DOC026.53.80104

OTT Acoustic Digital Current

(ADC) Meter

05/2013, Edition 3 (North American Version) 10.500.001.B.U.

User Manual

Table of Contents

Specifications..............................................................................................................3

General information..................................................................................................4

Safety information........................................................................................................4

Use of hazard information............................................................................................ 4

Precautionary labels....................................................................................................5

Certification..................................................................................................................5

Product overview.......................................................................................................6

System components....................................................................................................6

About the sensor..................................................................................................8

Temperature compensation.................................................................................. 8

Installation.....................................................................................................................8

About the power supply and battery............................................................................8

Battery specifications ........................................................................................... 9

Charge the battery................................................................................................9

Connect the sensor cable to the handheld unit...........................................................9

To disconnect the sensor...................................................................................10

Attach the handheld display unit to the wading rod...................................................10

Attach the sensor to a wading rod.............................................................................12

Operation.....................................................................................................................12

Turn the handheld unit On and Off............................................................................12

Display screen...........................................................................................................13

Operating key icons ..................................................................................................13

Menu navigation and data entry................................................................................14

Display symbols ........................................................................................................14

Main Menu ................................................................................................................15

System settings.........................................................................................................15

Advanced settings ....................................................................................................16

Upgrade firmware......................................................................................................17

Performing measurements..................................................................................18

Station set up.............................................................................................................18

Angle of flow.......................................................................................................19

Quality control............................................................................................................19

Adjust quality thresholds..................................................................................... 20

Quick quality checks..................................................................................................21

Internal quality check.................................................................................................22

Calibrate the pressure cell (depth calibration)...........................................................22

Turn the depth sensor on or off..........................................................................23

About sensor offsets..................................................................................................23

Perform a single point measurement.........................................................................24

Velocity and discharge measurement methods.........................................................24

Methods for velocity measurement..................................................................... 24

Methods of discharge calculation.......................................................................26

Measurement settings menus.................................................................................... 28

Measurement settings [1/3] ...............................................................................28

Measurement settings [2/3]................................................................................28

1

Measurement settings [3/3]................................................................................29

Field quality checks...................................................................................................30

Perform a discharge measurement...........................................................................30

Perform an ICE measurement...................................................................................33

Discharge measurement window .............................................................................. 34

QReview discharge measurement summary file.......................................................35

Delete a file................................................................................................................36

QReview software....................................................................................................36

Overview....................................................................................................................36

QReview main menu options ............................................................................. 37

Installation..................................................................................................................37

Install the QReview software..............................................................................37

Operation...................................................................................................................37

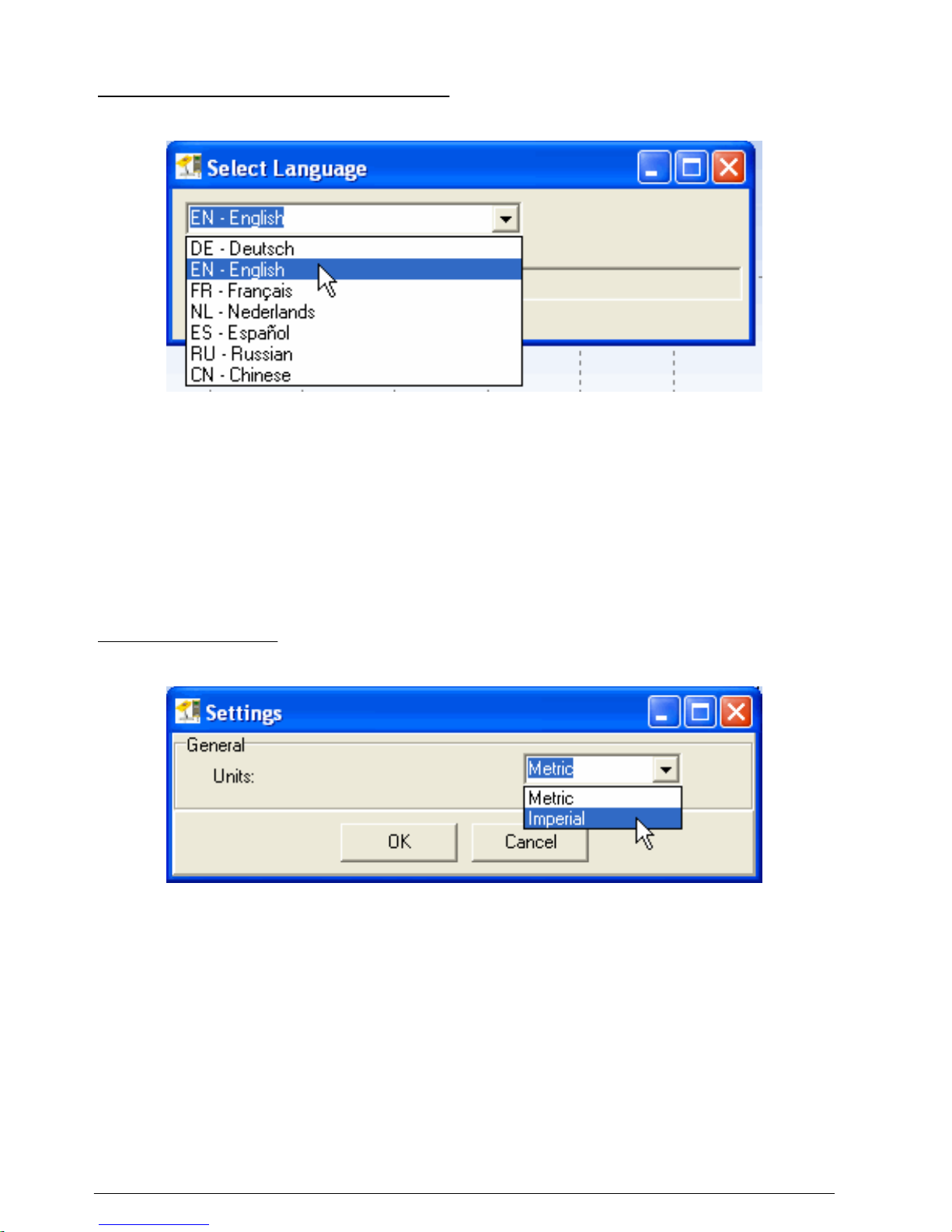

Change the language.........................................................................................37

Change the units................................................................................................38

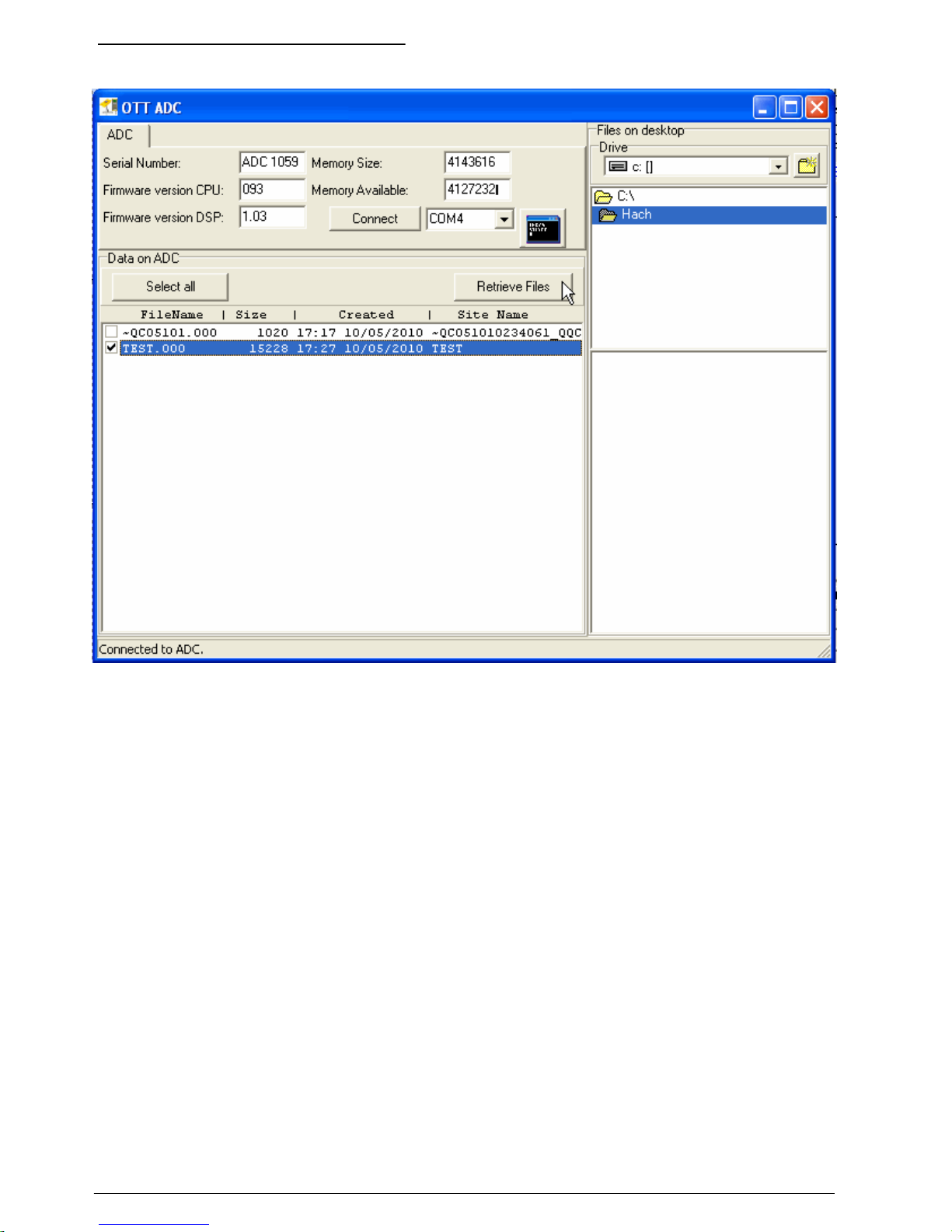

Connect the ADC................................................................................................ 38

Retrieve ADC data.............................................................................................. 39

