Page 1

INSTRUCTIONS FOR OPERATION AND CARE

XVGA GRATER/SHREDDER AND

XVSA SLICER ATTACHMENTS

Our versatile grater/shredder attachments can be used to grate and shred cheeses, raw vegetables, nuts, breadcrumbs, etc.

depending on the plate selected. Our S/S plates are available with 3/32", 3/16", 1/4", 5/16" or 1/2" size holes and a special

grating plate for breadcrumbs & hard cheeses. A plate holder with shaft and one 3/16" plate are included with the XVGA

attachment.

Our slicer attachments can be used for slicing potatoes (from 1/16" to 5/8" thickness); cutting vegetables for salads and coleslaw; or for slicing fruits and nuts.

An adjustable slicer plate with shaft are included with the XVSA attachment.

WARNING

There are sharp rotating knives behind the front door; keep hands out of hopper

and use a feed pusher or stomper to push product into the hopper – do not use

your fingers. Always stop power unit before opening front for changing, cleaning,

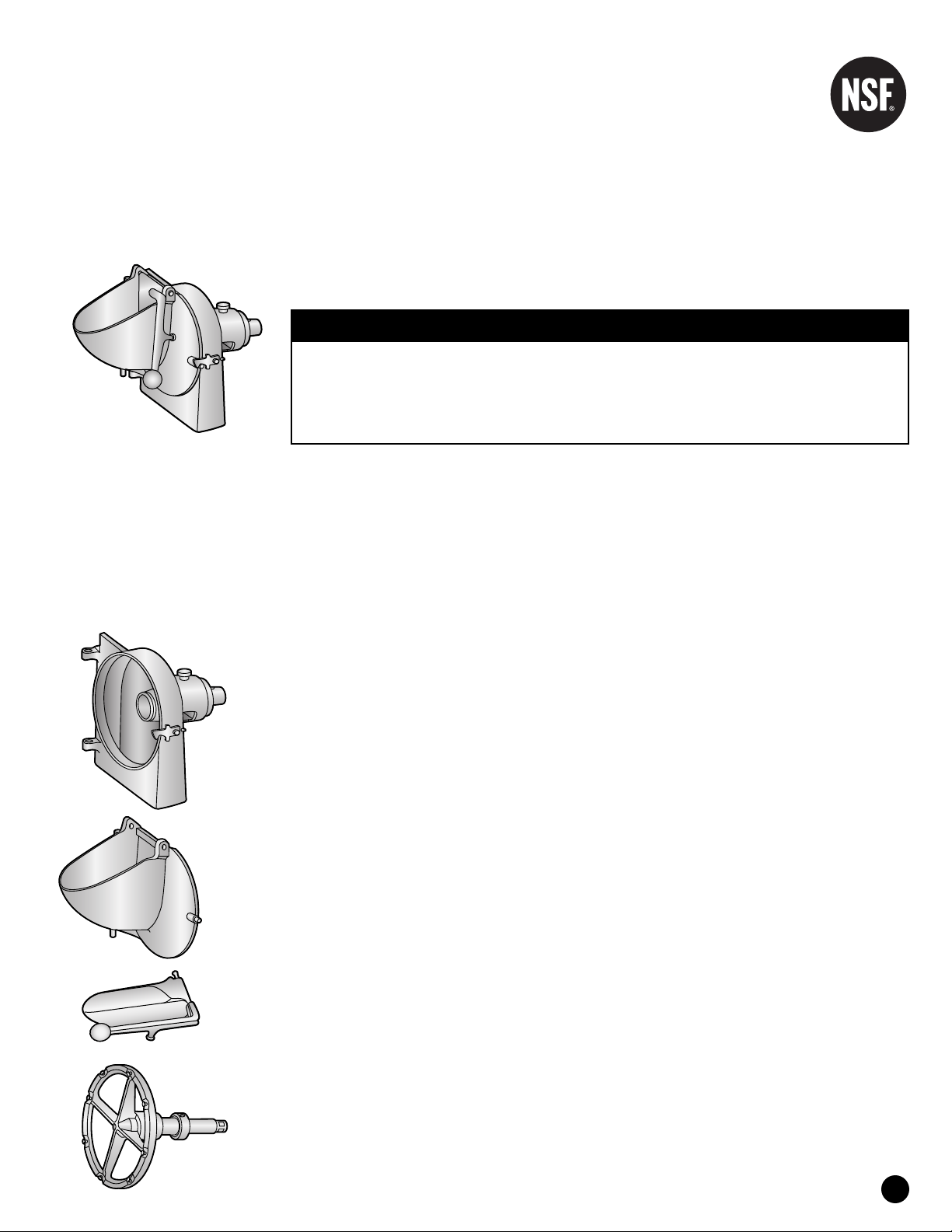

XVGA

XVSA

These attachments are made up of the following four basic components:

1. XVSH Housing

2. XVSD Front Door or Hopper

3. XVSP Pusher Plate

4. Plate Holder or Adjustable Slicer Plate units

1. Adjustable Slicer Shaft XASP with S/S "S" knife

2. Shredder Plate Holder XPH

or servicing anything on this unit. Only trained and qualified persons 18 years

and older should use these attachments.

XVSH

XVSD

XVSP

XPH

HOUSING OR BACK CASE

The housing or back case mounts into the attachment socket of a mixer, food cutter or

power drive unit and is retained by the pointed thumbscrew that goes through the attachment hole into the indentation on the neck of the machine.

DOOR OR HOPPER

The front door is a hopper and lever feed design. It hinges onto the back case and is held

closed with an adjustable latch. To remove the front door, lift the latch and swing the door

open while lifting it from the hinge holes.

PUSHER PLA

The pusher plate has an integrated handle to push the food into the rotating disc or slicer

knife. It has pins at both ends of the top and hinges into the front door. The pusher plate

has a rubber-tipped stop screw (XP1018) under the handle that can be adjusted to prevent

the plate from coming in contact with the plate or blade.

TE

TE HOLDER WITH SHAFT

PLA

Shredder plates are available with 3/32", 3/16", 1/4", 5/16" or 1/2" hole sizes.

have keyhole slots for attaching to shouldered studs on the plate hubs.

