Orion Car Audio OE331-21 User Manual

GPC Plus Controlle

r

General Information &

Application Guide

OE331-21-GPC

A

GPC Plus Controller

Description

The OE331-21 General Purpose Controller Plus (GPC Plus) is used for controlling equipment or processes that

cannot be controlled using HVAC controllers. The Prism computer front end

software is used to interface with the

GPC Plus controller functions. The

GPC Plus Controller provides the flexibility to control, schedule and/or monitor

equipment such as unit heaters, exhaust fans, motorized louvers, etc.. The

GPC Plus has (6) configurable inputs

which will accept signals from thermistor temperature sensors, 4-20mA or 05VDC transmitters or dry contact closures. An additional modular input is

provided for connection of an OE271

static pressure sensor. The GPC Plus

has (5) relay outputs for on/off control

and (2) analog outputs. With the addition of the OE352 2 Slot Expansion

Base Board and (1) OE357 4 Relay

Expansion Board, (4) additional relay

outputs are available providing for a

maximum of (9) usable relay outputs.

The GPC Plus also has (5) separate 2

event per day schedules, each with its

own optimal start functions built in. In

addition the GPC Plus provides lead/lag

start capabilities.

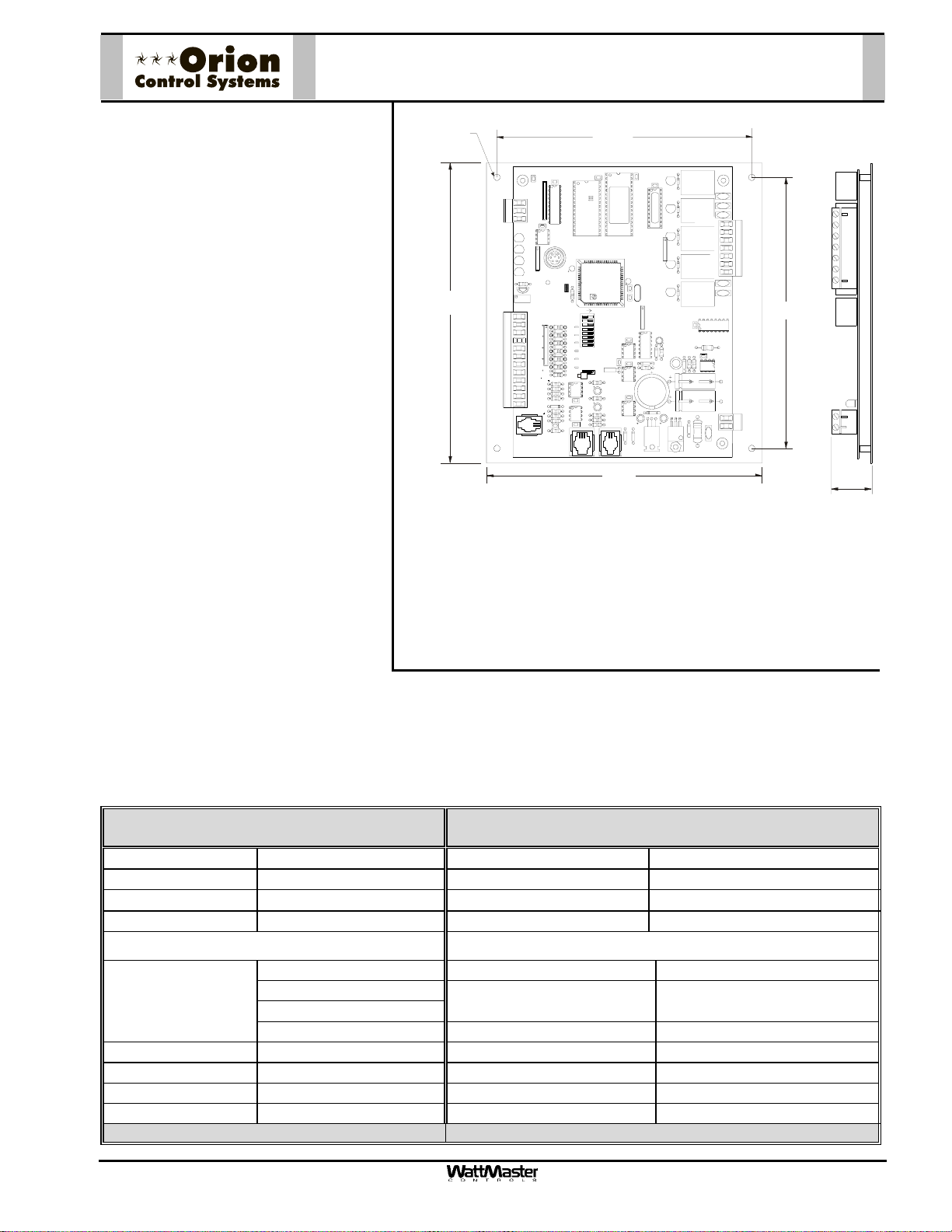

.20 Dia.

Typ. of 4

7.3”

TB1

COMM

T

SHLD

R

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

C21

RN1

1

CX5

1

RN3

+VREF

TEST POINT

RV1

VREF ADJ

C10

EXPANSION

6.2“

CX1

U1

U5

RS-485

COMM

HH

C1

P1

5.11V

EWDOG

R28

RN5

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

D14

C12

D15

