHUNT B and SHUNT C

STATUS/DC/SHUNT

end of shunt

status menu

UP TOP STATUS

Press the <STATUS> soft key.

21

STATUS/DC

STATS

METER SHUNT BATT TOP

STATUS/DC/BATT

total days at 100%

0.5

DOWN UP RESET

Press the <BATT> soft key to view the FlexNet DC

battery readings

STATUS/DC/BATT displays the number of days the

battery has been at 100% SOC. Press the <RESET>

soft key to restart the timer. Press the <DOWN> soft

key to view the next battery status screen.

Page 23

STATUS/DC/BATT

days since charge

parameters met 5.9

DOWN UP TOP

STATUS/DC/BATT provides the number of days since the

battery last met its charge parameters. Press the <RESET>

soft key to restart the timer. Press the <DOWN> soft key to

view the next battery status screen.

STATUS/DC/BATT

battery min today

12.4 vdc

DOWN UP RESET TOP

STATUS/DC/BATT

battery max today

12.7 vdc

DOWN UP RESET TOP

STATUS/DC/BATT

temp comp’d batt

setpoint 14.2 vdc

DOWN UP TOP

STATUS/DC/BATT

system battery

temperature 29 C

DOWN UP TOP

STATUS/DC/BATT

cycle charge

factor 78%

DOWN UP TOP

batttery min(imum) displays the minimum battery voltage

since it was last reset by the user. Pressing the <RESET>

soft key resets the battery minimum voltage; it also resets

automatically at midnight. Press the <DOWN> soft key to

view the next battery status screen.

batttery max(imum) displays the maximum battery voltage

since it was last reset by the user. Pressing the <RESET>

soft key resets the battery maximum voltage; it also resets

automatically at midnight. Press the <DOWN> soft key to

view the next battery status screen.

temp comp’d batt setpoint shows the temperature compensated end of charge volts when a network RTS is part of the

system. Press the <DOWN> soft key to continue.

When an RTS is present and the temperature is less than 60 C

and greater than10 C, the temperature is displayed in Celsius

(C). Instead of a temperature reading, ### will appear if an RTS

is not present, is damaged, or the temperature is less than

10 C or greater than 60 C. Press the <DOWN>soft key to

continue.

cycle charge factor displays the last cycle amp hours removed

and amp hours returned (as a percentage). Press the

<DOWN> soft key to continue.

22

STATUS/DC/BATT

cycle KwHr charge

effi ciency 65%

DOWN UP TOP

cycle KwHr charge e ciency states the last cycle kilowatt hours

removed and kilowatt hours returned (as a percentage). Press

the <DOWN> soft key to view the next screen.

Page 24

STATUS/DC/BATT

lifetime kAH removed 5

DOWN UP RESET TOP

STATUS/DC/BATT--------------- end of battery

status menu

UP TOP STATUS

MAIN------------------------------ 11:30:55A

SUM STATUS SETUP ADV

lifetime kAH removed shows the total kilowatt amp hours

removed from the battery. This is essentially an “odometer” for

battery usage. Press the <DOWN> soft key to continue.

Press the rst two soft keys to return to the MAIN menu.

Press the <ADV> soft key.

ADV/SETTINGS/WARNING

Changes made could adversely

effect system performance

ADV/PASSWORD

enter the password

132

ENTER INC DEC EXIT

ADV/PASSWORD

enter the password

141

ENTER INC DEC EXIT

ADV-------------------------------choose device:

This screen acts as a warning intended to keep those

unfamiliar with an OutBack system from altering the settings.

Push any key to advance to the enter the password screen.

Push the <INC> soft key until 141 appears; this is the

password.

When 141 appears on the screen, press the <ENTER> soft

key.

Press the <DC> soft key.

23

FX CC DC MATE

Page 25

ADV/DC/PAGE 1---------------choose category

ADV BAT SHUNT PG2

Press the <BAT> soft key.

ADV/DC/BAT------------------battery capacity

amp hours

TOP INC DEC ADV

ADV/DC/PAGE 1---------------choose category

ADV BAT SHUNT PG2

ADV/DC/SHUNT 1 --------------shunt 1 mode

DOWN EN DIS TOP

Pressing the <DOWN> soft key

changes the shunt being enabled

or disabled.

