Page 1

www.orioncontrols.com

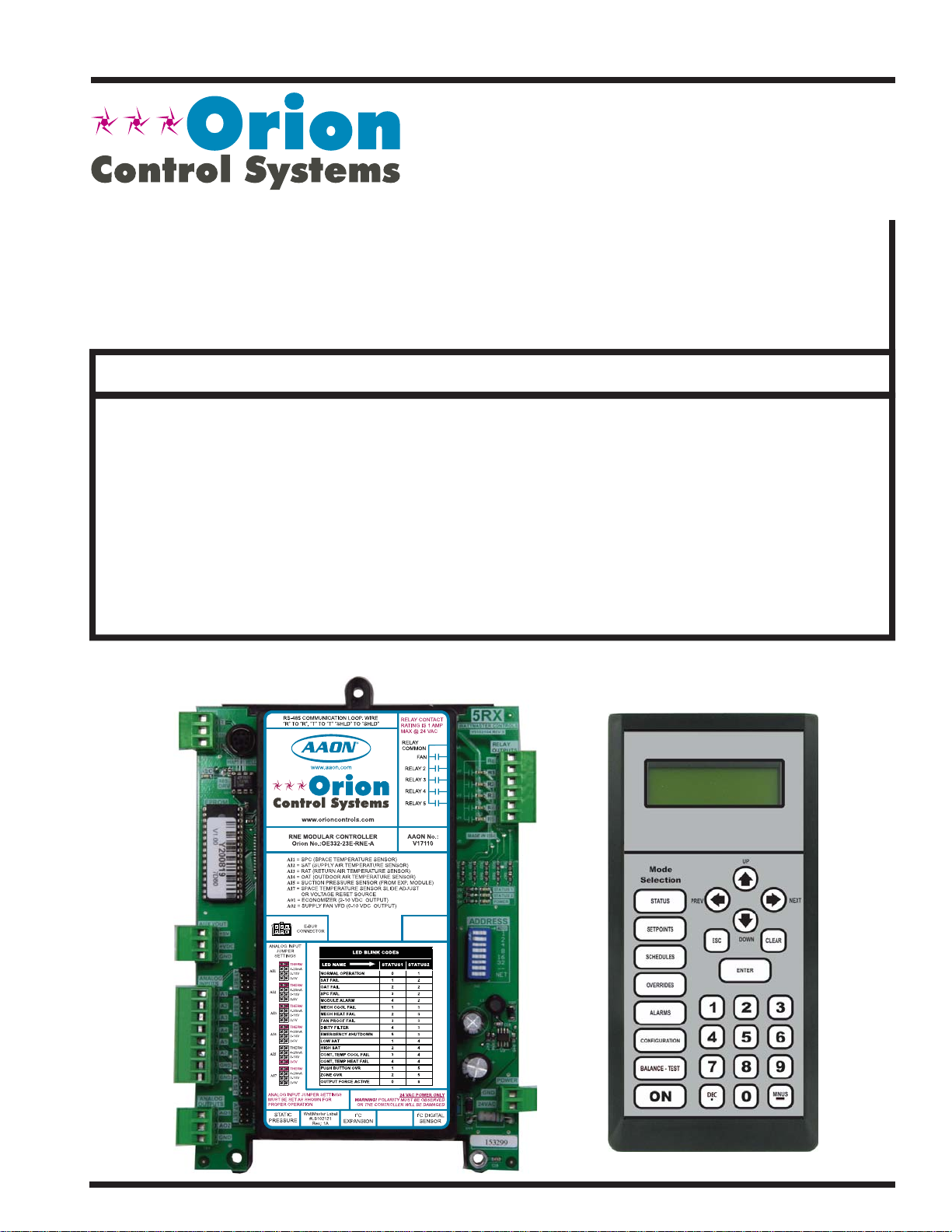

Modular Service Tool SD

Quick Start Guide

Requires Modular Service Tool SD Code: SS1063

VCC-X Controller Code: SS1062 Version 2.0 and up

VCB-X Controller Code: SS1051 Version 2.0 and up

VCM-X Controller Code: SS1026

VCM-X E-BUS Controller Codes: SS1030, SS1032, SS1033, SS1034

RNE Controller Code: SS1045

SA E-BUS Controller Code: Y200921

VCM Controller Code: SS1016

VAV/CAV Controller Code: SS1003 and MUA II Controller Code: SS1004

VAV/Zone Controller Codes: SS1001, SS1005, SS1025

MiniLink PD Code: SS0040

Page 2

IMPORTANT NOTICE

This Quick Start guide provides instructions for operating the Modular

Service Tool SD.

The Modular Service Tool SD Operator Interface Guide for each controller

is available for download from our website at orioncontrols.com or if you

have the Modular Service Tool SD Card available, the technical guides can

also be printed from the SD card.

VCC-X Controller - OR-VCCXOISD-TGD

VCM-X & VCM-X E-BUS Controllers - OR-VCMXRNEOISD-TGD

RNE Controller - OR-VCMXRNEOISD-TGD

SA E-BUS Controller - AA-SAOISD-TGD

VCB-X Controller - OR-VCBXOISD-TGD

VCM Controller - OR-VCMOISD-TGD

VAV/CAV and MUA II Controllers - OR-VAVCAVMUAOISD-TGD

SD CARD UPDATING INSTRUCTIONS

Your Modular Service Tool comes with an SD memory card that contains

the software to communicate to the various controllers. This SD card can

be removed and easily updated through a computer by downloading

updates, as they become available, from our website to your computer.

In order to perform any updates, your computer needs an SD card drive or

you will need to purchase an SD card adapter.

Download instructions are found in Appendix B of this manual.

www.orioncontrols.com

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101

E-mail: mail@wattmaster.com

Visit our website at www.orioncontrols.com

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

WattMaster Controls, Inc. assumes no responsibility for errors

or omissions.

This document is subject to change without notice.

Form: OR-QSOISD-TGD-01F

Copyright May 2015 WattMaster Controls, Inc.

