Page 1

INSTRUCTIONS FOR O.S. TYPE 20C AUTOMATIC CARBURETTOR

This carburettor, as fitted to the new O.S. MAX-32SX-H helicopter engine, incorporates an automatic

mixture control device which ensures that the engine receives a correctly balanced mixture of fuel and air

at all throttle settings. It ensures steady revolutions and a smooth response for reliable helicopter ascent

and descent.

Two adjustable controls are provided on this carburettor.

• The Needle Valve:

When set to produce maximum power at full throttle,

this establishes the basic fuel/air mixture strength. This

is then maintained by the carburettor's automatic mixture control system to cover the engine's requirements

at reduced throttle settings.

• The Mixture Control Valve (Mixture Control Screw):

For adjusting the mixture strength at part-throttle and

idling speeds, to obtain steady idling and smooth acceleration to medium speeds. The Mixture Control Valve has

been factory set for the approximate best result. First,

run the engine as received, and re-adjust the Mixture

Control Valve only when necessary.

A PROVISIONAL SETTING

• Open the Needle Valve 1-1/2 turns from the fully closed

position.

• Be sure to use a muffler-pressurized fuel feed.

Note: This carburettor is not fitted with a throttle stop screw.

Instead, idling speed is adjusted by means of the throttle

trim lever on the transmitter. This enables the full r.p.m.

range, from idling to full power, to be controlled by the

throttle stick, and then allows the engine to be stopped, from

the transmitter, by closing the throttle completely with the

trim lever. Set up the throttle linkage as follows:

With the transmitter throttle trim lever fully retarded, adjust

the throttle servo linkage so that the throttle rotor is (a) fully

open when the transmitter throttle stick is fully advanced

and (b) fully closed (i.e. engine stopped) when the stick is

fully retarded.

The idling speed is then set by advancing the throttle trim

lever to the point where the engine runs, steadily and reliably,

at the desired idling speed.

