Orphee Mystic 18 Service manual

19, chemin du champ-des-filles

CH-1228 Geneva / Plan-les-Ouates

SWITZERLAND

Tel : +41 (0) 22 706 1840

Fax : +41 (0) 22 794 4391

http://www.orphee-medical.com

ORPHEE

MYTHIC 18

SSEERRVVIICCEE MMAANNUUAALL

REF : M18-SM-001 Rev 02

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 1/68

REF : M18-SM-001 Rev 02

REVISIONS

Revision Nb Date Author Software Comments

01 19/07/04 HC V 0.6x Creation

02 28/02/05 HC V 1.0X Update of all parts

CONTACT ADDRESS

LOCAL REPRESENTATIVE

MANUFACTURER

M

AUTHORIZED REPRESENTATIVE

WORLDWIDE

C2 Diagnostics

2214, Bd de la Lironde

34397 Montpellier Cedex 5

FRANCE

ORPHEE SA

19, chemin du champ-des-filles

CH-1228 Geneva / Plan-les-Ouates

SWITZERLAND

Tel : +41 (0) 22 706 1840

Fax : +41 (0) 22 794 4391

http://www.orphee-medical.com

Page 2/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

IMPORTANT SAFETY INSTRUCTIONS

RISK OF DANGER ! Indicates a procedure to be strictly respected in order to

avoid any risks for the operator (user) or damages on the instrument or on the

quality of results.

Indicates that wearing gloves is mandatory before performing the described

operation due to risk of contact with materials that may be infectious.

NOTA : Indicates important additional information.

BEFORE TO INSTALL OR TO

MAINTAIN A MYTHIC 18 YOU

HAVE TO READ AND TO REFER

TO THE USER’S MANUAL.

OPERATORS MUST HAVE

RECEIVED ADEQUATE TRAINING.

BE CAREFUL WITH THE EDGE OF THE METAL SHEETS

AFTER HAVING DISMANTLED THE COVERS.

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 3/68

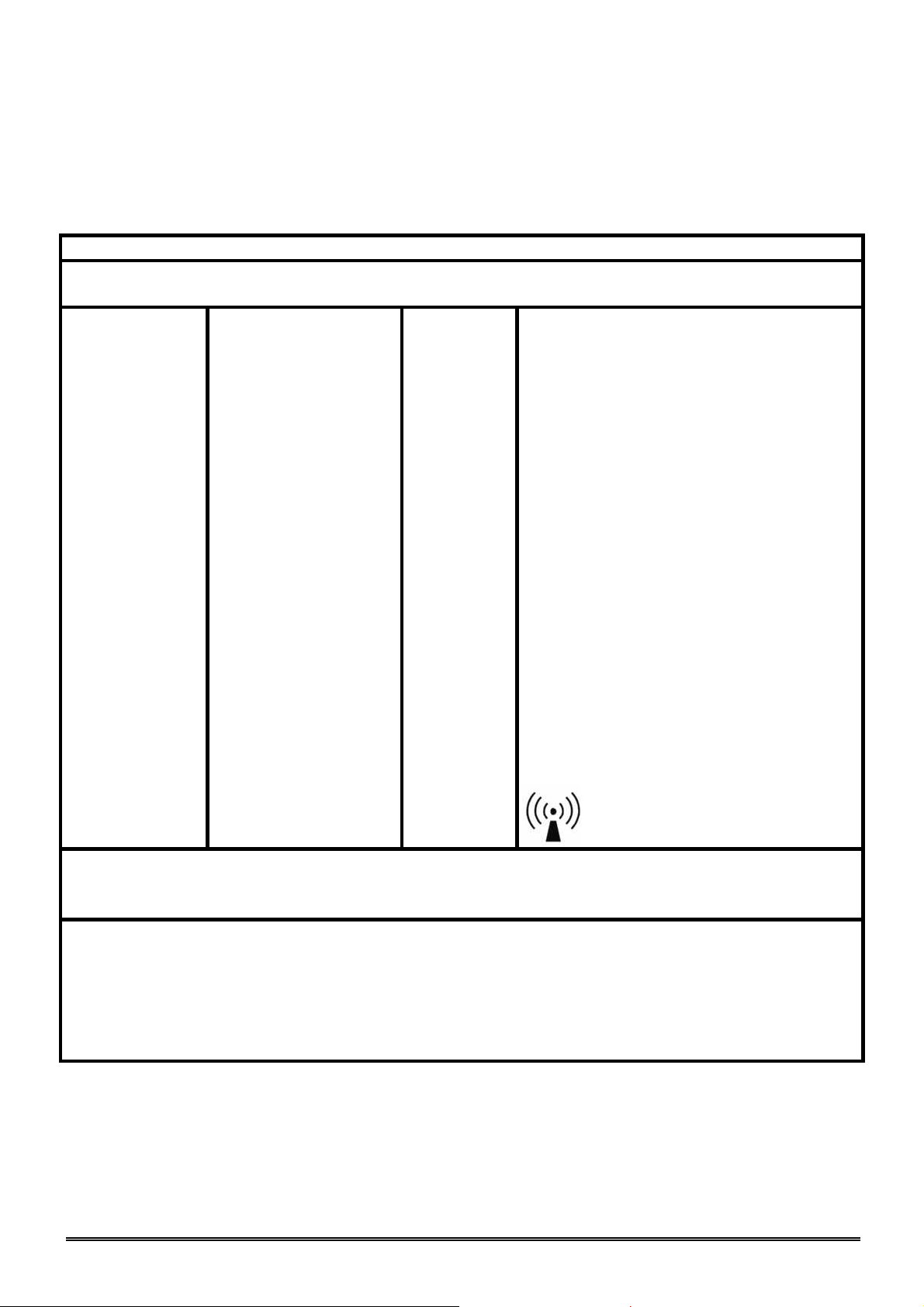

REF : M18-SM-001 Rev 02

This equipment needs special precautions regarding EMC and needs to be installed and put

into service according to the EMC information listed below

Guidance and manufacturer’s declaration – Electromagnetic immunity

The MYTHIC 18 is intended for use in the electromagnetic environment specified below. The customer or

the user of the MYTHIC 18 should assure that it is used in such environment.

