Form No. 102841

For Use

With

Single-

Acting

Cylinders

(Pump

includes

2-Way

Valve)

Double-

Acting

Cylinders

(Pump

includes

4-Way

Valve)

Order

No.

4000 1 0.069

0.160

0.662

0.160

2.600

0.160

7.350

0.294

2.600

0.160

7.350

0.294

1.1

2.6

10.8

2.6

42.6

2.6

120.5

4.6

42.6

2.6

120.5

4.6

10000

10000

325

10000

325

10000

325

10000

325

10000

325

10000

700 75

145

145

140

90

140

90

34.0

65.8

65.8

63.5

40.8

63.5

40.8

A 12 197

901

901

2491

9.5 l

2491

9.5 l

9

45

45

137

460

137

460

148

738

738

2245

7539

2245

7539

5.7 2.6

7.2

7.8

11.8

24.9

12.7

26.3

15.8

17.2

26.0

54.9

27.9

57.9

55

55

152

2.5 gal.

152

2.5 gal.

B

B

B

C

B

C

700

22

700

22

700

22

700

22

700

22

700

1

1

2

1

2

1

2

1

2

1

2

4002

4012

4016

4008

4017

4009

Volume & Pressure

Stage

Volume per

Stroke

In.

3

cm

3

Maximum

Pressure

psi bar

Handle

Effort

Reservoir

lbs. kg

Type

Oil

Capacity

In.

3

cm

3

Usable Oil

Capacity

In.3cm

3

Product

Weight

lbs. kg.

