Page 1

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the vehicle, radio control equipment, etc.,

are accessible for checking at the same time.

CONTENTS

SAFETY INSTRUCTIONS AND

WARNINGS ABOUT YOUR O.S. ENGINE

INTRODUCTION, BASIC ENGINE PARTS

INSTALLATION OF THE ENNGINE

INSTALLATION OF THE CARBURETOR

AIR CLEANER TYPE201

NOTES CONCERNING THE RECOIL STARTER

GLOWPLUG

TOOLS, ACCESSORIES, etc.

CARBURETOR CONTROLS,

PRESSURIZED FUEL SYSTEM

STARTING THE ENGINE &

RUNNING-IN('Breaking-in)

2-5

7-8

9-12

12

13

13-14

15

15-18

IF THE ENGINE FAILS TO START

FINAL ADJUSTMENT

6

CARBURETOR CLEANLINESS

8

BEFORE STARTING THE ENGINE

CARE AND MAINTENANCE

GUARANTEE

O.S. GENUINE PARTS & ACCESSORIES

ENGINE EXPLODED VIEW

& ENGINE PARTS LIST

CARBURETOR EXPLODED VIEW

& PARTS LIST

THREE VIEW DRAWING

1

18

18-19

20

21

21-22

22

23

24-27

28-29

30

Page 2

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE

Remember that your engine is not a "toy", but a highly efficient internalcombustion machine whose power is capable of harming you, or others, if it is

misused.

As owner, you, alone, are responsible for the safe operation of your engine, so act

with discretion and care at all times.

If at some future date, your O.S. engine is acquired by another person, we would

respectfully request that these instructions are also passed on to its new owner.

The advice which follows applies basically to ALL MODEL ENGINES and is

grouped under two headings according to the degree of damage or danger

which might arise through misuse or neglect.

WARNINGS

!

These cover events which

might involve serious (in

extreme circumstances, even

fatal) injury.

!

•

Model engine fuel is poisonous. Do not allow it to

come into contact with the

eyes or mouth. Always store

it in a clearly marked container and out of the reach

of children.

Model engine fuel is also

•

highly flammable. Keep it

away from open flame,

excessive heat, sources of

sparks, or anything else

which might ignite it. Do not

smoke or allow anyone else

to smoke, near to it.

These cover the many other

possibilities, generally less obvious

sources of danger, but which, under

certain circumstances, may also

cause damage or injury.

2

WARNINGS

•

Never operate your engine in an enclosed space. Model engines, like

automobile engines, exhaust deadly

carbon-monoxide. Run your engine

only in an open area.

Model engines generate

•

considerable heat. Do not

touch any part of your

engine until it has cooled.

Contact with the muffler

(silencer), cylinder head

or exhaust header pipe, in

particular, may result in a

serious burn.

!

NOTES

3

Page 3

!

This engine is intended for model cars.

•

Do not attempt to use it for any other

purpose.

Mount the engine in your model

•

securely, following the manufacturers'

recommendations, using appropriate

screws and locknuts.

Fit an effective silencer (muffler).

•

Frequent close exposure to a noisy

exhaust (especially in the case of the

more powerful highspeed engines)

may eventually impair your hearing

and such noise is also likely to cause

annoyance to others over a wide area.

NOTES

•

The wearing of safety glasses is also

strongly recommended.

Take care that the glowplug clip or

•

battery leads do not come into contact

with rotating parts. Also check that the

linkage to the throttle arm is secure.

For their safety, keep all onlookers

•

(especially small children) well back

(at least 20 feet or 6 meters) when

preparing your model for running.

4

!

•

To stop the engine, fully retard the

throttle stick and trim lever on the

trans-mitter, or, in an emergency, cut

off the fuel supply by pinching the fuel

delivery tube from the tank.

Do not attempt to disassemble the

•

recoil starter.

If you do so, the very strong spring

inside will be suddenly ejected. This

can be very dangerous.

Do not extend the starter cord more

•

than 45cm (18"). Do not abruptly

release the operating handle. Allow

the cord to rewind smoothly while

still holding the handle.

NOTES

•

Pull the operating handle straight out

when starting the engine, so that the

cord does not rub against the vehicle

body or engine. This will help prevent

the cord from being damaged by

abrasion or engine heat.

•

Warning! Immediately after a glowplugignition engine has been run and is still

warm, conditions sometimes exist

whereby it is just possible for the engine

to abruptly restart if it is rotated over

compression WITHOUT the glowplug

battery being reconnected.

5

Page 4

The MAX-21RG Series has been developed for

1/8 scale off-road 'buggy' and scale cars.It

provides a combination of performance and

value that brings it within the reach of a larger

group of R/C model vehicle enthusiasts, from

newcomers to experienced competitors. All

major parts of the MAX-21RG have been

redesigned. Its potential is very close to that of

the top-ranking MAX-21RZ motors, but it

remains easy to operate and is considerably

less expensive. The MAX-21RG has a

conventional crankshaft, while the MAX21RG(P) employs a special crankshaft with

integral pilot shaft. The MAX-21RG-X and

MAX-21RG(P)-X have the addition of a built-in

O.S. recoil starting system. The starter unit

eliminates the need for a separate electric

starter and battery.

NOTE: With this engine, the piston will feel tight at

the top of its stroke when the engine is cold. This

is normal. The piston and cylinder are designed to

achieve a perfect running clearance when they

reach their normal running temperatures.

