Page 1

FLEXmax Extreme Charge Controller

Owner’s Manual

Page 2

T

About OutBack Power Technologies

OutBack Power Technologies is a leader in advanced energy conversion technology. OutBack products include

true sine wave inverter/chargers, maximum power point tracking charge controllers, and system communication

components, as well as circuit breakers, batteries, accessories, and assembled systems.

Grid/Hybrid™

As a leader in off-grid energy systems, which are designed around energy storage, OutBack Power is an

innovator in Grid/Hybrid system technology which provides the best of both worlds: grid-tied system savings

during normal or daylight operation, and off-grid independence during peak energy times or in the event of a

power outage or an emergency. Grid/Hybrid systems have the intelligence, agility, and interoperability to

operate in multiple energy modes quickly, efficiently, and seamlessly, in order to deliver clean, continuous and

reliable power to residential and commercial users while maintaining grid stability.

Contact Information

Address: Corporate Headquarters

17825 – 59

Suite B

Arlington, WA 98223 USA

elephone:

Email: Support@outbackpower.com

Website: http://www.outbackpower.com

+1.360.435.6030

+1.360.618.4363 (Technical Support)

+1.360.435.6019 (Fax)

th

Avenue N.E.

European Office

Hansastrasse 8

D-91126

Schwabach, Germany

+49.9122.79889.0

+49.9122.79889.21 (Fax)

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER TECHNOLOGIES:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF

ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

OutBack Power Technologies cannot be responsible for system failure, damages, or injury resulting from

improper installation of their products.

Notice of Copyright

FLEXmax Extreme Charge Controller Owner’s Manual © 2013 by OutBack Power Technologies. All Rights Reserved.

Trademarks

OutBack Power, the OutBack Power logo, FLEXpower ONE, and Grid/Hybrid are trademarks owned and used

by OutBack Power Technologies, Inc. The ALPHA logo and the phrase “member of the Alpha Group” are

trademarks owned and used by Alpha Technologies Inc. These trademarks may be registered in the United

States and other countries.

Date and Revision

June 2013, Revision A

Part Number

900-0150-01-00 Rev A

Page 3

Table of Contents

Introduction ................................................................................................................................................................. 5

Audience................................................................................................................................................................................................... 5

Features .................................................................................................................................................................................................... 5

Firmware ................................................................................................................................................................................................... 5

Components and Accessories ........................................................................................................................................................... 6

Battery Types ..................................................................................................................................................................................... 6

Installation .................................................................................................................................................................... 7

Standards and Requirements ............................................................................................................................................................ 7

Dimensions ........................................................................................................................................................................................ 7

Mounting the Charge Controller ...................................................................................................................................................... 8

Installing the Fan ................................................................................................................................................................................. 10

Installing the AXS Card ...................................................................................................................................................................... 11

Wiring ...................................................................................................................................................................................................... 12

Grounding ........................................................................................................................................................................................ 12

Wiring Size and Requirements .................................................................................................................................................. 12

Physical Requirements and Conduit ....................................................................................................................................... 13

PV and Battery Terminals ............................................................................................................................................................ 13

Accessory Terminals and Ports .................................................................................................................................................. 16

HUB/Display Port ...................................................................................................................................................................... 16

Remote Temperature Sensor ............................................................................................................................................... 16

AXS Card ...................................................................................................................................................................................... 16

Fan Port ........................................................................................................................................................................................ 16

Accessory Terminal Block ...................................................................................................................................................... 16

AUX Terminals ..................................................................................................................................................................... 17

Battery Sense Terminals ................................................................................................................................................... 18

External Fault Terminals ................................................................................................................................................... 18

Power Up ................................................................................................................................................................................................ 21

Setting the Nominal Voltage ...................................................................................................................................................... 21

Resetting to Factory Defaults ..................................................................................................................................................... 22

Initial Operation ................................................................................................................................................................................... 22

Status and Information .......................................................................................................................................... 23

LED Indicators ....................................................................................................................................................................................... 23

Modes of Operation ................................................................................................................................................................ 25

Bulk .......................................................................................................................................................................................... 25

Absorb .................................................................................................................................................................................... 26

Floating .................................................................................................................................................................................. 27

EQ ............................................................................................................................................................................................. 27

Silent ....................................................................................................................................................................................... 28

MATE3 System Display and Controller ......................................................................................................................................... 29

Battery Status Indicators .............................................................................................................................................................. 29

Charger Indicator ........................................................................................................................................................................... 29

Charge Controller Soft Key ......................................................................................................................................................... 30

Status Screen ............................................................................................................................................................................. 30

Stats Screen ...................................................................................................................................................................................... 31

Error Screen ...................................................................................................................................................................................... 32

Temps Screen .................................................................................................................................................................................. 32

DataLog Screen .............................................................................................................................................................................. 33

900-0150-01-00 Rev A 1

Page 4

Table of Contents

Graph Screens ................................................................................................................................................................................. 34

Programming the FLEXmax Extreme ............................................................................................................... 35

Menu Structure in the MATE3 ......................................................................................................................................................... 35

Charge Controller Settings ............................................................................................................................................................... 36

Charger .............................................................................................................................................................................................. 36

MPPT ................................................................................................................................................................................................... 37

Temperature Compensation ...................................................................................................................................................... 38

Battery Equalize .............................................................................................................................................................................. 38

Grid-Tie Mode.................................................................................................................................................................................. 39

Auxiliary Output ............................................................................................................................................................................. 39

Auxiliary Mode Screens .......................................................................................................................................................... 40

Restart Mode ................................................................................................................................................................................... 45

Calibrate ............................................................................................................................................................................................ 45

Reset Charge Controller to Factory Defaults ........................................................................................................................ 45

Firmware Revision .................................................................................................................................................................... 46

Updating the Firmware .................................................................................................................................................... 46

Device Data Logs ................................................................................................................................................................................. 47

Saving Data Logs for the FLEXmax Extreme ......................................................................................................................... 47

Data Log File Format ......................................................................................................................................................... 48

MATE/MATE2 Screens ............................................................................................................................................ 49

Summary Screens ................................................................................................................................................................................ 49

Status Screens ....................................................................................................................................................................................... 50

MODE Screens ................................................................................................................................................................................. 50

METER Screens ................................................................................................................................................................................ 51

SETPT Screens ................................................................................................................................................................................. 52

LOG Screens ..................................................................................................................................................................................... 53

STAT Screens ................................................................................................................................................................................... 54

Advanced Menus ................................................................................................................................................................................. 55

Accessing the Advanced Menus ............................................................................................................................................... 55

CHGR Menu ...................................................................................................................................................................................... 56

CC ADVANCED Menu .................................................................................................................................................................... 57

EQ Menu ............................................................................................................................................................................................ 58

AUX Menu ......................................................................................................................................................................................... 59

Troubleshooting ...................................................................................................................................................... 61

Specifications ............................................................................................................................................................ 63

Electrical and Mechanical Specifications ..................................................................................................................................... 63

Environmental Specifications .......................................................................................................................................................... 63

Regulatory Specifications ................................................................................................................................................................. 64

FCC Information to the User ....................................................................................................................................................... 64

Firmware Revision ............................................................................................................................................................................... 64

Temperature Range and Derating ................................................................................................................................................. 65

Default Settings and Ranges ............................................................................................................................................................ 66

Applications ............................................................................................................................................................... 69

Array Design .......................................................................................................................................................................................... 69

Sizing Guidelines ............................................................................................................................................................................ 69

Maximum-Power Voltage (Vmp) ................................................................................................................................................. 69

Open Circuit Voltage (Voc) ........................................................................................................................................................... 69

Weather Conditions ...................................................................................................................................................................... 70

Maximum Power Point Tracking .................................................................................................................................................... 70

Three-Stage Battery Charging ......................................................................................................................................................... 71

Bulk ..................................................................................................................................................................................................... 71

Absorption ....................................................................................................................................................................................... 71

Float .................................................................................................................................................................................................... 72

2 900-0150-01-00 Rev A

Page 5

Table of Contents

Equalize ............................................................................................................................................................................................. 72

Battery Temperature Compensation ....................................................................................................................................... 72

FLEXnet DC Battery Monitor (FN-DC) ........................................................................................................................................... 73

Positive-Ground Systems .................................................................................................................................................................. 74

Networked Devices ....................................................................................................................................................................... 74

Non-Networked Devices.............................................................................................................................................................. 74

Grid-Interactive Settings ................................................................................................................................................................... 75

Hydroelectric and Fuel Cell Applications Performance Optimization ............................................................................... 75

Auto Track Mode ............................................................................................................................................................................ 75

U-Pick Mode ..................................................................................................................................................................................... 75

Definitions .............................................................................................................................................................................................. 77

Index ............................................................................................................................................................................. 79

List of Tables

Table 1 Components Included ..................................................................................................................................................... 6

Table 2 LED Indicators ................................................................................................................................................................... 24

Table 3 Absorption Timer ............................................................................................................................................................. 26

Table 4 Reasons for Silent Mode ................................................................................................................................................ 28

Table 5 Battery Status LED Indicators ....................................................................................................................................... 29

Table 6 AUX Mode Functions ...................................................................................................................................................... 40

Table 7 Troubleshooting .............................................................................................................................................................. 61

Table 8 Electrical and Mechanical Specifications for All Models ..................................................................................... 63

Table 9 Environmental Specifications for All Models .......................................................................................................... 63

Table 10 FLEXmax Settings (MATE3) ........................................................................................................................................... 66

Table 11 Maximum Input Wattage Per Charge Controller .................................................................................................. 69

Table 12 Examples of Compensation ......................................................................................................................................... 73

Table 13 Terms and Definitions .................................................................................................................................................... 77

900-0150-01-00 Rev A 3

Page 6

Table of Contents

THIS PAGE INTENTIONALLY LEFT BLANK.

4 900-0150-01-00 Rev A

Page 7

Introduction

Thank you for purchasing a FLEXmax Extreme Series Charge Controller. These

efficient, safe, multi-stage recharging process that prolongs battery life and assures peak performance from a

PV array.

charge

controllers offer an

Audience

This manual is intended for use by anyone required to install and operate this equipment. Be sure to review this

manual carefully to identify any potential safety risks before proceeding. Installers and operators must be

familiar with all the features and functions of this equipment before proceeding. Failure to install or use this

equipment as instructed in the manual can result in damage to the equipment that may not be covered under

the limited warranty. This product is only serviceable by qualified personnel.

IMPORTANT:

This manual provides safety guidelines and installation information for the FLEXmax

Extreme charge controller. It does not provide information about specific brands of PV

modules and supplies limited information on batteries.

Contact the supplier of the PV modules or batteries for additional information.

Features

The FLEXmax Extreme charge controller uses continuous Maximum Power Point Tracking (MPPT). This function

continuously seeks out the maximum power available from a PV array and harvests it. This power is used to

recharge the batteries. Without MPPT, the system can only harvest power at the level of the battery voltage.

See page 70 for a description of MPPT.

The FLEXmax Extreme has the following features:

Designed for FLEXgrid™ operation as part of an OutBack Grid/Hybrid™ system

Supports 12, 24, 36, 48, and 60 Vdc battery voltages

Performs voltage step-down capability allowing the use of a higher-voltage PV array configuration

Controls an equalization cycle manually or automatically

Capable of delivering full current without derating in temperatures up to 45°C (113°F)

Capable of full current without derating up to 55°C (131°F) when using optional fan kit

Rain-proof enclosure

Logs up to 128 days of operational data

Field-upgradeable firmware

Can be remotely monitored and configured (up to 300 feet or 100 meters away) using the optional MATE3

system display

Can be remotely monitored and upgraded using the optional AXS Card product

Firmware

This manual covers FLEXmax Extreme firmware revision 001.xxx.000.

