Orphee Mythic 22-AL User manual

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 1/109

Revision Nb

Date

Author

Software

Comments

01

28/05/10

HC

> V0.4.0

Creation.

02

25/06/10

HC

> V0.5.0

Update of the entire document.

03

04/08/10

HC

> 1.0

Update of the sections 3.4.3/3.4.1/3.4.4/5.10.1/7.2

04

13/08/10

HC

> 1.0

Add the Declaration of Conformity

M

ORPHEE SA

19, chemin du champ des filles

CH-1228 Plan-les-Ouates

SWITZERLAND

Tel : +41 22 884 90 90

Fax : +41 22 884 90 99

http://www.orphee-medical.com

CONTACT ADDRESS

MANUFACTURER

REVISIONS

LOCAL AGENT

REF : M22AL/UM/EN/004

Page 2/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

CAUTION - RISK OF DANGER

Indicates a procedure to be strictly respected in order to avoid any risks for the

operator (user) or damages on the instrument or on the quality of results.

CAUTION – BIOHAZARD RISK

Indicates that wearing gloves is mandatory before performing the described

operation due to risk of contact with materials that may be infectious.

CAUTION – HOT SURFACE

Indicates hot temperatures surfaces and risk of burns

CAUTION – CLASS 2 LASER RADIATION

Indicates laser radiation and do not stare into the beam

NOTA

Indicates important additional information

WARNING

Important Safety Instructions

Must be read before attempting to install the product.

The slots and openings in the back or bottom are provided for necessary ventilation. To

ensure reliable operation of this apparatus or its DC adaptor, and to protect it from

overheating, these openings must never be blocked or covered.

Do not place this apparatus or its DC adaptor near or over a radiator or heat resistor, or

where it is exposed to direct sunlight.

Do not place a vessel containing liquid on this apparatus and its DC adaptor, as this can result

in a risk of fire or electric shock.

Do not expose this apparatus or its DC adaptor to rain or place it near water. If this

apparatus or its DC adapter accidentally gets wet, unplug it and contact your service center

immediately.

Make sure to pull out the power cord from the outlet before cleaning.

Do not overload wall outlets, extension cords or adaptors beyond their capacity, since this

can result in fire or electric shock.

Do not use travel power adapter

Power-supply cords should be routed so that they are not likely to be walked on or pinched by

items placed upon or against them.

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 3/109

To protect apparatus or its DC adaptor from a lightning storm, or when it is left unused for

long periods of time, unplug it from the wall outlet. This will prevent damage to the set due to

lightning and power line surges.

Before connecting the AC power cord to the DC adaptor outlet, make sure the voltage

designation of the DC adaptor corresponds to the local electrical supply.

Never insert anything metallic into the open parts of the DC adaptor. Doing so many create a

danger of electric shock.

To avoid electric shock, never touch the inside of the DC adaptor.

Make sure to plug the power cord in until it is firmly inserted. When removing the power

cord, make sure to hold the power plug when pulling the plug from the outlet. Do not touch

the power cord or DC adaptor with wet hands.

If this apparatus does not operate normally – in particular, if there are any unusual sounds or

smells coming from it – unplug it immediately and contact your service center.

Be sure to contact an authorized service center, when installing your set in a location with

heavy dust, high or low temperatures, high humidity or chemical substances. Failure to do so

may cause serious damage to your set.

Use only a properly grounded plug and receptacle. An improper ground may cause electric

shock or equipment damage.

To disconnect the apparatus from the mains, the plug must be pulled out from the mains

socket, therefore the mains plug shall be readily operable.

Do not install the product in an unstable location such as a shaky table or a location exposed

to vibration.

Do not drop or impart any shock to the product. If the product is damaged, disconnect the

power cord and contact your service center.

Always replace or use parts of the apparatus supplied by your service center.

The MYTHIC 22 AL is an automated hematology analyzer for in vitro diagnostic to be used in

clinical laboratories by an authorized people.

Only human blood or artificial control blood should be run.

Only the reagents mentioned in this manual are permitted to be used.

The optimum performances can be only achieved if the cleaning and maintenance

procedures are carefully followed.

All parts or surfaces of this apparatus could be potentially infective. Use adequate

protection to prevent any risk of contamination (gloves, glasses, disinfectant).

The elimination of waste supplied by this apparatus must be done in compliance with your local

authorities.

REF : M22AL/UM/EN/004

Page 4/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

ATTENTION

RAYONNEMENT LASER DE CLASSE 2

EN CAS D’OUVERTURE NE PAS REGARDER DANS LE FAISCEAU

CAUTION

CLASS 2 LASER RADIATION

WHEN OPEN DO NOT STARE INTO THE BEAM

This equipment has an embedded class 2 laser product.

By removing the protect cover operator could have exposure to hazardous laser

radiation.

Do not stare into the beam

All operations of service must be do after equipment is switched off.

Wavelength: 650nm

Beam divergence: 54°

Pulse duration and repetition rate: 200 scans/s

Maximum power: 1mW

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 5/109

Guidance and manufacturer’s declaration – Electromagnetic emissions

The MYTHIC 22 AL is intended for use in the electromagnetic environment specified below. The customer or

the user of the MYTHIC 22 AL should assure that it is used in such an environment.

Emissions test

Compliance level

Electromagnetic environment - guidance

Harmonic emissions

IEC 61000-3-2

Class A

The MYTHIC 22 AL is suitable for use in all establishments, including

domestic establishments and those directly connected to the public

low-voltage power supply network that supplies buildings used for

domestic purposes.

Voltage fluctuations/flicker

emissions

IEC 61000-3-3

Complies

Guidance and manufacturer’s declaration – Electromagnetic immunity

The MYTHIC 22 AL is intended for use in the electromagnetic environment specified below. The customer or

the user of the MYTHIC 22 AL should assure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance

level

Electromagnetic environment - guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

Complies

Floors should be wood, concrete or ceramic tile. If floors

are covered with synthetic material, the relative

humidity should be at least 30 %.

Electrical fast

transient/burst

IEC 61000-4-4

±2 kV for power supply lines

±1 kV for input/output lines

Complies

Mains power quality should be that of a typical

commercial or hospital environment.

Surge

IEC 61000-4-5

±1 kV differential mode

±2 kV common mode

Complies

Mains power quality should be that of a typical

commercial or hospital environment.

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

<5 % UT

(>95 % dip in UT) for 0,5 cycle

40 % UT

(60 % dip in UT) for 5 cycles

70 % UT

(30 % dip in UT) for 25 cycles

<5 % UT

(>95 % dip in UT) for 5 sec

Complies

Mains power quality should be that of a typical

commercial or hospital environment. If the user of the

MYTHIC 22 AL requires continued operation during

power

mains interruptions, it is recommended that the MYTHIC

22 AL be powered from an uninterruptible power

supply or a battery.

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

3 A/m

Complies

Power frequency magnetic fields should be at levels

characteristic of a typical location in a typical commercial

or hospital environment.

NOTE UT is the a.c. mains voltage prior to application of the test level.

This equipment needs special precautions regarding general requirements for safety.

REF : M22AL/UM/EN/004

Page 6/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

Guidance and manufacturer’s declaration – Electromagnetic immunity

The MYTHIC 22 AL is intended for use in the electromagnetic environment specified below. The customer or

the user of the MYTHIC 22 AL should assure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance

level

Electromagnetic environment - guidance

Portable and mobile RF communications equipment should

be used no closer to any part of the MYTHIC 22 AL,

including cables, than the recommended separation

distance calculated from the equation applicable to the

frequency of the transmitter.

Recommended separation distance

Conducted RF

IEC 61000-4-6

3 Vrms

150Khz to 80Mhz

3 Vrms

d

= 1,2√P

Radiated RF

IEC 61000-4-3

3 Vrms

80Mhz to 2,5Ghz

3 Vrms

d

= 1,2√P 80MHz to 800MHz

d

= 2,3√P 800MHz to 2,5GHz

Where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey,a should be

less than the compliance level in each frequency range

Interference may occur in the vicinity of equipment

marked with the following symbol:

NOTE 1 At 80Mhz and 800MHz, the higher frequency range applies.

NOTE 2 Theses guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios,

amateur radio, AM an FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the

electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should considered. If the measured field

strength in the location in which the MYTHIC 22 AL is used exceeds the applicable RF compliance level above, the MYTHIC 22 AL

should be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the MYTHIC 22 AL.

b

Over the frequency range 150KHz to 80MHz, field strengths should be less than 3V/m.

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 7/109

The symbol on the product indicates that this product may not be treated as household waste. Instead it shall be handed over

the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of

correctly, you will help prevent potential negative consequences for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product. For more detailed information about recycling of this product, please contact

your local city office or your distributor of this product.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

The user may find the following booklet, prepared by the Federal Communications Commission, helpful:

How to identify and Resolve Radio/TV Interference Problems. This booklet is available from the U.S. Government

Printing Office, Washington, D.C. 20402, Stock No. 004-000-00345-4.

Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment not expressly approved by C2

REF : M22AL/UM/EN/004

Page 8/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

Name und Adresse der Firma

Nom et adresse de l’entreprise

Nome e indirizzo della ditta

Name and address of the firm

Orphée S.A.

19 Chemin du Champ des Filles

1228 Plan Les Ouates

Wir erklären in alleiniger Verantwortung, dass

Nous déclarons sous notre propre responsabilité que

Dichiariamo sotto nostra responsabilità che

We declare under our sole responsibility that

das Medizinprodukt für die In-vitro-Diagnostik

le dispositif médical de diagnostic in vitro

il dispositivo medico-diagnostico in vitro

the in vitro diagnostic medical device

Mythic 22 AL

Ref. M22AL

mit folgender Klassifizierung nach der Richtlinie über In-vitro-Diagnostika 98/79/EG

avec la classification selon la directive relative aux dispositifs médicaux de diagnostic in vitro 98/79/CE

con la classificazione secondo la direttiva relativa ai dispositivi medico-diagnostici in vitro 98/79/CE

classified as follows according to the directive on in vitro diagnostic medical devices 98/79/EC

Produkt der Liste A, Anhang II / Dispositif de la liste A, annexe II /

Dispositivo dell’elenco A, allegato II / Device of List A, Annex II

Produkt der Liste B, Anhang II / Dispositif de la liste B, annexe II /

Dispositivo dell’elenco B, allegato II / Device of List B, Annex II

Produkt zur Eigenanwendung, das nicht in Anhang II genannt ist /

Dispositif destiné à l’autodiagnostic non listé dans l’annexe II /

Dispositivo per test autodiagnostico non elencato nell’allegato II /

Device for self-testing not listed in Annex II

Sonstiges Produkt / Autre dispositif / Altro dispostivo / Other device

allen Anforderungen der Richtlinie über In-vitro-Diagnostika 98/79/EG entspricht, die anwendbar sind.

remplit toutes les exigences de la directive relative aux dispositifs médicaux de diagnostic in vitro 98/79/CE

qui le concernent.

soddisfa tutte le disposizioni della direttiva relativa ai dispositivi medico-diagnostici in vitro 98/79/CE che lo

riguardano.

meets all the provisions of the directive on in vitro diagnostic medical devices 98/79/EC which apply to it.

