Page 1

DOM-OBK03 Rev. A

OUTBACK

HITCH OWNER’S MANUAL

Effective January, 2003

Last Edit May, 2003

Page 2

Page 3

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Definitions of Safety and Service Statements . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Sign Locations and Care . . . . . . . . . . . . . . . . . . 4

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tractor Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting the Tilt Sensor . . . . . . . . . . . . . . . . . . . . . . . 9

Routing the Hitch Control Cable . . . . . . . . . . . . . . . . . . 9

Mounting the Console . . . . . . . . . . . . . . . . . . . . . . . . . 10

Console Cable Connections . . . . . . . . . . . . . . . . . . . . 11

Get Acquainted with the Controls . . . . . . . . . . . . . . . . 12

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hitch Pin Position Calibration . . . . . . . . . . . . . . . . . . . 13

Curvature Compensation . . . . . . . . . . . . . . . . . . . . . . 13

Slope Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Follow GPS Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Match Tracks Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

This manual has been prepared to assist you in the

operation and maintenance of your OUTBACKHitch

Drawbar Implement Guidance System and to provide the

necessary part numbers to keep it in near original condi-

tion.

OutbackHitch Serial Number_____________________

Congratulations on your purchase of an OUTBACK

Hitch Drawbar Implement Guidance System. We at RHS

wish to thank you for your patronage and appreciate your

confidence in OUTBACKequipment. Your OUTBACK

Hitch has been carefully designed and ruggedly built to

provide many years of dependable service in return for

your investment.

TABLE OF CONTENTS

INTRODUCTION

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Initial Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Grease Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replace Worn Components . . . . . . . . . . . . . . . . . . . . 15

Trouble-Shooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . 15

Contacting the Factory . . . . . . . . . . . . . . . . . . . . . . . . . 16

Outback Warranties . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix A - Parts Listings . . . . . . . . . . . . . . . . . . . . . . .

Outback-Hitch Drawbar Guidance System . . . . . . . . . A1

Console Mounting Details . . . . . . . . . . . . . . . . . . . . . . A2

Tilt Sensor Mounting Details . . . . . . . . . . . . . . . . . . . A2

Hydraulic & Electrical Assembly . . . . . . . . . . . . . . . . . A3

Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . A4

Drawbar Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . A5

Hydraulic Component Details. . . . . . . . . . . . . . . . . . . . A6

Mounting Hardware Details . . . . . . . . . . . . . . . . . . . . . A7

Clevis Hitch Attachment [Optional]. . . . . . . . . . . . . . . . A8

Footnotes: OUTBACK and OUTBACK Guidance are registered trademarks of RHS, Inc. OUTBACK Guidance Center, Steering Guide, and Hitch are proprietary

trademarks of RHS, Inc. The OUTBACKS and OutbackHitch are protected under U.S. Patent No. 6,539,303 and patents pending.

Page 4

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

2

Definitions of Safety and Service Statements

TAKE NOTE! THIS SAFETY ALERT SYM-

BOL FOUND THROUGHOUT THIS MANU-

AL IS USED TO CALL YOUR ATTENTION

TO INSTRUCTIONS INVOLVING YOUR

PERSONAL SAFETY AND THE SAFETY

OF OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN

INJURY OR DEATH.

!

THIS SYMBOL MEANS

- ATTENTION!

- BECOME ALERT!

- YOUR SAFETY IS INVOLVED!

All safety statements in this manual, as well as those

found on safety decals, are preceded by the following

warning symbols. Carefully read and follow the instruc-

tions provided.

Indicates an imminently hazardous situation

that, if not avoided,

will result in death or

serious injury. This signal word is to be limited to

the most extreme situations typically for machine

components which, for functional purposes, cannot

be guarded.

Indicates a potentially haz-

ardous situation that, if not

avoided, could result in

death or serious injury and

includes hazards that are exposed when guards are

removed. It may also be used to alert against unsafe

practices.

Indicates a potentially haz-

ardous situation that, if not

avoided, may result in

minor or moderate injury.

It may also be used to alert against unsafe practices.

The IMPORTANT notice gives

important instructions to prevent

damage to the machine or systems.

A Note will give general information

about the correct operation and

maintenance of the machine and systems.

DANGER:

!

WARNING:

!

CAUTION:

!

IMPORTANT:

NOTE:

