Page 1

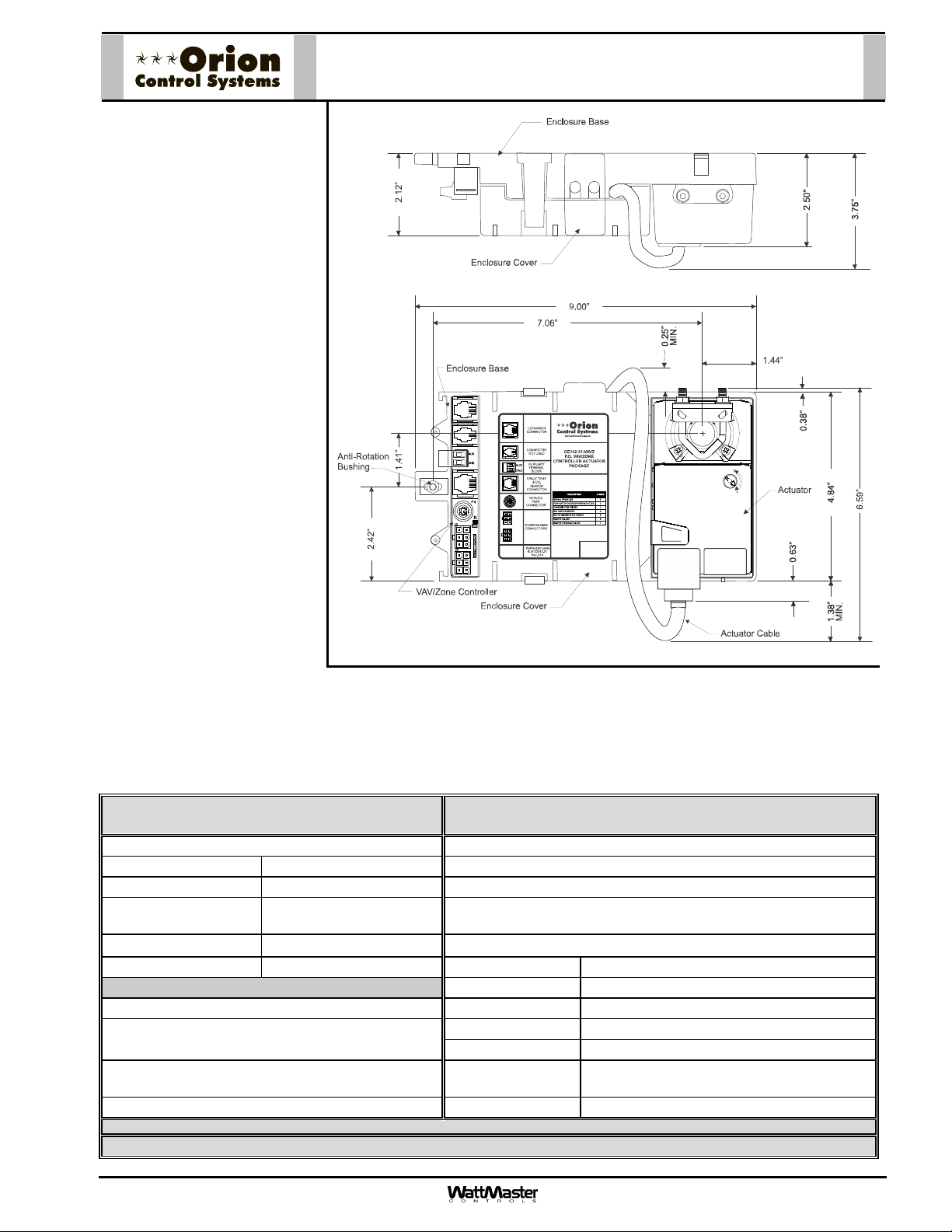

OE742-31-VAVZ VAV/Zone

Controller Actuator Package

Description

The OE742-31-VAVZ VAV/Zone

Controller Actuator Package with

Power/Comm connectors provides a new solution for zone

damper applications. The new

package includes a VAV/Zone

Actuator and a VAV/Zone Controller mounted in a plastic enclosure. An optional conduit cover is

also available that mounts over

the control terminals for installations requiring conduit connections. The VAV/Zone Controller

Actuator Package is designed for

left- or right-hand mounting on a

VAV Terminal unit. Each package

comes standard with a right-hand

label and the actuator positioned

for right-hand use. For left-hand

units, the actuator can be rotated

180 degrees by removing two

screws that secure it to the enclosure, rotating the damper actuator, and re-fastening the actuator

to the enclosure. A left-hand label

is also supplied that can be applied over the right-hand label for

left-hand applications.