KONFORMITÄTSERKLÄRUNG /

DECLARATION DE CONFORMITE

DECLARATION OF CONFORMITY /

DICHIARAZIONE DI CONFORMITA

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 9/109

Angewandte Gemeinsame Technische

Spezifikationen, harmonisierte Normen,

nationale Normen oder andere normative

Dokumente

Spécifications techniques communes,

normes harmonisées, normes nationales et

autres documents normatifs appliqués

Specifiche tecniche comuni, norme

armonizzate o nazionali applicate, altri

documenti normativi applicati

Applied common technical specifications,

harmonised standards, national standards or

other normative documents

IEC 60825-1:2007

IEC 61010-1:2001

IEC 61010-2-101:2002

IEC 61010-2-081:2001 and A1:2003

IEC 61326-2-6:2005

Konformitätsbewertungsverfahren

Procédure d’évaluation de la conformité

Procedimentodi valutazionedellaconformità

Conformity assessment procedure

Annex III

Konformitätsbewertungsstelle (falls beigezogen)

Organe respons. de l'évaluat.de la conformité(si

consulté)

Organo incaric. della valutaz. della conform. (se

consultato)

Notified Body (if consulted)

N/A

Ort, Datum / Lieu, date /

Luogo, data / Place, date

Geneva, 10.08.2010

Name und Funktion / Nom et fonction /Nome e

funzione / Name and function

Tomasz Tuora

CEO & President

REF : M22AL/UM/EN/004

Page 10/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 11/109

TABLE OF CONTENTS

1. INSTALLATION ..................................................................................................... 14

1.1 UNPACKING .................................................................................................................................................................................................. 14

1.1.1 Introduction ................................................................................................................................................................................................. 14

1.1.2 Unpacking Procedure ................................................................................................................................................................................... 14

1.1.3 Visual checking ............................................................................................................................................................................................. 15

1.2 INSTALLATION CONSTRAINTS .................................................................................................................................................................. 16

1.2.1 Installation place ......................................................................................................................................................................................... 16

1.2.2 Installation environment ............................................................................................................................................................................ 16

1.3 ELECTRICAL CONNECTIONS ........................................................................................................................................................................ 16

1.3.1 Rear connectors ........................................................................................................................................................................................... 16

1.3.2 Front connectors ......................................................................................................................................................................................... 17

1.3.3 Power supply block ....................................................................................................................................................................................... 17

1.4 PRINTER CONNECTION ................................................................................................................................................................................ 17

1.5 CONNECTION, CHANGE AND PRIMING REAGENTS .................................................................................................................................... 18

1.5.1 Connection ..................................................................................................................................................................................................... 18

1.5.2 Priming ............................................................................................................................................................................................................ 19

1.6 TRANSPORTATION AND STORAGE ............................................................................................................................................................. 21

2. GENERAL OVERVIEW ............................................................................................... 22

2.1 INTENDED USE ........................................................................................................................................................................................... 22

2.2 GENERALITIES ............................................................................................................................................................................................ 22

2.3 OVERVIEW ................................................................................................................................................................................................... 23

2.4 MAIN PART DESCRIPTION .......................................................................................................................................................................... 23

2.4.1 Display ............................................................................................................................................................................................................ 23

2.4.2 Dilution fluidic part ..................................................................................................................................................................................... 25

2.4.3 Power Supply Block ...................................................................................................................................................................................... 26

2.4.4 Reagent tray ................................................................................................................................................................................................. 27

2.4.5 Sampler .......................................................................................................................................................................................................... 27

3. INSTRUMENT SET UP .............................................................................................. 28

3.1 USER’S IDENTIFICATION.......................................................................................................................................................................... 28

3.1.1 Start Up Machine ........................................................................................................................................................................................ 28

3.1.2 In process ..................................................................................................................................................................................................... 28

3.2 SYSTEM STATUS......................................................................................................................................................................................... 29

3.3 SET UP ......................................................................................................................................................................................................... 29

3.4 ADVANCED SET-UP ..................................................................................................................................................................................... 30

3.4.1 Sampler option: ............................................................................................................................................................................................ 30

3.4.1 Analysis options: .......................................................................................................................................................................................... 30

3.4.2 Lab. parameters: .......................................................................................................................................................................................... 31

3.4.3 Other Setting: ............................................................................................................................................................................................. 34

3.4.1 Printer set up: .............................................................................................................................................................................................. 34

3.4.1 Communication: ............................................................................................................................................................................................. 35

3.4.2 Calibration factor: ....................................................................................................................................................................................... 36

3.4.3 Storage options: ........................................................................................................................................................................................... 36

3.4.4 Version release:............................................................................................................................................................................................ 37

4. SPECIFICATIONS ................................................................................................... 38

4.1 ANALYTICAL SPECIFICATIONS ................................................................................................................................................................. 38

4.2 PHYSICAL SPECIFICATIONS ...................................................................................................................................................................... 40

4.3 REAGENTS SPECIFICATIONS .................................................................................................................................................................... 42

4.3.1 Diluent ............................................................................................................................................................................................................ 42

4.3.2 Lytic reagent “OnlyOne” ............................................................................................................................................................................ 43

4.3.3 Cleaning solution ........................................................................................................................................................................................... 44

4.4 ANALYTICAL LIMITATIONS ...................................................................................................................................................................... 45

4.4.1 Recommendations ......................................................................................................................................................................................... 45

4.4.2 Interferences............................................................................................................................................................................................... 45

REF : M22AL/UM/EN/004

Page 12/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

5. SAMPLE ANALYSIS ................................................................................................. 50

5.1 VERIFICATIONS BEFORE STARTING ......................................................................................................................................................... 50

5.2 SWITCH ON ................................................................................................................................................................................................ 50

5.3 REAGENT REPLACEMENT ............................................................................................................................................................................. 50

5.4 START UP RINSING...................................................................................................................................................................................... 51

5.5 PREPARATIONS BEFORE ANALYSIS ........................................................................................................................................................... 52

5.5.1 Blood collection ............................................................................................................................................................................................ 52

5.5.2 Blood sample collection tube ..................................................................................................................................................................... 52

5.6 ANALYSIS ................................................................................................................................................................................................... 53

5.6.1 Introduction ................................................................................................................................................................................................. 53

5.6.2 Working rules ............................................................................................................................................................................................... 53

5.6.3 Work list ........................................................................................................................................................................................................ 54

5.6.4 Modify an order ........................................................................................................................................................................................... 55

5.6.5 New Order .................................................................................................................................................................................................... 55

5.6.6 Display run ..................................................................................................................................................................................................... 55

5.6.7 Run Rack......................................................................................................................................................................................................... 56

5.6.8 STAT or other vial Sample Identification ............................................................................................................................................. 59

5.6.9 STAT or other vial sample run .................................................................................................................................................................. 60

5.7 DISPLAY RUNS ............................................................................................................................................................................................. 61

5.8 PRINTING .................................................................................................................................................................................................... 63

5.8.1 PCL3/LX 300 (USB) model report ............................................................................................................................................................ 63

5.8.1 PCL6 model report ....................................................................................................................................................................................... 64

5.9 LOGS INTERVENTIONS .............................................................................................................................................................................. 65

5.10 ARCHIVE ...................................................................................................................................................................................................... 66

5.10.1 Results ........................................................................................................................................................................................................... 66

5.10.2 View ................................................................................................................................................................................................................ 67

5.11 STAND BY AND SHUT DOWN ...................................................................................................................................................................... 68

6. QUALITY CONTROL ................................................................................................ 69

6.1 INTRODUCTION .......................................................................................................................................................................................... 69

6.2 QUALITY CONTROL .................................................................................................................................................................................... 69

6.2.1 Change ............................................................................................................................................................................................................ 70

6.2.2 Run control blood ......................................................................................................................................................................................... 71

6.3 REPEATABILITY .......................................................................................................................................................................................... 72

7. CALIBRATION ....................................................................................................... 73

7.1 RUN CALIBRATOR ........................................................................................................................................................................................ 74

7.1.1 Calibration blood analysis ........................................................................................................................................................................... 74

7.1.2 Calibration ..................................................................................................................................................................................................... 74

7.2 TARGET VALUES MODIFICATIONS ............................................................................................................................................................ 75

8. TECHNOLOGY ....................................................................................................... 76

8.1 DETECTION PRINCIPLE ............................................................................................................................................................................... 76

8.1.1 WBC, RBC, PLT Counting............................................................................................................................................................................. 76

8.1.2 Five part diff measurement ...................................................................................................................................................................... 77

8.1.3 Hemoglobin measurement .......................................................................................................................................................................... 78

8.2 LEUKOCYTE ANALYSIS ............................................................................................................................................................................... 78

8.2.1 Measurement ................................................................................................................................................................................................ 78

8.2.2 Local blood control limitations .................................................................................................................................................................. 79

8.3 ERYTHROCYTE ANALYSIS ........................................................................................................................................................................... 80

8.4 ANALYSIS OF PLATELETS ........................................................................................................................................................................... 81

8.5 FLAGS ........................................................................................................................................................................................................... 81

8.5.1 General Flags ................................................................................................................................................................................................ 81

8.5.2 Instrument Flags ......................................................................................................................................................................................... 82

8.5.3 Leukocytes Flags .......................................................................................................................................................................................... 82

8.5.4 Erythrocyte and HGB Flags ....................................................................................................................................................................... 83

8.5.5 Platelet Flags ................................................................................................................................................................................................ 83

8.5.6 QC Flags ........................................................................................................................................................................................................ 83

8.5.7 STARTUP Flags ............................................................................................................................................................................................ 83

8.6 HYDRAULIC & MECHANIC DESCRIPTION .................................................................................................................................................. 84

8.6.1 Auto loader module ...................................................................................................................................................................................... 84

8.6.2 Sampling module ........................................................................................................................................................................................... 84

8.6.3 Counting bath module .................................................................................................................................................................................. 84

8.6.4 Syringes module ........................................................................................................................................................................................... 84

8.6.5 Optical manifold ........................................................................................................................................................................................... 84

REF : M22AL/UM/EN/004

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 13/109

8.6.6 Optical bench ................................................................................................................................................................................................ 85

8.7 SOFTWARE .................................................................................................................................................................................................. 85

8.7.1 Common Functionalities .............................................................................................................................................................................. 85

8.7.2 Menu tree ...................................................................................................................................................................................................... 86

9. SERVICE ............................................................................................................. 87

9.1 MAINTENANCE ........................................................................................................................................................................................... 87

9.1.1 Maintenance table ....................................................................................................................................................................................... 87

9.1.2 Concentrate cleaning ................................................................................................................................................................................... 88

9.1.3 Piston greasing ............................................................................................................................................................................................. 90

9.1.4 In line filter cleaning .................................................................................................................................................................................. 91

9.1.5 Barcode cleaning .......................................................................................................................................................................................... 91

9.2 CLEANING CYCLES ....................................................................................................................................................................................... 92

9.3 TROUBLESHOOTING SCREEN ..................................................................................................................................................................... 92

9.3.1 Sampler .......................................................................................................................................................................................................... 93

9.3.2 Check sensors ............................................................................................................................................................................................... 93

9.3.3 Check valves .................................................................................................................................................................................................. 93

9.3.4 Check motors fluidics ................................................................................................................................................................................. 94

9.3.5 Log errors ...................................................................................................................................................................................................... 94

9.4 REPAIRING .................................................................................................................................................................................................. 94

9.4.1 Emergency stop ............................................................................................................................................................................................ 94

9.4.2 Needle or o-ring replacement ................................................................................................................................................................... 95

9.4.3 Baths dismantling ......................................................................................................................................................................................... 98

9.4.4 Baths o-ring replacement ......................................................................................................................................................................... 100

9.4.5 Aperture block replacement..................................................................................................................................................................... 101

9.5 TROUBLESHOOTING OCCURENCES ........................................................................................................................................................... 102

9.5.1 Analytical problems ................................................................................................................................................................................... 102

9.5.2 Other problems .......................................................................................................................................................................................... 103

9.6 TROUBLESHOOTING MESSAGE ................................................................................................................................................................. 105

9.7 HYDRAULIC DIAGRAM ................................................................................................................................................................................ 108

1. INSTALLATION

REF : M22AL/UM/EN/004

Page 14/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

If the MYTHIC 22 AL has been stored at a temperature lower than 10°C it must be left at room

temperature during 24 hours before power on.