Page 5

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

3

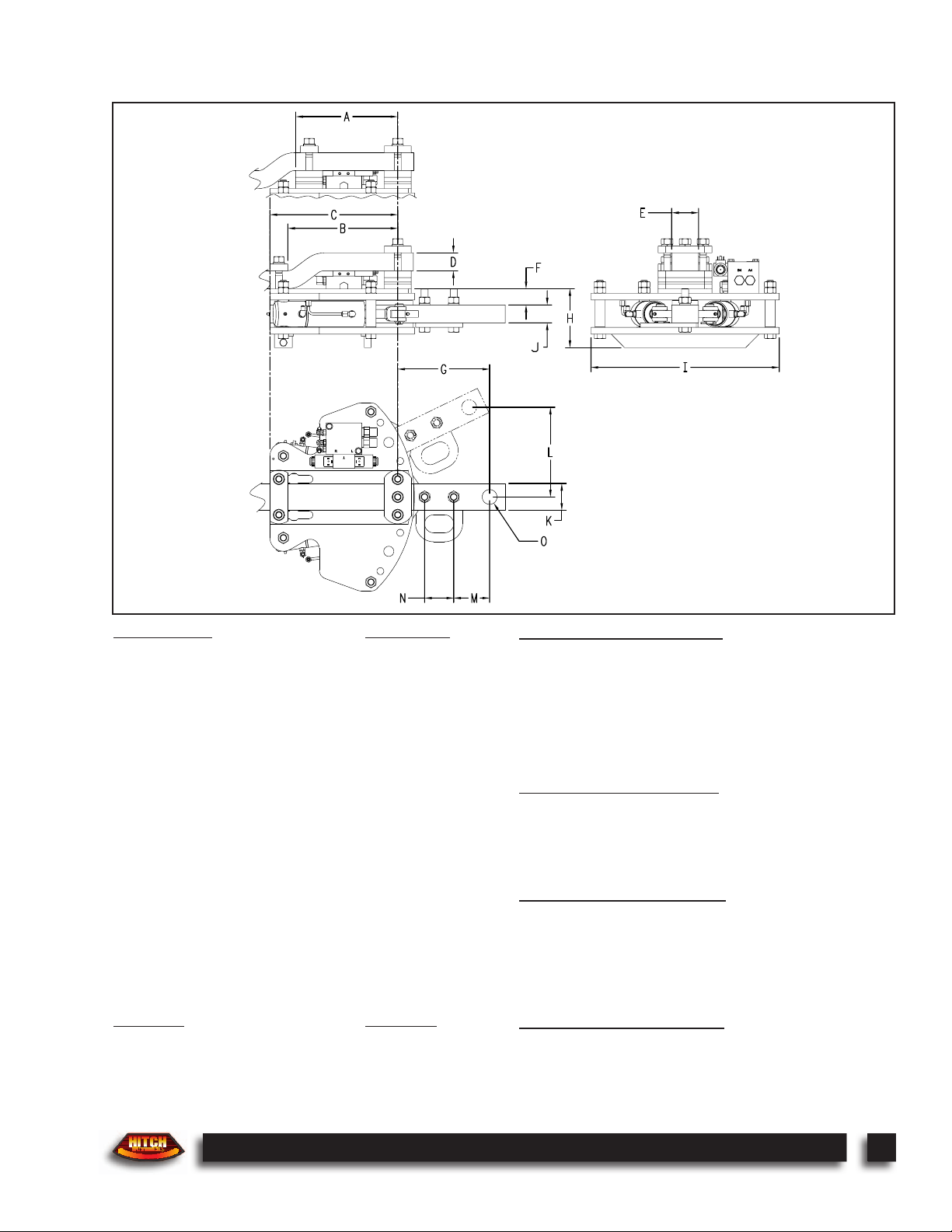

Specifications

Dimensions: Inch (mm)

(A) Min. Long Drop Clearance 11.5 (292)

(B) Max. Short Drop Clearance 12.25 (311)

(C) Min. Mounting Clearance 14.25 (362)

(D) Tractor Drawbar Thick. Range 1.5 - 2.0 (38 - 51)

(E) Tractor Drawbar Width Range 2.25 - 3.25 (64 - 83)

(F) Hitch Pin Point Below Tractor 1.75 (46)

(G) Hitch Pin Point Behind Tractor 10.25 (260)

(H) Hitch Clearance Below Tractor 6.5 (165)

(I) Hitch Overall Width 21 (534)

(J) Hitch Drawbar Thickness 2.0 (51)

(K) Hitch Drawbar Width 3.0 (76)

(L) Hitch Drawbar Swing ±10.0 (±254)

(M) Hitch Pin to Rear Clevis Hole 4.0 (102)

(N) Hitch Clevis Hole Spacing 3.25 (83)

(O) Hitch Pin Hole Diameter 1.67 (42)

Weights: Lbs (Kg)

Hitch Assy. (less mount. hardware & clevis) 220 (100)

Hitch System Shipping Weight 300 (136)

Clevis Attachment Shipping Weight 25 (11)

Hydraulic Requir

ements:

Single Remote Hydraulic Outlet, Continuous Duty

Flow Rate (fixed) 1.5 gpm

Pressure Range 2250 - 3000 psi

Not compatible with open-center hydraulic systems.

Electrical Requirements:

Max. Current 3.5 amp

Voltage Range 9 - 16 vdc

Capacity & Performance:

Max. Vertical Static Load 4000 lbs. (1800 kg)

Power Rating 80 - 228 h.p. (60 - 170 kW)

Left / Right Travel 20 in. (508 mm) swing

6 sec. stop to stop

Standards & Limitations:

ASAE S482 compliant drawbar extender.

Not for use on articulated 4WD or tracked tractors.

Not for use with PTO drive-line powered equipment.

Page 6

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

4

Safety Sign Locations and Care

!

A

C

B

C

P/N DEC-MT4163 C

P/N DEC-HAZ01 B

P/N 60257 A

Safety Sign Care:

•

Keep safety signs clean and legible at all times.

•

Replace safety signs that are missing or have become

illegible.

•

Replaced parts that displayed a safety sign should also

display the current sign.

•

Replacement safety signs are available from your

distributor, dealer, or online at outbackguidance.com

Installing Safety Signs:

•

Be sure that the installation area is clean and dry.

•

Decide on the exact position before you remove the

backing paper.

•

Remove the smallest portion of the split backing

paper.

•

Align the decal over the specified area, and carefully

press the small portion with the exposed sticky backing

in place.

•

Slowly peel back the remaining paper, and carefully

smooth the remaining portion of the decal in place.

•

Small air pockets can be pierced with a pin and

smoothed out using the piece of decal backing paper.

Page 7

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

5

Safety Information

!

As the manufacturer of your Outback Hitch Drawbar

Implement Guidance System, we care about your safety. In

fact, this machine and its systems have been designed to

provide maximum safety. Unfortunately, no machine

design can prevent operator error or carelessness.

This operator’s manual provides instructions for the

safe operation and maintenance of the OutbackHitch.

Please read and understand this manual before operating

the machine.

DO NOT Use with PTO Drive-line Powered Equipment. A tractormounted PTO drive shaft is not designed for use with a swinging drawbar

extender, such as the Outback

Hitch.

WARNING:

!

DO NOT Exceed Weight Limits. Review tractor specific limits for drawbar

extender application. The maximum vertical static load is 4000 lbs. (1800 kg).

WARNING:

!

HIGH-PRESSURE FLUID HAZARD. The Hitch utilizes hydraulic compo-

nents. Always relieve pressure on the system before repairing or adjusting. To

avoid hazard, wear proper hand and eye protection, and keep in good repair.

WARNING:

!

MOVING PARTS HAZARD. To avoid injury, keep hands and fingers

away from the swinging Hitch drawbar area.

WARNING:

!

ALWAYS Attach Safety Chain Between Tractor and Implement.

WARNING:

!

Page 8

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

6

INSTALLATION

1. Tractor Preparation: Before attempting to install the

Outback® Hitch, park the tractor on a smooth level floor

with adequate clearance to work around the drawbar area.

Remove any accessories installed on the tractor drawbar

including the hammerstrap clevis and safety chain holder.

If the tractor is equipped with a drop-style drawbar, remove

the drawbar and flip it upside down. Reinstall the drawbar

as shown. The Outback® Hitch requires a minimum

mounting clearance of 14-1/4 in. (362mm) between the

center of the drawpin hole and the rear of the tractor support casting.

2. Determine Proper Mounting Configuration: The

Outback® Hitch is supplied with a universal mounting kit

(packaged in a burlap bag) and includes all necessary hardware to mount the hitch to most CAT II or III tractor drawbars. Not all parts included in the kit are required for each

specific installation.

Carefully review the mounting hardware details shown on

page A7 for your tractor specific mounting configuration.

Identify the required parts as shown.

Label

Description Qty

A 3/4” x 4” Hex Bolt, Gr5 5

B 3/4” x 6” Hex Bolt, Gr5 5

C 3/4” Lock Washer 5

D 3/4” Hex Nut, Gr5 5

E Hitch Hammer Strap Plate 1

F Hitch Spacer Plates:

3/4” Thick 3

1/2” Thick 4

1/4” Thick 2

G Draw Pin Bushings:

1-5/8”OD x 3/4”ID x 1-15/16”Lg 1

1-1/2”OD x 3/4”ID x 1-11/16”Lg 1

1-1/4”OD x 3/4”ID x 1-7/16”Lg 1

H CAT II Draw Bar Bushing:

1-3/8”OD x 13/16”ID x 1-7/16”Lg 4

14-1/4” (362mm) Min.