Page 3

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................4

Modular Service Tool ...............................................................................................................................4

SYSTEM CONNECTION .....................................................................................................5

Modular Service Tool ...............................................................................................................................5

INTERFACE OVERVIEW .....................................................................................................6

Display Screens and Data Entry Keys .....................................................................................................6

Mode Selection Buttons ...........................................................................................................................6

INITIALIZA TION ................................................................................................................ 7

Initialization & Setting the Time & Date ...................................................................................................7

Setting the Operating Mode & Energy Timer ...........................................................................................8

Alarm & Override Search .........................................................................................................................9

Schedules & Holidays ............................................................................................................................10

Schedule Override ................................................................................................................................. 11

TROUBLESHOOTING .......................................................................................................12

Outputs Force ........................................................................................................................................ 12

APPENDIX A - SAVING, LOADING, AND COPYING SETPOINTS .....................................14

APPENDIX B - UPDATING THE SD MEMORY CARD ........................................................16

APPENDIX C - UPDATING CONTROLLERS & E-BUS MODULE SOFTWARE .................... 17

Modular Service Tool SD

3

Page 4

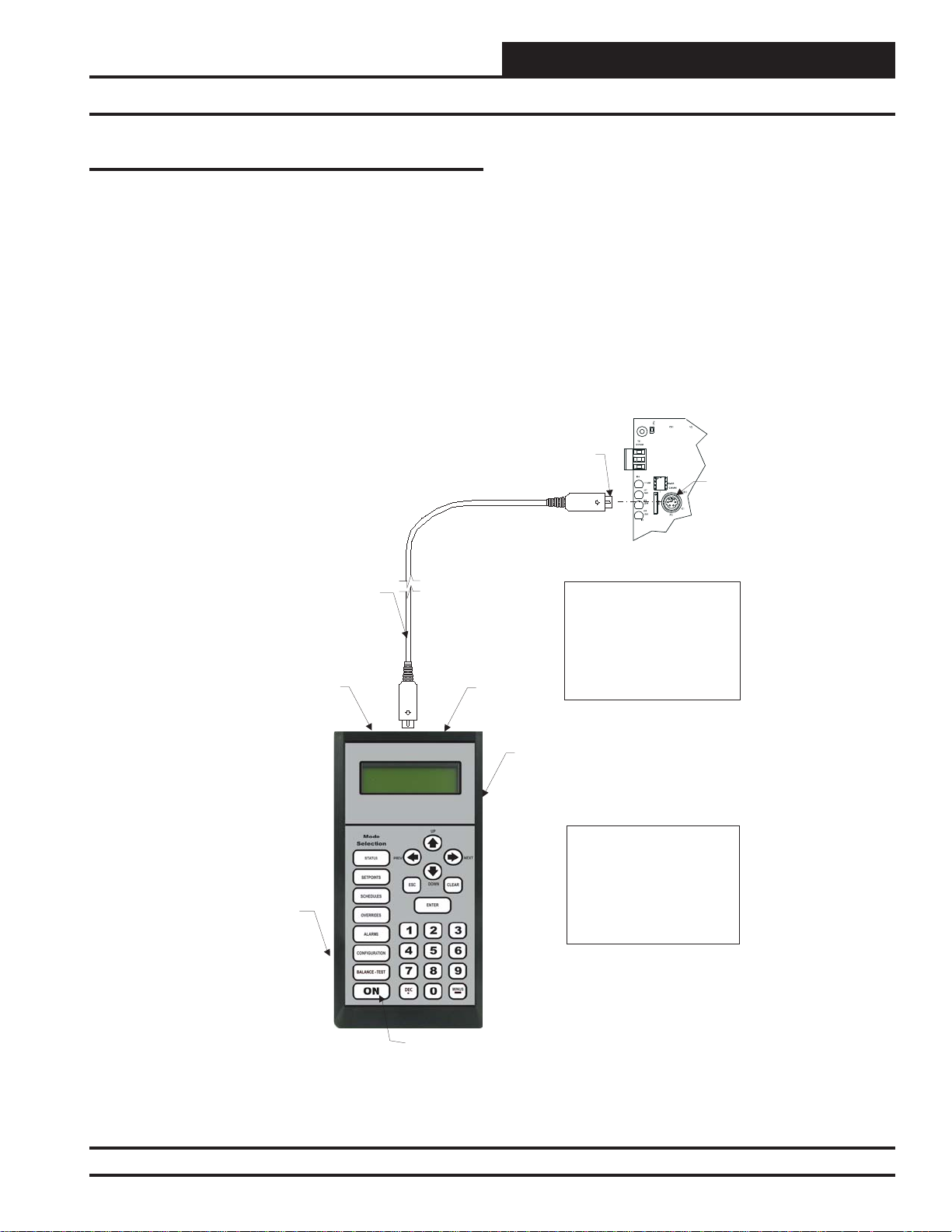

SYSTEM CONNECTION

Modular Service Tool SD

Zone

Zone

Modular Service Tool SD

The OE391-12 Modular Service Tool is a system operator interface that

provides a direct link to enable the system operator to view the status,

confi gure, and adjust the setpoints of the VCM-X, VCM-X E-BUS,

SA E-BUS, RNE, VCB-X, VCM, VAV/CAV, MUA II or VAV/Zone

Controller on the control system communications loop.

The Modular Service Tool is housed in an attractive black plastic

enclosure. The display area is covered with a clear plastic bezel for

protection of the display screen. The Modular Service Tool has a

4-line-by-20-character display panel with adjustable contrast control

and a 27-key membrane keypad for data selection and entry. All keypad

operations are simple and straight forward, utilizing non-cryptic plain

English language messages. Menu-driven programming allows for

easy setup and operation without the need for specialized training. The

Modular Service T ool is supplied with a programmable 4 Gigabyte SD

memory card, with (4) AA 1.5 V batteries, a wall mount a DC power

supply, a mini-Din communication cable, and an E-BUS communication

cable. The mini-Din cable allows you to connect the Modular Service

Tool to any Orion controller which has a mini-Din connector socket for

programming, monitoring, and troubleshooting purposes.