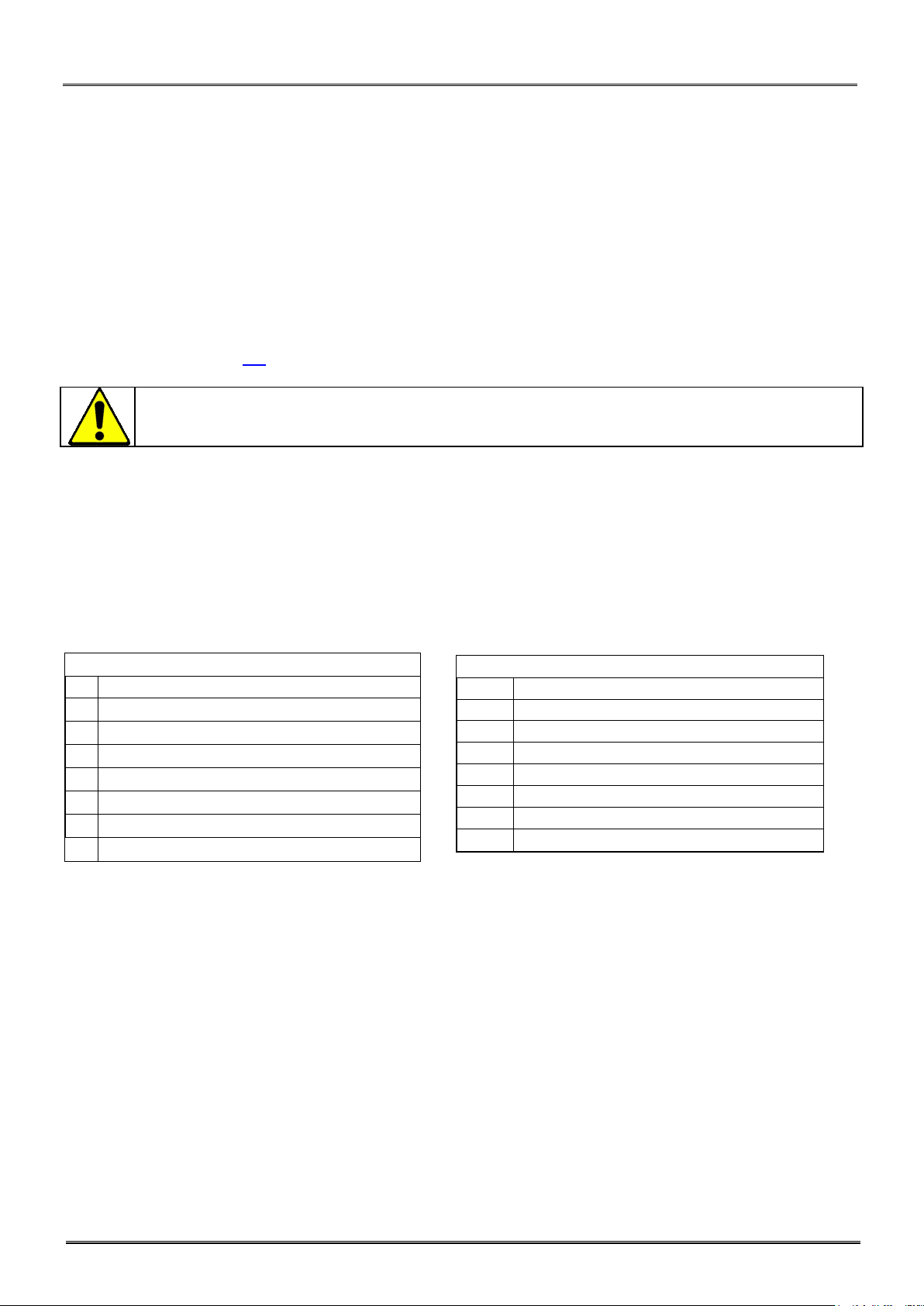

INSTALLATION KIT

QTY

Designation

1

Tubing 23 - DILUENT

1

Tubing 24 - WASTE

1

150W DC adaptor

1

European Power line cord

1

MYTHIC 22 AL User’s manual

1

Screwdriver Slot 1/4"

10

Racks

MAINTENANCE KIT

QTY

Designation

1

Tubing 50

10

Silicon Sleeve

5

Tie wraps

2

Rinsing Head O-ring

1

Silicon grease (3gr)

1

Short Arm TORX T10 Tool

1

Short Arm TORX T20 Tool

1. INSTALLATION

1.1 UNPACKING

1.1.1 Introduction

The MYTHIC 22 AL is an automated hematology analyzer for in vitro diagnostic use in clinical laboratories by an

authorized and trained people.

- Only human blood or artificial blood (recommended control or calibrator) should be run.

- Only the reagents mentioned in this manual are permitted to be used.

- The optimum performances can only be achieved if the cleaning and maintenance procedures are carefully

followed (see section 9.1).

1.1.2 Unpacking Procedure

Before unpacking the instrument, we recommend to check the box of the instrument and notify any damage to the

carrier.

- Open the box on the top, remove the starter kit.

- Remove the MYTHIC 22 AL from the box.

Starter kit contents:

REF : M22AL/UM/EN/004

1. INSTALLATION

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 15/109

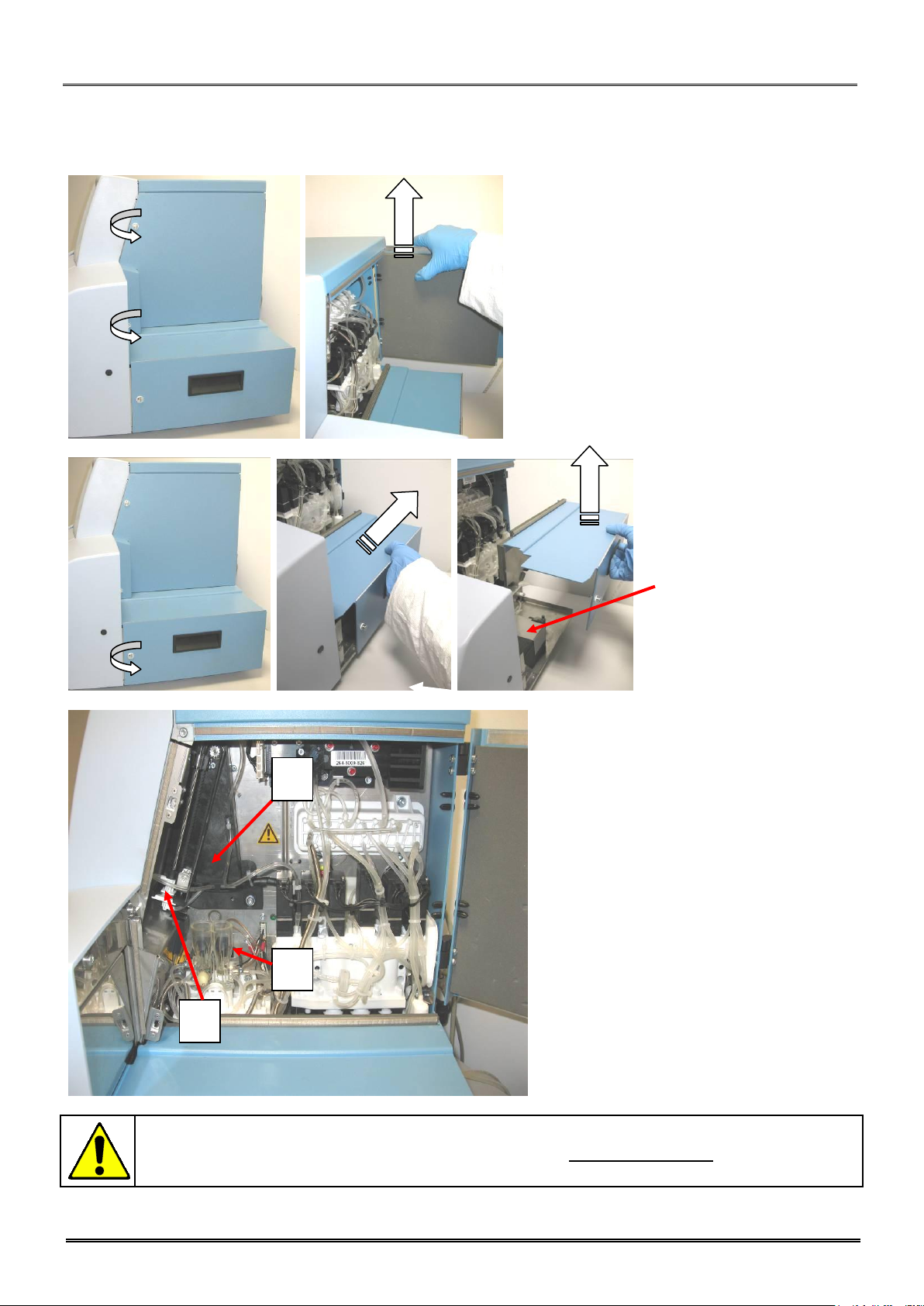

- Open the door on the right side by unscrewing

the two quarter turn screws with the key

provided in the kit.

- Open completely the door, then lift it to

remove.

- Unscrew the two quarter

turn screws with the key

provided in the kit.

- To remove the unloading

table, push to the back first

then lift it.

- Check the good fixation of

the air pump.

Remove the plastic wedge of the bath block.

To be checked:

1- Counting chambers perfectly locked in

their manifold locations.

2- Needle’s dismountable system located

in the rocker.

3- Rocker in front position at the

maximum course.

HAZARDOUS MOVING PARTS, BEWARE TO STAY AWAY FROM THESE PARTS WHEN THE

MACHINE IS SWITCHED ON. THE BARCODE READER IS A LASER CLASS II; NEVER

DISMANTLE THE COVER, IN CASE OF PROBLEM CALL ORPHEE REPRESENTATIVE.

1

2

3

1.1.3 Visual checking

1. INSTALLATION

REF : M22AL/UM/EN/004

Page 16/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

NOTA

Please contact Orphee’s representative if you want to use the instrument in special conditions (altitude higher

than 2000 m or special power supply conditions).