A

B

E

F

C

D

H

G

Page 9

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

7

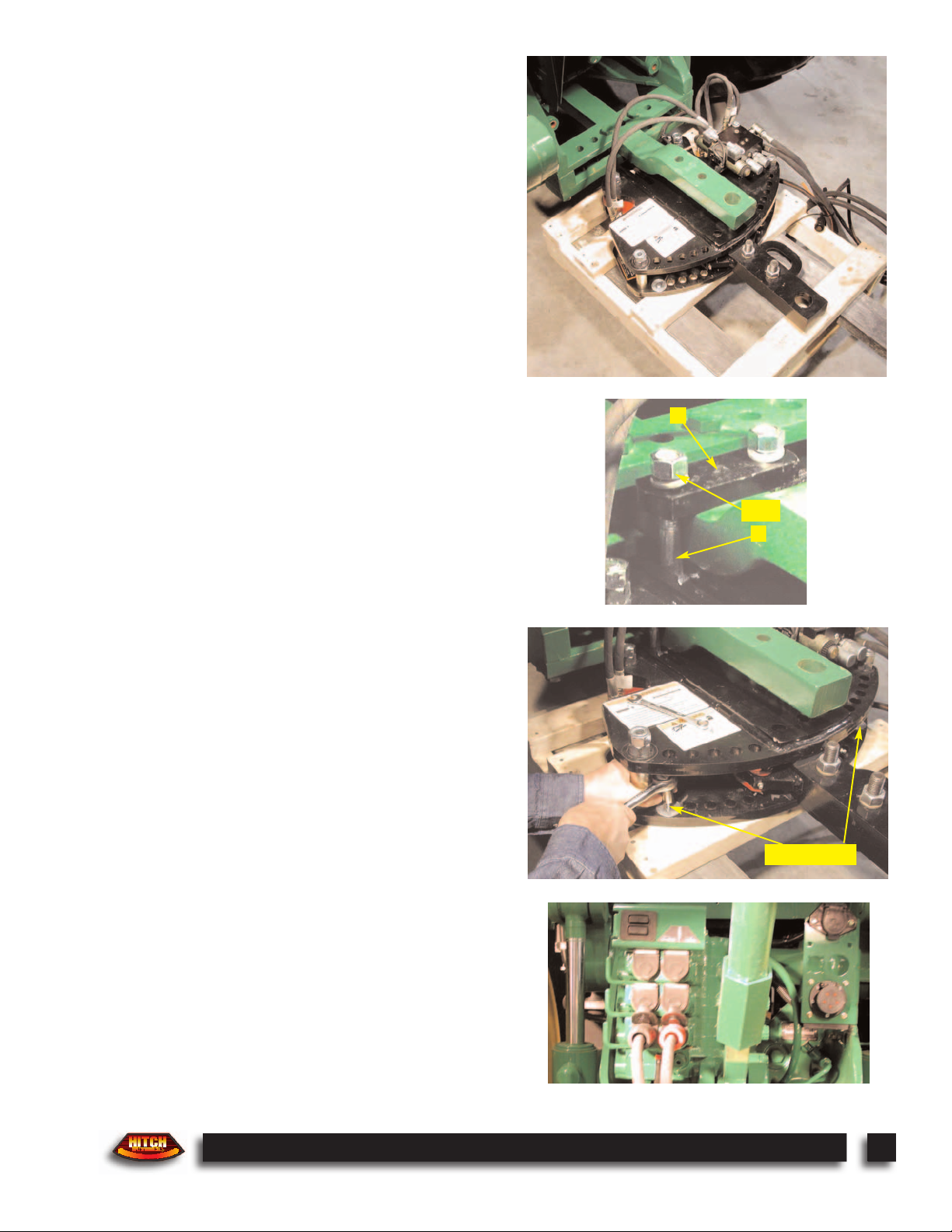

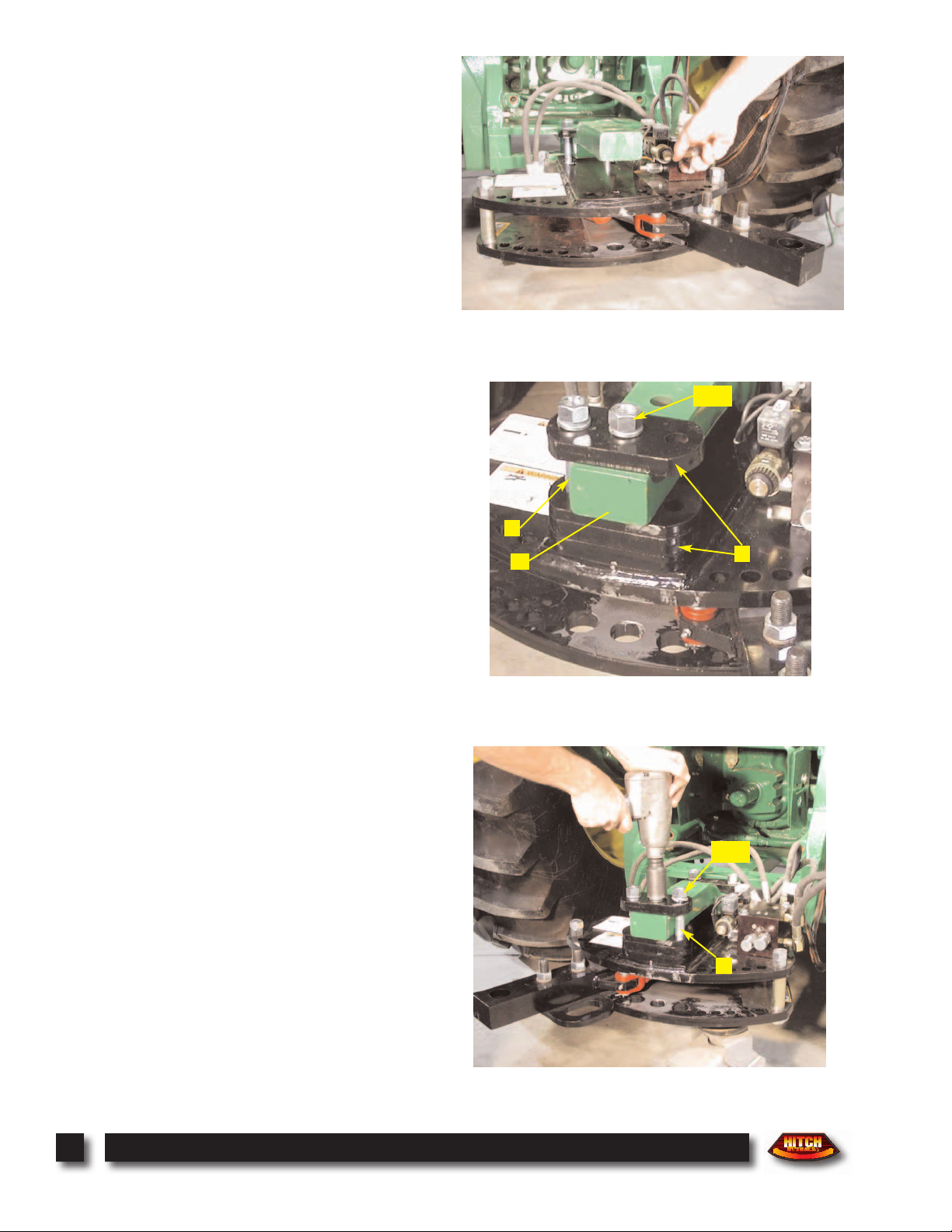

3. Mounting the Hitch: Using a forklift, floor jack, or

chain hoist, position the Outback® Hitch under the tractor

drawbar as shown. Notice that the hydraulic hoses to the

left cylinder must route over the top of the tractor drawbar.

Center the hitch directly under the tractor drawbar with the

drawpin hole lined up over the center of the corresponding

hitch mounting hole.

4. Install Hammerstrap at Front of Hitch: Insert

mounting bolt (A) into the front slot of the hitch, on both

sides of the drawbar, and install hammerstrap plate (E).

Secure with lock washers (C) and hex nuts (D). Do not

tighten hardware at this time. Slight adjustments of the

hitch forward or backward may be required to install

mounting hardware at the rear of the hitch.

5. Remove Hitch Shipping Pallet: The hitch is secured

to the shipping pallet with two lag screws and washers.

Remove both screws and lower the shipping pallet, allowing the hitch to be suspended from the front hammerstrap.

6. Connect Hydraulic Feed Hoses: The hitch hydraulic

supply lines have colored grips. Connect the supply lines

to the tractor remote outlets so that the red grip is pressure

and the black grip is return. During operation the hitch

requires a fixed 1.5 gpm oil flow, up to 3000 psi. Adjust

the tractor remote outlet oil flow to closely match this

requirement.

E

A

C D

REMOVE

Page 10

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

8

7. Move Hitch Drawbar Right: Start the tractor and

enable the hitch hydraulic remote outlet. The coils on the

hitch hydraulic control block have manual push button

overrides. Using a small screwdriver or common nail,

push the manual override at the center of the rear coil to

move the hitch drawbar to the far right extent. Disable the

hitch hydraulic remote outlet, and shut off the tractor.

8. Install Mounting Hardware at Rear of Hitch: Add

necessary hitch spacer plates (F) between the hitch and the

tractor drawbar so that the hitch is level. Insert the proper

sized draw pin bushing (G) into the tractor hitch pin hole.

Make certain that the bushing is not longer than the thickness of the tractor drawbar. Insert mounting bolts (B) up

from the bottom of the hitch through the top hitch plate,

spacer plates, and draw pin bushing. Install 3/4” thick

spacer plate (F) on top of the tractor drawbar, and secure

with lock washers (C) and hex nuts (D).

9. Move Hitch Drawbar Left: Start the tractor and

enable the hitch hydraulic remote outlet. Push the manual

override at the center of the front coil to move the hitch

drawbar to the far left extent. Disable the hitch hydraulic

remote outlet, and shut off the tractor.

10. Complete the Hitch Mounting: Insert the remaining

mounting bolt (B) up from the bottom of the hitch along

the right side of the tractor drawbar, and secure with lock

washer (C) and hex nut (D). Securely tighten all mounting

hardware (5 places), beginning with the rear center hex nut.

Make certain that the spacer plates tighten uniformly so

that no gaps are observed between the hitch and the tractor

drawbar.

B

C D

B

C D

F

G

Page 11

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

9