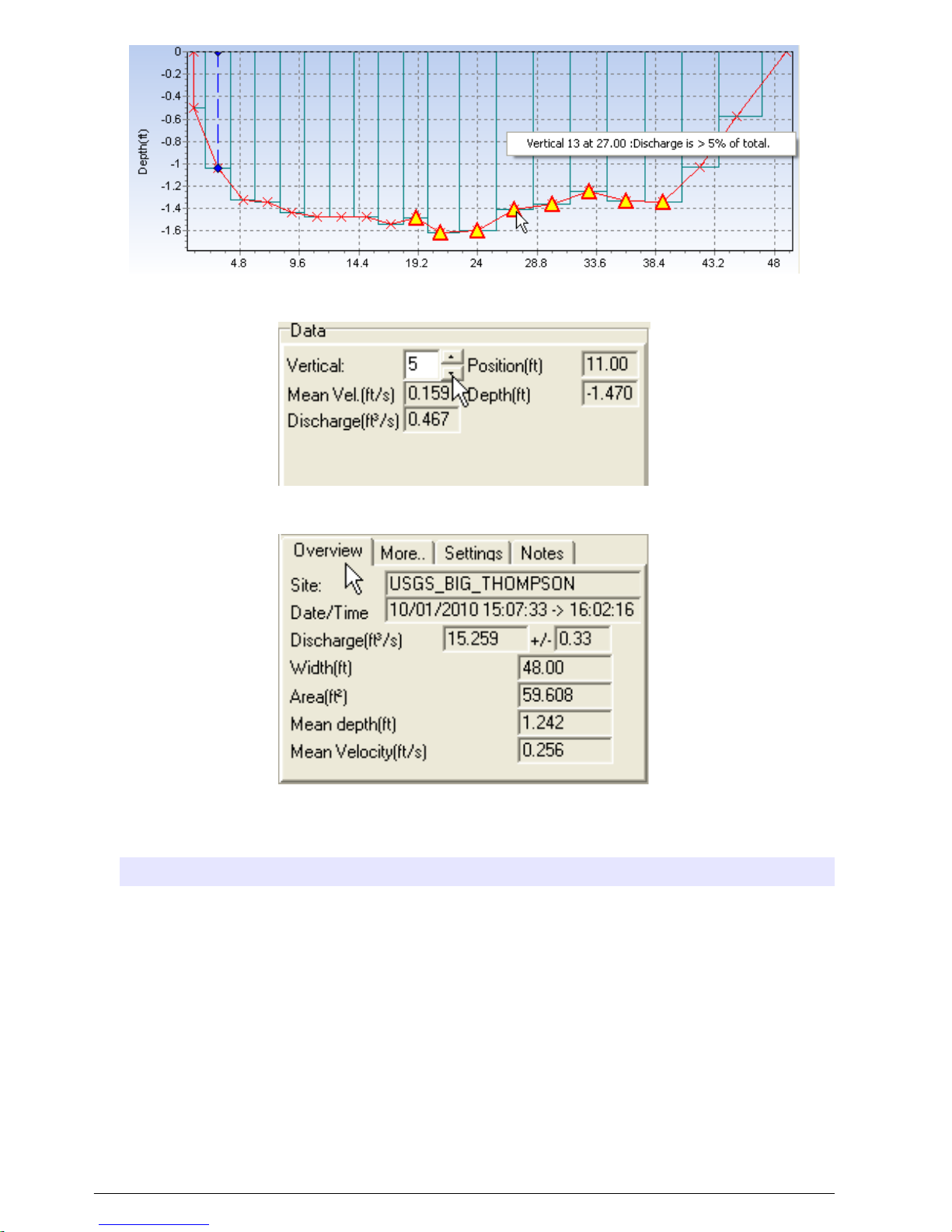

Open and view ADC data files............................................................................ 40

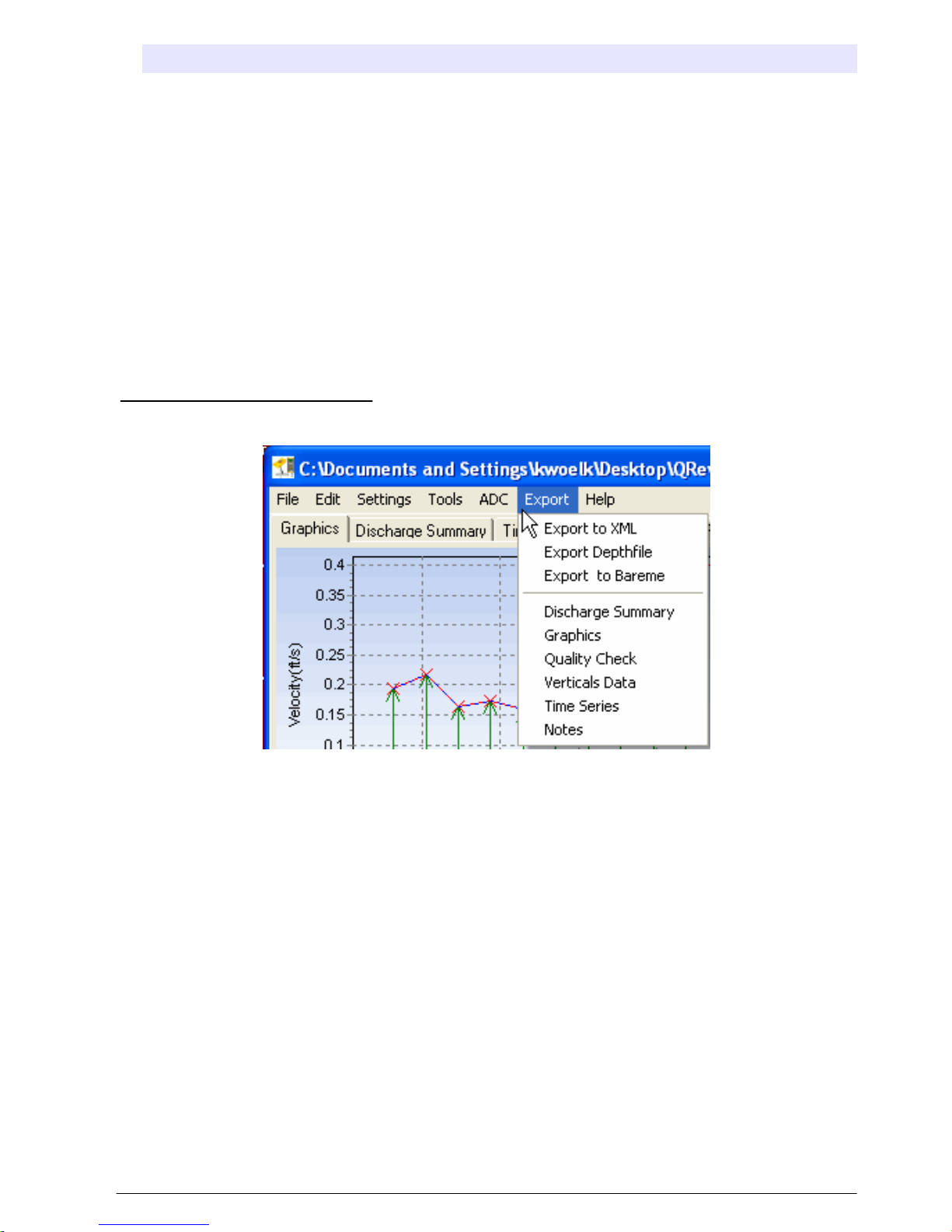

Export data.........................................................................................................43

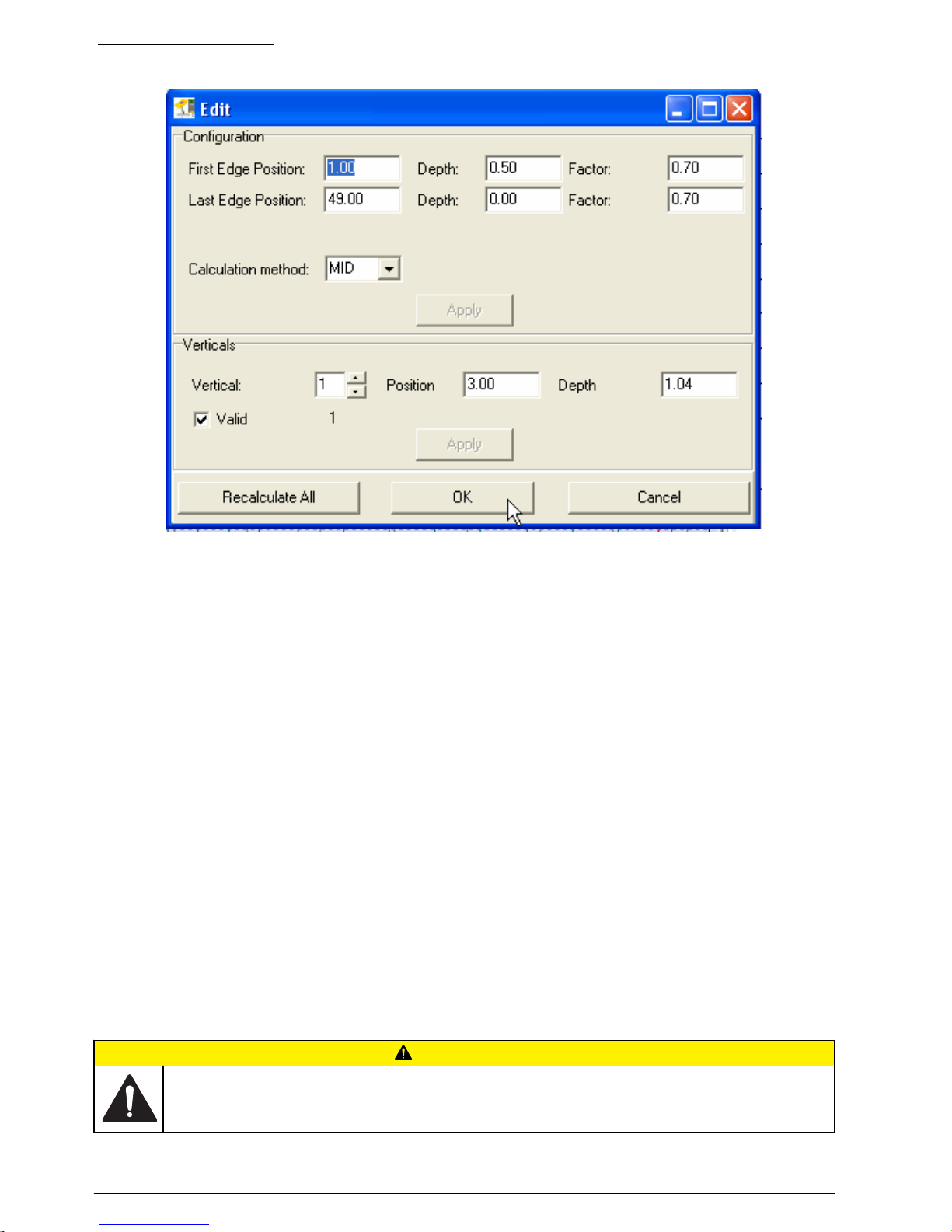

Edit screen.......................................................................................................... 43

Print a report.......................................................................................................44

Maintenance...............................................................................................................44

Handheld unit maintenance.......................................................................................45

Sensor maintenance..................................................................................................45

Troubleshooting.......................................................................................................45

Measurement guidance.............................................................................................45

Common problems....................................................................................................45

Device warning messages ........................................................................................46

Measurement warnings and errors ...........................................................................47

View system status....................................................................................................48

Contact information................................................................................................48

Table of Contents

2

Specifications

Specifications are subject to change without notice.

Specification Details

Velocity measurement (Acoustic

Ultrasonic Transducers)

Measurement range: – 0.2 m/s to 2.4 m/s (–0.65 ft/s to 7.87 ft/s)

Accuracy: ±1% of the measured value, ±0.25 cm/s (±0.01 ft/s)

Resolution: 0.001 m/s (0.001 ft/s)

Ultrasonic transducers

Frequency: 6 MHz

Beam angle: 20°

Measured volumes

Distance from the sensor: 10 cm (3.93 in.)

Diameter: 1 cm (0.39 in.) per sound pulse

Length: 5 cm (1.97 in.)