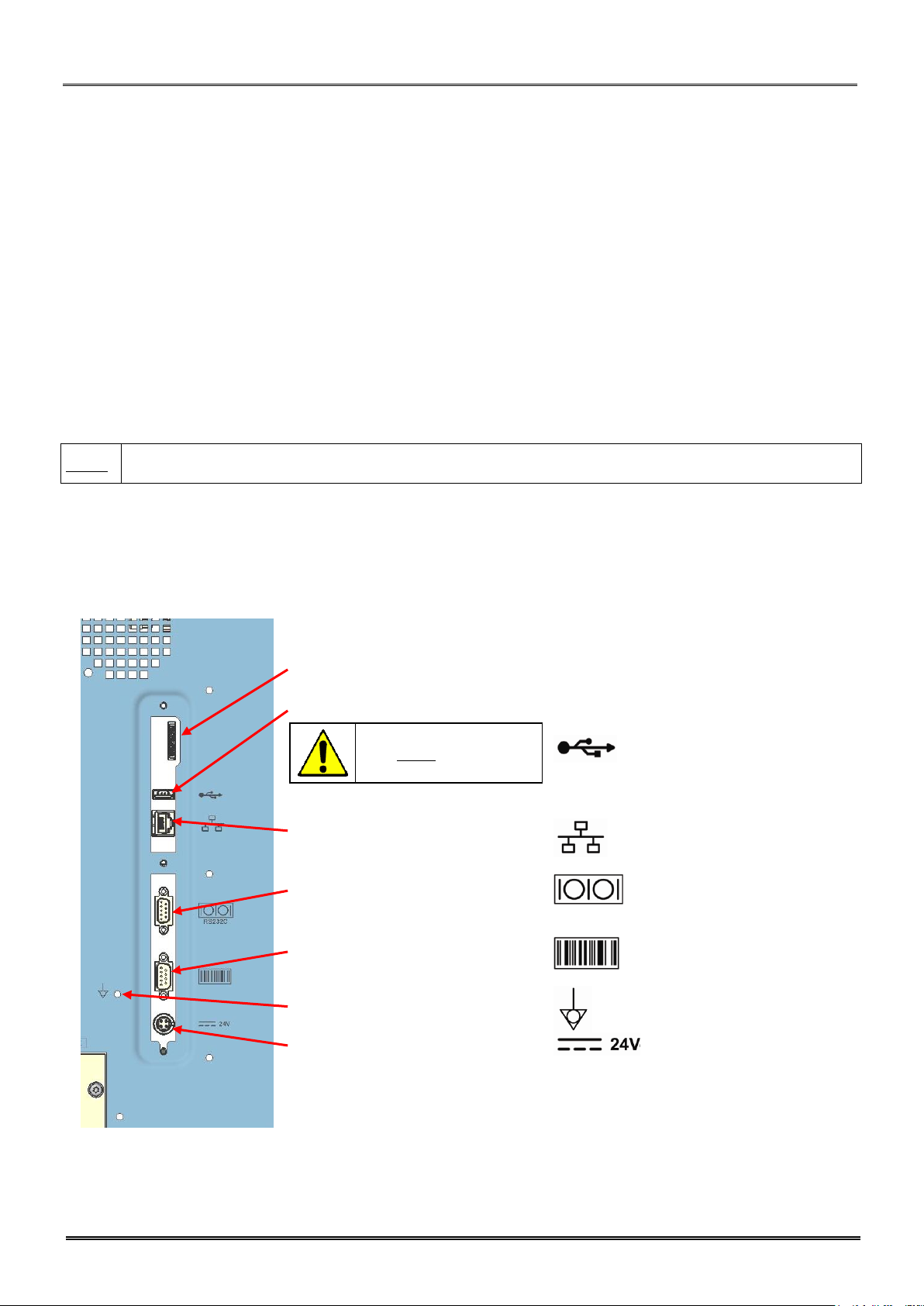

CONNECTION :

SYMBOL :

- Not available

- 1 USB port:

- Ethernet connection (TCP/IP):

- Host connection (RS232C):

- External barcode reader (RS232C):

- Equipotentiality:

- Power supply cord connection:

This USB port can be

used ONLY for the

printer connection.

1.2 INSTALLATION CONSTRAINTS

1.2.1 Installation place

To ensure that the MYTHIC 22 AL fulfills its function, place the instrument on a table which supports the weight of the

instrument, printer and reagents (~40 Kg). Leave a space of 10 cm at the rear of the instrument to ensure a wellventilated place. Avoid a place that can be exposed to direct sunlight.

1.2.2 Installation environment

a) Indoor use;

b) Altitude up to 3 000 m (see NOTA hereafter);

c) Temperature 18 °C to 34 °C;

d) Maximum relative humidity 80 % for temperatures up to 31 °C decreasing linearly to 50 % relative humidity at 40 °C;

e) MAIN supply voltage fluctuations up to ±10 % of the nominal voltage;

f) Transient over voltages typically present on the MAIN supply.

g) Rated pollution degree II.

1.3 ELECTRICAL CONNECTIONS

1.3.1 Rear connectors

REF : M22AL/UM/EN/004

1. INSTALLATION

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 17/109

3 USB ports

Any output or input connections (except the printer and the barcode reader supplied by ORPHEE)

cannot be done without the ORPHEE’s representative authorization.

In case of replacement of the main power wire, supplied with the MYTHIC 22 AL, the new one must

comply with the local regulation (31.5mm cable and 250V 10A plug).

The MYTHIC 22 AL has been certified with the power supply provided with the instrument. If another

power supply is used with the instrument, Orphee or its representative will not apply any warranty on

this power supply and on the instrument. Please contact Orphee or its local representative before using

such material.