Immunity test IEC 60601 test level Compliance

level

Recommended separation distance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

Where P is the maximum output power rating of the

Field strenghts from fixed RF transmitters, as

Interference may occur in the vicinity of equipment

3 Vrms

150Khz to 80Mhz

3 Vrms

80Mhz to 2,5Ghz

3 Vrms

3 Vrms

Electromagnetic environment - guidance

Portable and mobile RF communications equipment should

be used no closer to any part of the MYTHIC 18,

including cables, than the recommended separation

distance calculated from the equation applicable to the

frequency of the transmitter.

d

= 1,2√P

d

= 1,2√P 80MHz to 800MHz

d

= 2,3√P 800MHz to 2,5GHz

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

a

determined by an electromagnetic site survey,

less than the compliance level in each frequency range.

marked with the following symbol:

should be

b

NOTE 1 At 80Mhz and 800MHz, the higher frequency range apllies.

NOTE 2 Theses guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

a

Field strenghts from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios,

amateur radio, AM an FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the

electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should considered. If the measured field

strenght in the location in which the MYTHIC 18 is used exceeds the applicable RF compliance level above, the MYTHIC 18 should be

observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as re-orienting

or relocating the MYTHIC 18.

b

Over the frequency range 150KHz to 80MHz, field strenghts should be less than 3V/m.

Page 4/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 5/68

REF : M18-SM-001 Rev 02

TABLE OF CONTENTS

1. INTRODUCTION 8

2. FLUIDICS 9

2.1 GENERALITIES ...................................................................................................................................................................................... 9

2.2 FLUIDICS SEQUENCES DESCRIPTION :................................................................................................................................................ 9

2.3 FLUIDICS VIEW ...................................................................................................................................................................................11

2.4 FLUIDICS PARTS DESCRIPTION.......................................................................................................................................................... 12

2.4.1 Sampling module .....................................................................................................................................................................12

2.4.2 Counting bath module ...........................................................................................................................................................12

2.4.3 Syringes module..................................................................................................................................................................... 12

2.5 FLUIDICS DIAGRAM............................................................................................................................................................................ 13

2.5.1 General Diagram .....................................................................................................................................................................13

2.5.2 Manifold tubing position...................................................................................................................................................... 14

2.6 SIZE & LENGTH TUBING ..................................................................................................................................................................... 15

3. ELECTRIC & ELECTRONIC 16

3.1 GENERALITIES .................................................................................................................................................................................... 16

3.2 ELECTRICS PARTS VIEW ..................................................................................................................................................................... 16

3.2.1 Main board ...............................................................................................................................................................................16

3.2.2 GUI board................................................................................................................................................................................ 17

3.2.3 Preamplifier board ................................................................................................................................................................17

3.2.4 Power supply block................................................................................................................................................................. 17

3.3 ELECTRONIC DIAGRAM ....................................................................................................................................................................... 18

3.4 WIRING DIAGRAM .............................................................................................................................................................................. 19

3.4.1 General view............................................................................................................................................................................. 19

3.4.2 Stepper motor........................................................................................................................................................................20

3.4.3 Rocker optical sensor ........................................................................................................................................................... 21

3.4.4 Syringe optical sensor..........................................................................................................................................................22

3.4.5 Needle optical sensor...........................................................................................................................................................23

3.4.6 Syringe valve cable................................................................................................................................................................24

3.4.7 Counting valve cable..............................................................................................................................................................25

3.4.8 Start key switch....................................................................................................................................................................26

3.4.9 Fluidic door switch................................................................................................................................................................27

3.4.10 Temperature sensor............................................................................................................................................................28

4. SPECIFICATIONS 29

4.1 ANALYTICAL SPECIFICATIONS ..........................................................................................................................................................29

4.2 REAGENTS SPECIFICATIONS ............................................................................................................................................................29

4.3 LIMITATIONS.....................................................................................................................................................................................29

5. OUTPUT FORMAT 30

5.2 C2 FORMAT .........................................................................................................................................................................................30

5.2.1 General principle.....................................................................................................................................................................30

5.2.2 FRAMES...................................................................................................................................................................................30

5.2.2.1 REQUEST TO SEND RESULTS.............................................................................................................................. 30

5.2.2.1.1 Request to send results..................................................................................................................................... 30

5.2.2.1.2 ACKNOWLEDGEMENT REQUEST TO SEND RESULTS............................................................................................... 30

5.2.2.1.3 ACKNOWLEDGEMENT RESULTS............................................................................................................................... 30

5.2.2.2 ROUTINE RESULTS ..................................................................................................................................................31

5.2.2.2.1 Alarm list.............................................................................................................................................................. 32

5.2.2.2.2 WBC pathologic alarms..................................................................................................................................... 32

5.2.2.2.3 RBC pathologic messages ................................................................................................................................. 33

5.2.2.2.4 PLT pathologic messages.................................................................................................................................. 33

5.2.2.3 CALIBRATION ........................................................................................................................................................... 33

5.2.2.3.1 Results................................................................................................................................................................... 34

5.2.2.4 QC................................................................................................................................................................................... 34

5.2.2.4.1 Results................................................................................................................................................................... 34

5.2.2.5 REPEATABILITY........................................................................................................................................................ 35

Page 6/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

5.2.2.5.1 Results................................................................................................................................................................... 35

5.2.3 CHECKSUM .............................................................................................................................................................................35

6. PARTS LIST & BLOW UP VIEW 37

6.1 PARTS LIST..........................................................................................................................................................................................37

6.1.2 Two years spare parts kit....................................................................................................................................................37

6.1.2 Maintenance kit ......................................................................................................................................................................37

6.1.2 O-rings kit................................................................................................................................................................................38

6.1.2 Tubing kit .................................................................................................................................................................................38

6.1.2 All spare parts ........................................................................................................................................................................39

6.2 BLOW UP VIEW.................................................................................................................................................................................... 41

6.2.1 Counting Module ..................................................................................................................................................................... 41

6.2.2 Sampling Module ....................................................................................................................................................................42

6.2.3 Syringe Module ......................................................................................................................................................................43

6.2.4 CPU-PREAMPLIFIER Module..............................................................................................................................................46

6.2.5 Front cover Module...............................................................................................................................................................47