Depth measurement (Piezoresistive

pressure cell (absolute))

Measurement range: 0 to 5 m (0 to 16.4 ft)

Accuracy: 0.1% FS

Resolution: 0.01% FS

Maximum overload: 1.5 times the measuring range

Temperature measurement

Measuring range: –5 to 40°C (23 to 104 °F)

Accuracy: ± 0.5 °C

Resolution: 0.1 °C (0.1 °F)

Salinity Range: 0 to 50 ppt (mg/L)

Power supply

Type of batteries: Rechargeable NiMH, fixed battery pack

Life duration: > 14 hours (the battery lifetime is affected by

environmental conditions and charging cycles)

Charging cycles: > 500 (charging cycles vary by use, environment and

other factors)

Nominal voltage: 9.6 VDC

External class II AC/DC power supply: Input 90–240V, 50/60 Hz

Output voltage of power supply: 18 VDC/VAC

Operating conditions

Operating temperature range: –20 to 60 °C (–4 to 140 °F)

Storage temperature range: –40 to 85 °C (–40 to 185 °F)

Shock resistance: compatible with EN 60068-2-32

Dimensions and weight

Cylindrical sensor body: Ø 40 mm (0.20 in.)

Length: 14.5 cm (5.71 in.)

Weight in air: 800 g (1.76 Ib)

Weight in water: 620 g (1.37 Ib)

Handheld unit:

Dimensions: 23.3 x 8.3 x 3.2 cm (9.20 x 11.41 x 1.26 in.)

Weight: 700 g (1.76 Ib)

English 3

Specification Details

Material

Sensor housing: Delrin®/stainless steel

Screws: stainless steel

Handheld unit: aluminium, powder coated

Keypad: Autotex V 150 XI

IP protection class

Handheld unit: IP65 (housing, keypad)

Sensor: IP68

EMC

EN 61000-6-2

EN 61000-6-4

FCC Part 15

EMC Directive 2004/108/EU, Article 5

Internal data memory Capacity: 4 MB (flash)

OTT QReview software

Operating system: Windows®98, Windows®ME, Windows®NT,

Windows®2000, Windows®XP, Windows® Vista, Windows® 7

Functionality: Data transfer from handheld unit, Data check and

processing, Data export (XML, ASCII)

General information

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

4 English

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This symbol, if noted on the instrument, references the instruction manual for operation and/or

safety information.

This symbol indicates that a risk of explosion is present.

This symbol indicates that a risk of fire is present.

This symbol indicates the need for protective eye wear.

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems after 12 August of 2005. In conformity with European local and national regulations (EU

Directive 2002/96/EC), European electrical equipment users must now return old or end-of-life

equipment to the Producer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

Certification

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

English

5

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

Product overview

The OTT Acoustic Digital Current meter (ADC) is a mobile acoustic current meter designed

specifically for measuring point velocities and water depth in open channels and natural streams.

Examples of ideal uses include single or multiple point velocity measurements and discharge

measurements.

Velocity and depth information from the sensor is displayed in real time on the graphical display of

the handheld unit.

Discharge measurements are based on standard vertical or sub-section measurement techniques

associated with MID and MEAN section discharge calculations. The process used to calculate

discharge measurements is based on internationally recognized USGS and ISO748 standards. Mean

velocity and depth measurements taken by the OTT ADC, along with the position of a vertical relative

to a reference, are used to calculate the discharge.

All measurements, including quality checks, velocity and discharge measurements can be

downloaded using the QReview application software. QReview displayed provides basic analysis

tools, graphics, one-second time series, reports, and review of potential quality issues. Data can be

exported in different formats.

System components

The system consists of two components: the sensor, and the handheld display with sensor

connection cable. The sensor itself contains two 6 MHz acoustic transducers, along with a

temperature and depth sensor.

Other components of the system include wading rod adapter, power adapters, charging and

connection cables. Refer to Figure 1 for a complete list of system components.

The handheld unit contains calibration data for the temperature sensor and the pressure cell of the

relevant sensor. Sensors and handheld units that are used together as part of the same

measurement system must have the same serial numbers. The sensor serial number is engraved on

the rear of the sensor body, below the sensor cable connector. The serial number is also listed on

the gray label on the back of the handheld display.

6

English

Figure 1 OTT ADC components

1 Location of user documentation and software 6 Wading rod (accessory)

2 USB charging cable 7 Mounting clamp

3 USB download cable 8 Sensor

4 Power charger (not shown, located below handheld

unit)

9 ADC handheld unit

5 AC/DC adapter

English 7

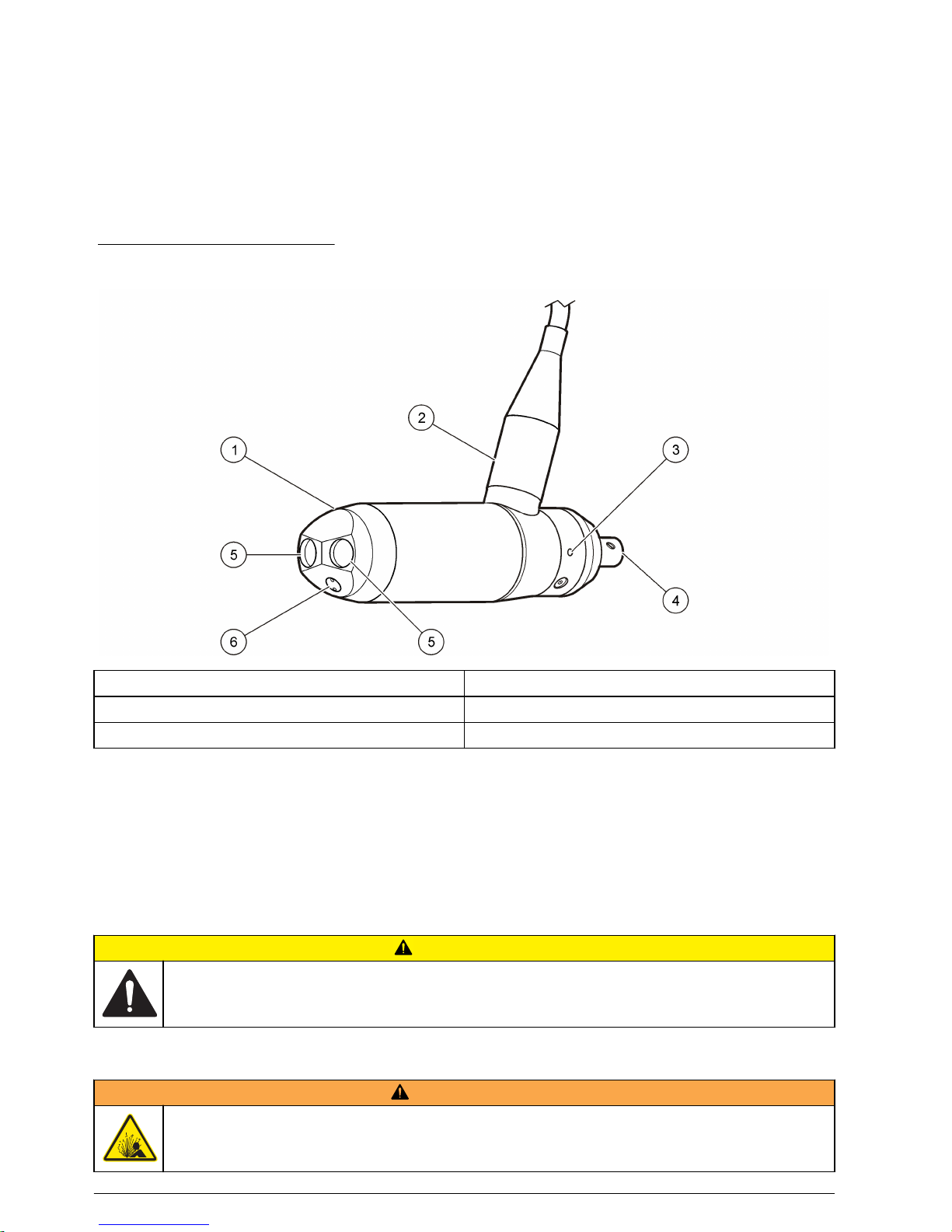

About the sensor

The sensor components are shown in Figure 2.

The transducers transmit ultrasonic signals which are reflected back to the sensor by air bubbles or

particles suspended in the water column. These received backscatter echoes are amplified in the

sensor head and digitized in the digital signal processor (DSP) inside the handheld display. This

transmit-and-receive process is repeated to generate a second echo pattern. The DSP uses a pulsecoherent technique to calculate the phase of each returned pulse echo. Phase differences (lag time)

between the returned pulse echoes is proportional to the flow velocity. Each measurement is

validated against quality thresholds for accuracy.

Figure 2 Sensor components

1 Sensor head 4 Sensor end piece (for attachment to wading rod)

2 Sensor connection cable 5 Ultrasonic transducers

3 Pressure cell chamber 6 Temperature sensor

Temperature compensation

The OTT ADC is equipped with a temperature sensor. Water temperature is an important parameter,

both for the calculation of the speed of sound and for the temperature-compensated depth

measurement given by the pressure cell. Therefore, a best practice when starting a measurement is

to allow the sensor to adjust to the water temperature. The temperature adjustment of the sensor

under extreme conditions (from approximately 50 ºC to 5 ºC) takes approximately 5 to 6 minutes.

Installation

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

About the power supply and battery

W A R N I N G

Explosion hazard. Incorrect battery installation can cause the release of explosive gases. The battery

pack cannot be replaced by the user. Contact technical support.

8 English

Power for both the sensor and handheld unit is provided by a rechargeable battery installed in the

handheld unit. A battery symbol in the upper right corner of the display indicates the battery charge

level. The charge level can also be viewed by selecting Main menu>System Status>Battery.

A fully charged battery can provide more than 14 hours of measurement operation. The battery can

be charged more than 500 times. Charging cycles vary by use, environment and other factors.

All data saved on the handheld unit are retained even if the battery becomes fully discharged.

The battery cannot replaced by the user. Attempts by a user to replace the battery will void

applicable warranties. Refer to Contact information on page 48 for repair contact information.

Battery specifications

Values listed in the table are typical and approximate.

Hours of measurement operation per charge 14

Number of possible charge cycles 500

Length of charge cycle, in hours (complete discharge to

full charge)

2

Charge the battery

W A R N I N G

Fire and explosion hazard. The power supply is designed specifically for this product. Do not attempt to

use this product with any other power supply even if the device conforms to the USB standard. This

may cause damage to the battery.

Although the unit is shipped with the battery partially charged, the manufacturer recommends that the

battery be charged to full capacity before the system is used.

A completely discharged battery will reach full charge after approximately 2 hours of charging time.

Entries may be made in the handheld unit while the battery is being charged.

1. Connect the charging cable connector of the power supply to the charging cable with the barrel

connector.

2. Connect the charging cable to the handheld unit with the USB connection.

3. Connect the plug of the power supply to the electrical outlet.

The battery begins to charge and the unit switches on. A charging icon appears in the upper right

corner of the display. The battery icon will appear solid when the battery is fully charged.

Note: The battery can also be charged with a vehicle voltage converter, available as an accessory. Refer to the

Parts and Accessories list for more information.

