Page 1

O.S.2B.2CA.2CB.2H

INSTRUCTIONS FOR O.S. TYPE 2B, 2CA, 2CB & 2H AUTOMATIC CARBURETTOR

This new carburettor incorporates an automatic mixture control device which ensures that the engine receives a

correctly balanced mixture of fuel and air at all throttle settings. The device progressively reduces the effective

size of the fuel jet orifice as the throttle is closed, thereby preventing the engine from running too rich at low

speeds. This also means that an airbleed is no longer required and, with its elimination, maximum suction is maintained at the fuel jet at all times. This is a most important factor where manoeuvres have to be executed at low engine

speeds and through wide variations of fuel level within the fuel tank.

Under

average

normally function satisfactorily as factory set. Simply start the

engine in the normal way and adjust the needle-valve for

maximum r.p.m. On closing the throttle, the engine should idle

at between 2,500 and 3,000 r.p.m. and also run steadily at all

intermediate speeds. However, different fuels and/or climatic

conditions, may require minor readustments for optimum

results.

operating

conditions,

the

carburettor

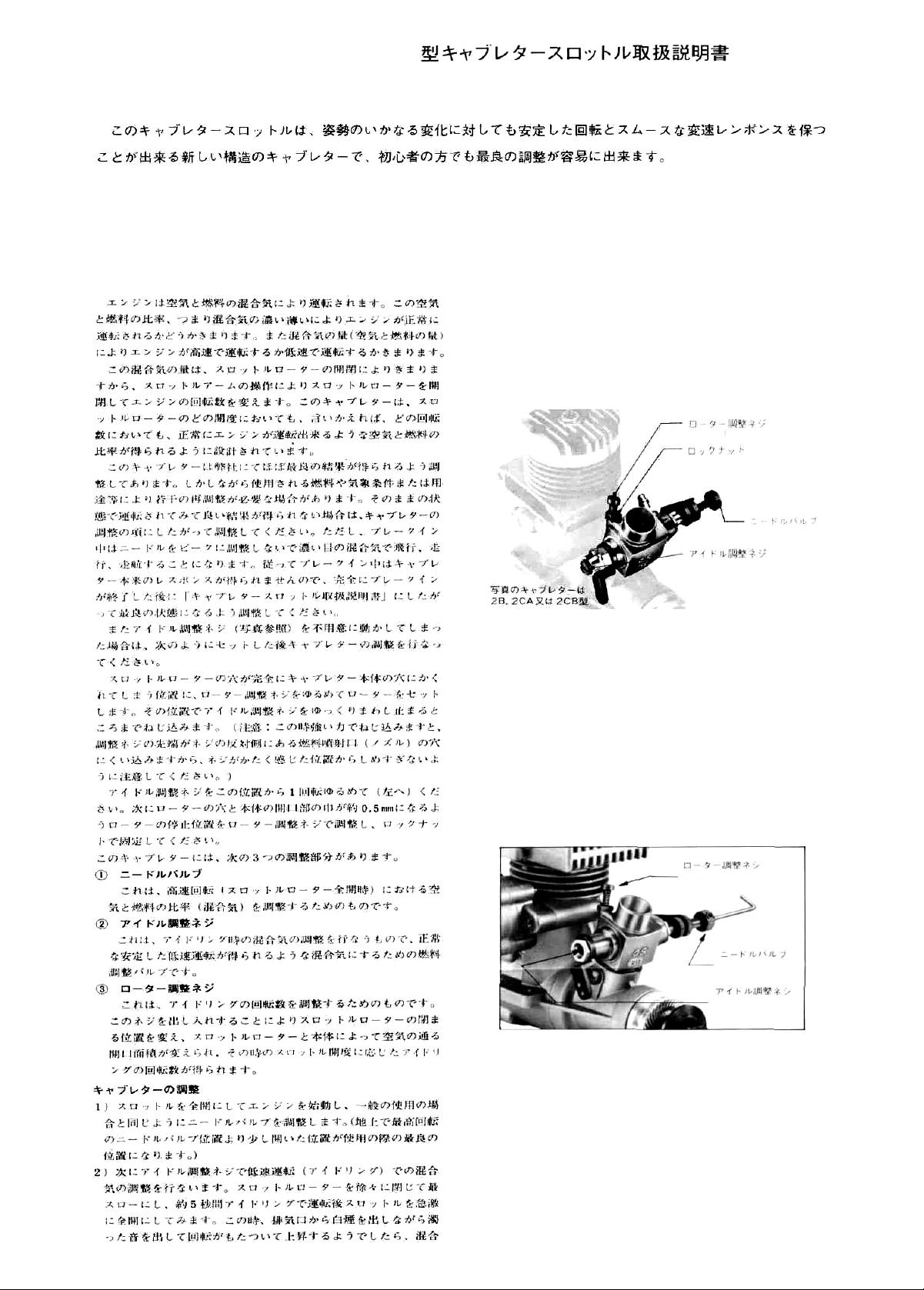

Throttle Rotor Set-Screw

Lock Nut

will

Needle Valve

Mixture Control Screw

Photo shows carburettor

type 2B. 2CA or 2CB.