These plates

1

Page 2

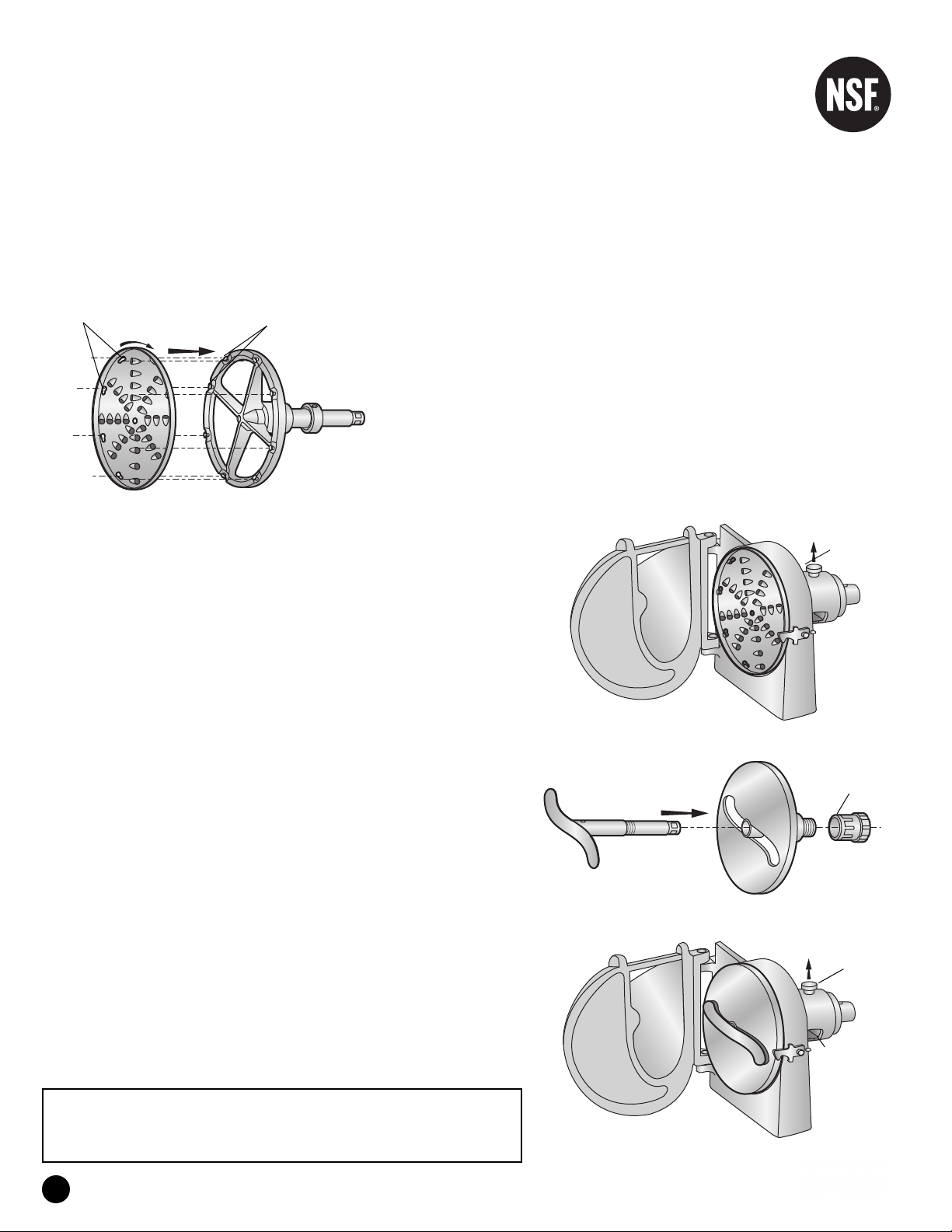

TO INSTALL SHREDDER OR GRATER DISCS

Stop the machine. Orient the plate with the cutting edge away from the shaft assembly. Locate the keyhole slots on the plate

and slide the wide part of the slots over the studs on the plate holder. When the plate is flush with the holder, rotate it clockwise to lock it in position. It is possible to loosely assemble the plate to the hub (sharp edge out), then place it on a work surface (the teeth on the plate will mar a finished table). Press down and turn the hub until plate locks into place.

"teeth" should face out on the holder. To detach the plate from the hub, reverse the installation procedure. A safe method is

to use protective gloves and press the palm of one hand against the plate to rotate it.

Note: The plates are slightly bent to provide holding pressure when in position.

The sharp

Keyhole Slots

Studs

SHREDDER PLATE

The coarse plates are normally used for making chopped slaw, cutting

vegetables for soup stock, salad blends or "hash brown" potatoes.

The medium and finer plates are for fine shredding of carrots, beets,

turnips, etc., and for salads. See our application chart at the end of

these instructions.

GRATER PLATE

The grater plate may be used for crumbling hard cheese or grating

hard vegetables.

TO INSTALL XPH PLATE HOLDER ASSEMBLY

Stop the machine. With door open, pull the locking pin XP1007 up and

insert XPH until the square end of the shaft fits snugly into the power

unit. Then release the locking pin to hold the XPH in proper position.

ADJUSTABLE SLICER PLATE ASSEMBLY

& INSTALLATION

Turn off and unplug the machine. Adjust the slicing thickness from

approximately 1/16" to 5/8" by turning the gray plastic adjusting nut

XP1022. Lift the silver locking pin XP1007 on the top of the rear of the

housing and open the front door and slide the slicer unit back into

operating position. The square end of the shaft may have to be manually rotated to seat into the machine socket properly. Secure the unit

to the machine by tightening the pointed thumbscrew in the hole on the

top side of the attachment hub. Attach the pusher plate XVSP and

close and latch the door XVSD before turning the machine on.

TO ADJUST THICKNESS OF SLICES

Stop the machine. While you can adjust the thickness of slices with

Adjustable Slicer Plate Assembly in position, by turning the gray plas-

Adjusting Knob XP1022, accessed through the opening in the rear

tic

housing, we recommend that you remove the Adjustable Slicer Plate

Assembly from the housing and turn the Adjusting Knob while carefully holding the plate.

Locking Pin

Open Door

Adjustment

Nut

Locking Pin

Adjustment

Nut Access

CAUTION: The adjusting nut turns with the shaft and adjust

ments should not be attempted unless the power unit is turned

off and unplugged.