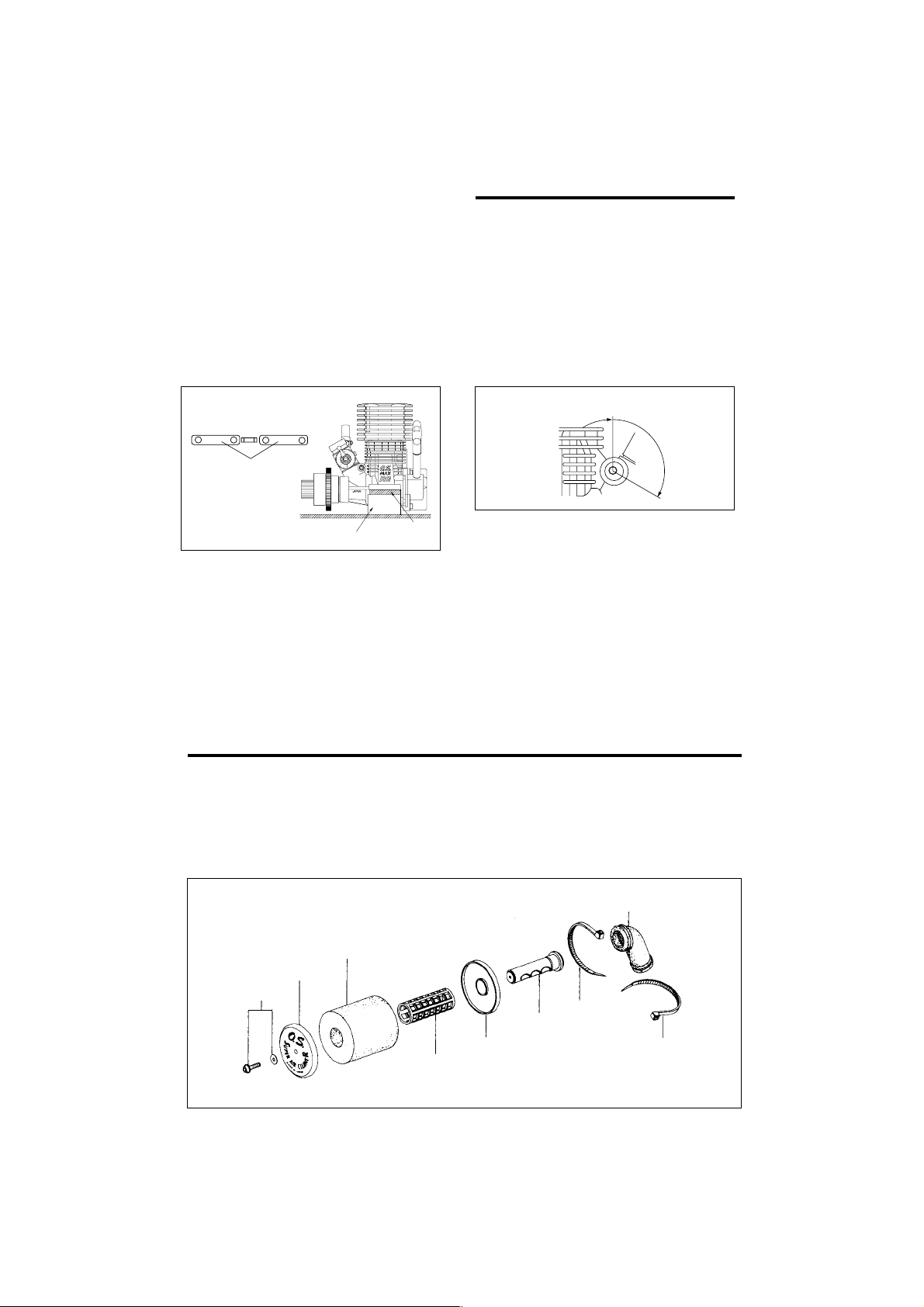

BASIC ENGINE PARTS

Carburetor

Beam Mount

Crankcase

Crankshaft

6

Heatsink Head

Starter Handle

Recoil Starter

Assembly No.5

MAX-

21RG-X

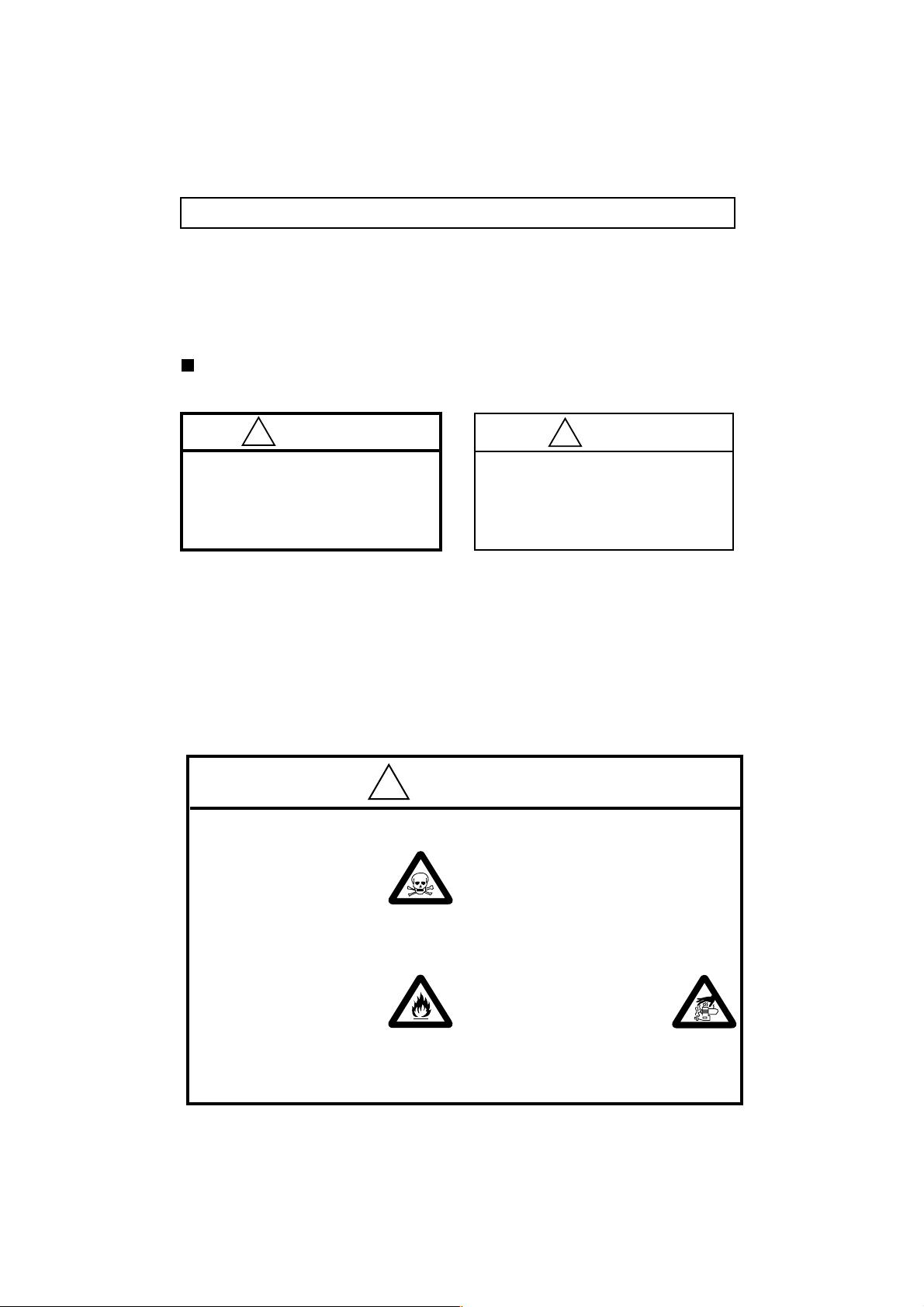