7. SOFTWARE 48

7.1 INTRODUCTION...................................................................................................................................................................................48

7.2 SPECIFIC TECHNICIAN DISPLAY ........................................................................................................................................................48

7.2.1 Technician password..............................................................................................................................................................48

7.2.2 Technician display .................................................................................................................................................................48

7.2.2.1 Technician ..................................................................................................................................................................... 48

7.2.2.2 Counting parameters.................................................................................................................................................. 49

7.2.2.3 Prod. adjust.................................................................................................................................................................. 49

7.2 SOFTWARE ARBORESCENCE................................................................................................................................................................50

8. MAINTENANCE 51

8.1 MAINTENANCE TABLE......................................................................................................................................................................... 51

8.2 CONCENTRATED CLEANING ................................................................................................................................................................52

8.3 CLEAN OUT..........................................................................................................................................................................................53

9. REPAIRING 54

9.1 EMERGENCY STOP ................................................................................................................................................................................54

9.2 SAMPLING MODULE.............................................................................................................................................................................54

9.2.1 Needle replacement...............................................................................................................................................................54

9.2.2 Complete rocker module replacement..............................................................................................................................54

9.3 COUNTING BATHS MODULE................................................................................................................................................................56

9.3.1 Baths dismantling...................................................................................................................................................................56

9.3.2 Baths o-ring replacement....................................................................................................................................................56

9.3.3 Aperture block replacement...............................................................................................................................................56

9.3.4 Complete baths module replacement................................................................................................................................56

9.4 SYRINGE MODULE ...............................................................................................................................................................................57

9.4.1 Piston greasing........................................................................................................................................................................57

9.4.2 O-ring or piston replacement.............................................................................................................................................57

9.4.3 Complete syringe module replacement.............................................................................................................................58

9.5 BOARDS REPLACEMENT.......................................................................................................................................................................59

9.5.1 GUI board replacement........................................................................................................................................................59

9.5.2 Main board replacement ...................................................................................................................................................... 61

9.5.3 Main board...............................................................................................................................................................................63

9.5.3.1 Fuse replacement ........................................................................................................................................................ 63

9.5.3.2 Battery replacement.................................................................................................................................................. 63

9.5.4. Preamplifier board replacement.......................................................................................................................................65

10. TROUBLESHOOTING 66

10.1 ANALYTICAL PROBLEMS ....................................................................................................................................................................66

10.2 OTHER PROBLEMS .............................................................................................................................................................................66

10.3 TROUBLESHOOTING MESSAGE.........................................................................................................................................................67

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 7/68

1. INTRODUCTION

1. INTRODUCTION

BEFORE TO INSTALL OR TO

MAINTAIN A MYTHIC 18 YOU HAVE

TO READ AND TO REFER TO THE

USER’S MANUAL

The following chapters describe the different technical parts of the MYTHIC 18

- Fluidic

- Electric & electronic

- Technical specification

- Output format

- Spare parts list and blowup view

- Maintenance procedure

REF : M18-SM-001 Rev 02

Page 8/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

2. FLUIDICS

2. FLUIDICS

2.1 GENERALITIES

MYTHIC 18 is a fully automated analyzer performing hematological analysis on whole blood.

The human blood venous sample must be collected in an EDTA K3 (Ethylene Diamine Tetracetic Acid, tri

potassic) tube in sufficient quantity. The LMG results are available for six hours after the blood draw. The

use of EDTA K2 leads to a poor quality level of the LMG results.

It must be correctly homogenized before analysis. It is recommended to use a rotary agitator turning

between 20 to 30 turns/mn during 10 minutes.

A volume of insufficient blood for the quantity of anticoagulant or a bad mixing may involve

an erroneous result.

Two dilution rate are performed :

~1/237 to 1/257 for WBC/HB (depend of the lysis quantity, see section 7.2.2.2)

~1/15000 for RBC/PLT

2.2 FLUIDICS SEQUENCES DESCRIPTION :

SAMPLING SEQUENCE :

1- Syringes down : (no valve)

~Less than 9,8 µl of blood sample are draw inside the sampling needle

Diluent prime

Vacuum prime

2- Needle up and syringe up (valve 3+4)

Needle outside cleaning with diluent and waste vacuum

3-Rocker move above the WBC bath

and the syringes up to drain the waste (valve 7)

4- Needle down to the rinsing position

5- Syringe down

WBC bath drain (valve 1)

6- Syringe up

Second outside needle cleaning (valve 4)

Waste syringe drain (valve 7)

7- Syringe down

WBC bath drain (valve 1)

8- Syringe up

Waste syringe drain (valve 7)

WBC DILUTION :

9- Needle down to the dilution position

and the syringes down to prime the diluent (valve 8)

10- Syringe up for the WBC dilution (~2 ml)

Diluent outside of the needle (valve 4)

Diluent inside the needle (valve 4+5)

Bubble to mix the dilution (valve 1)

RBC DILUTION AND LYSING :

11- Syringe down (no valve)

Drawing sample of the first dilution (~20µl)

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 9/68

2. FLUIDICS

Diluent prime

Vacuum prime

12- Needle up and syringe up

Rocker move above the RBC bath

Needle outside cleaning with diluent and waste vacuum (valve 3+4)

13- Needle down to the rinsing position

14 Syringe up

Second outside needle cleaning (valve 4+8)

Lysis in the WBC bath (0,3 to 0,5ml) (valve 9)

Bubble to mix the dilution (valve 1)

15 Syringe down

RBC bath drain (valve 2)

16- Needle down to the dilution position

17- Syringe up for the RBC dilution (~1,5ml)

Waste syringe drain (valve 7)

Diluent outside of the needle (valve 4+8)

Diluent inside the needle (valve 5)

Bubble to mix the dilution and diluent to rinse the counting head (valve 6+10+2)

MEASUREMENTS :

18- Syringe down to process the vacuum counting (valve 10)

19- First measurement sequences (valve 10)

20- Syringe up

Diluent back pressure (valve 4+6)

21- Syringe down to perform the vacuum counting (valve 10)

22- Second measurement sequences (valve 10)

DRAIN AND RINSE BATH :

22- Syringe down

Cleaning the apertures (valve 11)

WBC bath drain (valve 1)

RBC bath drain (valve 2)

23- Syringe up

RBC bath rinse diluent (valve 4)

Waste syringe drain (valve 7)

24- Needle up and syringes up for back flush (valve 4+6)

25- Rocker move above the WBC bath

26- Syringe up

WBC bath rinse diluent (valve 4)

Waste syringe drain (valve 7)

NEEDLE BACK AND WASTE DRAIN :

27- Syringe down

Dry the outside of the needle (valve 3)

28- Rocker move in the sampling position

26- Syringe up

Waste syringe drain (valve 7)

30- Needle down in sampling position

The MYTHIC 18 is ready to perform a new analyze.