C17

C20

R26

PJ2

U3

CX2

U2

EPROM

RAM

TUC-5R PLUS

(1 MEG)

YS101816 REV. 2

U6

C2

PHILIPS

C3

ADD

DDRESS

1

2

4

8

16

CX10

32

TOKEN

NETWORK

U10

SW1

C11

X2

0-5

0-1

VDC

VDC

JP1

U13

R15

U12

CX14

C14

R19

U14

CX13

U15

C15

R22

R24

R25

CX15

D17

PJ3

T'STAT

6.7”

D1

CX3

CX4

U4

RLY1

RLY2RLY3RLY4RLY5

PAL

1

RN2

CX6

X1

1

RN4

U9

C7

R7

D10

L1

CX12

D12

R13

SC1

D19

D18

C19

C18

VR1

VR2

V1

D2D3D4D5

V2

V3

COM1-3

R1

R2

R3

R4

R5

COM4-5

TB2

V4

V5

U8

NE5090NPB3192

0PS

CX8

R6

C9

R10

D13

9936

R11

U11

MC34064A

C13

C16

TB4

GND

R27

D16

V6

POWER

7824CT

24VAC

M

6.6”

1.1”

Mounting

The GPC Plus is provided with an integral backplate for mounting inside of a control enclosure. It is recommended that the GPC Plus be mounted in the HVAC unit control enclosure, or in a control enclosure in the

building equipment room. An optional factory control enclosure for the GPC Plus is available.

Technical Data OE331-21-GPCPLUS

GPC Plus Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Inputs: Outputs:

Types of Allowed

Inputs

Total Inputs Available 7 Analog Output Qty. 2

Static Pressure Inputs 1 (Modular ) Analog Output Signal 0-10 VDC

Configurable Inputs 6 Optimal Start Schedules (5) Total - (1) for Each Schedule

Schedules Available (5) 2 Event per day Lead Lag Scheduling (1) Output can be Configured

Three Year Warranty WattMaster reserves the right to change specifications without notice

Type III-10kohm sensors Total Relay Qty. On Board 5

4-20ma sensors

N.O. Binary Contact

N.C. Binary Contact Relay Power Rating (2 Amp @ 24 VAC)

