Page 1

INSTRUCTIONS FOR O.S. TYPE 20A & 20B AUTOMATIC CARBURETTORS

These slide-throttle carburettors have been designed expressly for O.S. racing car engines. They release the

full

potential

output.

The

shank of

mission of heat from the crankcase to the carburettor body. This prevents excessive pre-heating of the incom-

ing

charge

and maximum power output.

of

these engines,

the

carburettor

is

and maintains steady

providing

fitted

with

running

instant

an

insulating

throttle

characteristics

response,

sleeve

with

rapid

rapid

acceleration

of

engineering plastic

deceleration,

as

well

and

to

minimize

as

instant

high

peak

power

the

trans-

acceleration

When supplied with the engine, the carburettor is

fitted loosely in the intake boss. Secure it in the

following manner.

1. Loosen the carburettor retainer screw and rotate

the carburettor to its proper position in the intake

boss.

2. The carburettor is aligned vertically and sealed

against air leaks by a sealing washer in the bottom

of the intake boss and by a heatproof rubber

gasket between the carburettor body and the rim

of the intake boss. Therefore, press the carburettor

firmly down into the intake boss while rotating

the retainer screw. Rotate the screw gently until

it stops, then tighten a further 120~180°.

Note: The two-piece retainer is designed to pinch the

carburettor from both sides and the insulating

sleeve effectively prevents the assembly from

vibrating loose.

Warning! Do not over-tighten the retainer screw as

this will damage the insulator.

Important: These carburettors require muffler pres-

surized fuel feed. Make sure that the fuel

tank is completely sealed when filled and

that there are no leaks in the pressure line

or delivery pipe.