If

mixture control

re-setting

(1) Unscrew the throttle rotor set screw and set the rotor at a

(2) With the rotor set as above, slowly screw-in the mixture

(3) Re-set the rotor so that the rotor hole opens approximately

(4) Do the final setting of the mixture control screw in accord-

as

position where the rotor hole is completely closed from the

carburettor body hole.

control screw until it reaches the maximum point. Avoid

trying to force it in abruptly. Otherwise, the tapered tip

of the mixture control screw ruins the fuel jet hole. Unscrew the mixture control screw one turn from the maximum point.

0.5 mm (0.02 in.) from the fully closed position. Screw-in

the throttle rotor set screw and fix it with lock-nut.

ance with the carburettor adjustment stated below.

screw is moved unnecessarily, observe the

follows:

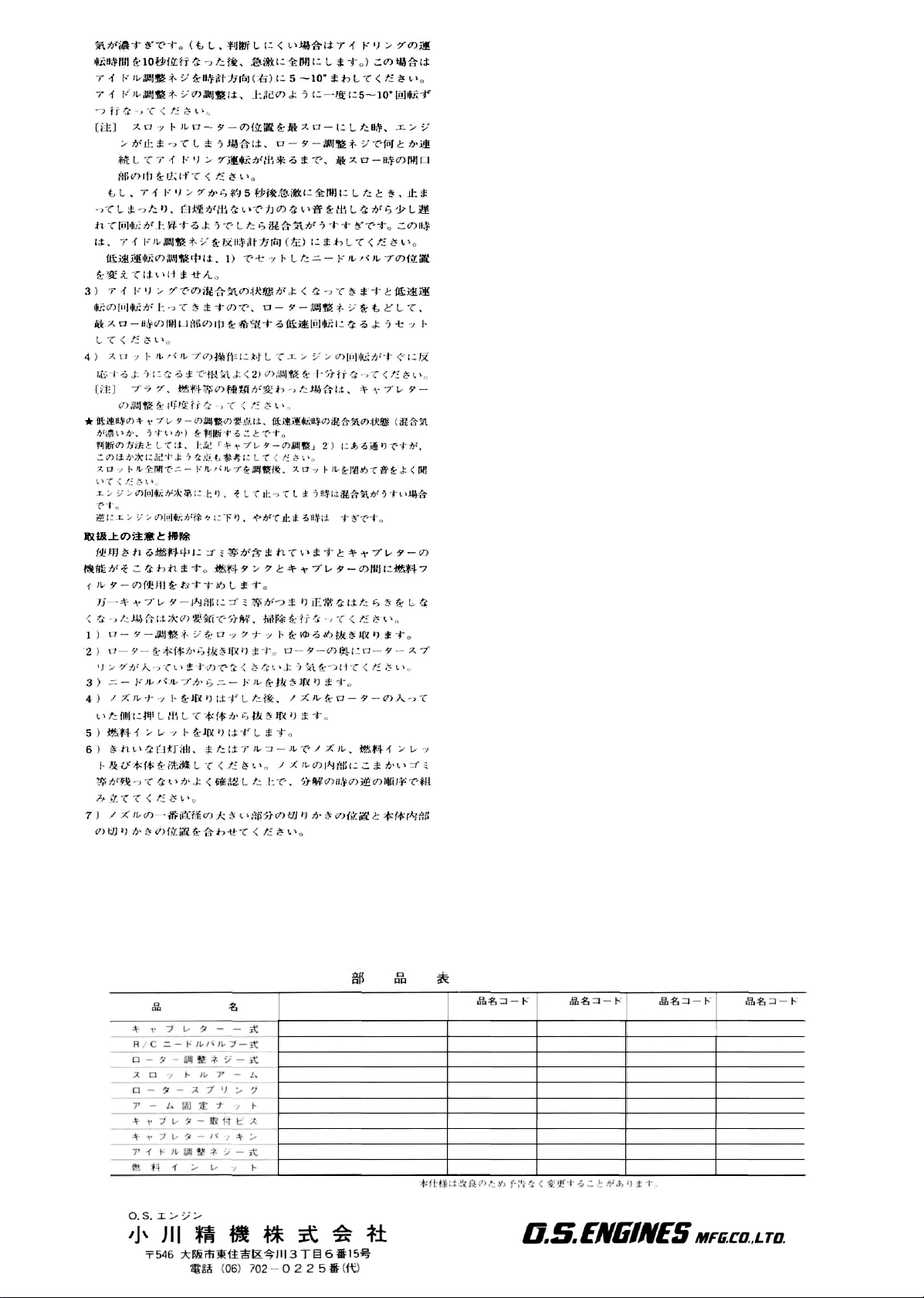

Throttle Rotor Set-Screw

Needle Valve

Mixture Control

Screw

Phot shows carburettor type 2H.