Mounting

The VAV/Zone Actuator package

is very easy to mount on your

terminal unit. It is installed by

simply loosening the damper

shaft u-bolt on the actuator and sliding the entire Zone Controller Actuator Package Assembly over the terminal unit’s damper

shaft, tightening the actuator u-bolt around the damper shaft, and inserting a self-tapping screw into the anti-rotation bushing

located at the opposite end of the enclosure base. Detailed mounting and installation instructions are provided with each

package. A conduit enclosure is available as an option which provides conduit knockouts and encloses the electrical connections for applications where code requirements mandate conduit be used for low voltage electrical wiring.

Technical Data OE742-31-VAVZ

VAV/Zone Controller Actuator Package

Zone Controller: Outputs:

Supply Power 24 VAC (1) RJ-45 Cable Connection For Auxiliary Relay Board

Power Consumption 6 VA Maximum (1) RJ-45 Cable Connection To Damper Actuator

Operating Tempera-

ture

Operating Humidity 90% RH Non-Condensing

Communications RS-485 – 9600 Baud Programming Port Mini-DIN Jr. Port

Inputs:

(1) RJ-45 Cable Connection For Digital Temperature

Or Analog Temperature

(2) Auxiliary Terminals For Duct Temperature Sensor

(1) Molex Connector For Power/Comm In Airflow Ports Barbed Tube Fittings (PI Versions Only)

WattMaster reserves the right to change specifications without notice.

Three Year Warranty

Form: Orion-OE742-31-VAVZ-ZCAP-Sub-01C.doc Page 1 of 1

10F to 149F

Enclosure Material Fire Rated ABS Plastic

Zone Controller Factory Mounted Inside The Enclosure

Zone Actuator Factory Mounted To The Enclosure

Actuator Rating 35 in/lbs (6 ft2 Damper Area Max.)

Labeling Right Hand & Left Hand

(1) Molex Connector For Power/Comm Out

Features:

Page 2

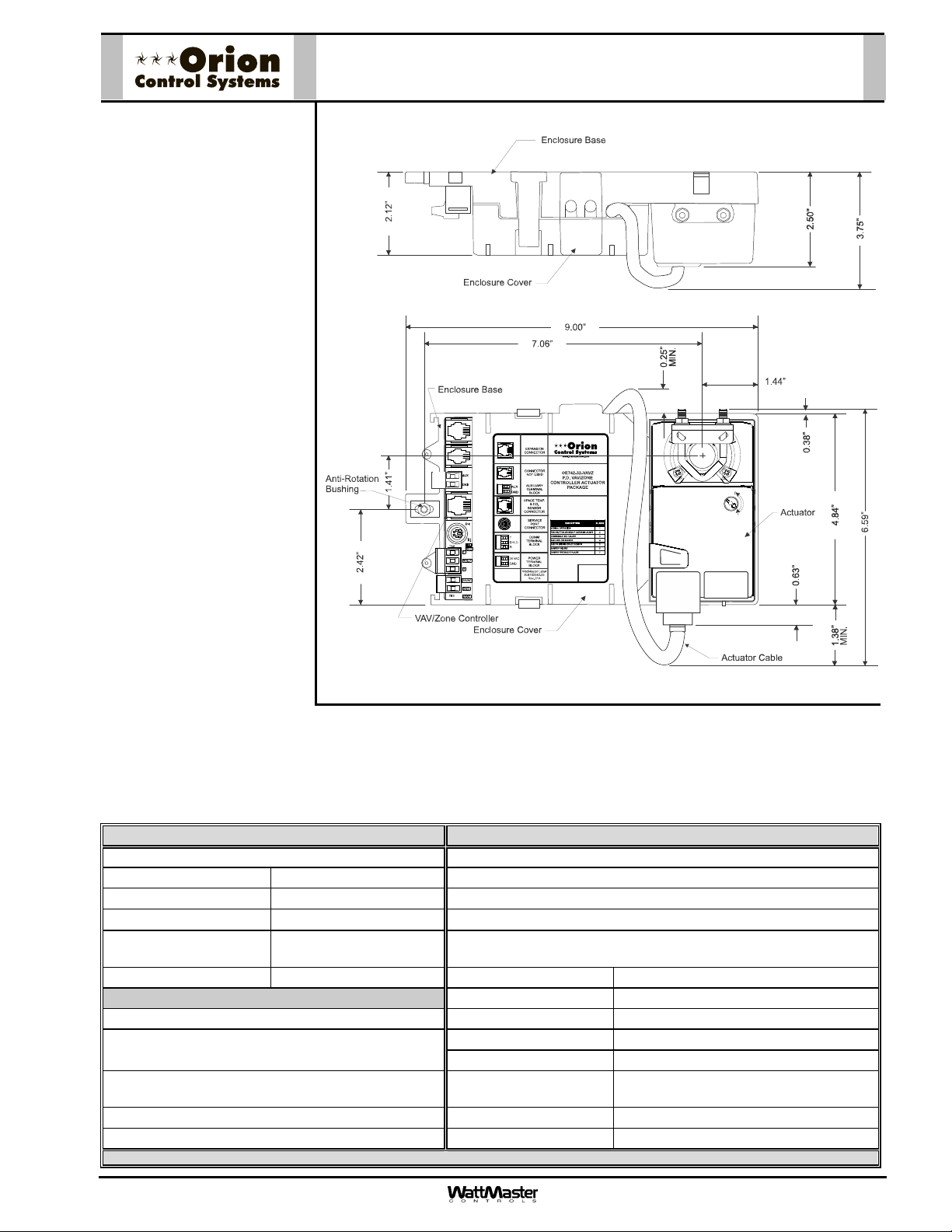

OE742-32-VAVZ VAV/Zone

Controller Actuator Package

Description

The OE742-32-VAVZ

VAV/Zone Controller Actuator

Package with Terminal Block

connectors provides a new solution for zone damper applications. The new package includes a VAV/Zone Actuator

and a VAV/Zone Controller

mounted in a plastic enclosure.

An optional conduit cover is

also available that mounts over

the control terminals for installations requiring conduit connections. The VAV/Zone Controller

Actuator Package is designed

for left- or right-hand mounting

on a VAV Terminal unit. Each

package comes standard with a

right-hand label and the actuator positioned for right-hand

use. For left-hand units, the

actuator can be rotated 180

degrees by removing two

screws that secure it to the enclosure, rotating the damper

actuator, and re-fastening the

actuator to the enclosure. A lefthand label is also supplied that

can be applied over the righthand label for left-hand applications.

Mounting

The VAV/Zone Actuator package is very easy to mount on

your terminal unit. It is installed

by simply loosening the damper shaft u-bolt on the actuator and sliding the entire Zone Controller Actuator Package Assembly

over the terminal unit’s damper shaft, tightening the actuator u-bolt around the damper shaft, and inserting a self-tapping

screw into the anti-rotation bushing located at the opposite end of the enclosure base. Detailed mounting and installation instructions are provided with each package. A conduit enclosure is available as an option which provides conduit knockouts

and encloses the electrical connections for applications where code requirements mandate conduit be used for low voltage

electrical wiring.

Technical Data OE742-32-VAVZ VAV/Zone Controller Actuator Package

Zone Controller: Outputs:

Supply Power 24 VAC (1) RJ-45 Cable Connection For Auxiliary Relay Board

Power Consumption 6 VA Maximum (1) RJ-45 Cable Connection To Damper Actuator

Operating Temperature

Operating Humidity 90% RH Non-

Communications RS-485 – 9600 Baud Programming Port Mini-DIN Jr. Port

Inputs:

(1) RJ-45 Cable Connection For Digital Temperature

Or Analog Temperature

(2) Auxiliary Terminals For Duct Temperature

Sensor

(1) Terminal Block Connector For Power In Airflow Ports Barbed Tube Fittings (PI Versions Only)

(1) Terminal Block Connector For Comm In

WattMaster reserves the right to change specifications without notice. Three Year Warranty

Form: Orion-OE742-32-VAVZ-ZCAP-Sub-01B.doc Page 1 of 1

10F to 149F

Condensing

Enclosure Material Fire Rated ABS Plastic

Zone Controller Factory Mounted Inside The Enclosure

Zone Actuator Factory Mounted To The Enclosure

Actuator Rating 35 in/lbs (6 ft2 Damper Area Max.)

Labeling Right Hand & Left Hand

Uses Same 3 Conductor Terminal Block as Comm Input

Features:

Page 3

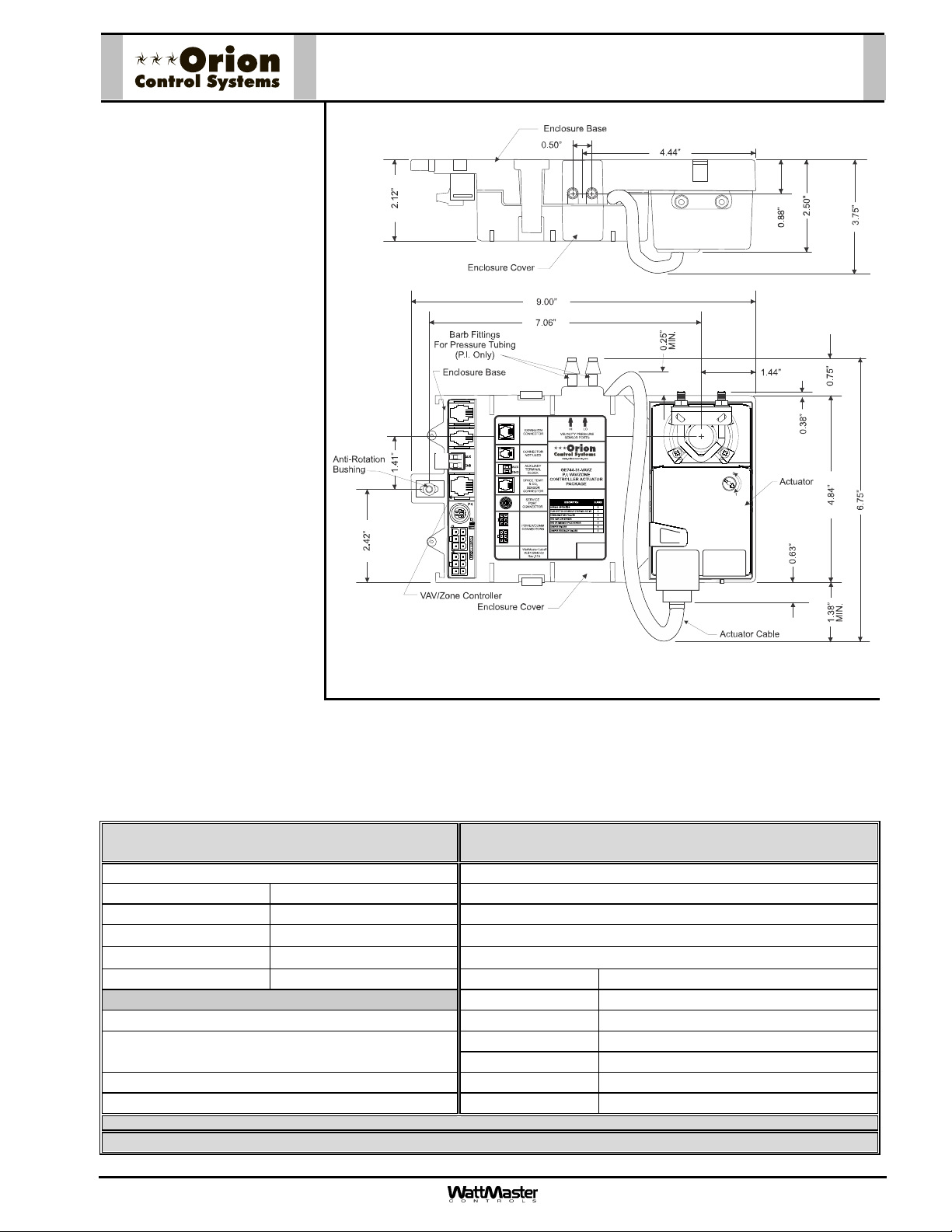

OE744-31-VAVZ VAV/Zone

Controller Actuator Package

Description

The OE744-31-VAVZ VAV/Zone

Controller Actuator Package with

Power/Comm connectors provides a new solution for zone

damper applications. The new

package includes a VAV/Zone

Actuator, a VAV/Zone Controller,

and an Airflow Sensor all mounted in a plastic enclosure. An optional conduit cover is also available that mounts over the control

terminals for installations requiring conduit connections. The

VAV/Zone Controller Actuator

Package is designed for left- or

right-hand mounting on a VAV

Terminal unit. Each package

comes standard with a right-hand

label and the actuator positioned

for right-hand use. For left-hand

units, the actuator can be rotated

180 degrees by removing two

screws that secure it to the enclosure, rotating the damper actuator, and re-fastening the actuator to the enclosure. A left-hand

label is also supplied that can be

applied over the right-hand label

for left-hand applications.

Mounting

The VAV/Zone Actuator package

is very easy to mount on your

terminal unit. It is installed by

simply loosening the damper

shaft u-bolt on the actuator and

sliding the entire Zone Controller Actuator Package Assembly over the terminal unit’s damper shaft, tightening the actuator ubolt around the damper shaft, and inserting a self-tapping screw into the anti-rotation bushing located at the opposite end of

the enclosure base. Detailed mounting and installation instructions are provided with each package. A conduit enclosure is

available as an option which provides conduit knockouts and encloses the electrical connections for applications where code

requirements mandate conduit be used for low voltage electrical wiring.

Technical Data OE744-31-VAVZ

VAV/Zone Controller Actuator Package

Zone Controller: Outputs:

Supply Power 24 VAC (1) RJ-45 Cable Connection For Auxiliary Relay Board

Power Consumption 6 VA Maximum (1) RJ-45 Cable Connection To Damper Actuator

Operating Temperature

Operating Humidity 90% RH Non-Condensing

Communications RS-485 – 9600 Baud Programming Port Mini-DIN Jr. Port

Inputs:

(1) RJ-45 Cable Connection For Digital Temperature

Or Analog Temperature

(2) Auxiliary Terminals For Duct Temperature Sensor Labeling Right Hand & Left Hand

(1) Molex Connector For Power/Comm In Airflow Ports Barbed Tube Fittings (PI Versions Only)

WattMaster reserves the right to change specifications without notice.