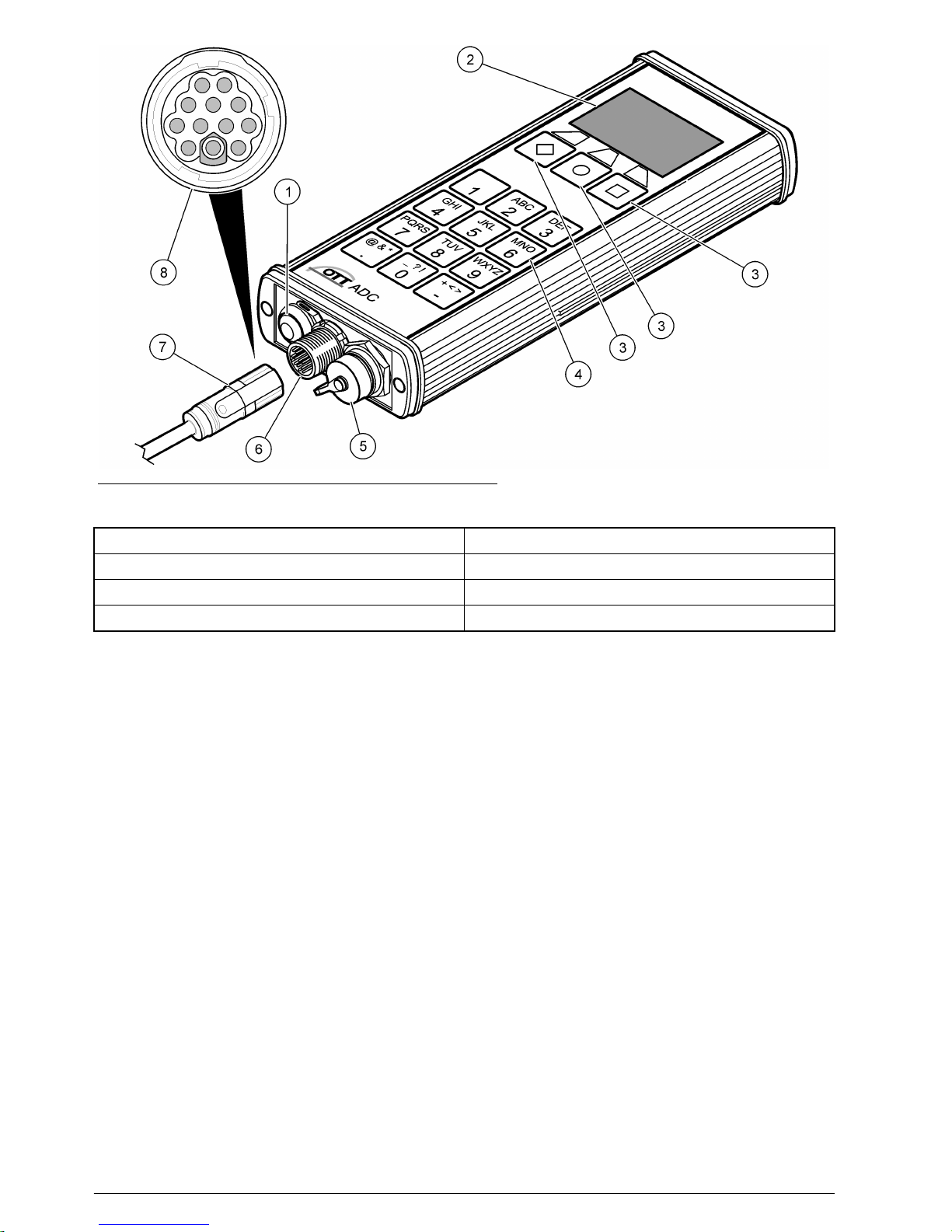

Connect the sensor cable to the handheld unit

Refer to Figure 3 and the steps to connect the sensor to the handheld unit.

English

9

Figure 3 Handheld unit overview and connections

1 On/Off switch 5 USB connection

2 Liquid crystal display (LCD) 6 Sensor connection

3 Operating keys 7 Sensor cable

4 Keypad 8 Connector contact pins

1. Align the red markings on the sensor connector cable and the handheld unit connector.

2. Grasp the sensor connector cable plug and push it on to the handheld unit connector until it

snaps in place.

3. Turn the sensor connector cable plug clockwise until clicking sounds are heard. The clicks

indicate the connection is secure.

To disconnect the sensor

1. Grasp the sensor cable connector and turn it counterclockwise until the red mark on the sensor

cable is aligned with the red mark on the handheld unit.

2. Pull back on the sensor cable connector plug until it disengages from the handheld unit.

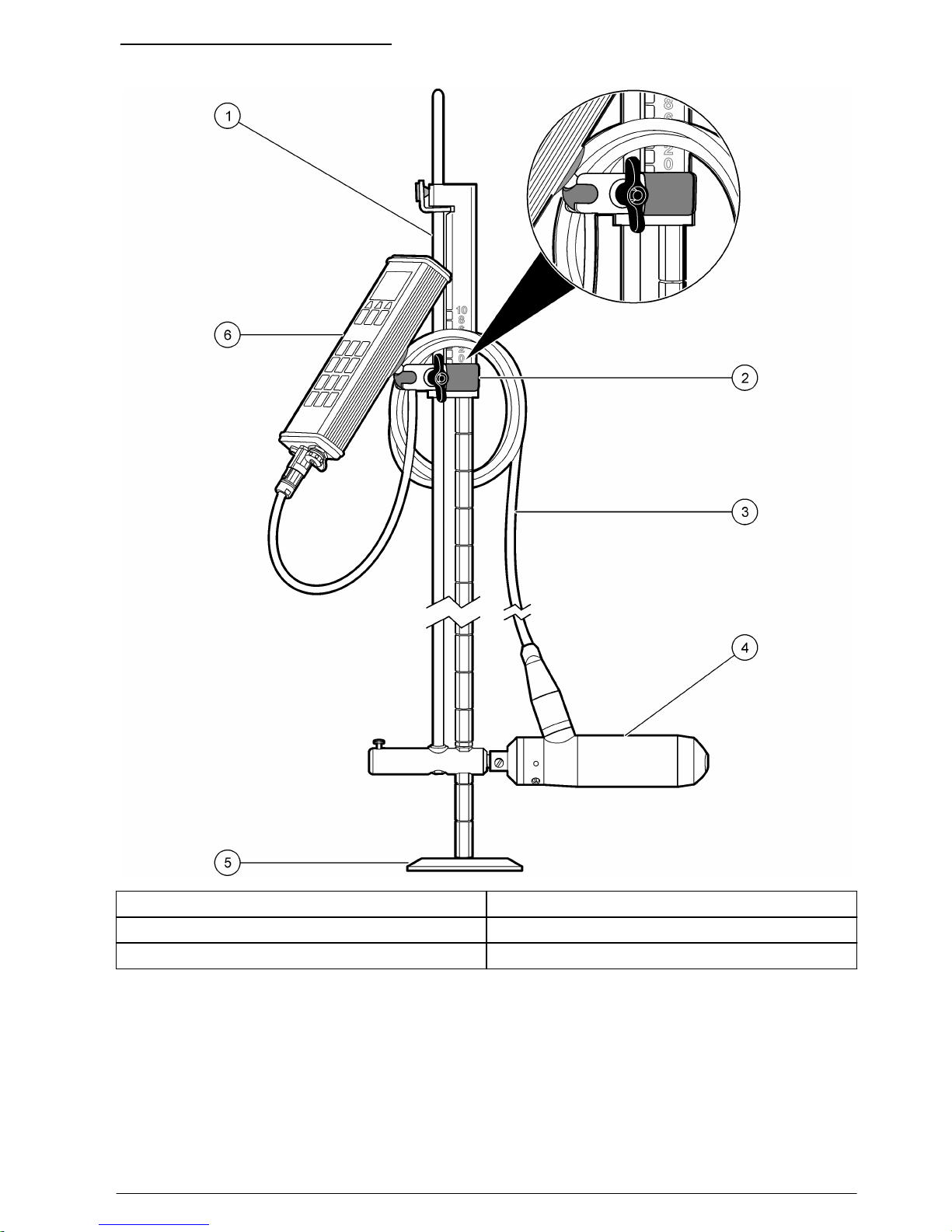

Attach the handheld display unit to the wading rod

The OTT ADC is supplied with a universal attachment for USGS wading rods. The unit is

manufactured with a fixing plate on the rear of the handheld unit that contains a ball head. This

arrangement allows the unit to move and rotate in different directions.

Refer to the steps and Figure 4 to attach the handheld unit to the wading rod.

Note: Attach the sensor cable to the handheld display before attaching the handheld display to the wading rod.

10

English

Figure 4 Attach the handheld unit

1 Wading rod assembly 4 Sensor

2 Handheld unit clamp 5 Wading rod base plate

3 Sensor connection cable 6 Handheld display unit

1. Attach the silver ends of the universal wading rod mounting bracket to the ball on the backside of

the handheld display.

2. Place the black ends of the universal wading rod mounting bracket on the handle of the topsetting wading rod, or near the top of the standard wading rod.

Note: Make sure that the handheld display faces in the direction opposite of the sensor. Also make sure the

relocating rod of the top-setting wading rod can move freely when the sensor is raised or lowered.

3. Tighten the wingnut on the bracket to secure the clip to the wading rod.

4. To position the sensor vertically, press the rubber stopper of the catch on the handle, move the

sensor to the new position, and release the rubber stopper to secure.

English

11

Attach the sensor to a wading rod

• OTT ADC sensor with sensor end piece.

• USGS type standard or top-setting wading rod

• Extensions for rod if necessary

Refer to Figure 5 for a top-setting wading rod. Refer to Figure 6 for a standard wading rod. Follow the

steps to attach the sensor.

1. Push the sensor on to the receiver of the meter/sensor bracket of the wading rod. Make sure the

sensor connection cable is vertically aligned with the wading rod.

2. Secure the sensor by tightening the mechanical adapter fixing screw.

3. Extend the rod as required.

Figure 5 Attachment of the sensor to a top-setting wading rod

1 Meter/sensor bracket 2 Sensor end piece

Figure 6 Attachment of the sensor to a USGS rod

1 Meter/sensor bracket 2 Sensor end piece

Operation

Turn the handheld unit On and Off

To turn the unit on or off, press the On/Off switch and hold it for approximately one second. The

startup process takes approximately ten seconds. During this time, the upper edge of the display will

show a series of + symbols until the startup process is complete.

12

English

Note: To conserve battery power, the unit is equipped with an automatic shut off feature. If no key presses or

communications have occured for 15 minutes while the unit is under battery power, the unit turns off. Remove the

USB data cable to make sure this feature operates correctly.

Display screen

Saved data and current measurement information are shown on the display screen (Figure 7).

To conserve battery power, if no keys are pressed for 30 seconds, the display background

illumination turns off. The auto turn-off feature is active by default but can be made inactive through

the Display Settings menu.

Figure 7 Display screen

1 Data quality (correlation) indicator 6 Actual depth indicator

2 Battery charge indicator 7 Position of the verticals

3 Target submersion depth (set value) 8 Distance of verticals from the reference point

4 Position of the sensor on the vertical 9 Flow velocity

5 Key function indicator 10 Measurement progress indicator

Operating key icons

The function of the operating keys depends on the current operating situation. The function

associated with a key is shown in the display directly above the key. Symbols and their functions are

shown in Table 1.

Table 1 Symbols and functions

Call main menu Return to previous menu

OK and continue Delete character

Delete or Cancel Confirm entry

English 13

Table 1 Symbols and functions (continued)

Move Up or Down in multipart menu or

list

Call help

Switch between two display views Start measurement

Menu navigation and data entry

To select a menu or menu option, press the key with the menu or option number.