The Modular Service Tool is also equipped with an EBC E-BUS port

and an RS-485 three conductor terminal block port. The E-BUS port and

included E-BUS cable are used for updating E-BUS Module software

(described in Appendix C, page 17). The RS-485 port is used for hard-

wiring to older controllers that do not have a mini-DIN connector socket.

The Modular Service Tool is designed to be hand-carried. Its rugged

plastic housing provides superior protection for the electronic components housed inside. The Modular Service Tool is a top-quality service

tool that will stand up to the demands of the typical job site environment

for many years.

Figure 1: Modular Service Tool Dimensions

4

Modular Service Tool SD

Page 5

SYSTEM CONNECTION

Modular Service Tool SD

Modular Service Tool SD

Whether you have a Stand Alone, Interconnected, or Networked Orion

Controls System, the Modular Service Tool always connects to the

controller or a VAV/Zone Controller via a prefabricated cable that is

supplied with the service tool. The Modular Service Tool cable is terminated on both ends with a mini-DIN connector. Attach one end to the

Modular Service Tool and the other end to the mini-DIN connector on

the controller. If this is an Interconnected System, all controllers that are

interconnected with communications cable can be programmed from any

controller on the loop. If this is a Networked System, all controllers on

the entire Networked System can be programmed from one controller.

Male DIN Connector

Connector Cable

RS-485

Port

Be sure that the Modular Service Tool’s SD memory card is inserted

correctly and that the Modular Service T ool has fresh batteries installed

or that it is connected to a power source using the supplied power pack

before attempting any programming of the controller. See Figur e 2 for

connection details.

Female DIN

Connector

Typical Controller Board

EBC

E-BUS

Port

The Modular Service Tool Can Be

Connected To

Or VAV/Zone Controller By

Plugging One End Of The

Supplied Cable Into the

Modular Service Tool DIN

Connector And The Other End

Into The DIN Connector On The

Controllers.

A Unit Controller

SD Memory Card

Figure 2: Modular Service Tool SD

Modular Service Tool SD

Power On Button

Modular Service Tool SD

Be Sure The Modular Service

Tool Is Connected ToThe

Supplied Power Pack Or Has

Fresh Batteries Installed Before

Attempting Programming Of The

Controller. Be Sure The Power Is

Turned Off On The Modular

Service ToolBefore Connecting

The Cable To The Controller.

5

Page 6

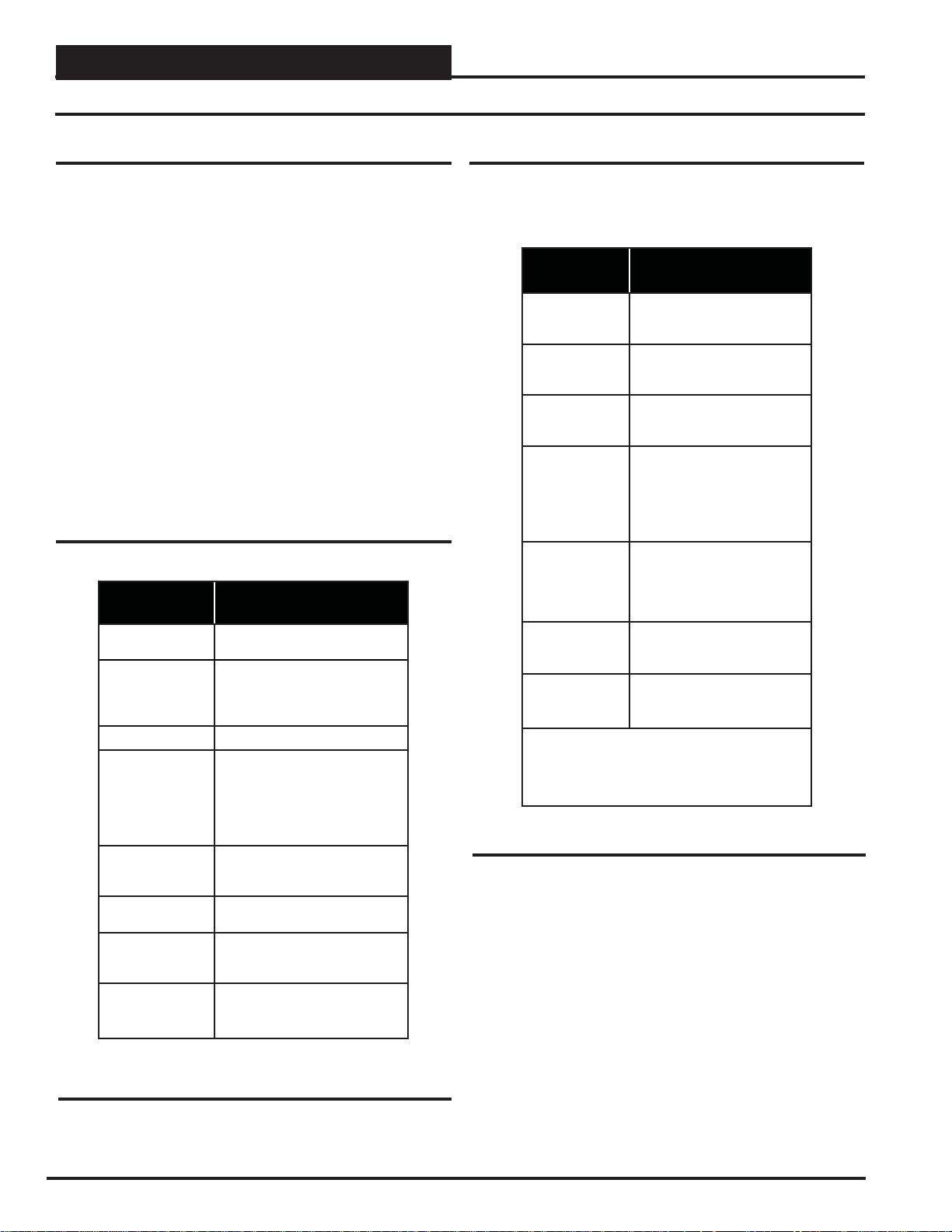

INTERFACE OVERVIEW

Modular Service Tool Keys

Operator Interfaces

In order to confi gure and program the Orion System controllers, you

must have an Operator’s Interface or a personal computer with the Prism

2 computer front-end software installed. Three different Operator Interfaces are available for programming of the Orion Controls System—the

Modular Service Tool SD, the Modular System Manager (VCM-X and

VAV/Zone Controllers only), and/or the System Manager TS II. These

devices allow you to access the status and setpoints of the controllers on

your communications loop. This manual describes the Modular Service

Tool SD. If using the Modular System Manager or System Manager TS

II, please see the VCM-X / RNE Operator Interfaces Technical Guide

or the System Manager TS II Technical Guide. If using Prism 2, please

see the Prism 2 Technical Guide.