INSTALLING

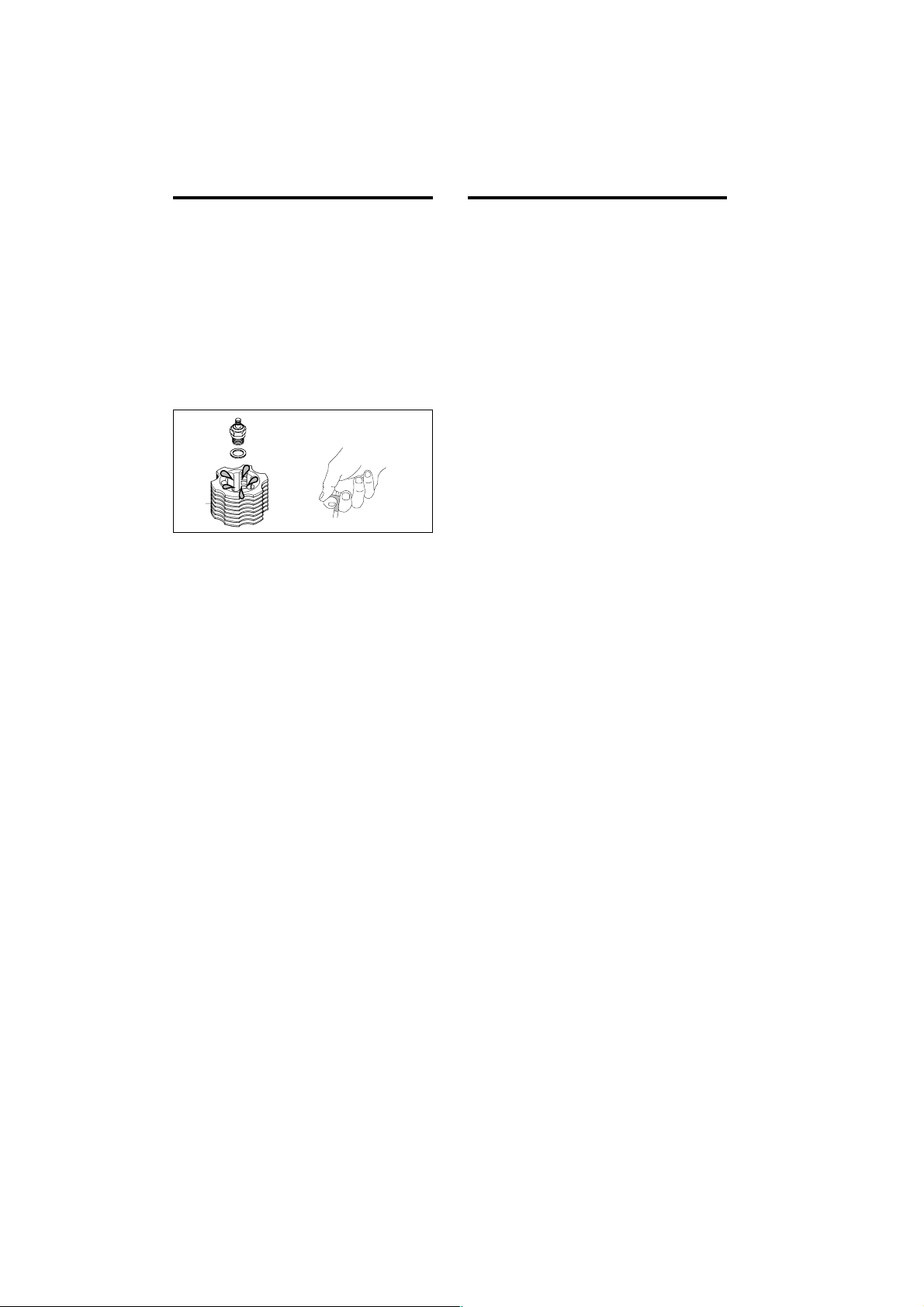

THE GLOWPLUG

Install the washer on the

glowplug and insert carefully into

cylinder-head, making sure that it

is not cross-threaded before

tightening firmly.