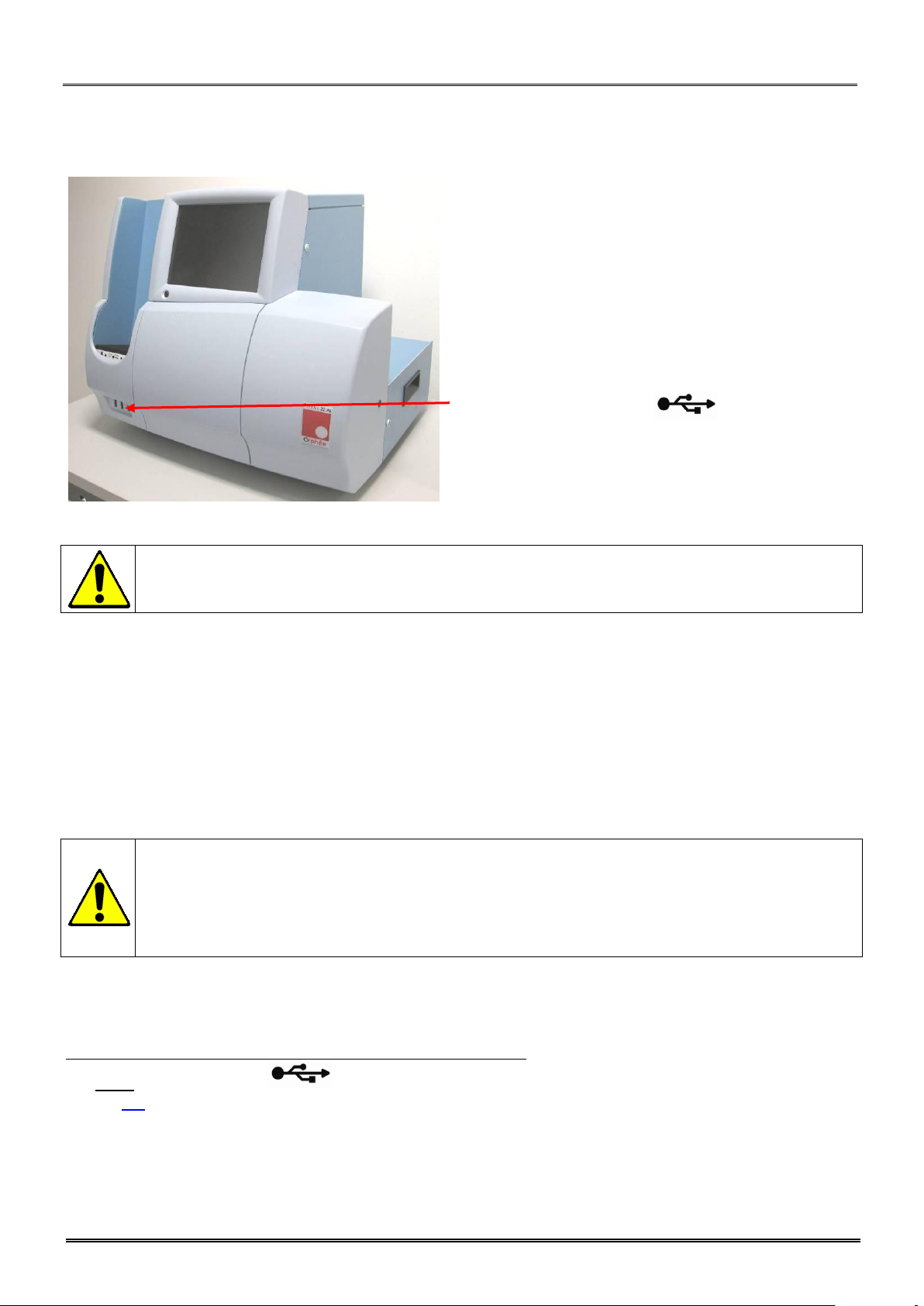

1.3.2 Front connectors

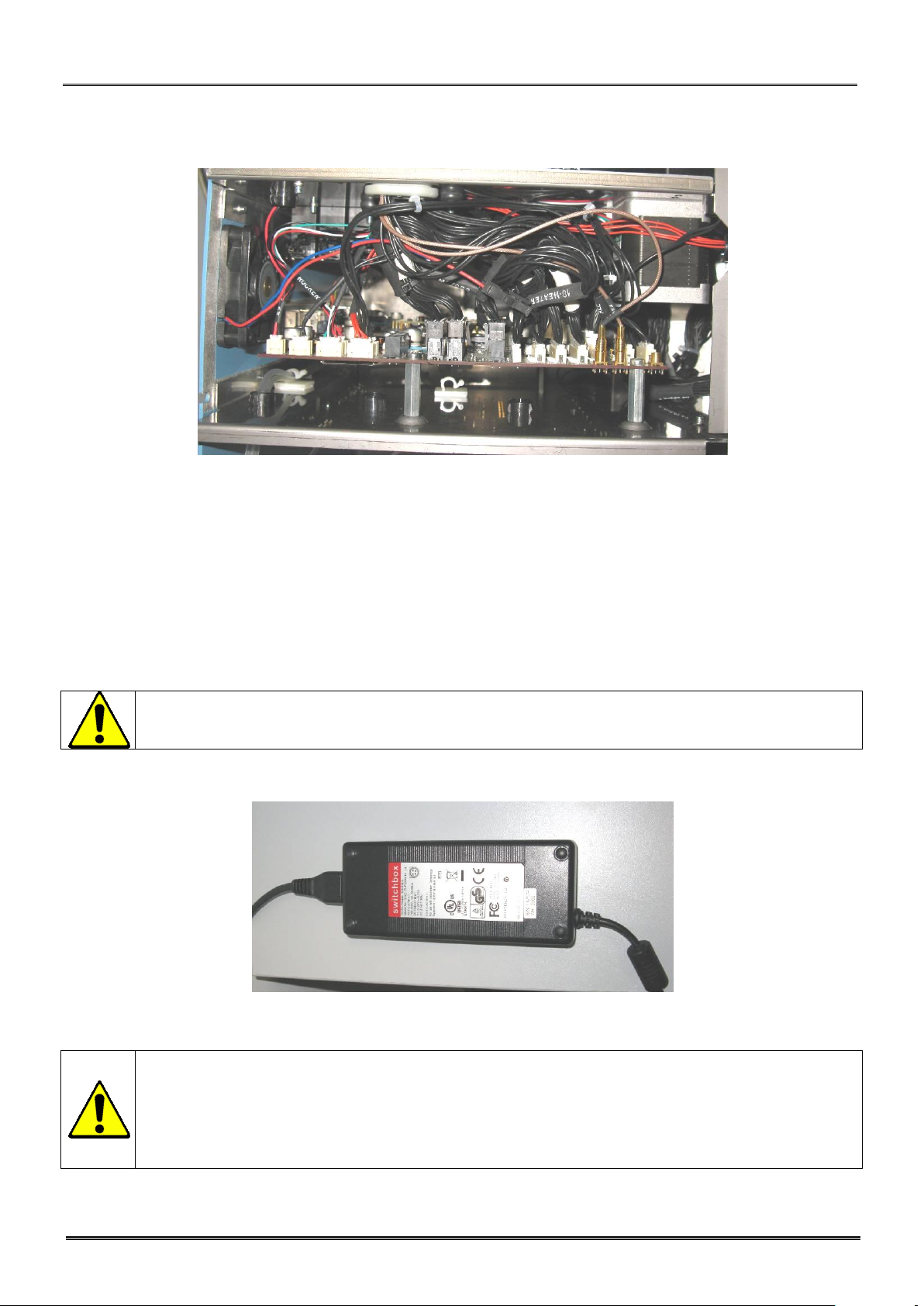

1.3.3 Power supply block

MYTHIC 22 AL must be connected to the power with the power supply block provided with the starter kit. Choose a

well-ventilated place for the block and be sure to connect this power supply in a socket-outlet with a correct earth

connection.

The power supply block must be placed at the rear of the MYTHIC 22 AL and, if possible, in an upper position to avoid

the contact with any liquid.

To disconnect electrically the MYTHIC 22 AL, remove the power supply plug from the main circuit.

1.4 PRINTER CONNECTION

Connect the printer cable in conformity with the printer user’s manual.

Use ONLY the rear USB plug ( ) of the MYTHIC 22 AL to connect the printer cable. Select the printer driver

(section 3.3).

1. INSTALLATION

REF : M22AL/UM/EN/004

Page 18/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

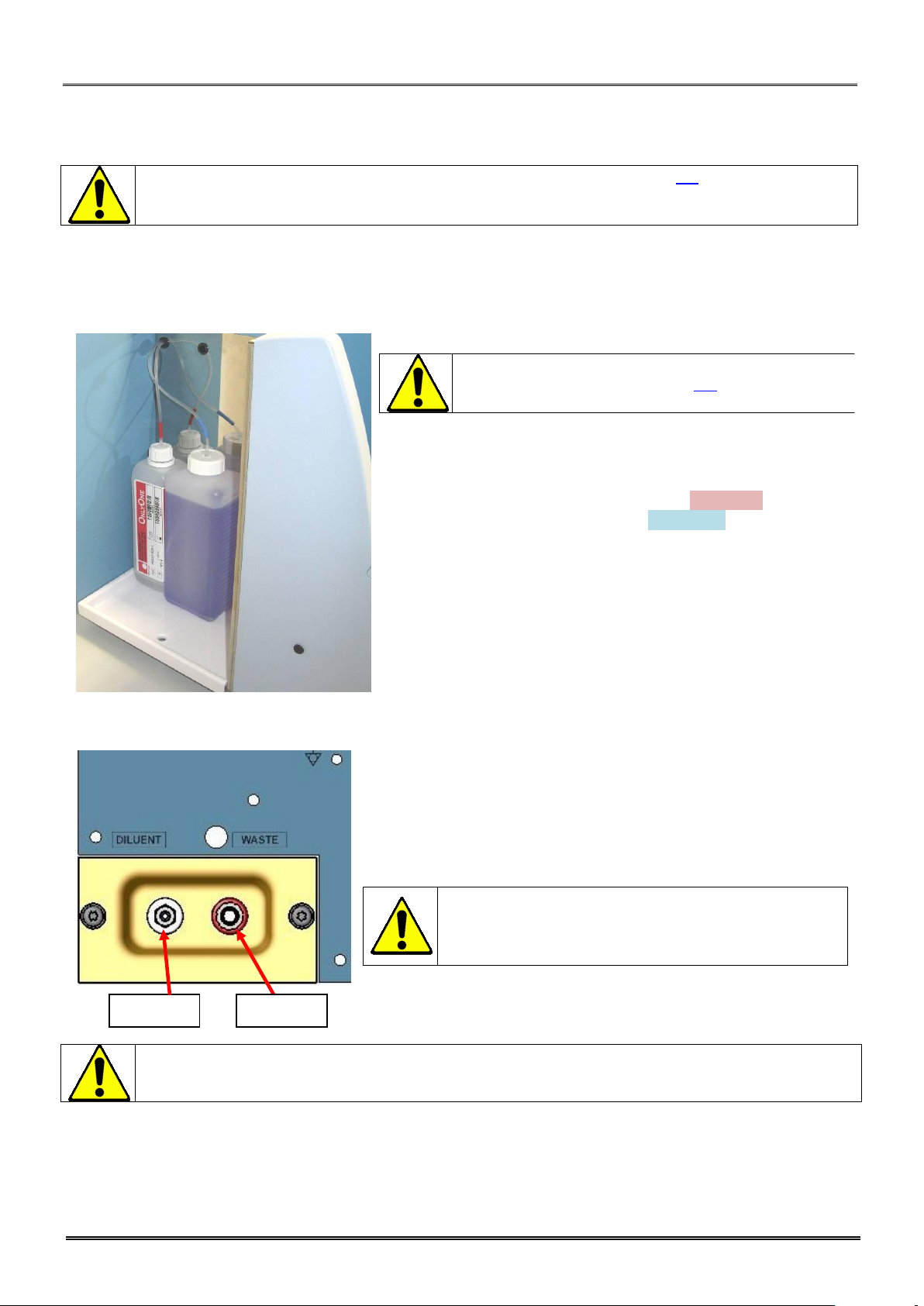

MYTHIC 22 AL works exclusively with the reagents described in section 4.3. Orphee or its local

representative will not be responsible for the quality of the results and for the maintenance of the

instrument if other commercial reagents are used.

Before handling the reagents, read carefully their

specifications described in section 4.3 and check if their

shelf life dates are not reached.

- Remove the door on the left side of the instrument.

- Put the reagent bottles into the dedicated location.

- Remove the caps of the bottles.

- Tighten the red caps on the OnlyOne bottle (red sticker) and the

blue one on the cleaning solution bottle (blue sticker).

- Connect the diluent tube (male connector) on the outlet on the bottom

and tighten the cap on the diluent container.

- To use 20 liters diluent container, add the tubing straw adaptor

supplied with the installation kit.

- Connect the waste tube (female connector) on the outlet on the top and

tighten the cap on an empty container.

Do not modify the type and the length of the diluent

and waste tubes.

The diluent must be placed at the same level as the

MYTHIC 22 AL.

It is mandatory to collect the waste in a container and to treat it in compliance with your local

regulations.

Diluent

Waste

1.5 CONNECTION, CHANGE AND PRIMING REAGENTS

1.5.1 Connection

Lytic reagent and cleaning solution:

Diluent and waste:

REF : M22AL/UM/EN/004

1. INSTALLATION

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 19/109

Before starting, be sure that all the reagent and waste tubes are properly connected.

The reagents must be stored 24 hours minimum at room temperature before use.

1.5.2 Priming

When using the MYTHIC 22 AL for the first time, it is necessary to perform a complete prime of the fluidic circuit.

This operation should be done by a Field Service Engineer.

Priming procedure:

Switch on:

- Connect the power supply block (see section 2.3.4).

- Press the ON/OFF button.

- The logo Orphee appears during a few seconds.

Login:

- The operator’s identification display appears.

- Enter the user’s identification, the password (see section

3.1).

- To validate or not the modification, see section 8.7.1.

- AUTONOMY (run) indicates the number of samples (runs)

you can perform (calculated with the smaller volume of

reagents).

1. INSTALLATION

REF : M22AL/UM/EN/004

Page 20/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

NOTA

To do an emergency stop in case of problem

push briefly on the on/off button

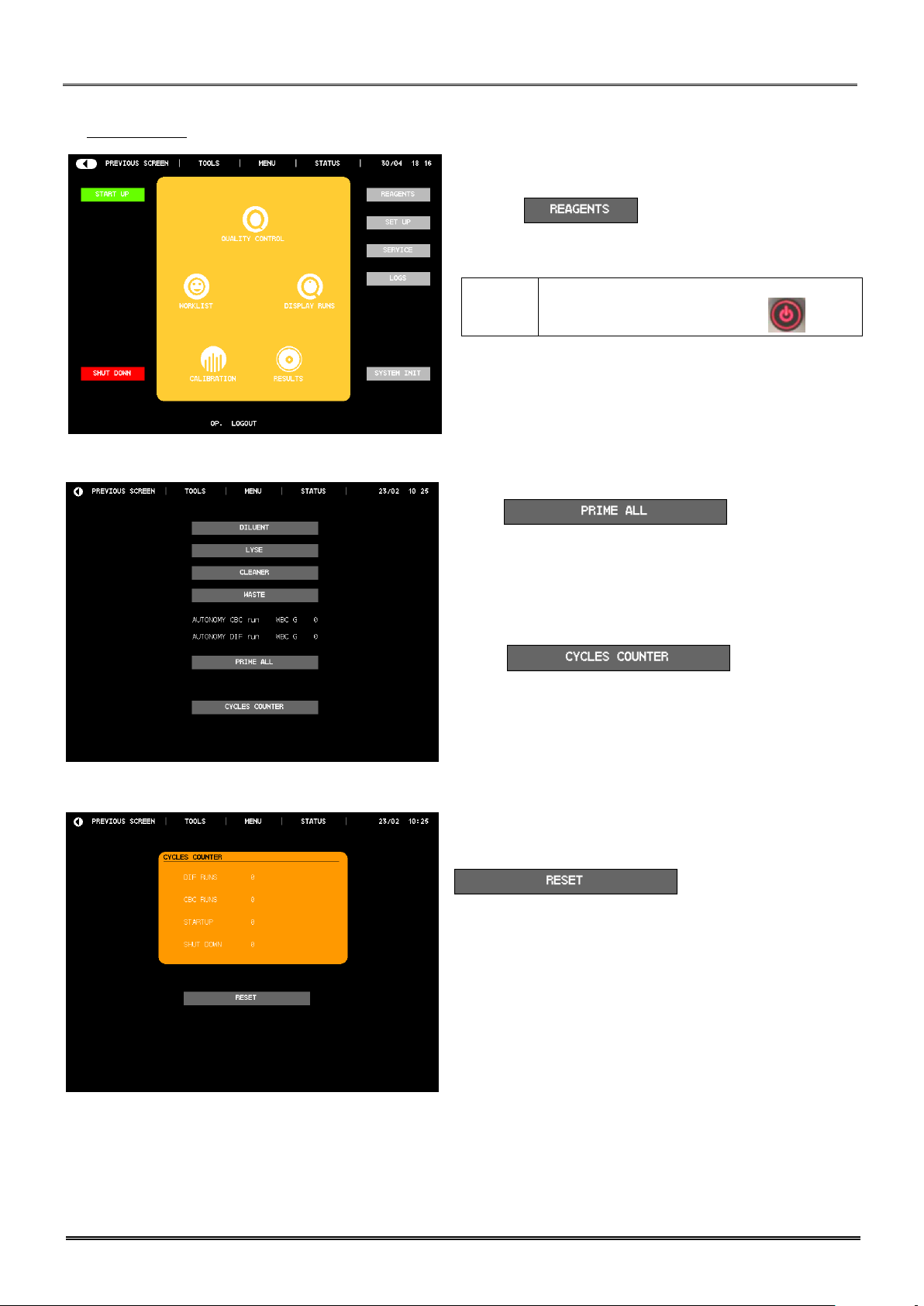

System priming:

- The main menu is displayed.