Three Year Warranty

Form: Orion-OE744-31-VAVZ-ZCAP-Sub-01C.doc Page 1 of 1

10F to 149F

Enclosure Material Fire Rated ABS Plastic

Zone Controller Factory Mounted Inside The Enclosure

Zone Actuator Factory Mounted To The Enclosure

Actuator Rating 35 in/lbs (6 ft2 Damper Area Max.)

(1) Molex Connector For Power/Comm Out

Features:

Page 4

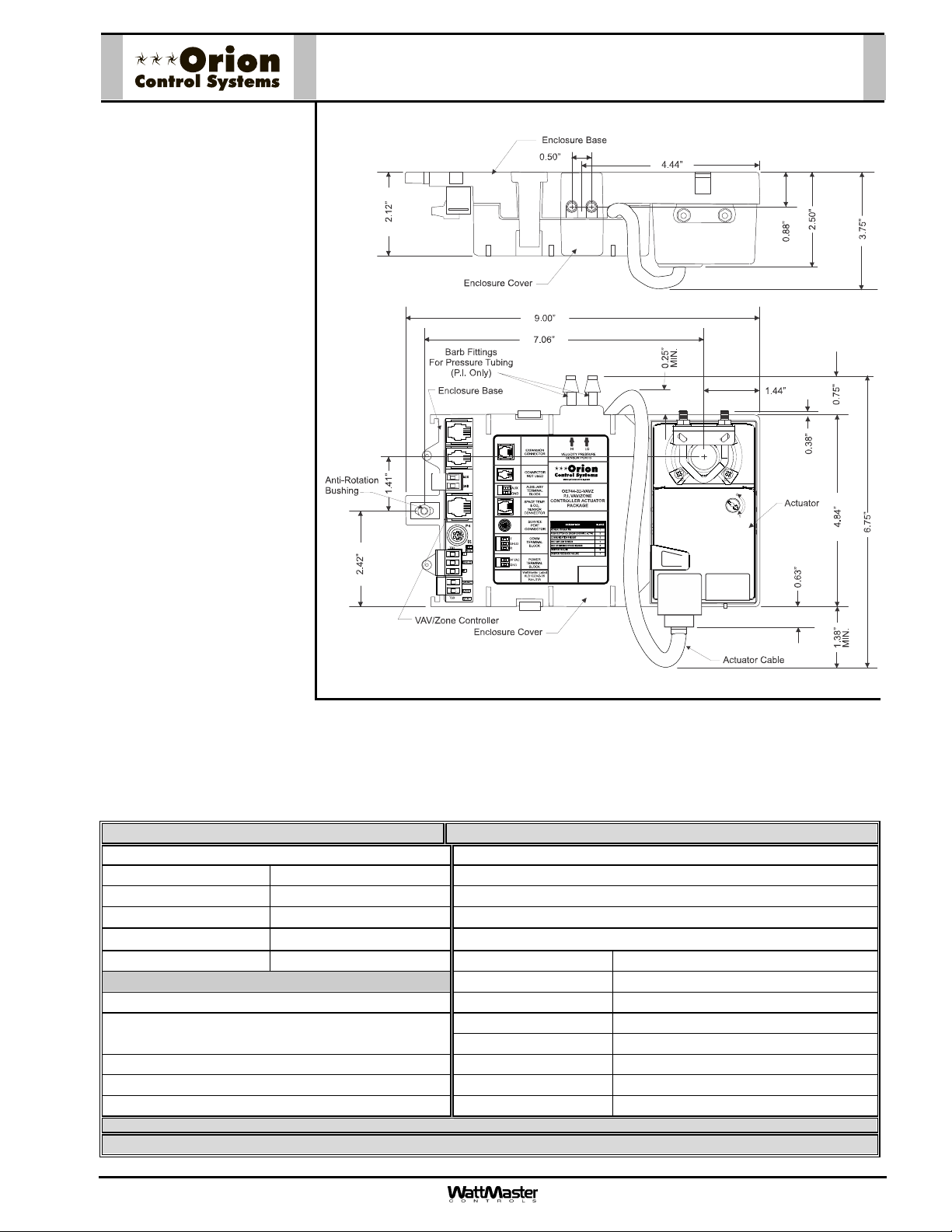

Description

The OE744-32-VAVZ

VAV/Zone Controller Actuator

Package with Terminal Block

connectors provides a new solution for zone damper applications. The new package includes a VAV/Zone Actuator, a

VAV/Zone Controller, and an

Airflow Sensor all mounted in a

plastic enclosure. An optional

conduit cover is also available

that mounts over the control

terminals for installations requiring conduit connections. The

VAV/Zone Controller Actuator

Package is designed for left- or

right-hand mounting on a VAV

Terminal unit. Each package

comes standard with a righthand label and the actuator

positioned for right-hand use.