REF : M18-SM-001 Rev 02

Page 10/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

2. FLUIDICS

2.3 FLUIDICS VIEW

All the fluidics part is on the right side of the instrument and consists of only three modules :

- Sampling module :

o Rocker (patent pending) : Manages the rise and descent of the needle.

- Syringe module (patent pending) consists of one block :

o Reagent syringes (Diluent, lysis), sampling and air syringes.

o Liquid valve manifold assembly and tubing.

- Counting chambers :

o WBC and RBC counting chambers and hemoglobin measurement.

o Liquid valve manifold assembly and tubing.

Sampling module

Syringe Module

Counting module

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 11/68

2. FLUIDICS

REF : M18-SM-001 Rev 02

2.4 FLUIDICS PARTS DESCRIPTION

The hydraulic part of the MYTHIC 18 is very simple and made of only three modules :

- Sampling module.

- Counting bath module.

- Syringes module.

The modules are connected together by semi rigid tubing.

2.4.1 Sampling module

This module (patent pending) enables to draw the sample and to perform the WBC and RBC/PLT dilutions.

It is assembled with a rotating rocker moving around a support which maintains the system to move up and

down the sampling needle.

A very reliable system of rack-gear moves the rocker.

The cleaning system of the sampling needle can be removed without tool (see section 9.3.2 in the user

manual).

The o-ring of the needle included in the cleaning system can also be removed without tool (see section 9.3.2

in the user manual).

The maintenance of these parts is very easy to perform.

2.4.2 Counting bath module

This module allows to count the WBC and RBC/PLA and to measure the HGB.

It is made with a manifold maintaining the reagent commutation valves and the counting bath block with their

measurement block including the apertures.

The counting bath block assembly and these apertures can be removed without tool (see section 9.3.3/4/5

in the user manual).

2.4.3 Syringes module

This module (patent pending) enables :

to draw the sample

to distribute the reagents

to drain the baths

to do the vacuum necessary for counting

and to push the waste to the waste container.

It is made with a manifold maintaining the fluid commutation valves and with the syringes bloc including five

syringes :

The sampling syringe

The lysis syringe

The two waste and vacuum/pressure syringes

And the diluent syringe.

Only one motor drives the five syringes.

The diluent input and the waste output are also included in this manifold.