900-0150-01-00 Rev A 5

Page 8

Introduction

Components and Accessories

Table 1 Components Included

1 x FM Extreme-150VDC

2 x Mounting Bracket 1 x Silicone Grease Package

2 x Ferrite Clamp, EMI Suppression (install on HUB/DEVICE port and RTS port; see page 16)

WARNING: Shock Hazard

This unit is not provided with a GFDI device. This charge controller must be used with

an external GFDI device as required by Article 690 of the National Electrical Code for the

installation location.

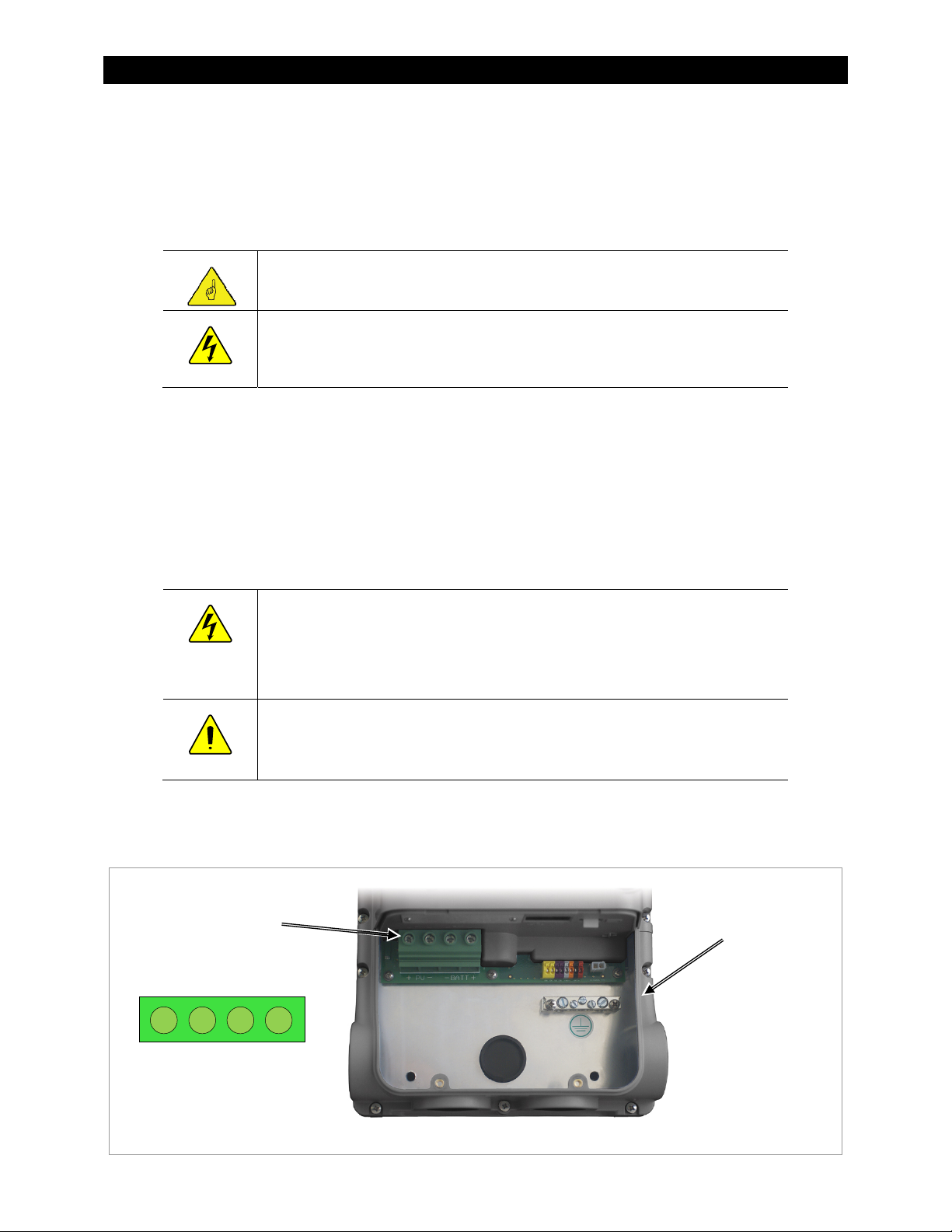

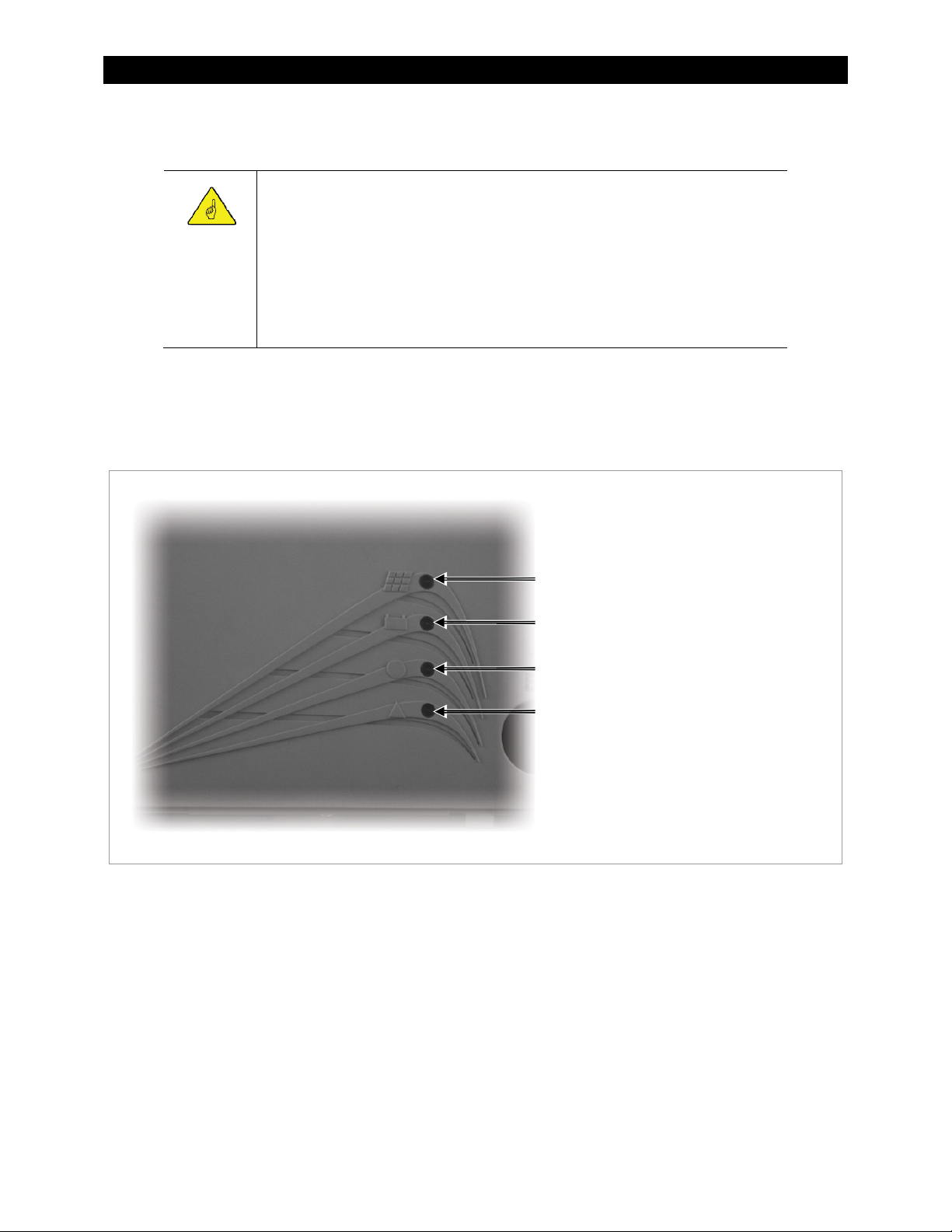

Rainproof

enclosure

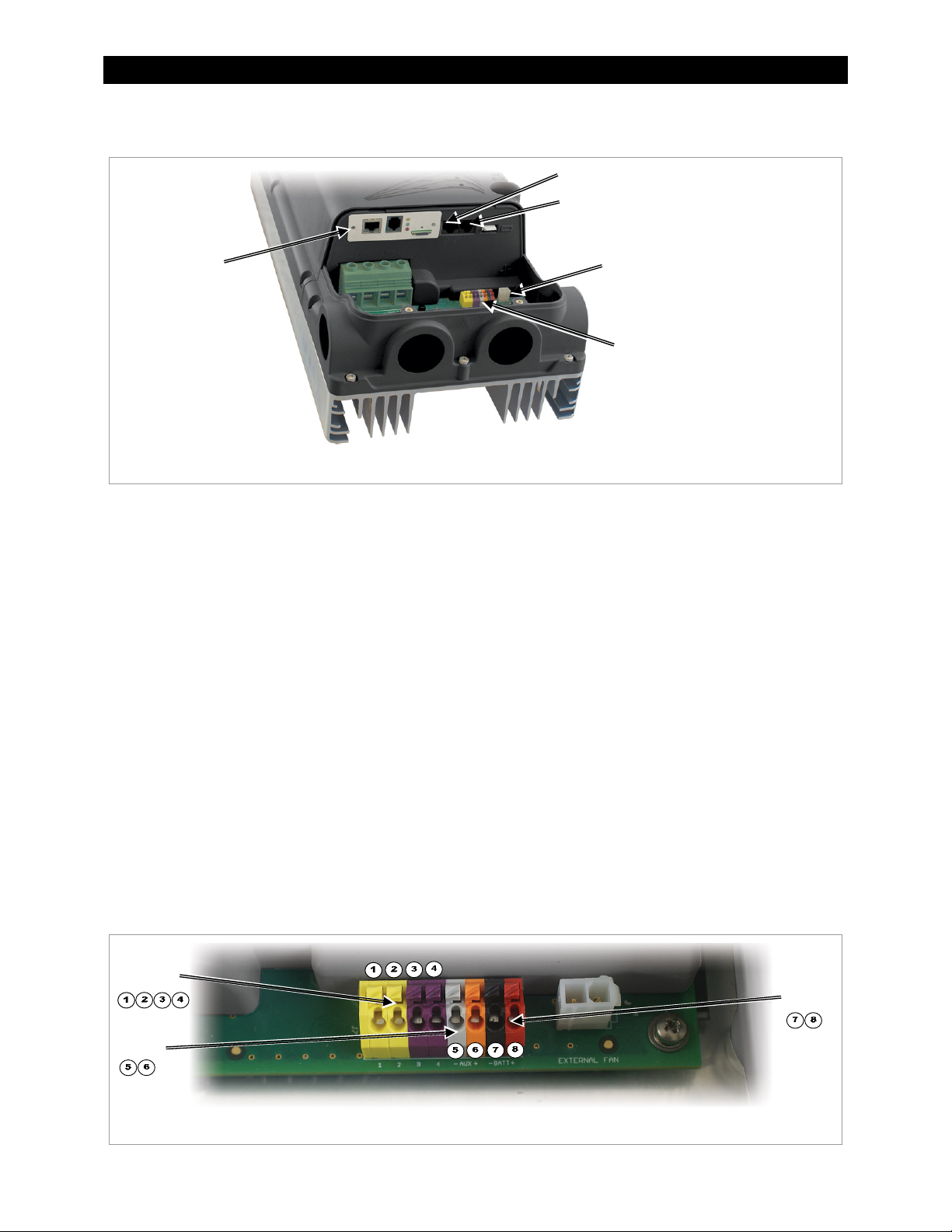

Status indicators

with universal symbols

Equalize switch

Easily accessible

wiring

compartment

To remove the wiring compartment cover:

1. Using a Phillips screwdriver, remove the two

screws from the bottom of the compartment

cover. (See above.)

