Page 1

Subwoofer

OWNER'S MANUAL

MODEL

XTRPRO102

XTRPRO104

XTRPRO122

XTRPRO124

XTRPRO152

XTRPRO154

Page 2

TABLE OF CONTENTS

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Español. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Português . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Practice Safe Sound™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What's in the box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Tools of the Trade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Finding Speaker Mounting Locations . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . 2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wiring Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Enclosure Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back cover

INTRODUCTION

Thank you for your purchase of the Orion XTRPRO Subwoofers. These woofers

represent a combination of incredible performance and value. We at Orion strive to

give you the latest up to date information about this product. What we can’t give

you with the manual is personal installation or technical experience. If you have

questions concerning the use or application of this product please refer to the nearest

Orion dealer for assistance, visit www.orioncaraudio.com, or call the technical support

hotline at 1-800-876-0800. As we are always finding new ways to improve our product,

the features and specifications are subject to change without notice.

PRACTICE SAFE SOUND™

Continuous exposure to sound pressure levels over 100dB may cause permanent

hearing loss. High powered automotive sound systems can generate sound pressure

levels in excess of 130dB. When playing your system at high levels, please use hearing

protection and prevent long term exposure.

Model Number: _______________

Serial Number: _______________

Date of Purchase: _______________

© 2008 directed electronics—all rights reserved 1

Page 3

WHAT’S IN THE BOX

Included in this box are all the necessary mounting hardware and cables for your basic

installation. Listed below is a detailed list of the components included in this system

package.

Quantity Description

1 Owner's Manual

1 Orion XTRPRO woofer

1 Mounting template

1 Trim ring with hardware..

TOOLS OF THE TRADE

Listed are the majority of the tools required to perform the installation. Having the

proper tools will make the installation much easier. It is very difficult when you get

half way through the installation and discover that you require a specific tool to

get yourself through a particular part of the installation. Some of these tools are

necessities. Some make the job much easier.

• Marking Pen • Electric Drill and assorted Bits

• Phillips Screwdriver • Wire Strippers

• Allen Wrenches • Volt/Ohm Meter (Optional)

• Table Saw • Jig Saw

• Wire Cutters • Wire Crimpers

INSTALLATION

The performance of these XTRPRO subwoofers is directly proportional to the quality

of the installation. Care taken with the installation process will be rewarded by years

of satisfying performance. If you are unsure of your installation abilities, please

refer to your local authorized ORION dealer for assistance. Orion dealers are trained

professionals dedicated to extracting the maximum performance out of your Orion

system. If you decide to install this speaker system yourself, please read the entire

section on sealed and vented enclosures before starting the installation.

FINDING SPEAKER MOUNTING LOCATIONS

Choosing the correct speaker locations will have the greatest effect on the sound

quality of the system. Different considerations are needed when choosing the

locations that best suit your needs. The locations must be large enough for the

speakers to fit. Care is needed to ensure that the location you have chosen will not

affect any of the mechanical or electrical operations of the vehicle.

Determining the best location for the speakers will depend on your cosmetic needs

and your vehicle’s interior. Usually the woofers are installed in the trunk, rear seat, or

rear of the vehicle..

2 © 2008 directed electronics—all rights reserved

Page 4

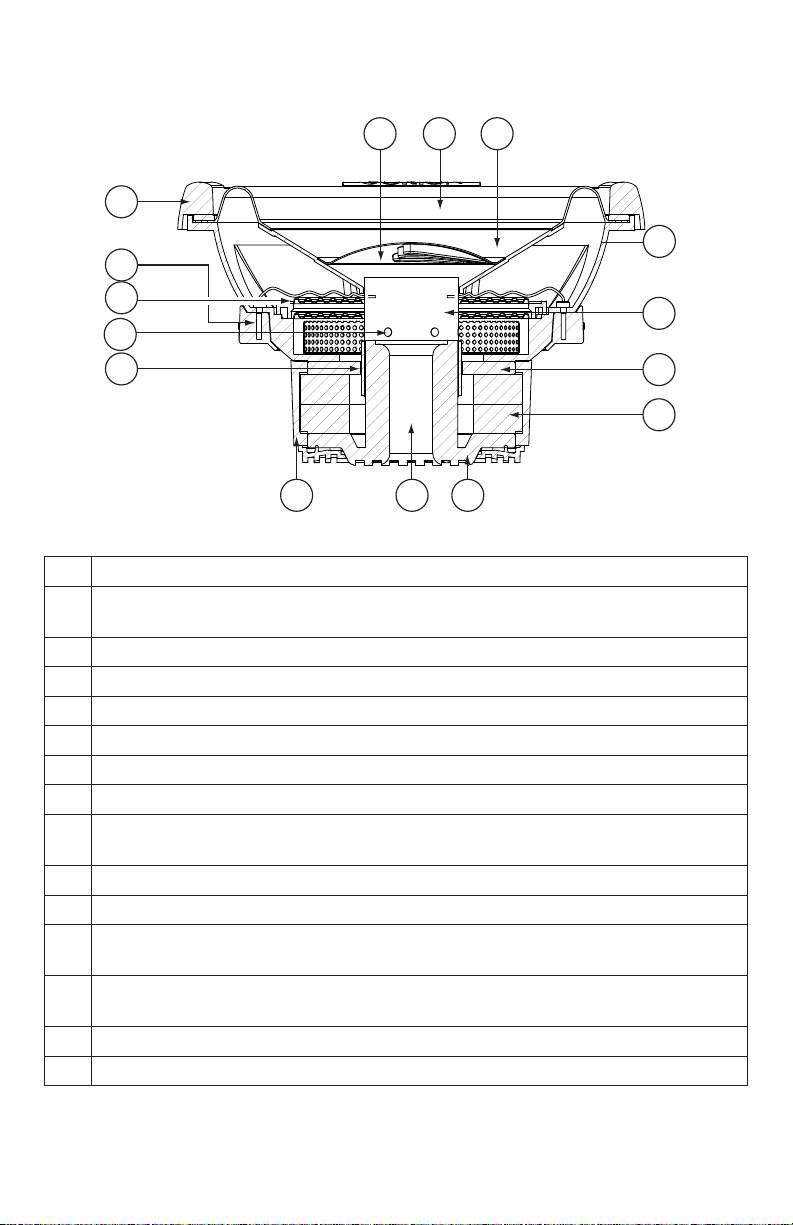

FEATURES

15

14

13

12

123

4

5

11

6

7

Figure 1

Figura 1

Abbildung 1

8910

1 Polypropylene dust cap - moisture and UV resistant.

2 Oversized NBR (Nitrile-butadiene Rubber) surround for linear controlled

long excursion.

3 Paper cone - moisture and UV resistant.

4 Custom cast aluminum frame.

5 Vented Aluminum voice coil former (2.5" voice coil former).

6 8mm steel front plate.

7 Large 2 stack ceramic magnets.

8 8mm steel back plate/pole piece T yoke assembly.

9 1.125" vent. Part of the enhanced voice coil cooling system (forced

convection).

10 PVC magnet protector.

11 High temperature Copper dual 2 ohm or dual 4 ohm voice coil.

12 Venting in voice coil former. Part of the enhanced voice coil cooling system

(forced convection).

13 Dual Interlaced Conex spider with stitched and looped tinsel leads

attached.

14 Custom terminal blocks.

15 ABS Trim Ring.

© 2008 directed electronics—all rights reserved 3

Page 5

WIRING CONFIGURATIONS

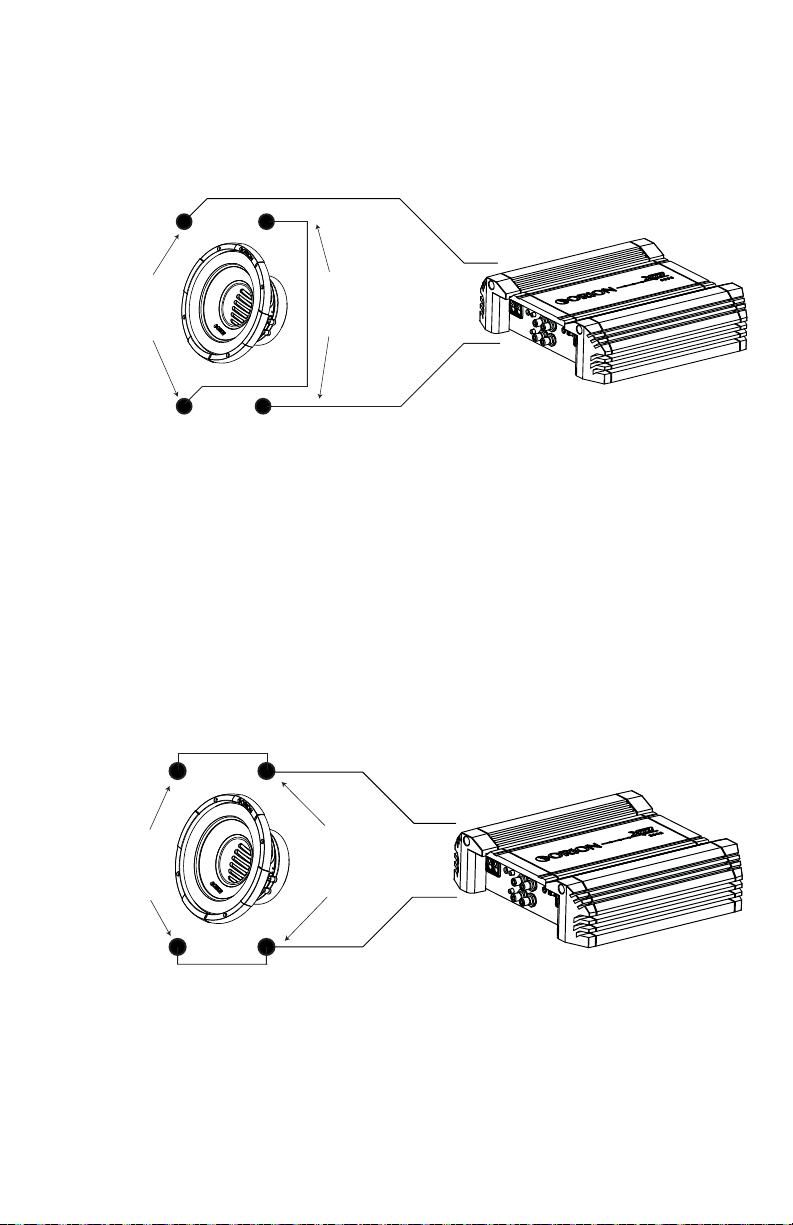

Series - One Speaker (dual 2 ohm voice coils)

One dual 2 ohm voice coil woofer with voice coils in connected in series results in a 4

ohm load to the amplifier.

__

_

2 ohm

+

Figure 2

Figura 2

Abbildung 2

2 ohm

++

1. Connect the woofer in series by connecting the negative (-) of one terminal to the

positive (+) terminal of the other coil.

2. Wire the positive (+) terminal of the first coil to the positive (+) terminal on the

amplifier. Wire the negative (-) terminal of the second coil to the negative (-)

terminal on the amplifier.

Parallel—One Speaker (dual 2 ohm voice coils)

One dual 2 ohm voice coil woofer with voice coils in parallel results in a 1 ohm load

to the amplifier.

_

_

_

2 ohm

+

Figure 3

Figura 3

Abbildung 3

2 ohm

++

1. Connect the speaker in parallel by connecting the two positive (+) terminals

together and the two negative (-) terminals together.

2. Wire the positive (+) terminals of the woofer to the positive (+) terminal on

the amplifier. Wire the negative (-) terminals of the woofer to the negative (-)

terminal on the amp.

4 © 2008 directed electronics—all rights reserved

Page 6

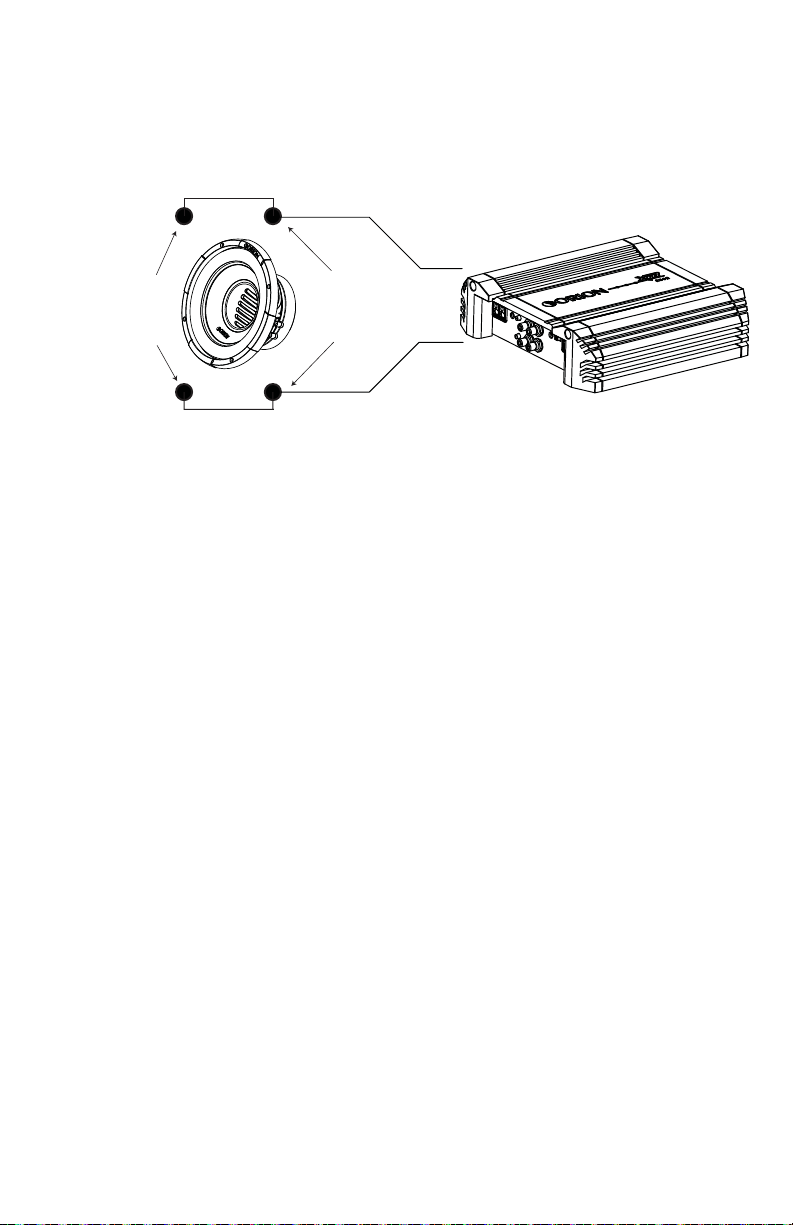

Parallel — One Speaker (dual 4 ohm voice coils)

One dual 4 ohm voice coil woofer with voice coils in parallel results in a 2 ohm load

to the amplifier.

_

_

_

4 ohm

Figure 4

Figura 4

Abbildung 4

1. Connect the speaker in parallel by connecting the two positive (+) terminals

together and the two negative (-) terminals together.

2. Wire both positive (+) terminals of the woofer to the positive (+) terminal on

the amplifier. Wire both negative (-) terminals of the woofer to the negative (-)

terminal on the amplifier.