Protocol HSI Open Protocol Token Passing

Total Relay Qty. Available With

Optional Expansion Board

9

Form: ORION-OE331-21-GPCPlusController-01A.doc Page 1 of 1

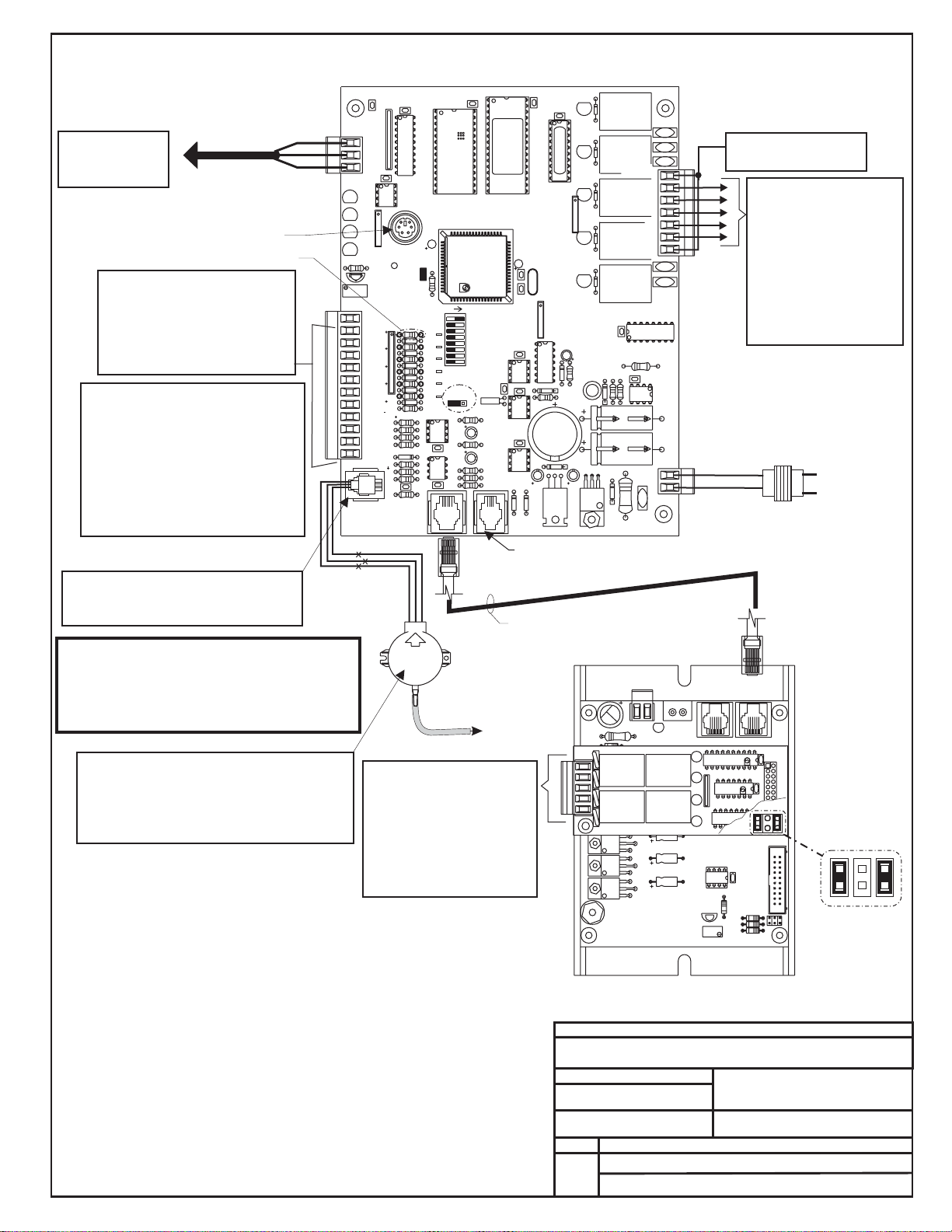

All Communication Loop Wiring Is

Straight Through

T To T, R To R, SHLD To SHLD

Local Loop RS-485

Connect To

9600 Baud

Next Device On

The Local Loop

Mini DIN Connector

For Connection Of Modular

Service Tool

Pull-up Resistor- Typical

Analog Inputs AIN1Thru AIN7

Can Be Used For 10kOhm

Type III Thermistor, 0-5VDC

Signal, 4-20mA Signal Or Dry

Contact Closure Inputs.