2. Grasp the lower edge as shown. Swing the

Cover screws

cover out while pulling downward.

Figure 1 Features & Wiring Cover

Battery Types

The FLEXmax Extreme charge controller works best with lead-chemistry batteries intended for deep discharge.

These include batteries for marine, golf-cart, and forklift applications. They also include gel-cell batteries and

absorbed glass-mat (AGM) batteries. OutBack Power recommends the use of batteries designed specifically for

renewable energy applications. Lithium-based batteries and other advanced battery technologies may require

special considerations. Please contact OutBack Technical Support at +1.360.618.4363 before implementing

advanced battery technologies.

6 900-0150-01-00 Rev A

Page 9

Installation

Standards and Requirements

All installations must comply with national and local electrical codes. Professional installation is recommended.

A FLEXmax Extreme charge controller operating in unventilated or in other conditions where the ambient

temperature exceeds 45°C (113°F) will have a derated power output. See page 65 for more information.

If damaged or malfunctioning, the FLEXmax Extreme should only be serviced by qualified personnel.

Please contact the local renewable energy dealer/installer for assistance.

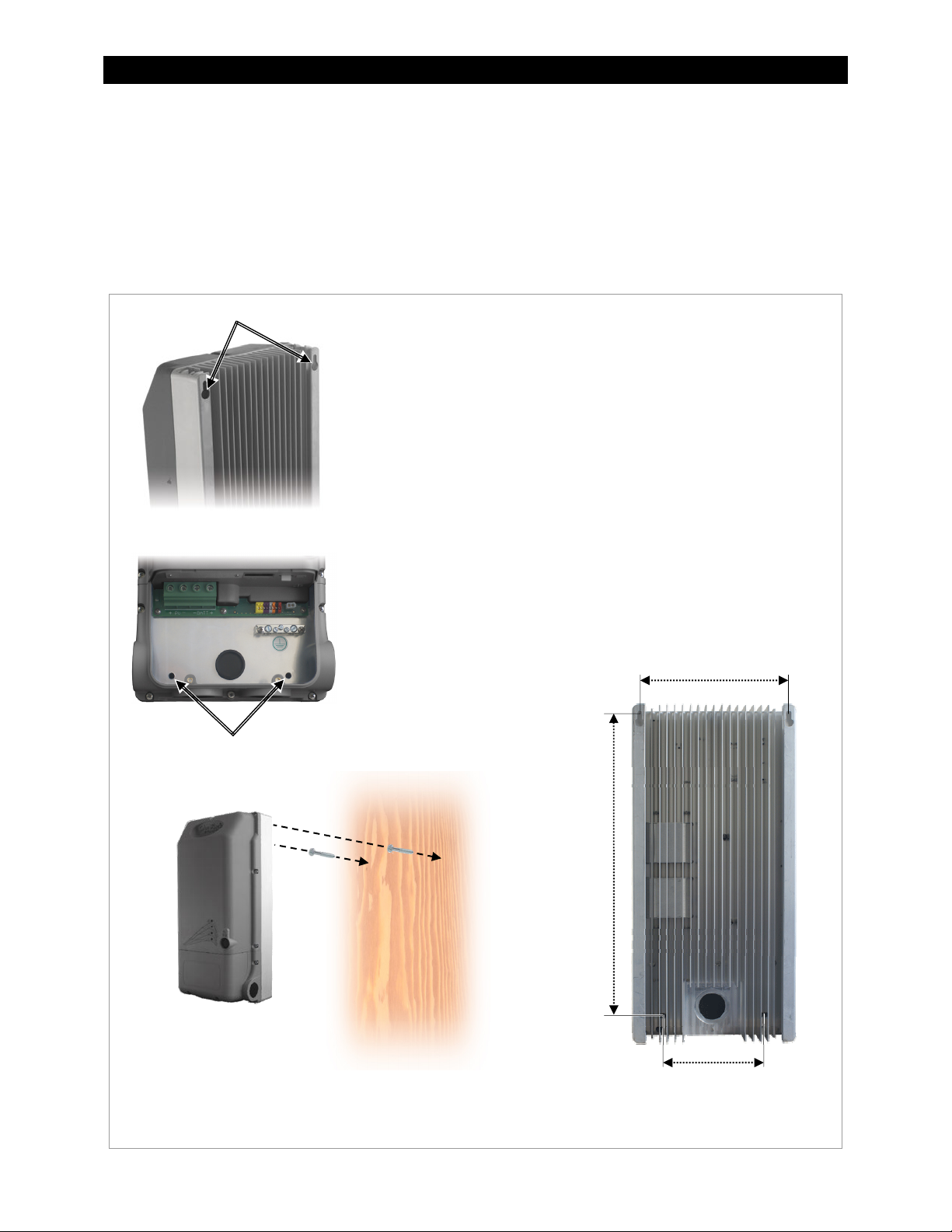

Dimensions

Wiring box

height 4.4”

(11.2 cm)

Width 8.8” (22.4 cm)

Depth 6.0” (15.2 cm)

Height 18.6”

(47.1 cm)

Wiring box opening width 6.9” (17.6 cm)

Side Plugs:

3.27” (8.3 cm)

For height with optional fan installed, see page 10

Bottom Plugs:

3.3” (8.4 cm)

Figure 2 FLEXmax Extreme Dimensions

900-0150-01-00 Rev A 7

Page 10

Installation

Mounting the Charge Controller

The FLEXmax Extreme must be mounted upright on a wall or similar flat upright mounting surface. It must be

mounted at least 36” (91.4 cm) above the ground or floor. No other mounting positions are allowed. Installation

in shade is recommended.

Clearance requirements are a minimum of 6“ (15.2 cm) above and below the controller.

Two mounting methods are available. The first method uses keyhole slots on the back of the controller for

hanging directly on a wall. This method is useful for a standalone installation.

Keyhole slots

To mount using keyhole slots:

1. Use two slotted #14 wood screws. The mounting surface must be

strong enough to support the weight of the FLEXmax Extreme.

NOTE: OutBack is not responsible for damage resulting from

inadequate mounting hardware or preparation.

2. Mark the locations where the screws will be inserted on the surface.

Space them according to the keyhole slot locations (see below).

NOTE: The brackets included with the controller have holes with

the same spacing which can be used as a marking template.

3. Using the appropriate tools, set the screws into the surface

(see below). The heads should protrude by 1/8” (0.3 cm).

4. Hang the FLEXmax Extreme by placing its back against the

mounting surface and aligning the keyhole slots with the screws.

Settle the controller so that the screws are seated in the narrow end

of each slot.

5. Secure the base of the controller to the surface by inserting two ¼”

hex head lag screws into the holes shown to the left.

Slot spacing 7.9” (20.1 cm)

Securing holes

Distance

16.9” (42.9 cm)

Hole spacing 5.5” (13.9 cm)

Mounting is complete. Proceed to charge controller wiring or other installation steps.

Figure 3 Mounting the Charge Controller (keyhole)

8 900-0150-01-00 Rev A

Page 11

Installation

The second mounting method uses brackets on the top and bottom of the controller. This method is useful

when mounting the controller next to an OutBack inverter system, as the conduit openings will align. It is also

useful for mounting without making advance measurements. The FLEXmax Extreme controller comes with two

identical brackets.

To mount using brackets:

1. Using two ¼” hex head lag screws, mount the lower

bracket with the tabs facing upward. The mounting

surface must be strong enough to support the added

weight of the FLEXmax Extreme.

NOTE: OutBack is not responsible for damage

resulting from inadequate mounting preparation.

2. Lower the FLEXmax Extreme onto the bracket as

shown to the left. The bracket tabs can be inserted in

one of two positions: forward or rear.

To mount the controller flush against the wall,

insert the tabs in the forward slots as shown below.

To mount the controller 0.83” (2.1 cm) from the

wall to align with an OutBack mounting plate,

insert the tabs in the rear slots as shown below.

Forward

slot

Rear

slot

NOTE: The charge controller can rest on the lower

bracket for the rest of the procedure, although it will

need at least one hand to steady it.

3. Insert the upper bracket into the same set of slots as

were used with the lower bracket (forward or rear) as

shown to the left.

4. Using two ¼” hex head lag screws, attach the upper

bracket to the mounting surface as shown to the left.

Mounting is complete. Proceed to charge controller

wiring or other installation steps.

Figure 4 Mounting the Charge Controller (brackets)

900-0150-01-00 Rev A 9

Rear

slot

Forward

slot

Page 12

Installation

T

Installing the Fan

An optional fan is available for the FLEXmax Extreme to provide additional cooling. The fan is mounted on the

bottom of the charge controller. The total unit height with the fan attached is shown below. See page 65 for

information on the fan’s effects on unit performance.

To install the optional cooling fan:

1. Place the fan against the base of the FLEXmax Extreme.

he fan is equipped with two locking tabs. Two of the heat sink

fins have holes which receive the tabs. Align the tabs with

these fins (see below).

2. Press the fan straight along the fins until the tabs snap into

the holes.

Height

with fan

22.06” (56 cm)

Heat sink fins

Tab

3. Insert the fan connector into the fan

port in the controller’s wiring box. It

may be necessary to remove the rear

plug and insert a bushing. (See

illustration to the left; also see page 16.)

Installation is complete. The fan will

operate automatically based on the

FLEXmax Extreme internal temperature.

See page 32 to read the temperature using

the MATE3 System Display. This page also

lists the temperatures at which the fan

turns on and off.

Figure 5 Installing the Fan

10 900-0150-01-00 Rev A

Page 13

Installation

p

Installing the AXS Card

An optional AXS Card enables Ethernet access to the FLEXmax Extreme using the Modbus protocol. (The AXS

Card is identical in function to the OutBack AXS Port product. See the AXS Port SunSpec Modbus Interface Owner’s

Manual for more information. NOTE: The AXS Port product is not interchangeable with the AXS Card and

cannot be used in this compartment.

To install the AXS Card:

1. Remove the factory-installed blank

compartment cover from the FLEXmax

Extreme. The cover is held in place with

two Phillips screws.

Screws

3. Install the alternate compartment cover

which was included with the AXS Card.

Use the Phillips screws which were

removed from the blank cover.

Insert

Screws

2. Insert the AXS Card onto the rails

on each side of the compartment.

Slide it in until the card presses

firmly onto the connector at the

rear of the com

artment.

Installation is complete. See the AXS Port SunSpec Modbus Interface Owner’s Manual for information on use.

Figure 6 Installing the AXS Card

900-0150-01-00 Rev A 11

Page 14

Installation

Wiring

This section provides instructions on installing PV array wiring into the charge controller. See page 69 for more

notes on PV array sizing. All wiring must comply with local and national codes.

Grounding

This product is intended to be installed as part of a permanently grounded electrical system. This is shown in the

wiring diagrams in this book. Grounding methods must comply with local and national codes.

The FLEXmax Extreme equipment ground is marked with this symbol:

IMPORTANT:

Article 690 of the NEC requires ground-fault protection such as the OutBack GFDI.

It is recommended to bond one of the DC conductors to the ground on the battery

side of the system.

The DC conductor is connected to the ground as a result of installing the OutBack

GFDI. They should not be bonded separately. If a separate bond is already present

in the system, it should be removed. If present, it will defeat the GFDI protection.

(See page 19.)

