Page 1

180, 3e avenue – PO Box 188, L'Islet, Qc, G0R 2C0

Tél. :(418)247-3947 ou 1-800-463-7043,

FAX: 418-247-7801

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS FOR

EXPLOSION-PROOF

HEATER "SERIES OPX"

I. GENERAL

The Explosion-proof Heater i s CSA and FM approved

for use in industrial areas that are classif ied as Class

I, Division 1, Groups. B, C & D, and Class II, Division

1, Groups E, F & G. The heaters are also available in

corrosion resistant construction, suit able for NEMA 3,

and corrosive environments. The specific heat er

ratings are shown on the data plate. The heat er s ar e

intended for horizontal wall or floor mounting in

industrial applications only. Surface temperat ur es

of the cabinet may exceed those normally expected

with residential equipment, so the heater should

never be installed in a residential or similar

environment where drapes or upholst er y may come

into contact with the heater or w here unintended

personnel contact may occur.

The maximum operating temperature ignition code is

stamped on the data plate. NEVER operate th e heat er

in an atmosphere with an ignition code temperatur e

lower than this rating. The heater s ar e designed f or

convection airflow in a maximum ambient

temperature of 40°C, 104°F. NE VE R operate the

heater in a vertical mounting orientat ion or w here the

ambient temperature may exceed 40°C, 104°F.

For details on the particular hazardous environments

having the potential for explosion, refer to Section 18

of the Canadian Electrical Code, Part I.

A. The Explosi on -proof Heater is inten ded to be

permanently mounted to a wall by mounting brackets

supplied with the heater or floor mounted with the

optional floor mounting brackets. A high temperature

limit control is built into the heater. All heaters

connected to a 3 phase voltage source and all single

phase heaters above 277 Volts or 25 amps will requir e

a control contactor, operated by the limit cont r ol, t o

control the heater. Certain optional cont r ols such as

a thermostat and/or contactor and contr ol voltage

transformer are available and wh en supplied w ith the

heater they are supplied inside their own r at ed

enclosures mounted on the right side of th e cabinet or

supplied as remotely mounted items. When mounted

on the cabinet the enclosures are connected to th e

heater terminal box using rigid metal conduit and the

controls are factory wired. Remot ely locat ed cont rols,

outside the hazardous area, may be in a standard

enclosure, area permitting. All wiri ng connect ions t o

the heater must be made using rigid metal conduit,

and an explosion-proof conduit seal must be located

immediately adjacent to the heater. All wiring must

comply with all national and local codes for equipment in

hazardous locations.

The heaters are specifically designed for each application

and should be properly installed, operated and

maintained for optimum service life.

B. Disassembly of the unit for installation is not required

or authorized. When installing:

1. Observe all heater nameplate ratings, war n ings

and notes.

2. Follow the wirin g di ag ram supplied with the h e at er

in making all electrical connections.

3. Keep all electrical connections tight.

4. Keep the heater terminal enclosure and heating

elements clean.

5. Never cover the heater w h ile in oper ation.

6. Carefully read and comply with all warnings and

cautions.

II. INSTALLATION

A. Site Selection.

1.) The Explosion-proof Heater is designed f or use

only while permanently mounted in a horizontal

orientation at a minimum of 6" (152mm) above the

floor.

2.) The site must allow suff icient free space around

the heater for safe and easy installation and

maintenance access. Workspace for heater

maintenance should be at least 3 feet (914mm) all

around the front of the heat er cabinet and

terminal box.

3.) Airflow thr ough t h e heat er should not be restricted

or blocked in any manner.

4.) The site must have adequat e means t o suppor t the

weight of the heater, and prov ide physical

protection to the heater.

Ouellet strongly recommends this heater be installed by qualified

personnel familiar with the Canadian Electrical Code requirements for

hazardous locations as well as any local codes. It is the responsibility

of the installer to verify the safety and suitability of the installation.

The heater must be mounted horizontally.

Disassembly of the unit, for installation, is not required or authorized.

Do not cover the heater or obstruct the free flow of air into or out of the

heater.

=WARNING=

=WARNING=

=WARNING=

=WARNING=

Page 2

=WARNING=

Do not install the heater in a residential or similar environment where

drapes or upholstery may come into contact with the heater or where

unintended personnel contact may occur.

B. Mechanical Installation. Once an acceptable

location has been determined, follow these

instructions to complete the mechanical installation.

=WARNING=

Disassembly of the unit for installation is not required or authorized.

