Page 1

INSTRUCTIONS FOR THE O.S. TYPE 9B CARBURETTOR

The O.S. Type 9B carburettor has been designed

to

provide a correctly balanced mixture of fuel and air at all throttle settings. It

ensures steady power and a smooth response — even to abrupt operation of the throttle. With the special O.S. mixture control

system featured by this carburettor, adjustment can be made easily and accurately.

INSTALLATION AND LINKAGE

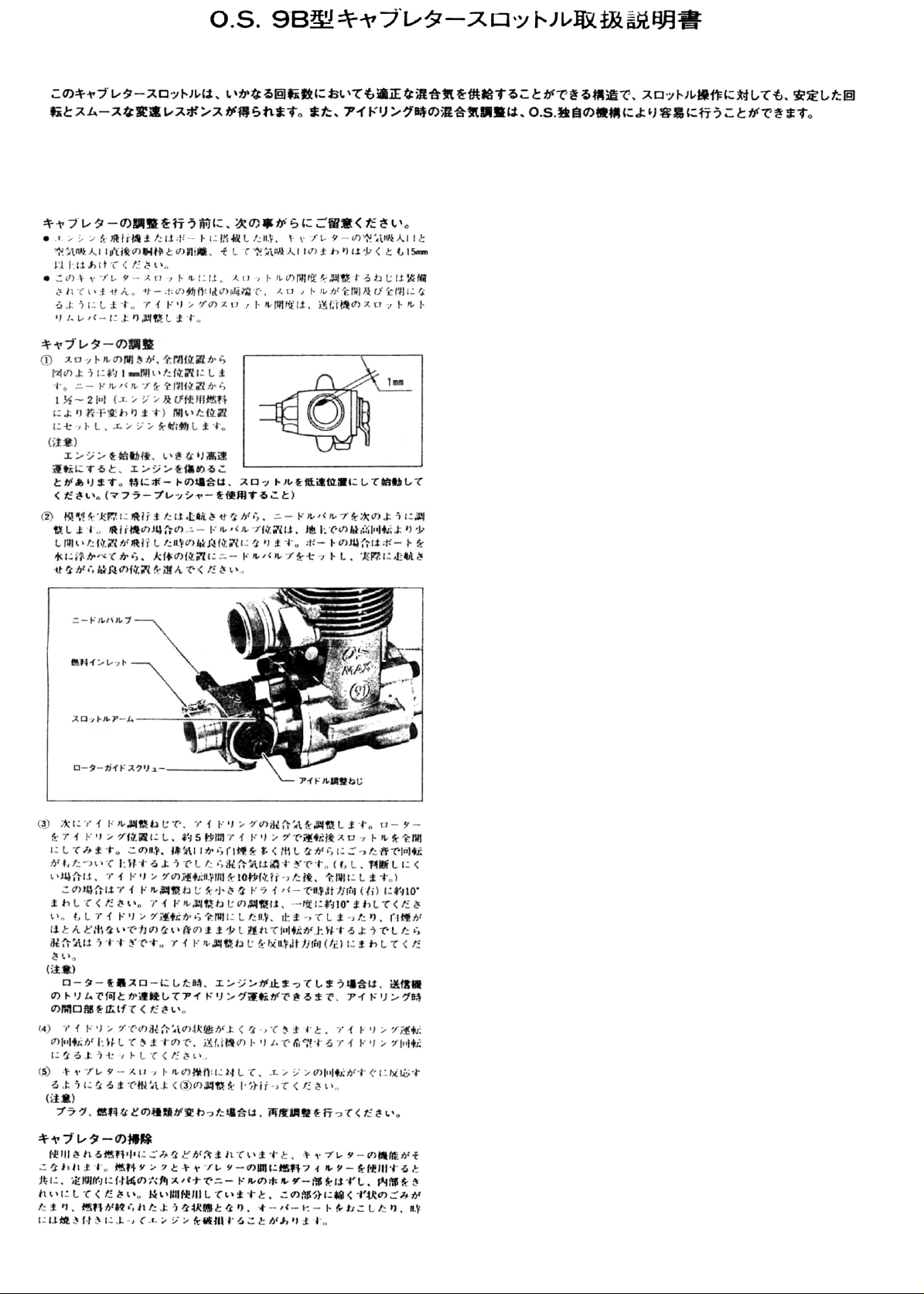

Needle Valve

Fuel inlet

Throttle Lever

Rotor Guide Screw

Mixture Control Screw

• Make sure, when the engine is installed in the aircraft or

that there is a clearance of at least 15mm between the carburettor

air intake and the firewall or adjacent bulkhead.

• This carburettor is not provided with a screw for setting the

throttle opening at the idling position. Instead, the throttle is

set up as follows:

Connect the throttle lever linkage so that the throttle rotor is (a)

fully open when the transmitter throttle stick is fully advanced

and (b) fully closed when the throttle stick is fully retarded.