Use the battery capacity screen to set the battery bank

capacity using either the <INC> or <DEC> soft key. When

nished, press the <TOP> soft key.

Press the <SHUNT> soft key.

Shunt 1 is, by default, enabled or active when the FX is

powered up. Pressing the <DIS> soft key disables the rst

shunt. Pressing the <DOWN> soft key leads to the shunt 2

mode and shunt 3 mode screens. These shunts are disabled

at power-up and are enabled by pressing the <EN> soft key.

When the setup for all shunts has been completed, press the

<DOWN> soft key for the next screen.

ADV/DC/SHUNT----------------shunt setup complete

TOP ADV MAIN

ADV-------------------------------choose device:

FX CC DC MATE

ADV/DC/PAGE 1---------------choose category

ADV BAT SHUNT PG2

Press the <ADV> soft key.

Press the <DC> soft key.

Press the <PG2> soft key.

24

Page 26

ADV/DC/PAGE 2---------------choose category

PG1 CHARGE AUX PG3

Press the <CHARGE> soft key.

ADV/DC/CHARGE-------------return amps

DOWN INC DEC TOP

ADV/DC/CHARGE--------------battery charge

DOWN INC DEC TOP

ADV/DC/CHARGE--------------parameters met time

minutes

DOWN INC DEC TOP

The return amps screen allows the user to set the end of

charge amps using the <INC> and <DEC> soft keys. Press the

<DOWN> soft key to view the battery charge screen.

Set the end of charge voltage using the <INC> or <DEC>

soft keys. Next, press the <DOWN> soft key.

Press the <INC> or <DEC> soft keys to determine the

amount of time the charge parameters must be met before

they are considered an accurate state of charge. The default

period is one minute. By establishing a time, momentary

spikes in voltage are accounted for. Press the <DOWN> soft

key to view the charge factor screen.

ADV/DC/CHARGE-------------charge factor %

DOWN INC DEC TOP

ADV/DC/CHARGE-------------charge parameters

complete

TOP ADV MAIN

ADV-------------------------------choose device:

FX CC DC MATE

Set the charge factor (see page 13) using the <INC> and

<DEC> soft keys. When nished, press the <DOWN> soft key.

Press the <ADV> soft key.

Press the <DC> soft key.

25

Page 27

ADV/DC/PAGE 1---------------choose category

ADV BAT SHUNT PG2

ADV/DC/PAGE 2----------------choose category:

PG1 CHARGE AUX PG3

Press the <PG2> soft key.

Press the <AUX> soft key.

ADV/DC/AUX CONTROL-------currently: Auto On

DOWN OFF AUTO ON

ADV/DC/AUX HIGH VOLT-----high volts vdc

DOWN INC DEC TOP

ADV/DC/AUX LOW VOLT-----low volts vdc

DOWN INC DEC TOP

ADV/DC/AUX SOC HIGH-------SOC high %

DOWN INC DEC TOP

Pressing the <OFF> or <ON> soft keys will manually shut the

AUX o (the relay is open) or turn it on (the relay is closed),

respectively. In AUTO mode, the AUX is controlled by userdetermined set points. After setting the AUX control, press

the <DOWN> soft key.

Use the high volts screen and the <INC> and <DEC> soft

keys to control the AUX by a high voltage value. Press the

<DOWN> soft key to view the low volts screen.

Use the low volts screen and the <INC> and <DEC> soft

keys to control the AUX by a low voltage value. Press the

<DOWN> soft key to view the SOC high % screen.

Use the <INC> and <DEC> soft keys to change the SOC high

percentage to trigger the AUX function. Press the <DOWN>

soft key to view the SOC low % screeen.

26

Page 28

ADV/DC/AUX SOC LOW-------SOC low %

DOWN INC DEC TOP

Change the SOC low % values using the <INC> and <DEC>

soft keys. Press the <DOWN> soft key to continue.

ADV/DC/AUX/HI DELAY HIGHhigh setpoint delay

minutes

DOWN INC DEC TOP

ADV/DC/AUX/LO DELAY HIGHlow setpoint delay

minutes

DOWN INC DEC TOP

ADV/DC/AUX/INVERT--------invert logic

DOWN YES NO TOP

ADV/DC/AUX---------------aux parameters

complete

TOP ADV MAIN

Change the high setpoint delay minutes using the <INC> and

<DEC> soft keys. Press the <DOWN> soft key to continue.