Glow plug

Washer

ENGINE INSTALLATION

Make sure that the vehicle's engine mounting surfaces

are level and in the same plane. Poor installation may

cause distortion of the crankcase, bearings, etc.,

resulting in erratic running and loss of performance.

The recommended screws for securing the engine are

3mm or 4-40 steel Allen hexagon socket type.

If existing holes in the engine mount do not align

perfectly with engine mounting lugs, enlarge them

slightly with a needle-file so that screws align with the

mounting holes.

Chassis

Chamfer inside edges of bearers.

Do not allow bottom

of crankcase to touch

chassis.

7

Page 5

Avoid forcing the screws. Secure with locknuts. If the

bottom of the recoil starter housing touches the car

chassis, install the engine mount spacers (supplied)

between the engine's mounting lugs and the engine

mount. Use the M3x15 screws provided. With some

vehicles, it may be necessary to make minor trimming

modifications to chassis or body when fitting the engine.

NOTE:

Where spacers are supplied joined in pairs (see

sketch) separate them as shown.

Either face may be placed downwards.

INSTALLATION OF THE CARBURETOR

As delivered, the engine has its carburetor lightly

fitted into its intake boss. Secure it as follows.

Loosen the retainer screw, rotate the carburetor to

1.

its correct position and make sure that it is pressed

well down into the intake boss, compressing the

rubber gasket, before retightening screw.

Rotate the retainer screw gently until it stops, then

2.

tighten a further 90-120˚.

Do not overtighten the screw as this will damage

the carburetor body.

Separate

←→

Rotate the retainer nut

gently until it stops.

Tighten a further 90-120˚

Mount Spacer

Engine Mount

Engine Mount

Spacer

8

AIR CLEANER TYPE 201

This is a heavy-duty wet type air cleaner that has been developed specifically for 3.5cc 'off-road' model car

engines. It contains a specially impregnated filter element which more positively prevents highly damaging dust and

dirt from being drawn through the carburettor, yet allows engine performance to be maintained for longer periods

between element renewals. It is more compact than the standard O.S. HD Air Cleaner and this makes it easier to

install within a car body. This air cleaner is also supplied with a newly designed intake elbow that provides more

secure attachment to the caburetor.

Assembly Screw

End Plate

Filter Element

Center Screen

Element Base

9

Intake Elbow

Strap

Center T ube

Strap

Page 6

ASSEMBLY

Slide the element base over the center tube (See

1.

Fig.1) and press down.

If it is tight at the bottom, apply one or two drops of

・

fuel at the point marked in Fig.2

Press down near to the center (not the outside) to

・

avoid risk of breaking the element base.

Apply pressure until the element base fits firmly

・

against the collar of the center tube (Fig.3).

Element Base

Center T ube

Fig.1

2. Installing the element.

The element is already impregnated with a special

・

filter oil. As this oil is very sticky, take care, when

handling it, to prevent dust or dirt adhering to the

element, especially to its inner surface before

insertion of the center screen.

Press at center.

Apply one or two

drops of fuel.

Fig.2

Press down

firmly.

Fig.3

If your fingers become contaminated, wash them with

soap and water.

NOTE: During storage, the oil may have become

unevenly dispersed through the element. This will

be indicated if the blue color of the element

material appears patchy.

In this case, place the element in a small plastic

bag and gently rub the element between finger

and thumb to redistribute the oil.

Now insert the cylindrical center screen into the

・

element, followed by the center tube.

Do not, at anytime, omit the screen: it is essential for

releasing air to the engine evenly.

Fit the end plate, washer and retaining screw,

・

making sure that the element fits correctly between

the end plate and base.

Element

misaligned

10

INSTALLATION

Apply instant setting

1.

glue to the joint between the air cleaner

and the intake elbow

and secure with strap

supplied.

Fit the other end of

2.

Apply instant fixing glue.

Washer

Assembly

Do not apply

glue to

carburettor

Screw

Strut

the elbow over the carburettor intake and secure with

strap supplied. Do not use glue at this point.

It is advisable to brace the outer end of the air

3.

cleaner to the car chassis with a piano wire strut.

This will restrain the cleaner in the event of the

vehicle overturning or being involved in a collision.

REPLACEMENT OF ELEMENT

Under very dusty conditions, it is advisable to

1.

replace the filter element after each hour of running

time.

2.

Under less severe conditions, however, it may be

possible to operate for longer periods. The rate at

which the elements become unusable may be

determined as follows.

After one hour of running time, remove the element

・

but, before discarding it, check the penetration of

foreign matter by cutting through the wall of the

element. If dirt has

penetrated 1/3rd or more from the

outer surface, each element must always be

replaced within one hour, when the vehicle is run

under similar conditions. If, on the other hand, the

element is much less deeply soiled, the engine may

be run a little longer before another new element is

installed, but remember to check the condition of the

discarded element, as before. If the old element is

examined in this way

every time a new element

is fitted, one can more

closely estimate the safe

life of the element under

known running conditions.

・

Remember that the condition of the filter element will

depend on weather, as well as track conditions. If, for

example, the element surface is still visible and

remains moist, further running is permissible.

If, however, the surface is no longer visible, or if dust

・

adhering to the surface has become dry, it is time to

replace the element.

11

1

3

Page 7

FURTHER PRECAUTIONS

When removing the air cleaner, check the inside of the

center tube and carburetor venturi. If any dirt is detected,

this indicates that the filter element was incorrectly

installed or should have been replaced earlier.In this

event, it is vitally important to wash out the inside of the

engine thoroughly, with alcohol or fuel,before it is used

again, otherwise rapid wear of the piston,

cylinder,bearings, connecting-rod, etc., will occur.

Obviously, it will be necessary to carry out the same

procedure with the air cleaner and to replace the filter

element.

NOTE: Be careful not to splash alcohol or fuel

over the filter element, or the filter oil will be

diluted, and the filter capacity lowered.

NOTES CONCERNING THE RECOIL STARTER

REMINDER!