Adjustment of the throttle rotor opening at the idling position

can then be made with the throttle trim lever on the transmitter.

ADJUSTING THE CARBURETTOR

1. Advance the throttle trim lever so that the throttle rotor opens

approximately 1 mm from the fully closed position as sketched.

Set the needle-valve 1-1/2 to 2 turns (depending on the size of the

engine and type of fuel) open from the fully closed position, and

start the engine.

Warning: When a watercooled marine engine is started on shore

2. In the case of a marine installation, put the boat on the water

3. The Mixture Control Screw is for adjusting fuel mixture strength

4. If. after carrying out mixture adjustments, the idling speed is

Note: Once the correct carburettor settings have been established, it

avoid running it at high r.p.m. without load. either by

keeping the throttle in the idling position, or by opening

the needle-valve to reduce speed. Although the engine is

designed to run at high r.p.m. even when new. such components as the cylinder, piston, connecting-rod, etc. will

be seriously damaged if they are allowed to become overheated.

before opening the throttle and then adjust the Needle-Valve for

the approximate best setting.

In the case of a ducted fan model, adjust the Needle-Valve in the

same way as for a normal propeller driven aircraft.

at part throttle and idling speeds. Having set the needle-valve as

detailed above, close the throttle. The engine should idle conti-

nuously and steadily. (If it stops immediately, first try advancing

the throttle trim lever on the transmitter to raise the idling speed

a little.)

(a) If, however, the engine idles unevenly and hesitates when the

throttle is re-opened, it is probable that the idling mixture is

too rich. Check this by closing the throttle again and reopening it after about 10 seconds. If the engine now puffs

out a good deal of smoke and hesitates or even stops, it will

be necessary to close the Mixture Control Screw. Therefore,

turn it a few degrees clockwise. (Turn the Mixture Control

Screw in steps of about 10 degrees only, re-checking the

running qualities each time.)

(b) If, instead of being set too rich, the Mixture Control Screw is

set too lean. the engine will stop when the throttle is closed,

or will lose speed while idling and then cut out abruptly

(without smoking) when the throttle is opened again. In this

case. turn the Mixture Control Screw counter-clockwise.

Mixture Control Screw adjustment is not critical and, by remembering the symptoms of rich and lean running quoted above.

it is a simple matter to establish the best setting.

The correct mixture for part-throttle (medium speed) running is

automatically controlled by the Mixture Control Screw when it

has been adjusted to the best idling setting.

found to be too high, the throttle trim lever should be moved

downward until the desired idling speed is achieved.

should be unnecessary to alter them. Such slight needle-valve

adjustments as may be required to cope with variations in

atmospheric conditions, will not normally affect the other

controls. A small readjustment may be required if the fuel

and/or plug are changed to different types.