Set the low setpoint delay minutes using the <INC> and

<DEC> soft keys. Press the <DOWN> soft key to continue.

To activate the invert logic function, press the <YES> soft key;

press the <NO> soft key to deactivate it. Press the <DOWN>

soft key to view the last AUX screen.

Press the <ADV> soft key.

27

ADV-------------------------------choose device:

FX CC DC MATE

ADV/DC/PAGE 1---------------choose category

ADV BAT SHUNT PG2

Press the <DC> soft key.

Pressing the <PG2> soft key.

Page 29

ADV/DC/PAGE 2----------------choose category:

PG1 CHARGE AUX PG3

Press the <PG3> soft key.

ADV/DC/AUX/PAGE 3---------choose category:

PG2 RESET CLR MAIN

Pressing the <RESET> soft key resets the FLEXnet DC

to its factory default settings.

Pressing the <CLR> soft key clears the data log

memory.

28

Page 30

Technical Notes

Battery Charge Factor (BCF)

Some energy is lost both when recharging and discharging a battery. The FLEXnet DC

compensates for these losses by discounting the amp-hours charging the battery, meaning

it doesn’t count every hour used for recharging as actually recharging. Some of them are lost

due to heat and gassing. The FLEXnet DC’s default BCF is 94, which means for every 100 amp

hours of charge to the battery, only 94 are shown in the amp hour display for a BCF of 94%.

This means 6% of the amp hours is lost.

As the system goes through a few recharging cycles, the range of state-of-charge (SOC)

percentages will vary, but should fall into a predictable range. This allows the user to change

the BCF if necessary for more e cient recharging. If the SOC displays as full before the battery

charge settings are met (either before the time setting or amp hour setting is satis ed), the

BCF should be lowered because it’s assuming too many amp hours have been recharging the

battery. By lowering the BCF, the FLEXnet DC will read more hours as being unused due to

ine ciency.

29

Page 31

2-Year Limited Warranty

FLEXnet Products

OutBack Power Systems, Inc. (“OutBack”) provides a two year (2) limited warranty (“Warranty”)

against defects in materials and workmanship for its FLEXnet products (“Products”) if installed

in xed location applications.

For this Warranty to be valid, the Product purchaser must complete and submit the applicable

Product registration card within ninety (90) days of the eligible Product’s rst retail sale. This

Warranty applies to the original OutBack Product purchaser, and is transferable only if the

Product remains installed in the original use location. The warranty does not apply to any

Product or Product part that has been modi ed or damaged by the following:

• Installation or Removal;

• Alteration or Disassembly;

• Normal Wear and Tear;

• Accident or Abuse;

• Corrosion;

• Lightning;

• Repair or service provided by an unauthorized repair facility;

• Operation contrary to manufacturer product instructions;

• Fire, Floods or Acts of God;

• Shipping or Transportation;

• Incidental or consequential damage caused by other components of the power system;

• Any product whose serial number has been altered, defaced or removed; or

• Any other event not foreseeable by OutBack.

30

OutBack’s liability for any defective Product, or any Product part, shall be limited to the repair

or replacement of the Product at OutBack’s discretion. OutBack does not warrant or guarantee

workmanship performed by any person or rm installing its Products. This Warranty does not

cover the costs of installation, removal, shipping (except as described below), or reinstallation

of Products.

Revision.2007-08-29

Page 32

To request warranty service, you must contact OutBack Technical Services at (360) 435-6030

or support@outbackpower.com within the e ective warranty period. If warranty service is

required, OutBack will issue a Return Material Authorization (RMA) number. A request for an

RMA number requires all of the following information:

1. Proof-of-purchase in the form of a copy of the original Product purchase invoice or receipt

con rming the Product model number and serial number;