Bonding the negative and ground is most common. However, the FLEXmax

Extreme can be used normally in either negative-ground or positive-ground

systems. Page 14 shows examples of both types of system wiring. See below for

restrictions on positive grounding. Also see page 74.

CAUTION: Equipment Damage

The FLEXmax Extreme can be used in a positive-ground system when networked with

one OutBack inverter. This requires a HUB Communications Manager. (See page 15.)

It cannot be networked in a positive-ground system with multiple inverters. For use of

the FLEXnet DC Battery Monitor or other devices in these applications, see page 74.

Failure to follow these instructions can damage the controller and other devices. This

damage is not covered under warranty.

The following important restrictions apply unless superseded by local or national codes:

The grounding conductors must be routed separately from all battery conductors.

The battery conductor (positive or negative) must be bonded to the grounding system at only one point.

Wiring Size and Requirements

IMPORTANT:

Wire sizes must comply with local and national codes. Input conductors and circuit

breakers must be rated at 1.56 times the short-circuit current of the PV array (per NEC).

OutBack 100% duty continuous circuit breakers only need to be rated at 1.25 times the

short-circuit current.

Please refer to the NEC and other electrical codes for PV array cable sizing, cable length, and cable ampacity.

Use #4 AWG (25 mm

bar conductors. Smaller cables can reduce performance and possibly damage the unit.

The output can accept up to #2 AWG (35 mm2) wire. Larger conductors will reduce losses and ensure

highest performance of the FLEXmax Extreme.

Install properly sized overcurrent protection devices. The required AIC rating of the device is 4000 Adc.

12 900-0150-01-00 Rev A

2

) wire (minimum) for the output between the FLEXmax Extreme and the battery bus

Page 15

Installation

The largest PV array must have a rated short-circuit current of 64 amps or less under STC (Standard

Test Conditions). The output current limit of the FLEXmax Extreme is 80 amps.

DC battery overcurrent protection must be used as part of the installation. OutBack offers both circuit

breakers and fuses for overcurrent protection.

Physical Requirements and Conduit

IMPORTANT:

Conduit hubs must connect to the conduit before connecting to the FLEXmax Extreme.

WARNING: Burn Hazard

The heat sink can become hot when the charge controller is operating. Use caution

when touching it during operation.

All wire lugs and ground terminals are to be tightened to a torque value of 4 Nm (35 in-lb).

Use copper wiring only. Wiring must be rated at 90°C or higher.

If installing in a wet location, any conduit hubs must comply with the requirements of UL 514B.

Run positive and negative cables side by side.

~ Tie or twist cables together as much as possible to allow the inductive currents to cancel.

~ Ensure paired cables pass through the same knockout and conduit fittings.

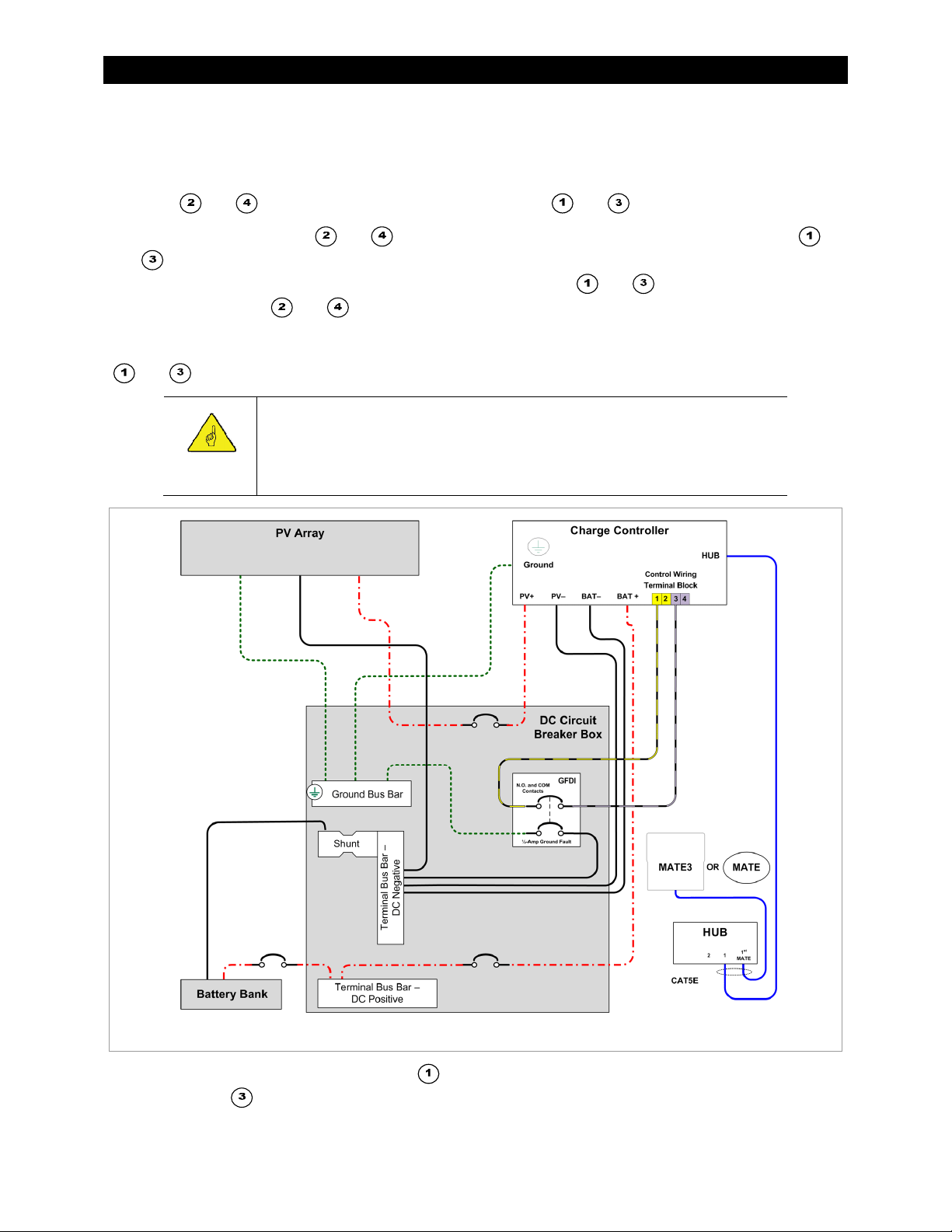

PV and Battery Terminals

WARNING: Shock Hazard

When a PV array is exposed to light, it immediately generates a voltage. Make sure all

DC circuit breakers are OFF (open) BEFORE making any wiring connections. Open both

the battery disconnect devices and the array disconnect devices to ensure isolation of

the controller. Use a DVM to check for voltage on all wires.

CAUTION: Equipment Damage

Each FLEXmax Extreme requires its own PV array. DO NOT PARALLEL PV+ and PVTERMINALS OF MULTIPLE CONTROLLERS ON THE SAME ARRAY!

The negative (-) PV and negative (-) BAT terminals are connected internally. Only one wire is needed to connect

to the negative (-) wire lugs if the negative (-) PV and BAT conductors are bonded at the negative bus bar.

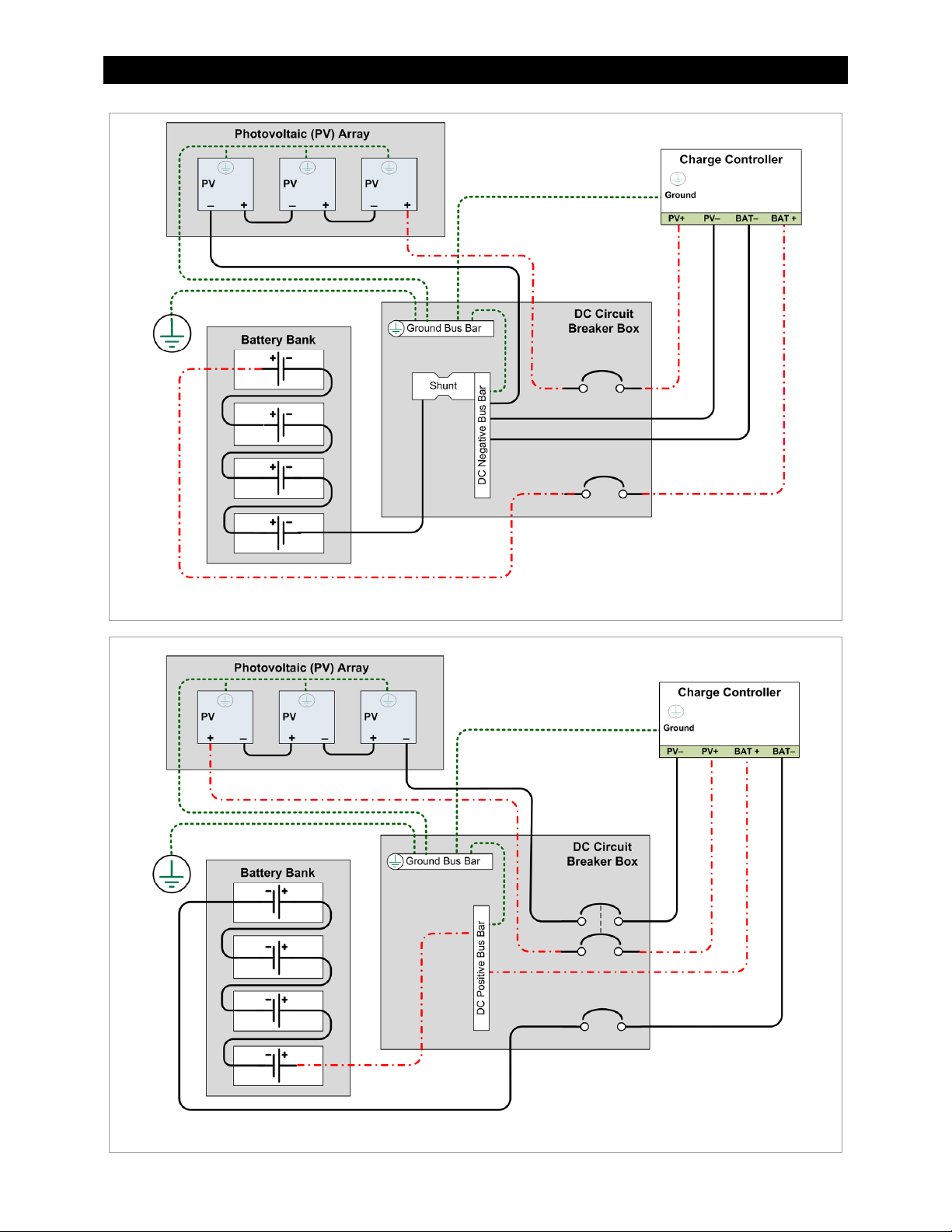

See Figure 8, Figure 10, Figure 16

DC

Terminals

DC TERMINALS

PV + PV - BAT - BAT +

, and Figure 17 for sample wiring diagrams.