11. Determine Tilt Sensor Location: The tilt sensor

should be mounted directly onto the rear tractor frame in

an area protected from mud and flying debris. The sensor

must be oriented relative to the forward travel direction as

shown on the sensor decal. Orient the sensor with the label

up and the connector towards the rear. The sensor may

require re-orientation onto the sensor bracket to accommodate mounting directly to the tractor frame.

12. Mounting the Tilt Sensor: The preferred tilt sensor

mounting technique is to locate an extra bolt hole in the

rear tractor casting. The large slot on the sensor mounting

bracket can be slipped under the head of a mounting bolt

(customer supplied) and tightened. Make certain that the

sensor is oriented with the label up, level with the tractor,

and with the connector towards the rear.

13. Routing the Hitch Contol Cable: Route the hitch

control cable up from the drawbar past the tilt sensor and

through the back window of the tractor cab. Install the tilt

sensor cable connection. Secure the control cable with the

tie straps provided. Make certain that the control cable is

clear of any pinch points around the three-point linkage

and is protected from mud and flying debris.

Page 12

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

10

14. Exchange Power Cable: Install the Outback® S,

using the instruction booklet provided. Do not use the

power cable provided with it. Locate the Power/CAN

cable in the Hitch package. It has two connectors and a

cigarette lighter plug. Install the connector with two cables

coming out into the S Power/CAN port as shown. Twist

the connector firmly until it locks into place.

Note: The Outback® Hitch may also be used in combination with the optional Outback® 360. If a 360 is

already installed, step 14 is not required as the twoconnector Power/CAN cable is installed between the

S and the 360. Instead, a three-connector CAN

expansion cable is installed between the 360 and the

Hitch as described in step 15.

15. Daisy Chain Power Cable: Install the optional

Outback® 360, using the instruction booklet provided.

Locate the CAN expansion cable in the Hitch package. It

has three connectors in a ‘Y’ arrangement with a male and

female connector on one end and a female connector on the

other end. Disconnect the CAN connector from the 360

and insert the ‘Y’ end of the CAN expansion cable as

shown. Twist connectors firmly until they lock into place.

16. Rotate Suction Cup: Remove the Hitch console from

its package, and loosen the center adjusting bolt on the suction cup so the cup can be rotated 180 degrees. This puts

the pump button on top for easy access.

17. Mounting the Console: Find a desirable mounting

location inside the cab and THOROUGHLY clean the

glass. Remove the red cap from the vacuum mount, press

it to the window, and pump the button located on the vacuum mount. Pump until the red line is no longer visible on

the button. (Check it periodically. If the red line becomes

visible, you may have to pump it a little to maintain suction.) Adjust the display for proper viewing angle.

Note: Do not leave the console unattended for

extended periods of time. If possible, remove the unit

from glass when not in use. Continued exposure to

the elements (such as direct sunlight) can be harmful

to the suction cup.