Do not attempt to disassemble the recoil starter.

◆

If you do so, the very strong spring inside will be

suddenly ejected. This can be very dangerous.

Do not extend the starter cord more than

◆

45cm(18"). Do not abruptly release the operating

handle. Allow the cord to rewind smoothly while

still holding the handle.

Pull the operating handle straight out when

◆

starting the engine, so that the cord does not

rub against the vehicle body or engine.

This will help prevent the cord from being

◆

damaged by abrasion or engine heat.

Try to avoid spilling fuel over the starter unit and

◆

its cord. Some fuels have a detrimental effect on

these parts.

The starter prevents the engine from being ro-

◆

tated in the wrong direction.The unit will be

damaged if you attempt to force the flywheel in

the opposite direction (i.e. clockwise when

viewed from the crankshaft end).

NOTE:

Because, in the interests of personal safety,

dismantling of the starter mechanism is strongly

discouraged, the Recoil Starter is available for

replacement only as a pre-assembled unit.

However, some related parts, such as Starting

Shaft and Rear Adaptor, are obtainable separately.

(See Parts List.)

12

GLOWPLUG

Since the glowplug and fuel combination used may

have a marked effect on performance and reliability, it

would be worthwhile to experiment with different plug

types. An O .S. N o.8 gl owplug is supplied with the

engine. Other Recommended O.S. plugs are A3 and

A5. Carefully install plug finger-tight, before final tightening with the correct size plug wrench.

The role of the glowplug

With a glowplug engine, ignition is initiated by the

application of a 1.5-volt power source. When the

battery is disconnected, the heat retained within the

combustion chamber remains sufficient to keep the

plug filament glowing, thereby continuing to keep the

engine running. Ignition timing is 'automatic' : under

reduced load, allowing higher rpm, the plug becomes

hotter and, appropriately, fires the fuel/air charge

earlier; conversely, at reduced rpm, the plug become

cooler and ignition is retarded.

Glowplug life

Particularly in the case of very high performance

engines,

glowplugs must be regarded as expendable

items. However, plug life can be extended and engine

performance maintained by careful use, i.e.:

Install a plug suitable for the engine.

•

Use fuel containing a moderate percentage of

•

nitromethane unless more is essential for racing

events.

Do not run the engine too lean and do not leave the

•

battery connected while adjusting the needle.

When to replace the glowplug

Apart from when actually burned out, a plug may

need to be replaced because it no longer delivers its

best performance, such as when:

Filament surface has roughened and turned white.

•

Filament coil has become distorted.

•

Foreign matter has adhered to filament or plug

•

body has corroded.

Engine tends to cut out when idling.

•

Starting qualities deteriorate.

TOOLS, ACCESSORIES, etc.

The following items are necessary for operating the

engine.

FUEL

Generally, it is suggested that the user selects a fuel that

is commercially available for model two-stroke eengines

13

Page 8

and contains between 10% and 30% nitromethane. As

a starting point, we recommend a fuel containing 10%

nitromethane, changing to a fuel containing more nitro

if necessary. When the brand of fuel is changed, or the

nitro content increased, it is advisable to repeat the

running-in procedure referred to in the RUNNING-IN

paragraphs. For consistent performance and long

engine life, it is essential to use a good quality fuel

containing NOT LESS THAN 18% lubricant. Please

note that with high-nitro fuels, although power may be

increased for competition purposes, glowplug elements

do not last so long and engine life will be shortened.

Reminder!

Model engine fuel is poisonous. Do not

allow it to come into contact with the eyes or

!

mouth. Always store it in a clearly marked

container and out of the reach of children.

Model engine fuel is also highly flammable.

Keep it away from open flame, excessive heat,

!

sources of sparks, or anything else which

might ignite it.

GLOWPLUG BATTERY

The power source for heating the glowplug ma y be either

a large heavy-duty 1.5V olt dry cell, or a 2-Volt rechargeab le

lead-acid cell with extended leads (or a resistance) to

reduce the applied voltage to approximately 1.5-V.

BATTERY LEADS

These are used to conduct current from the battery to

the glowplug. For convenience,special leads with a

suitable clip to fit the glowplug terminal, are

commercially available.

LONG SOCKET WRENCH

Recommended for easy removal and

replacement of the angled and recessed

glowplug, the O.S.Long Socket Wrench

incorporates a special grip.

FUEL BOTTLE OR PUMP

For filling the fuel tank, a simple, polyethylene

"squeeze" bottle, with a suitable spout, is required.

ELECTRIC STARTER AND STARTER BATTERY

Use an electric starter with 12-volt

battery for starting the MAX21RG/RG(P).

SILICONE FUEL LINE

Heatproof silicone fuel line of approx. 5mm

o.d. and 2mm bore is required for the piping

between the fuel tank and engine.

14

CARBURETOR CONTROLS

Three adjustable controls are provided on this

carburetor.

・

The Needle-Valve:

For adjusting the mixture strength when the throttle

is fully open.

・

The Mixture Control Screw:

For adjusting the mixture strength at part-throttle

and idling speeds, to obtain steady idling and

smooth acceleration to mid speeds.

The Throttle Stop Screw:

・

For setting the minimum idling speed:

Ball Link

Slide Valve

Guide Screw

NOTE: Readjustment may be necessary,

occasionally to allow for changes in fuel formula,

gear ratio or clutch engagement point.

Needle Valve

Mixture Control Valve

Assembly Screw

Throttle Stop Screw

PRESSURIZED FUEL SYSTEM

The somewhat violent changes of vehicle attitude

•

that occur in off-road running, combined with the

fact that, in buggy type cars, the fuel tank is often

located some way from the carburetor, means that

fuel 'head' at the carburetor can vary a and upset

running.Therefore,it is recommended that a muffler

pressurized fuel feed system be used.

Never run your vehicle without installing the air

•

cleaner. Dust and dirt that may otherwise be drawn

into the engine will rapidly shorten its life.