Ground

Bus

Figure 7 Wiring Compartment

900-0150-01-00 Rev A 13

Page 16

Installation

NOTE: Ground Fault and system-specific

wiring not shown

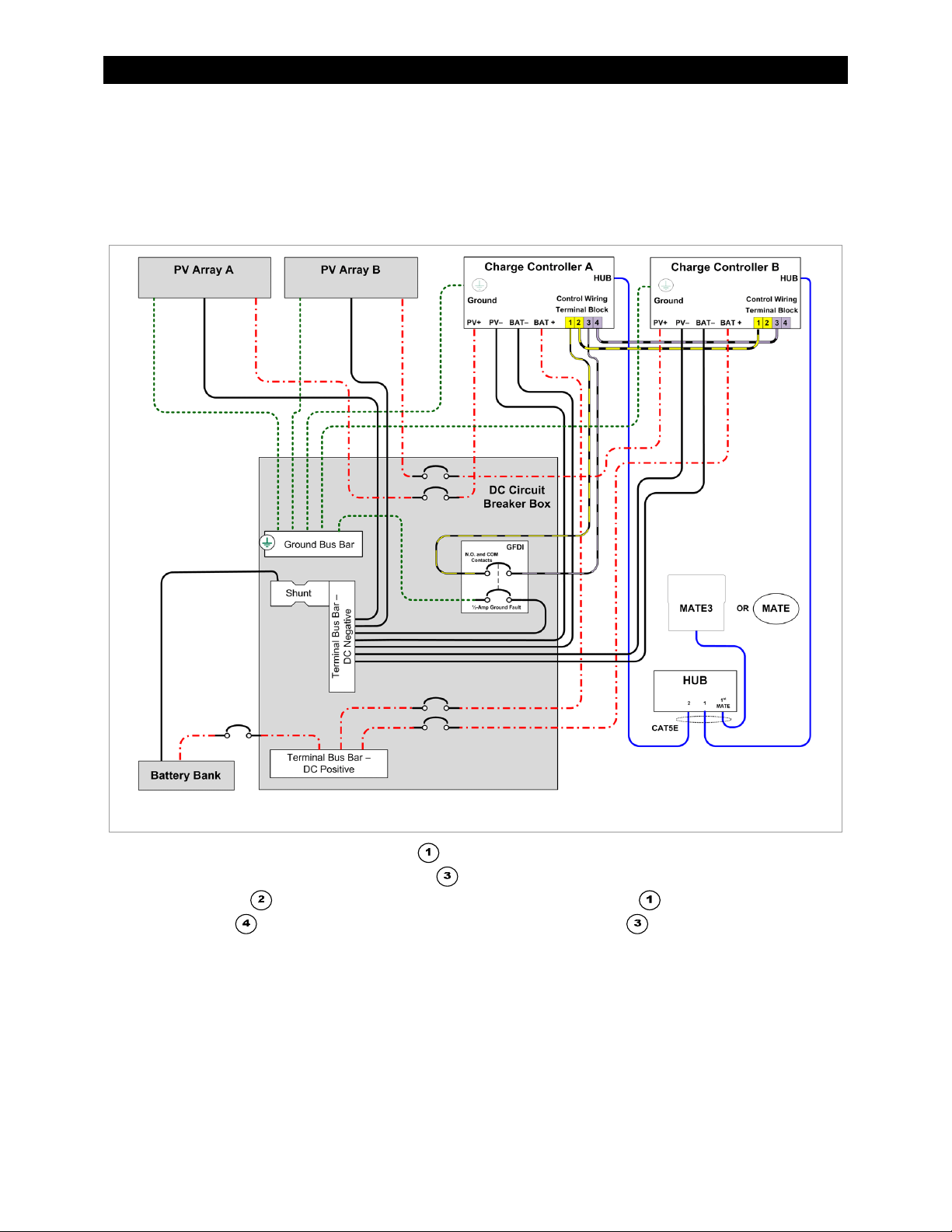

Figure 8 Wiring Diagram – Single Charge Controller with PV Array

NOTE: Ground Fault and system-specific

wiring not shown

Figure 9 Wiring Diagram – Single Charge Controller (Positive-Ground)

14 900-0150-01-00 Rev A

Page 17

Installation

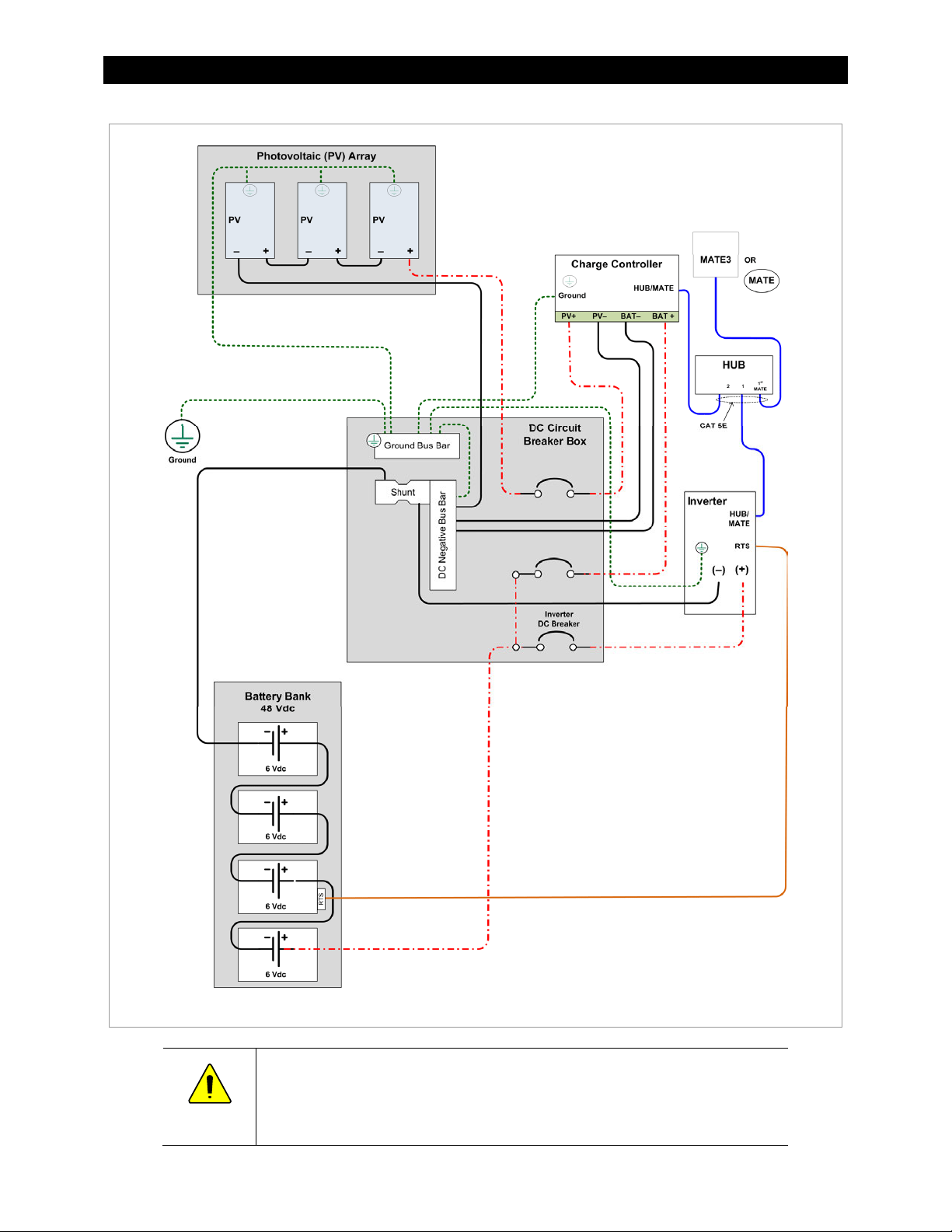

NOTE: Ground Fault and system-specific wiring not shown

Figure 10 Wiring Diagram – Charge Controller with PV Array and Inverter

CAUTION: Equipment Damage

The FLEXmax Extreme can be used in a positive-ground system with one OutBack

inverter as shown above. It cannot be used in a positive-ground system with multiple

OutBack inverters. For other devices or configurations, see page 74.

900-0150-01-00 Rev A 15

Page 18

Installation

Accessory Terminals and Ports

HUB/System Display Port

Remote

Temperature

Sensor (RTS) Port

AXS Card

(optional)

Fan Connector

Accessory Terminal Block

Figure 11 Wiring Compartment

HUB/Display Port

This is an RJ-45 port for a CAT5 cable to connect OutBack system displays or communications managers. A

ferrite clamp (see page 6) should be installed on this cable inside the compartment.

Remote Temperature Sensor

An optional battery Remote Temperature Sensor (RTS) is recommended for accurate battery charging. A ferrite

clamp (see page 6) should be installed on this cable inside the compartment.

When the system includes an OutBack HUB Communications Manager and a system display, only one RTS is

needed for multiple inverters and charge controllers. Specialized temperature compensation is available.

See page 38 for more information.

AXS Card

This is the location for the AXS Card, which is available as an option for the FLEXmax Extreme. See page 11.

Fan Port

This is the connection for the FLEXmax Extreme cooling fan. See page 10.

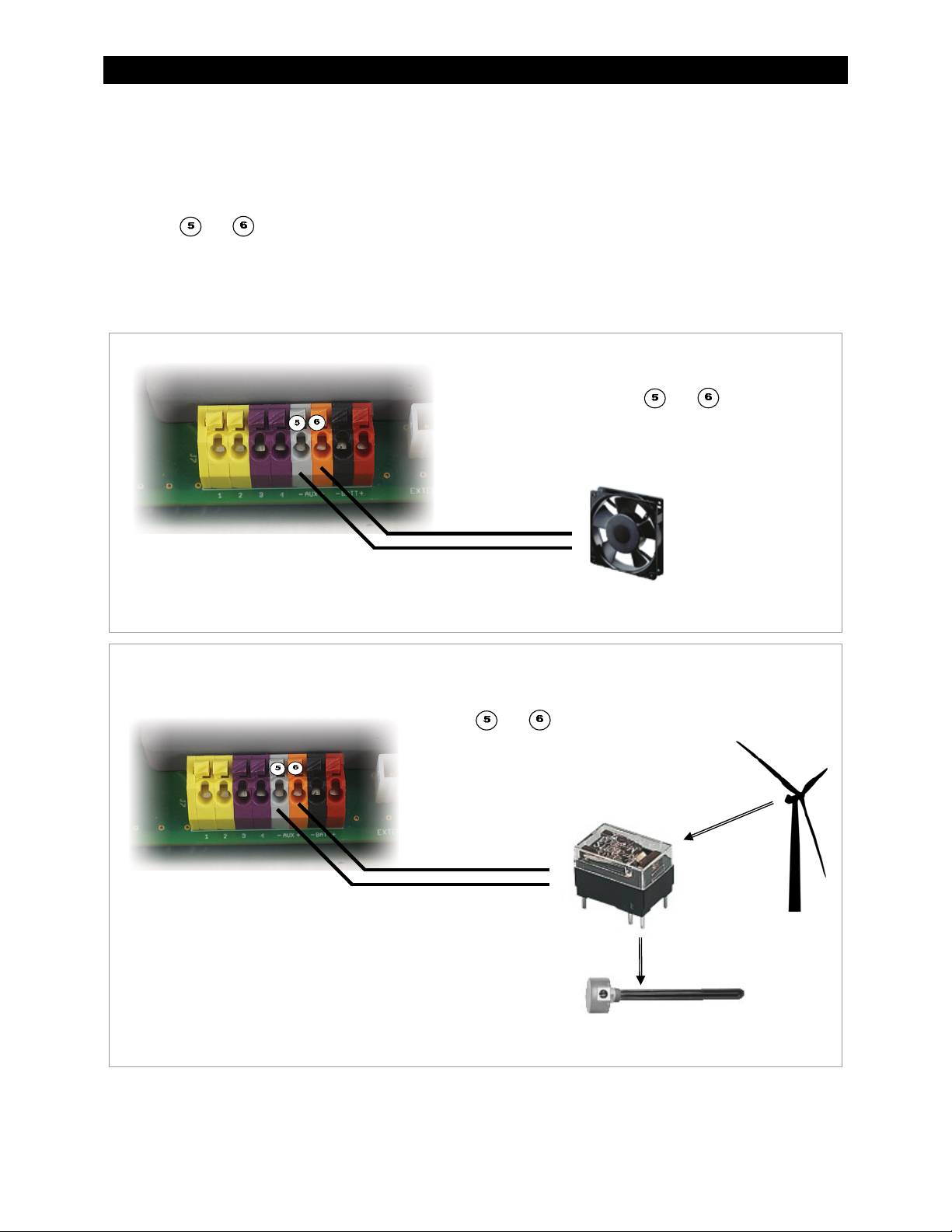

Accessory Terminal Block

This block of terminals has connections for the AUX output, for the Battery Sense function, and for the External

Fault function. The terminals accept wire from 16 AWG to 24 AWG.