As Required.

Note: When Using Sensors or

Transducers With 4-20 mA Input

Signal, The Pull-up Resistor For

The Input Being Used Must Be

Removed From The Controller

Board And A 250 Ohm Resistor

Must Be Wired Between The Input

Terminal And The Ground Terminal

On The Controller Board

C21

TB1

COMM

T

SHLD

R

CX5

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

RV1

VREFADJ

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

OE331-21-GPCPLUS

GPC Plus Controller

CX1

RN1

1

U5

RS-485

COMM

1

RN3

P1

+VREF

5.11V

TEST POINT

EWDOG

RN5

C10

C12

C17

R26

EXPANSION

CX2

U2

U1

RAM

HH

U6

C1

PHILIPS

R28

ADD

ADDRESS

1

2

PU1

4

D6

8

PU2

16

32

D7

PU3

TOKEN

NETWORK

D8

PU4

SW1

D9

PU5

D11

PU7

0-1

0-5

VDC

VDC

D14

JP1

U13

CX13

D15

U15

C20

CX15

PJ3

PJ2

X2

R15

C14

R19

C15

R22

R24

R25

U3

EPROM

TUC-5R PLUS

YS101816 REV.2

C2

CX10

U10

C11

U12

CX14

U14

D17

T'STAT

CX4

CX3

U4

PAL

(1 MEG)

CX6

X1

C3

1

RN4

U9

D10

CX12

D12

R13

D18

C18

VR1

Not Used

D1

COM1-3

COM4-5

NE5090NPB3192

0PS

R6

C9

R11

R27

V6

R1

R2

R3

R4

R5

U8

9936

V1

V2

V3

TB2

V4

V5

U11

MC34064A

C13

C16

TB4

GND

POWER

24VAC

24VAC Power

For Relay Outputs

5 Relay Outputs Are

Available On Board For

On/Off Control Of

Equipment. When

Required 4 Additional

Relay Outputs Are

Available By Using The

Optional OE357 4 Relay

Output Expansion

Board. See Below.

GND

Line Voltage

24VAC

24VAC Transformer

10 VA Mini mum

RLY1

D2

RLY2

D3

1

RLY3

D4

RN2

RLY4

D5

RLY5

C7

SC1

CX8

R7

L1

R10

D13

D19

D16

C19

VR2

Analog Input AIN6 Can Only Be Used

Splice If Req’d

For Connection Of A Static Pressure

Transducer With Modular Connector

Warning:

24 VAC Must Be Connected So That All

Ground Wires Remain Common. Failure To

Do So Will Result In Damage To The

Controller

Connect Tubing To High Pressure

Port (Bottom Tube) and Route To Static

Pressure Pickup Probe Located In Unit

Discharge. Leave Port Marked “Lo” Open

To Atmosphere

Connect To

Expansion Board

Base (When Used)

S.P.

Transducer

4 Additional Relay Outputs

Are Available By Using The

OE357 4 Relay Output

Expansion Board. The

OE352 2 Slot Expansion

Base Board Is also

Required To Mount The

OE357 Board.

TB2

TB1

+24VDC-OUT

C6

GND

R14

D3

V1

TB1

V4

4RLY IO BD.4RLY IO BD.