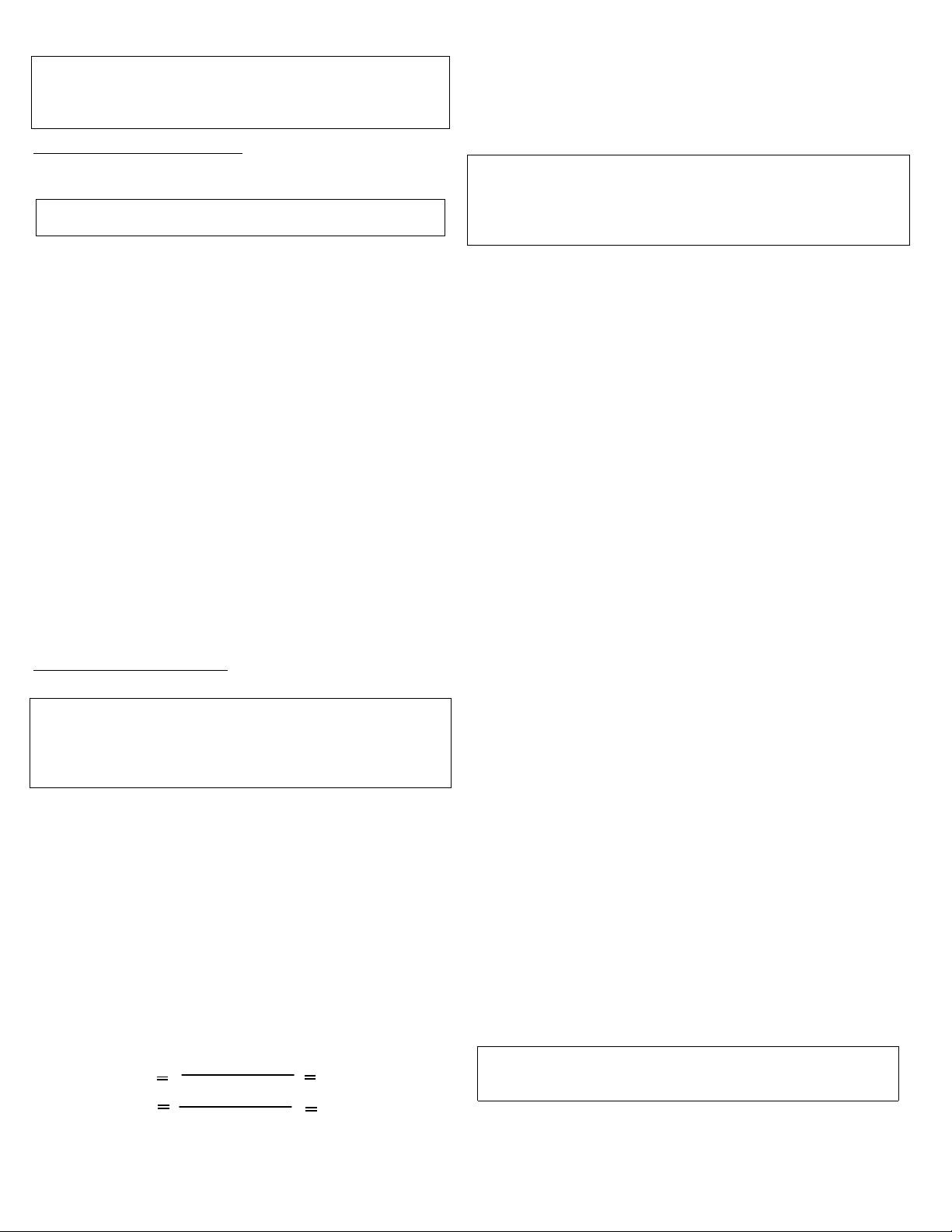

1.) Wall mounted heater.

a.) Refer to Figure 1.

b.) Mark the mounting screw locations or the

wall mounting brackets on the vertical

surface.

c.) Center punch and/or pilot drill the

mounting screw locations.

d.) Using four screws (not supplied w i t h t h e

heater) attach the wall mounting brackets

to the vertical surface.

e.) Lift the heater up and then dow n over the

mounting brackets so that the “V” lip at the

top of the brackets engage the slots in t h e

back of the heater cabinet.

f.) Make sure that the heater is resting in th e

bottom of the “V” lip so that the mounting

holes at the bottom of the wall mounting

bracket align with the mounting holes in

the heater cabinet.

g.) Fasten the heater to the wall mounting

brackets using the 2 screws, washers and

nuts provided.

C. Electrical Installation.

Follow these instructions

to complete the electrical installation:

=WARNING=

Potentially lethal voltages are present. Be sure to lock the branch

circuit disconnect switch in the off position and tag the circuit “Out for

Maintenance” before working on this equipment.

1.) Follow th e w i ring diagram and any Code

recommendations in making all electrical

connections.