3/8 NPTF oil port(s) on all pumps

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Phone: (507) 455-7000

Tech. Serv.: (800) 533-6127

Fax: (800) 955-8329

Order Entry: (800) 533-6127

Fax: (800) 283-8665

I

nternational Sales: (507) 455-7223

Fax: (507) 455-7063

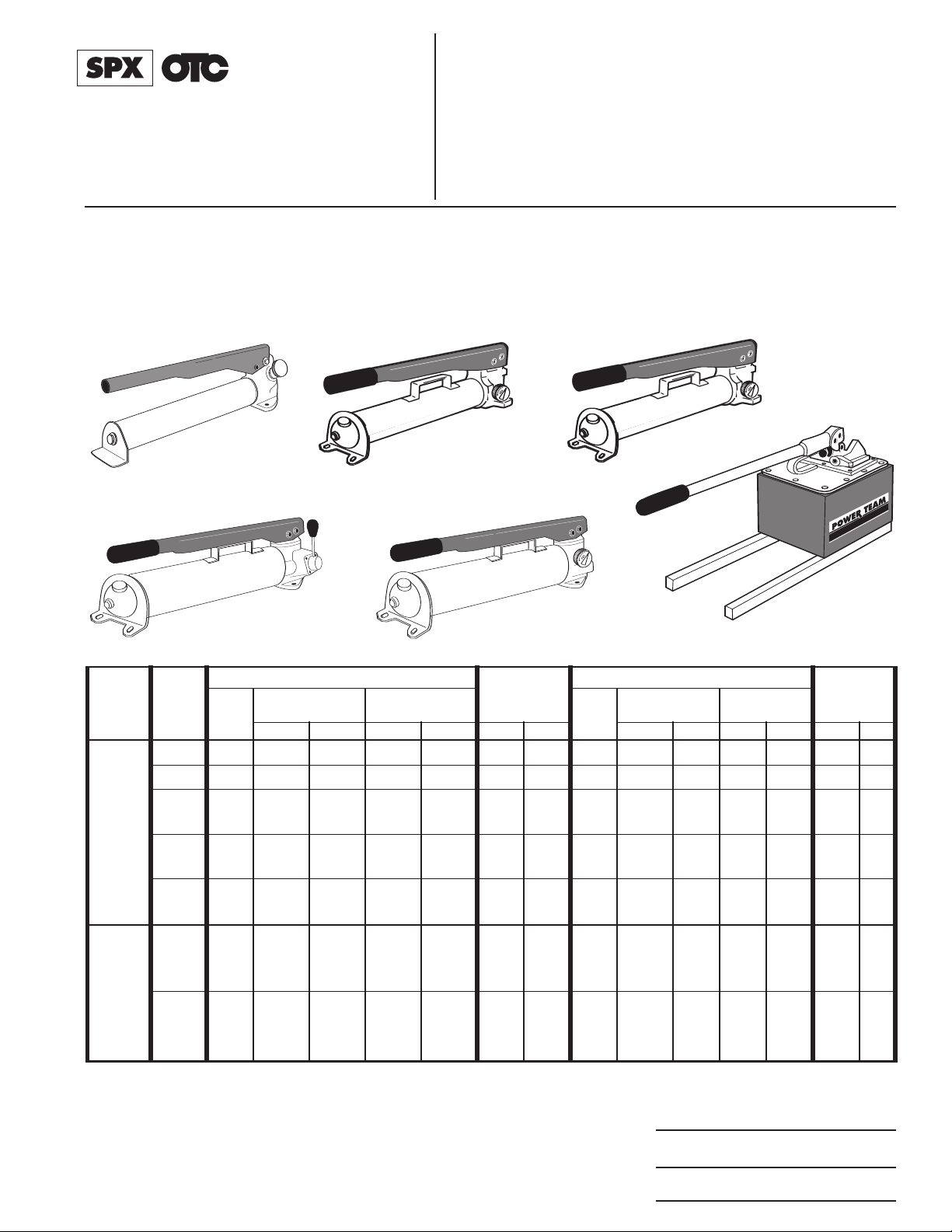

Operating Instructions for:

1U-5230

(See 4002)

4000

4002

4002-ER

(See 4002)

4008

4009

4012

4016

4017

61522 (See 4002)

61821 (See 4016)

61869 (See 4016)

61871 (See 4016)

61872 (See 4016)

JTO5845

(See 4016)

SINGLE-STAGE AND TWO-STAGE

HYDRAULIC HAND PUMP

Max. Pressure: See Pump Data Plate

Definition: A hydraulic hand pump delivers hydraulic fluid under pressure by directly applied manual effort.

Note: Illustrations depict general pump configurations.

4012

4000

4002

4002-ERA

1U-5230

© SPX Corporation

4017

4016

JTO5945

61821 / 61871 / 61872

61869 / 61522

Table 1

Sheet No. 1 of 3

Rev. 4 Date: 23 Jan. 2001

4008

4009

Operating Instructions, Form No. 102841, Back sheet 1 of 3

SAFETY EXPLANATIONS

Two safety symbols are used to identify any action or lack of action that can cause personal injury. Your

reading and understanding of these safety symbols is very important.

DANGER - Danger is used only when your action or lack of action will cause serious human injury or

death.

WARNING - Warning is used to describe any action or lack of action where a serious injury can occur.

IMPORTANT - Important is used when action or lack of action can cause equipment failure, either immediate

or over a long period of time.

Pictogram Definition

Do not remove this component. For service only. Pressure must be released.

WARNING: It is the operator's responsibility to read and understand the following

safety statements,

• Only qualified operators should install, operate, adjust, maintain, clean, repair, or

transport this machinery.

• These components are designed for general use in normal environments. These

components are not specifically designed for lifting and moving people, agri-food

machinery, certain types of mobile machinery or special work environments such as:

explosive, flammable or corrosive. Only the user can decide the suitability of this

machinery in these conditions or extreme environments. OTC will supply information

necessary to help make these decisions.

These instructions are intended for end-user application needs. Most problems with new equipment are caused by

improper operation or installation. Detailed service repair instructions or parts lists can be obtained from your nearest

OTC facility.

Operating Instructions Form No. 102841

SAFETY PRECAUTIONS

ARNING: To help prevent personal injury,

W

• Before operating the pump, all hose connections must be tightened with the proper tools. Do not

vertighten. Connections need only be tightened securely and leak-free. Overtightening may cause

o

premature thread failure or high pressure fittings to split at pressures lower than their rated capacities.

• Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the pump

and shift the control valve twice to release all pressure. Never attempt to grasp a leaking hose under

pressure with your hands. The force of escaping hydraulic fluid could cause serious injury.

• Do not subject the hose to any potential hazard such as fire, extreme heat or cold, sharp surfaces, heavy

impact. Do not allow the hose to kink, twist, curl, or bend so tightly that the fluid flow within the hose is

blocked or reduced. Periodically inspect the hose for wear because any of these conditions can damage

the hose and result in personal injury.

• Do not use the hose to move attached equipment. Stress may damage the hose and cause personal

injury.

• Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must not

come in contact with corrosive materials such as creosote-impregnated objects and some paints.

Consult the manufacturer before painting a hose. Never paint the couplers. Hose deterioration due to

corrosive materials may result in personal injury.

• All components in the hydraulic system must match the maximum pressure rating of the pump.

Pump

• Do not exceed the PSI rating noted on the pump nameplate or tamper with internal high pressure relief

valve. Creating pressure beyond rated capacities may result in personal injury.

• Before adding hydraulic fluid, retract the system to prevent overfilling the pump reservoir. An overfill

may cause personal injury due to excess reservoir pressure created when cylinders are retracted.

• The load must be under operator control at all times.

Cylinder

• Do not exceed rated capacities of the cylinders. Excess pressure may result in personal injury.

• Do not set poorly-balanced or off-center loads on a cylinder. The load may tip and cause personal injury.

• Stay clear of lifted loads and keep others away.

• Extensions are not recommended for lifting applications.