With OBK-360, Insert Daisy Chain Power Cable Here

Page 13

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

11

18. Install CAN Cable: Install the remaining

Power/CAN connector (from either Step 14 or 15) into the

upper CAN port on the Hitch console as shown. Twist

connector firmly until it locks into place. For permanent

installations, we recommend removal of the cigarette

lighter plug and hard wiring the leads to a reliable 12-volt

power supply. The red wire goes to positive and the black

wire to negative.

Note: Cigarette lighter sockets are notorious for intermittent power. For maximum portability, install a

female cigarette lighter receptacle wired directly to the

battery for each application. For permanent installation, we recommend wiring directly to the battery.

19. Install Hitch Control Cable: Install the Hitch control

cable connector (from Step 13) into the lower HITCH port

on the Hitch console as shown. Twist the connector firmly

until it locks into place.

20. Install Auxiliary Power Cable: Locate the auxiliary

power cable in the Hitch package. It has a connector on

one end and a pair of ring terminals on the other. Install

the cable connector into the upper right PWR IN port on

the Hitch console as shown. Twist the connector firmly

until it locks into place. Route the auxiliary power cable

directly to the tractor battery. The red wire goes to positive, and the black wire goes to negative.

Page 14

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

12

GET ACQUAINTED WITH THE CONTROLS

RUN/HOLD

CENTER

LEFT/RIGHT ARROWS

MODE

S PRESENT

INDICATOR

HITCH POSITION

INDICATORS

HITCH POSITION INDICATORS: A series of 21 lights

indicate the current hitch pin position relative to the center

of the tractor. Each light represents approximately one

inch of hitch pin offset.

S PRESENT INDICATOR: This light indicates the presence of the Outback® S along with its GPS operational status. If the light is off, communication with the S cannot be

established. A blinking light indicates that the S cannot

establish DGPS. A solid green light must be present to

provide automatic hitch control.

MODE: Press the MODE button to change the current

hitch operating mode. Indicator lights show the current

mode as either Follow GPS, Match Tracks, or Manual.

LEFT/RIGHT ARROWS: Press the Left or Right Arrow

buttons to manually position the hitch pin position. The

arrow buttons are also used in Match Tracks mode to adjust

the amount of compensation necessary to match the implement tracks to the tractor. The light between the arrows

indicates when the left and right arrow buttons are active.

RUN/HOLD: Pressing these buttons enables or disables

the active hitch position control. The RUN button enables

the active hitch control in the selected mode, whereas the

HOLD button suspends active control of the hitch position.

Note: As a safety feature, the tractor must be traveling faster than one mile per hour before the RUN button can enable active hitch control.

CENTER: Press the CENTER Button to easily move the

hitch pin to center position and quickly prepare for road

travel. This CENTER feature may be initiated at any time

in all operating modes. A single press of the CENTER button automatically centers the hitch pin, puts the operating

mode in manual, and puts the status in hold.

Page 15

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

13

POWER UP

1. Power up both units: Turn on the power switches of

the S and Hitch in any order. The S will boot up and begin

acquiring a DPGS signal. The Hitch will establish communication with the S and wait for the DPGS signal to be

acquired.

2. Power up S only: Turn the power switch of the S on

and leave the Hitch off. This causes the S to operate as

normal. Refer to the Outback® S Manual for operation.

Outback®S Power Switch

Outback®Hitch Power Switch

SETUP

Configuration of the Outback® Hitch is accomplished

through the S, or 360, menu system. During power-up, the

Hitch is detected, and an additional menu option is included to configure the Hitch for operation.

To access the menu: Press the MENU button. Then

choose the HITCH CALIBRATE item. All functions in the

Outback® S console menu are navigated and selected

using the UP/DOWN ARROWS and the ENTER key.

1. POSITION: This function establishes the relation

between the actual hitch pin position and the measured

position as displayed on the Hitch console. Selecting this

function brings up three successive display screens to calibrate the left, right, and center hitch pin positions. Use the

LEFT/RIGHT ARROWS on the Hitch console to position

the physical hitch pin at the required location; then press

ENTER to update the calibration values.

2. CURVE: This function adjusts the amount of hitch pin

compensation necessary to match the implement tracks to

the tractor while driving around a curve. Drive the tractor

and implement to an open area which is relatively flat.

Proceed to drive around a large curve (typically 150 foot

radius or more). Observe how the implement is trailing

behind the tractor and use the LEFT/RIGHT ARROWS on

the Hitch console to adjust the hitch pin position so the

implement tracks match those of the tractor. Press ENTER

to update the curvature compensation value.

3. SLOPE: This function enables the Tilt Sensor for side

slope compensation and establishes a level reference value.

Selecting this function first displays an ON/OFF choice

selection. Selecting ON brings up a subsequent display

screen to adjust the level reference value. Park the tractor

on a nearly level surface. Press ENTER to update the level

reference value.

POSITION

Menu Item Display Sequence

Instructions

Press LEFT ARROW until hitch pin is at far left position.

Press ENTER to update left position.

Press RIGHT ARROW until hitch pin is at far right position.

Press ENTER to update right position.

Press LEFT ARROW until hitch pin is in the center.

Press ENTER to update center position.

ADJ LEFT ??

ENTER TO UPDATE

ADJ RIGHT ??

ENTER TO UPDATE

ADJ CENTER ??

ENTER TO UPDATE

CURVE

ADJ CURVE ??

ENTER TO UPDATE

Drive around a curve on relatively flat ground and observe trailing implement

tracking. Press LEFT or RIGHT ARROW until implement track matches those

of the tractor. Press ENTER to update curvature compensation value.

SLOPE

>ON

OFF

LEVEL GND ??

ENTER TO UPDATE

Select if Tilt Sensor is to be used for side slope compensation.

Park the tractor on a nearly level surface.

Press ENTER to update the level reference value.

SETUP : HITCH CALIBRATE MENU

Page 16

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

14

Follow GPS Mode: This mode causes the hitch to seek

the GPS guideline you are following. For example, if you

drive right of the

guideline, the hitch

will move left to compensate.

In follow GPS mode,

use the Outback® S as

normal. You can

establish a guideline

using either straight or

contour guidance.

Simply drive the tractor near the guideline,

and the Hitch will

position the hitch pin

directly over the line.

Note: When operating with the Hitch in follow GPS

mode, the Outback® S and 360 use the actual hitch

pin position for contour guidance logging and application mapping.

OPERATION

GPS Guideline

Hitch positions

implement on

GPS Guideline

Tractor off

to right of

GPS Guideline

Match Tracks Mode: This mode is for driving through

standing crop in side-hills and curves. For example, when

the tractor leans left on a sidehill, the hitch adjusts right so

the implement tires don’t damage the crop. The amount of

adjustment is proportional to

the measured tilt of the tractor.

The sensitivity of the slope

compensation may be adjusted

using the LEFT/RIGHT

ARROWS, as you drive

through the standing row crop.