2.) Use only an approved explosion-proof m e an s of

wiring, such as insulated copper conductors in

rigid metal conduit with threaded connect ions

per Canadian Electrical Code to make the

electrical connections to the heater.

3.) Determine the v oltage, phase and KW rating of

the heater from the heater dat a plate.

4.) The branch circuit volt age and phase must

match the heater voltage and phase rating.

5.) Calculate the rat ed load cur rent of the heater

as follows:

Single Phase units

Three Phase Units

Kilowatts x 1000

Voltage

Kilowatts x 1000

Votalge x 1.73

Rated Load Current

Rated Load current

6.) Use branch circuit supply wires r a t e d f or 75°C

(167°F) and the rated load current to connect the

heater.

7.) For heaters without optional bui l t on thermostat

or contactor:

=WARNING=

When making electrical connections to the heater, be sure to follow the

wiring diagram provided with the heater. The heater must not be operated

without the safety high temperature limit cutout properly connected in the

circuit.

a.) All 3 phase heaters and all single phase

heaters above 277 volts or 25 amps must have

a safety contactor to disconnect the power if

the temperature high limit opens. The

contactor, must be CSA approved for 150,000

cycles with a resistive rating per pole equal t o

or greater than the heater rated load current.

The holding coil voltage rating of the contactor

cannot exceed 277 volts.

b.) Install an appropriately rate d expl osi on -proof

conduit sealing fitting in the 3/4" NPT

connection hub in the bottom of the heater

terminal box.

c.) Remove the terminal box cover.

d.) Pull t he heater power connection wires labeled

L1, L2 and if 3 phase L3 and th e h i g h

temperature control wires labeled C1 and C2

out of the terminal box through the cover

nipple.

e.) Run the branch circuit supply w ir es and the

contactor control wires, if any, through the

conduit and conduit sealing fitting into the

bottom of the terminal box and out through

the cover nipple.

f.) Select the appropriate wiring diagram that

matches the installation and make the wiring

connections using approved wiring connectors.

g.) Push the wires back into the heater t er minal

box.

h.) Install the terminal box cover, making sure it

is screwed tightly in place.

i.) Pour the explosion-proof seal in the sealing

fitting.

j.) Before application of electrical power, recheck

all connections to ensure compliance with the

wiring diagram and any code requirements.

Remove any foreign objects from the terminal

enclosure. Reinstall cover tightly.

k.) See oper at ing inst r uct ions, Sect ion V, before

operating the heater.

8.) For heaters with optional built on thermostat or

contactor follow the instructions provided with the

control(s).

=WARNING=

When making electrical connections to the heater, be sure to follow the

wiring diagram provided with the heater.

2

Page 3

III. FIELD INSTALLED CONTROLS

=WARNING=

When making electrical connections to the heater, be sure to follow the

wiring diagram provided with the heater. The heater must not be

operated without the safety high temperature limit cutout properly

connected in the circuit.

1.) All 3 phase heaters and all single phase heaters

above 277 volts or 25 amps r ated load current

must have a safety contactor to disconnect t h e

power if the temperature high limit opens. The

contactor, must be CSA approved for 150,000

cycles with a resistive rating per pole equal t o

or greater than the heater rated load current.

The holding coil voltage rating of the contactor

cannot exceed 277 volts.

2.) Any field installed controls cannot exceed the

electrical ratings of the high temperat ur e limit

switch, which i s rated for 125 VA at 277 VAC

maximum.

IV. OPERATION

The Explosion-proof Heater m ay be operated normally

with ambient temperatures of 104°F (40°C) or less,

and in atmospheres containing less than 21% oxygen

by volume. The temperature classificati on of the

heater must be less than the ignition temper ature of

the area hazard classification, and the hazar dous

group classification of the heater must match or

exceed the area classification. All of th ese condit ions

must be met before attempting to operate the heater.

The heater should never

be operated in an oxygenenriched atmosphere or with an ambient t emperature

above 104°F (40°C). At high am bi en t conditions the

safety high temperature limit cutout may activate. If

this occurs, the installation must include some means

to de-energize the heater, such as an automatic

temperature control thermostat or a manually

operated disconnect switch, to prevent excessive

cycling of the controls.

=WARNING=

NEVER operate the heater in an atmosphere with an ignition

temperature lower than the heater marking.

=WARNING=

The heater must be mounted horizontally to maintain the ignition

temperature rating.

1. Initial Operation. Check to make sure th e

mechanical and electrical installation is

complete and that it is safe to operate t h e

heater.

a.) Air Supply. Airflow through the heater

must not be blocked or obstructed i n any

manner. Make sure the area below the

heater is clear, and that nothing is laying

on top of or draped over the top of the

heater cabinet.

b.) Close the branch circuit or unit disconnect

switch servicing the heater.

c.) If a control thermostat is used t ur n the

temperature set point above ambient

temperature.