boat,

SUBSEQUENT OPERATION AND CARE

It is important that the carburettor operates under perfectly clean

conditions. Make sure that fuel is properly filtered before use. We

also

advise

engine. Foreign matter in the fuel system can reduce the flow of

fuel, thereby weakening the mixture and risking damage to the

engine by overheating. Check filters at regular intervals and remove

any dirt or fibres. It is also advisable to check the cleanliness of the

fitting a filter

in

the

delivery tube between the tank and

Page 2

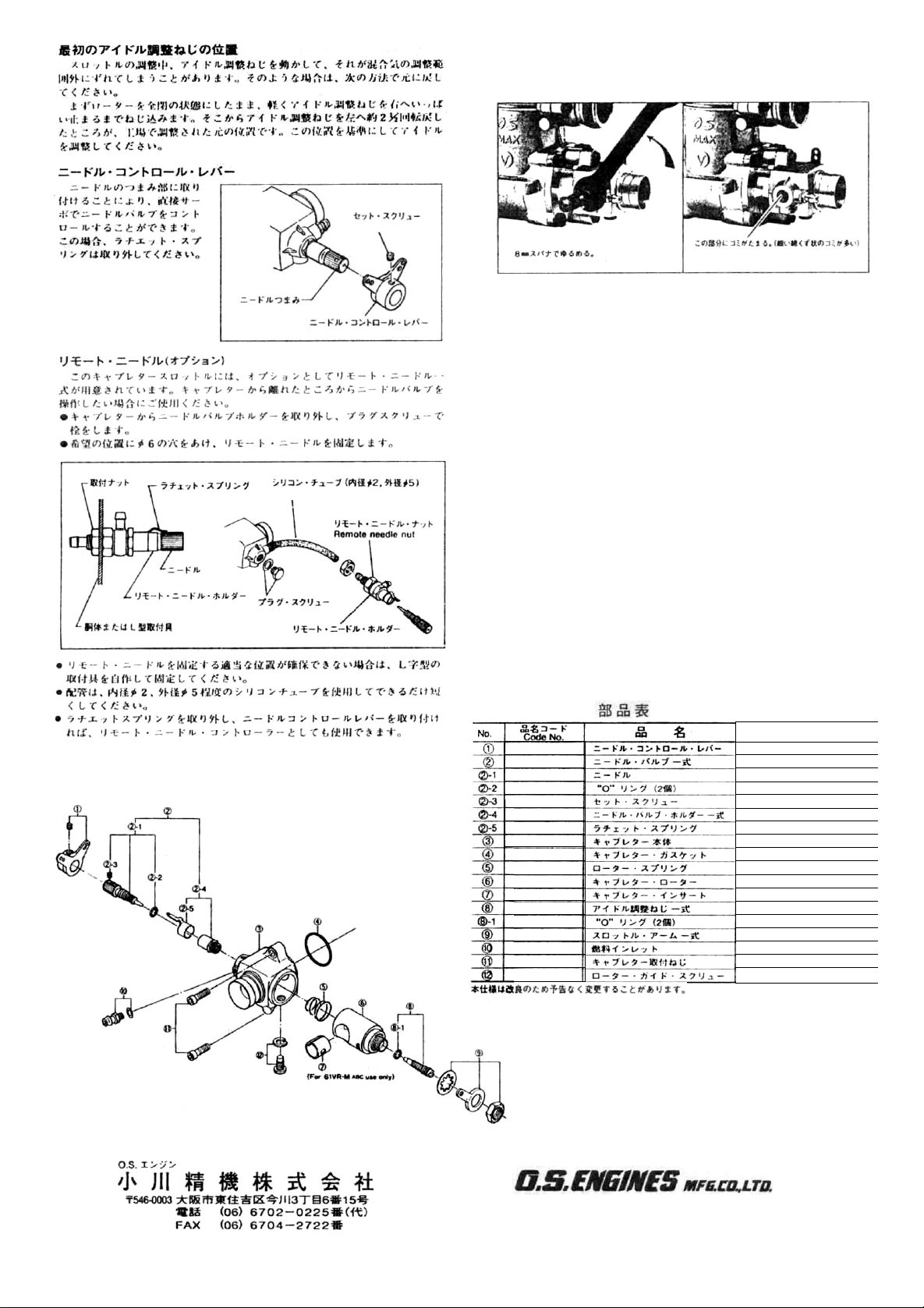

Set-screw

carburettor periodically. Using the wrench supplied, remove the

needle-valve holder from the carburettor body and wash out the

interior to remove any minute particles that may have escaped

through the filters.

Dirt and librous matter mostly

Remove this with an 8mm wrench

accumulate here

Fixing nut

Model or fitting plate

Ratchet spring

Remote needle holder

Needle

Needle knob

Silicone tubing

Plug screw

Needle-valve control lever

Remote needle holder

REALIGNMENT OF MIXTURE CONTROL SCREW

The Mixture Control Screw is factory set at the approximate best

position. If, however, the Mixture Control Screw has been

tampered with, or moved accidentally, set it at the original position

as follows. Screw in the Mixture Control Screw until it stops while

keeping the rotor fully closed. Then. unscrew 2-1/2 turns. This is the

original position of the Mixture Control Screw.

Needle Control Lever

By fitting the Needle Control Lever (supplied) to the needle knob,

the needle-valve can be adjusted by radio-control. Before fitting the

Lever, remove the needle ratchet spring.

Type 9B Remote-mounting Needle Valve Assembly

This is an optional extra part. It enables the Needle Valve to be

installed separately from the engine in a position where (especially

with a cowled or enclosed engine) it may be more accessible for

adjustment. (See sketch.) Install as follows:

• Remove the needle-valve holder from the carburettor and fit the

plug screw in its place.

• Drill a 6mm dia. hole in the required position on the model and

insert the Remote Needle Valve Assembly. If necessary, install a

suitable mounting plate in the model to which the Remote

Needle Valve Assembly may be fitted.

• For piping, use heavy-duty silicone tubing of at least 2mm bore

and 5mm outer diameter. Tube length should be kept as short as

possible.

• You may also use the Needle Control Lever in conjunction with

the Remote-mounting Needle Valve Assembly.

PARTS LIST

Description

28282300

28281900

28281970

24981837

26381501

27381940

26711305

28281110

29315000

28281500

28281200

28281210

28281300

27881820

28281400

22681953

24925202

28281600

The specifications are subject to alteration (or improvement without notice.

Needle Control Lever

Needle Valve Assembly

Needle

"0" Ring(2pcs.)

Set-Screw

Needle Valve Holder Assembly

Ratchet Spring

Carburettor Body

Carburettor Rubber Gasket

Rotor Spring

Carburettor Rotor

Carburettor Insert

Mixture Control Screw

"0" Ring(2pcs.)

Throttle Lever Assembly

Fuel Inlet

Carburettor Fixing Screw

Rotor Guide Screw

6-15 3-Chome Imagawa Higashisumiyoshi-ku

Osaka 546-0003. Japan TEL. (06)6702-0225

FAX (06)6704-2722

Loading...

Loading...