VR4

MC

7812CT

VR5

MC

7824CT

VR6

MC

7824CT

24VAC-IN

24VAC-IN

K1

UL 5A250VACUL 5A250VAC

CONTACT:

24VDC

G5L-114P-PS

OMRON

UL 5A250VAC

UL 5A250VAC

CONTACT:

24VDC

G5L-114P-PS

OMRON

K4

LD1

PWR

YS101790

GND

C3

C4

C5

+24VDC-OUT

K2

UL 5A250VAC

UL 5A250VAC

CONTACT:

24VDC

G5L-114P-PSG5L-114P-PS

OMRON

UL 5A250VAC

UL 5A250VAC

CONTACT:

24VDC

G5L-114P-PSG5L-114P-PS

OMRON

K3

YS101780

2 SLOT MODULAR I/O2 SLOT MODULAR I/O

PJ2

PJ1

CX1

P1

ULN2803A/

K1

74HC04N

K2

K3

RN1

PCF8574P

K4

U2

LM358N

CX2

VR1

R10

R4

R5

R6

R12

OE357

U1

4 Relay Output

CX2

Board

U2

CX3

U3

P2

JP2

OE352 2 Slot Expansion Base Board

Jumper

Setting

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

4.)It Is Recommended That All

Controllers Address Switches Are

Set Before Installation.

FILENAME

G-GPC-PlusCNTRL1A.CDR

DATE:

03/08/05

PAGE

DESCRIPTION:

OE331-21-GPCPLUS

1Of2

GPC Plus Controller

JOB NAME

DRAWN BY:

B. Crews

This Switch Should Be

In The OFF Position

As Shown

ADDRESS ADD

Address Switch Shown Is

Set For Address 1

The Address For Each Controller

Must Be Unique To The Other Controllers

For Auto-Zone Systems The Address Must Be

For All Other Systems The Address Can Be Set

ADDRESS ADD

Controller

Address Switch

On The Local Loop.

Set Between 18 to 30

Between 1 to 59

1

2

4

8

16

32

TOKEN

NETWORK

ADDRESS ADD

Address Switch Shown Is

Set For Address 13

Note:

The Power To The Controller Must Be Removed

And Reconnected After Changing The Address

Switch Settings In Order For Any Changes To

Take Effect.

Caution

Disconnect All Communication Loop Wiring

From The Controller Before Removing Power

From The Controller. Reconnect Power And

Then Reconnect Communication Loop Wiring.

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

EXPANSION

C10

RN5

C17

C12

R26

C20

D15

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

D14

PJ2

ADDRESS

U13

CX13

CX15

ADD

1

2

4

8

16

32

TOKEN

NETWORK

SW1

X2

0-1

0-5

VDC

VDC

JP1

R15

C14

R19

U15

C15

R22

R24

R25

PJ3

CX10

U10

D17

U12

CX14

D18

CX12

C18

C11

U14

D10

D12

R13

C7

R6

R7

SC1

D19

C19

L1

R10

D13

D16

C9

R11

U11

C13

C16

TB4

GND

R27

V6

POWER

24VAC

VR1

VR2

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

4.)It Is Recommended That All

Controllers Address Switches Are

Set Before Installation.

FILENAME

G-GPC-PlusCNTRL1A.CDR

DATE:

03/08/05

PAGE

DESCRIPTION:

OE331-21-GPCPLUS

2Of2

GPC Plus Controller

JOB NAME

DRAWN BY:

B. Crews

General Purpose Controller

(GPCPlus )

January 31, 2005

Description

The GPCPlus is a controller designed to “fill in the blanks” between standard off the

shelf programs and minor non-standard applications. An example of a non-standard

application might be exhaust fan control, based on building pressure or a simple boiler

enable controller based on schedules or outdoor air temperature.

The remainder of this document will describe the I/O configurations that are possible and

will also include a few sample applications to aid the user in determining if this controller

will meet their specific requirements.