Likewise, when following rows

around a curve to the right, the

hitch adjusts left to minimize

crop damage. The amount of

adjustment is proportional to

the sharpness of the turn. The

sensitivity of the curve compensation is adjusted in the HITCH

CALIBRATE setup menu.

Note: When operating with the Hitch in match tracks

mode, the Outback® S displays MATCH TRACKS

and does not provide driving guidance. The

Outback® 360 operates as normal and records the

GPS antenna position for application mapping.

Implement Matches Tracks

Downhill Slope

GPS Guideline

Implement Matches Tracks

The operation of the Outback® Hitch is quite simple.

Turn it on, activate the tractor hydraulics, select the desired

MODE, press RUN, and the rest is automatic.

Note: As a safety feature, the tractor must be traveling faster than one mile per hour before the RUN button can enable active hitch control.

Manual Mode: This mode allows the operator to position

the hitch pin at any desired offset using the LEFT/RIGHT

ARROWS. When operating with the Hitch in manual

mode, the Outback® S and 360 operate as normal. All

functions of the S and 360 are affected by the presence of

the hitch.

Page 17

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

15

MAINTENANCE

Proper maintenance of the Outback® Hitch mechanical

components will ensure years of dependable service and

protect your investment.

Initial Installation: After the first few hours of operation,

check the tightness of all Hitch mounting bolts and hardware. Substantial wear will occur to the Hitch and tractor

drawbar if mounting bolts are not properly tensioned.

Grease Fittings: Proper lubrication of the 5 grease locations at 12-hour intervals will dramatically prolong the life

of friction production parts. Use an SAE multi-purpose

type grease. Make sure to clean the fittings thoroughly

before using any grease gun.

Replace Worn Components: At the begining of each

application season, check the hitch drawbar for any signs

of free-play, both up and down and side to side. All wear

points of the Hitch include serviceable replacement parts.

Refer to pages A4 and A5 for details.

TROUBLE-SHOOTING TIPS

12 Hours

(3 Places)

12 Hours

(2 Places)

GREASE LOCATIONS

Problem - Probable Cause. Action

Hitch Drawbar Doesn’t Move

√ Tractor Hydraulics Not Active. Make sure hydraulic hoses are hooked up correctly (red hand grip to pressure;

black hand grip to return). Use push button over-rides on hydraulic block coils to verify operation.

√ Poor Electrical Connection. Check the indicator lights on the hydraulic block coil connectors. If no lights,

check cable connections. If lights show, then replace coil.

Hitch Drawbar Moves in the Wrong Direction

√ Tractor Hydraulics Reversed. Make sure hydraulic hoses are hooked up correctly (red hand grip to pressure;

black hand grip to return).

Page 18

CONTACTING THE

FACTORY

Outback Guidance®

Division of RHS, Inc.

2005 West Oregon Street, Box 394

Hiawatha, KS 66434

USA

All correspondence to the factory must be in English.

ONLINE:

http://www.outbackguidance.com

PHONE:

Monday Through Friday 8 A.M. - 5 P.M. U.S. Central Time

U.S:

1-800-247-3808 (Customer Service & Ordering)

Canada:

1-866-888-4472 (Customer Service & Ordering)

From all other countries:

01-785-742-2949

E-MAIL:

24 hours / 7 days a week

Your inquiry will receive a response from one of our

Customer Support Representatives within one business day.

Sales: outbacksales@outbackguidance.com

Customer Service: outbackcs@outbackguidance.com

Website Feedback: outbackweb@outbackguidance.com

FAX:

24 hours / 7 days a week

Your inquiry will receive a response from one of our

Customer Support Representatives within one business day.

1-785-742-4584

16

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

Page 19

Limited Outback® Hitch

One-Year Warranty

RHS, Inc. ("RHS") manufactures its hardware products

from parts and components that are in accordance with

industry standard practices. RHS warrants that the hardware products it manufactures will be free from defects in

materials and workmanship. The limited warranty term is

one year, beginning on the date of invoice to the original

purchaser.

Damage caused by shipping the product(s) to the original

purchaser is covered under this limited warranty.

Otherwise, this limited warranty does not cover damage

due to external causes, including accident, abuse, misuse,

problems with electrical power, servicing not authorized by

RHS, usage not in accordance with product instructions,

failure to perform required preventive maintenance and

problems caused by use of parts and components not supplied by RHS.

This limited warranty does not cover any items that are in

one or more of the following categories: software (RHS

authorized revision updates may be purchased), external

devices (except as specifically noted), accessories or parts

added to an Outback® Hitch system after the system is

shipped from RHS, accessories or parts that are not

installed in the RHS factory.

RHS will repair or replace product(s) covered under this

limited warranty that are returned to the RHS facility. To

request warranty service, you must call RHS (800-247-

3808) or go to outbackguidance.com for information, within the warranty period. If warranty service is required,

RHS will issue a Return Material Authorization Number.

You must ship the products back to RHS in their original or

equivalent packaging, prepay shipping charges, and insure

the shipment or accept risk of loss or damage during shipment. RHS will ship by UPS Ground Service the repaired

or replacement products, within 5 business days, freight

paid. In any instance in which RHS issues a Return

Material Authorization Number, RHS must receive the

product(s) for repair prior to the expiration of the warranty

period in order for the repair(s) to be covered by the limited

warranty.

RHS owns all parts removed from repaired products. RHS

uses new and reconditioned parts made by various manufacturers in performing warranty repairs and building

replacement products. If RHS repairs or replaces a product, its warranty term is the remainder of the limited warranty term.

RHS MAKES NO EXPRESS WARRANTIES OR CONDITIONS BEYOND THOSE STATED IN THIS LIMITED

WARRANTY STATEMENT. RHS DISCLAIMS ALL

OTHER WARRANTIES AND CONDITIONS, EXPRESS

OR IMPLIED, INCLUDING WITHOUT LIMITATION

IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. SOME STATES (OR JURISDICTIONS) DO

NOT ALLOW LIMITATIONS ON IMPLIED WARRANTIES OR CONDITIONS, SO THIS LIMITATION

MAY NOT APPLY TO YOU.

RHS RESPONSIBILITY FOR MALFUNCTIONS AND

DEFECTS IN HARDWARE IS LIMITED TO REPAIR

AND REPLACEMENT AS SET FORTH IN THIS LIMITED WARRANTY STATEMENT. THESE WARRANTIES

GIVE YOU SPECIFIC LEGAL RIGHTS, AND YOU

MAY ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE (OR JURISDICTION TO

JURISDICTION).

RHS DOES NOT ACCEPT LIABILITY BEYOND THE

REMEDIES SET FORTH IN THIS LIMITED WARRANTY STATEMENT OR LIABILITY FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING

WITHOUT LIMITATION ANY LIABILITY FOR PRODUCTS NOT BEING AVAILABLE FOR USE OR FOR

LOST DATA OR SOFTWARE.