Some menus, such as the Main Menu and Measurement Settings menus, are divided in to multiple

parts. Each part may be divided in to other sub-menus and screens.

The current menu and the number of available menus are shown in the display screen next to the

main heading. For example, Main Menu [1/2] means the user is in the first of two available Main

Menu divisions. Navigate to the next division of the menu by pressing the down arrow key.

Fields accept alpha and numeric data depending on the use and application. Entry modes are

automatically selected by the handheld unit.

To enter data in a field, press the key that shows the letter or number. The first key press causes the

first alpha character on the key to appear in the display. Additional key presses will cause the rest of

the letters to appear in order, followed by the key number before the cycle begins again. For

example, to enter the letter K, press the 5 key two times in quick succession. To enter the numeral 5,

press the 5 key four times.

Approximately one second after an alpha or numeric entry is made, the entry is saved and the cursor

automatically moves one space to the right. To move the cursor back to a previous position, press

the backspace key.

Display symbols

Display symbols give information on the system status and the current measurement. During a

measurement, the symbols give information on the sensor position. Display symbols and their

meaning are shown in Table 2.

Table 2 Display symbols and meaning

Battery charge indicator

Distance of verticals from cross-section zero

point

Data quality (correlation) indicator Position of vertical

Measurement progress indicator

Position of sensor on the vertical (actual

value)

Water temperature Position of sensor on the vertical (set value)

Battery power supply Depth of the sensor (actual value)

14 English

Table 2 Display symbols and meaning (continued)

Flow velocity

Note: Leave sensor at current position

(depth)

No signal (symbol flashes) Note: Position sensor further up or down

Main Menu

The Main Menu of the OTT ADC is divided in to two windows, each with specific options. The

function of the menu options are given in the tables in the steps below. More details can be found in

the respective sections of this manual.

1. If the unit shows the measurement window, press the menu key to view the first Main Menu

window [1/2].

Option Description

Load Load basic settings from a saved file.

Quick Quality Check Choose this option to perform a quick quality check of the handheld unit.

Measurement Settings Choose this option to enter basic settings for a measurement.

Start Measurement Choose this option to start a discharge measurement.

View Data Choose this option to view data from a completed measurement.

2. Scroll down to view the second window of the Main Menu [2/2].

Option Description

Depth calibration Choose this option to perform a depth calibration.

Delete Files Choose this option to delete existing files.

System Status Choose this option to view system information, including amount of available memory,

unit serial number, firmware revision and amount of battery charge.

System Settings Choose this option to change the date and time, sound level and display characteristics.

Advanced [1/2] In the first Advanced Settings window, change the quality thresholds, turn the

measurement guidance feature on or off, format the memory, or reset the handheld unit

settings to the default values.

Advanced [2/2] In the second Advanced Settings window, turn the key sound on or off and set the units

to be used in measurements.

System settings

Use the System Settings menu to set the Date and Time, Display, and Sound Level options for the

handheld unit. From the second Main Menu [2/2], select System Settings.

1. To change the date or time, select Date and Time and change or update the entries. The current

date and time will show in the display when all entries are completed. Push OK to save the

information. An example of the date and time display is shown below the table.

Option Description

Hour (0 - 24) Current time in whole hours

Minutes (0 - 60) Current time in minutes

Seconds (0 - 60) Current time in seconds

English 15

Option Description

Day (1 - 31) Current day

Month (0 - 12) Current month

Year (0 - 99) Current year

Time:

14:22:32

Date: 11/13/08

2. To change the display options, in the System Settings menu, select Display and change or

update the entries. Press OK to save the information.

Option Description

Backlight --On,

Automatic, Off

If set to on, the display illumination remains turned on until the handheld unit is

switched off. Use of this option may increase the rate of battery discharge.

If set to Automatic, the illumination turns off after 30 seconds if no entry or

communication has occurred. If a key is pressed, the illumination turns on and the

timer is again set to 30 seconds.

If set to Off, there is no display illumination.

Contrast (0 - 10) Sets the display contrast (1 = low contrast, 10 = maximum contrast)

Velocity display-Continuous, Result

only

If set to continuous, the measurement results for flow velocity measurement are

continuously displayed and updated each second.

Note: The continuous display allows a visual impression of the waterway flow

turbulence.

If set to Result Only, only the end result of the flow velocity measurement is

displayed.

3. To change the sound volume for key clicks and feedback sounds, go to System menu and select

Sound Level. Enter a value between 0 and 10 (0=no sound, 10= maximum volume). Push OK to

save the setting.

Advanced settings

The Advanced option has two windows. The second window in the Advanced menu is used to set the

language, key sound and units options, format the memory, and reset the unit to the default values.

To update any of these options, in the second Main Menu [2/2] window, select option 5 Advanced.

Measurement Guidance and Quality Thresholds settings can also be accessed through the

Advanced menu. Details for these options are given in respective sections in this manual.

1. To change the language, scroll to the second Advanced menu window [2/2] and select 1.

Language. Press the number of the language to be used in the handheld unit display.

Option Description

1. English

2. Dutch

3. German

4. Spanish

5. French

6. Russian

Available languages for the handheld display.

16 English

The display switches to the selected language.

2. To turn the key sound on or off, select option 2 Key Sound in the Advanced [2/2] window. Press

the number 2 key to toggle the sound on and off. The current state is shown in the display.

Option Description

On The unit emits sound when keys are pressed (default).

Off The unit does not emit a sound when keys are pressed.

3. To set the units used in measurement displays, select option 3 Units in the Advanced [2/2]

window and enter the option number.

Option Description

1. Metric Measurement values are shown in metric units.

2. Imperial Measurement values are shown in imperial units (default).

4. Depth can be measured with the water surface or the streambed as a reference. To change the

reference depth settings, scroll to the Advanced Menu [2/2] and select Option 4 Depth Reference.

Option Description

Surface The water surface is used as the reference point. Depth and sensor positions are shown as

distance from the water surface. During a measurement, the depth is shown on the display by an

underlined arrow pointing down. If a manual depth entry is required, the value entered must be

equal to the distance from the water surface. The distance displayed in the point results screen is

referenced to the water surface.

Bottom The bottom, i.e., the streambed, is used as the reference point. Depth and sensor positions will be

shown as distance from the streambed. During a measurement, depth is shown on the display by

an underlined arrow pointing up. If a manual depth entry is required, the value entered must be

equal to the distance from the streambed. The distance displayed in the point results screen is

referenced to the streambed.

5. To format the memory, scroll up to the first Advanced [1/2] menu window, and select option

4 Format Recorder (a warning statement will appear). To begin the formatting process, select 1.

To return to the menu without formatting, press the BACK key.

Note: The Format Recorder option will cause all data stored in memory to be erased. Make sure all data is

downloaded before the format process is started.

6. To reset the handheld unit settings to their default values, select option 4 in the first Advanced

[1/2] window. A warning statement will appear. To continue, press the number 1 key. To return to

the menu without resetting the values, press the BACK key.

Upgrade firmware

Each handheld unit is supplied with a particular version of firmware. The manufacturer periodically

releases new versions of the firmware. The firmware should be periodically upgraded to make sure

the instrument has the most current features and functionality.

• Download all saved data before the upgrade is started. The upgrade will cause a hard format and

all saved data will be lost.

• Make sure the battery is fully charged

• Make sure that the QReview software is installed on the PC

• Make sure the handheld unit USB driver is installed on the PC

• Make sure the current firmware is saved on the PC

The current version of the firmware can be viewed through the second Main Menu [2/2]. Select

System Status, System Info to view the current version.

Information about current or new firmware releases is available at http://www.ott.com. The firmware

file name has the naming convention ADC_Vxxx.bin, where xxx is the version number. Do not

change the filename.

English

17

To start the firmware upgrade process, do the following:

Note: During the upgrade, the On/Off switch is disabled.

1. Place the handheld unit in upgrade mode.

a. Switch off the device.

b. Connect the handheld unit to the PC via the USB connection.

c. Press and hold the . and the - keys and turn on the handheld unit.

The message FIRMWARE UPGRADE CHECKING STATUS appears on the display. After a

few seconds a prompt for the upgrade code appears.

d. Enter the upgrade code (1234) and push OK.

The handheld unit is now in firmware upgrade mode.

2. Start the QReview application.

3. From the Tools menu, select ADC Firmware Upgrade.

4. In the window under Upgrade file, select the current firmware and click Open.

5. Select the COM port (serial port) used by the USB interface.

6. Click Start.

The upgrade process begins and a progress indicator shows the upgrade status. When the

upgrade is complete, a message appears indicating the process is complete. The unit is placed

into ready mode and switches off automatically.

Performing measurements

Station set up

Measurement quality is dependent on the correct selection of a measurement cross section. The first

step in making a current-meter measurement is to select a reach of stream with the following

characteristics:

• Cross section lies within a straight reach and stream lines are parallel to each other.

• The streambed is stable and free of large rocks, weeds, and protruding obstructions such as piers

that create turbulence.

• The streambed has a flat profile. This helps eliminate vertical velocity components.

It is often impossible to completely satisfy all of the above conditions. Use the criteria to select the

best possible reach and then select a cross section.

Number of verticals and vertical spacing

For a well-chosen cross-section, 25 to 30 partial sections is typically sufficient. If the cross section is

very smooth and the velocity distribution is consistent, the number of sections can be reduced.

The partial sections should be spaced so that no individual section contains no more than 10 percent

of the discharge. The ideal measurement is one in which each partial section contains 5 percent or

less (<=5%) of the total discharge, but this is rarely achieved when 25 sections are used. Partial

sections should not have equal widths across the entire cross section unless the discharge is welldistributed.

Distances between verticals are generally smaller where water depth and flow velocities change

significantly. Places where depth and velocities may change significantly include bank areas, vertical

or steep slopes, ledges in divided cross-sections and transitions from the main stream bed to the

foreland. Verticals should also be located at points of significant changes in the stream bed profile.

The measurement cross section must be set at right angles to the direction of flow. Avoid cross

sections with still areas, counter currents or eddies. Do not place the sensor in deep pools, below

large inflows, or near ship moorings, ferries or sluices.

The percentage of the computed discharge for each measured vertical is automatically calculated by

the OTT ADC and is shown on the display of the handheld unit when the vertical measurement is

complete.