The Modular Service T ool allows you to view any input or output status

and change any setpoint to fi ne-tune the operations of the total system. All

keypad operations are simple and straightforward, utilizing non-cryptic

plain English messages.

Display Screens & Data Entry Keys

See the chart below for a list of the keypad descriptions and functions.

Keypad

Key Function

Description

NEXT

ESC

ENTER

Clear

Minus

DEC

Use this key to access the

Setup Screens.

Use this key to exit from screens or

from data entry or to return to the

Main Screen from any screen in the

system.

Use this key to enter a new value.

If a data entry mistake is made,

press this key to clear the data entry

fi eld and start over. This key also

turns off the power to the Service

Tool when on the

Main Screen

If a setpoint with a negative value

is required, press this key for the

minus sign.

Press this key when entering data

that requires a decimal point.

Use these keys to change values

in the Confi guration screens as

prompted.

Use these keys to step backward or

forward through the screens.

Mode Selection Buttons

The Modular Service Tool is provided with “Mode Selection Buttons.”

These buttons give you instant access to the specifi c mode desired without

having to scroll through several menu screens to get there.

Button

Description

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

CONFIGURATION

BALANCE-TEST

Notes:

(1) The Modular Service T ool will only search the Over rides one loop at a time. Y ou must enter the Loop number

and the MiniLink PD unit ID (60).

Table 2: Button Descriptions

Mode Selection Buttons

Pressing this button takes you

directly to the controller

“Status” screens.

Pressing this button takes you

directly to the controller

“Setpoints” screens.

Pressing this button takes you

directly to the controller

“Schedules” screens.

Pressing this button takes you

directly to the controller “Overrides” screen. See the “Override

Button” section on page 9 for a

description of this function.

See Note 1 below.

Pressing this button takes you

directly to the controller

“Alarms” screen. See the “Alarms

Button” section on page 9 for a

description of this function.

Pressing this button takes you

directly to the controller

“Confi guration” screens.

Pressing this button takes you

directly to the controller

“Balance-Test” screens.

Table 1: Keypad Descriptions

6

Modular Service Tool SD

Page 7

INITIALIZATION

Initialization & Setting the Time & Date

Modular Service Tool Initialization

Modular Service Tool Initialization Screen and

Setup Screens

After connecting the Service Tool to the controller with the supplied

cable, press <ON>. The Initialization Screen will appear followed by

the Setup Screens as shown below. If there is no SD card installed, the

second screen will display, “No SD Card Connected! Powering Down!”

Initializing

Service Tool vX.XX

WattMaster Controls

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

3) Energy Saving

4) Update Software

NEXT) More Options

ESC) Exit Menu

Although the times are displayed on the Main Screen in a standard 12hour format, you must program them using the 24-hour military format.

If you confi gured the Unit Controller to use its own Internal Schedules,

the Occupied/Unoccupied modes are calculated on the basis of the current real time clock reading.

The two screens that follow will appear. To scroll through the fi elds,

press

<> or <ENTER>. In order to save a new value, you must press

<ENTER>.

Program Time/Date

Day (Sunday=0): X

Enter Hr. (0-23): XX

Enter Minutes : XX

Day - Enter the Day of the Week (0 to 6)

Sunday = 0

Hours (Hr) - Enter Hours in 24-Hour Military Format

(17 = 5:00 PM)

Minutes - Enter the Minutes

(0 to 59)

Programming the Date

NOTE: Once you press <ESC> while at the Setup Screens shown

above, you can access them again by pressing <NEXT>

or cycling power.

Setting The Time & Date

The Modular Service Tool is equipped with a real time clock chip

allowing it to maintain the correct time. Once you have programmed

the correct time and date, the information is broadcast globally to all

controllers on the entire system.

NOTE: If you are in a time zone that has daylight savings, you

will need to manually adjust the time twice a year.

Programming the Time

From the Setup Screen shown below, press <1> on your keypad to access the Set Time & Date Screens. (You may have to press <NEXT>

to access this screen).

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

To scroll through the fi elds, press <> or <ENTER>. In order to save

a new value, you must press <ENTER>.

Program Time/Date

Month (1-12): XX

Day (1-31): XX

Year (0-99): XX

Month - Enter the Month (1 to 12)

Day - Enter the Day of the Month (1 to 31)

Year - Enter the current Year (0 to 99)

When you have fi nished programming the time and date, press <ESC>

to return to the Setup Screen shown below.

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

Modular Service Tool SD

7

Page 8

INITIALIZATION

Setting the Operating Mode and Energy Saving Timer

Setting the Operating Mode

The Operating Mode is displayed on the last line of the Main Screen

as shown below. The factory default setting for the Service Tool is LS

(Low Speed) Stand Alone Mode.

Service Tool SD vX.XX

Wednesday Operations

01/16/13 02:21 PM

LS Stand Alone *00*

If you are using this Service Tool on a communications loop and have

an installed MiniLink PD or CommLink, you will need to change the

setting to LS (Low Speed) Network Mode.

If you are using a VCC-X, VCB-X, or GPC-XP Controller that is set

for high speed, you will need to change the setting to HS (High Speed)

Stand Alone Mode or HS (High Speed) Network Mode.