++

4 ohm

+

© 2008 directed electronics—all rights reserved 5

Page 7

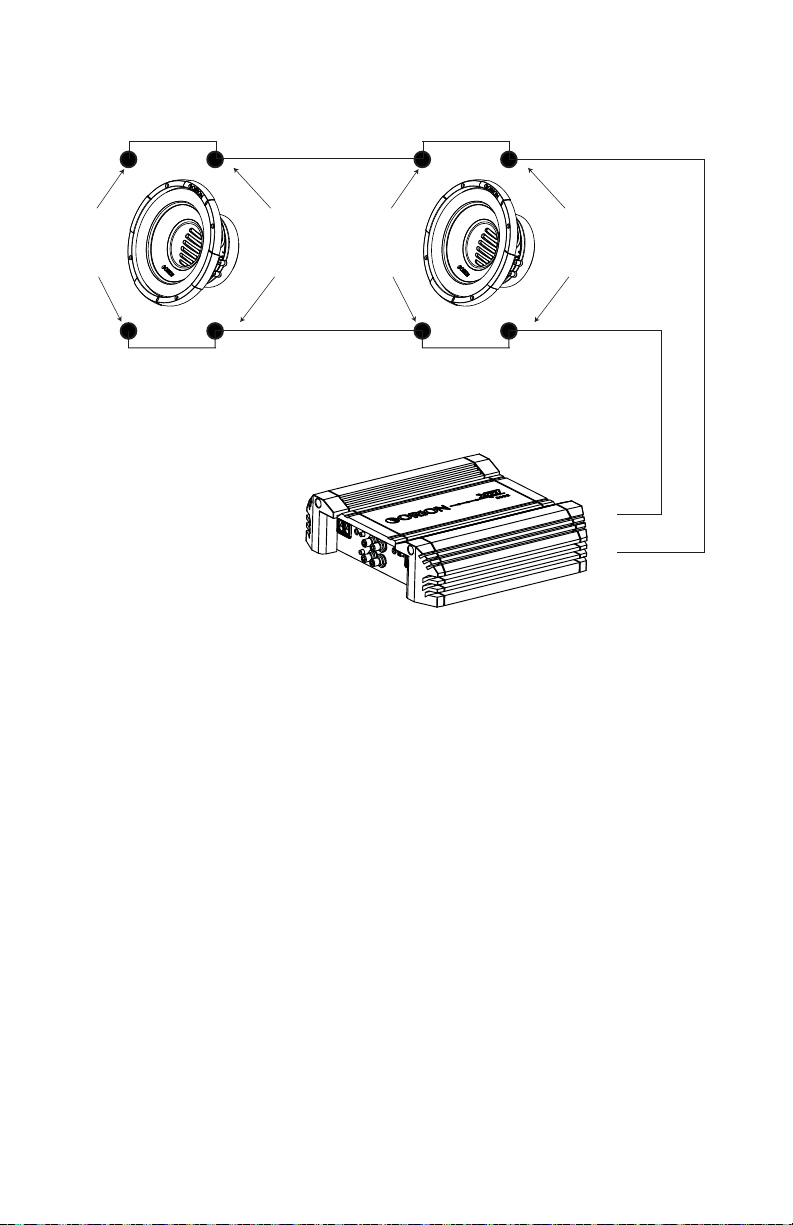

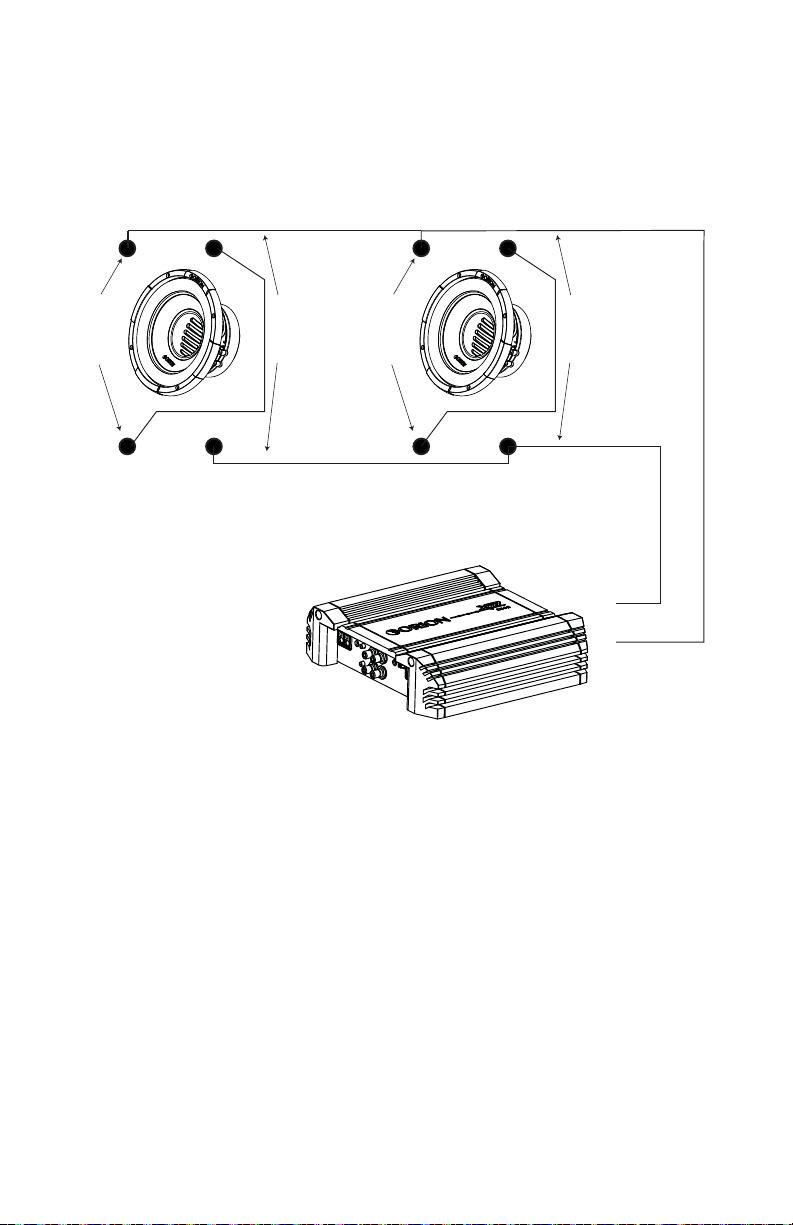

Parallel - Two Speaker (dual 4 ohm voice coils)

Two dual 4 ohm voice coil woofers with voice coils in parallel and the two woofers in

parallel results in a 1 ohm load to the amplifier.

--

4 ohm

+

Figure 5

Figura 5

Abbildung 5

+

4 ohm

--

4 ohm

+

+

4 ohm

+

-

1. Connect the speaker in parallel by connecting the four positive (+) terminals

together and the four negative (-) terminals together.

2. Wire the positive (+) terminals of the woofers to the positive (+) terminal on

the amplifier. Wire the negative (-) terminals of the woofers to the negative (-)

terminal on the amplifier.

6 © 2008 directed electronics—all rights reserved

Page 8

Series/Parallel - Two Speakers (dual 2 ohm voice coils)

Note: Verify and ensure that the woofer wiring is connected as shown with

the negative connection from the first woofer coil connected to the positive

connection of the second woofer coil.

Two dual 2 ohm voice coil woofers with voice coils in series and then parallel the two

series woofers results in a 2 ohm load to the amplifier.

--

2 ohm

+

Figure 6

Figura 6

Abbildung 6

+

2 ohm

--

2 ohm

+

+

2 ohm

+

-

1. Connect each woofer in series by connecting the negative (-) of the first coil to the

positive (+) terminal of the second coil.

2. Wire the positive (+) terminal of the first coil on each woofer to the positive (+)

terminal on the amplifier. Wire the negative (-) terminal of the second coil on

each woofer to the negative (-) terminal on the amplifier.

© 2008 directed electronics—all rights reserved 7

Page 9

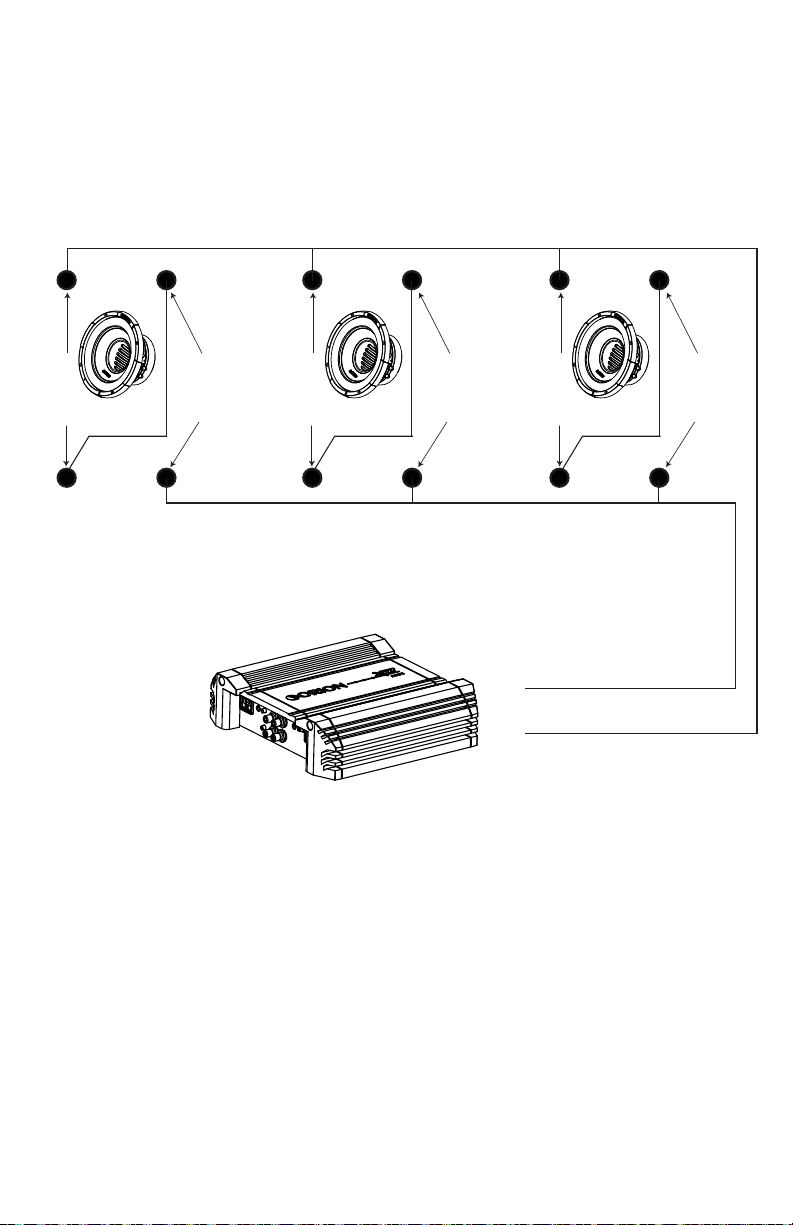

Series/Parallel - Three Speakers (dual 4 ohm voice coils)

Note: Verify and ensure that the woofer wiring is connected as shown with

the negative connection from the first woofer coil connected to the positive

connection of the second woofer coil.

Three dual 4 ohm voice coil woofer with voice coils of each woofer wired in series and

then parallel the three woofers for a resulting 2.67 ohm load to the amplifier.

--

4 ohm

+

Figure 7

Figura 7

Abbildung 7

1. Connect each woofer in series by connecting the negative (-) of the first coil to the

positive (+) terminal of the second coil.

+

4 ohm

--

+

4 ohm

+

4 ohm

--

4 ohm

+

+

+

-

4 ohm

2. Wire the positive (+) terminal of each woofer’s first coil to the positive (+) terminal

on the amplifier. Wire the negative (-) terminal of each woofer’s second coil to the

negative (-) terminal on the amplifier.

8 © 2008 directed electronics—all rights reserved

Page 10

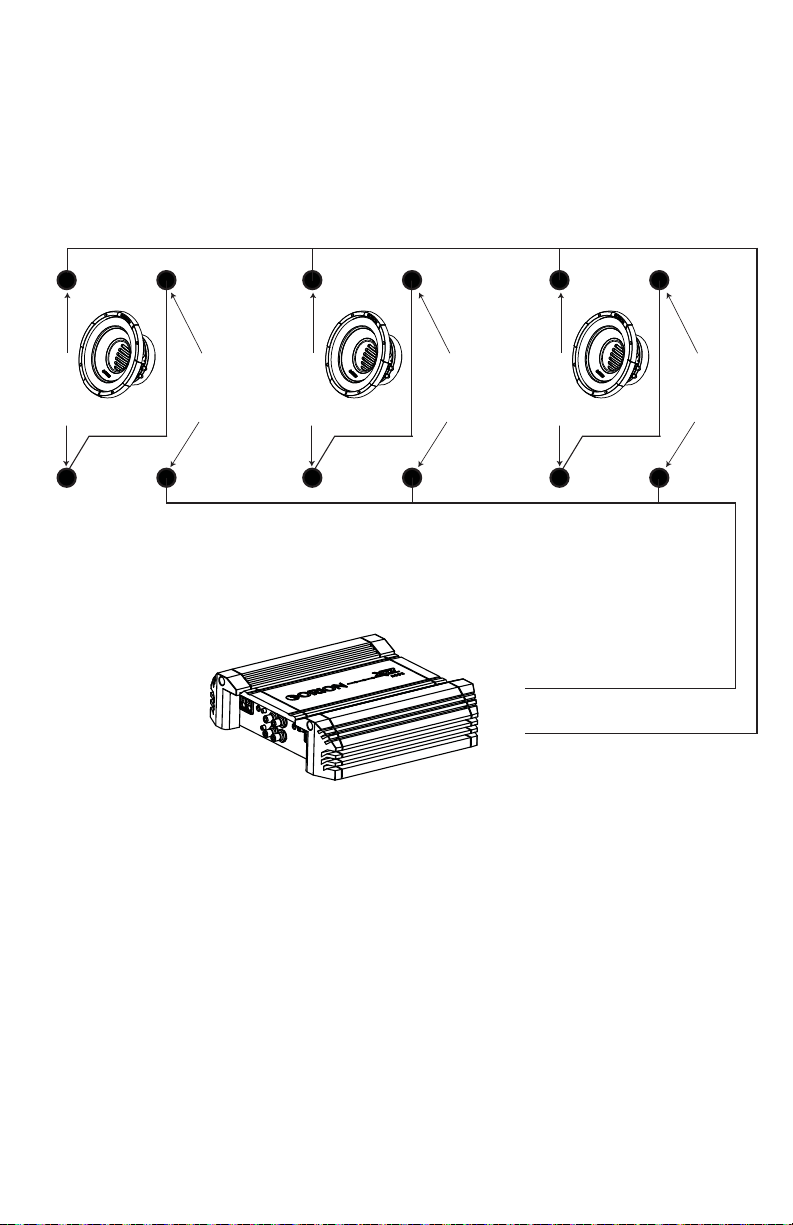

Series/Parallel - Three Speakers (dual 2 ohm voice coils)

Note: Verify and ensure that the woofer wiring is connected as shown with

the negative connection from the first woofer coil connected to the positive

connection of the second woofer coil.

Three dual 2 ohm voice coil woofer with voice coils of each woofer wired in series and

then parallel the three woofers for a resulting 1.33 ohm load to the amplifier.

--

2 ohm

+

Figure 8

Figura 8

Abbildung 8

1. Connect each woofer in series by connecting the negative (-) of the first coil to the

positive (+) terminal of the second coil.

+

2 ohm

--

+

2 ohm

+

2 ohm

--

2 ohm

+

+

+

-

2 ohm

2. Wire the positive (+) terminal of each woofer’s first coil to the positive (+) terminal

on the amplifier. Wire the negative (-) terminal of each woofer’s second coil to the

negative (-) terminal on the amplifier.