- Press on .

- Press : The MYTHIC 22

AL performs a complete priming cycle.

- AUTONOMY (run) indicates the number of samples (runs).

- To prime or to know the quantity of reagent, press the

dedicated button.

- Press to display the

cycle counters.

- To reset the counter with the button

, please contact your

Orphee’s representative.

REF : M22AL/UM/EN/004

1. INSTALLATION

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 21/109

MYTHIC 22 AL IS NOW READY TO OPERATE.

DILUENT PRIME:

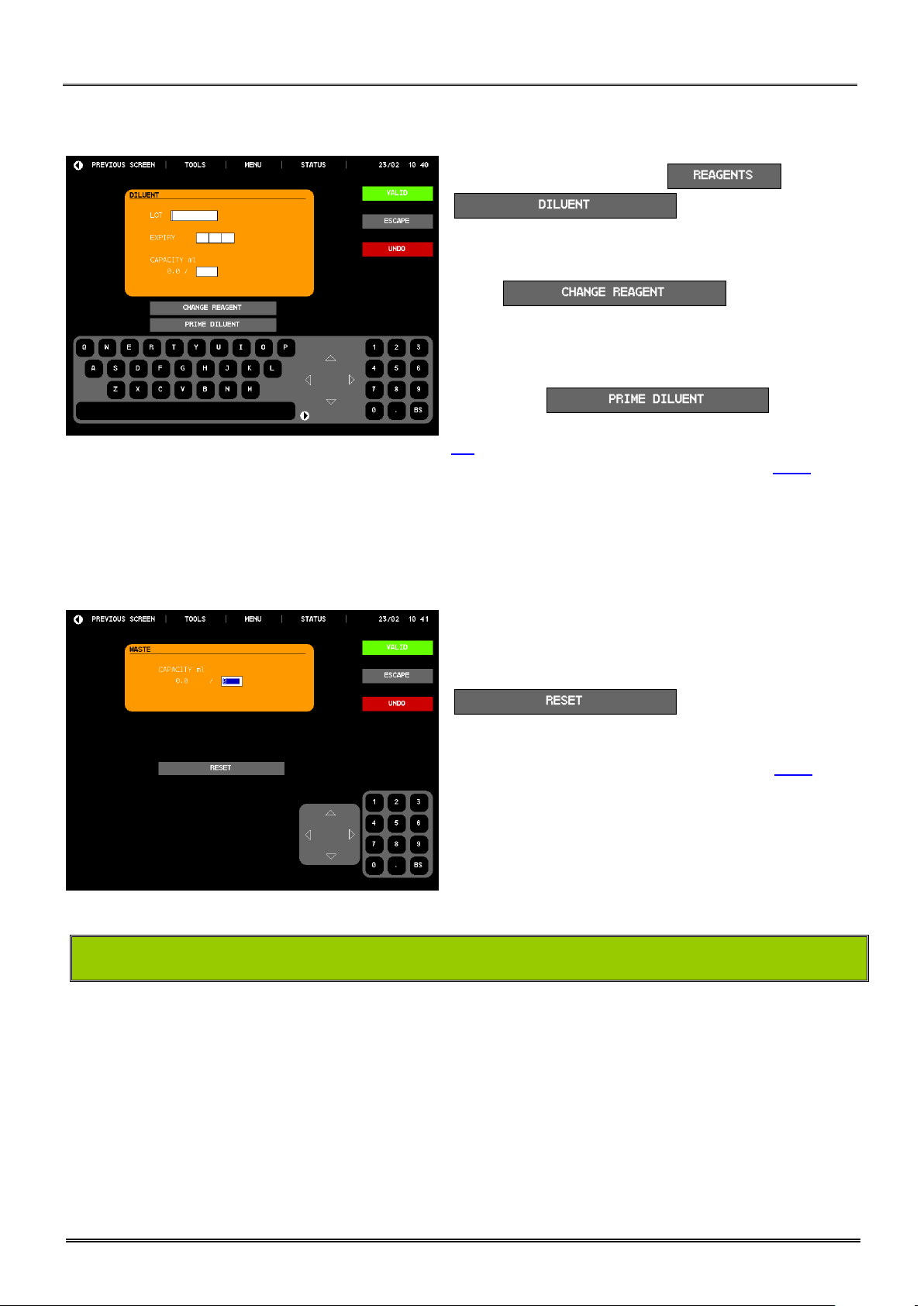

LYSE AND CLEANER PRIME:

Proceed as described above for the diluent.

WASTE:

- From the MAIN MENU, press then

to have access to this

screen.

- Enter lot number, the expiry date and the container

capacity.

- Press to validate the new

entry or after changing a new container with the same

information.

- If needed, enter the container volume in milliliter.

- After the replacement of a new container or to prime the

diluent, press

- A new entry is automatically done in the logs (see section

5.9)

- To validate or not the modification, see section 8.7.1.

- Only enter the capacity of the container.

- After replacement of the waste container, press

to initialize the waste

calculation.

- To validate or not the modification, see section 8.7.1.

1.6 TRANSPORTATION AND STORAGE

Before transportation outside the laboratory, perform a complete cleaning with a disinfectant in compliance with the

local regulations.

Storage temperature: -10°C to +50°C.

If the MYTHIC 22 AL has been stored at a temperature lower than 10°C, it must be left at room temperature during 24

hours.

2. GENERAL OVERVIEW

REF : M22AL/UM/EN/004

Page 22/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

2. GENERAL OVERVIEW

2.1 INTENDED USE

The MYTHIC 22 AL is an automated hematology analyzer for in vitro diagnostic use in clinical laboratories by an

authorized and trained people.

- Only human blood or artificial blood (recommended control or calibrator) should be run.

- Only the reagents mentioned in this manual are permitted to be used.

- The optimum performances can be only achieved if the cleaning and maintenance procedures are carefully

followed (see section 9.1).

2.2 GENERALITIES

MYTHIC 22 AL is a fully automated analyzer performing hematological analysis on whole blood collected on EDTA K2 or

K3 tubes.

- Sampling volume: 18,2 µl (inside the needle, the total volume could be upper according to the blood remaining outside

of the needle).

- Two sampling modes: - closed tube in 10 racks of 5 tubes

- opened other vial in a special position (front door open)

- Throughput: close tube mode: > 40 samples/hour

Other vial mode: > 45 samples/hour

- 22 analysis parameters in DIF mode and 12 parameters in CBC mode:

Leukocyte parameters:

WBC White Blood Cells

LYM Lymphocytes in % & # (DIF mode only)

MON Monocytes in % & # (DIF mode only)

NEU Neutrophils in % & # (DIF mode only)

EOS Eosinophils in % & # (DIF mode only)

BAS Basophils in % & # (DIF mode only)

Erythrocyte parameters

RBC Red Blood Cells

HGB Hemoglobin

HCT Hematocrit

MCV Mean Corpuscular Volume

MCH Mean Corpuscular Hemoglobin

MCHC Mean Corpuscular Hemoglobin Concentration

RDW Red Blood cells Distribution Width

Thrombocyte parameters

PLT Platelet

MPV Mean Platelet Volume

PDW* Platelet Distribution Width

PCT* Thrombocrit

* For Investigation Use only in the United States of America

REF : M22AL/UM/EN/004

2. GENERAL OVERVIEW

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 23/109

Use only a soft paper to clean the screen, never use direct liquid otherwise the screen could be

damaged.

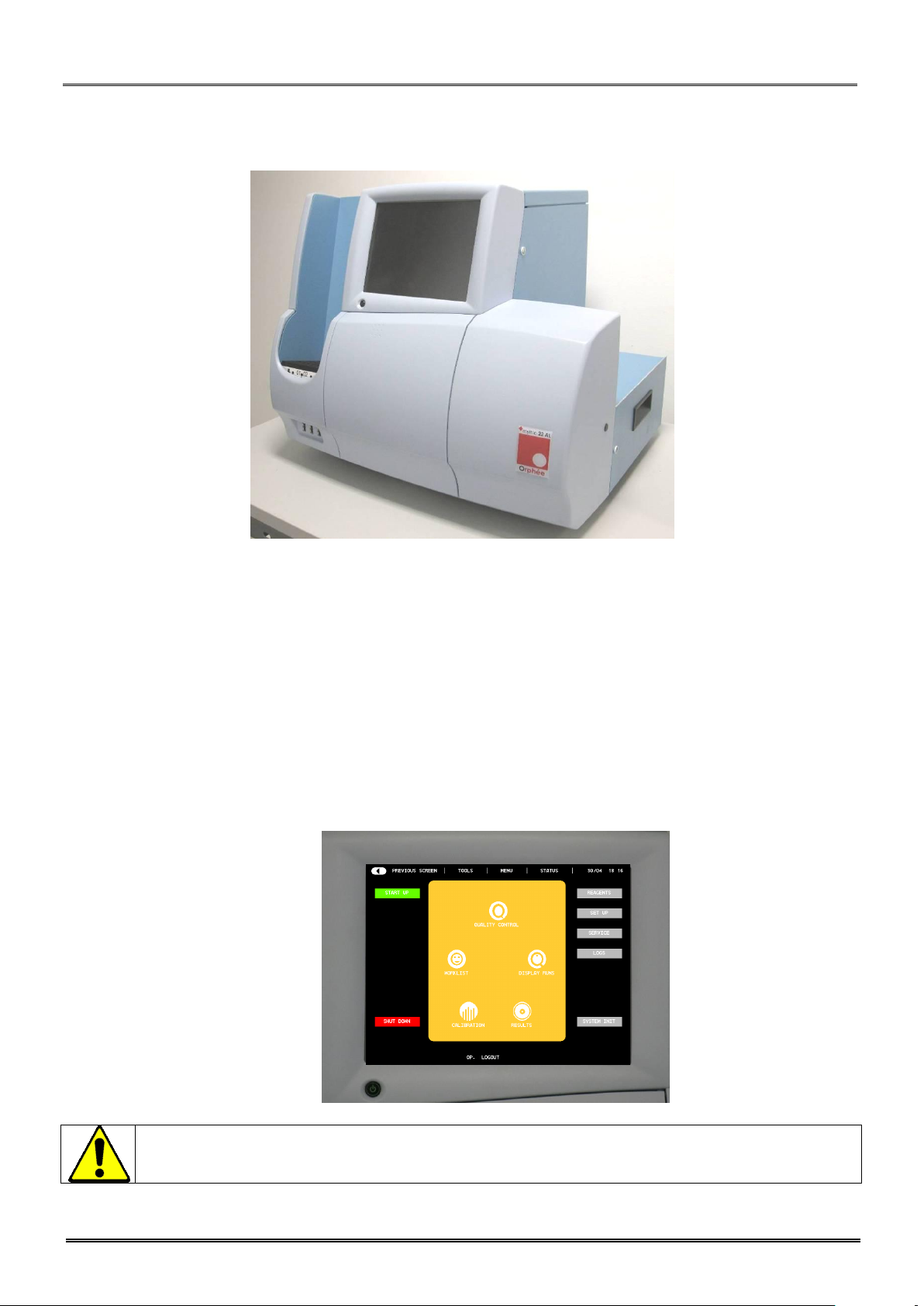

2.3 OVERVIEW

2.4 MAIN PART DESCRIPTION

2.4.1 Display

MYTHIC 22 AL consists of 9 main parts:

1. Auto loader system

2. Display.

3. Dilution hydraulic part.

4. Mono electronic board.

5. Reagent tray.

6. Connection.

7. External power supply block.

8. Printer.

9. Barcode reader (option).

2. GENERAL OVERVIEW

REF : M22AL/UM/EN/004

Page 24/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

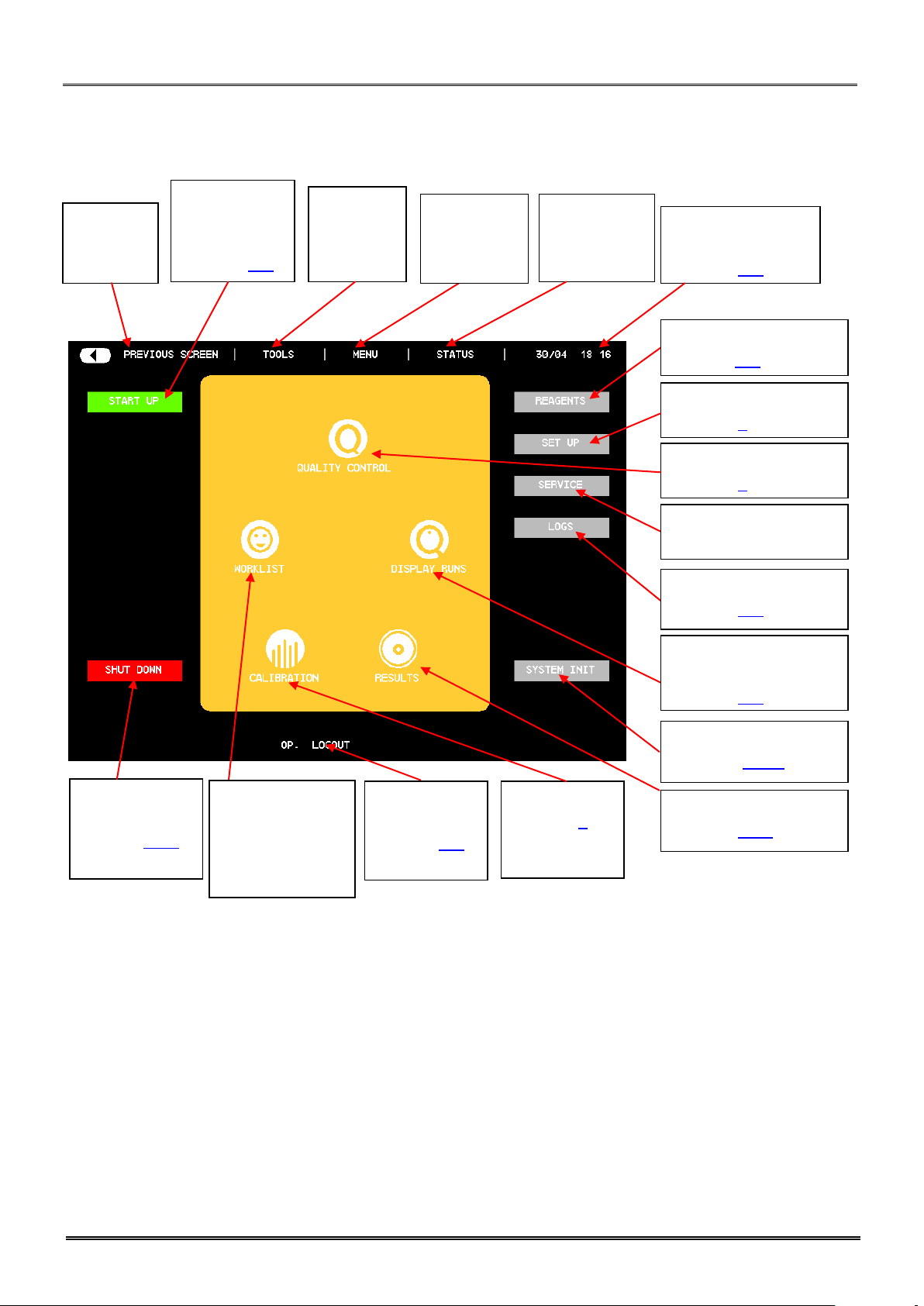

Back to

previous

screen

Print,

Send,

Select

Options

Direct

access to

main menu

Start Up

rinsing and

blank control

(Section 5.2)

Cleaning and

standby mode

(section 5.11)

Patient Archive

(Section 5.10)

Quality Control

(Section 6).

Calibration

(Section 7).

Mythic Parameters

(Section 3).

Maintenance and

Service Menu

Work list

management and

Analysis

performing

(section 5.5).

Mythic Events Logs

(Section 5.9).

Reagent replacement

(section 5.3).

Log In and

Log Out

(section 3.1)

Date and Time.

System status

(Section 3.2).

Full screen run

displayed

(Section 3.1).

Display of

the sampler

status

System init

(Section 9.4.1)

Main Menu description

REF : M22AL/UM/EN/004

2. GENERAL OVERVIEW

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 25/109

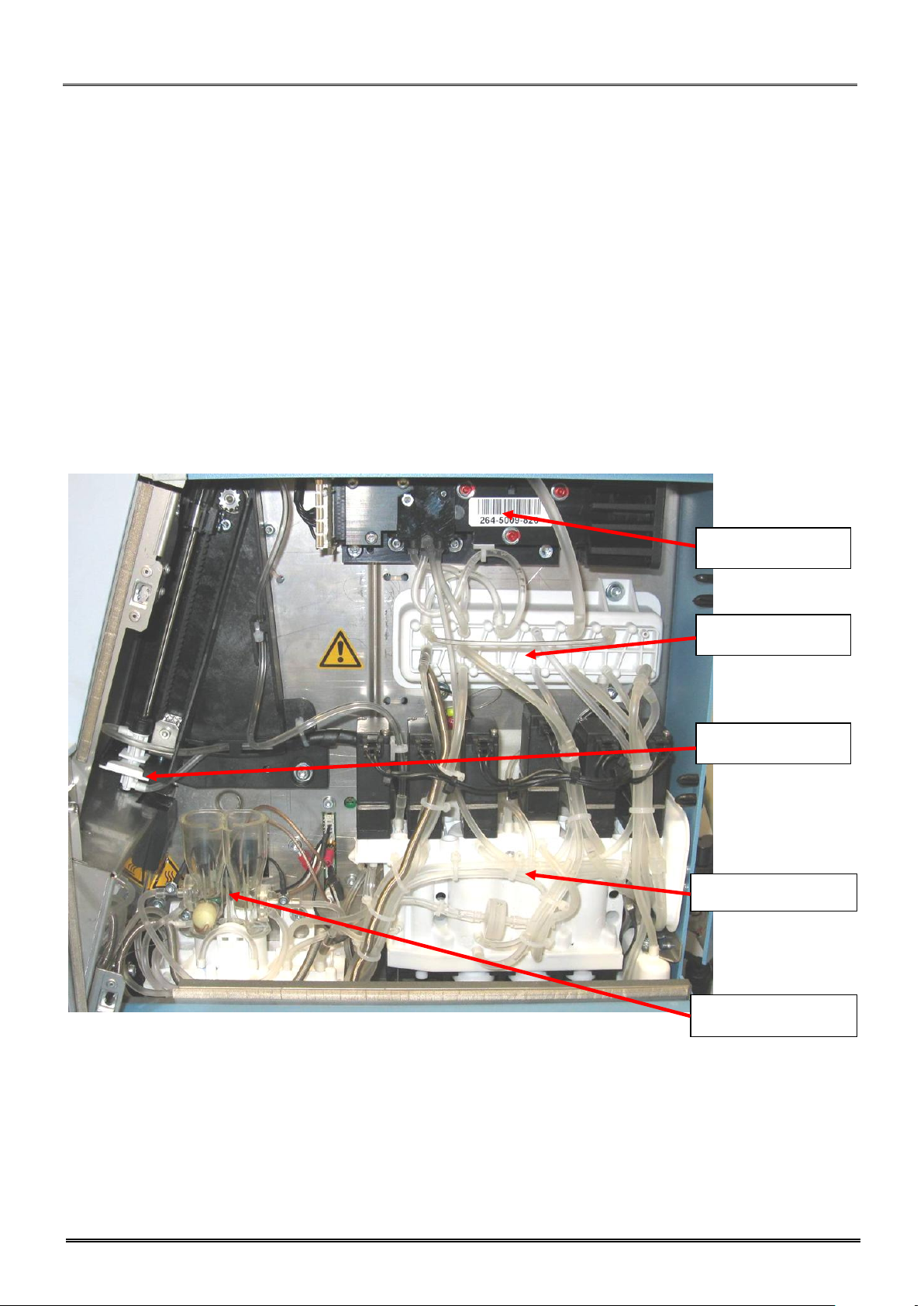

Sampling module

Syringe module

Counting module

Optical manifold

Optical bench

2.4.2 Dilution fluidic part

All the fluidic part is on the right side of the instrument and consists of five modules only:

- Sampling module :

o Rocker (patented) : Manages the rise and descent of the needle.

- Syringe module (patented) consists of one block :

o Reagent syringes (Diluent, lysis), sampling and air syringes.

o Liquid valve manifold assembly and tubing.

- Counting chambers :

o WBC and RBC counting chambers and hemoglobin measurement.

o Liquid valve manifold assembly and tubing.

- Optical Manifold :

o Liquid valve manifold assembly and tubing.

- Optical bench :

o Optical bench (patented) with its flow cell (patented).

2. GENERAL OVERVIEW

REF : M22AL/UM/EN/004

Page 26/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

To avoid all deterioration risks, only the field service engineer may touch this electronic

board.

- In case of replacement of the main power wire supplied with the MYTHIC 22 AL, the new one must

be in compliance with the local regulations.