If your display indicates a different mode than the one you need, press

<2> at the Setup Screen shown below . Y ou may have to press <NEXT>

to access this screen.

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

The Communications Screen will appear as shown below.

Setting the Energy Saving Timer

The Modular Service T ool has a built-in timer that can be programmed

to shut the Service T ool off after a specifi ed period of time if no buttons

are pressed. This is a very useful feature if you are powering the Service

Tool from the internal batteries.

To set the Ener gy Saving T imer, press

and

<3> at the second Setup Screen shown below. (You may have to

press <NEXT> to access these screens).

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

3) Energy Saving

4) Update Software

NEXT) More Options

ESC) Exit Menu

The Energy Saving Screen will appear as shown below:

Energy Saving

Automatic Power Down

Minutes: xx

Press ESC to Exit

<NEXT> at the fi rst Setup Scr een

Stand Alone Mode

Lo Speed Connection

Use Left/Right Arrow

To Change Selections

Press <> or <> if you need to change the mode of operation.

When you have made your selection, press <ENTER>. The following

screen will appear.

You Have Changed The

System Mode

Press Any Key To

Continue

Press any key to continue. The Setup Screen will appear as shown below:

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

Enter the number of minutes you want the Service Tool to stay active

before it automatically powers down and press <ENTER>. To cancel

the automatic power down, enter <99> and press <ENTER>. After

you have entered a number between 1 and 99 minutes, press <ESC>

to exit the screen. The Setup Screen will appear again.

Updating Software

The Modular Service T ool SD has the capability to update the software

for certain Controllers and E-BUS Modules using the appropriate

cable(s) and a computer with internet access.

The instructions for Updating Software - Option 4 on the second Setup

Screen shown below are found in Appendix C, page 17.

3) Energy Saving

4) Update Software

NEXT) More Options

ESC) Exit Menu

8

Modular Service Tool SD

Page 9

INITIALIZATION

Alarm and Override Search

Modular Service Tool Alarm Search

NOTE: When you press the <ALARMS> button on the Modular

Service T ool, it will search only the unit ID that you have

entered; therefore, you must search each unit individually

to access all alarms for that controller.

To search for alarms, press < ALARMS>while on any screen but the

Setup Screen(s). The Unit Selection Screen will be displayed.

Unit Selection

Enter Unit ID#

Selected ID#: XXXX

*00*

Enter the Unit ID of the controller the Service T ool is connected to and

press <ENTER>. Once communication is established, *00* at the bot-

tom right of the screen will go away. Then

NOTE: If the *00* remains, it indicates a communication failure

to the controller.

One of the following screens will appear:

press <>.

Modular Service Tool Override Search

When a space sensor with override option is used with any VAV/Zone

or Unit Controller, the Modular Service Tool can determine and report

any controllers that are currently operating in an override condition on

a specifi c Loop by entering a Loop ID number and then doing a search.

NOTE: When you press the <OVERRIDES> button on the

Modular Service Tool, it will search only the Loop

number that you enter; therefore, you must search each

loop individually to access all overrides.

To access the Overrides Screen, press

Modular Service Tool’s keypad. A screen will appear asking you to

enter the unit ID.

Unit Selection

Enter Unit ID#

Selected ID#: 160

*00*

Enter the Unit ID for the MiniLink PD (MLPD) of the loop you wish

to search. and press <ENTER>. The MLPD is always address 60 on

each loop. So the unit ID of any particular MLPD would be the loop

number followed by 60. In the example above, Loop 1, address 60 has

been entered. Once communication is established, *00* at the bottom

right of the screen will go away. Then

<OVERRIDES> from the

press <>.

CONTROLLER V.XXX

NO ALARMS

CONTROLLER V.XXX

ALARMS PRESENT

SCROLL DOWN TO VIEW

Press <> to scroll through all the alarms for the controller that the

Modular Service Tool is connected to.

To clear any alarms that are found, you must fi x the problem indicated

in the alarm. Once the problem is fi xed, the alarm will clear from the

screen the next time the unit is polled.

NOTE: If the *00* remains, it indicates a communication failure

to the controller.

If communications are successful, one of the following screens will

appear:

CONTROLLER V.XXX

NO OVERRIDES

CONTROLLER V.XXX

OVERRIDES PRESENT

SCROLL DOWN TO VIEW

After the Service Tool completes its search, it will post a message to

tell you if there are overrides present. If there are overrides, press

and all units on the loop will be listed showing ‘Override: Yes or No.’

Press

<OVERRIDES> again to access overrides on a different loop.

Enter the Unit ID of the MLPD of that loop.

<>

Modular Service Tool SD

9

Page 10

INITIALIZATION

Schedules and Holidays

Scheduling

You can access the Unit Controller Scheduling Screens by pressing

<SCHEDULES>. The Unit Selection Screen will be displayed.

Unit Selection

Enter Unit ID#

Selected ID#: XXXX

*00*

Enter the Unit ID of the controller the Service T ool is connected to and

press <ENTER>. Once communication is established, *00* at the bot-

tom right of the screen will go away. Then

NOTE: If the *00* remains, it indicates a communication failure

to the controller.

Press the

<> button and then press <ENTER> to access the schedul-

ing function you wish to view.

Schedule Menu

Schedule Override

Week Schedules

Holidays

press <>.

The screens will step through the Start Time and then the Stop Time

for each day of the week. You can quit at any point in the process by

pressing

<ESC>. There are two Start/Stop events available per day , so

the screen will show which event is being programmed. If you need

only one event, keep Event #2’s times set at ZERO.

All times are in 24-hour military format, so 5:00 PM would be entered

as 1700.

If both the Start and Stop Times are ZERO, the schedule is in a continuous OFF mode. (Also, use for Remote Forced Occupied applications

using the Forced Occupied Binary Input.)

If both the Start and Stop Times are 2359, the schedule is in a continuous ON mode.

NOTE: The second line displays which day of the week is cur-

rently being programmed. The day of the week automatically increments as you exit the Event #2 screen for the

day and continue to the next day’s Event #1 screen.