Page 12/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

2.5 FLUIDICS DIAGRAM

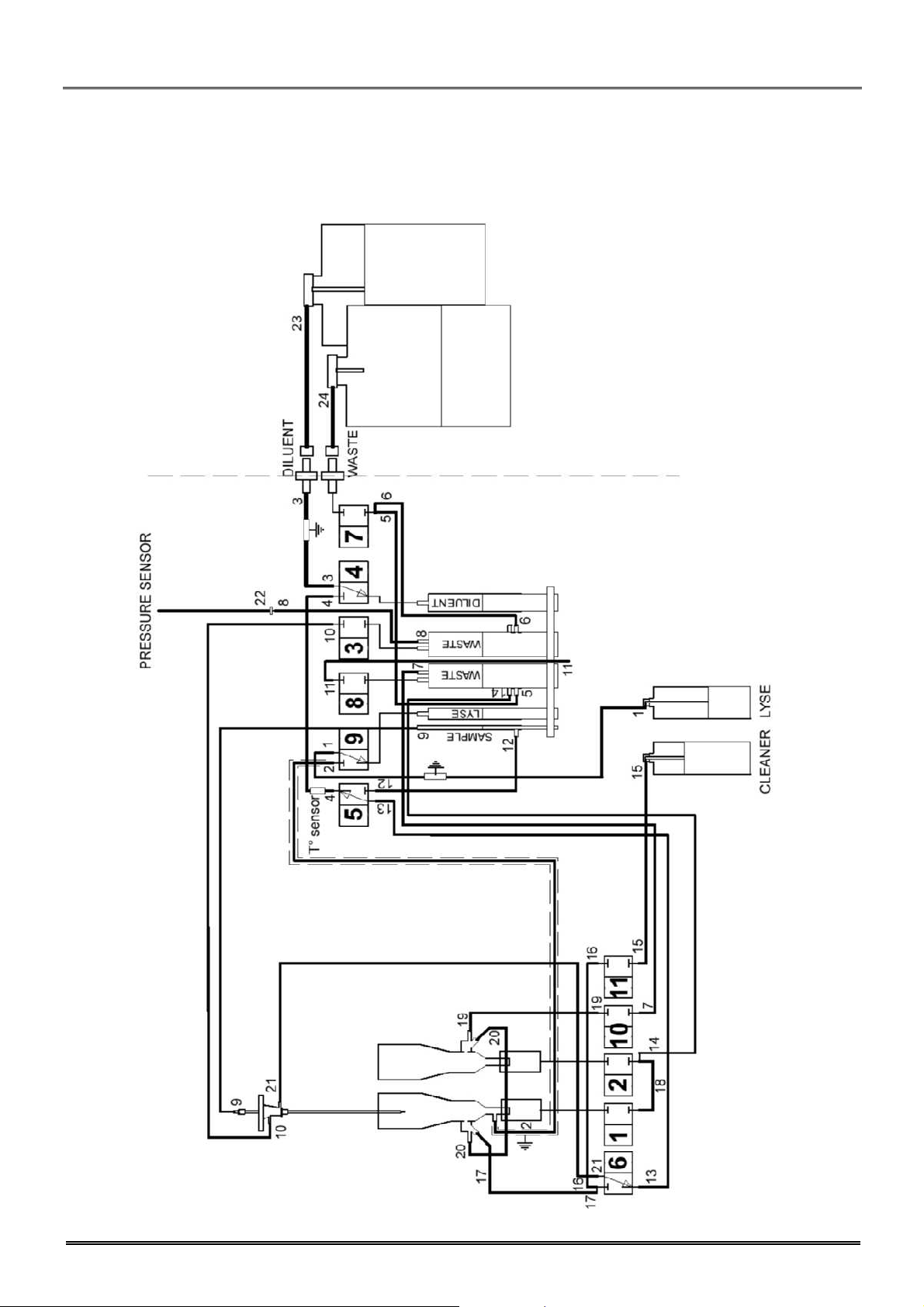

2.5.1 General Diagram

2. FLUIDICS

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 13/68

2. FLUIDICS

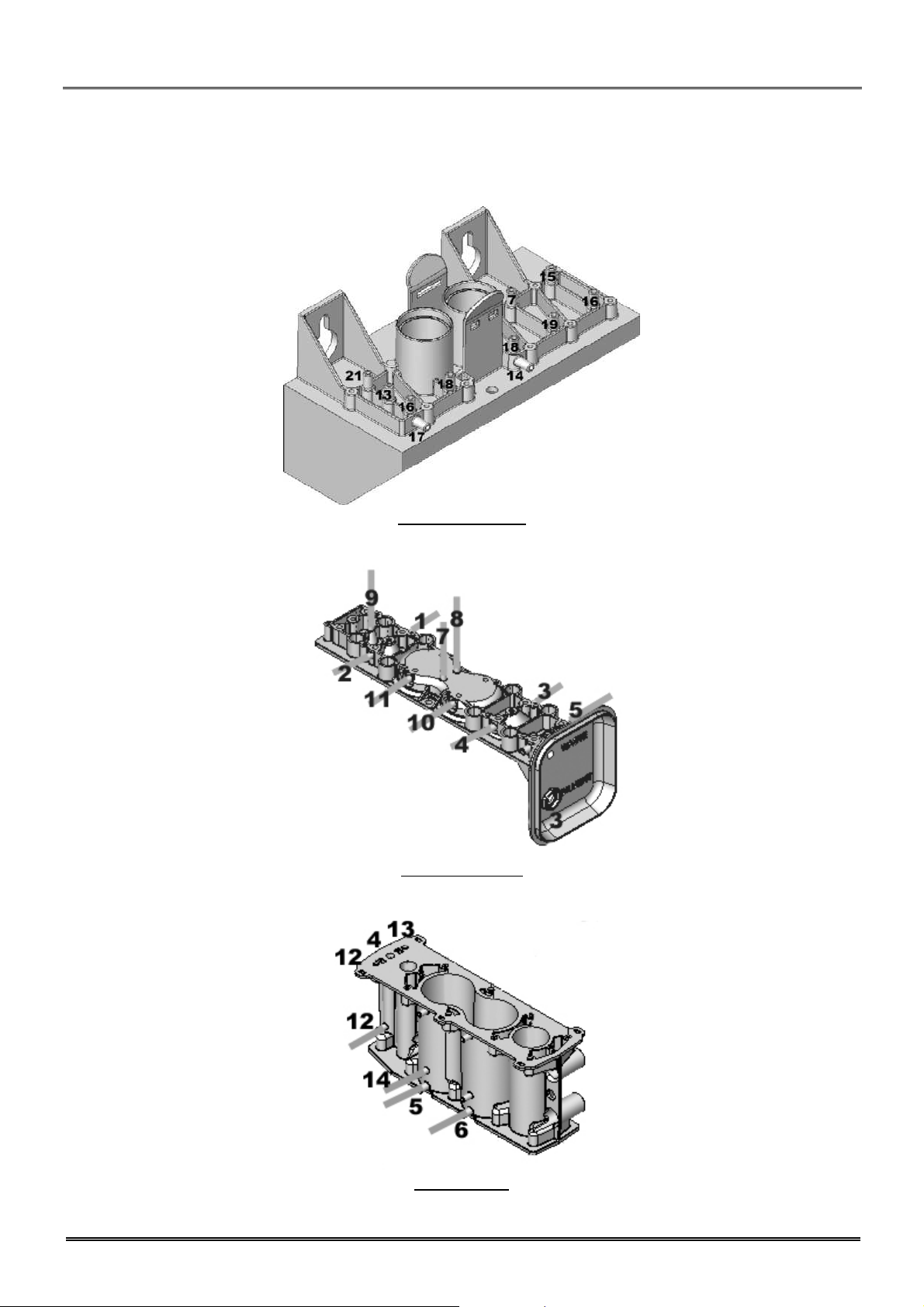

2.5.2 Manifold tubing position

Each figure corresponds to a tubing number (see the Fluidic diagram section 2.5.1)

Counting manifold

REF : M18-SM-001 Rev 02

Syringe manifold

Syringe body

Page 14/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

2. FLUIDICS

2.6 SIZE & LENGTH TUBING

To ensure perfect results it is mandatory to respect the size and the length of the tubing.

Tygon

tubing

Part Number REV Designation

005-1001-90 01 01 A Tubing 1-1 820mm

005-1001-90 01 02 A Tubing 1-2 180mm

005-1001-90 02 A Tubing 2 250mm

005-1001-90 03 01 A Tubing 3-1 135mm

005-1001-90 03 02 A Tubing 3-2 20mm

005-1001-90 04 01 A Tubing 4-1 175mm

005-1001-90 04 02 A Tubing 4-2 15mm

005-1001-90 05 A Tubing 5 210mm

005-1001-90 06 A Tubing 6 170mm

005-1001-90 07 B Tubing 7 220mm

005-1001-90 08 A Tubing 8 80mm

005-1001-90 09 B Tubing 9 425mm

005-1001-90 10 01 B Tubing 10-1 8mm

005-1001-90 10 02 A Tubing 10-2 370mm

005-1001-90 11 A Tubing 11 90mm

005-1001-90 12 A Tubing 12 60mm

005-1001-90 13 A Tubing 13 250mm

005-1001-90 14 B Tubing 14 250mm

005-1001-90 15 A Tubing 15 1000mm

005-1001-90 16 A Tubing 16 130mm

005-1001-90 17 A Tubing 17 80mm

005-1001-90 18 A Tubing 18 80mm

005-1001-90 19 A Tubing 19 80mm

005-1001-90 20 A Tubing 20 130mm

005-1001-90 21 B Tubing 21 600mm

005-1001-90 22 A Tubing 22 200mm

005-1001-90 23 A Tubing 23 - DILUENT 1500mm

005-1001-90 24 A Tubing 24 - WASTE 1500mm

005-1001-90 25 A Tubing 25 55mm (45°)