2

-

Open Door

Page 3

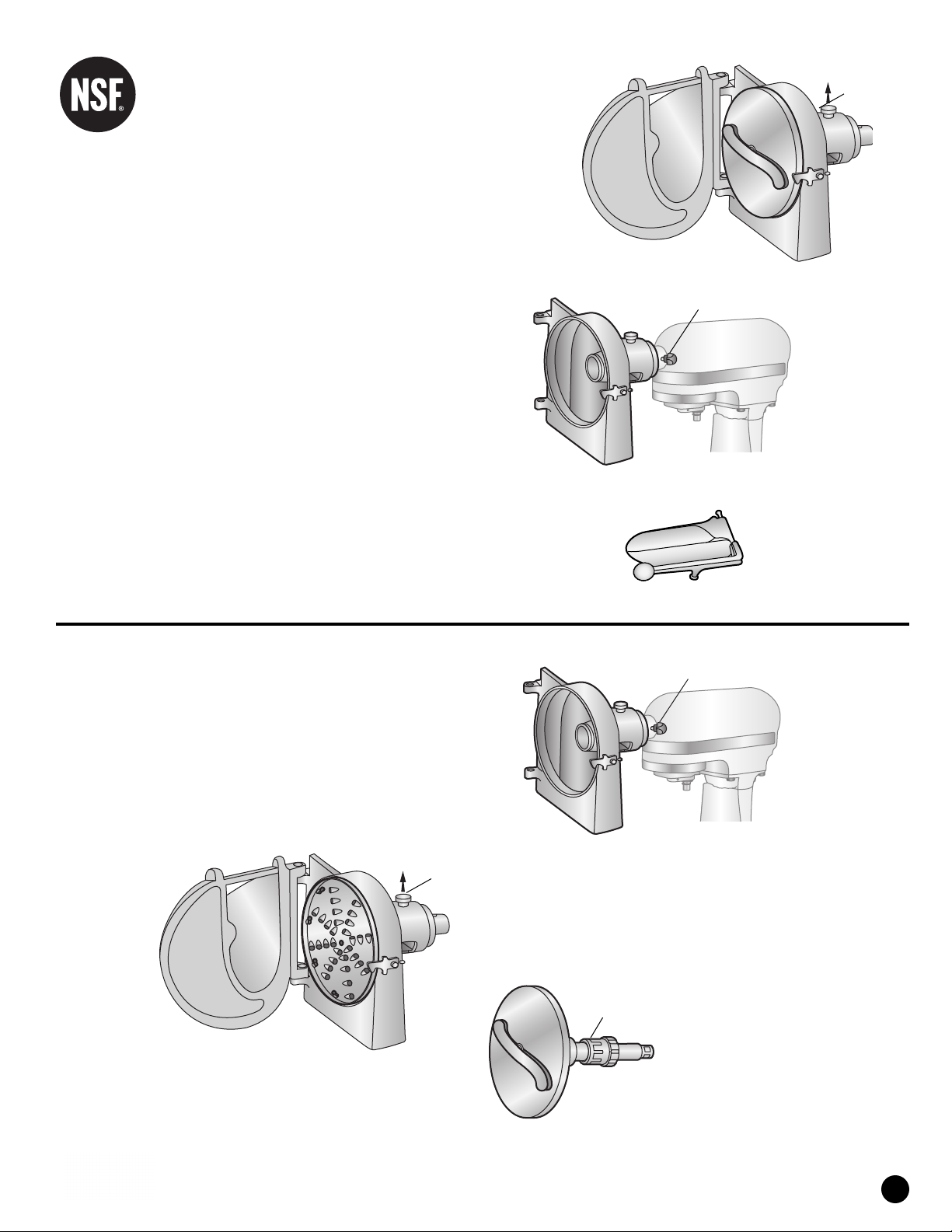

TO REMOVE XASP ADJUSTABLE SLICE PLATE ASSEMBLY FROM

HOUSING

Open the door all the way and raise the locking pin XP1007 (on top of

rear of housing) and the assembly will be free for removal by pulling

outward.

TO REMOVE ATTACHMENT FROM POWER UNIT

Loosen thumbscrew on power unit until hub is free for removal

from unit.

Locking Pin

Open Door

Thumb Screw

PUSHER PLATE REMOVAL

Raise the Pusher Plate and slide it out of the slot in the door XVSD.

OPERATION

1. Stop the power unit (mixer, food cutter, chopper,

power drive etc.)

2. Attach the housing of slicer to the attachment

socket of the companion machine with the

thumbscrew.

Locking Pin

3. Select the grater/shredder or slicer assembly to be used.

Thumb Screw

Lift the locking pin and insert the plate and shaft assembly into the drive position. Release the locking pin.

Set the slice adjustment (if used) to the proper thickness.