External

Fault

AUX

Figure 12 Accessory Terminal Block

16 900-0150-01-00 Rev A

Battery

Sense

Page 19

Installation

AUX Terminals

The AUX (Auxiliary) output is a small power supply that provides a 12 Vdc output current to an isolated load. The

AUX output can respond to many criteria and control many functions. These include cooling fans, vent fans,

load diversion, fault alarms, and automatic generator control. The AUX can only control one function at a time.

Terminals

and are the + and – terminals for the AUX output. These terminals are colored gray (–) and

brown (+) for easy reference. The terminals can supply up to 250 mA at 12 Vdc (3 W). The AUX circuit contains

electronic overcurrent protection, which resets after being overloaded. No additional fuses are required for the

AUX terminals.

The AUX LED illuminates when the output becomes active. (See page 23 for an illustration of LED indicators.)

In this example, the AUX output directly drives a

12-volt vent fan. The – and + wires on the fan are

connected to terminals

AUX+ terminals.

and , the AUX– and

Figure 13 AUX Vent Fan

In this example, the AUX output drives a relay that

diverts wind power. The relay’s coil is connected to

terminals

terminals. When the AUX output closes the relay

(based on battery voltage), the relay diverts excess

power to a water heating element.

NOTE: Relays and elements shown are examples only and may

vary depending on the installation.

Figure 14 AUX Diversion Control

and , the AUX+ and AUX–

Relay

Element

Turbine

900-0150-01-00 Rev A 17

Page 20

Installation

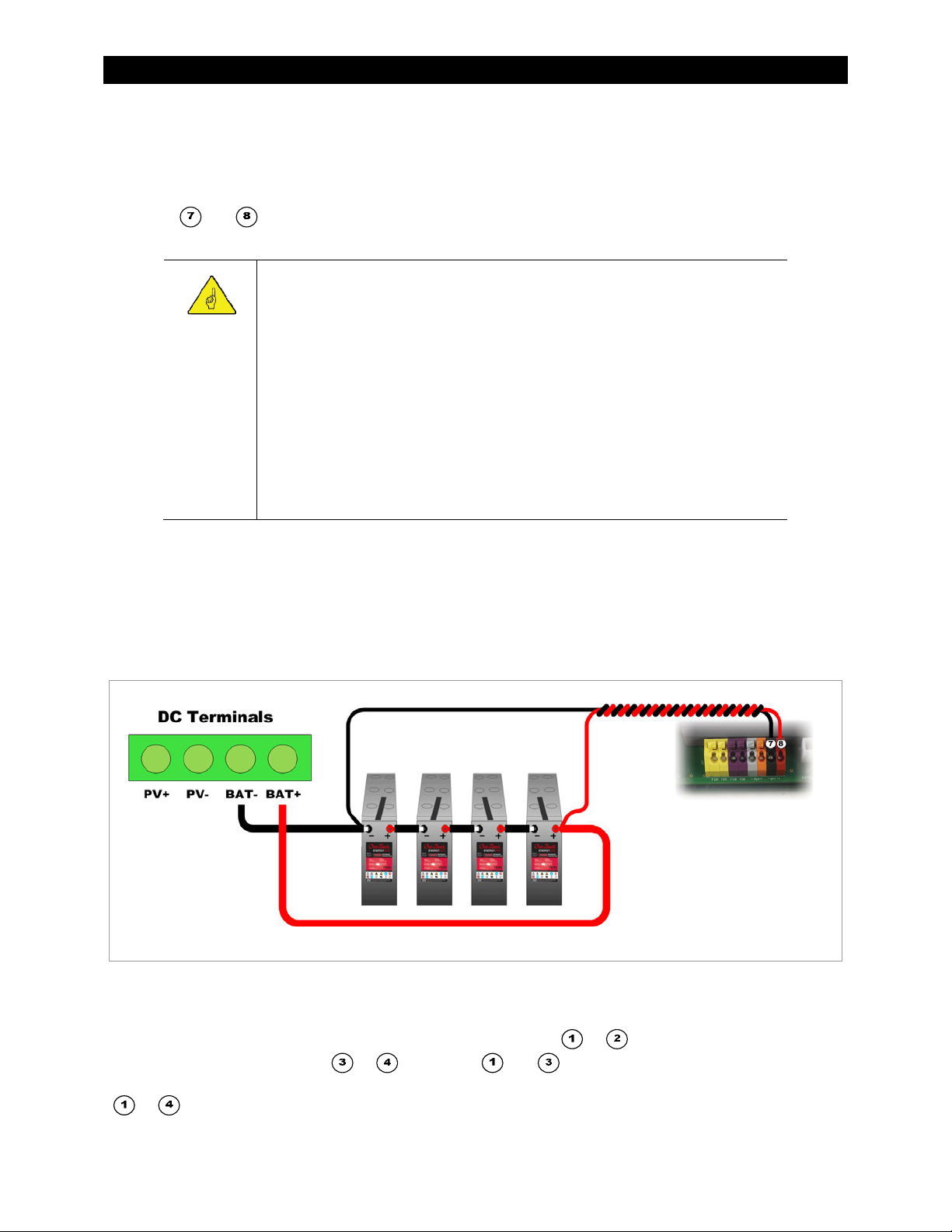

Battery Sense Terminals

The remote Battery Sense terminals are used for accurate voltage monitoring. These terminals connect directly

to the batteries. Using the controller’s main battery cables for voltage sensing is less accurate. This is due to

voltage rise caused by charging currents on the battery conductors.

Terminals

black (-) and red (+) for easy reference. A twisted-pair cable is recommended. (See wire sizing on page 16.)

This function operates automatically when it detects a voltage within 2 volts of the battery voltage reading at

the charge controller’s main terminals. If the reading varies by more than 2 volts, the Battery Sense function is

disabled. The assumption is that the terminals are not connected. (If the terminals are connected, there may be

a wiring problem.)

The MATE3 allows the user to calibrate the battery meter at the charge controller’s main terminals. (See page 45

and the MATE3 manual for more information.) This calibration does not affect the Battery Sense function. If

Battery Sense is in use, calibration changes can be made, but will have no effect until Battery Sense is disabled.

and are the – and + terminals for the Battery Sense function. These terminals are colored

IMPORTANT:

The MATE3 display shows the system voltage as measured at the battery terminals of

various devices. (See Figure 26 on page 29.) This voltage is used for generator starting

and other functions.

If no other devices are present, it will show the reading of the FLEXmax Extreme.

If OutBack inverters are present, the inverter voltage replaces the FLEXmax

Extreme as the system voltage reading.

If the FLEXmax Extreme Battery Sense terminals are in use, this reading replaces

the inverter or the regular charge controller readings as the system voltage.

The FLEXnet DC Battery Monitor is the highest priority and will replace the

Battery Sense reading as the system voltage.

The Battery Sense reading is still shown on the Charge Controller screen. (See Figure 27

on page 30.) This reading is still used to adjust the FLEXmax Extreme charging.

NOTE: Overcurrent protection is

not shown. Recommended

protection for sense conductors is:

Fast-acting device

80 Vdc or greater

1 A or smaller

Cold resistance 10 ohms or less

Figure 15 Battery Voltage Sensing

External Fault Terminals

The External Fault terminals are used to make connections to the OutBack Ground Fault Detector/Interruptor

(GFDI) product. A single wire is run from one of the yellow terminals (

from one of the purple terminals (

or ). Terminals and are the most commonly used. These wires

are connected to a normally-open set of contacts on the OutBack GFDI. Figure 16 and Figure 17 show terminals

to without the rest of the control terminal block.

18 900-0150-01-00 Rev A

or ). A second single wire is run

Page 21

Installation

The terminals detect electrical continuity. These contacts remain closed as long as the GFDI bonding switch

remains closed. If a ground-fault event occurs, both the GFDI switch and the GFDI contacts will open. The

External Fault circuit will detect the loss of continuity and will shut down the charge controller.

If multiple charge controllers are in use, they can be paralleled so that all controllers use a common GFDI.

Terminals

and are a parallel set of connections to terminals and .

In the first controller, terminals

and

that it will react accordingly. If a third controller is present, its terminals

connecting to terminals

can be added as needed.

If the terminals are not in use, this function should be disabled. This is performed by directly shorting terminals

on the second controller. This allows the second controller to sense the same conditions as the first so

and with a small jumper wire.

and should have a parallel set of wires which connect to terminals

and should have wires

and on the second controller, and so on. (See Figure 17.) Additional controllers

IMPORTANT:

The FLEXmax Extreme will not function unless either the OutBack GFDI or the

disabling jumper is installed. Initial power-up will result in an External Fault

signal. (See page 61.)

Figure 16 Charge Controller with PV Array Ground Fault Protection

In Figure 16, a wire has been run from terminal to one of the dedicated GFDI terminals. A wire has also been

run from terminal

will read as electrically continuous to the External Fault circuit.

In the event of a ground fault or any other condition which trips the GFDI, these terminals will register loss of

900-0150-01-00 Rev A 19

to the other side of the GFDI. As long as the GFDI remains closed, that pole of the GFDI

Page 22

Installation

continuity. The External Fault circuit will detect this loss immediately and shut down the the controller. The red

Fault LED indicator will illuminate. See pages 24, 32, and 61.

Other possible uses for the External Fault terminals include devices such as arc fault protection, or an Emergency

Power Off (EPO) switch for a fast manual shutdown. Any device with normally open contacts can work with this

function. If more than one device is used, all contacts must be wired in series so that any one device will shut

down the controller.

Figure 17 Two Charge Controllers with PV Array Ground Fault Protection

In Figure 17, a wire has been run from terminal on Charge Controller A to one of the dedicated GFDI

terminals. A wire has also been run from terminal

In addition, Terminal

Similarly, Terminal

places the External Fault circuits on both controllers in parallel.

As long as the GFDI remains closed, that pole of the GFDI will read as electrically continuous to the External Fault

circuit on both controllers. In the event of a ground fault or any other condition which trips the GFDI, these

terminals will register loss of continuity. The External Fault circuit on both controllers will detect this loss

immediately. Both controllers will shut down and display the red Fault LED indicator. See pages 24, 32, and 61.

To reset the controller after an external fault:

1. Remove all sources of power (PV and battery) from the controller.

2. Correct the cause of the fault condition.

3. Follow the power-up procedure on page 21.

20 900-0150-01-00 Rev A

on Charge Controller A has been connected to terminal on Charge Controller B.

on Charge Controller A has been connected to Terminal on Charge Controller B. This

to the other side of the GFDI.

Page 23

Installation

Power Up

IMPORTANT:

The charge controller automatically senses the nominal battery voltage upon

connection. Once set, it retains the nominal voltage setting. Following any type of

shutdown or disconnect, it will return to operation automatically.

The PV array voltage is automatically detected upon connection. The PV array

voltage must never exceed 150 V

It is recommended to restore the FLEXmax Extreme to factory default settings

(see page 45) and reset the nominal voltage (see below) any time the system is

substantially revised or the controller is relocated.