SOME STATES (OR JURISDICTIONS) DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

PRECEDING EXCLUSION OR LIMITATION MAY NOT

APPLY TO YOU.

These provisions apply to the RHS Limited Outback®

Hitch One-Year Warranty only. For provisions of any

extended service plan covering your system, refer to your

invoice or the separate extended service plan that you

received.

RHS reserves the right to make improvements in design or

changes in specifications at any time, without incurring any

obligation to owners of units previously sold.

No one is authorized to alter, modify, or enlarge this warranty nor the exclusions, limitations, and reservations.

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

17

Page 20

Limited Outback®

Hitch Three-Year

Extended Service Plan

The Outback® Hitch ESP only applies to the electronic

components of the product. Including the console, console

mounting, tilt sensor and related cables. The term “hardware” below applies only to the non-software portions of

the electronic components. Coverage for the mechanical

portions of Outback® Hitch are described in the one-year

warranty statement.

RHS,Inc. ("RHS") manufactures its hardware products

from parts and components that are in accordance with

industry standard practices. RHS warrants that the hardware products it manufactures will be free from defects in

materials and workmanship. The limited plan term is three

years, beginning on the date of invoice to the original purchaser.

Damage caused by shipping the product(s) to the original

purchaser is covered under this limited plan. Otherwise,

this limited plan does not cover damage due to external

causes, including accident, abuse, misuse, servicing not

authorized by RHS, usage not in accordance with product

instructions, failure to perform required preventive maintenance and problems caused by use of parts and components

not supplied by RHS.

This limited plan does not cover any items that are in one

or more of the following categories: software (except for

RHS authorized revision updates), external devices (except

as specifically noted), accessories or parts added to an

Outback® Hitch system after the system is shipped from

RHS, accessories or parts that are not installed in the RHS

factory.

RHS will provide, on an exchange basis and subject to the

RHS Exchange Policy in effect on the date of the exchange,

replacement parts (up to and including a complete

Outback® Hitch system) for the Outback® Hitch

product(s) covered under this limited plan when parts

require replacement. To request service, you must call

RHS (800-247-3808) or go to outbackguidance.com for

information within the plan period. If replacement is

required, RHS will issue a Return Material Authorization

Number and will ship by UPS Next Day Air & Saturday

Delivery the replacement parts within 1 business day. You

must ship by UPS Ground Service collect the original product(s) back to RHS in this packaging. In any instance in

which RHS issues a Return Material Authorization

Number, RHS must receive the original part(s) prior to the

expiration of the plan period in order for the replacement(s)

to be covered by the limited plan. Failure to return original

part(s) for which replacement(s) have been sent within 30

days of initial shipment will result in the issuance of an

invoice for the cost of the sent parts. RHS uses new and

reconditioned parts made by various manufacturers in performing warranty repairs and building replacement products. If RHS repairs or replaces a product, its plan term is

the remainder of the limited plan term.

RHS MAKES NO EXPRESS WARRANTIES OR CONDITIONS BEYOND THOSE STATED IN THIS LIMITED

WARRANTY STATEMENT. RHS DISCLAIMS ALL

OTHER WARRANTIES AND CONDITIONS, EXPRESS

OR IMPLIED, INCLUDING WITHOUT LIMITATION

IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. SOME STATES (OR JURISDICTIONS) DO

NOT ALLOW LIMITATIONS ON IMPLIED WARRANTIES OR CONDITIONS, SO THIS LIMITATION

MAY NOT APPLY TO YOU.

RHS RESPONSIBILITY FOR MALFUNCTIONS AND

DEFECTS IN HARDWARE IS LIMITED TO REPAIR

AND REPLACEMENT AS SET FORTH IN THIS LIMITED WARRANTY STATEMENT. THESE WARRANTIES

GIVE YOU SPECIFIC LEGAL RIGHTS, AND YOU

MAY ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE (OR JURISDICTION TO

JURISDICTION).

RHS DOES NOT ACCEPT LIABILITY BEYOND THE

REMEDIES SET FORTH IN THIS LIMITED WARRANTY STATEMENT OR LIABILITY FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING

WITHOUT LIMITATION ANY LIABILITY FOR PRODUCTS NOT BEING AVAILABLE FOR USE OR FOR

LOST DATA OR SOFTWARE.

SOME STATES (OR JURISDICTIONS) DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

PRECEDING EXCLUSION OR LIMITATION MAY NOT

APPLY TO YOU.

These provisions apply to the RHS Limited Outback®

Hitch Three-Year Extended Service Plan only.

RHS reserves the right to make improvements in design or

changes in specifications at any time, without incurring any

obligation to owners of units previously sold.

No one is authorized to alter, modify, or enlarge this warranty nor the exclusions, limitations, and reservations.

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

18

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

Page 21

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A1

Outback-Hitch Drawbar Guidance System

REF. P/N DESCRIPTION QTY.

1 OBK-S Outback-S Guidance System

2 OBK-360 Outback-360 Mapping System

3 60081 CAN/Power Cable, OBK-360/Hitch - 10ft Lg/15ft Lg, CLA 1

4 60099 Cable, CAN Expansion - 5' 1

5 60098 Cable, Auxiliary Power - 12' 1

6 Console Mounting Details, see page A2

7 AB674 Cable, Hitch Interface - OBK Hitch 1

8 TS-7R Tie Strap, 7" - Releasable 6

9 Tilt Sensor Mounting Details, see page A2

10 Mounting Hardware Details, see page A7

11 Hydraulic & Electrical Assy, see page A3

12 Mechanical Assy, see page A4

DOM-OBK03 Owner's Manual, OBK-Hitch 1

PARTS LISTING

Page 22

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A2

Tilt Sensor Mounting Details

REF. P/N DESCRIPTION QTY.

1 AB673 Tilt Sensor - OBK Hitch 1

2 AB677 Bracket, Tilt Sensor Mount - OBK Hitch 1

3 B#8.12 Bolt, #8 x 1/2 Phil Rnd Hd, ZP 2

4 LN#8K Nut, Keeper Lock - #8-32 2

Console Mounting Details

REF. P/N DESCRIPTION QTY.

1 60066 Vacuum Cup, 4-1/2" /w 1/4NC Insert 1

2 60063 Washer, Rubber - 2-1/4OD x 3/8ID x 1/8T 1

3 AB440 Base, Console Mounting - OBK-S/360 1

4 60065 Knob, 3-Arm - 1/4NC x 1/2 Stud, 1-1/8 Dia. 3

5 60064 Washer, Rubber - 1-1/2OD x 3/4ID x 3/32T 2

6 AB441 Frame, Console Mounting - OBK-S 1

7 60097 Outback Hitch Console 1

8 60068 Knob, Thumbscrew - #8-32 x 1/4" Stud 2

Page 23

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A3

Hydraulic & Electrical Assembly

REF. P/N DESCRIPTION QTY.