For left-hand units, the actuator

can be rotated 180 degrees by

removing two screws that secure it to the enclosure, rotating

the damper actuator, and refastening the actuator to the

enclosure. A left-hand label is

also supplied that can be applied over the right-hand label

for left-hand applications.

OE744-32-VAVZ VAV/Zone

Controller Actuator Package

Mounting

The VAV/Zone Actuator package is very easy to mount on your terminal unit. It is installed by simply loosening the damper shaft u-bolt on the actuator and

sliding the entire Zone Controller Actuator Package Assembly over the terminal unit’s damper shaft, tightening the actuator ubolt around the damper shaft, and inserting a self-tapping screw into the anti-rotation bushing located at the opposite end of

the enclosure base. Detailed mounting and installation instructions are provided with each package. A conduit enclosure is

available as an option which provides conduit knockouts and encloses the electrical connections for applications where code

requirements mandate conduit be used for low voltage electrical wiring.

Technical Data OE744-32-VAVZ VAV/Zone Controller Actuator Package

Zone Controller: Outputs:

Supply Power 24 VAC (1) RJ-45 Cable Connection For Auxiliary Relay Board

Power Consumption 6 VA Maximum (1) RJ-45 Cable Connection To Damper Actuator

Operating Temperature

Operating Humidity 90% RH Non-Condensing

Communications RS-485 – 9600 Baud Programming Port Mini-DIN Jr. Port

Inputs:

(1) RJ-45 Cable Connection For Digital Temperature

Or Analog Temperature

(2) Auxiliary Terminals For Duct Temperature Sensor Labeling Right Hand & Left Hand

(1) Terminal Block Connector For Power In Airflow Ports Barbed Tube Fittings (PI Versions Only)

(1) Terminal Block Connector For Comm In

WattMaster reserves the right to change specifications without notice.

Three Year Warranty

10F to 149F

Enclosure Material Fire Rated ABS Plastic

Zone Controller Factory Mounted Inside The Enclosure

Zone Actuator Factory Mounted To The Enclosure

Actuator Rating 35 in/lbs (6 ft2 Damper Area Max.)

Form: Orion-OE744-32-VAVZ-ZCAP-Sub-01B.doc Page 1 of 1

Uses Same 3 Conductor Terminal Block as Comm Input

Features:

Page 5

Description

The OE325-01 4 Relay with Analog

Output Expansion board is used in

conjunction with the OE742-31VAVZ, OE742-32-VAVZ, OE74431-VAVZ, OE744-32-VAVZ

VAV/Zone Controller Actuator

Packages, the OE736-01, OE73602 Rectangular Damper Kits,the

OE520-XX-M, OE520-XX-T,

OE521-XX-M, OE521-XX-M Round

Zone Damper Assemblies. It

allows for control of fans, including

series and parallel flow fan

terminal units and/or heat. The

OE325-01 Analog Output

Expansion board provides 4 relay

outputs for pilot duty switching

control, (1 fan, 2 heat and 1

auxiliary) relay output and 1 Analog

output for control of a 0-10V

modulating hot water valve or SCR

controlled electric heating coil.

The OE325-01 4 Relay W/ Analog

Output Expansion board connects

to the VAV/Zone Controller board

by means of a 18” long modular

cable provided with the board.

Power is supplied to the board by

means of this modular cable.

Screw terminals are provided for

connection of field wiring to the

relay and analog outputs.

The relay outputs are N.O. contacts with one common terminal. All outputs and the relay common are electrically

isolated from all other circuitry on the board. All relay outputs are supplied with transient suppression devices

across each set of contacts to reduce EMI and arcing. The relay output contacts are rated for pilot duty control of

a maximum of 2 Amps @ 24 VAC or 24 VDC. The analog output provides a 0 – 10 VDC modulating signal output

into a 1k Ohm minimum load.