005-1001-90 26 A Tubing 26 5mm

005-1001-90 016

032

005-1001-90 020

040

005-1001-90 030

060

Tygon Tubing L=1000mm

A

1,6x3.2mm

A Tygon Tubing L=500mm 2x4mm 500mm

A 20L Tubing Straw adaptor 100mm

0,8x2,4mm

1000mm

Tygon

tubing

1,3x3mm

Tygon

tubing

1,6x3,2mm

Tygon

tubing

2x4mm

Tygon

tubing

3x6mm

Tygon

tubing

5x8mm

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 15/68

4. SPECIFICATIONS

3. ELECTRIC & ELECTRONIC

3.1 GENERALITIES

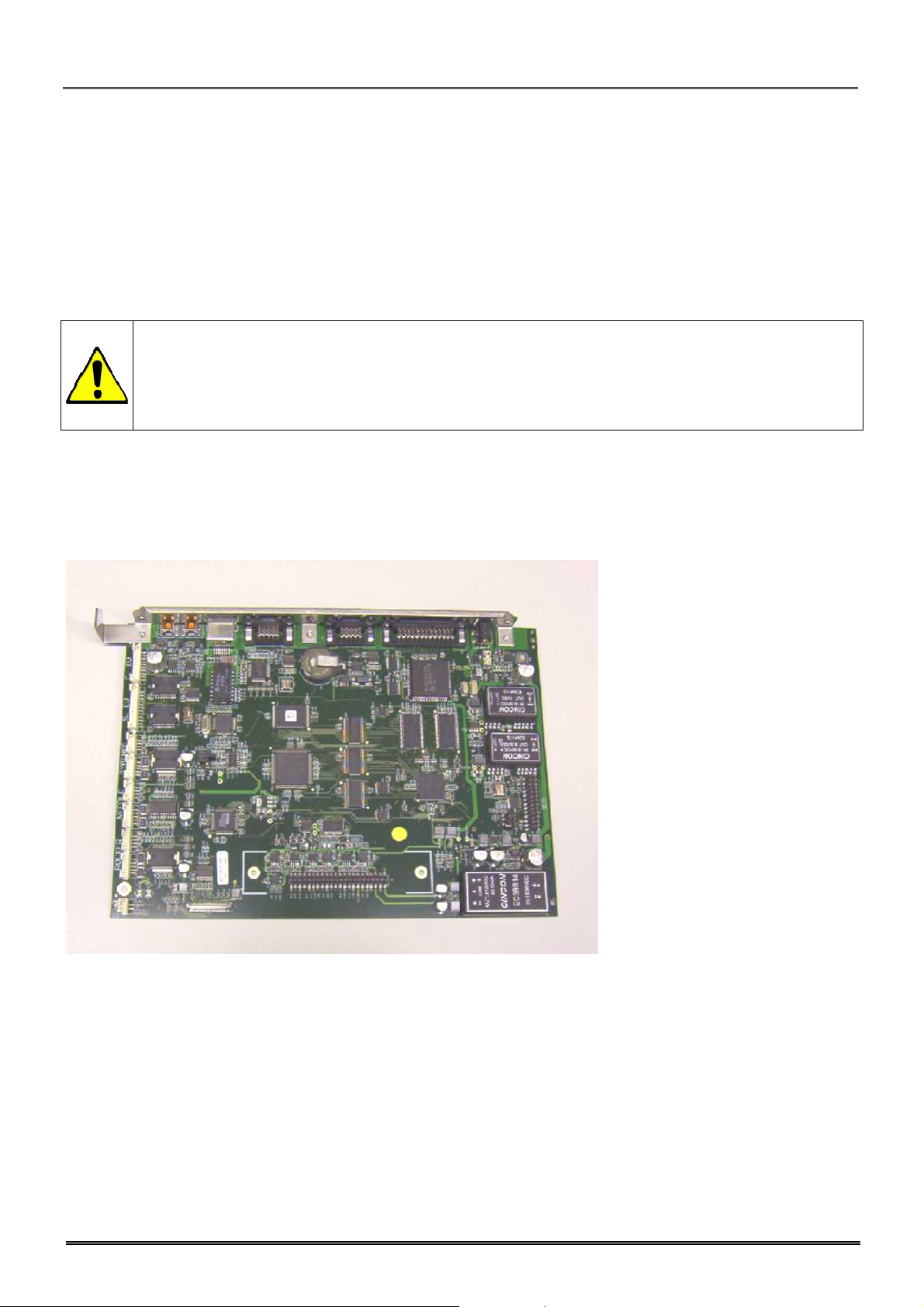

Only three boards compose the MYTHIC 18 :

- the main board

- the preamplifier board

- and the GUI board

- In the case of replacement of the main board or preamplifier board, be aware of the

sensibility of this board to the electrical static discharge (ESD).

- Before operating check the earth connection and use the antistatic bag supply with the

board. Please contact your Orphée for more information.

- Be careful with the edge of the metal sheets after having dismantled the covers.

3.2 ELECTRICS PARTS VIEW

3.2.1 Main board

REF : M18-SM-001 Rev 02

The mono electronic board is located between the hydraulic part and the reagent tray.

The board, driven by a 32-bit processor, manages the following parts :

- Sample needle, rocker, syringe block motors.

- Display and keyboard.

- Connexion mode (RS232, Ethernet, …).

- Printer.

- Measurement (Counting, hemoglobin measurement).

- Data processing.

- External barcode reader.

Page 16/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

3.2.2 GUI board

3.2.3 Preamplifier board

3. ELECTRICS & ELECTRONICS

3.2.4 Power supply block

MYTHIC 18 is supplied with an external power supply block.

- In case of replacement of the main power wire supplied with the MYTHIC 18, the new one

must comply with the local regulation.

- The MYTHIC 18 has been certified with the power supply box provided with the machine.