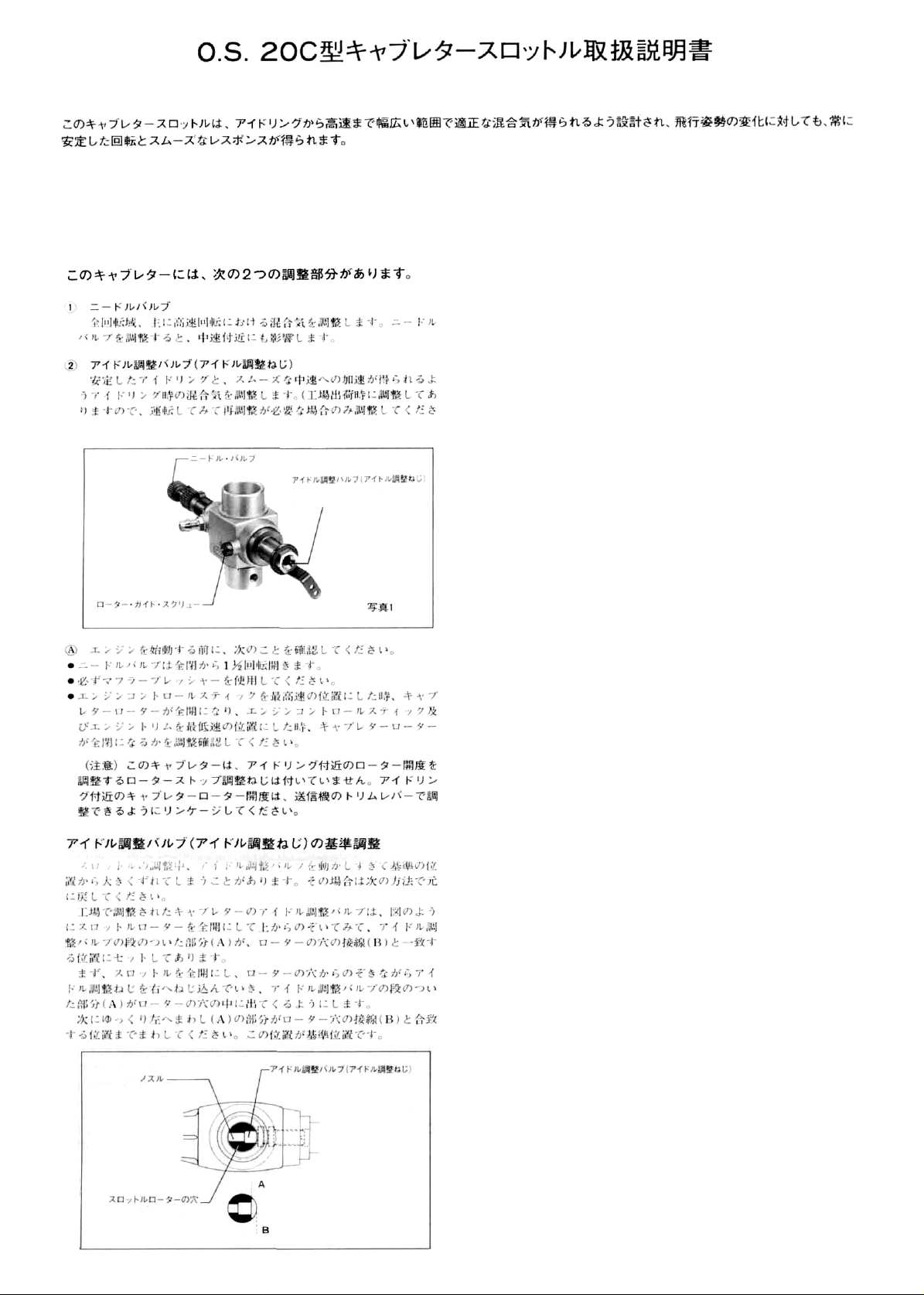

Rotor Guide Screw

Needle Valve

Mixture Control Valve

(Mixture Control Screw)

Photo 1

Nozzle

Throttle Rotor Hole

Mixture Control Valve

(Mixture Control Screw)

REALIGNMENT OF MIXTURE CONTROL VALVE

In the course of making carburettor adjustments, it is just

possible that the Mixture Control Valve maybe inadvertently screwed in or out too far and thereby moved beyond its

effective adjustment range.

Its basic setting can be reestablished as follows:

The

basic

(factory)

setting

is

as

shown in

the

main sketch,

i.e. with the shoulder portion 'A' exactly at a tangent to the

throttle rotor hole.

To return the Mixture Control Valve to its original position,

first screw in the Mixture Control Valve, while looking into

the rotor hole. Then gradually unscrew the Mixture Control

Valve until 'A' is precisely tangential to the rotor hole (i.e.

so that 'A' and 'B' are superimposed) as in the main sketch.

ADJUSTMENT

The following adjustments are approximately correct when

using a fuel containing 25% lubricant and 10—30% nitromethane.

Bear in mind that fuels containing relatively large percentages of power-boosting nitromethane operate at richer mixture settings than are needed for mild fuels and will, therefore, require the Needle Valve to be readjusted accordingly.

The type and percentage of lubricant used is also a factor

here, as noted later in these instructions.

B As a safety measure, first check the transmitter controls,

including the throttle stick and trim lever positions, and

hold the main rotor securely before starting the engine.

C Warm the engine by allowing it to idle for about 30

seconds. If the engine stops, advance the throttle trim

lever slightly to increase the idling rpm. Then open the

throttle sufficiently to 'float' the model above the

ground.

Page 2

D If, at this time, the engine is slow to pick up and pro-

duces an excess of exhaust smoke, the mixture is too

rich. Correct this condition by turning the Mixture

Control Screw clockwise. If the mixture is extremely

rich, engine rpm will become unstable: opening the

throttle will produce a great deal of smoke and rpm may

drop suddenly or the engine may stop. This condition

may also be initiated by an excessively prolonged warming-up period.

E If, on the other hand, the mixture is too lean, this will

be indicated by a marked lack of exhaust smoke and a

tendency for the engine to cut out when the throttle is

opened. In this case, turn the Mixture Control Screw

counter-clockwise to enrich the mixture.

F Turn the Mixture Control Screw 30 degrees at a time.

G Having provisionally set the idle mixture, the next step is

to adjust the mixture for hovering flight.

H Hover the model and actuate the throttle to observe res-

ponse over the medium speed range. If the engine smokes

excessively and throttle response is poor, the mixture is

too rich; in which case, land the model and turn the

Needle Valve clockwise. Do not close the Needle Valve

too much, keeping it a little on the rich side at this stage.

I If, on the other hand, hovering is not stable and response

to the throttle is over-sensitive, or if the engine tends to

overheat, this indicates that the mixture is too lean and

should be corrected by turning the Needle Valve counterclockwise.

J When satisfactory hovering flight has been achieved, land

the model again and re-check the engine's idling qualities.

K After about 10 seconds of idling, open the throttle to

'float' the model. If the transition is smooth, the idle

mixture is O.K. If the symptoms of either rich or lean

running are observed, readjust the Mixture Control

Screw accordingly.