Connect suitable length of

Fuel Tank

15

Silicone fuel line between fuel

tank and silencer.

Silicone fuel line

Silencer

Page 9

STARTING THE ENGINE & RUNNING-IN ('Breaking-in')

For long life and high performance, every engine needs

to be properly 'run-in' or 'broken-in'. The running-in

procedure for this engine can be carried out with the

engine installed in the model. Be sure to use a muffler

pressurized fuel system. The running-in procedure is

as follows.

Use the same fuel as is to be employed for all initial

•

running and containing NOT LESS THAN 18%

lubricant.

Temporarily remove the glowplug to check that it

•

glows bright red when energized.

Re-check the needle-valve and

•

throttle settings. Turn the needlevalve clockwise slowly and gently

until it stops. This is the fully closed

position.Do not use force to turn the

needle-valve beyond this point.

Open the Needle-Valve 3 turns

•

from the fully closed position.

Switch on the transmitter and receiver

•

and set the throttle very slightly

opened from the idling position.

Close

Open

0.3〜0.5mm

Needle Valve

DO NOT energize glowplug,

•

but apply electric starter to

draw fuel to carburetor.

Now connect glowplug battery

•

lead to heat the plug filament

and start the engine.

In case of the 21RG-X and

■

21RG(P)-X

Push the choke button on

•

the fuel tank several times to

deliver the fuel to the

carburetor. (Do not overprime or the recoil starter

cannot be pulled.)

Pull the starter handle

•

briskly straight out several

times to start the engine.

16

Glowplug

Starting battery

Front

Rear

Starter Handle

Rotating

Direction

Remember!

It is vitally important to set the

throttle at the correct position

before attempting to start the

engine.If the engine is

allowed to run with the

throttle too far open under

"no load" conditions, it will

rapidly overheat and may be seriously damaged.

When the engine starts, first allow it to operate in short

•

runs on its very rich starting settings, with the glowplug

battery still connected and with its driving wheels clear

of the ground.The rich mixture will, under these

conditions, provide adequate lubrication and cooling,

indicated by profuse smoke from the exhaust.

Next, disconnect the glowplug battery and try

•

running the car on the track. If the engine stalls, open

the throttle fractionally, but try to keep the engine

running as rich as possible: if it stops because of

being excessively over-rich, close the Needle-Valve

30˚ and try again.

Run the car on the track until one tank of fuel has been

•

consumed, then close the Needle-Valve 30˚ and run

the car for another full tank of fuel.

Repeat this procedure until 5 more tanks of fuel have

been consumed, during which time the throttle may

be opened for brief bursts of increased power. If the

engine stops at medium speeds, close the Mixture

Screw 30˚.

Needle

To stop the engine, close the throttle to idling speed,

•

then shut it off completely with the trim lever on the

transmitter. To cut off the fuel supply, pinch the fuel

delivery tube to the carburetor.

Remember!

If the engine should need to be disassembled (e.g.

for cleaning or minor parts replacement) it is

advisable to return the Needle-Valve to the original

rich, starting setting and check whether further

running-in time is required before the car is raced

again. In the event of any major working parts (e,g,

piston/cylinder liner assembly) being replaced, the

complete running-in should be repeated.

The position of the needle-valve

30º

when starting the engine.

30º

Close the needle-valve approx.

30º

30˚ after running the vehicle for

one full tank of fuel.

Repeat this procedure several

times.

17

Page 10

IF THE ENGINE FAILS TO START

Check the following:

Glowplug battery discharged or glowplug defunct.

•

Fuel not reaching carburetor.

•

Engine flooded. Do not over-prime. (This could also

•

cause hydraulic lock and damage the engine on

application of the electric starter.)

Remove glowplug, close needle-valve and apply

starter to pump out surplus fuel. At this time cover

the plug hole with a rag so that fuel will not splash

into your eyes or mouth.

In case of the 21RG-X and

21RG(P)-X

FINAL ADJUSTMENT

Run the vehicle (with throttle fully open) over the

•

longest available straight course, in order to observe

the model's speed. Next return the car to the starting

point, close the Needle-Valve 30˚ and repeat the

run, taking note of the improvement in performance.

Continue with further runs, gradually reducing the

Needle-Valve setting and aiming to achieve the

highest straight-line speed. Remember, however,

that, if the Needle-Valve is shut down too far, the

engine will overheat and, accompanied by visibly

diminished exhaust smoke, the model will lose

speed. At this point, throttle down immediately, stop

the vehicle and reopen the Needle-Valve 30˚.

Having established the optimum Needle-Valve

•

setting, check the Mixture Control Valve setting as

follows.

With the engine running, close the throttle and allow

•

it to idle for about five seconds, then reopen the

throttle fully. If, at this point, the engine puffs out an

excessive amount of smoke and the vehicle does

not accelerate smoothly and rapidly, it is probable

that the idling mixture is too rich.

18

In this case, turn the Mixture Control Valve

•

clockwise 30˚. If, on the other hand, the engine

tends to speed up momentarily and then cut out

abruptly when the throttle is opened,the idling

mixture is too lean. Correct this by turning the

Mixture Control Valve counter-clockwise 30~45˚.

NOTE:

Mixture Control Valve adjustment should be made

in steps of not more than 30~45˚, carefully

checking the effect,on throttle response, of each

small adjustment.

Carry out adjustments patiently, under actual

•

running conditions, until the engine responds

quickly and positively to the throttle control.

Warning!

Mixture adjustments (whether via the Mixture

Control Valve, or the Needle-Valve) cannot be

made accurately under 'no-load' conditions,

which, in any case, are not advised, since such

operation carries the risk of seriously damaging

the engine through over-revving and overheating.