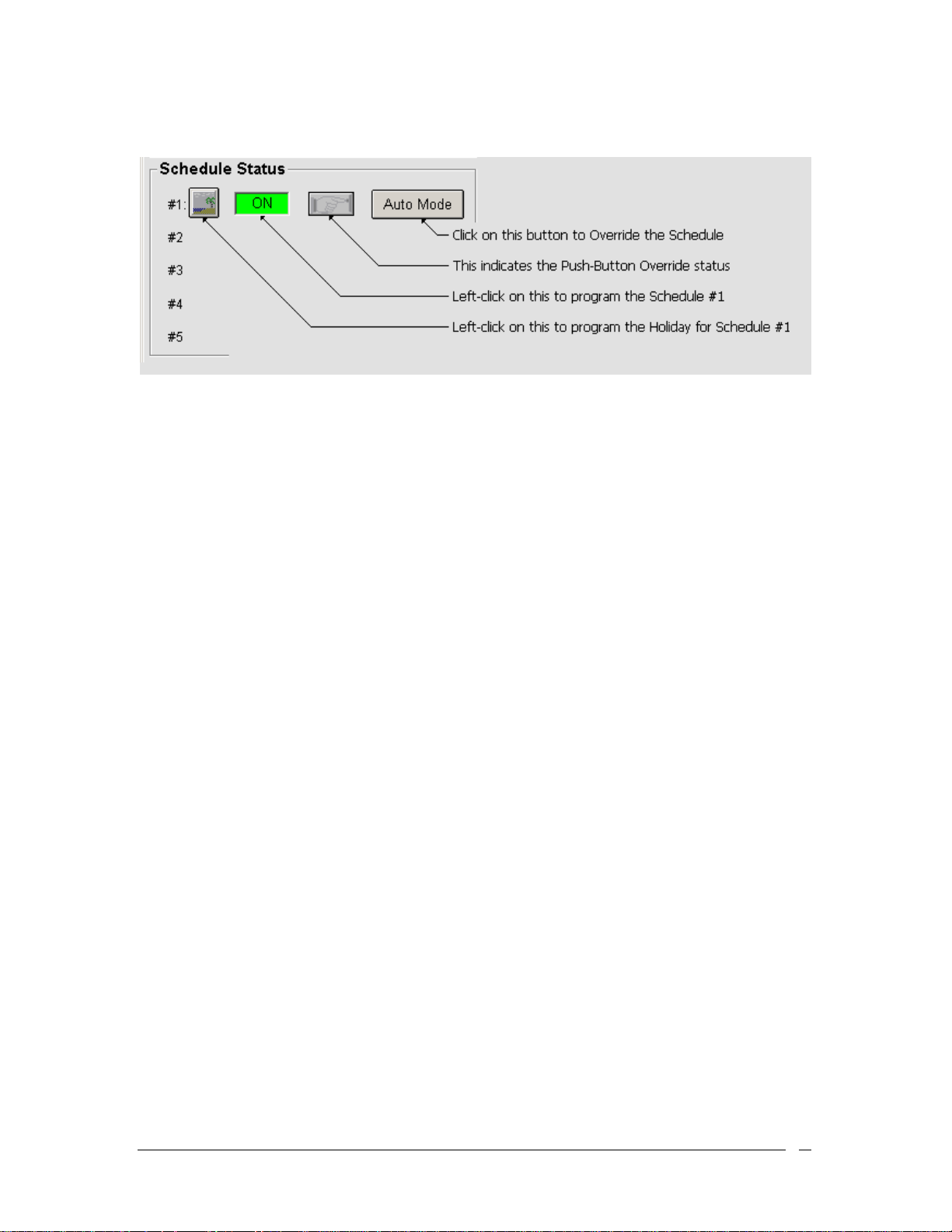

Main Status Screen

The Main Status Screen provides real-time live updates of the current operating

conditions and is used to access the various setpoint and configuration options.

No control takes place until the user “configures” the operation of the GPCPlus. Access

to the various configuration screens is made by a simple left mouse-click on the

individual reading or output status box for each I/O Point. As a general rule, a left click

1

accesses the configuration for the selected item and a right click accesses the force mode

options if any are available.