L Now adjust the Needle Valve to achieve the best per-

formance when the model is flying at full throttle. If, at

full throttle, acceleration is poor, the exhaust unduly

smoky and the model fails to reach expected straight

line speed, the mixture is too rich and the Needle Valve

setting will need to be reduced.

If, however, after smoothly accelerating to satisfactory

high-speed straight and level flight, power is lost when

the model is pulled up into a climb, the mixture is too

lean. In this case, land the model immediately and readjust Needle Valve to a richer setting.

M Now re-check hovering performance and, if necessary,

fine-tune the mixture for hovering flight.

N For helicopters, good throttle response at medium

revolutions (e.g. hovering speeds) is most important,

since this is a power range widely used in helicopter

flight. The optimum fuel/air mixture strength at medium

speeds is dependent on obtaining balanced adjustment of

both the Needle Valve and the Mixture Control Valve.

If both controls are already at their optimum setting,

some modification to these settings may be necessary

to achieve satisfactory mid-range throttle response, but

such readjustments should only be made within the

range where idling reliability and high-speed performance are not unduly compromised.

Readjustments should therefore be carried out as follows:

O If the mid-range throttle response is not rapid and posi-

tive (indicating a rich mid-range mixture), turn the

Needle Valve 2 or 3 clicks clockwise, or turn the Mix-

ture Control Screw 10—20 degrees clockwise.

P If, on the other hand, the response to mid-range throttle

movement is too sensitive (indicating a lean mid-range

mixture), turn the Needle Valve 2 or 3 clicks counter-

clockwise or turn the Mixture Control Screw 10—20

degrees counter-clockwise.

Q Throttle response at hovering speeds is also affected by

the relationship of the main rotor pitch angle to throttle

opening. If the optimum mid-range throttle response

cannot be obtained by the carburettor adjustments

described above, try adjusting the helicopter's pitch

control characteristics.

Page 3

SUBSEQUENT READJUSTMENTS

Once the engine has been run-in (see engine instructions)

and the carburettor controls properly set up, it should be

unnecessary to alter the mixture settings, except to make

minor adjustments to the Needle Valve occasionally, to

take account of variations in climatic conditions.

The use of a different fuel, however, particularly one containing more, or less, nitromethane and/or a different type

or proportion of lubricating oil, is likely to call for some

readjustment of the Needle-Valve.

Remember that, as a safety measure, it is advisable to

increase the Needle Valve opening by an extra half-turn

counter-clockwise, prior to establishing a new setting. The

same applies if the silencer type is changed. A different

silencer may alter the exhaust pressure applied to the fuel

feed and call for a revised Needle-Valve setting.

The use of a different glowplug, or changes to the main

rotor and its pitch angles may also require compensating

carburettor readjustments.

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends on its

small fuel orifices remaining clear. The minute particles of

foreign matter that are present in any fuel can easily partial-

ly obstruct these orifices and upset mixture strength so

that engine performance becomes erratic and unreliable.

It is recommended that fuel is passed through a filter when

the tank is filled and that a good in-line filter is installed

between the fuel tank and carburettor and, furthermore,

that this filter is frequently cleaned to remove dirt and lint

that accumulates on the filter screen. Finally, occasionally

remove the needle-valve holder from the carburettor as

shown in Photo 2 and extract any remaining foreign matter

that may have lodged in the location shown in Photo 3.

Remove this with

an 8mm spanner

Photo 2

ADJUSTING CHART

Open the Needle Valve 1 1/2 turns from the fully closed position.

Make sure that the Mixture Control Valve is at the factory setting

Turn the Mixture

Open the

Needle Valve

Warm up the engine

Idling OK

Hovering OK

("Float" the model)