2. Description of the problem; and

3. Shipping address for the repaired or replacement equipment.

After receiving the RMA number, pack the Product(s) authorized for return, along with a copy

of the original purchase invoice and warranty certi cate, in the original Product shipping

container(s) or packaging providing equivalent protection and mark the outside clearly with

the RMA number. The sender must prepay all shipping charges, and insure the shipment, or

accept the risk of loss or damage during shipment. OutBack is not responsible for shipping

damage caused by improperly packaged Products, the repairs this damage might require, or

the costs of these repairs. If, upon receipt of the Product, OutBack determines the Product is

defective and that the defect is covered under the terms of this Warranty, OutBack will then

and only then ship a repaired or replacement Product to the purchaser freight prepaid, nonexpedited, using a carrier of OutBack’s choice within the continental United States, where

applicable

Shipments to other locations will be made freight collect. The warranty period of any repaired

or replacement Product is twelve (12) months from the date of shipment from OutBack, or the

remainder of the initial warranty term, which ever is greater.

THIS LIMITED WARRANTY IS THE EXCLUSIVE WARRANTY APPLICABLE TO OUTBACK

PRODUCTS. OUTBACK EXPRESSLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTIES

OF ITS PRODUCTS, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. OUTBACK ALSO EXPRESSLY

LIMITS ITS LIABILITY IN THE EVENT OF A PRODUCT DEFECT TO REPAIR OR REPLACEMENT IN

ACCORDANCE WITH THE TERMS OF THIS LIMITED WARRANTY AND EXCLUDES ALL LIABILITY

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION ANY

LIABILITY FOR PRODUCTS NOT BEING AVAILABLE FOR USE OR LOST REVENUES OR PROFITS,

EVEN IF IT IS MADE AWARE OF SUCH POTENTIAL DAMAGES. SOME STATES (OR JURISDICTIONS)

MAY NOT ALLOW THE EXCLUSION OR LIMITATION OF WARRANTIES OR DAMAGES, SO THE

ABOVE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU.

31

Revision.2007-08-29

Page 33

net DC

TM

Limited Warranty Registration

Complete this form to request a Limited

Warranty and return it to:

Outback Power Systems Inc.

19009 62nd Ave. NE

Arlington, WA 98223

Note: A Limited Warranty Certi cate will only be issued if this Registration Card is received by OutBack

within 90 days of the date of the rst retail sale of the eligible Product. Please submit a copy (not the

original) of the Product purchase invoice, which con rms the date and location of purchase, the price

paid, and the Product Model and Serial Number.

Two Year Limited FLEXnet DC Warranty Registration

System Owner

Name: _______________________________ Country: _______________________________

Address: ______________________________ Telephone Number: _______________________

City, State, Zip Code: ____________________ E-mail__________________________________

Product

Product Model Number: _________________ Sold by: ________________________________

Product Serial Number: __________________ Purchase Date: ___________________________

Optional Extended Warranty* Coverage? (circle one): Yes No

Please circle the three most important factors a ecting your purchase decision:

• Price • Product Reputation • Product Features

• Reputation of OutBack Power Systems • Value

System

System Install/Commission Date: __________ Type of PV Modules: ______________________

System Battery Bank Size

(Amp Hours)

: ________ System Array Size: ________________________

Type of Batteries: _______________________ System Array Nominal Voltage: ______________

Please List Other sources of Back-up Power: ___________________________________________

______________________________________________________________________________

Devices Being Monitored by FLEXnet DC: _____________________________________________

______________________________________________________________________________

Installer

Installer: ______________________________ Contractor Number: ______________________

Installer Address: _______________________ Installer City, State, Zip: ____________________

Installer E-mail: _________________________

32

*Extended Warranty - OutBack Power Systems o ers an optional three year extension to the standard two year Limited

Warranty in North America for the FLEXnet DC product. To request a 3-year Limited Warranty extension for a total e ective

warranty coverage period of ve years(5); include a check or money order in the amount of $50USD payable to OutBack

Power Systems, Inc. along with your Warranty Registration.

Revision .2007-09-17

Page 34

Corporate O ce

19009 62nd Avenue NE

Arlington, WA USA

Phone: (+1) 360.435.6030

www.outbackpower.com

European Sales O ce

C/ Castelló, 17

08830 - Sant Boi de Llobregat

BARCELONA, España

Phone: (+34) 93.654.9568

900-0093-01-00 REV B

Loading...

Loading...