Analog Inputs

Relays

Analog Outputs

2

Week Schedules & Holidays

3

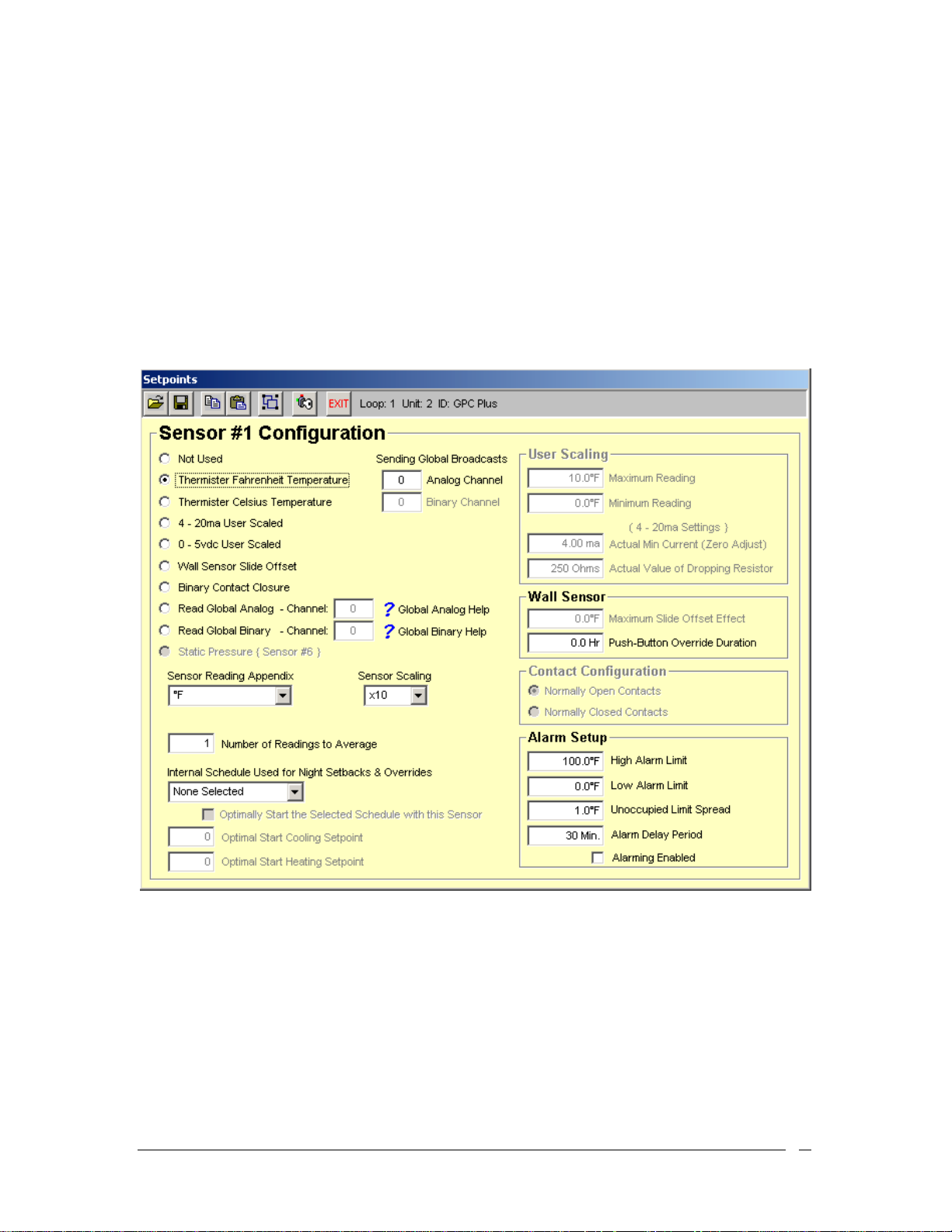

Analog Input

Configurations

The first five analog inputs and input #7 can be configured in several different ways.