- The MYTHIC 22 AL has been certified with the power supply box provided with the machine. - If

another power supply is used with the instrument, Orphee or its representative will not apply any

warranty on this power supply and on the instrument. Please contact Orphee or its local representative

before using such material.

Mono electronic board

The mono electronic board is located between the hydraulic part and the reagent tray.

The board, driven by a 32-bit processor, manages the following parts:

- Fluidics: sample needle, rocker, syringe block motors.

- Autoloader: loading, transfer, mixing and unloading.

- Display and keyboard.

- Connection mode (RS232, Ethernet …).

- Printer.

- Measurement (Optical and resistive counting, hemoglobin measurement).

- Data processing.

- External barcode reader.

2.4.3 Power Supply Block

MYTHIC 22 AL is supplied with an external power supply block.

REF : M22AL/UM/EN/004

2. GENERAL OVERVIEW

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 27/109

2.4.4 Reagent tray

The reagent tray is dedicated to the OnlyOne lysing reagent and cleaning solution bottles.

2.4.5 Sampler

- This module enables to load, transfer, mix and unload the racks. Ten racks of five tubes can be loaded. The

loading can be done continually.

- The rack are loaded on the guide rail by a loading screw then displaced by another screw (transfer screw).

- The rail which maintains the rack can also rotated for mixing the blood inside the tubes.

- When all the samplings are performed for a rack, it is unloaded by the unloading motor.

3. INSTRUMENT SET UP

REF : M22AL/UM/EN/004

Page 28/109

Copyright© Orphee SA. All Rights Reserved.

MYTHIC 22 AL

3. INSTRUMENT SET UP

3.1 USER’S IDENTIFICATION

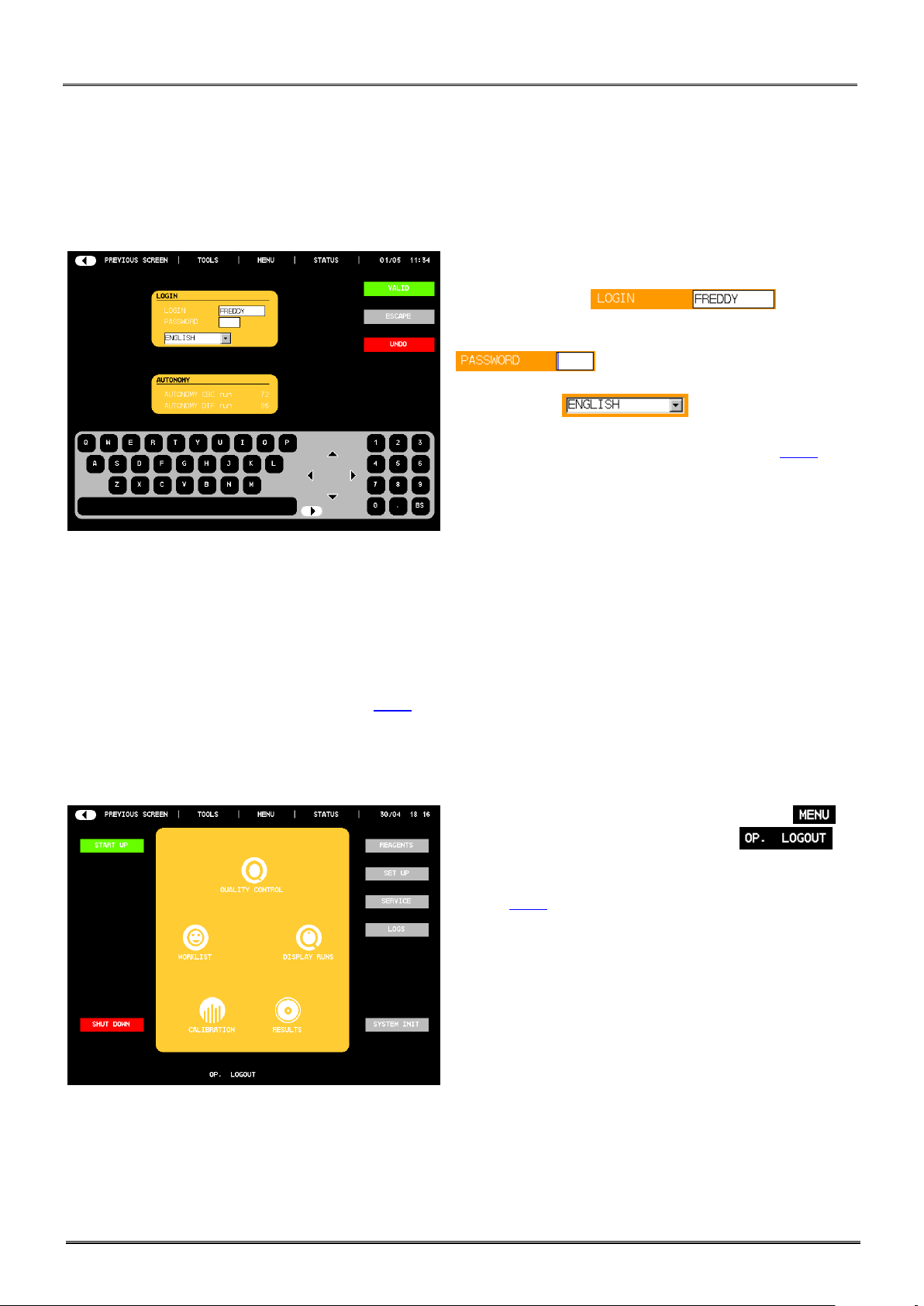

3.1.1 Start Up Machine

- After the instrument’s initialization, the identification

window is displayed.

- In the window , the last

operator’s identification appears.

- Either the identification is yours, press

identification is not, enter your login with the keyboard.

- The window enables to change the

language.

- To validate or not the modification, see section 8.7.1.

- AUTONOMY (run) indicates the number of samples (runs)

you can perform (calculated with the smaller quantity of

reagents).

- Enter your identification name with the alphabetic keyboard.

- Place the cursor in the Password window.

- Enter your password for identification.

- For the first login, MYTHIC 22 AL proposes 3 access levels:

o User : No password

o Biologist : Password by default 1- 2- 3

o Service people

- Biologist Password can be modified in section 3.3.6.

3.1.2 In process

- To change operator during the process, press to

return to the main menu, and then press on

- To change identification, proceed as described above

(section 3.1.1).

and enter your password or the

REF : M22AL/UM/EN/004

3. INSTRUMENT SET UP

MYTHIC 22 AL

Copyright© Orphee SA. All Rights Reserved.

Page 29/109

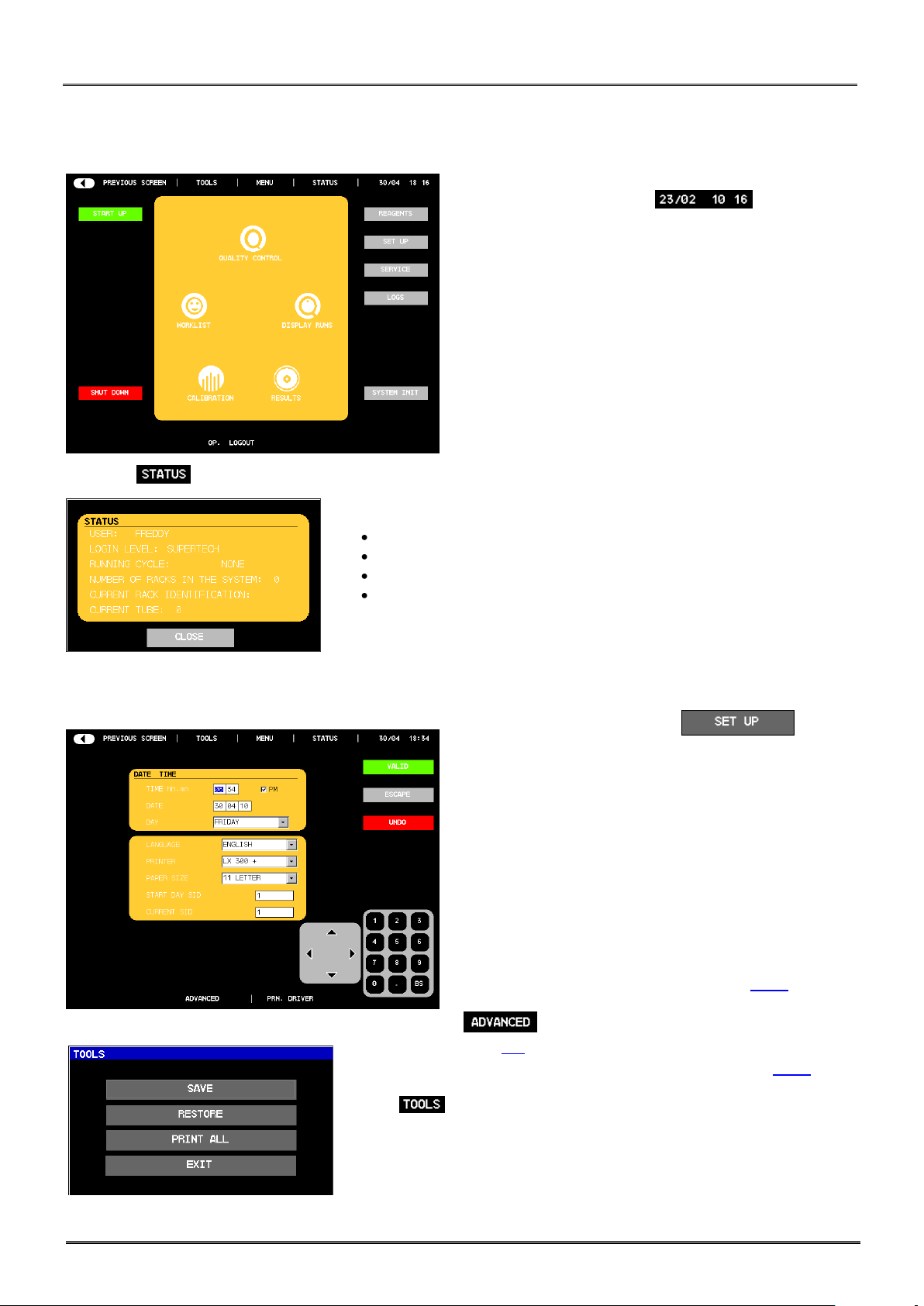

3.2 SYSTEM STATUS

- Press on the date and hour to have access

to the system information window.

- Press on to have access to the status of the MYTHIC 22 AL.

- Different information are displayed:

Name of the operator

Level of access

Name of the cycle in progress

Number of racks

3.3 SET UP

- From the MAIN MENU press on

- This menu is available for all users.

- The DATE & TIME window enables to modify the time, the

date and the day.

- To select the language of the Mythic menu, choose the right

one in the LANGUAGE combo box.

- PRINTER: Select the printer or no printing.

- PAPER SIZE: Select the paper size per result.

- Two SID are available;

START DAY SID enables to select the first SID for

each new day.

CURRENT SID enables to fix the beginning of the

current SID number (which will be used in the AUTO

SID number in the work list, see section 5.6.2)

- : Biologist reserved for complete settings. (See

section 3.4).

- To validate or not the modification, see section 8.7.1.

- Press to save, load (RESTORE), print or delete all the settings, from

an USB key. Three pages are required to print all the settings.

Loading...

Loading...