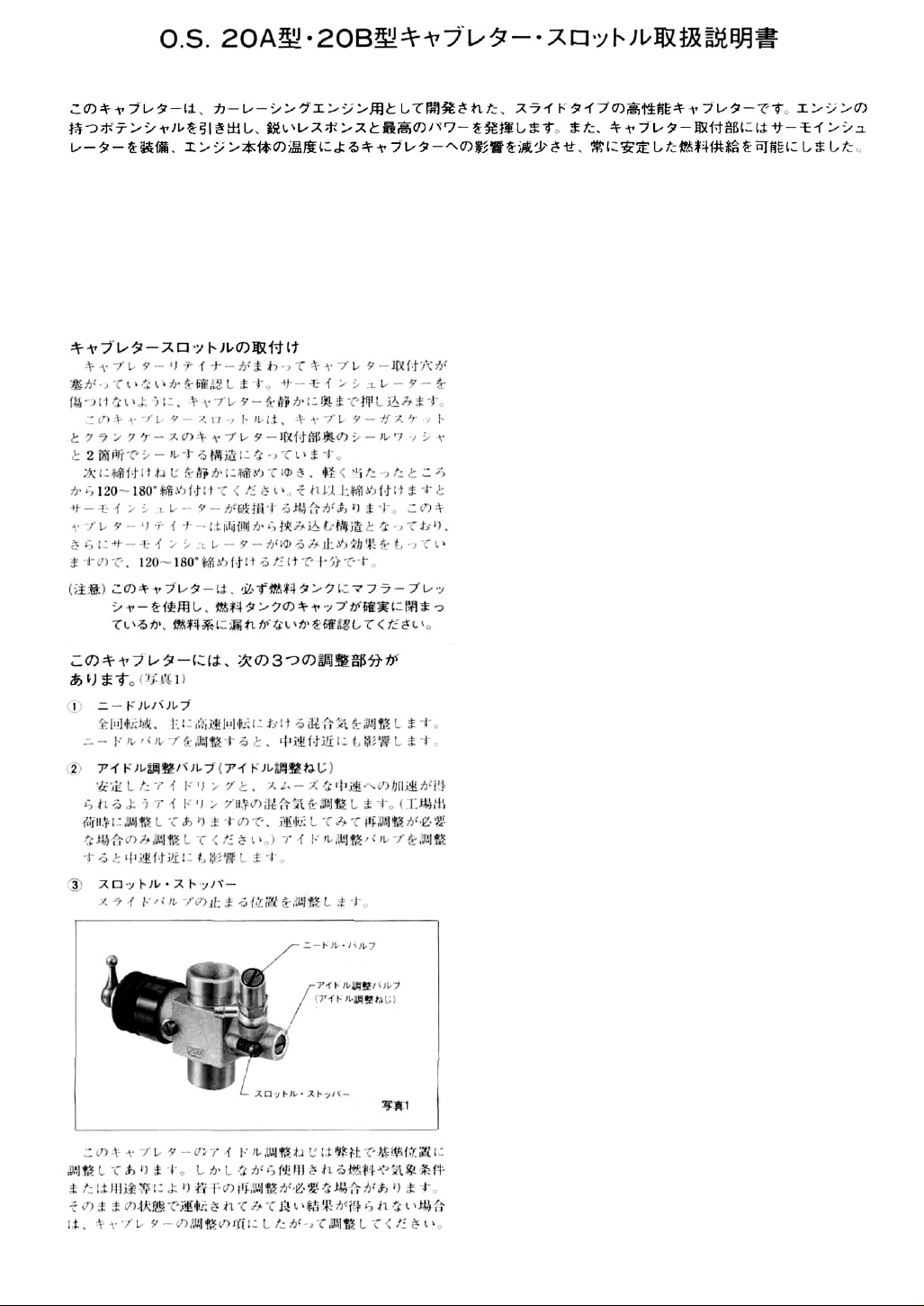

Needle Valve

Mixture Control Valve

(Mixture Control Screw)

Throttle Stop Screw

Photo1

ADJUSTING THE CARBURETTOR

Three adjustable controls are provided on this carbuettor.

• The Needle Valve:

When set to produce maximum power at full

throttle, this establishes the basic fuel/air mixture

strength, which is then maintained by the carburettor's automatic mixture control system to cover

the engine's requirements at reduced throttle settings.

• The Mixture Control Valve (Mixture Control

Screw):

For adjusting the mixture strength at part-throttle

and idling speeds, to obtain steady idling and

smooth acceleration to medium speeds. The Mixture Control Valve has been factory set for the

approximate best result. First, run the engine as

received, and re-adjust the Mixture Control Valve

only when necessary.

• The Throttle Stop Screw:

For setting the position where the carburettor

rotor is closed.