© 2008 directed electronics—all rights reserved 9

Page 11

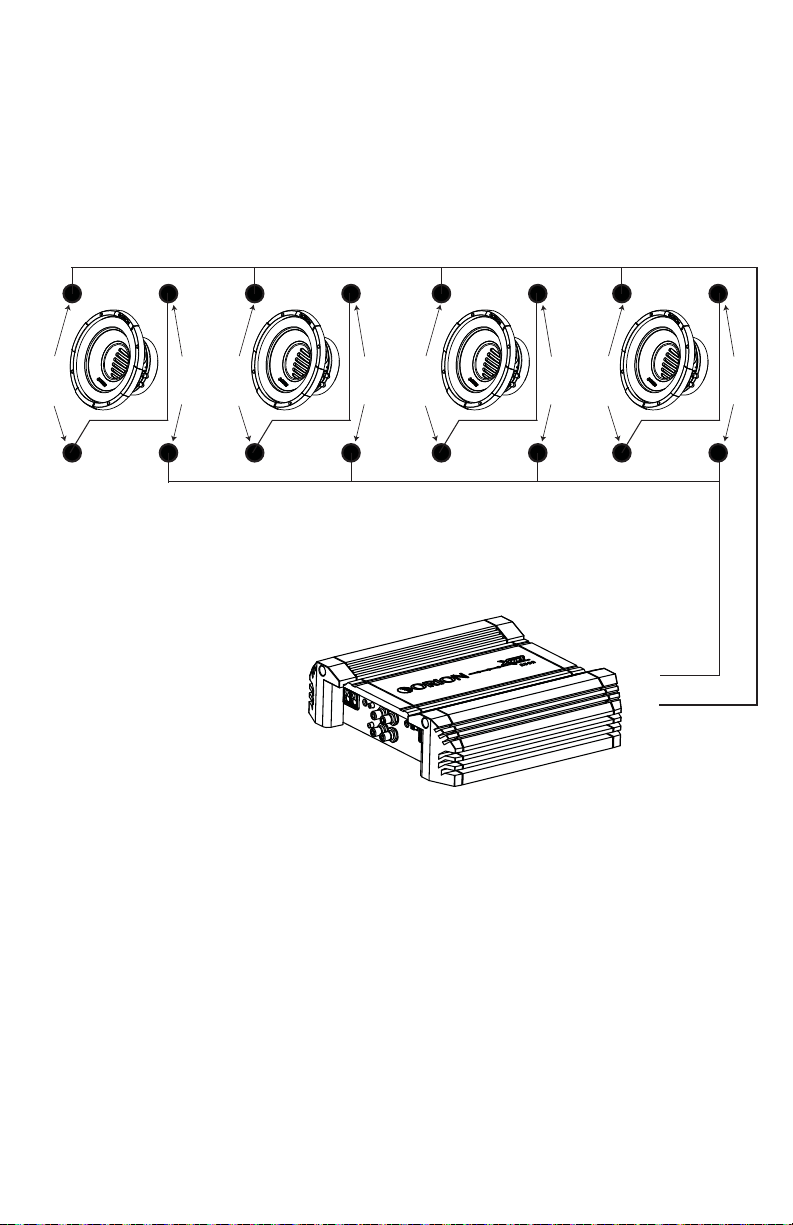

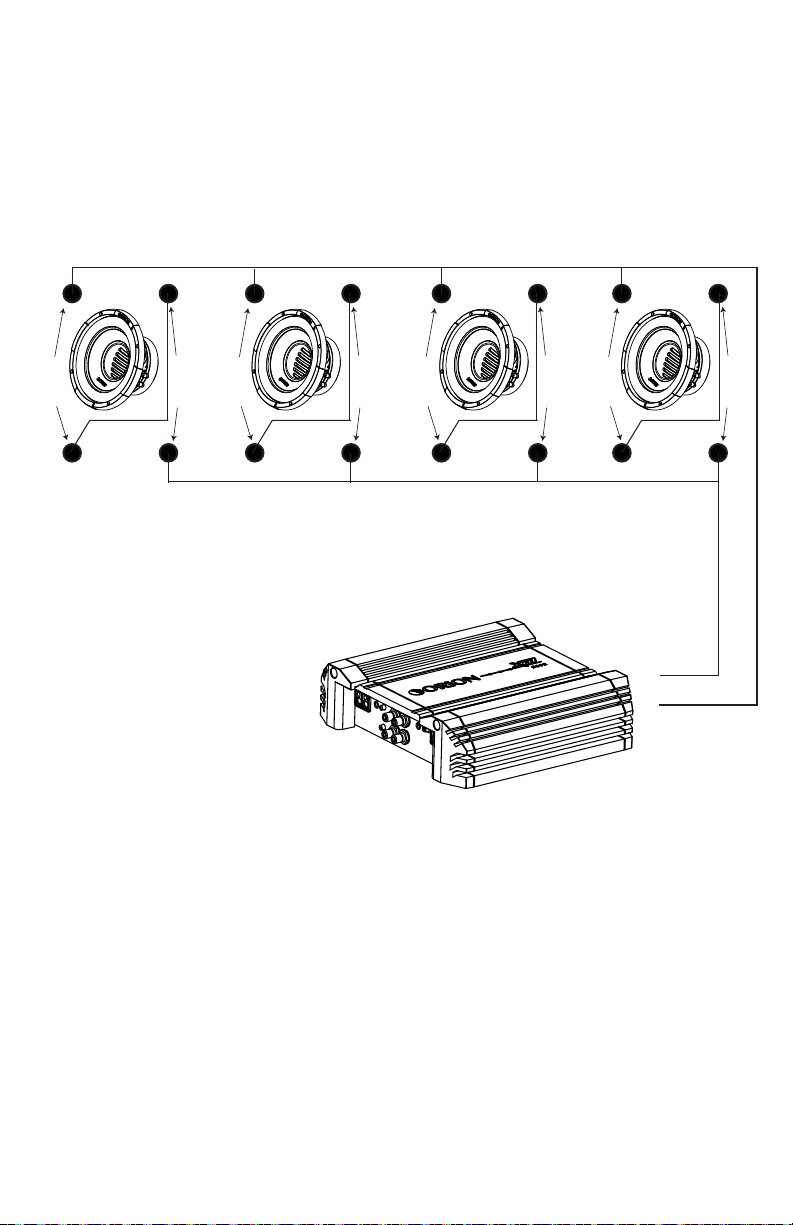

Series/Parallel - Four Speakers (dual 4 ohm voice coils)

Note: Verify and ensure that the woofer wiring is connected as shown with

the negative connection from the first woofer coil connected to the positive

connection of the second woofer coil.

Four dual 4 ohm voice coil woofers should be wired with the voice coils on each

woofer in series and then parallel the four woofers for a resulting 2 ohm load to the

amplifier.

--

4 ohm

+

+

--

4 ohm

4 ohm

+

Figure 9

Figura 9

Abbildung 9

--

4 ohm

4 ohm

+

+

+

--

4 ohm

4 ohm

+

+

+

-

1. Connect each woofer in series by connecting the negative (-) of the first coil to the

positive (+) terminal of the second coil.

4 ohm

2. Wire the positive (+) terminals of the first coil of each woofer to the positive (+)

terminal on the amplifier. Wire the negative (-) terminal of the second coil of each

woofer to the negative (-) terminal on the amplifier.

10 © 2008 directed electronics—all rights reserved

Page 12

Series/Parallel - Four Speakers (dual 2 ohm voice coils)

Note: Verify and ensure that the woofer wiring is connected as shown with

the negative connection from the first woofer coil connected to the positive

connection of the second woofer coil.

Four dual 2 ohm voice coil woofers should be wired with the voice coils on each

woofer in series and then parallel the four woofers for a resulting 1 ohm load to the

amplifier

--

2 ohm

+

+

--

2 ohm

2 ohm

+

Figure 10

Figura 10

Abbildung 10

--

2 ohm

+

2 ohm

+

+

--

2 ohm

2 ohm

+

+

2 ohm

+

-

1. Connect each woofer in series by connecting the negative (-) of the first coil to the

positive (+) terminal of the second coil.

2. Wire the positive (+) terminals of the first coil of each woofer to the positive (+)

terminal on the amplifier. Wire the negative (-) terminal of the second coil of each

woofer to the negative (-) terminal on the amplifier.

© 2008 directed electronics—all rights reserved 11

Page 13

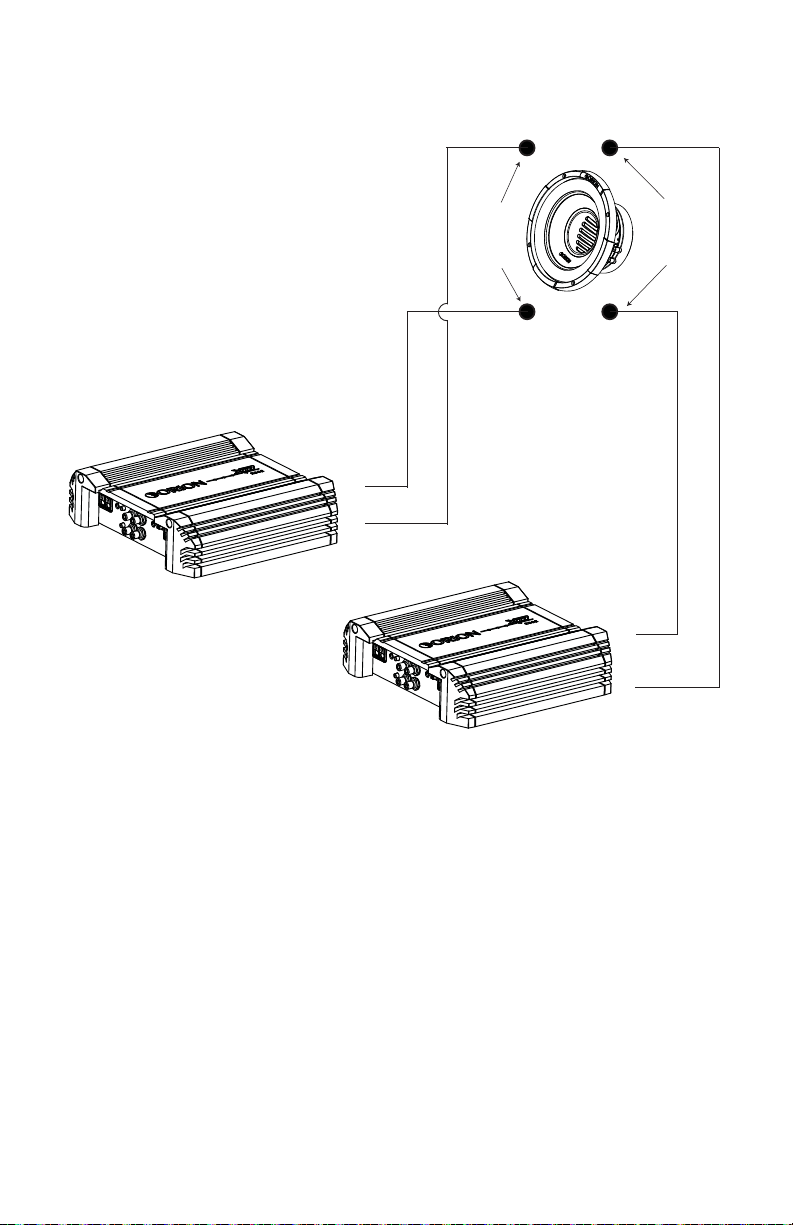

2 Amplifiers - One Speaker (dual 2 ohm voice coils)

One dual 2 ohm voice coil woofer with each voice coil connected to an individual

amplifier, resulting in a 2 ohm load to each amplifier.

--

2 ohm

2 ohm

++

+

-

Figure 11

Figura 11

Abbildung 11

+

-

1. Connect one of the speaker’s voice coils to the first amplifier by connecting

the positive (+) terminal and the negative (-) terminal from the speaker to the

respective positive (+) terminal and the negative (-) terminal from the first

amplifier.

2. Connect the other of the speaker’s voice coils to the second amplifier by

connecting the positive (+) terminal and negative (-) terminal from the speaker

to the respective positive (+) terminal and the negative (-) terminal from second

amplifier.

12 © 2008 directed electronics—all rights reserved

Page 14

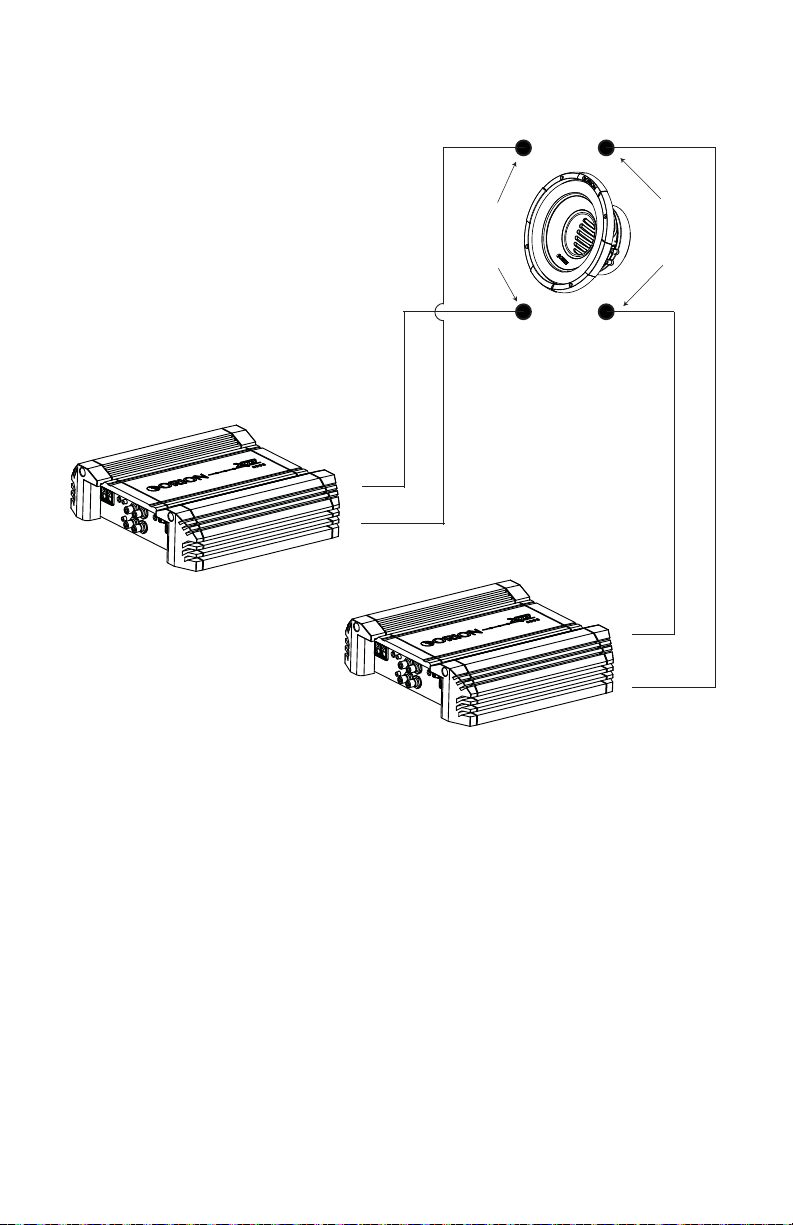

2 Amplifiers - One Speaker (dual 4 ohm voice coils)

One dual 4 ohm voice coil woofer with each voice coil connected to an individual

amplifier, resulting in a 4 ohm load to each amplifier.

--

4 ohm

4 ohm

++

+

-

Figure 12

Figura 12

Abbildung 12

+

-

1. Connect one of the speaker’s voice coils to the first amplifier by connecting

the positive (+) terminal and the negative (-) terminal from the speaker to the

respective positive (+) terminal and the negative (-) terminal from the first

amplifier.

2. Connect the other of the speaker’s voice coils to the second amplifier by

connecting the positive (+) terminal and negative (-) terminal from the speaker

to the respective positive (+) terminal and the negative (-) terminal from second

amplifier.