The use of another external power supply box is not guaranteed. Please contact Orphée.

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 17/68

3. ELECTRICS & ELECTRONICS

3.3 ELECTRONIC DIAGRAM

REF : M18-SM-001 Rev 02

Page 18/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

3.4 WIRING DIAGRAM

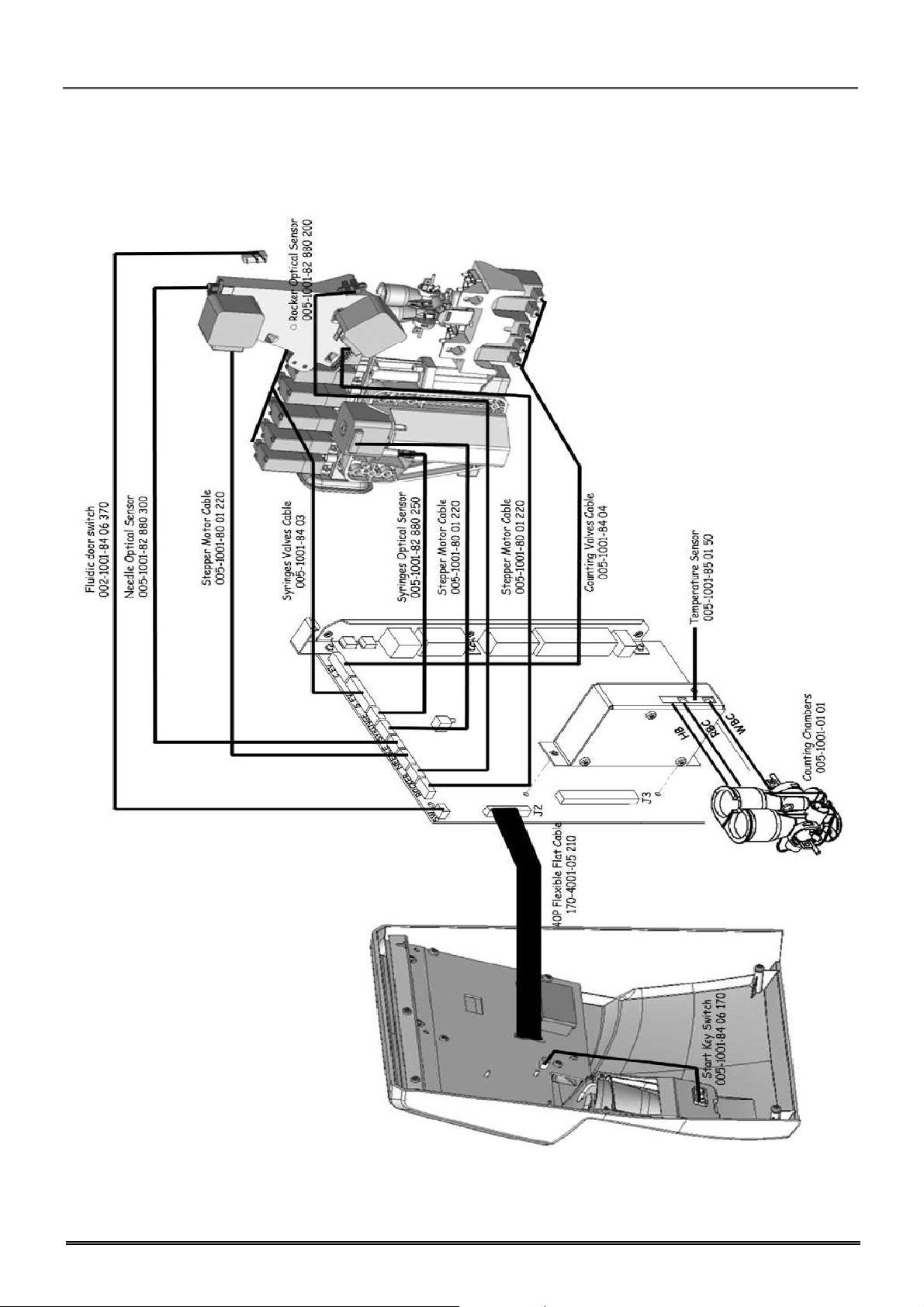

3.4.1 General view

3. ELECTRICS & ELECTRONICS