2.) High temperature limit switch. The high

temperature limit switch is an automatic reset

type. If it trips It will automatically reset once the

temperature has dropped 20°F t o 30°F (10°C to

15°C)below its trip point. The automatic r eset

high temperature limit control is also a fail safe

device. If the sensing bulb is damaged or broken

the automatic reset temperature limit control

contacts will open and stay open, preventing

heater operation until the control is replaced.

=WARNING=

The heater must not be operated without the safety high temperature limit

cutout properly connected in the circuit.

=WARNING=

Replacement electrical components must be obtained from the factory to

maintain the hazardous location rating.

3.) Normal Operation.

a.) Inspect the heater installation for loose bolts,

covers, signs of overheating or cor rosion that

could impair the ability of the heater to operate

safely. Loose bolts should be tightened prior

to operation.

b.) Check the cabinet for restrictions, or

blockages.

c.) Place the heater in service.

V. MAINTENANCE

A. Electrical

=WARNING=

Potentially lethal voltages are present. Be sure to lock the branch

circuit disconnect switch in the off position and tag the circuit “Out for

Maintenance” before working on this equipment.

=WARNING=

Replacement of electrical components should only be done by

authorized personnel familiar with the requirements of maintaining

electrical equipment in an explosion-hazard area.

=WARNING=

Replacement electrical components must be obtained from the

factory to maintain the hazardous location rating.

1.) Annually inspect all wiring connections and visible

insulation for damage, looseness, fraying, etc., as

applicable. Tighten any loose wiring connections

and replace or repair dama g ed or deteriorated

insulation.

2.) If reduced heat output is suspected v er i fy the

condition of the heating elements by using an

ammeter to check the current draw of each input

line. All input lines should draw approximately

equal current which should agree with calculated

rated load current. If they do not, one or more of

the heating elements could be burned out.

3.) High temperature limit switch. The high

temperature limit switch is an automatic reset

type. If it trips It will automatically reset once the

temperature has dropped 20°F t o 30°F (10 to

3

Page 4

15°C) below its trip point. The automatic r eset

high temperature limit control is also a fail safe

device. If the sensing bulb is damaged or

broken the automatic reset temper at ur e limit

control contacts will open and stay open,

preventing heater operation until t he cont rol is

replaced.

=WARNING=

The heater must not be operated without the safety high temperature

limit cutout properly connected in the circuit.

=WARNING=

Replacement electrical components must be obtained from the

factory to maintain the hazardous location rating.

B. Mechanical

1.) Check t h e t er m inal enclosur e, and conduit

connections for evidence of water leaks or

moisture collection. Tighten connections and

check covers as required.

2.) The explosion-pr oof control box is designed

with threaded joints and metal-to-metal contact

NOTE: MOUNTING SCREWS/BOLTS ARE NOT SUPPLIED WITH HEATER MAXIMUM DIA IS 3/8” (9.65mm)

CABINET DIMENSIONS A B C Approx. Weight

26 x 4.44 x 6 po. 22.0 in 2 in 8.125 in 13.0 lbs

660.40 x 112.78 x 152.40 mm 558.80 mm 203.20 mm 206.38 mm 5.90 kg

26 x 8.00 x 16 po. 14.0 in 9 in 9.500 in 27.0 lbs

660.4 x 203.2 x 406.4 mm 355.60 mm 228.60 mm 241.30 mm 12.25 kg

39 x 8.00 x 16 po. 27.0 in 9 in 9.500 in 36.0 lbs

990.60 x 203.20 x 406.40 mm 685.80 mm 228.60 mm 241.30 mm 16.33 kg

67.5 x 8.00 x 16 po. 55.5 in 9 in 9.500 in 60.0 lbs

1714.50 x 203.20 x 406.40 mm 1409.70 mm 228.60 mm 241.30 mm 27.22 kg

at the cover joint to prev ent an explosion. Do not

attempt to install gasket material of any type at

these joints.

3.) Annually check t he tightness of all mounting bolts

and nuts.

4.) Check t he heating element fins for dirt build up or

corrosion, and clean as required. Report signs of

overheating or corrosion to the f act or y.

VI. REFERENCE DATA

1.) Wiring Diagrams. Please r ef er to the enclosed

wiring diagrams in making all electrical

connections to the heater and in performing any

required maintenance.

2.) Data Plate Information. The dat a pl ate contains

the catalog number and rating information.

Please copy this information down and have it

available when communicating with the fact or y.

Keep these instructions with the heater for future reference

Lbs.

.

25-2525-83

4

Loading...

Loading...