© 2008 directed electronics—all rights reserved 13

Page 15

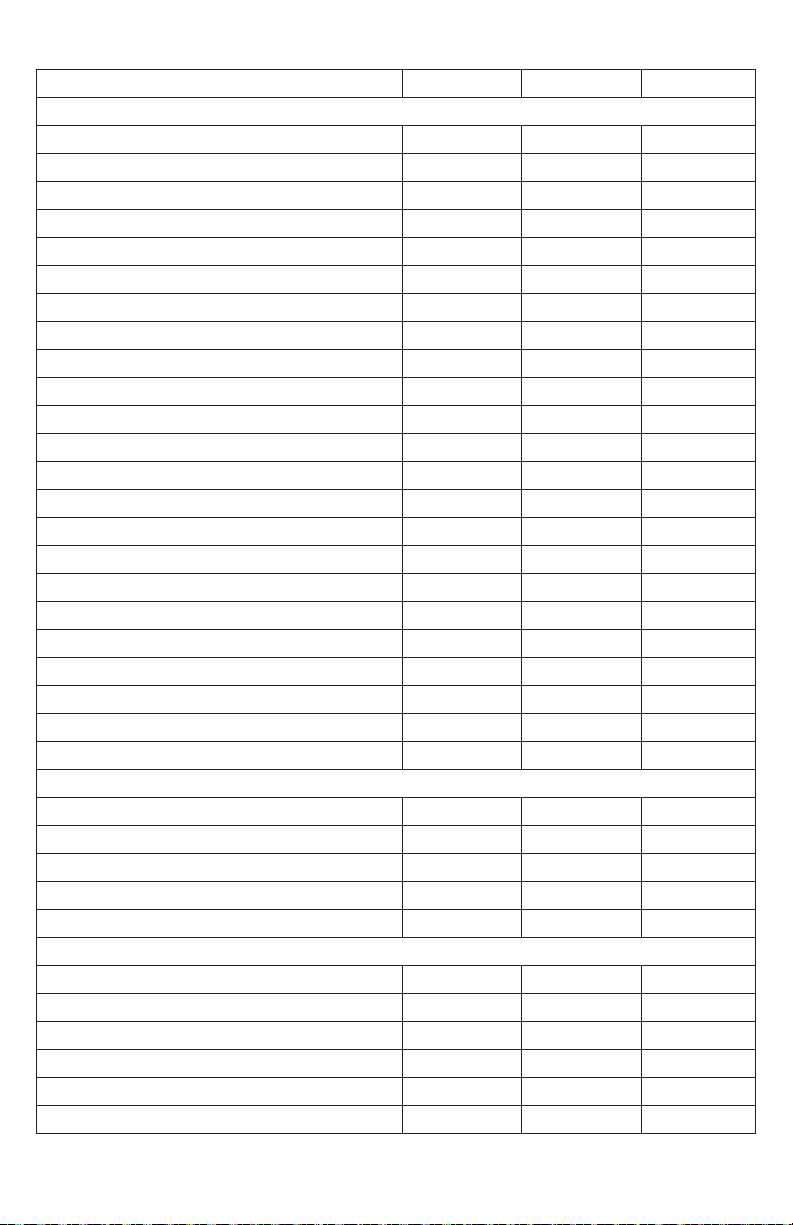

SPECIFICATIONS

Model/Part Number XTRPRO102 XTRPRO104 XTRPRO122

Thiele/Small Parameters

Fs (free-air resonance, Hz) 28.0 32.1 30.5

Vas (equivalent compliance, cu. ft.) 0.681 0.587 1.198

Vas (equivalent compliance, liters) 19.300 16.630 33.950

Qms (Q, mechanical) 5.00 5.12 6.02

Qes (Q, electrical) 0.48 0.54 0.62

Qts (total driver Q) 0.44 0.49 0.56

Re (DC resistance, ohms) 4.1 7.2 4.1

Z (nominal impedance, ohms) 4 8 4

Le (inductance, mh) 2.03 3.00 2.06

Efficiency (1W @ 1M, dB) 81.3 81.9 83.7

Efficiency (2.86 V @ 1M, dB) 84.7 82.7 87.2

Xmax (one way linear excursion, in.) 0.702 0.702 0.702

Xmax (one way linear excursion, mm) 17.825 17.825 17.825

Pe (continuous power handling, watts) 500 500 500

Peak power handling (music, watts) * 1000 1000 1000

Mms (total moving mass, grams) 190.65 168.39 244.17

Cms (mechanical compliance, mm/N) 0.170 0.146 0.112

Bl (motor strength, Tesla-M) 16.85 21.23 17.05

Sd (effective radiating area, sq. cm.) 283.529 283.529 463.770

Sd (effective radiating area, sq. m.) 0.028 0.028 0.046

Sd (effective radiating area, sq. in.) 43.964 43.964 71.912

Frequency range (Hz) 28 - 500 32.1 - 500 30.5-500

Energy Bandwidth Product (EBP) ** 58 59 49

Driver Physical Dimension

Speaker Displacement (cu ft) 0.068 0.068 0.091

Mounting hole diameter (inches/mm) 8.85/225 8.85/225 10.91/277

Mounting depth (inches/mm) 5.86/149 5.86/149 6.45/164

Magnet Weight (Oz) 96.00 96.00 96.00

Basket diameter (inches/mm) 10.23/260 10.23/260 12.28/312

Recommended Enclosures

Typical sealed enclosure (cu. ft.) 0.75 0.75 1.50

Vented enclosure (cu. ft.) *** 0.75 0.75 1.50

Port tuning frequency (Hz) 44.00 44.00 40.00

Port diameter (inside, inches) 3.00 3.00 4.00

Port square equivalent (inches) 2.659 x 2.659 2.659 x 2.659 3.545 x 3.545

Port length (inches) 11.19 11.19 11.26

Specifi cations are subject to change without notice

14 © 2008 directed electronics—all rights reserved

Page 16

SPECIFICATIONS

Model/Part Number XTRPRO124 XTRPRO152 XTRPRO154

Thiele/Small Parameters

Fs (free-air resonance, Hz) 32.3 23.4 28.7

Vas (equivalent compliance, cu. ft.) 1.256 3.464 3.207

Vas (equivalent compliance, liters) 35.590 98.130 90.860

Qms (Q, mechanical) 5.89 5.49 5.93

Qes (Q, electrical) 0.66 0.67 0.84

Qts (total driver Q) 0.59 0.61 0.73

Re (DC resistance, ohms) 7.1 4.2 7.2

Z (nominal impedance, ohms) 8 4 8

Le (inductance, mh) 2.82 1.96 3.05

Efficiency (1W @ 1M, dB) 84.4 86.3 85.9

Efficiency (2.86 V @ 1M, dB) 85.1 89.2 86.9

Xmax (one way linear excursion, in.) 0.680 0.680 0.680

Xmax (one way linear excursion, mm) 17.25 17.25 17.25

Pe (continuous power handling, watts) 500 500 500

Peak power handling (music, watts) * 1000 1000 1000

Mms (total moving mass, grams) 214.58 405.83 290.58

Cms (mechanical compliance, mm/N) 0.113 0.114 0.106

Bl (motor strength, Tesla-M) 21.62 16.57 21.18

Sd (effective radiating area, sq. cm.) 471.435 779.311 779.311

Sd (effective radiating area, sq. m.) 0.047 0.078 0.078

Sd (effective radiating area, sq. in.) 73.100 120.839 120.839

Frequency range (Hz) 32.3-500 23.4-500 28.7-500

Energy Bandwidth Product (EBP) ** 49 35 34

Driver Physical Dimension

Speaker Displacement (cu ft) 0.091 0.143 0.143

Mounting hole diameter (inches/mm) 10.91/277 13.85/352 13.85/352

Mounting depth (inches/mm) 6.46/164 7.48/190 7.48/190

Magnet Weight (Oz) 96.00 96.00 96.00

Basket diameter (inches/mm) 12.28/312 15.27/388 15.27/388

Recommended Enclosures

Typical sealed enclosure (cu. ft.) 1.50 2.00 2.00

Vented enclosure (cu. ft.) *** 1.50 3.00 3.00

Port tuning frequency (Hz) 40.00 36.00 36.00

Port diameter (inside, inches) 4.00 4.00 4.00

Port square equivalent (inches) 3.545 x 3.545 3.545 x 3.545 3.545 x 3.545

Port length (inches) 11.26 5.42 5.42

Specifi cations are subject to change without notice

© 2008 directed electronics—all rights reserved 15

Page 17

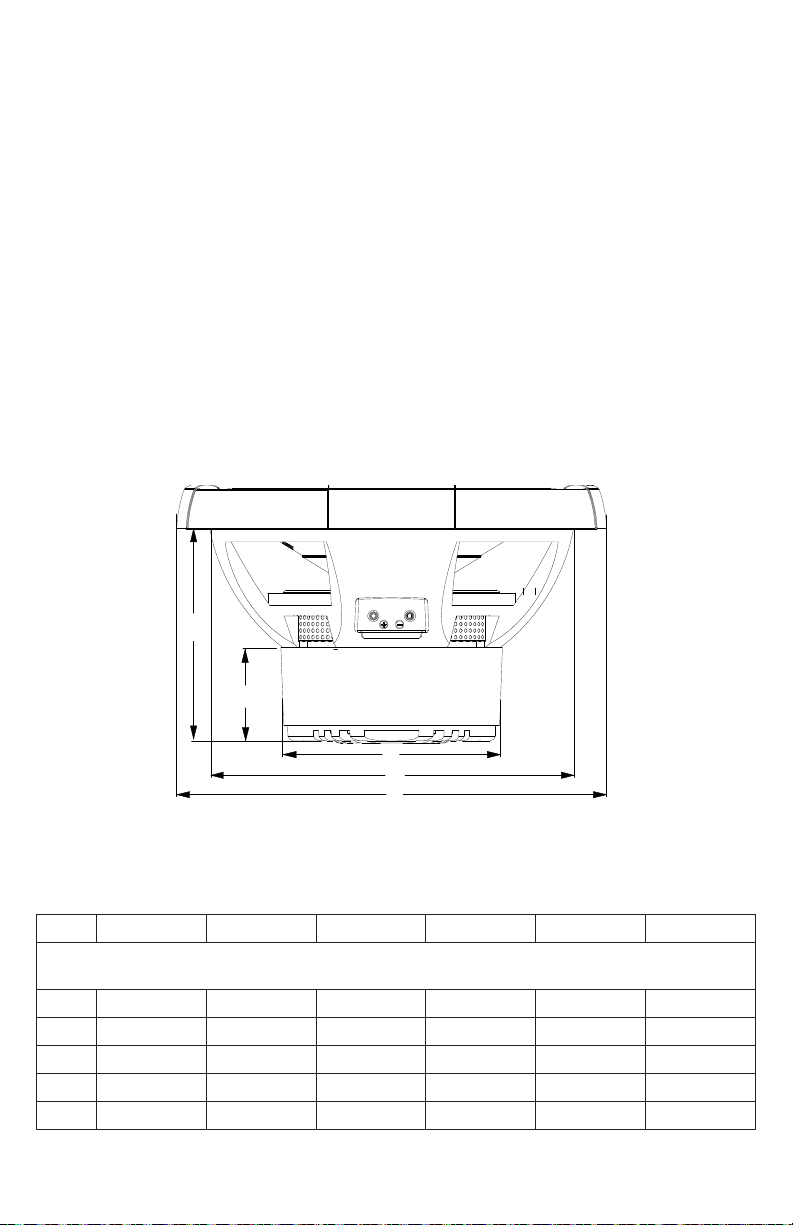

Enclosure Details

Parameters listed are for conventional applications only, for further help please 1.

call Audio Tech Support.

At least 0.75" MDF (Medium Density Fiberboard) is recommend for any XTRPRO 2.

enclosure.

Recommended enclosures are NET box volumes, speaker and port displacement 3.

are calculated into the volume of the enclosure, you will not need to add these

volumes to calculate GROSS volume for the enclosure.

Notes

* Due to the high power capabilities and long excursion of the XTRPRO woofers, the

Thiele/Small Parameters were calculated and measured using a Klippel analyzer

system.

** Energy Bandwidth Product (EBP) is determined by the following formula Fs/

Qes=EBP. EBP values of 50 and lower suggest a sealed enclosure is best, 50 to90

means the subwoofers versatile and 90 and above mean vented Enclosure is

recommended.

*** Subsonic filter should always be used and adjusted specifically for vented box

designs.

A

B

C

D

E

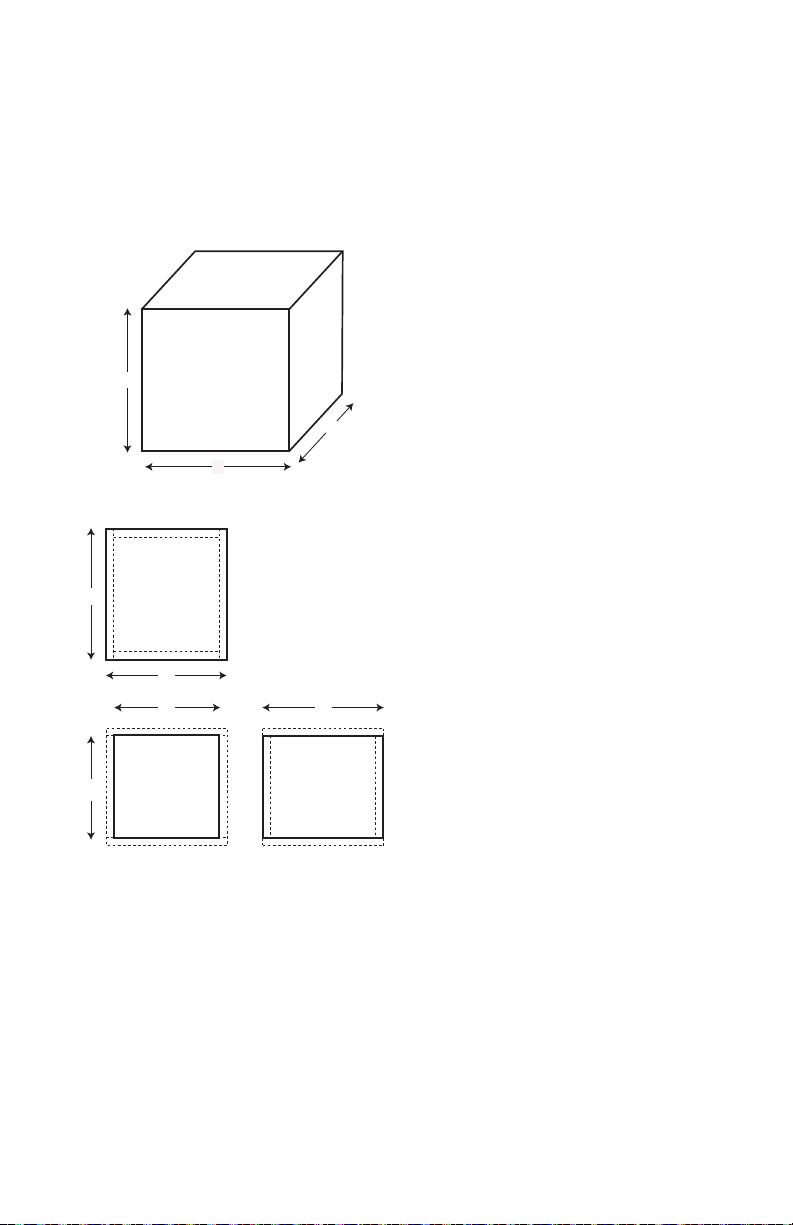

Figure 13

Figura 13

Abbildung 13

XTRPRO102 XTRPRO104 XTRPRO122 XTRPRO124 XTRPRO152 XTRPRO154

Dimensions inches/mm, Dimensions po/mm, Dimensiones plg./mm, Abmessungen Zoll/mm,

Dimensioni pollici/millimetri, Dimensões polegadas/mm

A 5.87/149 5.87/149 6.46/164 6.46/164 7.49/190 7.49/190

B 2.84/72 2.84/72 2.84/72 2.84/72 2.84/72 2.84/72

C 6.15/156 6.15/156 6.15/156 6.15/156 6.15/156 6.15/156

D 8.87/225 8.87/225 10.91/277 10.91/277 13.87/352 13.87/352

E 10.24/260 10.24/260 12.29/312 12.29/312 15.29/388 15.29/388

16 © 2008 directed electronics—all rights reserved

Page 18

Explanation of Enclosure Specifications

There are many different factors that help determine the best style of enclosure for

you or your vehicle. Listed below are some factors that should be considered.

The size of the enclosure is directly proportional to the efficiency and power handling

of that speaker. A woofer in a smaller enclosure will handle more power than the

same woofer in a larger enclosure. The exact opposite is true for efficiency, a larger

enclosure will play lower frequencies at a louder volume with less power than a

smaller enclosure.

The following will explain differences in sealed enclosures. A large enclosure is

best suited if you have smaller amounts of power (25% to 50% of speaker’s power

handling), have a larger vehicle or looking for greater output. While the smaller

enclosure should be utilized if you have recommended power (50% to 100% of

speaker’s rated power handling), have a smaller (high gain) vehicle or are looking for

more accurate sound reproduction. A smaller sealed enclosure will yield more control,

this audible translates into faster and more accurate bass.

A vented enclosure will offer greater efficiency and stronger low bass output compared

to a sealed design. A vented enclosure uses the back wave (sound from the back side

of the cone) to reinforce the output from the speaker. A properly tuned enclosure will

yield gain across the entire bandwidth of the subwoofer system and offer more cone

control than a sealed enclosure. A low tuning will yield less overall gain but greater

extension (low bass). A high tuned enclosure will offer more gain but limit the low

end response of the system. One of the advantages of having a vented enclosure is

because it is tunable to a specific frequency and that tuning frequency is known as the

“Fb”. Another important box specification is “F3”, which is the roll-off frequency at

which the driver's response is down -3dB. This is an important number when it comes

to setting your high-pass filter or your ORION Intelli-Q. The Intelli-Q should be set at

the same frequency as the “F3”as this will keep the speaker from damaging or what

is know as over-loading.