ADJUSTING THE CARBURETTOR

Three adjustable controls are provided on this carburettor:

(1) The Needle Valve (located on left-hand side of

carburettor).

(2) The Mixture Control Screw (located on right-hand side).

(3) The Throttle Rotor Set-Screw (angled at rear of body).

I. The Needle-Valve is used in the same way as on all model

engines, i.e., for adjusting the high-speed mixture strength.

Start the engine and, with the throttle fully open, gradually

close the Needle-Valve until it is running at its maximum

speed. Caution: Do not close Needle-Valve to too "lean" a

setting as this will cause the engine to overheat and slow up.

Page 2

Set

the Needle-Valve very slightly

to

the

"rich"

side

of the

peak r.p.m. setting. Make sure that the engine is fully

"broken-in" (about 1 hour of total running time in short runs)

before operating it continuously at full throttle.

II.

The Mixture Control Screw is for adjusting fuel mixture

strength at part-throttle and idling speeds. Having set the

Needle-Valve as detailed above, close the throttle. The engine

should idle continuously and steadily without further

adjustment.

(a) If, however, the engine begins to idle unevenly, open the

throttle.

If the engine then

hesitates

before picking up

to

full

speed, it is probable that the idling mixture is too rich. Check

this by closing the throttle again and letting the engine idle for

a little longer before again opening up. If the engine now puffs

out a good

deal

of smoke and

hesitates

or

even

stops,

it

will

be necessary to close the Mixture Control Screw. Do this by

turning it clockwise. About 5 ~ 10° turn should be sufficient.

(b) If instead of being set too rich, the Mixture Control

Screw is set too lean, the engine will stop when the throttle is

closed, or will lose speed while idling and then cut-out

abruptly (without smoking) when the throttle is opened again.

In this case, turn the Mixture Control Screw about 5 ~ 10°

turn counter-clockwise.

Mixture Control Screw adjustment is not critical and by

remembering the symptoms of rich and lean running quoted

above, it is a very simple matter to establish the best setting.

III. The Throttle Rotor Set-Screw

is for establishing the

minimum idling speed. If the engine runs too fast with the

throttle closed, the Rotor Set-Screw should be turned

counter-clockwise to allow the throttle opening to be reduced.

SUBSEQUENT OPERATION AND CARE

Once the required settings, have been established it should be

unnecessary to alter them. Such slight needle-valve alterations

as may be necessary to cope with differences in atmospheric

conditions or fuels, do not affect the other two adjustments.

The engine should start readily with the throttle in the idle

position.

It is important that the carburettor operates under clean

conditions. Make sure that fuel is properly filtered before use.

We advise fitting a filter to your fuel can and another filter in

the delivery tube between tank and engine, to reduce the risk

of the carburettor jet becoming partially clogged and upsetting

running adjustments.

If dust or dirt is stuck in the carburettor causing it not to function properly, dismantle and clean the carburettor in the following way:

(1) Loosen the lock-nut and take off the throttle rotor set

screw.

(2) Pull off the rotor from the carburettor body. Be careful

not to lose the rotor spring set in the depth of the rotor.

(3) Get the needle out of the needle valve.

(4) Screw out the nozzle-nut and push the nozzle out of the

carburettor body from the side where the rotor was set.

(5) Take off the fuel inlet.

(6) Clean the nozzle fuel inlet and carburettor body with the

clean kerosene or alcohol. After confirming no dust or

dirt is left inside of the nozzle, assemble the parts in the

opposite manner from that of dismantling.

(7) Fit the notch at the nozzle's largest diameter with the

notch inside of the carburettor body.

Description

Carburettor complete

R/C Needle valve assembly

Rotor stop set-screw assembly

Throttle lever

Rotor spring

Throttle lever fixing nut

Throttle fixing screw

Carburettor gasket

Mixture control screw

Fuel inlet

PARTS LIST

2B

Code No.

22681005

22681908

22681306

22681419

22481506

22481420

25081700

22615000

22481628

22681953

The specification is subject to alteration for improvement without notice.

2CA

Code No.

2248026

2268908

2268306

2268419

2248506

2248420

2508700

2261000

2248628

2268953

2CB

Code No.

22481035

22681908

22681306

22681419

22481506

22481420

25081700

22615000

22481628

22681953

2H

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL. Osaka (06) 702-0225

Code No.

22781000

45181919

22681306

22781400

22481506

22781420

25081700

22615000

22781600

22681953

38207

Loading...

Loading...