CAUTION: The controller ships with all schedules set to

zero so that the controller will not attempt to heat

or cool before you have confi gured the system.

Week Schedules

Event #1

Schd

Sunday Event #1

Start Time..: XXXX

Stop Time...: XXXX

Event #2

Schd

Sunday Event #2

Start Time..: XXXX

Stop Time...: XXXX

If you are using the internal scheduling capability of the Unit Controller, set the schedule hours and holiday periods from the menu shown

above. You can also force the unit to operate continuously in occupied

or unoccupied mode by selecting the Schedule Override menu item and

entering the desired command.

Holiday Start/Stop Day Selection

Hldy

Holiday # 1

Start Mon/Day.: XXXX

[ July 4

Stop Mon/Day.: XXXX

[ July 5

The screens will step through the fourteen possible holidays, one period

at a time. Line 2 shows which holiday is currently being programmed.

Since a holiday period can encompass more than one day, you need to

program the day the holiday starts and the day the holiday ends. If your

holiday only lasts one day, simply set both the Start Day and the Stop

Day to the same value. Remember to combine the month and day into

a single four-digit value.

EXAMPLE: 704 = July 4

1225 = December 25

th

= 704 ]

Hldy

Holiday # 1

th

= 705 ]

th

(NOTE: Leading zero not required)

th

If you are using an external contact closure to signal the occupied mode,

you must access the Week Schedule Screens and set all start and stop

times to zero to prevent the internal schedule from turning the equipment on when you don’t want it to operate.

10

Modular Service Tool SD

Page 11

INITIALIZATION

Holiday Scheduling and Schedule Override

Holiday Start/Stop Times

Hldy

Holiday Schedule

Start Event #1: XXXX

Stop Event #1: XXXX

Hldy

Holiday Schedule

Start Event #2: XXXX

Stop Event #2: XXXX

The fourteen holidays all use the same Start and Stop times which you

program on this screen and the next. You must enter the time in 24-hour

military format, the same as a regular week schedule.

Normally, the holidays will operate in an unoccupied mode or a reduced

schedule mode. There are two start/stop events available on holidays to

match the standard schedule number of events.

Schedule Override

Ovrd

Schedule Override

Enter Override...: X

[0=Auto 1=ON 2=OFF]

If you want to force the unit to operate in a continuous Occupied or

Unoccupied mode, select this menu item to activate the desired method.

If a Schedule Override is active, all other methods of schedule control

are ignored (Push-Button, Internal, and Remote).

As you can see on the last line of the display, enter

ously in the Occupied Mode or <2> to run continuously in the Unoccupied Mode. To restore normal schedule operations, enter <0>.

This override remains in effect until canceled and does not time-out

like the Output Overrides do after 10 minutes of no communications.

NOTE: Do not use the Force OFF mode in place of setting all

the week schedules to ZERO if you are using a Remote

Signal for your scheduling since the Override has priority

over the Remote Signal.

<1> to run continu-

Modular Service Tool SD

11

Page 12

TROUBLESHOOTING

Outputs Force

Zone

Zone

Outputs Force

Outputs Force settings are available for testing or troubleshooting the

system. These Force settings can only be accessed and programmed

from the Modular Service Tool. The System Manager does not allow

for programming of this function.

CAUTION: The Outputs Force settings should only be applied

by qualifi ed service personnel. Serious damage to

the HVAC unit could result from improper use of

these Outputs Force settings.

To access the Outputs Force settings, simply press the

TEST> button on the Modular Service T ool. You will then see the Unit

Selection Screen. Enter the unit ID of the Unit Controller you wish to

access and press

at the bottom of the screen will go away. Then

then see the screen shown below. Press <ENTER> to save entered data

and

press <> to scroll through the screens.

NOTE: If the *00* remains, it indicates a communication failure

NOTE: The Outputs Force settings are only available for the Unit

<ENTER>. Once communication is established, *00*

to the controller.

Controllers. They are not supported for the VAV/Zone

Controllers or other Add-on controllers.

Outputs Force

Para Blocks

Save / Load / Copy

<BALANCE -

press <>. You will

The next screen displays the Relay Overrides for Relay 2. After pressing

<ENTER> to save any changes, press <> to have the next relay

displayed. All 20 Relay Override Scr eens (including the AHU fan relay)

are available by pressing

<ENTER>.

After the screen for relay 21 or 23 (23 for VCB-X) is displayed, the fi rst

Analog Output Override Screen will be displayed. For VCC-X, after

Relay 8, EM1 Relays 1-5 will display and then 12 Relay Bd Relays

1-12 will display.

<> after each setting is saved by pressing

Relay Overrides

Relay 2 Override

Auto

Use < Or > To Change

VCM-X, VCM & RNE Controllers

Analog Output 1 Screen

Economizer Overrides

Analog Output #1

Override Volts: -1.0

[-1.0=Auto]

The default setting for normal operation is -1.0 volts. Voltages between

0 to 10.0 can be set for any of the Analog Output Overrides. Press

<ENTER> after making a setting change and then press <> and the

next Analog Output Override Screen will be displayed.

Analog Output 2 Screen

Place the cursor on Outputs Force and press <ENTER> to access the

Outputs Force Screen.

Supply Fan Override

Auto

Use < Or > To Change

The fi rst Outputs Force Screen allows the AHU fan relay to be set for

Auto, Force On, or Force Off. The default setting is Auto. After you

complete all troubleshooting or testing procedures, all relays should be

changed back to this setting. The Force On setting will force the relay

to the ON (energized) position. The Force Off selection will force the

relay to the OFF (de-energized) position.