With the optimum mixture control position, light

•

smoke is visible during high speed running,and the

engine revolutions increase smoothly during

acceleration. Remember that, if the engine is

operated with the fuel/air mixture slightly too lean, it

will overheat and run unevenly. As with all engines,

it is advisable to set both needle-valve and mixture

control screw very slightly on the rich side of the best

rpm setting, as a safety measure.

If the engine runs too fast with the throttle closed,

•

the throttle stop screw should be turned counterclockwise to allow the throttle opening to be

reduced.

Finally, beyond the nominal break-in period, a slight

•

readjustment toward a leaner needle setting may be

required to maintain performance.

19

Page 11

CARBURETOR CLEANLINESS

The correct functioning of the carburetor depends on

its small fuel orifices remaining clear.

(See Care and Maintenance section on Page21.)

■

BALL LINK AND SLIDE VALVE EXTENSION

When readjusting the position of the Ball Link, always

apply a 6mm spanner (wrench) to the flats in the

Slide Valve Extension, before attempting to loosen or

tighten the ball link retaining screw. Carefully ease

back the Dust Cover bellows to allow access to the

flats. If it should become necessary (e.g. for cleaning)

to disassemble the throttle parts, first unscrew the

Slide Valve guide screw and withdraw the complete

sub-assembly from the carburettor body. Use the

correct size (8mm) wrench when unscrewing the

Slide Valve from the Slide Valve Extension.

'Flats' for spanners

■

REALIGNMENT OF MIXTURE CONTROL VALVE

In the course of making carburetor adjustments, it is

just possible that the Mixture Control Valve may be

inadvertently screwed in or out too far and thereby

moved beyond its effective adjustment range.Its basic

position can be found by first rotating the Mixture

Control Valve until its slotted head is flush with the

carburettor body. The valve is then screwed in exactly

1 turn to re-establish its neutral position.

First rotate the Mixture Control

Valve until its slotted head is

flush with the carburetorbody.

Then screw the valve in exactly

1 turn.

This is the standard position.

Mixture Control Valve

Carburetor Body

Slide Valve

Slide Valve Extension

BEFORE STARTING THE ENGINE

Before starting the engine for the first run of the day,

1.

remove the glowplug and check the engine by

rotating the flywheel by hand. It should rotate

smoothly. Now turn the engine with an electric

starter until fuel is drawn into the carburetor. At first,

rotation may feel 'sticky' due to oily residue

remaining within the engine. The engine should

rotate freely after fresh fuel has been drawn into the

working parts.

Check the glowplug. If the plug element is distorted,

2.

off-center, or has a white appearance, engine

performance may be below par. With racing type

engines, glowplugs have to be regarded as

consumable items. Therefore, replace the plug if

necessary.

3.Re-install the glowplug and start the engine.

4.

When re-starting the engine, turn the flywheel by

hand, as before (but without removing the glowplug) to make sure that there is nothing unusual,

before energising the glowplug and applying the

starter.

20

Warning!

Do not attempt to turn the engine with the starter

if the engine is over-primed (flooded) with fuel.

To do so is likely to seriously damage the engine.

CARE AND MAINTENANCE

1.

The minute particles of foreign matter, that are

present in any fuel may, by accumulating and

partially obstructing fuel flow, cause engine

performance to become erratic and unreliable.

O.S. 'Super-Filters' (large and small) are available,

as optional extras, to deal with this problem.

One of these filters, installed the outlet tube inside

your refueling container, will prevent the entry of

foreign material into the fuel tank. It is also

recommended that a good in-line filter be installed

between the tank and carburetor.

Do not forget to clean the filters regularly to remove

2.

dirt and lint that accumulate on the filter screens.

Also, clean the carburetor itself occasionally.

At the end of each operating session, drain out any

3.

fuel that may remain in the fuel tank.

Afterwards,energize the glow-plug and try to restart

the engine, to burn off any fuel that may remain

21

Page 12

inside the engine. Repeat this procedure until the

engine fails to fire. Do this while the engine is still

warm.

Then, inject some after-run oil into the engine, and

4.

rotate the engine with an electric starter for 4 to 5

seconds to distribute the oil to all the working

parts.

Note:

Do not inject after-run oil into the carburetor as

this may cause the O-rings inside the carburetor

to deteriorate. These procedures will reduce the

risks of starting difficulties or corrosion after a

period of storage.

Finally, when cleaning the exterior of the engine,

5.

use methanol or kerosene. Do not use gasoline or

any solvent that might damage the silicone fuel

tubing.

Caution:

The rear crankshaft bearing of this engine uses a

special plastic retainer. If the front housing needs

to be heated to remove or replace the bearing, do

not allow the bearing to exceed 120˚C (248˚F),

otherwise it may be damaged and rendered

unserviceable.

GUARANTEE

This engine is constructed from the very best

materials available and to the very highest

engineering standards, using the most advanced

precision machinery. However, the extremely high

stresses imposed by car racing operation under very

severe conditions, stresses which are exacerbated by

the use of powerful fuels containing very high

concentrations of nitromethane, constitute hazards

which are beyond a manufacturer's control.

Accordingly, we regret that it is not possible to extend

our usual warranty terms to this particular engine -i.e.

no guarantee is offered against material wear, or

damage resulting therefrom, in actual use.

22

RACING ENGINE PARTS

Drive Hub

■

(23908000)

Glow Plug

■

No.8

(71608001)

Super Joint Tube 21

■

(72106300)

A5

(71605100)

■

■

O.S. GENUINE PARTS & ACCESSORIES

T-2030Tuned Silencer

(72106030)

Crankshaft Clamp

1521

(71530200)

■

Long Socket Wrench

With Plug Grip

(71521000)

23

Exhaust Header Pipe For

■

21RG-X

(72103510)

Cap Screw Set

■

(10pcs. set)

M2.6x7

M2.6x15

M2.6x18

(79871020)

(79871050)

(79871055)

Page 13

21RG, 21RG(P) ENGINE EXPLODED VIEW

C.M2.6x15

24

1

2

6

4

C.M2.6x18

7

8

3

5

9

13

10

4

11

C.M3x8

12

12-A

C.M2.6x7

14

21RG, 21RG(P) ENGINE PARTS LIST

No.