Page 2

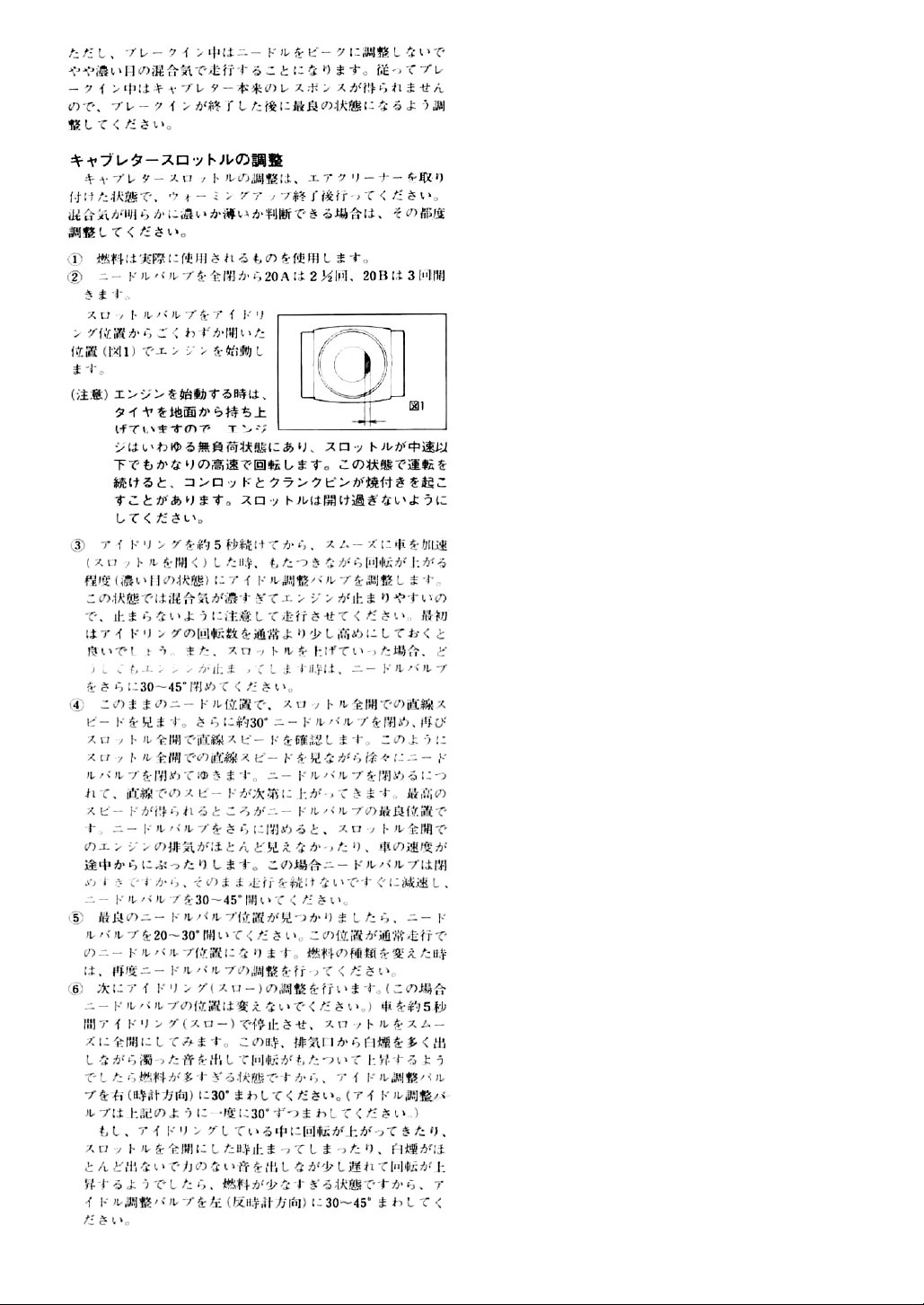

0.3-0.5mm

Fig.1

ADJUSTMENT

Note: Optimum carburettor performance is possible

only after the engine has been adequately runin - as described in the engine instruction leaflet.

Carburettor adjustment procedures should then

be carried

out

(with

the

air

cleaner

fitted,

where appropriate) as follows.

1. Use the same fuel as you intend to use for normal

running.

2. Open the Needle-Valve 2 1/2 turns (20A carburettor)

or 3 turns (20B carburettor) from the fully closed

position. Set the throttle very slightly open from

the idling position (0.3mm~0.5mm from the fully

closed position). Start the engine and allow it to

warm up.

3. Now check that the Mixture Control Valve is set

slightly rich, i.e. so that, after idling for five

seconds, the engine hesitates, when the throttle is

opened, before picking up speed. If the engine

stops due to being over-rich, set the idling speed

slightly higher by means of the Throttle Stop

Screw. Operate the car smoothly, avoiding abrupt

throttle movements at this stage. If, however, the

engine still stops through being over-rich, close

the Needle-Valve about 30° and try again.

4. Run the vehicle with this needle-valve setting (and

with throttle fully open) over the longest available

straight course, in order to observe the model's

speed. Next, return the car to the starting point,

close the Needle-Valve 30° and repeat the run,

taking note of the improvement in performance.

Continue with further runs, gradually reducing the

Needle-Valve setting and aiming to achieve the

highest straight-line speed. Remember, however,

that, if the Needle-Valve is shut down too far, the

engine will overheat and, accompanied by visibly

diminished exhaust smoke, the model will lose

speed. At this point, throttle down immediately,

stop the vehicle and reopen the Needle-Valve 30~

45°.

5. Re-check performance, making small readjustments

to the Needle-Valve, until a setting is found that

gives the highest speed without overheating, then

open the Needle-Valve 20~30° as a safety margin.

This is the optimum setting, although it may need

to be altered if a different fuel is used.

6. Having established the optimum needle-valve setting, check the Mixture Control Valve setting as

follows.

7. With the engine running, close the throttle and

allow it to idle for about five seconds, then open

the throttle fully. If, at this point, the engine puffs

out an excessive amount of smoke and the vehicle

does not accelerate smoothly and rapidly, it is

probable that the idling mixture is too rich. In this

case, turn the Mixture Control Valve clockwise

30°. If, on the other hand, the engine tends to

speed up momentarily and then cut out abruptly

when the throttle is opened, the idling mixture is

too lean. Correct this by turning the Mixture

Control Valve counter-clockwise 30~45°.

Note: Mixture Control Valve adjustment should be

made in steps of not more than 30°, carefully

checking the effect, on throttle response, of

each small adjustment.

Page 3

8. Carry out adjustments patiently, under actual running conditions, until the engine responds quickly

and positively to the throttle control.

9. With the optimum settings, light smoke is visible

during high-speed running and engine revolutions

increase smoothly during acceleration. Remember

that, if the engine is operated with the fuel/air

mixture only slightly too lean, it will overheat and

run unevenly. As with all engines, it is advisable, as

previously noted, to set both valves very slightly

on the rich side of the highest r.p.m. setting, as a

safety measure.