Good planning and proper construction will assure the best response from your

system. The next pages will outline many different enclosures and designs that allow

the XTRPRO subwoofers to perform best. As always, if you have any questions on

enclosure construction or design, call Technical Support 1-800-753-0800.

© 2008 directed electronics—all rights reserved 17

Page 19

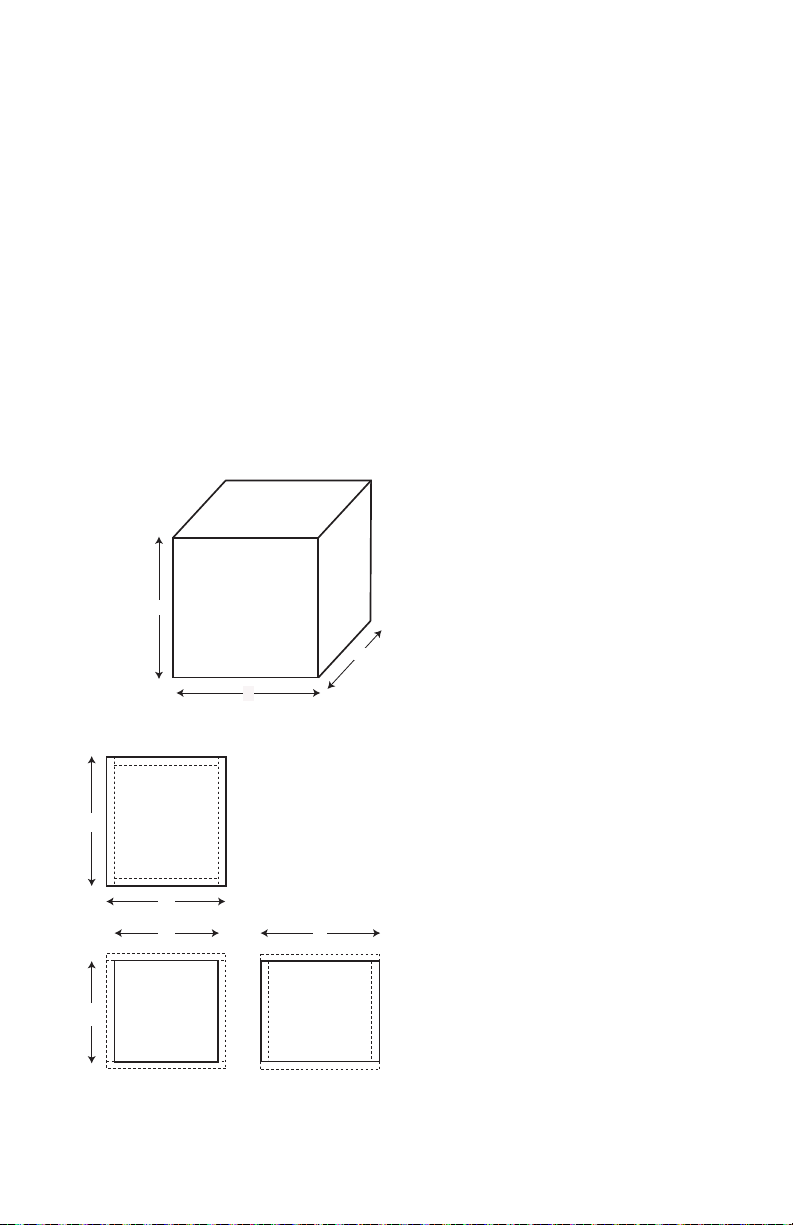

ENCLOSURE RECOMMENDATIONS

Enclosure Details

1. External dimensions calculated for 3/4” building material

2. Includes speaker displacement

3. Volumes given are net tuning volume

4. Enclosures include a minimal amount of damping material. Just enough material to

line the inside of the enclosure is required.

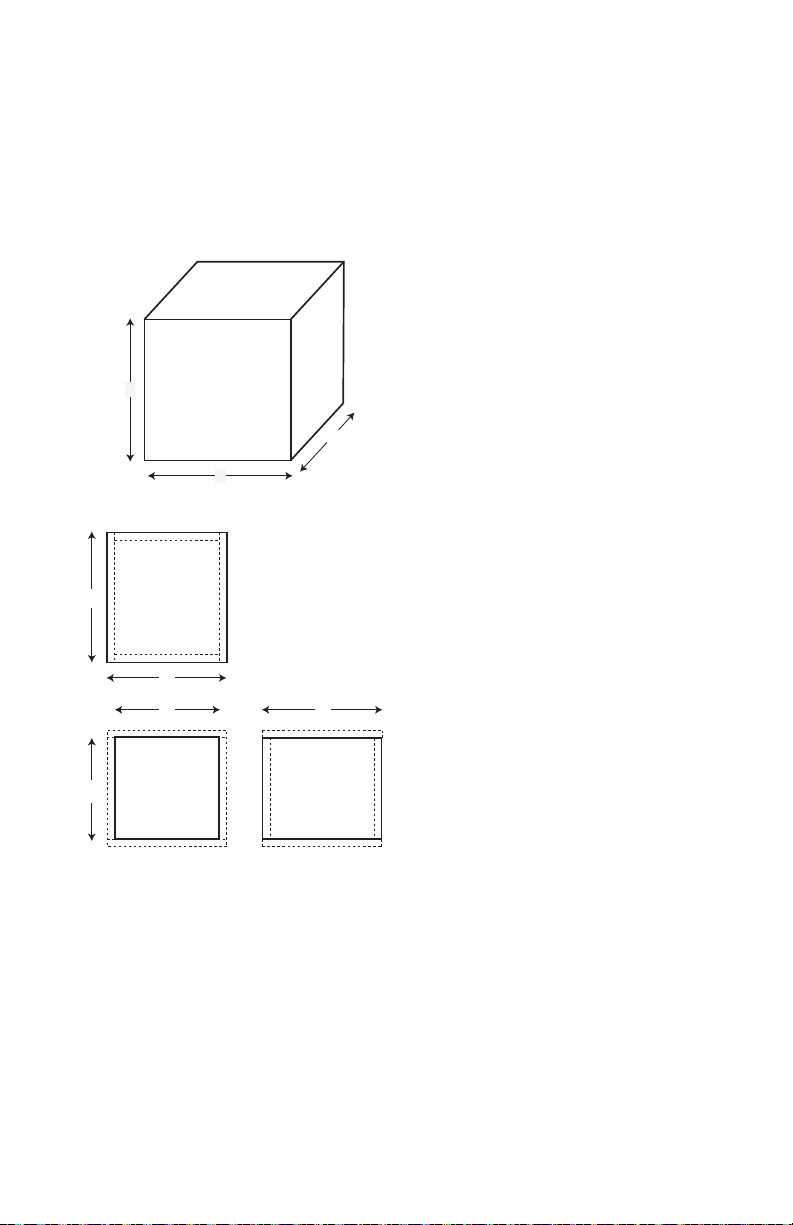

XTRPRO102 & 104 Sealed Enclosure Recommendations

Box Properties

— Description —

Type: Closed Box

Shape: Prism, Square

A

Top &

c

Bottom

b

d

Front &

a

Back

— Box Parameters —

Vb = 0.75 cu.ft

V(total) = 0.791 cu.ft

Qtc = 0.598

QL = 7

F3 = 50.61 Hz

Fill = none

External Dimensions

A = 12 in. (305 mm)

B = 15.5 in. (394 mm)

C = 10.8 in. (274 mm)

Internal Dimensions

A = 10.5 in. (267 mm)

B = 14 in. (356 mm)

C = 9.3 in. (236 mm)

C

B

c

Sides

Wall Thickness

Front = 0.75 in. (19 mm)

Side = 0.75 in. (19 mm)

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 10.8 in. (274 mm)

width (b) = 15.5 in. (394 mm)

thickness = 0.75 in. (19 mm)

1 Front, 1 Back:

height (a) = 10.5 in. (267 mm)

width (d) = 14 in. (356 mm)

thickness = 0.75 in. (19 mm)

2 Sides: height (a) = 10.5 in. (267 mm)

depth (c) = 10.8 in. (274 mm)

thickness = 0.75 in. (19 mm)

—Driver Mounting—

Figure 14

Figura 14

Abbildung 14

18 © 2008 directed electronics—all rights reserved

Mounting: Front

Page 20

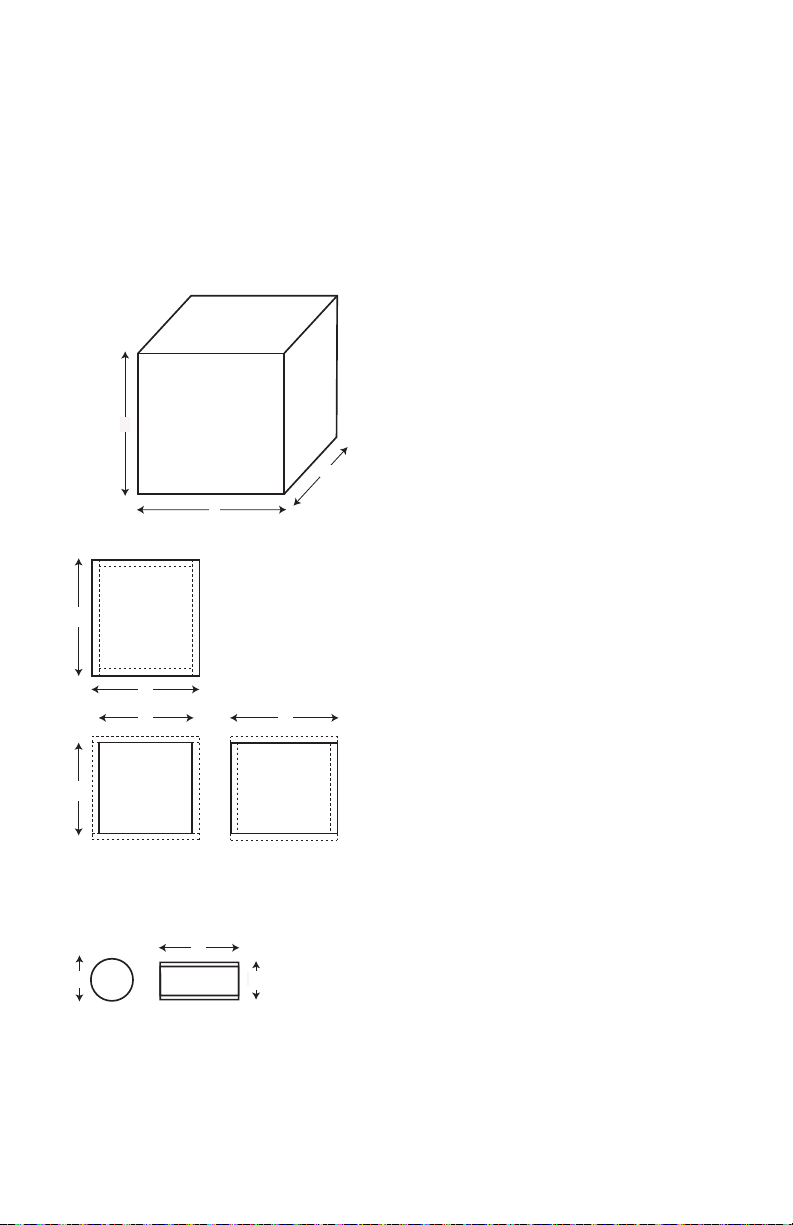

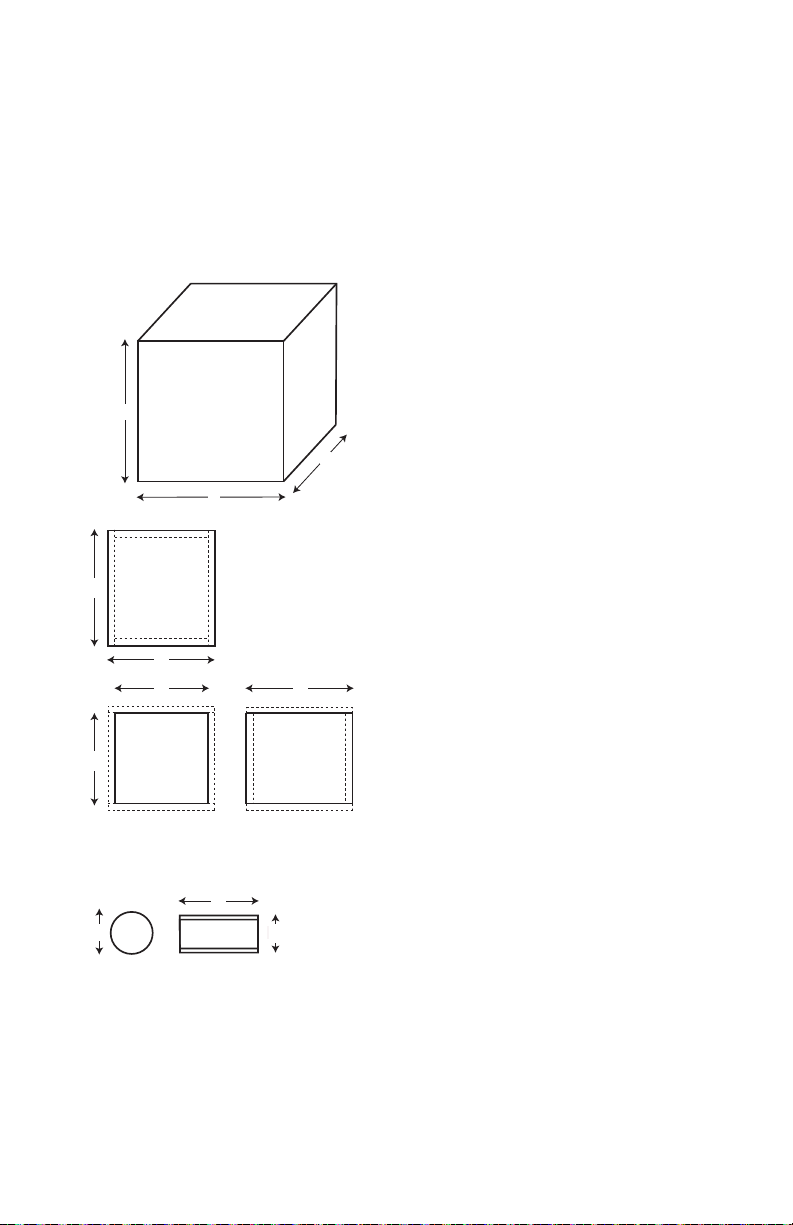

XTRPRO102 & 104 Vented Enclosure Recommendations

Box Properties

— Description —

Type: Vented Box

Shape: Prism, Square

Figure 15

Figura 15

Abbildung 15

A

Top &

c

Bottom

b

d

Front &

a

Back

— Box Parameters —

Vb = 0.75 cu.ft

V(total) = 0.841 cu.ft

Fb = 44 Hz

QL = 7

F3 = 35.24 Hz

Fill = none

External Dimensions

A = 12 in. (305 mm)

B = 15.5 in. (394 mm)

C = 11.39 in. (289 mm)

Internal Dimensions

A = 10.5 in. (267 mm)

B = 14 in. (356 mm)

C = 9.89 in. (251 mm)

Wall Thickness

C

Front = 0.75 in. (19 mm)

B

Side = 0.75 in. (19 mm)

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 11.39 in. (289 mm)

width (b) = 15.5 in. (394 mm)

thickness = 0.75 in. (19 mm)

1 Front, 1 Back:

c

height (a) = 10.5 in. (267 mm)

width (d) = 14 in. (356 mm)

thickness = 0.75 in. (19 mm)

2 Sides:

Sides

height (a) = 10.5 in. (267 mm)

depth (c) = 11.39 in. (289 mm)

thickness = 0.75 in. (19 mm)

— Vents —

No. of Vents = 1

Vent shape = round

Vent ends = one flush

Dv = 3 in. (76 mm)

Lv = 11.19 in. (284 mm)