18

English

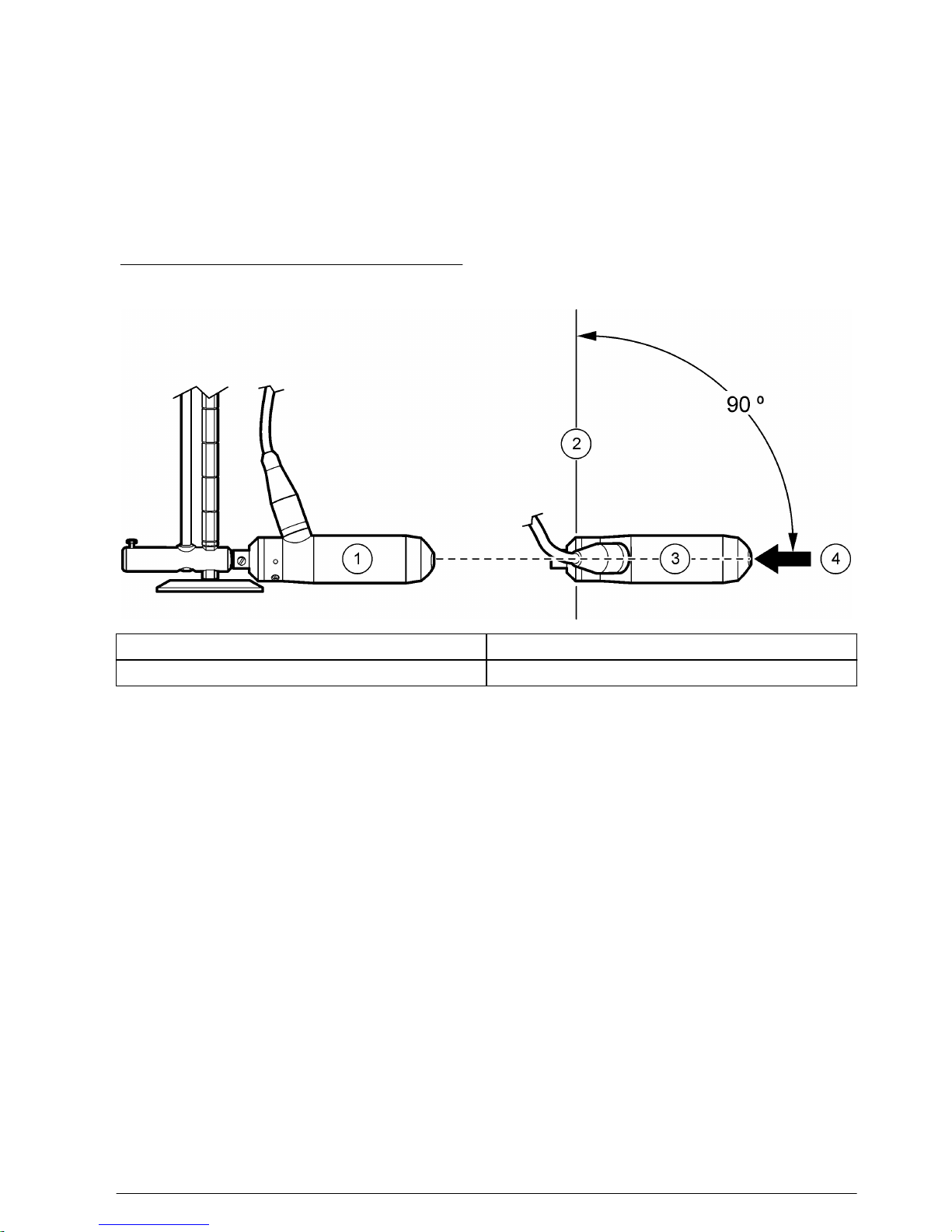

Angle of flow

The angle of flow is defined as the angle between the symmetry axis of the sensor and the direction

of flow. In an ideal situation, the flow angle is 0º.

The flow angle can affect the quality of measurement. The best measurement stations have a low

angle of flow when the sensor is positioned at right angles to the measurement cross-section and the

flow is parallel to the edges.

In the field, it may be difficult to achieve flow angles of 0º. In field tests of the OTT ADC, velocity

measurement has been found to be unaffected by flow angles of up to 10º. Flow angles of 20º and

30º typically result in measurement errors of approximately 6% and 8% respectively.

Figure 8 shows two views of a sensor in proper position.

Figure 8 Sensor position and angle of flow

1 Side view 3 Top view

2 Measurement cross section 4 Flow direction

Quality control

Quality parameters determine whether the measurement value is valid. Information about each

parameter is given below. Quality threshold values are output in the Discharge Summary File. If there

are no changes input by the user, the default settings appear. If the user has made changes to the

settings, the user-defined settings appear.

• Signal to Noise Ratio--The strength of the reflected acoustic signal relative to the noise in the

OTT ADC electronics.

• Maximum angle--Maximum angle (+/-) between the direction of a measured velocity and the Xaxis.

• Correlation--Pairs of echoes from the sensor are used to calculate the average velocity. In stable

flow conditions, the correlation between the averaged raw measurements is higher than 70% and

correspond to small standard deviations. Turbulent conditions result in lower correlation values.

The signal bars in the handheld display indicate the correlation value. Each bar corresponds to a

20% correlation. The default minimum is 40%. During the majority of a measurement, at least two

bars should be visible. The minimum correlation factor necessary for measurement can be

decreased to below 40. However, the quality of the measurement may be lower and may not meet

the same specifications. For example, if the correlation is reduced to 20, the associated

measurement error is 5%. Reducing the correlation threshold can be useful when working in

turbulent streams. If the correlation threshold is set to lower than 40 and the unit is turned off, the

display will show a correlation warning when the unit is again turned on.

• Velocity Gradient--The instantaneous measurement minus the previous measurement. A valid

measurement must have a velocity gradient below 0.82 ft/s (0.25 m/s). This helps make sure that

measurement spikes are not included in the final measurement value.

English

19

• Standard Deviation--Indicates measurement accuracy. The standard deviation is calculated only

from values that have passed the quality control.

• % Discharge per Vertical--Percentage of total discharge in a vertical. Defined ideal standard is

less than 5% and no more than 10%.

• 1-point Maximum Depth--Maximum depth for a 1 point measurement. If this depth is exceeded, a

warning message appears on the handheld unit and the user is prompted to change to a 2-point

measurement.

Table 3 gives the value range for each quality threshold. Default values are shown in parentheses.

Table 3 Quality threshold ranges

Quality threshold (resolution and units) Range

Minimum correlation xx.x% 01-100 (40)

Maximum angle ( xx.x º) 0-45 (20)

Velocity gradient (x.xx ft/s, m/s) 0.0-2.5 (0.82 ft/s)

Standard deviation (x.xx ft/m) 0.0-2.5 (0.33 ft)

% Discharge per vertical (xx %) 0-100 (5)

Minimum signal-to-noise ratio (SNR) (xx dB) 10-100 (10)

1-Point maximum depth (xx.x ft/m) User defined (1.5 ft)

If less than 50% of the measured values meet their defined criteria, the measurement is discarded

and the user is asked to repeat the measurement, accept the measurement as is or skip the

measurement. If the measurement is skipped, measured values will not be included in calculations.

Data from all valid measurements is stored in the handheld unit.

All valid averaged data is recorded in the Discharge Measurement Summary file. QReview can be

used to review and export this file and to review all one-second time series data.

Adjust quality thresholds

Quality thresholds can be adjusted for specific measurements.

1. From the second Main Menu [2/2], select Advanced.

The Advanced [1/2] window appears.

2. Select option 1, Quality Thresholds.

The QA Thresholds [1/2] window appears.

3. Enter the number of the quality threshold to be adjusted and update or change the entry.

Option Description

Minimum correlation xx.x, default 40.0

Maximum angle xx.x, default 20.0

Velocity gradient x.xx, default 0.82

Standard deviation x.xx, default 0.33

Minimum SNR xx, default 10%

4. Scroll down to view the second Quality Thresholds [2/2] window. Update or change the entries.

Option Description

%Discharge/Vertical xx%, default 5%

20 English

Option Description

1-Point Maximum Depth xx.x, default 1.5 ft

Set to defaults Reset to default settings.

5. To return to the Main Menu, scroll up to the first Quality Thresholds window, and press the BACK

key.

Quick quality checks

A Quick Quality Check (QQC) helps make sure the system is ready for use and will give reliable and

accurate measurement data. The Quick Quality Check option is found in the Main Menu [1/2] screen.

It is recommended that a Quick Quality Check be done before the system is moved to the field,

although this is not mandatory. A container with appropriate dimensions and a metal plate placed

4-6 inches in front of the sensor can be used. The metal plate should be at least as high as the depth

of water, and 10" wide. Refer to Figure 9 for minimum container dimensions and sensor placement.

At least 50% of the quick quality check parameters must be within their specified values for the

quality check to pass.

The results of a quick quality check are stored with a default or user-defined name and the file can be

downloaded with QReview. The file has a .QQC extension and the following default naming

convention: QCMMDDYYXXXXXX_QQC, where MM = month, DD = Day, YY = Year and XXXXXX =

the ADC serial number.

Figure 9 Container dimensions

1 Side view 3 Metal plate

2 Top view

To do a quick quality check, do the following:

1. From the Main menu, select Quick Quality Check.

2. Enter a name for the QQC file or proceed directly to the depth calibration. In the latter situation,

the default name for the QQC file will be used. (For example, QCMMDDYXXXXXX_QCC, where

XXXXXX is the device serial number). File names are limited to 20 alpha numeric characters.

3. Select option 2, Depth Calibration. Refer to Calibrate the pressure cell (depth calibration)

on page 22. The absolute pressure cell built in to the OTT ADC sensor body determines the

water and sensor depths. The pressure cell must be calibrated in the existing air pressure

conditions to make sure depth readings are accurate. If the depth sensor is not calibrated before

a QQC is started, a warning message will appear.

4. Place the sensor in the water, select option 3 and in the QQC screen press the start key to begin

the quality check. The following parameters are examined by the handheld unit during the quality

check: signal amplitude, signal-to-noise, depth, temperature, battery voltage, and noise.

English

21

The quality check starts. A PASS or FAIL message will appear in the handheld unit display. Scroll

to additional screens to view information about the test results. Push OK to confirm the quality

check results and return to the QQC menu.

5. To verify the depth sensor performance, check the instantaneous reading against a reference

such as the wading rod.

Internal quality check

Internal quality checks are closely linked to the flow velocity measurement process.

Each measured value is internally checked against the following criteria:

• Correlation > 40%

• Velocity > -0.25 m/s and < 0.25 m/s

• Velocity gradient (the difference between the current measurement and the previously measured

velocity) < 0.25 m/s

• Signal to Noise Ration (SNR) > 10 dB

Measured values that meet the criteria are saved. If the measurement time (integration time) is set to

30 seconds, for example, the OTT ADC collects a maximum of 30 values for each sound pulse. At

the end of the measurement time, the OTT ADC checks whether at least 50% of all measured values

meet the associated criteria. If the 50% standard is not met, the measurement is rejected and the

user is prompted to repeat the measurement.

If the measured values are confirmed, the OTT ADC calculates the mean and standard deviation for

the measured velocities in the cells closest to and furthest from the sensor. Based on the result of the

calculation, the final velocity is determined and shown in the display.

The focus of an internal quality check for flow velocity measurement is based on the parameters

given in Table 4.

Table 4 Internal quality check parameters for flow velocity measurement

Parameter Description Comment

Signal to Noise Ration (SNR) Indicator for the strength of the

reflections caused by particles in the

water.

If the SNR value is too low, a valid

measurement is not possible. Limit

SNR > 10 db.

Correlation Factor (CF) Indicator for the consistency of

sequentially received scan patterns

Limit CF > 40%

Peaks Outliers in the measured velocity

values caused by environmental

conditions

Peaks are eliminated in the velocity

gradient check

Standard deviation Standard deviation for the velocity

indicator for the measurement

accuracy

Standard deviation is decisive for

the determination of the valid

measuring range.

%Q Percentage proportion of a

discharge segment to the total

discharge

Ideal < 5%

Maximum 10%

After a measurement is completed,

the percentage proportion of each

segment of the total discharge is

shown on the display of the

handheld unit. The user can then

decide whether additional verticals

need to be allocated.