Idling OK

High Speed Flight

Photo 3

Rich mixture

Turn the Mixture

Dirt and fibrous matter

mostly accumulate here

Open the

Adjust pitch control

High speed fliqht OK

Response loo slow

Hoverinq OK

Control Screw 10-20

Adjust pitch control

Page 4

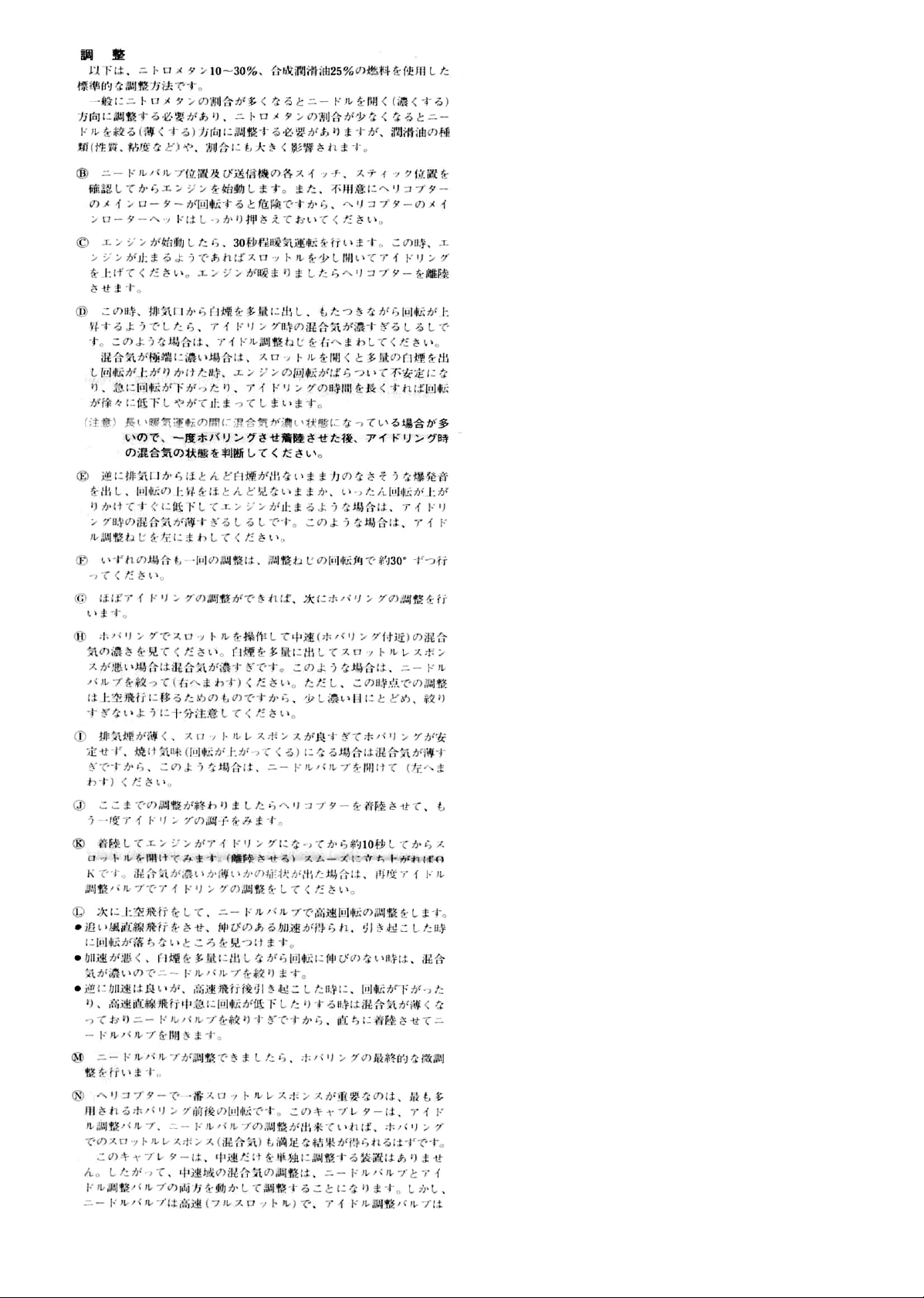

INSTALLATION

After fitting the engine in the helicopter, please observe the following recommendations when linking the throttle servo to the

carburettor.

CORRECT-Throttle lever movement should be

disposed symmetrically, as shown.

Locate the servo so that its output arm and the

throttle pushrod are, as closely as possible, directly in line with the carburettor's throttle arm, as

shown.

Note: If differential throttle movement is required, make necessary

adjustment at the servo output arm, not at the throttle lever.

When the throttle is fully open or fully closed, the

throttle lever angle should not be more than 45° either

side of the mid-point of its travel (and where it is at a

90° angle to the pushrod), otherwise throttle rotor movement may become inhibited or may even lock up.

Also, some lubricants may affect the throttle rotor

movement.

Please note that the throttle lever angles of the O.S.

Type 20C carburettor are well within these limitsrequiring only 75° from the fully open to fully closed

positions.

Fully open

position

Use outer hole.