—Driver Mounting—

Mounting: Front

h

e

g

Ven t Par t s

1 Duct:

outside diameter (e) = 3.25 in. (83 mm)

inside diameter (g) = 3 in. (76 mm)

length (h) = 11.19 in. (284 mm)

© 2008 directed electronics—all rights reserved 19

Page 21

XTRPRO122 & 124 Sealed Enclosure Recommendations

Box Properties

— Description —

Type: Closed Box

Shape: Prism, Square

A

B

Top &

c

Bottom

b

d

Front &

a

Back

c

Sides

— Box Parameters —

Vb = 1.5 cu.ft

V(total) = 1.55 cu.ft

Qtc = 0.717

QL = 6.886

F3 = 43.09 Hz

Fill = none

External Dimensions

A = 16 in. (406 mm)

B = 16 in. (406 mm)

C = 14.24 in. (362 mm)

Internal Dimensions

A = 14.5 in. (368 mm)

B = 14.5 in. (368 mm)

C = 12.74 in. (324 mm)

Wall Thickness

C

Front = 0.75 in. (19 mm)

Side = 0.75 in. (19 mm)

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 14.24 in. (362 mm)

width (b) = 16 in. (406 mm)

thickness = 0.75 in. (19 mm)

1 Front, 1 Back:

height (a) = 14.5 in. (368 mm)

width (d) = 14.5. (368 mm)

thickness = 0.75 in. (19 mm)

2 Sides:

height (a) = 14.5 in. (368 mm)

depth (c) = 14.24 in. (362 mm)

thickness = 0.75 in. (19 mm)

Figure 16

Figura 16

Abbildung 16

20 © 2008 directed electronics—all rights reserved

—Driver Mounting—

Mounting: Front

Page 22

XTRPRO122 & 124 Vented Enclosure Recommendations

Box Properties

— Description —

Type: Vented Box

Shape: Prism, Square

Figure 17

Figura 17

Abbildung 17

A

Top &

c

Bottom

b

d

Front &

a

Back

— Box Parameters —

Vb = 1.5 cu.ft

V(total) = 1.637 cu.ft

Fb = 40 Hz

QL = 6.886

F3 = 32.19 Hz

Fill = none

External Dimensions

A = 13.5 in. (343 mm)

B = 18.5 in. (470 mm)

C = 15.36 in. (390 mm)

Internal Dimensions

A = 12 in. (305 mm)

B = 17 in. (432 mm)

C = 13.86 in. (352 mm)

Wall Thickness

C

Front = 0.75 in. (19 mm)

B

Side = 0.75 in. (19 mm)

c

Sides

— Vents —

No. of Vents = 1

Vent shape = round

Vent ends = one flush

Dv = 4 in. (102 mm)

Lv = 11.26 in. (286 mm)

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 15.36 in. (390 mm)

width (b) = 18.5 in. (470 mm)

thickness = 0.75 in. (19 mm)

1 Front, 1 Back:

height (a) = 12 in. (305 mm)

width (d) = 17 in. (432 mm)

thickness = 0.75 in. (19 mm)

2 Sides:

height (a) = 12 in. (305 mm)

depth (c) = 15.36 in. (390 mm)

thickness = 0.75 in. (19 mm)

—Driver Mounting—

Mounting: Front

h

e

g

Ven t Par t s

1 Duct:

outside diameter (e) = 4.25 in. (108 mm)

inside diameter (g) = 4 in. (102 mm)

length (h) = 11.26 in. (286 mm)

© 2008 directed electronics—all rights reserved 21

Page 23

XTRPRO152 & 154 Sealed Enclosure Recommendations

Box Properties

— Description —

Type: Closed Box

Shape: Prism, Square

A

B

Top &

c

Bottom

b

d

Front &

a

Back

C

c

Sides

— Box Parameters —

Vb = 2 cu.ft

V(total) = 2.078 cu.ft

Qtc = 0.963

QL = 5.281

F3 = 37.55 Hz

Fill = none

External Dimensions

A = 17.5 in. (445 mm)

B = 17.5 in. (445 mm)

C = 15.52 in. (394 mm)

Internal Dimensions

A = 16 in. (406 mm)

B = 16 in. (406 mm)

C = 14.02 in. (356 mm)

Wall Thickness

Front = 0.75 in. (19 mm)

Side = 0.75 in. . (19 mm)

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 15.52 in. (394 mm)

width (b) = 17.5 in. (445 mm)

thickness = 0.75 in. (19 mm)

1 Front, 1 Back:

height (a) = 16 in. (406 mm)

width (d) = 16 in. (406 mm)

thickness = 0.75 in. (19 mm)

2 Sides:

height (a) = 16 in. (406 mm)

depth (c) = 15.52 in. (394 mm)

thickness = 0.75 in. (19 mm)

Figure 18

Figura 18

Abbildung 18

22 © 2008 directed electronics—all rights reserved

—Driver Mounting—

Mounting: Front

Page 24

XTRPRO152 & 154 Vented Enclosure Recommendations

Box Properties

— Description —

Type: Vented Box

Shape: Prism, Square

Figure 19

Figura 19

Abbildung 19

A

Top &

c

Bottom

b

d

Front &

a

Back

— Box Parameters —

Vb = 3 cu.ft

V(total) = 3.116 cu.ft

Fb = 36 Hz

QL = 5

F3 = 29.7 Hz

Fill = none

External Dimensions

A = 18.5 in. (470 mm)

B = 23.5 in. (597 mm)

C = 15.9 in. (404 mm)

Internal Dimensions

A = 17 in. (432 mm)

B = 22 in. (559 mm)

C = 14.4 in. (366 mm)

Wall Thickness

C

Front = 0.75 in. (19 mm)

B

Side = 0.75 in. (19 mm)

c

Sides

— Vents —

No. of Vents = 1

Vent shape = round

Vent ends = one flush

Dv = 4 in. (102 mm)

Lv = 5.422 in. (138 mm)

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 15.9 in. (404 mm)

width (b) = 23.5 in. (597 mm)

thickness = 0.75 in. (19 mm)

1 Front, 1 Back:

height (a) = 17 in. (432 mm)

width (d) = 22 in. (559 mm)

thickness = 0.75 in. (19 mm)

2 Sides:

height (a) = 17 in. (432 mm)

depth (c) = 15.9 in. (404 mm)

thickness = 0.75 in. (19 mm)

—Driver Mounting—

Mounting: Front

h

e

g

Vent Parts --- Square

1 Duct:

outside diameter (e) = 4.25 in. (108 mm)

inside diameter (g) = 4 in. (102 mm)

length (h) = 5.422 in. (138 mm)

© 2008 directed electronics—all rights reserved 23

Page 25

FRANÇAIS

INSTALLATION

Les performances de ces haut-parleurs de graves XTRPRO sont directement liées à la

qualité de l’installation. Les précautions prises lors de l’installation se traduiront par

des années de bon fonctionnement. Si vous doutez de pouvoir obtenir une bonne

installation, veuillez demander l’assistance technique d’un revendeur Orion agréé. Les

revendeurs Orion sont des professionnels compétents spécialisés, capables d’obtenir

les meilleures performances des systèmes Orion. Si vous décidez d’installer vous-même

ce système de haut-parleurs, veuillez lire toute la section relative aux caissons clos et

aux caissons à évent accordé avant de commencer l’installation.

CHOIX DES EMPLACEMENTS DE MONTAGE DES HAUTPARLEURS

Le choix des emplacements de montage des haut-parleurs a une très grande influence

sur la qualité sonore du système. Pour choisir les emplacements répondant le mieux

aux besoins de l’utilisateur, de nombreux facteurs doivent être pris en compte. Il

faut qu’il y ait suffisamment de place pour y placer les haut-parleurs. Vérifiez que

l’emplacement choisi est compatible avec le fonctionnement mécanique et électrique

du véhicule.

Le choix des meilleurs emplacements pour les haut-parleurs est conditionné par

l’esthétisme et le décor intérieur du véhicule. En général, les haut-parleurs de graves

sont installés dans le coffre, le siège arrière ou à l’arrière du véhicule.

© 2008 directed electronics—Tous droits réservés 25

Page 26

CARACTÉRISTIQUES

15

14

13

12

123

4

5

11

6

7

8910

1 Calotte pare-poussière en polypropylène, résistante à l’humidité et aux UV.

2 Suspension surdimensionnée en caoutchouc nitrile-butadiène permettant une

longue course contrôlée.

3 Cône papier – résistant à l’humidité et aux UV.

4 Châssis sur mesure en fonte d’aluminium.

5 Corps de bobine mobile en aluminium avec évents (corps de bobine mobile

de 2,5”).

6 Plaque avant en acier 8 mm.

7 Pile de 2 gros aimants céramique.

8 Plaque arrière en acier 8 mm / bloc de pièce polaire en T.

9 Évent de 29 mm faisant partie du système de refroidissement amélioré de la

bobine mobile (convection forcée).

10 Protecteur d’aimant en PVC.

11 Bobine mobile en cuivre haute température 2 ohms double ou 4 ohms

double.

12 Évents dans le corps de bobine mobile. Font partie du système de refroidissement

amélioré de la bobine mobile (convection forcée).

13 Anneau de centrage double Conex entrelacé avec fils rosettes cousus et en

boucles.

14 Borniers personnalisées.

15 Enjoliveur en ABS.

26 © 2008 directed electronics—Tous droits réservés

Page 27

CONFIGURATIONS DE CÂBLAGE

Série – Un haut-parleur (deux bobines mobiles de 2 ohms)

Voir la figure 2 à la page 4

Un haut-parleur de graves à deux bobines mobiles de 2 ohms raccordées en série

constitue une charge de 4 ohms pour l’amplificateur.

1. Configurez le haut-parleur de graves en série en raccordant l’une des bornes

négatives (-) à la borne positive (+) de l’autre bobine.

2. Raccordez la borne positive (+) de la première bobine à la borne positive (+) de

l’amplificateur. Raccordez la borne négative (-) de la seconde bobine à la borne

négative (-) de l’amplificateur.

Parallèle – Un haut-parleur (deux bobines mobiles de 2 ohms)

Voir la figure 3 à la page 4

Un haut-parleur de graves à deux bobines mobiles de 2 ohms raccordées en parallèle

constitue une charge de 1 ohm pour l’amplificateur.

1. Configurez le haut-parleur de graves en parallèle en raccordant entre elles les

deux bornes positives (+) et les deux bornes négatives (-).

2. Raccordez les bornes positives (+) du haut-parleur de graves à la borne positive (+)

de l’amplificateur. Raccordez les bornes négatives (-) du haut-parleur de graves à

la borne négative (-) de l’amplificateur.

Parallèle – Un haut-parleur (deux bobines mobiles de 4 ohms)

Voir la figure 4 à la page 5

Un haut-parleur de graves à deux bobines mobiles de 4 ohms raccordées en parallèle

constitue une charge de 2 ohms pour l’amplificateur.

1. Configurez le haut-parleur de graves en parallèle en raccordant entre elles les

deux bornes positives (+) et les deux bornes négatives (-).

2. Raccordez les deux bornes positives (+) du haut-parleur de graves à la borne

positive (+) de l’amplificateur. Raccordez les deux bornes négatives (-) du hautparleur de graves à la borne négative (-) de l’amplificateur.

Parallèle – Deux haut-parleurs (deux bobines mobiles de 4 ohms)

Voir la figure 5 à la page 6

Deux haut-parleurs de graves en parallèle avec pour chacun les deux bobines

mobiles de 4 ohms raccordées en parallèle constituent une charge de 1 ohm pour

l’amplificateur.

1. Configurez le haut-parleur de graves en parallèle en raccordant entre elles les

quatre bornes positives (+) et les quatre bornes négatives (-).

2. Raccordez les bornes positives (+) des haut-parleurs de graves à la borne positive

© 2008 directed electronics—Tous droits réservés 27

Page 28

(+) de l’amplificateur. Raccordez les bornes négatives (-) des haut-parleurs de

graves à la borne négative (-) de l’amplificateur.

Série-parallèle – Deux haut-parleurs (deux bobines mobiles de 2 ohms)

Voir la figure 6 à la page 7

Remarque : Vérifiez que le câblage du haut-parleur de graves est conforme à

l’illustration, avec la borne négative de la première bobine du haut-parleur de

graves reliée à la borne positive de la seconde bobine.

Deux haut-parleurs de graves en parallèle avec pour chacun les deux bobines

mobiles de 2 ohms raccordées en série constituent une charge de 2 ohms pour

l’amplificateur.

1. Configurez chaque haut-parleur de graves en série en raccordant la borne

négative (-) de la première bobine à la borne positive (+) de la seconde.

2. Raccordez la borne positive (+) de la première bobine de chaque haut-parleur de

graves à la borne positive (+) de l’amplificateur. Raccordez la borne négative (-)

de la seconde bobine de chaque haut-parleur de graves à la borne négative (-) de

l’amplificateur.

Série-parallèle – Trois haut-parleurs (deux bobines mobiles de 4 ohms)

Voir la figure 7 à la page 8

Remarque : Vérifiez que le câblage du haut-parleur de graves est conforme à

l’illustration, avec la borne négative de la première bobine du haut-parleur de

graves reliée à la borne positive de la seconde bobine.

Trois haut-parleurs de graves en parallèle avec pour chacun les deux bobines

mobiles de 4 ohms raccordées en série constituent une charge de 2,67 ohms pour

l’amplificateur.

1. Configurez chaque haut-parleur de graves en série en raccordant la borne

négative (-) de la première bobine à la borne positive (+) de la seconde.

2. Raccordez la borne positive (+) de la première bobine de chaque haut-parleur de

graves à la borne positive (+) de l’amplificateur. Raccordez la borne négative (-)

de la seconde bobine de chaque haut-parleur de graves à la borne négative (-) de

l’amplificateur.

Série-parallèle – Trois haut-parleurs (deux bobines mobiles de 2 ohms)

Voir la figure 8 à la page 9

Remarque : Vérifiez que le câblage du haut-parleur de graves est conforme à

l’illustration, avec la borne négative de la première bobine du haut-parleur de

graves reliée à la borne positive de la seconde bobine.

Trois haut-parleurs de graves en parallèle avec pour chacun les deux bobines

mobiles de 2 ohms raccordées en série constituent une charge de 1,33 ohms pour

l’amplificateur.

28 © 2008 directed electronics—Tous droits réservés

Page 29

1. Configurez chaque haut-parleur de graves en série en raccordant la borne

négative (-) de la première bobine à la borne positive (+) de la seconde.

2. Raccordez la borne positive (+) de la première bobine de chaque haut-parleur de

graves à la borne positive (+) de l’amplificateur. Raccordez la borne négative (-)

de la seconde bobine de chaque haut-parleur de graves à la borne négative (-) de

l’amplificateur.

Série-parallèle – Quatre haut-parleurs (deux bobines mobiles de 4 ohms)

Voir la figure 9 à la page 10

Remarque : Vérifiez que le câblage du haut-parleur de graves est conforme à

l’illustration, avec la borne négative de la première bobine du haut-parleur de

graves reliée à la borne positive de la seconde bobine.

Quatre haut-parleurs de graves en parallèle avec pour chacun les deux bobines

mobiles de 4 ohms raccordées en série constituent une charge de 2 ohms pour

l’amplificateur.

1. Configurez chaque haut-parleur de graves en série en raccordant la borne

négative (-) de la première bobine à la borne positive (+) de la seconde.

2. Raccordez la borne positive (+) de la première bobine de chaque haut-parleur de

graves à la borne positive (+) de l’amplificateur. Raccordez la borne négative (-)

de la seconde bobine de chaque haut-parleur de graves à la borne négative (-) de

l’amplificateur.

Série-parallèle – Quatre haut-parleurs (deux bobines mobiles de 2 ohms)

Voir la figure 10 à la page 11

Remarque : Vérifiez que le câblage du haut-parleur de graves est conforme à

l’illustration, avec la borne négative de la première bobine du haut-parleur de

graves reliée à la borne positive de la seconde bobine.

Quatre haut-parleurs de graves en parallèle avec pour chacun les deux bobines mobiles

de 2 ohms raccordées en série constituent une charge de 1 ohm pour l’amplificateur.

1. Configurez chaque haut-parleur de graves en série en raccordant la borne

négative (-) de la première bobine à la borne positive (+) de la seconde.