Calibrate the pressure cell (depth calibration)

Water depth is given by an absolute pressure cell built in to the OTT ADC sensor body. The pressure

cell must be calibrated to make sure the sensor measurement values are correct. This calibration

must be done under the current air pressure conditions with the sensor outside of the water in air. A

depth calibration is done before a measurement is started. Once a measurement is started, an

22

English

internal timer in the handheld unit prompts for a depth calibration every 30 minutes unless the depth

sensor is turned off.

In some situations, it may be convenient or even necessary to turn the depth sensor off. This can be

done through the third Measurement Settings [3/3] menu.

Note: If the depth sensor is turned off, a calibration is still required because calibration data is related to the noise

level measurement. However, the automatic calibration prompts are disabled, and the ADC assumes the noise

level from the last calibration unless a quick quality check has been done.

To do a depth calibration:

1. With the sensor in the air, from the first of the two Main Menus [1/2], select Depth Calibration.

2. Verify the sensor offset and current reading and push Start.

3. When the reading on the handheld unit display is stable, push OK to accept the calibration.

Turn the depth sensor on or off

By default, the depth sensor is turned on. To turn the depth sensor off, do the following:

1. From the first Main Menu [1/2], select Measurement Setting.

2. Scroll to the third Measurement Setting [3/3] screen and select option 2, Depth Sensor.

Each time the number 2 key is pressed, the sensor turns on or off, whichever is opposite of the

current state.

About sensor offsets

This is the offset between the depth sensor and the wading rod. Rod Offsets can be changed in the

third [3/3] Measurement Settings menu. Two offsets can be entered, a Sensor Offset or a Point

Offset.

The Point Offset refers to the distance between the flat base and a pointed end. Standard USGS topsetting and standard wading rods do not have a point below the flat base. Therefore, the point offset

for each is set to zero and does not need to be entered.

A sensor offset must be entered. For a standard USGS top-setting wading rod this offset should be

around 0.10 feet. This is the default value. Refer to Figure 10.

Figure 10 Sensor offset

Do the steps below to verify if the offset is correct.

1. Set the OTT ADC to the bottom of the wading rod and rest the rod base on the bottom of the

channel or stream.

2. Compare the displayed depth read by the pressure sensor with the depth indicated on the wading

rod.

3. If the depths indicated are different, adjust the Sensor Offset until the depths are the same.

English

23

Perform a single point measurement

Place the handheld unit in Measure mode.

1. Place the sensor in the flow. Make sure the sensor faces upstream and is aligned perpendicular

to the cross section.

2. With the sensor in the flow, push the START key.

The unit performs a measurement. The measurement duration is based on the average setting in

the Measurement Settings [2/3] screen.

3. Enter a filename at the prompt.

The measurement file is stored with the entered name.

Note: If a warning message appears at the end of the measurement, the filename prompt will appear after the

warning is acknowledged.

Velocity and discharge measurement methods

Discharge in a waterway with flow is defined as the volume of water that flows through a particular

cross-section per unit time. Discharge is normally given in m³/s or ft³/s and is the product of the

discharge cross-section and the average velocity of the water through the cross-section.

Figure 11 shows an example of a cross-section used for discharge measurement.

Figure 11 Discharge cross section

The discharge measurement method that uses the classic verticals process is an indirect

measurement method. When the average flow velocity of the specified verticals and the discharge

cross-section have been determined, a mathematical model is used to calculate the discharge.

Methods for velocity measurement

The average flow velocity at a vertical is calculated from a defined number of individual

measurements at different depths. These individual velocities when applied to the vertical depth give

an image of the velocity distribution. The quotient of velocity surface and water depth equals the

average flow velocity.

Figure 12 shows how the average flow velocity is calculated.

24

English

Figure 12 Example of average flow-velocity calculation, multi-point method

There are various ways to arrange the individual points. Methods include the Reduced Measure

Points Method, the 2-point KREPS measurement, the Velocity Distribution Method (Multi-point

Method), and supplementary methods. More information about each type of method is given below.

• Reduced measurement points methods (1 or 2-point)--These require less time, but assume a

consistent, logarithmic velocity distribution. Confirm the accuracy of these methods through

comparison to multi-point measurements.

• 2-point KREPS measurement--Velocity measurements are taken near the surface and at 38% of

the depth. Also requires less time and assumes consistent distribution. Should be confirmed

through comparative multi-point measurements.

• Multi-point methods--Measurement points are freely determined based on depth and flow

conditions. Highest and lowest measurement points should be as close to the surface and the

bottom as possible. The multi-point method gives a more precise reading of the velocity surfaces,

but measurement reliability decreases as water levels vary. Table 5 gives a guide to the number of

measurement points for a given water depth.

• Supplementary methods--In methods where the velocity near the surface (Vo) and the velocity

near the bed (Vs) are measured, the sensor must be positioned as near as possible to the surface

and the bed. The sensor must be submerged when near the surface, and the high and low points

must be the same for each vertical to the extent possible. Measurements made below the surface

must not be influenced by wind or surface waves.

Table 5 Water depth and number of measurement points (valid for multi-point method)

Water depth in feet Number of measurement points

< 3.3 3-4

3.3 - 9.8 4-6

13 - 23 5-8

> 23 6-10

English 25

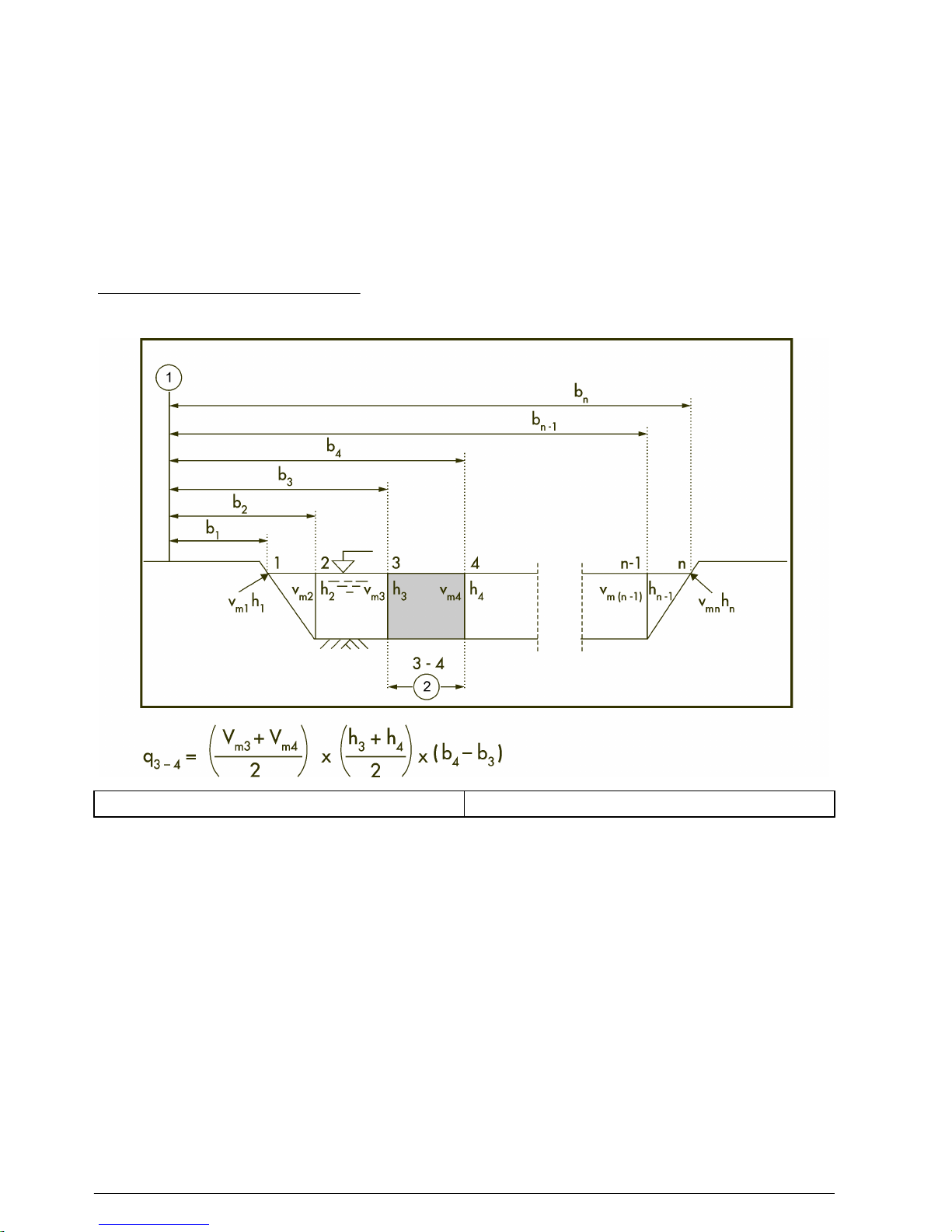

Methods of discharge calculation

Discharge calculation can be done with graphical or arithmetic methods. The OTT ADC supports

arithmetic calculation methods including the MEAN section method, and the MID section method.

More information about each is given below.

MEAN section method (procedure with average cross-section)

With this method, the measurement cross-section is divided in individual flow segments. Each partial

segment is limited by two adjacent verticals.

The equation describes the discharge calculation for an individual segment for the MEAN section

method. The total discharge is equal to the sum of the partial discharges of all segments. The MEAN

section method is illustrated in Figure 13.

Note: The additional discharge element of the two edge segments is calculated with the assumption that speed and

depth at the edges are zero.

Figure 13 MEAN section method

1 Cross section zero point 2 Segment

MID section method (mid cross section method)

In this method, the measurement cross section is also divided in to individual segments. The

individual segments do not lie between the verticals, but are defined by half the distance to the

neighboring vertical in each case. For this reason, the first and last verticals should be as close to the

edges as possible when this method is used. Figure 14 illustrates the concept.

The equation gives the the discharge calculation for an individual segment when the MID section

method is used. The total discharge is the sum of the partial discharges of all segments.

26

English

Figure 14 MID section method

1 Cross section zero point

Experience shows that the MID section method gives more exact results when compared to the

average cross section method, and requires less calculation time. For these reasons, it is the default

setting for the handheld unit of the OTT ADC.

Vertical edges and measurements

The flow element in the edge areas with vertical edge walls is accounted for with the method

illustrated in Figure 15. In the equation, KR equals the edge factor that allows for the roughness of

the edge wall.

Figure 15 Vertical edges in discharge calculations

The edge factor is dependent on the roughness of the edge. Use KR values listed below as guide

values.

English

27

Edge characteristics K

R

Smooth edge with no vegetation (e.g. concrete, steel,

cement)

0.8 - 0.9

Brick sides with vegetation 0.7

Rough walls with heavy vegetation 0.6 - 0.5

Measurement settings menus

Measurement settings [1/3]

The Measurement Settings menu is divided into three screens where the basic settings for a

discharge measurement are entered. These settings are used as input parameters for internal

advance planning of measurements and for calculating partial flows and complete discharge. The

settings available in the first screen are described in the steps below. Scroll down to view the other

Measurement Settings screens.

Note: Step 1 describes how to load settings from a previous measurement or continue from the point where a

previous measurement was halted.

1. To use settings from a previous measurement or to continue a previous measurement, navigate

to the first Main Menu [1/2] and select Load.