Adjustment

Nut

3

Page 4

4. Drop the hinge pins of the front door into

the holes in the housing.

Pusher Plate

Pusher Plate

Lever

CAUTION: Keep Hands out of Hopper – use a

stomper or food pusher.

MAINTENANCE INSTRUCTIONS

5. Close the slicer front door and fasten the latch.

6. Start the machine. Set at a speed to produce the best

product (see machine manual)

7. Raise the pusher plate lever.

8. Place the food to be sliced in the hopper and gently press

down on the pusher plate lever.

Note: Too much pressure crushes the food and causes

irregularity in the slices. Large items may have to

be cut down to fit into the hopper.

CLEANING

1. Stop the power unit (mixer, food cutter, power drive, etc.).

2. Release the latch and remove the front door.

3. Lift the locking pin and withdraw the shredding or slicing

unit from the housing.

4. The shredder and grater plates can be easily removed from

the plate hub by rotating plate counter-clockwise to release

the keyhole slot from the studs.

CAUTION: These plates are sharp and must be

handled with care.

5. All components of these attachments may be cleaned by HAND WASHING ONLY, using mild detergent in warm water.

These units are NOT DISHWASHER SAFE due to the corrosive nature of commercial detergents, which can discolor aluminum and turn it black. Rinse in hot, clear water and dry immediately

attachments before they dry

.

Note: Frequent lubrication with a USDA approved grease is necessary to prevent shaft seizing.

. It is important that juices be cleaned from the

4

Page 5

6.When using the adjustable slicer plate, make sure it is

cleaned frequently to assure easy thickness adjustment.

Adjustment

Nut

Thrust

Bearing

Occasionally disassemble the slicer plate for a thorough

cleaning. To do this it is necessary to unscrew the

knurled thrust bearing, which has a left hand thread, to

release the spring. Withdraw the knife and shaft assem-

Spring

bly. Unscrew the adjusting nut from the plate. Use a drop

of approved food machinery oil on the shaft and adjustment threads after cleaning.

Note: After cleaning, to prevent damage the thrust bearing must be tightened until sealed against shoulder on shaft.

Failure to properly reassemble can result in damage to knives, shaft and slicer plate. Do not clean any of these components in a dishwasher with strong detergents or chemicals. Use a USDA approved grease on the shaft for best operation.

CAUTION: Do not permit water or moisture to remain on or in the hub, shaft, or the rear opening in the hous-

ing. This condition will result in rusting which will eventually destroy the rear end components and shaft and

void the factory warranty.

KNIFE SHARPENING

Occasional touching up along the edges of the knife with a honing stone will keep cutting operations at peak performance.

PUSHER PLATE STOP

Frequently check that the pusher plate does not hit the grater plate holder or knife shaft assembly. The Pusher Plate Stop

XP1018 can be adjusted to avoid touching the internal moving parts. With proper care and maintenance, your Vegetable

Grater/Shredder/Slicer Attachment will provide you with many years of performance.

XP1012

XVSP

Pusher Plate

XP1035

XVSD

XP1036

XP1017

XP1018

XVSD Door

with Hopper Opening

XP1013

Plate

XP571

(Knife only)

XPH Plate Holder

XP1030

XP1014

XP1571 (Knife and Shaft)

XASP Adjustable Slicer Plate Assembly

XP1026A

XP1026 Brass

Housing

XP1024 Brass

XP1023

XP1022 Plastic

XP1007

XP1010

XP1011

XP1005A

XP1004

XP1005

XVSH Housing

XP1009

XP1008

5

Page 6

PART NUMBER LISTING

XVSH HOUSING

XVSH Housing size 12

XP1004 Threaded (Hex) Pin for housing latch

XP1005 Latch with setscrew

XP1005A

XP1007 Shaft Lock knob - top

XP1008 Housing Hub with locating pin – six holes

XP1009 Flat Head Machine Screw (6) for hub

XP1010 Knife Lock Screw

XP1011 Fiber gasket

XPH PLATE HOLDER

XPH Plate Holder Assembly Complete

XP1026 Brass Collar with set screw

XP1026A

XP1030 Stud for Plate Holders

XSP332 3/32" S/S Shredder Plate

XSP316 3/16" S/S Shredder Plate

XSP14 1/4" S/S Shredder Plate

XSP516 5/16" S/S Shredder Plate

XSP12 1/2" S/S Shredder Plate

XGP S/S Grater Plate

Latch setscrew only

Set Screw for Collar

XASP ADJUSTABLE SLICER PLATE

XP571

XP1571

XP1022 Knife Adjusting Nut- Gray Plastic

XP1023 Tension Spring

XP1024 Bronze Lock Nut or Thrust Bearing

XVSD DOOR

XP1012 Upper Hinge Pin (long)