The FLEXmax Extreme uses power from the battery bank to operate. The battery voltage must be at least

10.5 volts or higher to power up the charge controller. When battery power is detected, the charge controller

will flash each of its LED indicators twice in a self-test.

The Status indicator (see page 23) will then flash to show the nominal system voltage that was detected. Each

flash indicates an increment of 12 volts; therefore, one flash = 12 Vdc, two flashes = 24 Vdc, and so on.

.

oc

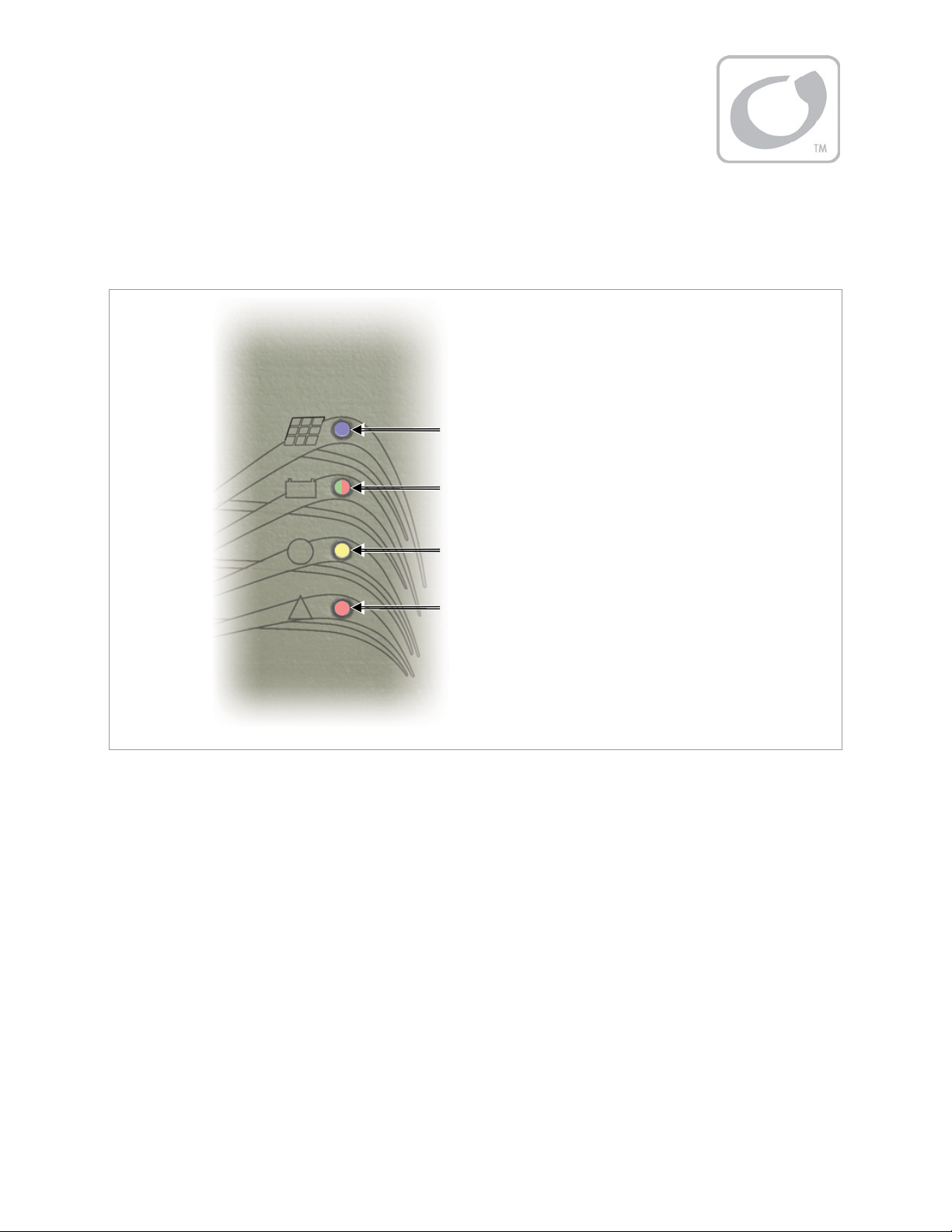

Charging Indicator — Blue LED

Status Indicator — Green/Red (or Amber) LED

AUX Indicator — Yellow LED

Fault Indicator — Red LED

Figure 18 LED Indicators

Setting the Nominal Voltage

Upon initial power-up, the FLEXmax Extreme will sense the battery voltage and use this reading to determine

the nominal system voltage — a battery bank of 12, 24, 36, 48, or 60 volts DC.

The ranges of detection for each nominal battery voltage are:

12-volt system — 10.5 Vdc to 15.7 Vdc

24-volt system — above 15.7 Vdc to 31.4 Vdc

36-volt system — above 31.4 Vdc to 43.2 Vdc

48-volt system — above 43.2 Vdc to 62.8 Vdc

60-volt system — above 62.8 Vdc to 78 Vdc

The batteries must be within the appropriate voltage range for the controller to take the correct reading. A

severely discharged 24-volt battery bank, for example, could read as a 12-volt bank and cause the controller to

900-0150-01-00 Rev A 21

Page 24

Installation

charge inappropriately (or not at all).

Normally the nominal system voltage is retained. If the FLEXmax Extreme is disconnected from the batteries or

otherwise loses power, upon a new power-up it will continue using the nominal voltage and settings

determined previously.

If it is necessary to change the nominal voltage:

1. Reset the FLEXmax Extreme to factory default settings as described below.

2. Remove all sources of power (PV and battery) from the FLEXmax Extreme and then reconnect battery

power. The controller will sense the battery voltage and use this reading to determine the new nominal

system voltage. This will not occur until the power is turned off and then on again.

Resetting to Factory Defaults

The MATE3 system display can be used to reset the FLEXmax Extreme to its factory default settings. See page 45

for more information.

To reset to defaults without using the MATE3:

1. Remove all sources of power (PV and battery) from the FLEXmax Extreme.

2. Press and hold the Equalize switch (see page 6) while reconnecting battery power.

3. Continue holding the Equalize switch. After approximately 10 seconds, the Status indicator will blink

green rapidly. Continue holding the switch until the Status indicator begins blinking amber more slowly.

4. Release the Equalize switch and disconnect the batteries.

Initial Operation

When the PV input circuit breaker is turned on, the FLEXmax Extreme automatically detects the PV input voltage.

It then enters the “Wakeup” state (see page 28) and prepares to charge the batteries by tracking the maximum

power point of the solar array. During the initial tracking, the input PV source is gradually loaded from the

open-circuit voltage (V

power point. The amount of time required before starting operation is dependent on the module type, ambient

temperature, and the amount of sunlight directly on the PV array. Normally, the FLEXmax Extreme starts in the

morning within a few minutes of the PV array being exposed to direct sunlight.

Once the controller begins maximum power point tracking, it will enter a three-stage battery charging cycle.

This cycle can be observed with the controller’s LED indicators. (See page 23.) If the OutBack MATE3 or another

system display is available, it is possible to observe the specific charging stage, mode messages, and readings of

the charge controller.

) to ½ of the Voc. Within this range, the FLEXmax Extreme seeks the maximum

oc

22 900-0150-01-00 Rev A

Page 25

LED Indicators

Status and Information

Charging Indicator — Blue LED

Status Indicator — Green/Red (or Amber) LED

AUX Indicator — Yellow LED

Fault Indicator — Red LED

Figure 19 LED Indicators

The FLEXmax Extreme charge controller has no graphical display. It is equipped with four LED indicators that

show the charge controller’s condition.

The top LED, the Charge indicator, is blue. It illuminates when more than 10 watts of PV power is available.

It is solid when bulk or equalization charging. It flashes when absorption or float charging. The MATE3

system display represents these stages as operating modes in the Status menu. See page 30 for a list of

modes. See page 71 for a description of charging stages.

The Charge indicator will not turn solid if less than 10 watts of PV power is available. It will flash in

constant-voltage charging regardless of how much PV power is available. Note that in some cases it may

illuminate when power is available but the controller is not charging. (See Table 4 on page 28.)

This indicator will flash while performing firmware updates to the FLEXmax Extreme (see page 46).

The second LED down is the Status indicator. It is a tri-color LED which can be red, green, or amber. This

LED is used to indicate either battery voltage or charger status. See Table 2 on page 24.

The following patterns usually indicate particular charging stages.

~ The indicator turns amber (a combination of the red and green colors) if the batteries are equal or

greater than 1.91 volts per cell (Vpc). This often accompanies Bulk or Absorption stage.

~ It turns green upon entering the Float stage. It will remain green regardless of the battery voltage until

it falls below 2.08 Vpc. This will trigger a new charge cycle.

~ It will alternate amber/green during equalization. It can also flash amber/red. (See pages 27 and 72.)

900-0150-01-00 Rev A 23

Page 26

Operation

NOTE: The Status indicator turns red if the battery voltage falls below 1.91 Vpc. The red color shows an urgent

condition, indicating that the batteries are discharged. A red flash means the batteries have fallen below 1.75

Vpc, a critically low voltage. These patterns will appear regardless of the charging stage. If it appears, the Status

indicator cannot show the stage, although it may still be shown by the blue Charge indicator.

IMPORTANT:

The LED indicators do not necessarily tell the amount the controller is actively charging.

The Charge indicator may still indicate Absorption and the Status indicator may indicate

rising battery voltage, even if another charging source is doing most of the work.

Table 2 LED Indicators

Indicator Controller State

Name Color Pattern Bulk Absorb Float EQ Other

Off Off N/A < 10 W PV available Battery rest

Charge

Status

AUX Yellow Solid (see page 17) Any AUX active

Fault Red Solid N/A External Fault

Blue Solid X X

Blue Flash long (see page 26) X

Blue Flash short (see page 27) X Float

Amber Solid X X ≥ 1.91 Vpc

Green Solid X

Red Solid X X Battery discharge <1.91 Vpc

Red Flash X X Critical battery discharge <1.75 Vpc

Amber/Green Flash (see page 26) X ≤ EQ

Amber/Red Flash (see page 27) X Critical battery discharge <1.75 Vpc

The third LED, the AUX indicator, is yellow. This indicator illuminates when the AUX output becomes active.

Voltage

The fourth (bottom) LED, the Fault indicator, is red. It will turn solid if the charge controller shuts down due

to an External Fault condition. See pages 19 and 20 for more information on the External Fault circuit. If the

MATE3 System Display is present, it will deliver a

Fault Input Active

error message (see page 32).

See Table 7 beginning on page 61 for information on resetting this error.

24 900-0150-01-00 Rev A

Page 27

Operation

Modes of Operation

The FLEXmax Extreme goes through many states during its operation. Figure 20 shows an example of the

various stages of battery charging and several states when the controller is not charging. (The graph in Figure

20 shows a typical day of charging with a nominal 24-volt system. Charging is described in detail on page 71.)

The MATE3 system display has five “mode” messages which represent all states of operation. The following

sections use the names displayed by the MATE3. (See page 30.) These sections describe the controller operation

and show the LED indicators illuminated in each mode.

Figure 20 FLEXmax Extreme Battery Charging and Modes

Bulk

This is a Maximum Power Point Tracking mode which harvests the maximum wattage available from the PV

array. The controller is trying to regulate the battery voltage towards the Absorb Voltage set point. Normally

the charge controller enters this mode at the beginning of the day or when a new charge cycle begins. The

controller may also enter this stage if there is not enough PV energy to maintain a different stage such as

Absorption. See page 26 for more information.