Code No.

1

23604010

2

23603000

3

23906000

4

23817000

5

23605000

6

15

25

7

8

9

10

11

12

12-A

13

14

15

23618001

23981700

41614000

23601000

23626100

22830000

23602000

23602010

23614000

23607000

22447005

72411000

72411020

72411050

72411010

72411040

72411030

71608001

The specifications are subject to alteration for improvement without notice.

Heatsink Head

Cylinder & Piston Assembly

Piston Pin

Piston Pin Retainer (2pcs.)

Connecting Rod

Carburetor Complete (Type 20E)

Carburetor Retainer (with screw)

Crankshaft Ball Bearing (Front)

Crankcase

Exhaust Adaptor (No.5)

Crankshaft Ball Bearing (Rear)

Crankshaft (For 21RG)

Crankshaft (For 21RG(P))

Gasket Set

Cover Plate

Screw Set

Super Air Cleaner 201 (W/two filter elements)

201 Filter Elements (4pcs.)

Element Plate Set Comprising:

Center Screen

Intake Elbow

Center Tube

Glow Plug No.8

Description

Type of screw

C...Cap Screw M...Oval Fillister-Head Screw

F...Flat Head Screw N...Round Head Screw S...Set Screw

Page 14

21RG-X, 21RG(P)-X ENGINE EXPLODED VIEW

21RG-X, 21RG(P)-X ENGINE PARTS LIST

C.M2.6x15

1

7

6

4

C.M2.6x18

9

8

13

26

15

Type of screw

C...Cap Screw M...Oval Fillister-Head Screw

F...Flat Head Screw N...Round Head Screw S...Set Screw

5

2

3

4

10

C.M2.6x7

14

No.

Code No.

1

23604010

2

23603000

3

23906000

4

23817000

5

23605000

6

23618001

7

12

27

M.+M2.6x7

11

11-A

8

9

10

11

11-A

12

13

14

15

16

16-1

16-2

23981700

41614000

23601000

22830000

23602030

23602020

23614000

23602050

23601800

22447005

73003000

73003100

73003200

72404110

72411000

72411020

16-2

16-1

16

72411050

72411010

72411040

72411030

71608001

The specifications are subject to alteration for improvement without notice.

Heatsink Head

Cylinder & Piston Assembly

Piston Pin

Piston Pin Retainer (2pcs.)

Connecting Rod

Carburetor Complete (Type 20E)

Carburetor Retainer (with screw)

Crankshaft Ball Bearing (Front)

Crankcase

Crankshaft Ball Bearing (Rear)

Crankshaft (For 21RG-X)

Crankshaft (For 21RG(P)-X)

Gasket Set

Starting Shaft

Rear Adaptor

Screw Set

No.5 Recoil Starter Assembly

No.5 Recoil Starter Body

No.5 Oneway Clutch

Mount Spacer

Super Air Cleaner 201 (W/two filter elements)

201 Filter Elements (4pcs.)

Element Plate Set Comprising:

Center Screen

Intake Elbow

Center Tube

Glow Plug No.8

Description

Page 15

CARBURETOR EXPLODED VIEW

3-2

3-1

3

2

1-1

1-2

1

Type of screw

C...Cap Screw M...Oval Fillister-Head Screw

F...Flat Head Screw N...Round Head Screw S...Set Screw

3-3

3-4

4

5

6

11

7

8

9

10

C.M2.6x7

28

CARBURETOR PARTS LIST

No.

Code No.

23818180

1

46066319

1-1

22781800

1-2

23818500

2

23618190

3

23618197

3-1

46066319

3-2

23618194

3-3

23818176

3-4

23618102

4

45581820

5

23818251

6

23818310

7

23818220

8

22884220

9

23818400

10

29015019

11

The specifications are subject to alteration for improvement without notice.

Mixture Control Valve Assembly

Description

"O" Ring(L) (2pcs.)

"O" Ring(S) (2pcs.)

Throttle Stop Screw

Needle Valve Assembly

Needle Assembly

"O" Ring

Needle Holder Assembly

Universal Nipple No.9

Carburetor Body

Slide Valve Guide Screw

Slide Valve

Metering Needle Assembly

Slide Valve Extension

Dust Cover

Ball Link No.1

Carburetor Rubber Gasket

29

Page 16

THREE VIEW DRA WING

Displacement

Bore

Stroke

Practical R.P.M.

Power output

Weight

SPECIFICATIONS

3.46 cc / 0.211 cu. in

16.6 mm / 0.654 in

16.0 mm / 0.630 in

3,000-35,000 r.p.m.

1.9 ps / 30,000 r.p.m.

325g / 11.47 oz.(RG,RG(P))

397.5g / 14.03 oz.(RG-X,RG(P)-X)

29.6

45

UNF1/4-28

30

44

84 (65.6)

Dimensions(mm)

33.5

21

37

10.5

4- 3.3

54

80.7

95.8

40

( ) -RG/RG(P)

E

R

C

P

I

S

I

Y

O

T

I

L

A

U

Q

D

E

L

L

A

U

Q

E

N

U

E

S

T

A

B

L

I

S

H

I

N

G

T

H

E

S

S

T

D

A

R

N

A

D

C

Copyright 2000 by O.S.Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan.

N

&

P

E

R

F

O

R

M

A

N

C

E

E

C

N

E

L

L

E

C

X

E

F

O

6-15 3-Chome Imagawa Higashisumiyoshi-ku

Osaka 546-0003, Japan

URL : http://www.os-engines.co.jp

TEL.(06) 6702-0225

FAX. (06) 6704-2722

60091020 050403

Loading...

Loading...