2. Raccordez la borne positive (+) de la première bobine de chaque haut-parleur de

graves à la borne positive (+) de l’amplificateur. Raccordez la borne négative (-)

de la seconde bobine de chaque haut-parleur de graves à la borne négative (-) de

l’amplificateur.

2 amplificateurs – Un haut-parleur (deux bobines mobiles de 2 ohms)

Voir la figure 11 à la page 12

Un haut-parleur de graves à deux bobines mobiles de 2 ohms raccordées chacune à un

amplificateur distinct constitue une charge de 2 ohms pour chaque amplificateur.

1. Raccordez l’une des bobines mobiles du haut-parleur au premier amplificateur en

reliant les bornes positive (+) et négative (-) du haut-parleur aux bornes positive

© 2008 directed electronics—Tous droits réservés 29

Page 30

(+) et négative (-) correspondantes du premier amplificateur.

2. Raccordez l’autre bobine mobile du haut-parleur au second amplificateur en

reliant les bornes positive (+) et négative (-) du haut-parleur aux bornes positive

(+) et négative (-) correspondantes du second amplificateur.

2 amplificateurs – Un haut-parleur (deux bobines mobiles de 4 ohms)

Voir la figure 12 à la page 13

Un haut-parleur de graves à deux bobines mobiles de 4 ohms raccordées chacune à un

amplificateur distinct constitue une charge de 4 ohms pour chaque amplificateur.

1. Raccordez l’une des bobines mobiles du haut-parleur au premier amplificateur en

reliant les bornes positive (+) et négative (-) du haut-parleur aux bornes positive

(+) et négative (-) correspondantes du premier amplificateur.

2. Raccordez l’autre bobine mobile du haut-parleur au second amplificateur en

reliant les bornes positive (+) et négative (-) du haut-parleur aux bornes positive

(+) et négative (-) correspondantes du second amplificateur.

SPÉCIFICATIONS

Explication des caractéristiques techniques, voir les détails en pages 14 et 15

Modèle/Référence XTRPRO###

Taille

Paramètres Thiele/Small

Fs (résonance à l’air libre, Hz)

Vas (conformité équivalente, pieds-cubes)

Vas (conformité équivalente, litres)

Qms (Q, mécanique)

Qes (Q, électrique)

Qts (Q total haut-parleur)

Re (résistance c.c., ohms)

Z (impédance nominale, ohms)

Le (inductance, mH)

Rendement (1W à 1 m, dB)

Rendement (2.86 V à 1 m, dB)

Xmax (course linéaire dans un sens, pouces)

Xmax (course linéaire dans un sens, mm)

Pe (puissance continue admissible, watts)

Puissance crête admissible (musique, watts) *

Mms (masse mobile totale, grammes)

Cms (conformité mécanique, mm/N)

Bl (intensité magnétique moteur, tesla-mètres)

30 © 2008 directed electronics—Tous droits réservés

Page 31

Sd (surface effective de rayonnement, cm2)

Sd (surface effective de rayonnement, m2)

Sd (surface effective de rayonnement, pouces-carrés)

Plage de fréquence (Hz)

Facteur d’efficacité (EBP) **

Encombrement du haut-parleur

Volume du haut-parleur (pieds-cubes)

Diamètre du trou de montage (pouces/mm)

Profondeur de montage (pouces/mm)

Poids de l’aimant (onces)

Diamètre du saladier (pouces/mm)

Caissons recommandés

Caisson clos courant (pieds-cubes)

Caisson à évent accordé (pieds-cubes) ***

Fréquence d’accord de l’évent (Hz)

Carré équivalent à l’évent (pouces)

Longueur de l’évent (pouces)

Spécifications sujettes à changement sans préavis

DÉTAILS DU CAISSON

Les paramètres indiqués ne sont valables que pour des applications convention-1.

nelles. Pour obtenir de l’aide, veuillez téléphoner au service d’assistance technique audio.

Panneau de fi bres de densité moyenne de 19 mm recommandé.2.

Les recommandations de caissons indiquent des volumes NETS. Les volumes du 3.

haut-parleur et de l’évent sont pris en compte dans le volume du caisson. Il n’est

pas nécessaire d’ajouter ces volumes pour obtenir le volume BRUT du caisson.

REMARQUES :

* En raison des possibilités de puissance élevée et de la longue course de ces haut-

parleurs de graves, les paramètres Thiele/Small ont été calculés et mesurés à

l’aide d’un système d’analyse Klippel.

** Le facteur d’efficacité (EBP) est déterminé par la formule suivante : Fs/Qes = EBP.

Les valeurs d’EBP inférieures ou égales à 50 indiquent qu’un caisson clos est préférable ; entre 50 et 90, les haut-parleurs de graves sont polyvalents ; pour une

valeur supérieure ou égale à 90, un caisson à évent accordé est recommandé.

*** Toujours utiliser et régler des filtres subsoniques en fonction des modèles de cais-

sons à évent accordé.

© 2008 directed electronics—Tous droits réservés 31

Page 32

EXPLICATION DES CARACTÉRISTIQUES TECHNIQUES

DES CAISSONS

De nombreux facteurs entrent en jeu dans la détermination du meilleur type de

caisson pour un utilisateur ou un véhicule donné. Voici quelques uns de ces facteurs.

La taille du caisson est directement proportionnelle au rendement et à la puissance

admissible du haut-parleur. La puissance admissible est plus élevée pour un hautparleur de graves dans un petit caisson que pour le même haut-parleur de graves dans

un plus grand caisson. Pour le rendement, c’est exactement le contraire : un grand

caisson permet de reproduire les très basses fréquences avec un volume plus élevé et

moins de puissance qu’un petit caisson.

Le type de caisson clos ci-dessous est le meilleur pour la qualité d’ensemble du son.

La taille du caisson dépend de la puissance et du type de véhicule dans lequel il doit

être placé. Les grands caissons conviennent mieux pour les faibles puissances (25 à 50

% de la puissance admissible du haut-parleur) et les grands véhicules, ou bien pour

obtenir un plus grand volume sonore. Il faut utiliser un petit caisson dans le cas d’une

forte puissance (50 à 100 % de la puissance admissible du haut-parleur) ou d’un petit

véhicule (gain élevé), ou bien pour obtenir une plus grande précision de reproduction

du son. Un caisson clos plus petit permet un meilleur contrôle, ce qui se traduit par des

graves plus rapides et plus précis.

Par rapport à un modèle clos, un caisson à évent accordé offre un meilleur rendement

et une puissance acoustique plus élevée dans les extrêmes-graves. Un caisson clos

utilise l’onde arrière (son provenant de l’arrière du cône) pour renforcer la puissance

acoustique du haut-parleur. Un caisson correctement accordé permet un gain élevé sur

toute la bande passante du caisson de graves et offre un meilleur contrôle qu’un caisson

clos. Un accord bas donne moins de gain d’ensemble mais une meilleure extension

(extrêmes-graves). Avec un caisson à accord haut, le gain est plus élevé mais la réponse

du système dans les extrêmes-graves est limitée. L’un des avantages d’un caisson à

évent accordé est la possibilité d’accord à une fréquence particulière, appelée « Fb ».

Une autre caractéristique importante du caisson est « F3 », la fréquence à laquelle la

réponse du haut-parleur est réduite de 3 dB. Il s’agit d’une valeur importante pour le

réglage du filtre passe-haut ou du dispositif ORION IntelliQ. Le dispositif IntelliQ doit

être réglé à la fréquence « F3 » car cela permet d’éviter d’endommager le haut-parleur

ou de le surcharger.

Une bonne préparation et une construction adéquate garantissent la meilleure réponse

du système. Les pages suivantes décrivent plusieurs types de caissons permettant

d’obtenir le meilleur fonctionnement des haut-parleurs de graves XTRPRO.

32 © 2008 directed electronics—Tous droits réservés

Page 33

RECOMMANDATIONS SUR LES ENCEINTES

Détails des enceintes

1. Dimensions externes calculées pour des matériaux de 3/4”

2. Inclut le volume d'encombrement des haut-parleurs

3. Les volumes indiqués sont le volume d'accord net

4. Les enceintes contiennent une quantité minimale de matériaux d'amortissement. Il

suffi t de prévoir assez de tissu pour le revêtement intérieur de l'enceinte.

Explication des diagrammes de caissons clos (voir les dimensions en pages 18, 20 et

22)

Propriétés du caisson

— Description —

Type : Caisson clos

Forme : Prisme, carré

A

B

Haut et

c

a

bas

b

d c

Avant et

arrière

C

Côtés

— Paramètres du caisson —

Vb =

V(total) =

Qtc =

QL =

F3 =

Remplissage =

— Dimensions externes —

A =

B =

C =

— Dimensions internes —

A =

B =

C =

— Épaisseur parois —

Avant =

Côtés =

—Éléments du caisson —

Forme du caisson : prisme carré

1 haut, 1 bas

profondeur (c) =

largeur (b) =

épaisseur =

1 avant, 1 arrière

hauteur (a) =

largeur (d) =

épaisseur =

2 côtés

hauteur (a) =

profondeur (c) =

épaisseur =

— Montage du haut-parleur —

Montage : Avant

© 2008 directed electronics—Tous droits réservés 33

Page 34

Explication des diagrammes de caissons à évent accordé (voir les dimensions en pages

19, 21 et 23)

Propriétés du caisson

— Description —

Type : Caisson à évent accordé

Forme : Prisme, carré

A

B

Haut et

c

a

bas

b

d c

Avant et

arrière

— Paramètres du caisson —

Vb =

V(total) =

Qtc =

QL =

F3 =

Remplissage =

— Dimensions externes —

A =

B =

C =

— Dimensions internes —

A =

B =

C

Côtés

C =

— Épaisseur parois —

Avant =

Côtés =

—Éléments du caisson —

Forme du caisson : prisme carré

1 haut, 1 bas

profondeur (c) =

largeur (b) =

épaisseur =

1 avant, 1 arrière

hauteur (a) =

largeur (d) =

épaisseur =

2 côtés

hauteur (a) =

profondeur (c) =

épaisseur =

— Évents —

Nb d’évents =

Forme évent = rond

Extrémité évent = une affleurante

Dv =

Lv =

— Montage du haut-parleur —

Montage : Avant

h

e

34 © 2008 directed electronics—Tous droits réservés

g

— Éléments de l’évent —

1 gaine :

diamètre extérieur (e) =

diamètre intérieur (g) =

longueur (h) =

Page 35

ESPAÑOL

INSTALACIÓN

El rendimiento de estos subwoofers XTRPRO es directamente proporcional a la calidad

de la instalación. El cuidado que se tenga durante el proceso de instalación será

recompensado con muchos años de rendimiento satisfactorio. Si no está seguro de sus

capacidades de instalación, pídale asistencia técnica al distribuidor autorizado local

de Orion. Los distribuidores de Orion son profesionales capacitados que se dedican a

extraer el rendimiento máximo de los sistemas Orion. Si decide instalar este sistema

de altavoces usted mismo, lea toda la sección sobre cajas selladas y ventiladas antes

de comenzar la instalación.

UBICACIONES DE MONTAJE DE LOS ALTAVOCES

Escoger la ubicación correcta de los altavoces tendrá un efecto máximo en la calidad

del sonido del sistema. Es necesario que usted tenga en cuenta varias consideraciones

cuando escoja el lugar que mejor se adapte a sus necesidades. Los lugares escogidos

deben ser lo suficientemente grandes como para que quepan los altavoces. Es

necesario que en la ubicación escogida no se afecte ninguna operación mecánica o

eléctrica del vehículo.

Determinar la mejor ubicación de los altavoces depende de sus necesidades cosméticas

y del interior del vehículo. Por lo general, los woofers se instalan en el maletero, el

asiento trasero o la parte de atrás del vehículo.

© 2008 directed electronics—Reservados todos los derechos. 35

Page 36

CARACTERÍSTICAS

15

14

13

12

123

4

5

11

6

7

8910

1 Tapa de polipropileno contra el polvo; resistente a la humedad y a los rayos

ultravioleta.

2 Envolvente de Goma de Butadieno de Nitrilo (NBR) para grandes desplazamientos

lineales controlados.

3 Cono de papel resistente a la humedad y los rayos ultravioleta.

4 Armazón de aluminio troquelado a la medida.

5 Formador de bobina acústica de aluminio ventilado (formador de bobina

acústica de 2.5 plg.).

6 Plancha delantera de acero de 8 mm.

7 2 imanes grandes de cerámica de 2 pilas.

8 Unidad de yugo en T de pieza polar y plancha trasera de acero de 8 mm.

9 Respiradero de 1.125 plg. Parte del sistema mejorado de enfriamiento de

bobina acústica (convección forzada).

10 Protector de imán de PVC.

11 Dos bobinas acústicas de alta temperatura de cobre de 2Ω o de 4 Ω.

12 Respiradero en el formador de la bobina acústica. Parte del sistema mejorado

de enfriamiento de bobina acústica (convección forzada).

13 Dos arañas Conex entrelazadas con conductores de oropel bordado y

enlazado.

14 Bloques de terminales a la medida.

15 Anillo de guarnición de Acrilonitrilo Butadieno Estireno (ABS).

36 © 2008 directed electronics—Reservados todos los derechos.

Page 37

CONFIGURACIONES DE CABLEADO

En serie: un altavoz (dos bobinas acústicas de 2 Ω)

Vea la figura 2 en la página 4

Un woofer con dos bobinas acústicas de 2 Ω y las bobinas acústicas en serie produce

una carga de 4 Ω en el amplificador.

1. Conecte el woofer en serie conectando la terminal negativa (-) de una de las

bobinas a la terminal positiva (+) de la otra bobina.

2. Conecte la terminal positiva (+) de la primera bobina a la terminal positiva (+) del

amplificador. Conecte la terminal negativa (-) de la segunda bobina a la terminal

negativa (-) del amplificador.

En paralelo: un altavoz (dos bobinas acústicas de 2 Ω)

Vea la figura 3 en la página 4

Un woofer con 2 bobinas acústicas de 2 Ω y las bobinas acústicas en paralelo produce

una carga de 1 Ω en el amplificador.

1. Conecte el woofer en paralelo conectando las dos terminales positivas (+) entre

sí y las dos terminales negativas (-) entre sí.

2. Conecte las terminales positivas (+) del woofer a la terminal positiva (+) del

amplificador. Conecte las terminales negativas (-) del woofer a la terminal

negativa (-) del amplificador.

En paralelo: un altavoz (dos bobinas acústicas de 4 Ω)

Vea la figura 4 en la página 5

Un woofer con 2 bobinas acústicas de 4 Ω y las bobinas acústicas en paralelo produce

una carga de 2 Ω en el amplificador.

1. Conecte el woofer en paralelo conectando las dos terminales positivas (+) entre

sí y las dos terminales negativas (-) entre sí.

2. Conecte las terminales positivas (+) del woofer a la terminal positiva (+) del

amplificador. Conecte las terminales negativas (-) del woofer a la terminal

negativa (-) del amplificador.

En paralelo: dos altavoces (dos bobinas acústicas de 4 Ω cada uno)

Vea la figura 5 en la página 6

Dos woofers con dos bobinas acústicas de 4 Ω cada uno, las bobinas acústicas en

paralelo y los woofers en paralelo, producen una carga de 1 Ω en el amplificador.

1. Conecte los woofers en paralelo conectando las cuatro terminales positivas (+)

entre sí y las cuatro terminales negativas (-) entre sí.

2. Conecte las terminales positivas (+) de los woofers a la terminal positiva (+) del

amplificador. Conecte las terminales negativas (-) de los woofers a la terminal

© 2008 directed electronics—Reservados todos los derechos. 37

Page 38

negativa (-) del amplificador.

En serie/paralelo: dos altavoces (dos bobinas acústicas de 2 Ω cada uno)

Vea la figura 6 en la página 7

Nota: Verifique y asegúrese de que el cableado del woofer es como se muestra:

la terminal negativa de la bobina de un woofer conectada a la terminal positiva

de la bobina del otro woofer.

Dos woofers con dos bobinas acústicas de 2 Ω cada uno, las bobinas acústicas en serie

y los 2 woofers en paralelo, producen una carga de 2 Ω en el amplificador.

1. Conecte cada woofer en serie conectando la terminal negativa (-) de una bobina

a la terminal positiva (+) de la otra bobina.