Blue (solid)

Amber (solid)

The Status indicator will remain amber as long as the battery

voltage remains above 1.91 volts per cell (Vpc), even if no

charging is occurring. The Charging indicator, however, will not

illuminate if less than 10 watts is used by the PV. This may occur if

charging is performed by another source.

Figure 21 LED Indicators (Bulk)

900-0150-01-00 Rev A 25

Page 28

Operation

Absorb

The MATE3 displays this message for the Absorption stage of a three-stage cycle. In this stage, the FLEXmax

Extreme regulates the battery voltage at the Absorb Voltage set point. Absorption is a constant-voltage,

variable-current charging stage. It usually involves a tapering current flow. However, it may deliver no current

and still display Absorb if another source maintains the batteries above the Absorb Voltage set point.

While the batteries are held at this voltage, the internal timer counts up from zero toward the Absorb time

setting. (See pages 30, 36, and 71.) The charger will exit this stage and enter the Float stage if the timer reaches

the time limit, or if the Absorb End Amps setting is reached. (See page 36.)

The absorption timer is internal to the FLEXmax Extreme and is not displayed as a real-time reading. However,

the Absorb reading shown on page 30 will display the total time spent in Absorption that day.

Blue (flash on 2 seconds, off ½ second)

Amber (solid)

Both indicators will remain in these states as long as the

battery voltage remains above 1.91 volts per cell (Vpc),

even if no charging is occurring. This may occur if

charging is performed by another source.

If the battery voltage drops below the Absorb Voltage set point (see page 36), the FLEXmax Extreme reverts

back to the Bulk charge stage. The MATE3 displays Bulk as shown on page 25.

The internal timer may not always begin at zero if the last charge was interrupted or ended early. If the batteries

drop below the voltages noted on Table 3, the timer will begin counting down toward zero. This adds to the

duration of the next Absorption stage. If the timer reaches zero, it will last for the full duration of the Absorb

time setting (see page 36).

Lower voltages will cause the timer to subtract minutes at a faster rate, as shown on Table 3. These voltages

indicate a significantly greater battery discharge, requiring a much longer charge cycle.

Table 3 Absorption Timer

Battery Voltage Timer Activity

Figure 22 LED Indicators (Absorb)

12.4 V, 24.8 V, 37.2 V, 49.6 V, or 62.0 V, and

less than the Absorbing voltage

<12.4 V, 24.8 V, 37.2 V, 49.6 V, or 62.0 V For every minute elapsed, 1 minute is subtracted

<12.0 V, 24.0 V, 36.0 V, 48.0 V, or 60.0 V For every minute elapsed, 2 minutes is subtracted

No change.

from the timer

from the timer

< 11.6 V, 23.2 V, 34.8 V, 46.6 V, or 58.0 V For every minute elapsed, 4 minutes is subtracted

from the timer.

26 900-0150-01-00 Rev A

Page 29

Operation

Floating

The MATE3 displays this message for the Float stage of a three-stage charging cycle. In this stage, the FLEXmax

Extreme regulates the battery voltage at the Float Voltage set point. This stage is temperature-compensated.

(See page 72.) Float is a constant-voltage, variable-current charging stage. It usually involves a minimal

(maintenance) current flow. However, it may deliver no current and still display Float if another source

maintains the batteries above the Float Voltage.

If the battery voltage drops below the Float Voltage, the FLEXmax Extreme will employ the MPPT function to

draw more power from the PV array. (This may occur if the batteries are powering loads.) If this occurs, the

operation may change to constant-current, variable-voltage. The mode will still show Float.

Blue (flash on ½ second, off 2 seconds)

Green (solid)

This indicator will remain green if the voltage rises

or drops, unless it decreases below 2.08 Vpc. This

will trigger a new charge cycle.

Figure 23 LED Indicators (Float)

EQ

The MATE3 displays this message if the charger is in a cycle of equalization. (See page 72 for an explanation of

equalization.)

Before equalizing, battery loads should be turned off and the battery should be charged so the charge controller

can quickly reach the Equalization Voltage set point. (See page 38.) Otherwise, the charge controller may have

difficulty reaching or maintaining the equalization process.

Equalization is not battery temperature compensated.

Blue (solid)

Amber/green (alternating once per second)

This indicator will alternate amber and red if the batteries

are below 1.75 volts per cell (Vpc) while equalizing. This is

usually a temporary condition.

Figure 24 LED Indicators (Equalization)

900-0150-01-00 Rev A 27

Page 30

Operation

Silent

The MATE3 displays the operating mode as Silent if the charge controller has stopped charging. This message

represents a variety of conditions, many of which are common. For example, Silent is shown at night or any

period of insufficient light. Table 4 lists the indicators and the PV open-circuit voltage which show specific Silent

conditions. In these cases, no indicators will be illuminated.

However, Silent may also appear in the event of an error shutdown. If the mode is Silent and the red Fault

indicator is illuminated, an External Fault may have occurred. See pages 19, 20, and 61.

Red (solid)

Figure 25 LED Indicators (Fault)

Table 4 Reasons for Silent Mode

Charge LED Status LED Fault LED Voc Other

No PV energy or “Sleep” mode. If the V

Below battery

No No No

Above battery

Intermittent Any No Above battery

battery voltage, the controller is “sleeping”. This is

normal at night. The threshold for Sleep mode is

settable. See page 37.

Low light or “Snooze” mode. V

voltage but not enough array current is available for

charging. This is normal in the morning, evening, or in

heavy clouds (low light). The threshold for Snooze

mode is settable. See page 37.

“Wakeup” mode. The controller has detected more than

the required 10 watts, but has not yet begun charging.

This condition only lasts a short time. The blue Charge

indicator may turn on and off briefly while the controller

is performing initial power tracking. This can also occur

if PV conditions change and the controller has to

calculate a new power point.

If continuous, this behavior may also indicate an

“unloaded output” condition where the batteries have

been disconnected from the charge controller.

is less than

oc

is greater than battery

oc

28 900-0150-01-00 Rev A

Page 31

MATE3 System Display and Controller

Battery Status Indicators (x3)

Charger Indicator

Operation

Charge Controller Soft Key

Figure 26 Display and LED Status Indicators

The MATE3 System Display and Controller is a display which allows the user to read the operating mode,

measurements, and any status messages from the FLEXmax Extreme charge controller. It can also change the

charge controller’s settings when the default settings are not enough.

.

80%

State of Charge (SOC).

Battery Status Indicators

Three LED indicators provide a visual reference to indicate the condition of the battery bank.

A GREEN LED means the batteries have an adequate charge at that time. It does not always mean they are

full. If the FLEXnet DC battery monitor is installed, this means the batteries are

A YELLOW LED means the batteries are somewhat discharged. If the FLEXnet DC is installed, this means the

batteries are

A RED LED means the batteries are greatly discharged and may require attention. If the FLEXnet DC is

installed, this means the batteries are

60%

and

70%

.

< 60%

Table 5 Battery Status LED Indicators

Color 12 Vdc Unit

GREEN 12.5 Vdc or higher 25.0 Vdc or higher 37.5 Vdc or higher 50.0 Vdc or higher ACCEPTABLE

YELLOW 11.5 to 12.4 Vdc 23.0 to 24.8 Vdc 34.5 to 37.2 Vdc 46.0 to 49.6 Vdc MARGINAL

RED 11.4 Vdc or lower 22.8 Vdc or lower 34.2 Vdc or lower 45.6 Vdc or lower LOW

NOTES:

Gaps in the table (higher-voltage units) are due to the resolution of the charge controller’s DC meter.

The Battery LED settings cannot be changed.

Voltages higher than shown in the GREEN row usually means that the batteries are charging.

24 Vdc Unit,

± 0.2 Vdc

36 Vdc Unit,

± 0.3 Vdc

48 Vdc Unit,

± 0.4 Vdc

Battery Status

Charger Indicator

The MATE3 is equipped with several LED indicators denoting status. The Charger indicator (see Figure 26) will

illuminate if the charge controller is delivering more than a minimal amount of charging power to the batteries.

It will flash if the charge controller is equalizing the batteries.

NOTE: The Charger indicator will illuminate for any device on the HUB Communications Manager that is

charging, including OutBack inverters. If a FLEXmax Extreme charge controller is accompanied by other devices,

this indicator may indicate charging by any device, not just that controller.

900-0150-01-00 Rev A 29

Page 32

Operation

A

Charge Controller Soft Key

The MATE3 is equipped with a series of “soft” keys with varying functions. From the Home screen, the far left key

is designated as the Charge Controller soft key any time a charge controller is connected. Pressing it will enter

the Status menu for the charge controller. (See page 30.)

Status Screen

Modes of Operation:

Bulk

Absorb

Float

EQ

Silent

See page 25 for a description of modes.

See page 71 for a description of battery

charging.

Soft Keys:

<Next> brings up a series of screens with

current statistics, totals, and other data. The

internal temperatures and any fault messages

are also displayed here. These screens are all

shown beginning on page 31.

<Graph> brings up a series of screens that

plot various charge controller information

over time. The graphs include inverter and

charger wattage, power imported from an AC

source, battery voltage, and others. These

screens are all shown beginning on page 34.

<Port> cycles through each device

connected to the network. If more than one

charge controller is installed in the system,

pressing the <Port> soft key will cycle

through each controller.

<Back> returns to the previous screen.

Figure 27 Charge Controller Soft Key Screens

Screen Items:

The upper left corner of the screen shows the FLEXmax charge

controller’s current mode of operation. Bulk is shown in this

illustration.

In displays the present PV array operating voltage and the

current being harvested from the array.

VOC displays the open-circuit voltage available from the PV.

Out displays the present battery voltage and the current

being delivered from the charge controller(s) to charge the

battery bank. To the right, this line displays the number of

kilowatt-hours and amp-hours accumulated that day.

Operating displays the total hours the charger has operated

that day in any stage.

Float displays the amount of time the controller has been in

the Float stage.

bsorb displays the amount of time the controller has been in

the Absorbing stage. The maximum duration is the Absorb

time setting. (See pages 26, 36, and 71.)

Maximum displays the maximum amperage and wattage

harvested from the PV array that day, and the time both were

recorded.

The lower right corner shows the current status of the charge

controller’s Auxiliary (AUX) output. (See page 39.)

NOTE: If the FLEXmax Extreme shuts down due to a fault condition, the MATE3 status messages do not indicate

the cause. The MATE3 will display the status as Silent. However, the Error screen (see page 32) will show the

cause if it is one of the defined errors on that screen. The MATE3 will show an Event in the appropriate menu.

(See the MATE3 manual for more information.).

See page 61 for additional information on troubleshooting Error conditions and faults.

30 900-0150-01-00 Rev A

Page 33

Operation

Stats Screen

From the Charge Controller screen, the <Next> soft key proceeds to the Charge Controller Stats screen. This

screen shows data which has been accumulated since the system went online, or since the last reset.

Screen Items:

The items under Maximum are not incremental.

They are updated only if a higher value is measured.

VOC displays the highest measured V

the VOC reading on page 30 for the current Voc.)

Battery displays the highest measured battery

voltage. (See the

current battery voltage.)

Wattage displays the highest measured wattage

harvested from the PV. (See the

page 30 for the current wattage. See the

reading for the highest wattage that day.)

Out

reading on page 30 for the

oc

Out

reading on

value. (See

Maximum

Soft Keys:

<Next> proceeds to the Error, Datalog, and Temps screens

(see pages 32 and 33).

<Reset> proceeds to the Reset screens for the items under

Maximum and Total. (See Figure 29.)

<Back> returns to the previous screen.

<Port> cycles through each device connected to the network.