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 19/68

3. ELECTRICS & ELECTRONICS

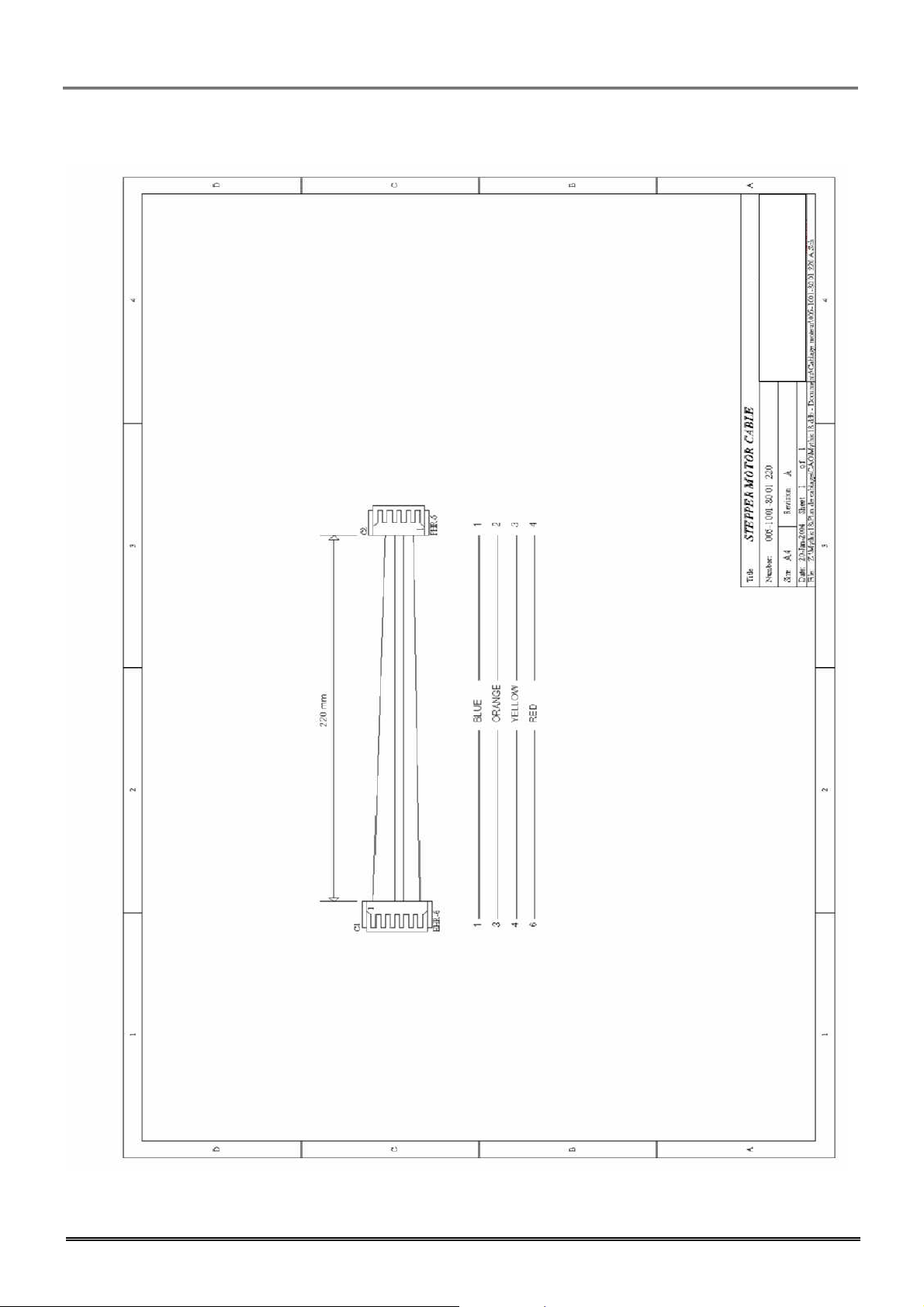

3.4.2 Stepper motor

REF : M18-SM-001 Rev 02

Page 20/68 Copyright© Orphée SA. All Rights Reserved. MYTHIC 18

REF : M18-SM-001 Rev 02

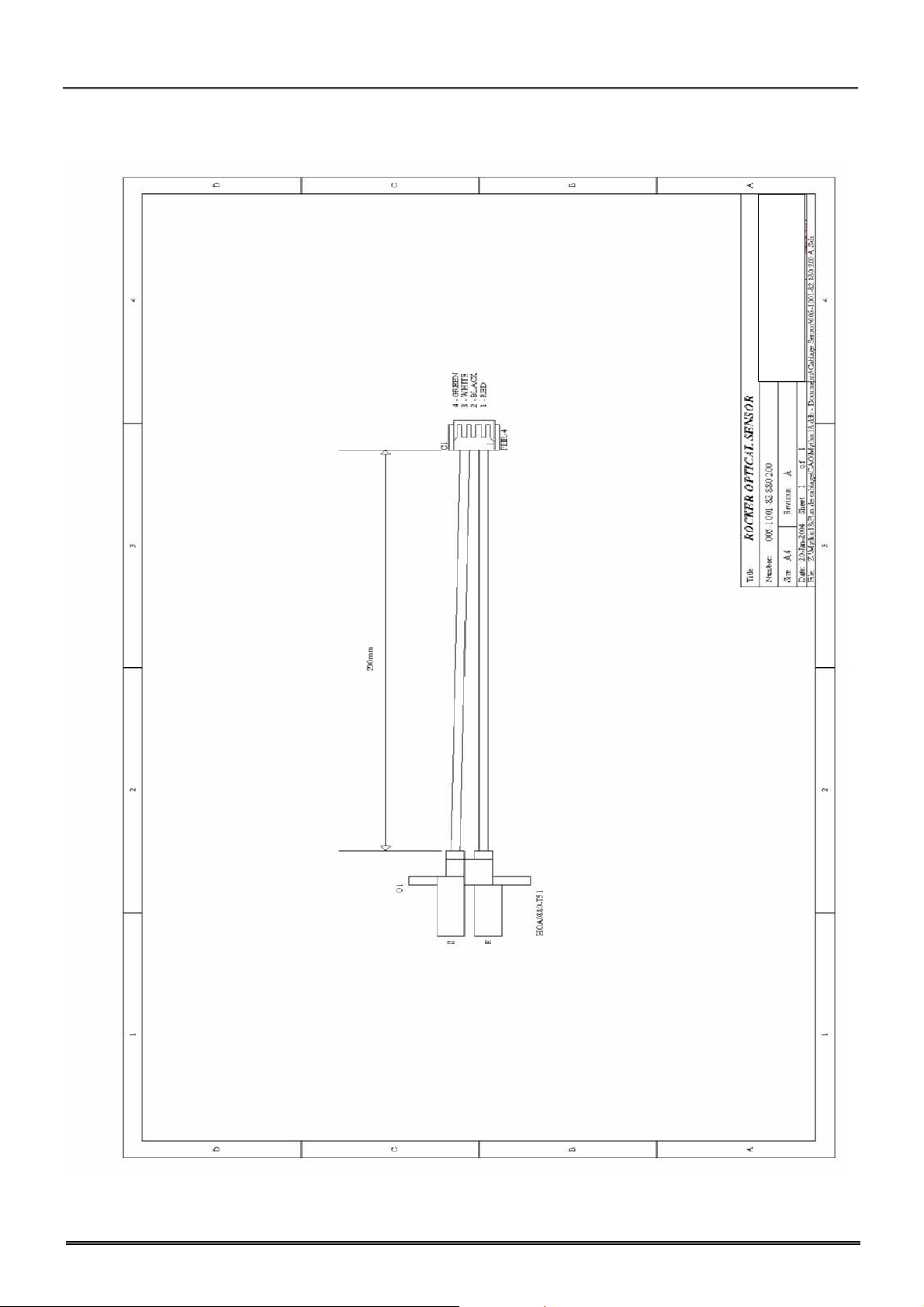

3.4.3 Rocker optical sensor

3. ELECTRICS & ELECTRONICS

MYTHIC 18 Copyright© Orphée SA. All Rights Reserved. Page 21/68

Loading...

Loading...