2. Conecte la terminal positiva (+) de la primera bobina de cada woofer a la terminal

positiva (+) del amplificador. Conecte la terminal negativa (-) de la segunda

bobina de cada woofer a la terminal negativa (-) del amplificador.

En serie/paralelo: tres altavoces (dos bobinas acústicas de 4 Ω cada uno)

Vea la figura 7 en la página 8

Nota: Verifique y asegúrese de que el cableado del woofer es como se muestra:

la terminal negativa de la bobina de un woofer conectada a la terminal positiva

de la bobina del otro woofer.

Tres woofers con dos bobinas acústicas de 4 Ω cada uno, las bobinas acústicas en serie

y los 3 woofers en paralelo, producen una carga de 2.67 Ω en el amplificador.

1. Conecte cada woofer en serie conectando la terminal negativa (-) de una bobina

a la terminal positiva (+) de la otra bobina.

2. Conecte la terminal positiva (+) de la primera bobina de cada woofer a la terminal

positiva (+) del amplificador. Conecte la terminal negativa (-) de la segunda

bobina de cada woofer a la terminal negativa (-) del amplificador.

En serie/paralelo: tres altavoces (dos bobinas acústicas de 2 Ω cada uno)

Vea la figura 8 en la página 9

Nota: Verifique y asegúrese de que el cableado del woofer es como se muestra:

la terminal negativa de la bobina de un woofer conectada a la terminal positiva

de la bobina del otro woofer.

Tres woofers con dos bobinas acústicas de 2 Ω cada uno, las bobinas acústicas en serie

y los 3 woofers en paralelo, producen una carga de 1.33 Ω en el amplificador.

1. Conecte cada woofer en serie conectando la terminal negativa (-) de una bobina

a la terminal positiva (+) de la otra bobina.

2. Conecte la terminal positiva (+) de la primera bobina de cada woofer a la terminal

positiva (+) del amplificador. Conecte la terminal negativa (-) de la segunda

bobina de cada woofer a la terminal negativa (-) del amplificador.

38 © 2008 directed electronics—Reservados todos los derechos.

Page 39

En serie/paralelo: cuatro altavoces (dos bobinas acústicas de 4 Ω cada uno)

Vea la figura 9 en la página 10

Nota: Verifique y asegúrese de que el cableado del woofer es como se muestra:

la terminal negativa de la bobina de un woofer conectada a la terminal positiva

de la bobina del otro woofer.

Cuatro woofers con dos bobinas acústicas de 4 Ω cada uno, las bobinas acústicas en

serie y los 4 woofers en paralelo, producen una carga de 2 Ω en el amplificador.

1. Conecte cada woofer en serie conectando la terminal negativa (-) de una bobina

a la terminal positiva (+) de la otra bobina.

2. Conecte la terminal positiva (+) de la primera bobina de cada woofer a la terminal

positiva (+) del amplificador. Conecte la terminal negativa (-) de la segunda

bobina de cada woofer a la terminal negativa (-) del amplificador.

En serie / paralelo: cuatro altavoces (dos bobinas acústicas de 2 Ω cada uno)

Vea la figura 10 en la página 11

Nota: Verifique y asegúrese de que el cableado del woofer es como se muestra:

la terminal negativa de la bobina de un woofer conectada a la terminal positiva

de la bobina del otro woofer.

Cuatro woofers con dos bobinas acústicas de 2 Ω cada uno, las bobinas acústicas en

serie y los 4 woofers en paralelo, producen una carga de 1 Ω en el amplificador.

1. Conecte cada woofer en serie conectando la terminal negativa (-) de una bobina

a la terminal positiva (+) de la otra bobina.

2. Conecte la terminal positiva (+) de la primera bobina de cada woofer a la terminal

positiva (+) del amplificador. Conecte la terminal negativa (-) de la segunda

bobina de cada woofer a la terminal negativa (-) del amplificador.

2 amplificadores: un altavoz (dos bobinas acústicas de 2 Ω)

Vea la figura 11 en la página 12

Un woofer con 2 bobinas acústicas de 2 Ω y cada bobina acústica conectada a su propio

amplificador produce una carga de 2 Ω en cada amplificador.

1. Conecte la terminal positiva (+) y la terminal negativa (-) de una de las bobinas

del altavoz a la terminal positiva (+) y la terminal negativa (-) correspondientes de

uno de los amplificadores.

2. Conecte la terminal positiva (+) y la terminal negativa (-) de la otra bobina del

altavoz a la terminal positiva (+) y la terminal negativa (-) correspondientes del

otro amplificador.

2 amplificadores: un altavoz (dos bobinas acústicas de 4 Ω)

Vea la figura 12 en la página 13

© 2008 directed electronics—Reservados todos los derechos. 39

Page 40

Un woofer con 2 bobinas acústicas de 4 Ω y cada bobina acústica conectada a su propio

amplificador produce una carga de 4 Ω en cada amplificador.

1. Conecte la terminal positiva (+) y la terminal negativa (-) de una de las bobinas

del altavoz a la terminal positiva (+) y la terminal negativa (-) correspondientes de

uno de los amplificadores.

2. Conecte la terminal positiva (+) y la terminal negativa (-) de la otra bobina del

altavoz a la terminal positiva (+) y la terminal negativa (-) correspondientes del

otro amplificador.

ESPECIFICACIONES

Traducción de las especificaciones, vea las páginas 14 y 15 para más detalles

Modelo / Nº de pieza XTRPRO###

Tamaño

Parámetros Thiele/Small

Fs (resonancia al aire libre, Hz)

Vas (cumplimiento de equivalencia, pies3)

Vas (cumplimiento de equivalencia, litros)

Qms (Q, mecánico)

Qes (Q, eléctrico)

Qts (Q total del excitador)

Re (resistencia CC, Ω)

Z (impedancia nominal, Ω)

Le (inductancia, mH)

Eficiencia (1 W a 1 m, dB)

Eficiencia (2.86 V a 1 m, dB)

Xmax (desplazamiento lineal de ida, plg.)

Xmax (desplazamiento lineal de ida, mm)

Pe (procesamiento continuo de potencia, W)

Procesamiento máximo de potencia (música, W)*

Mms (masa total en movimiento, g)

Cms (cumplimiento mecánico, mm/N)

Bl (fuerza del motor, Tesla-m)

Sd (área de radiación efectiva, cm2)

Sd (área de radiación efectiva, m2)

Sd (área de radiación efectiva, plg.2)

Gama de frecuencias (Hz)

Producto ancho de banda energía (EBP)**

Dimensiones físicas del excitador

Desplazamiento del altavoz (pies3)

40 © 2008 directed electronics—Reservados todos los derechos.

Page 41

Diámetro del agujero de montaje (plg./mm)

Profundidad de montaje (plg./mm)

Peso del imán (oz.)

Diámetro de la canasta (plg./mm)

Cajas recomendadas

Caja sellada normal (pies3)

Caja ventilada (pies3)***

Frecuencia de sintonización del puerto (Hz)

Equivalente cuadrado del puerto (plg.)

Longitud del puerto (plg.)

Especificaciones sujetas a cambio sin aviso previo

DETALLES DE LA CAJA

Los parámetros indicados son sólo para aplicaciones convencionales. Si necesita 1.

más asistencia, llame a Apoyo Técnico de Sonido.

Se recomienda MDF de 0.75 plg (19mm). de grosor. 2.

Los volúmenes de caja recomendados son NETOS. El desplazamiento del altavoz y 3.

del puerto se incluyen en el volumen de la caja. No es necesario agregarlos para

calcular el volumen BRUTO de la caja.

NOTAS:

* Debido a las capacidades de alta potencia y gran desplazamiento lineal de estos

woofers, los parámetros Thiele/Small se calculan y se miden con un sistema

analizador Klippel.

** El Producto Ancho de Banda Energía (Energy Bandwidth Product, EBP) se

determina por medio de la siguiente fórmula: Fs/Qes = EBP. Los valores EBP de

menos de 50 sugieren caja sellada; de 50 a 90, subwoofer versátil; más de 90, caja

con ventilación.

*** Se deben utilizar siempre filtros subsónicos ajustados específicamente al diseño de

la caja ventilada.

© 2008 directed electronics—Reservados todos los derechos. 41

Page 42

EXPLICACIÓN DE LAS ESPECIFICACIONES DE LAS CAJAS

Hay muchos factores que contribuyen a determinar el mejor estilo de caja para usted

o su vehículo. A continuación se presentan algunos factores que se deben tener en

cuenta.

El tamaño de la caja es directamente proporcional a la efi ciencia y el procesamiento

de potencia del altavoz. Un woofer en una caja pequeña procesa más potencia que el

mismo woofer en una caja grande. La efi ciencia es exactamente lo contrario: una caja

grande reproduce frecuencias más bajas a mayor volumen con menos potencia que

una caja pequeña.

El siguiente diseño de caja sellada da la mejor calidad de sonido en general. El

tamaño de la caja que se debe utilizar depende de la potencia y del tipo de vehículo

en que se va a instalar. Las cajas grandes son mejores si se tiene poca potencia (de

25% a 50% del procesamiento de potencia del altavoz), el vehículo es grande o

se desea mayor salida. Las cajas pequeñas se deben utilizar si se tiene la potencia

recomendada (de 50% a 100% del procesamiento de potencia nominal del altavoz),

el vehículo es pequeño (alta amplifi cación) o se desea reproducción de sonido más

precisa. Las cajas selladas pequeñas dan más control, lo cual se traduce en bajos más

rápidos y precisos.

Las cajas con ventilación tienen más efi ciencia y más salida de bajos en comparación

con las selladas. La caja ventilada aprovecha la onda de sonido trasera (el sonido que

sale por la parte de atrás del cono) para reforzar la salida del altavoz. Una caja correctamente sintonizada produce amplifi cación en todo el ancho de banda del sistema

de subwoofer y mayor control de cono que una caja sellada. La caja sintonizada a

baja frecuencia produce menos amplifi cación general, pero más extensión (bajos más

bajos). La caja sintonizada a alta frecuencia produce más amplifi cación, pero limita la

respuesta de bajos del sistema. Una de las ventajas de la caja con ventilación es que

se puede sintonizar a una frecuencia específi ca y esa frecuencia se conoce como Fb.

Otra de las especifi caciones importantes de la caja es la frecuencia de traspaso, F3,

en la que la respuesta del excitador ha bajado 3 dB. Este es un número importante

cuando se trata de ajustar el fi ltro de pasaaltas del ORION IntelliQ. El IntelliQ debe

tener la frecuencia F3 para evitar dañar o sobrecargar el altavoz.

La buena planificación y la construcción correcta garantizan la mejor respuesta

posible del sistema. En las siguientes páginas se presentan diversas cajas y diseños que

permiten que los subwoofers XTRPRO se desempeñen de la mejor manera posible.

42 © 2008 directed electronics—Reservados todos los derechos.

Page 43

RECOMENDACIONES PARA LA CAJA

Detalles de la caja

1. Las dimensiones externas se han calculado para un material de construcción de ¾

plg. de grosor

2. Incluye el desplazamiento del altavoz

3. Los volúmenes que se dan son volúmenes de sintonización neta

4. Las cajas contienen una cantidad mínima de material amortiguador. Se necesita

sólo material sufi ciente para recubrir la superfi cie interna de la caja.

Traducción del diagrama de la caja sellada (las medidas se encuentran en las páginas

18, 20 y 22))

Propiedades de la caja

— Descripción —

Tipo: caja cerrada

Forma: prisma cuadrado

A

B

Parte de

c

arriba y parte

de abajo

b

d c

Parte de

a

adelante y

parte de atrás

C

Lados

— Parámetros de la caja —

Vb =

V(total) =

Qtc =

QL =

F3 =

Fill =

— Dimensiones externas —

A =

B =

C =

— Dimensiones internas —

A =

B =

C =

— Grosor de la pared —

Parte de adelante =

Lados =

—Partes de la caja—

Forma de la caja: prisma cuadrado

1 parte de arriba, 1 parte de abajo

fondo (c) =

ancho (b) =

grosor =

1 parte de adelante, 1 parte de atrás

alto (a) =

ancho (d) =

grosor =

2 lados

alto (a) =

fondo (c) =

grosor =

— Montaje del excitador —

Montaje: adelante

© 2008 directed electronics—Reservados todos los derechos. 43

Page 44

Traducción del diagrama de la caja ventilada (las medidas se encuentran en las páginas 19, 21 y 23)

Propiedades de la caja

— Descripción —

Tipo: caja con respiradero

Forma: prisma cuadrado

A

B

Parte de arriba

c

y parte de abajo

b

d c

Parte de

a

adelante y

parte de atrás

— Parámetros de la caja —

Vb =

V(total) =

Fb =

QL =

F3 =

Fill =

— Dimensiones externas —

A =

B =

C =

— Dimensiones internas —

A =

B =

C

C =

— Grosor de la pared —

Parte de adelante =

Lados =

—Partes de la caja—

Forma de la caja: prisma cuadrado

1 parte de arriba, 1 parte de abajo

fondo (c) =

ancho (b) =

grosor =

1 parte de adelante, 1 parte de atrás

alto (a) =

ancho (d) =

grosor =

2 lados

alto (a) =

Lados

fondo (c) =

grosor =

— Montaje del excitador —

Montaje: adelante

— Respiraderos —

o

de respiraderos =

N

Forma del respiradero = redondo

Extremos del respiradero = uno al ras

Dv =

Lv =

h

e

g

— Partes del respiradero —

1 conducto:

diámetro externo (e) =

diámetro interno (g) =

largo (h) =

44 © 2008 directed electronics—Reservados todos los derechos.

Page 45

DEUTSCH

INSTALLATION

Die Leistung dieser XTRPRO-Subwoofer hängt direkt von der Qualität der Installation

ab. Ein sorgfältiges Vorgehen bei der Installation garantiert Ihnen jahrelange

Höchstleistungen. Wenn Sie sich nicht sicher sind, ob Sie die Installation selbst

ausführen können, wenden Sie sich bitte an Ihren örtlichen Orion-Fachhändler.

Orion-Händler haben ausgebildetes Fachpersonal, das aus Ihrem Orion-System das

Maximum an Leistung herausholen kann. Wenn Sie dieses Lautsprechersystem selbst

installieren wollen, sollten Sie vor Beginn der Installation den gesamten Abschnitt

über geschlossene Gehäuse und Bassreflexgehäuse durchlesen.

SO PLATZIEREN SIE DIE LAUTSPRECHER

Die Wahl der korrekten Lautsprecherposition hat große Auswirkungen auf die

Soundqualität des Systems. Bei der Wahl der Lautsprecherposition, die Ihren Ansprüchen am besten entspricht, sind mehrere Faktoren zu beachten. Es muss an der

Stelle genügend Platz für den Lautsprecher vorhanden sein. Sie müssen sicherstellen, dass die gewählte Stelle die mechanischen oder elektrischen Funktionen des

Fahrzeugs nicht beeinträchtigt.

Die Wahl der geeigneten Einbaustelle hängt sowohl von ästhetischen Faktoren als

auch vom Innenraum Ihres Fahrzeugs ab. Normalerweise werden die Tieftöner im

Kofferraum, im Rücksitz oder im hinteren Teil des Fahrzeugs installiert.

© 2008 directed electronics—Alle Rechte vorbehalten 45

Page 46

HÖHEPUNKTE

15

14

13

12

123

4

5

11

6

7

8910

1 Feuchtigkeits- und UV-beständige Polypropylen-Abdeckung

2 Extra große Sicke aus NBR (Nitrilgummi) für linear kontrollierten Langhub

3 Feuchtigkeits- und UV-beständige Papiermembran

4 Spezieller Rahmen aus Aluminiumguss

5 Aluminium-Schwingspulenträger mit Öffnungen (2,5-Zoll—

Schwingspulenträger)

6 8-mm dickes vorderes Abdeckblech

7 Große Double-Stack-Keramikmagneten

8 8-mm dickes hinteres Abdeckblech/Polplatten-T-Stück

9 1,125-Zoll-Öffnung. Teil des verbesserten Schwingspulen-Kühlsystems

(Zwangs-Konvektion)

10 PVC-Magnetschutz

11 Hochtemperatur-Kupferschwingspule (doppelt 2 Ohm oder doppelt 4

Ohm)