XP1013 Lower Hinge Pin (short)

XP1014 Latch Pin

PUSHER PLA

XVSP

XP1017 Stop Nut

XP1018 Stop Screw

XP1035 Ball End Hinge Pin

XP1036 Hinge Pin

TE

“

S” Knife only

“

S” Knife and Shaft Assembly

6

Page 7

Shredder and Grater Plate Hole

Sizes with Typical Applications

1/2" 5/16" 3/16" 3/32" Universal

Food Shredder Shredder Shredder Shredder Grater

Product Plate Plate Plate Plate Plate

000 0 3 7 14

Cole Slaw

Bread Crumbs

Cheese

Soft Cheese

For Pizza

Carrots For

Coloring

Cheese For

Tacos

Hard Cheese

Stainless steel Shredder Plate hole sizes (not drawn to scale)

3/32" 3/16"

1/4"

5/16"

1/2"

SS Grater Plate

For Hard

Cheese only

7

Page 8

LIMITED XVSA/XVGA ATTACHMENT WARRANTY

Globe Food Equipment Company (“GFE”) warrants to the original purchaser of new equipment that said equipment,

when installed in accordance with our instructions within North America and subjected to normal use, is free from defects

in material or workmanship for a period of 1 year from invoice date. The XVSA Vegetable Slicing Attachment and XVGA

Shredder/Grater Attachment have a 1-year replacement warranty. There is no labor warranty for mixer attachments.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED. GFE EXPRESSLY

DISCLAIMS ANY IMPLIED WARRANTY OF MERCHANTABILITY OR EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

GFE’S OBLIGATION AND LIABILITY UNDER THIS WARRANTY IS EXPRESSLY LIMITED TO

REPAIRING AND REPLACING EQUIPMENT WHICH PROVES TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP

WITHIN THE APPLICABLE WARRANTY PERIOD. All repairs pursuant to this

Warranty will be performed by an Authorized Designated GFE Service Location during normal working hours. IN NO

EVENT SHALL GFE BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES TO BUYER OR ANY THIRD

PARTY, INCLUDING, WITHOUT LIMITATION, LOSS OF PROPERTY, PERSONAL INJURY, LOSS OF BUSINESS OR

PROFITS OR OTHER ECONOMIC LOSSES, OR STATUTORY OR EXEMPLARY DAMAGES, WHETHER IN NEGLIGENCE, WARRANTY, STRICT LIABILITY, OR OTHERWISE.

This Warranty is given only to the first purchaser from a retail dealer. No warranty is given to subsequent transferees.

This Warranty does not cover product failures caused by: failure to maintain, neglect, abuse, damage due to excess

water, fire, normal wear, improper set up and use. Periodic maintenance is not covered.

THE FOREGOING WARRANTY PROVISIONS ARE A COMPLETE AND EXCLUSIVE STATEMENT BETWEEN THE

BUYER AND SELLER. GFE NEITHER ASSUMES NOR AUTHORIZES ANY

PERSONS TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY IN CONNECTION WITH SAID EQUIPMENT.

Example of items not covered under warranty, but not limited to just these items:

1. Acts of God, fire, water damage, vandalism, accident, theft.

2. Freight damage.

3. Improper installation or alteration of equipment.

4. Use of generic or after market parts.

5. Repairs made by anyone other than a GFE designated servicer.

6. Lubrication.

7.

8.

9.

Expendable wear parts – shredder/grater plates and “S” knife.

Cleaning of equipment.

Misuse or abuse.

FOR COMPLETE XVSA, XVGA AND SHREDDER PLATE SALES

TOLL FREE: 1-800-347-5423 FAX: 937-299-4147

FOR SP

ARE PARTS SALES:

TOLL FREE: 1-800-745-6238 FAX: 937-290-0585

GLOBE FOOD EQUIPMENT COMPANY

PO BOX 3209 DAYTON, OHIO 45439

www.globeslicers.com

8

Loading...

Loading...