1 Mechanical Assy, see page A4

2 60229 Hydraulic Valve Assy, see page A6 1

3 FW38N Washer, Narrow Flat - 3/4"OD x 13/32ID x 1/16"thk, ZP 2

4 B38.4 Bolt, 3/8NC x 4 Gr5 ZP 2

5 60233 Hose, Hyd. - 1/4"x24"lg, #4 Female JIC x #4 Male JIC 2

6 60232 Hose, Hyd. - 1/4"x18"lg, #4 Female JIC x #4 Male JIC 2

7 60231 Hose, Hyd. - 3/8"x60"lg, #6 Male ORB 90deg x 1/2" MPT 2

8 69266 Hydra Grip - One Pair, Red and Black 1

9 8FP-QM Adapter, Hyd. Quick Disconnect - Male Tip x 1/2"fpt 2

10 AB674 Cable, Hitch Interface 1

11 WA027 Clamp, Cushioned Cable - 1/2"DIA. x 1/2"WIDE 1

12 B14.34 Bolt, 1/4NC x 3/4 Gr5 ZP 1

13 60257 Decal, Hazard - Outback Hitch General Warning 1

14 DEC-HAZ01 Decal, Warning - High Pressure Fluid 1

15 DEC-MT4163 Decal, Warning - Pinch Point 2

Page 24

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A4

Mechanical Assembly

REF. P/N DESCRIPTION QTY.

1 AB663 Wment, Hitch Bottom 1

2 60214 Pin, Hitch Main 1

3 B12.212 Bolt, 1/2NC x 2-1/2 Gr5 ZP 1

4 LN12 Nut, Lock - 1/2NC ZP 1

5 B34.6 Bolt, 3/4NC x 6 Gr5 ZP 4

6 60220 Washer, Shim - 1-1/8"OD x 3/4"ID x 0.062"TH 8

7 60217 Washer, Shim - 1-5/8"OD x 1-1/8"ID x 0.047"TH 2

8 60216 Bushing, Hitch Spacer 4

9 Drawbar Sub-Assembly, see page A5

10 60218 Left Cylinder Assy, see page A6 1

11 60219 Right Cylinder Assy /w Sensor, see page A6 1

12 CLP34.2 Pin, Clevis - 3/4" x 2" ZP 2

13 60220 Washer, Shim - 1-1/8"OD x 3/4"ID x 0.062"TH 4

14 CP532.114 Pin, Cotter - 5/32" x 1-1/4", ZP 2

15 AB664 Wment, Hitch Top 1

16 N34 Nut, 3/4NC Gr5 ZP 8

Page 25

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A5

Drawbar Sub-Assembly

REF. P/N DESCRIPTION QTY.

1 AB665 Wment, Hitch Drawbar 1

2 LSI-2022-20 Sleeve, L280 - 1.25"ID x 1.375"OD x 1.25"Lg 2

3 60245 Bearing, Composite Sleeve - 3/4"ID x 7/8"OD x 3/4"Lg 2

4 69573 Zerk, Grease 1/4-28 Threaded 3

5 AB667 Wear Plate, Hitch Drawbar 2

6 B56.1FSC Bolt, Hex Socket Flat Head - 5/16NC x 1", ZP 6

7 AB676 Flat, Safety Chain Support 1

8 BM20.110 Bolt, Hex - 20m2.5 x 110, YZ 2

9 LWM20 Washer, Lock - M20, YZ 2

10 NM20 Nut, Hex - 20m2.5, YZ 2

11 60205 Key, 1/2”SQ. x 1-1/2” - 1018, ZP, undersized 4

Page 26

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A6

Hydraulic Component Details

REF. P/N DESCRIPTION QTY.

1 60239 Replacement Seal Kit /w Instructions 2

2 60240 Replacement Sensor Kit /w Instructions 1

3 4MB-4MJ90 Adapter, Hyd. - #4 Male ORB x #4 Male JIC, 90deg 4

4 60241 Assy, Hydraulic Tube 2

5 69573 Zerk, Grease 1/4-28 Threaded 2

6 60234 Coil, Directional Valve - D02, 12VDC, DIN 2

7 60235 Valve, Directional /w Coils - DO2 Closed Center, Standard 1

60236 Valve, Directional /w Coils - DO2 Tandem Center, Alternate

8 60237 Cartridge, Pressure Comp. - 1.5 GPM Fixed 1

9 60238 Cartridge, Counter Balance - Set 3000 PSI Crack 2

10 4MB-4FJ90 Adpater, Hyd. - #4 Male ORB x #4 Female JIC, 90deg 2

11 4MB-4MJ90 Adapter, Hyd. - #4 Male ORB x #4 Male JIC, 90deg 2

Page 27

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A7

Mounting Hardware Details

REF. P/N DESCRIPTION QTY.

1 B34.4 Bolt, 3/4NC x 4 Gr5 ZP 5

2 B34.6 Bolt, 3/4NC x 6 Gr5 ZP 5

3 N34 Nut, 3/4NC Gr5 ZP 5

4 LW34 Washer, Lock - 3/4" ZP 5

5 AB672 Flat, Hitch Mount Hammer Strap 1

6A AB671 Flat, Hitch Mount Spacer - 3/4" 3

6B AB669 Flat, Hitch Mount Spacer - 1/2" 4

6C AB670 Flat, Hitch Mount Spacer - 1/4" 2

7A 60223 Bushing, Hitch Draw Pin - 1-5/8"OD x 3/4"ID x 1-15/16"Lg 1

7B 60222 Bushing, Hitch Draw Pin - 1-1/2"OD x 3/4"ID x 1-11/16"Lg 1

7C 60224 Bushing, Hitch Draw Pin - 1-1/4"OD x 3/4"ID x 1-7/16"Lg 1

8 60221 Bushing, Hitch Cat II Mount Spacer 4

Page 28

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A8

Clevis Hitch Attachment [Optional]

REF. P/N DESCRIPTION QTY.

1 60246 Hammerstrap, Cat. 3 Drawbar 1

2 60248 Hitch Pin Trigger, Cat 3 Drawbar 1

3 60247 Hitch Pin, Cat 3 Drawbar 1

*4 BM20.110 Bolt, Hex - 20m2.5 x 110, YZ 2

*5 LWM20 Washer, Lock - M20, YZ 2

*6 AB676 Flat, Safety Chain Support 1

DIP-OB014 Installation Instructions, Clevis Hitch Attachment 1

*Items 4, 5, & 6 supplied with drawbar hitch assembly.

Page 29

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A9

Page 30

G

P

S

I

M

P

L

E

M

E

N

T

G

U

I

D

A

N

C

E

®

A10

Page 31

Page 32

Loading...

Loading...