12

Supply VFD Override

Analog Output #2

Override Volts: -1.0

[-1.0=Auto]

Analog Output 3 Screen

Exhaust VFD Override

Analog Output #3

Override Volts: -1.0

[-1.0=Auto]

Analog Output 4 Screen

Mod Heating Override

Analog Output #4

Override Volts: -1.0

[-1.0=Auto]

Modular Service Tool SD

Page 13

TROUBLESHOOTING

Outputs Force

Analog Output 5 Screen

Mod Cooling Override

Analog Output #5

Override Volts: -1.0

[-1.0=Auto]

Analog Output 6 Screen

RA Damper Override

Analog Output #6

Override Volts: -1.0

[-1.0=Auto]

Analog Output 7 Screen

RA Bypass Override

Analog Output #7

Override Volts: -1.0

[-1.0=Auto]

VCB-X & VCC-X Controllers

The default setting for normal operation is -1.0. Voltages between 0.0

and 10.0 can be set. Press <Enter> after making a setting change and

the next Analog Output Override Screen will be displayed.

Exhaust Fan Override Screen

Exhaust Fan Signal

Override Volts: -1.0

[-1.0 = Auto]

The default setting for normal operation is -1.0. Voltages between 0.0

and 10.0 can be set. Press

the next Analog Output Override Screen will be displayed.

Modulating Cool Override Screen

The default setting for normal operation is -10 percent. Percentages

between 0 to 100 can be set. Press <Enter> after making a setting

change and the next Analog Output Override Screen will be displayed.

<Enter> after making a setting change and

Modulating Cool

Override %...: -10%

[-10 = Auto]

Main Fan VFD Override Screen

Main Fan VFD

Override Volts: -1.0

[-1.0 = Auto]

The default setting for normal operation is -1.0 volts. Voltages between

0 to 10.0 can be set for any of the Analog Output Overrides. Press

<Enter> after making a setting change and the next Analog Output

Override Screen will be displayed.

Economizer Override Screen

Economizer

Override Volts: -1.0

[-1.0 = Auto]

The default setting for normal operation is -1.0. Voltages between 0.0

and 10.0 can be set. Press <Enter> after making a setting change and

the next Analog Output Override Screen will be displayed.

Modulating Heat Override Screen

Modulating Heat

Override Volts: -1.0

Modulating Condenser 1 & 2 Override Screens

The default setting for normal operation is -1.0. Voltages between 0.0

and 10.0 can be set.

Return Air Bypass Override Screen

The default setting for normal operation is -1.0. Voltages between 0.0

and 10.0 can be set.

Return Air Damper Override Screen

(VCB-X Only)

Mod. Condenser 1 & 2

Override Volts: -1.0

[-1.0 = Auto]

Return Air Bypass

Override Volts: -1.0

[-1.0 = Auto]

Return Air Damper

Override Volts: -1.0

[-1.0 = Auto]

[-1.0 = Auto]

Modular Service Tool SD

The default setting for normal operation is -1.0. Voltages between 0.0

and 10.0 can be set.

13

Page 14

APPENDIX A - SAVE, LOAD, COPY SETPOINTS

Saving & Copying Setpoints

Save Setpoints - Network Mode

Modular Service Tool Instructions

From any menu screen, press <BALANCE-TEST>. The Unit Selection

Screen will appear requesting that you enter the unit ID number. Enter

the network unit ID for the controller you want to save the setpoints

from. Example, ‘102’ for Loop 1 / Unit 2. Then press <ENTER>. Once

communication is established, *00* at the bottom of the screen will

go away. After a brief pause, press

Screen shown below.

Outputs Force

Para Blocks

Save/Copy/Restore

Scroll down to the ‘Save/Copy/Restore’ option and press <ENTER>.

This will take you to the Save Setpoints Screen shown below

Save Setpoints

Press Enter To Save

<> to get to the Balance - Test

Scroll down to the ‘Save /Copy/Restore’ option and press <ENTER>.

This will take you to the Save Setpoints Screen shown below.

Save Setpoints

Press Enter To Save

Press <> once to access the Copy Setpoints Screen shown below.

Copy Setpoints

From Loop 1

From Unit 2

Press Enter to Copy

In the ‘From Loop’ fi eld, enter the Loop of the controller you want to

copy the setpoints from. In this example it is ‘1’. Then press <ENTER>.

In the ‘From Unit’ fi eld, enter the Unit ID of the controller you want to

copy the setpoints from. In this example it is ‘2’. Then press <ENTER>.

Now your cursor will be on the last line, and you can press

once more to copy the setpoint fi le from unit 102 to unit 103.

<ENTER>

Press <ENTER> and a setpoint fi le will be saved to the SD card. You

will receive a message that the save was successful. This fi le is specifi c

to this controller on this loop.

Copy Setpoints - Network Mode

To copy a saved setpoints fi le to other controllers on the network do

the following:

<BALANCE-TEST>. The Unit Selection Screen will appear

Press

requesting that you enter the unit ID number. Enter the network unit

ID for the controller you want to save the setpoints to. Example, ‘103’

for Loop 1 / Unit 3. Then press

<> to get to the Balance - Test Screen shown below.

Outputs Force

Para Blocks

Save/Copy/Restore

<ENTER>. After a brief pause, press

You will receive a confi rmation that the copy was successful.

Save & Copy Setpoints - Stand-Alone

Mode

The instructions for Stand-Alone Mode are exactly the same as Network

Mode, except that there is no need to enter a Loop number in the Unit

ID number fi eld and in the Copy Setpoints Screen, enter a zero in the

‘From Loop’ fi eld.

14

Modular Service Tool SD

Page 15

APPENDIX A - SAVE, LOAD, COPY SETPOINTS

Restoring Previously Saved Setpoints

Restore Setpoints - Network or

Stand-Alone Mode

The Restore Setpoints feature is used to reload a saved setpoints fi le

from one controller back to itself. This could be useful if setpoints or

confi gurations were changed and need to be reset.

You can perform this function on a networked system; however, the

Modular Service Tool needs to be directly connected to the controller

you wish to restore previously saved setpoints to.

From any menu screen, press

tion Screen will appear requesting that you enter the unit ID number of

the controller. Enter the network unit ID for the controller you want

to restore setpoints to. Example, 2 for Unit 2. Then press

Once communication is established, *00* at the bottom right of the

screen will go away. After a brief pause, press

ance - Test Screen shown below.

Outputs Force

Para Blocks

Save/Copy/Restore

Scroll down to the ‘Save/Copy/Restore’ option shown above and press

<ENTER>. This will take you to the Save Setpoints Screen shown below .