10. If the engine runs too fast with the throttle closed,

the Throttle Stop Screw should be turned counterclockwise a few degrees to allow the throttle opening to be reduced. Readjustment may be necessary

to suit alterations in gear ratios or the clutch

engagement point.

SUBSEQUENT READJUSTMENTS

Mixture adjustments (whether via the Mixture Control

Valve, or the Needle-Valve) cannot be made accurately under 'no load' conditions, which, in any case, are

not advised, since such operation carries the risk of

seriously damaging the engine through over-revving

and overheating.

Once the engine has been run-in (see engine instructions) and the carburettor controls properly set up,

it should be unnecessary to alter the mixture settings,

except to make minor adjustments to the NeedleValve occasionally, to take account of variations in

climatic conditions.

The use of a different fuel, however, particularly

one containing more, or less, nitromethane and/or

a different type or proportion of lubricating oil, is

likely to call for some readjustment of the NeedleValve.

Remember that, as a safety measure, it is advisable

to increase the Needle-Valve opening by an extra

half-turn counter-clockwise, prior to establishing

a new setting. The same applies if the silencer type

is changed. A different silencer may alter the exhaust

pressure applied to the fuel feed and call for a revised

Needle-Valve setting.

'Flats' for

8mm wrench

Slide Valve

•Flats' for

6mm wrench

Slide Valve Extension

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends

on its small fuel orifices remaining clear. The minute

particles of foreign matter that are present in any

fuel, can easily partially obstruct these orifices and

upset mixture strength so that engine performance

becomes erratic and unreliable.

O.S. 'Super-Filters' (large and small) are available, as

optional extras, to deal with this problem. One of

these filters, fitted to the outlet tube inside your

refueling container, will prevent the entry of foreign

material into the fuel tank. It is also recommended

trial a good in-line filter be installed between the tank

and carburettor. Do not forget to clean the filters

regularly to remove dirt and lint that accumulate on

the filter screens. Also, clean the carburettor itself

occasionally.

Fig.2

Page 4

First rotate the Mixture Control Valve

until its slotted head is Hush with the

carburettor body

1.

0.5mm(20B)

Then screw the valve in exactly 1 turn

(20B carburettor), or 3 turns (20A

carburettor).

Mixture Control Valve

Carburettor Body

mm

(20

BALL LINK AND SLIDE VALVE EXTENSION

When readjusting the position of the Ball Link,

always apply a 6mm spanner or wrench to the flats

on the Slide Valve Extension, before attempting to

loosen or tighten the ball link retaining screw. Carefully ease back the Dust Cover bellows to allow access

to the flats. If it should become necessary (e.g. for

cleaning) to disassemble the throttle parts, first

2 turns

A)

1 turn

unscrew the Slide Valve guide screw and withdraw

the complete sub-assembly from the carburettor

body. Use the correct size (8mm) wrench when

unscrewing the Slide Valve from the Slide Valve

Extension. See Fig. 2 and parts drawing (below).

Fig.3

REALIGNMENT OF MIXTURE CONTROL VALVE

In the course of making carburettor adjustments, it

is just possible that the Mixture Control Valve may

be inadvertently screwed in or out too far and thereby moved beyond its effective adjustment range.

Its basic position can be found by first rotating the

Mixture Control Valve until its .slotted head is flush

with the carburettor body. The valve is then screwed

in exactly 1 turn (20B carburettor), or 3 turns (20A

carburettor), to establish its neutral position. See

Fig. 3 (above, left).

PARTS LIST

Description

Throttle Stop Screw (w/spring)

Mixture Control Valve Assembly

"0"Ring(L) for Mixture Control Valve

"0" Ring(S) for Mixture Control Valve

Needle Valve Assembly

"0" Ring for needle

Universal Nipple No.9(w/sealing washer)

Carburettor Body (fitted with Thermo-lnsulator)

Slide Valve Guide Screw

Carburettor Rubber Gasket

Carburettor Sealing Washer

Slide valve

Metering Needle Assembly (w/spring)

Slide Valve Extension

Dust Cover

Ball Link No.1

The specifications are subject to alteration for improvement without notice.

6-15 3-chome Imagawa Higashisurniyoshi-ku

Osaka 546, Japan. TEL (06) 702-0225

© Copyright 1995 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan

Code

No.

20A

23818500

23818180

46066319

22781800

23818150

46066319

23818176

23818100

45581820

29015019

23818190

23818201

23818300

23818211

22884210

23818400

FAX (06)704-2722

20B

23818110

23818251

23818310

60130180 29507

Loading...

Loading...