INCORRECT -One-way throttle lever movement should not

be more than 45°. \

Fully closed

position

Code No

23481400

22781420

22781410

22781411

23481200

23481650

26781506

23481100

24881824

45581820

22681953

22615000

23081706

27681900

27381940

26711305

27681970

24981837

26381501

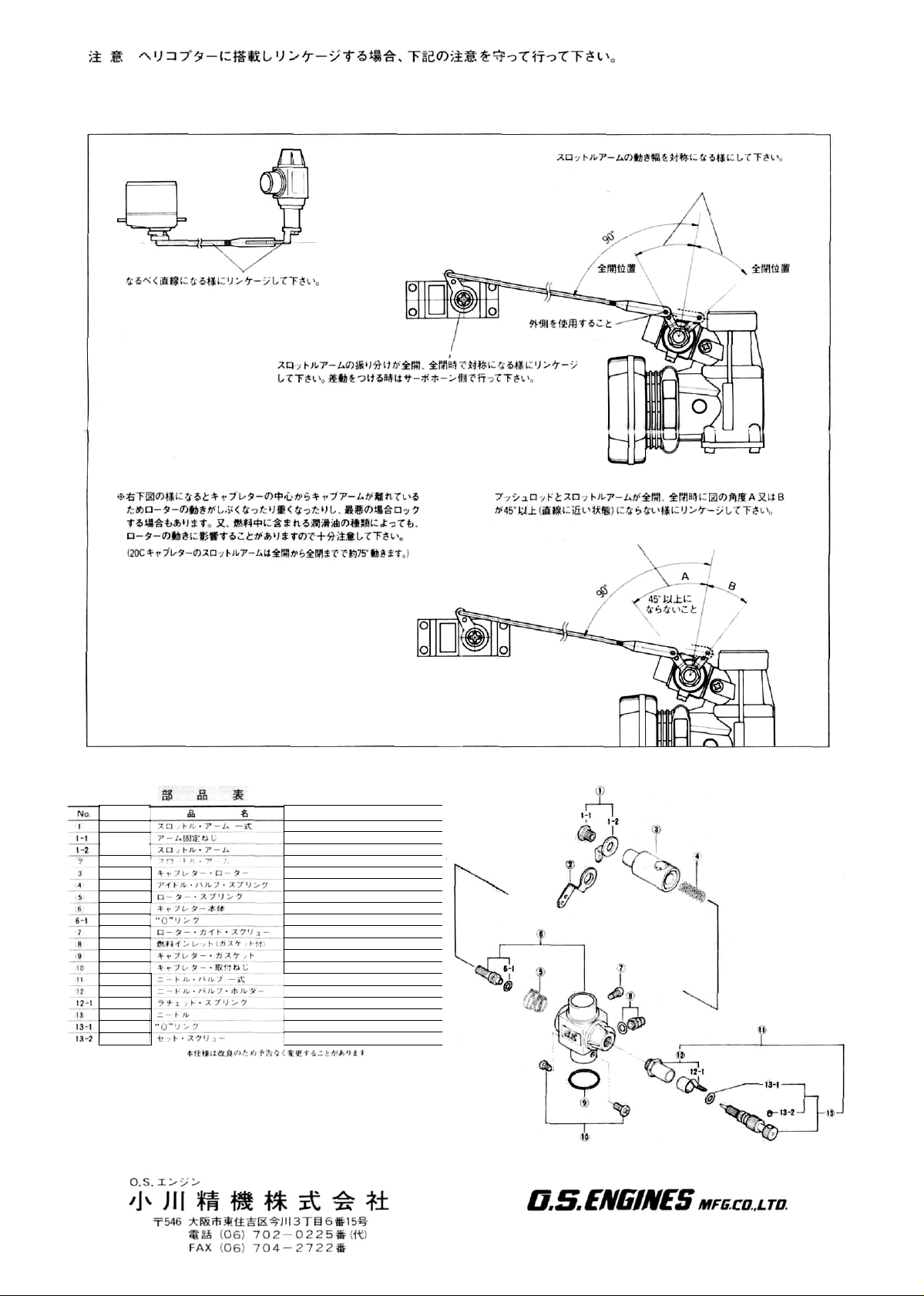

PARTS LIST

Throttle Lever Assembly

Throttle Lever Fixing Screw

Throttle Lever

Throttle Lever

Carburettor Rotor

Mixture Control Valve Spring

Rotor Spring

Carburettor Body

"0" Ring

Rotor Guide Screw

Fuel Inlet (w/Gasket)

Carburettor Rubber Gasket

Carburettor Fixing Screw

Needle Valve Assembly

Needle Valve Holder

Ratchet Spring

Needle

"0" Ring

Set Screw

The specifications are subject to alteration for improvement without notice.

Description

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL (06) 702-0225

FAX. (06) 704-2722

© Copyright 1994 by OS Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan.

60130270-39708

Loading...

Loading...