SET-UP

Hydraulic Connections

IMPORTANT: Seal all hydraulic connections with a high grade, nonhardening thread sealant. Teflon tape may

also be used to seal hydraulic connections if only one layer of tape is used. Apply the tape carefully, two

threads back, to prevent it from being pinched by the coupler and broken off inside the pipe end. Any loose

pieces of tape could travel through the system and obstruct the flow of fluid or cause jamming of precisionfit parts.

Clean all areas around the fluid ports of the pump and cylinder

1.

Remove thread protectors from the hydraulic fluid outlets, and connect the hose assembly. Couple hose to

cylinder.

2. The use of a hydraulic pressure or tonnage gauge (not included) is strongly recommended. Remove the pipe

plug from the gauge port of the valve, thread the gauge into this port and seal as noted above.

. Clean all hose ends, couplers, and union ends.

ARNING: T

W

o help prevent personal injury

,

• The gauge must have the same pressure rating as the pump and cylinder. Personal injury can result if

the wrong gauge is used.

• Release hydraulic pressure BEFORE removing

or tightening hose couplings.

Sheet No. 2 of 3

Rev

. 4

Date: 23 Jan. 2001

Operating Instructions, Form No. 102841, Back sheet 2 of 3

OPERATION

The 4008 can be operated only in the horizontal position. All other hand pumps can be operated in a horizontal

position or in a vertical position with head pointing downward.

Refer to Table 1 and your pump name plate to determine your style of pump.

IMPORTANT: Figure 1 illustrates

normal

the

experienced when all

two-stage pumps shift from

low pressure stage to

high pressure stage.

drop of handle effort

(except 4012)

High Pressure Stage

Handle Effort

Low Pressure Stage

Unloading

Pressure

Two-way Valve

Pumps with a two-way valve are for use with single-acting cylinders.

1. To extend the cylinder, turn the valve knob clockwise to a closed (seated) position.

the pump handle up and down to build pressure.

2. To release pressure, open the valve slowly by turning the knob counterclockwise to control the load.

Four-way Valve

Pumps with a three-position, four-way valve are for use with double-acting cylinders. The hose connection for

extending a cylinder can be made to either port. With the handle in the forward position, the fluid is directed to the top

fluid port. To maintain (hold) pressure, stop the pumping action. When the valve handle is in the center position, fluid

flow is blocked to both ports.

WARNING: The operator should always release the pressure slowly.

Pressure

Figure 1

Note: Hand tight only! Work

PREVENTIVE MAINTENANCE

IMPORTANT: Any repair or servicing that requires dismantling the pump must be performed in a dirt-free

environment by a qualified technician.

Lubrication

Apply lubricant regularly to all pivot and rubbing points. Use a good grade of No. 10 motor oil or grease. Do not use

dry lubricants.

Bleeding Air From the System

Air can accumulate in the hydraulic system during the initial set-up or after prolonged use, causing the cylinder to

respond slowly or in an unstable manner. To remove the air:

1. Position the cylinder at a lower level than the pump, and turn the cylinder rod end down.

Extend and retract the cylinder several times without putting a load on the system. Air will be released into the

2.

pump reservoir. Follow the fluid level instructions for your reservoir type, release the air from the reservoir, and

top off the fluid supply.

Bleeding Air From The Pump

When the pump is first put into use, or after refilling the pump's reservoir it may be necessary to bleed any trapped air

from the pump. If this is not done the pump will not function properly (will not build pressure or has very spongy

operation).

o bleed air from the pump, turn the pressure control knob counterclockwise (CCW) and operate the pump handle up

T

and down approximately twenty times. Turn the pressure control knob clockwise (CW) to its full stop position. The

pump should now be bled of air and ready to use.

Note: Shaded areas reflect last revision(s) made to this form.

Operating Instructions Form No. 102841

Hydraulic Fluid Level

WARNING: Cylinder(s) must be fully retracted before checking the fluid level. Release all system pressure

before breaking any hydraulic connection in the system.

heck the hydraulic fluid level in the reservoir periodically. Use a funnel with a filter to add hydraulic fluid if needed.

C

Refer to Table 1 for your reservoir type.

For models with Reservoir Type A: Place the pump in a

vertical position with the pump head facing upward. Unscrew

and remove the pump head from the reservoir. The fluid level

within the reservoir should come to the fluid level mark

indicated on the reservoir body decal. Before replacing the

pump head, visually inspect the o-ring which seals the pump

head/reservoir assembly. Replace this o-ring if it is worn or

damaged. Reinstall pump head to reservoir and tighten

securely. Check for leaks.

Note: Refer

to appropriate end

view for

your pump

model

For models with Reservoir Type B: Remove the filler cap.