Input #6 can be used for Static Pressure and accepts the standard pressure sensor with the

phone jack connector, available from WattMaster Controls.

The following configurations are available:

1. Thermister Type III Temperature Sensors (Scaled for Fahrenheit)

2. Thermister Type III Temperature Sensors (Scaled for Celsius)

3. 4 – 20ma User Scaled

4. 0 – 5 vdc User Scaled

5. Wall Sensor Slide Offset

6. Binary Contact Closure

7. Read Global Analog Broadcast from another Controller

4

8. Read Global Binary Broadcast from another Controller

9. Sensor #6 can be assigned to read Static Pressure

Each input is separately configured so combinations of any type of input on the same

controller are possible.

All readings can be overridden to specific values for test purposes. All thermister sensors

can also be calibrated by entering positive or negative offsets to be applied to the current

readings. All 4 – 20ma readings can be calibrated if the user has the exact current or

resistance values available for entering in the calibration fields.

Right-Click on the desired analog input reading to access the pop-up menu shown above

and then select the desired function. If you are calibrating or overriding the reading, the

following window will pop-up. Enter the desired calibration offset or specific reading

you wish to force the input to and press the Enter key. The window will automatically

close and send the command to the controller. If you select the Clear Sensor Override

option, a window will not appear but the clear command will be sent to the controller.

- OR -

5

Any or all readings can also be “broadcast” to other controllers on the communications

loop. For example, the Outdoor Air Temperature is broadcast on channel #2 by any unit

that happens to have the sensor attached. If none of the standard package units have the

outdoor air sensor attached, you could attach it to the GPCPlus and select it for broadcast

on channel #2. All other controllers would “hear” the broadcast and use it in their normal

operations. On the other hand, if you are measuring something like return air humidity,

do NOT select channel #2 to broadcast it on, since all the package unit controls are

expecting the outdoor air temperature. If no package controllers exist on your system

then you are free to use any available global channel for broadcast. There are 32 possible

global analog channels and 16 possible global binary channels.

Select global analogs to broadcast readings and global binary channels to broadcast

contact closure (on/off) information.

If you select one of the unassigned channels for broadcast, it is assumed that you have

other GPCPlus units installed that expect to receive information on those channels since

the standard package code does not listen for broadcasts on unassigned channels.

CAUTION: If you elect to broadcast a reading from the GPCPlus to all

other controllers on your installation, be sure to check the

HELP screen to identify which Global Channels have

already been assigned.

Each input also provides high and low alarm limits if the user requires out of range

values to notify service personnel. The alarm limits can be widened at night and they can

also be forced to be out of limits for a user defined amount of time before an alarm

occurs. This prevents false alarms if the reading temporarily exceeds the limit but then

recovers and stays within the limits the remainder of the time.

All readings are user scalable. That means you can display values with ± 1, ± 0.1, ± 0.1±

0.01 or higher resolutions. Just keep in mind that the maximum value that can be sent

from the controller is ±30,000 so if you have scaled your reading to ± 0.001 then the

maximum value you can send is ± 30 with the 3 additional decimal values (30.000).

6

Each input can also have an appendix selected to display with the reading to make them

more user friendly. The possible appendix values are:

• (None) No Appendix Required

• RH% Relative Humidity

• % Percentage

• °F Degrees Fahrenheit

• °C Degrees Celsius

• PPM Parts Per Million

• PSI Pounds Per Square Inch

• “WG Inches of Water Gauge

• “ Inches

• Ft. Feet

• RPM Revolutions Per Minute

• VDC Volts Direct Current

• BTU British Thermal Units

On inputs selected for Binary Input Contact Closure, the user can select Normally Open

or Normally Closed Contacts.

7

Loading...

Loading...