<BALANCE - TEST>. The Unit Selec-

<ENTER>.

<> to get to the Bal-

Press <> four times to access the Restore Setpoints Screen shown

below.

Restore Setpoints

Press Enter to Load

Press <ENTER>. This will reload the setpoints from the saved fi le. You

will receive confi rmation that the setpoints were loaded successfully.

Save Setpoints

Press Enter To Save

Modular Service Tool SD

15

Page 16

APPENDIX B - UPDATING THE SD CARD

SD Memory Card Update

Updating The SD Memory Card

You may need to update the SD memory card from time to time,

either for a new release or to add data for another Controller.

NOTE: Some older controllers might require updating the soft-

ware in the Service T ool itself. Contact T ech Support for

further information.

Follow the instructions below to download the update fi le from

our tech support web page:

1. Insert the SD memory card in your computer’s SD drive

and open the drive’s window.

2. Open your browser and type in the address:

http://wattmaster.com/techsupport.

3. On the Tech Support web page, locate the fi le

Modular_HH_Screens.zip and double-click your mouse

on it.

4. Click

and then click <OK>. This option will save the fi le to the

“Downloads” folder on your PC.

<Save File> when asked to save or open the fi le

6. Once you unzip the fi le, you will see a window similar

to the one below.

7. Press <CTRL> <A> to highlight the folders in the

window—App, Manuals & Scr. Press

copy the folders.

<CTRL> <C> to

5. Open the “Downloads” folder in Windows Explorer.

You will fi nd a folder labeled, “Modular_HH_Screens.

zip.” Right-click on this folder and choose “Extract All”

from the options list.

can be used to extract the zip folder’s contents, for

example, Winzip.

NOTE: Any compression software

8. Paste the folders into the SD memory card drive’s

window by pressing

9. Remove the SD Memory Card from your computer and

reinsert it in the Modular Hand Held Service Tool.

<CTRL> <V>.

16

Modular Service Tool SD

Page 17

APPENDIX C - UPDATING CONTROLLERS & MODULES

Updating Controller & E-BUS Module Software

Updating Controller and Module

Software Using the Modular Service

Tool SD

To update the software for various WattMaster controllers and E-BUS

modules, follow these simple steps.

1. Update your SD memory card with the new software fi le

for the controller or module you need to update. Follow

the steps on page 16 for Updating the SD memory card.

2. Connect the Modular Service Tool to the device you

wish to update using the mini DIN communication cable

or EBC E-BUS cable provided.

3. Power up the controller or E-BUS module you wish to

update.

4. Apply power to the Modular Service Tool SD and

press the

5. After initialization of the Modular Service Tool SD,

press <NEXT> at the fi rst Setup Screen and <4> at the

second Setup Screen shown below.

6. The Update Software Screen will appear as shown

below:

<ON> button.

1) Set Time & Date

2) Communications

NEXT) More Options

ESC) Exit Menu

3) Energy Saving

4) Update Software

NEXT) More Options

ESC) Exit Menu

Select Communication

1) WattMaster Comm

2) E-BUS Module

ESC) Exit Menu

WattMaster Controllers

1. Press <1> to update a WattMaster Controller.

The following screen will appear:

Enter Board Address

0

Esc) Exit Menu

2. Enter the address of the controller you are updating and

then press

3. The Software Version Screen will appear as shown

below. Enter <0> for the latest software version or enter

the number of an older version given to you by

Technical Support. Then press

4. The screen will display the following messages:

“Resetting Unit”

“Load Sys Info”

5. If communications are successful, the screen will

display, the name of the HEX fi le on the top line,

“Flash Memory Erased” on the second line, and the

progress percentage on the third line.

NOTE: If communications are not successful, the screen

will display, “Press Any Key to Continue. Cannot Load

Sys Info.” Make sure you have the right address and the

right software version on your SD card. If these two

items are correct and you still experience a problem,

contact Technical Support.

6. When updating is complete, the screen will display,

“Finish Download.”

<ENTER>.

<ENTER>.

Software Version

Enter 0 for Latest

0

Esc) Exit Menu

7. Follow the instructions for WattMaster Controllers or

E-BUS Modules.

Modular Service Tool SD

17

Page 18

APPENDIX C - UPDATING CONTROLLERS & MODULES

Updating Controller & E-BUS Module Software

E-BUS Modules

1. Press <2> to update an E-BUS Module.

The following screen will appear:

Enter Board Address

0

Esc) Exit Menu

2. Enter the address of the E-BUS module you are updating

and then press <ENTER>. The following is the list of

Module addresses:

WSHP-X2 - address 17

MHGRV-X - address 132

MODGAS-X - address 138

PREHEAT-X - address 157

RSM #1 - address 152

RSM #2 - address 153

RSM #3- address 154

RSM #4 - address 155

3 . The Software Version Screen will appear as shown

below. Enter

the number of an older version if given to you by

Technical Support. Then press <ENTER>.

<0> for the latest software version or enter

5. If communications are successful, the screen will

display, the name of the HEX fi le on the top line,

“Flash Memory Erased” on the second line, and the

progress percentage on the third line.

NOTE: If communications are not successful, the screen

will display, “Press Any Key to Continue. Cannot Load

Sys Info.” Make sure you have the right address and the

right software version on your SD card. If these two

items are correct and you still experience a problem,

contact Technical Support.

6. When updating is complete, the screen will display,

“Finish Download.”

Software Version

Enter 0 for Latest

0

Esc) Exit Menu

4. The screen will display the following messages:

“Resetting Unit”

“Load Sys Info”

18

Modular Service Tool SD

Page 19

NOTES

Modular Service Tool SD

19

Page 20

Form: OR-QSOISD-TGD-01F Printed in the USA May 2015

All rights reserved. Copyright 2015

WattMaster Controls Inc. 8500 NW River Park Drive Parkville, MO 64152

Phone: 866-918-1100 www.orioncontrols.com Fax (816) 505-1101

Loading...

Loading...