Option Description

Load settings only Calls the list of saved files. After selecting a file, the saved settings of that file are

loaded and will be used for the new measurement. The settings can be modified.

Continue previous

measurement

Calls the list of saved files. After a file is selected, the settings of the file are loaded.

Additional measurement points can be added. Press the START key three times to

return to the measuring mode. The vertical and position of the next measurement

point are shown.

2. For a new measurement, from the first Main Menu [1/2], select Measurement Setting.

3. In the Measurement Settings [1/3] screen, enter the information for the displayed options.

Option Description

File/Station name This is the name that will be given to the measurement file or station. The name can

be up to 20 alphanumeric characters.

Station Number This is the station identification number. The number can be up to 20 numeric

characters.

Measurement Number This is the Measurement identification number. Can be up to 8 numeric characters.

Operator This is the name of the operator who does the measurement.

Note: A file/station name and station number are required for a measurement. Entries for other settings are

optional, and if not changed, default values will be used.

Measurement settings [2/3]

This is the second of the three screens in the Measurement Settings menu.

1. Enter the information for the Estimated or Rated discharge.

2. Enter the estimated width of the discharge measurement cross section.

3. Enter the value for vertical spacing. This is the distance from one vertical to the next.

4. Enter the gage height at the start and finish verticals.

5. Enter a value for the averaging interval in seconds.

28

English

Measurement settings [3/3]

This is the third screen of the Measurement Settings menu. Update or change the entries for each

option.

1. Select Rod Offsets. Rod offsets compensate for the fact that the symmetry axis of the sensor

never lies directly on the waterway bed.

Option Description

Sensor offset (Range

0.00 - 1.00 ft)

Distance between the symmetry axis of the sensor and the base plate of the rod.

A sensor offset must be entered.

Point offset (Range

0.00 - 0.50 ft)

Distance between the base plate of the rod and the waterway bed. (Does not

apply to Standard USGS top-setting wading rods or standard wading rods.)

2. Select Depth Sensor to turn the sensor on or off.

Option Description

On During a measurement, the handheld unit prompts the user to perform a depth calibration every

30 minutes.

Off The handheld unit does not prompt the user to perform a depth calibration.

3. Select Salinity and enter a value in ppt. Range: 0 - 50. The salinity influences the speed of sound

and is used as a parameter in the velocity measurement. In freshwater waterways, the value is

generally 0 ppt. The current salinity value is shown in the display.

4. Select the Measurement Method.

Option Description

1-point Position of measure points: 0.6 x h

Mean velocity formula: Vm = V

0.6

2-point Position of measure points: 0.2 / 0.8 x h

Mean velocity formula: Vm = (V

0.2

+ V

0.8

)/2

3-point Position of measure points: 0.2 / 0.6 / 0.8 x h

Mean velocity formula: Vm = 0.25 x (V

0.2

+2 x V

0.4

+ V

0.8

)

4-point Position of measure points: 0.2 / 0.4 / 0.7 / 0.9 x h

Mean velocity formula: Vm = 0.25 x (V

0.2

+ V

0.4

+ V

0.7

+ V

0.9

)

5-point Position of measure points: near to surface / 0.2 / 0.6 / 0.8 x h / near to bed

Mean velocity formula: Vm = 0.1 x (Vo + 3 x V

0.2

+ 3 x V

0.6

+ 2 x V

0.8

+ Vs)

6-point Position of measure points: near to surface / 0.2 / 0.4 / 0.6 / 0.8 x h / near to

bed

Mean velocity formula: Vm = 0.1 x (Vo + 2 x V

0.2

+ 2 x V

0.4

+ 2 x V

0.6

+ 2 x V

0.8

+

Vs)

2-point Kreps Position of measure points: near to surface / 0.62 x h

Mean velocity formula: Vm = 0.31 x Vo + 0.634 x V

0.62

1-point ICE 0.5 Position of measure points: 0.5 x h

effective

Mean velocity formula: Vm = V

0.5

x K

ice

where K

ice

= 0.88 - 0.90 (ISO 1996)

1-point ICE 0.6 Position of measure points: 0.6 x h

effective

Mean velocity formula:Vm = V

0.6

x K

ice

where K

ice

= 0.92 (USGS)

2-point ICE Position of measure points: 0.2 / 0.8 x h

effective

Mean velocity formula: Vm = (V

0.2

+ V

0.8

) / 2

English 29

Option Description

Surface 1-point ISO Position of measure points: near to surface

Mean velocity formula: Vm = Vo X Ko where Ko = 0.84 - 0.9 (ISO 748)

Multi-point

measurement

Position of measure points: Number and position of measure points are freely

selected

Mean velocity formula: Refer to Calculation of Average Flow Velocity figure.

5. Enter the correction factor for the 1-point ice measurement and the surface 1-point measurement.

Range : 0.7 - 1.0.

Note: Can only be selected if Ice, Single point or ISO, surface method has been selected as the Measure

Method.

6. Select the Discharge Method. Press the number 5 key to toggle between the options.

Option Description

Mid-section Individual segments are defined by half the distance to the adjacent vertical.

Mean section The measurement cross-section is divided in to individual flow segments defined by a vertical

on either side.

Field quality checks

Quality checks can also be done while in the field environment. The Field Quality Check option can

be found in the Start Measurement screen. If a field QC is repeated, the previous check is

overwritten.

At least 50% of the quick quality check parameters must be within their specified values for the

quality check to pass. This rule applies whether user-defined parameter values or the default

parameter values are used for the quality check.

To do a field quality check, do the following:

Note: If necessary, adjust the quality thresholds for the site before the quality check is started.

1. Do a depth calibration. The absolute pressure cell built in to the OTT ADC sensor body

determines the water and sensor depths. The pressure cell must be calibrated in the existent air

pressure conditions to make sure depth readings are accurate. If the depth sensor is not

calibrated before a QQC is started, a warning message will appear.

Note: Depth sensor calibration is still required if the depth sensor is turned off.

2. Select number 3, Start Measurement.

3. Read the depth indicated on the wading rod.

4. Read the depth indicated on the handheld unit display.

5. Verify that the readings are within ± 0.01 ft. If the readings are not within this specification, check

the rod offset.

6. Place the sensor in the mean flow at 6/10 depth, as close to the middle of the cross section as

possible.

7. Push the start button to begin the field quality check.

The unit performs the field check, and the QC Results [1/3] screen will appear. Scroll down to

view additional screens. The information in these screens includes whether the field check

passed or failed, status of the amplitude and correlation checks, depth, temperature and other

parameters. The details of the field check can also be viewed in the QReview Summary File.

Perform a discharge measurement

Measurement notes

• The sensor is ideally positioned when the head points against the direction of flow and the

symmetry axis is at right angles to the measurement cross section.

• Make sure there are no obstructions near the sensor.

30

English

• Allow time for the temperature sensor of the OTT ADC to adjust to the water temperature

(5-6 minutes in extreme conditions).

• If conducting a wading measurement, stand so that submerged portions of the body (e.g., legs and

feet) give no or minimal resistance to the flow of water that reaches the sensor.

• All discharge measurement data are automatically saved on the handheld unit.

• After it is started, a measurement can be interrupted by switching off the unit. When the unit is

again powered on, a warning message will prompt the user to continue the measurement.

• If no name has been specified when the Start menu option is selected, the user is prompted to

enter a name for the measurement file.

• During a velocity measurement, the depth measurement display updates automatically every

3 seconds. If the tolerance for the actual depth compared to the target depth exceeds 1%

(assuming a minimum of 0.79 inches (2 cm), the target depth in the upper right corner blinks. An

up or down arrow appears on the display to indicate whether the depth needs to be increased or

decreased. When the actual and target depths are within the 1% tolerance, the arrow disappears

and is replaced by a black diamond.

1. Do a field quality check.

2. From the first Main Menu [1/2], select Measurement Setting.

3. In the Measurement Setting menu, select the Station Name option and enter a name for the

discharge measurement file. Push Enter to confirm.

4. Select the Station number option and enter a value. Push Enter to confirm.

5. The settings entered in the Measurement Settings menus will be used for the discharge

measurement. To use settings from a previous measurement, or to continue a previous

measurement, go to the Main Menu [1/2] and select Load.

Note: Both a Station Name and Station Number are required for a measurement. Other measurement settings

are optional. For example, an estimated/rated Discharge can be entered in the measurement settings, and the

measurement method and averaging time can be modified.

6. To start the discharge measurement, go to the first Main Menu [1/2] and select Start

Measurement.

If no name for the discharge measurement file has been entered, the unit displays a No

Filename warning. Enter a name for the file and press Enter, then select Start Measurement. The

Start Measurement screen appears.

7. Select one of the options in the Start Measurement screen, update the entries as necessary and

press OK to confirm.

Option Description

1. Depth

calibration

Choose this option to calibrate the depth sensor.

2. Field quality

check

Choose this option to initiate a field quality check.

3. Start Edge Choose this option to enter a value and position for the starting edge of the discharge

measurement.

1. Start at:-- Left or Right. Press the number 1 key to toggle between Left and Right.

2. Position:--Enter the position value of the starting edge. Range: 0.00-985.00 ft. The

position value = 0 if the near edge corresponds to the reference point for calculating

the position of the verticals. As a rule, the reference point is the cross section zero

point of a measured discharge cross section. The position value > 0 if the near edge is

not the reference point. The value is then equal to the distance of the near edge from

the reference point.

3. Depth:--Depth of the water at the near edge. (Range: 0.00 - 33.00 ft). The depth is

typically 0 for natural waterways and > 0 for right angled cross sections.

4. Roughness:--Roughness factor of the side wall. Range: 0 = rough, 1=smooth. This

value is relevant only for right angled cross sections and is used in calculating the

discharge proportion of the edge areas.

English 31

Option Description

4. First Vertical

[1/2]

Information about the first vertical is shown in the display. To update an entry, enter the

option number.

1. Position--Position of the first vertical in feet from the starting edge

2. Depth (if an ICE measurement, refer to the ICE Measurement section)--Depth in

feet of the first vertical. (When defining the depth of water associated with a vertical,

first lower the sensor to the bottom of the stream).

Note: If the vertical location of the depth sensor does not meet the 1% criteria, a

manual depth can be entered. This will be logged in QReview.

3. Number of points--Number of measurement points on the first vertical

4. Gage height--Height of the gage in feet

5. Notes--Used to enter notes about the first vertical

First Vertical

[2/2]

1. Define obstruction--Values for the first and last edge and width of a defined

obstruction

2. End measurement--Select this option to end the measurement

The point screen appears.

8. Update and verify the information in the point screen and press OK to confirm.

Option Description

1. Position Position of the measure point in feet

2. Water depth Water depth as measured by the pressure sensor (cannot be zero)

3. Current measurement method The measurement method currently used by the handheld unit

4. End this vertical Ends the vertical

The unit switches to measurement mode.

9. Place the sensor at the bottom of the channel or streambed. Raise or lower the sensor as

indicated on the display screen. A black diamond next to the depth reading indicates an

acceptable depth level for the sensor.

Note: If a Depth Calibration required warning appears, do a depth calibration, and press OK.

10. Press 2 to select the depth shown on the screen.

11. Push the START key to begin the measurement.

The measurement runs for the set averaging time. If the measurement is successful, the

measurement information for the point is displayed.

If the measurement is not successful, a warning message will appear. The specific warning