The fluid level should come to the bottom edge of the filler hole

when the pump is level and resting horizontally on its base and

the cylinders are retracted (see Figure 2 - appropriate view

depends on model of pump).

Figure 2

For models with Reservoir Type C: Remove the filler cap.

The fluid level should be 1/2 inch (12.7 mm) from the cover plate when the pump is level and resting horizontally

on its base and the cylinders are retracted.

OIL

LEVEL

OIL

LEVEL

Draining And Flushing The Reservoir

Drain, clean and replenish the reservoir with high-grade, approved hydraulic fluid yearly or more often if necessary.

The frequency of fluid change will depend upon the general working conditions, severity of use and

overall cleanliness and care given the pump.

IMPORTANT: Clean the exterior of the pump first. After draining and flushing the reservoir, drain and clean

the other hydraulic system components (hoses, cylinders, etc.) before connecting them to the pump again.

This will help prevent contaminated fluid from entering the pump.

Refer to Table 1 for your reservoir type.

For models with Reservoir Type A:

1. Unthread and separate the pump head from the reservoir. Drain the reservoir of the used hydraulic fluid.

2. Flush out reservoir with a small amount of clean hydraulic fluid. Clean the pump intake filter.

: Removing the filter from the pump assembly could result in its breakage. Attempt to clean it

IMPORT

as well as possible with it installed.

3. Refill the reservoir and reassemble the pump head to the reservoir. Tighten securely. Check for leaks.

For models with Reservoir Type B:

1. Remove the filler cap. Drain the hydraulic fluid through filler hole.

Remove the nut from the tie rod. Separate the reservoir from the pump body

2.

IMPORTANT

as well as possible with it installed.

3. Reassemble and fill the reservoir with hydraulic fluid. Replace the filler cap.

For models with Reservoir Type C:

Remove the ten screws fastening the reservoir cover to the reservoir

1.

Drain all hydraulic fluid and flush reservoir with a small amount of clean hydraulic fluid.

2.

Remove the pump assembly filter

3.

4. Refill the reservoir with hydraulic fluid. Place the pump and valve assembly

(with gasket) on the reservoir

ighten securely and evenly

T

ANT

. Clean the reservoir and filter

: Removing the filter from the pump assembly could result in its breakage. Attempt to clean it

, and lift the pump and valve assemblies off.

, rinse it clean, and reassemble.

, and thread the ten screws.

.

Sheet No. 3 of 3

.

Rev

. 4

Date: 23 Jan. 2001

Operating Instructions, Form No. 102841, Back sheet 3 of 3

TROUBLE-SHOOTING

WARNING: To help prevent personal injury, always release pump pressure and disconnect hoses(s)

rom pump before making repairs.

f

Refer to the appropriate pump parts list during trouble-shooting. Repairs must be performed in a dirt-free

environment by qualified personnel familiar with this equipment.

PROBLEM CAUSE SOLUTION

Pump losing pressure 1. System components leaking

2. Directional control valve leaks or

not adjusted properly

3. Fluid leaking past outlet check

seat(s)

Handle rises after each stroke 1. Fluid leaking past outlet check

seat(s)

Pump not delivering fluid 1. Low fluid level in reservoir

2. Intake filter is dirty

3. Seats worn and not seating

properly

Pump does not reach full pressure 1. Low fluid level in reservoir

2. System components leaking

3. Directional control valve leaks or

not adjusted properly

4. Improperly adjusted relief valve

5. Fluid leaking past inlet or outlet

checks or high pressure piston

seal damaged

1. Repair or replace as necessary

2.* Reseat, repair, or replace

directional control assembly and

correctly adjust

3.* Check for dirt. Reseat pump

body and/or replace poppet(s) or

ball(s)

1.* Check for dirt. Reseat pump

body and/or replace poppet(s)

or ball(s)

1. Check fluid level per instructions

2. Remove reservoir and clean

3.* Repair seats or replace pump

body

1. Check fluid level per instructions

2. Repair or replace as necessary

3.* Reseat, repair, or replace

directional control assembly and

correctly adjust

4.* Readjust

5.* Reseat or repair inlet or outlet

checks or replace high pressure

piston seal

Pump handle can be pushed down

(slowly) without raising the load

Pump handle operates with a

spongy action

Pump handle effort drops

significantly after some pressure

has been obtained

*OTC recommends these hand pump repairs be performed by an Authorized Hydraulic Service Center.

1. Inlet checks are not seating

2. Damaged piston assembly or

piston seals leaking

1. Air trapped in system

oo much fluid in reservoir

T

2.

1. This is normal operation on most

two-stage hand pumps

1.* Check for dirt and/or reseat

valve seats

2.* Replace piston assembly and/or

piston seals

1. Position cylinder lower than

pump. Extend and return

cylinder several times. Follow

bleeding instructions.

Check fluid level per instructions

2.

Loading...

Loading...