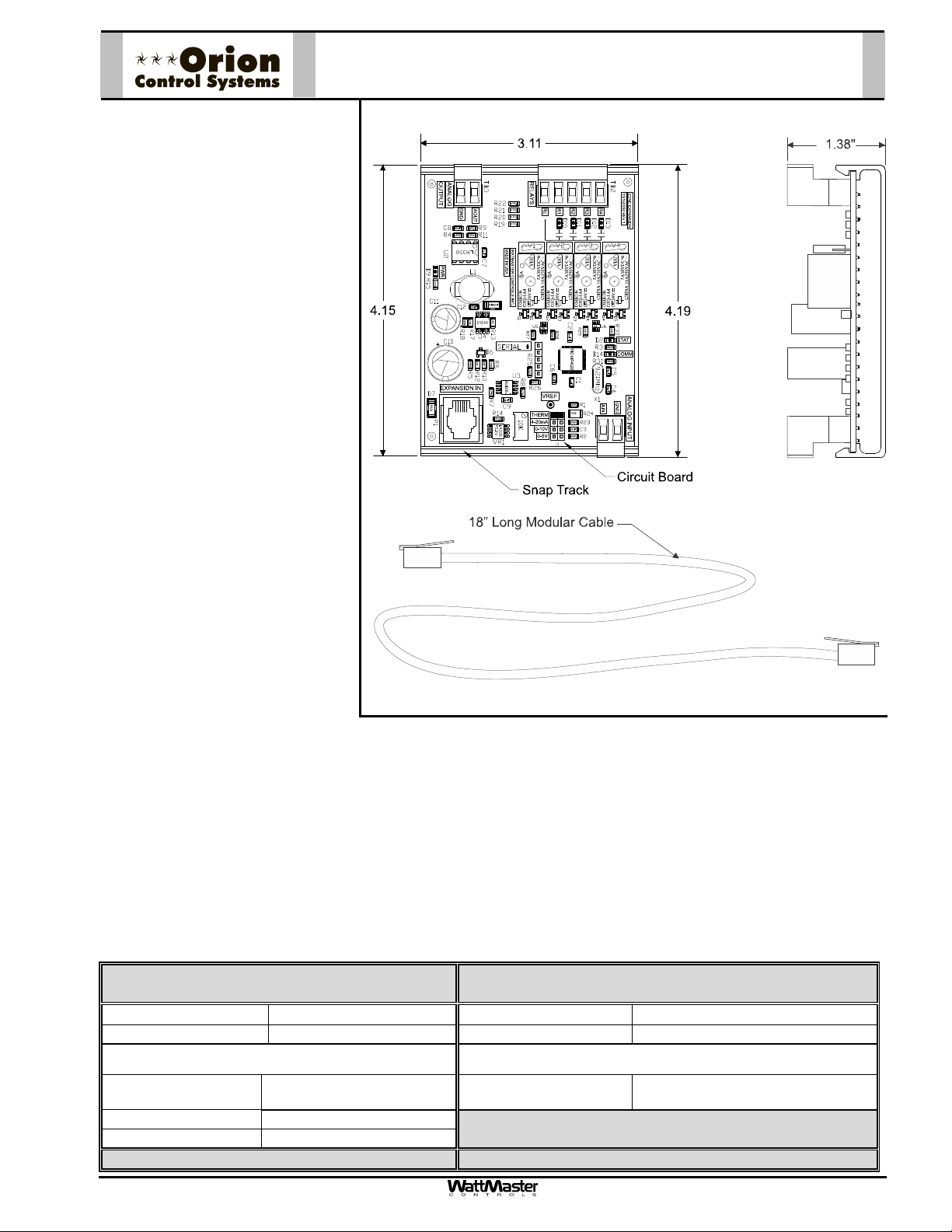

OE325-01 - 4 Relay W/ Analog Output

Expansion Board

Mounting

The OE325-01 4 Relay W/ Analog Output Expansion Board is supplied mounted on a plastic snap track channel.

The snap track channel has two mounting holes which are used to field mount the board with the provided

screws. The board should be mounted in close proximity to the VAVZ Zone Controller board to allow for

connection of the modular cable.

Technical Data OE325-01 4 Relay W/ Analog

Output Expansion board

Operating Temp

Weight 4 oz Connection to Controller: Modular Cable

10F to 149F

Operating Humidity 90% RH Non-Condensing

Outputs: Inputs:

Analog Output

Qty & Rating

Relay Output Qty. 4 – Electrically Isolated

Relay Contact Rating 2 Amp @ 24 VAC

Three Year Warranty

Form: ORION-OE325-01-4RelayW-AnalogOutputExpBrd-1B.doc Page 1 of 1

(1) 0-10 VDC @ 1k Ohm

Minimum load

Analog Input Application Specific

Universal Input

WattMaster reserves the right to change specifications without notice

Page 6

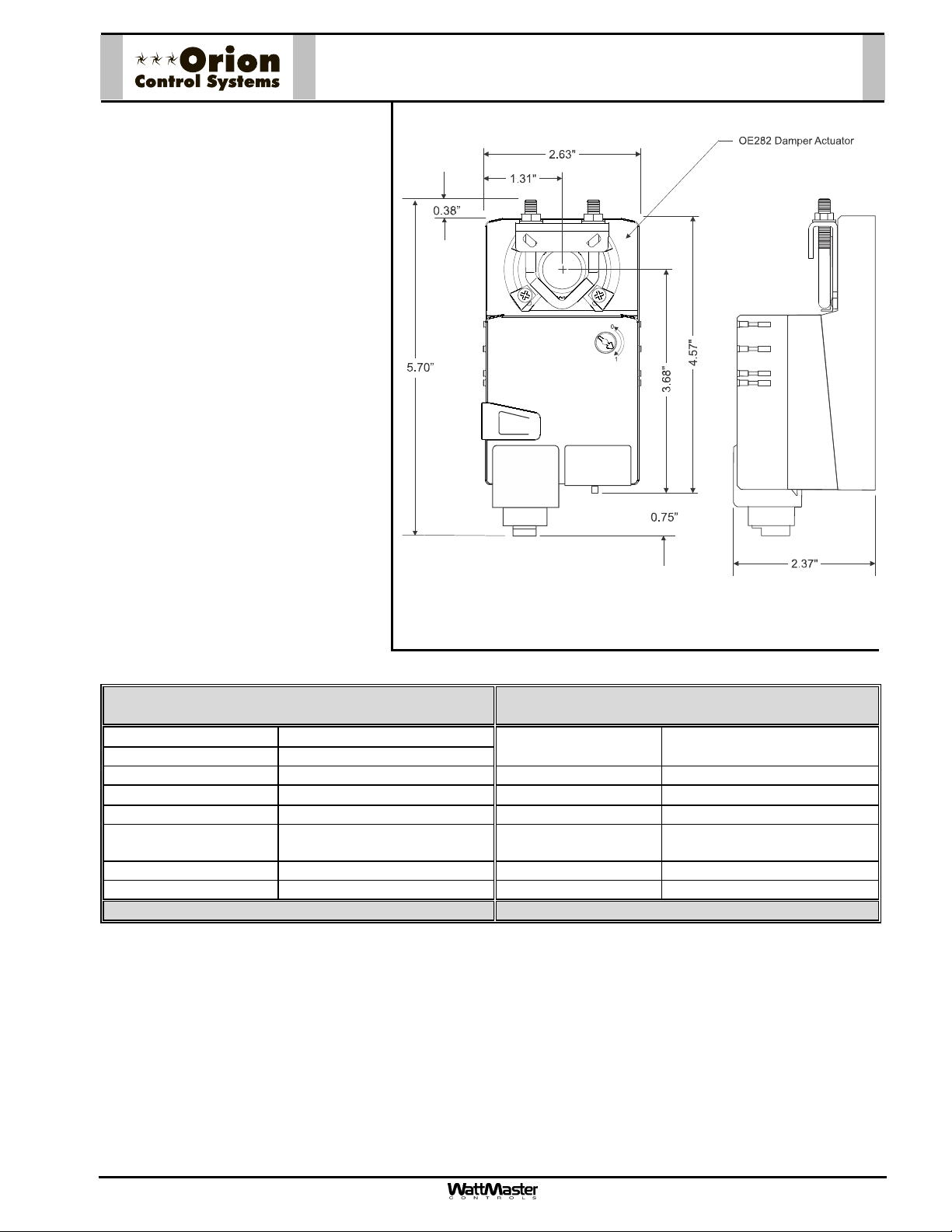

Description

The Orion OE282 Damper Actuator is

a shaft mounted, floating point control

actuator. Actuators are 24VAC/24VDC

with a 10K ohm feedback signal for position monitoring. Wiring connection to

the actuator is by means of a modular

phone cable connector located on the

actuator cover. The actuator is rated for

35 in-lb of torque. All actuators are

electronically protected against overload. The angle of rotation is mechanically limited to 95. When the end position of the actuator or damper is

reached, the actuator automatically

stops. For adjustment purposes, the

gears can be manually disengaged by

pushing the manual override button on

the actuator cover.

OE282 - Damper Actuator

Applications

The OE282 Damper Actuator is used to

provide control of air volume dampers

in an Orion VAV or zoning systems.

When used in VAV and Zoning applications it is typically used in conjunction

with an OE324-00-VAVZ Zone controller board.

Technical Data OE282

Power Supply

Life Cycle Rating 2.5 Million Cycles with Mechanical Stops

Power Consumption 3 VA Maximum Power Connection RJ-11 Modular Jack

Operating Temp

Operating Humidity 5 to 95% RH Non-Condensing Quality Standard ISO 9001

Overload Protection

Feedback Signal 10K ohm 1W Potentiometer Torque Minimum 35 in-lb

Running Time 80-110 Seconds. Weight 1.2 lb.

Three Year Warranty WattMaster reserves the right to change specifications without notice

24VAC 20% 50/60HZ

-22F to 122F

Electronic Throughout 0 to 95

Rotation

Angle of Rotation

Servicing Maintenance Free

Agency Listings UL873 listed

Damper Actuator

Max. 95, Adjustable

CSA 4813 02 Certified

Form: ORION-OE282-ProportionalDamper Actuator-1C.doc Page 1 of 1

Page 7

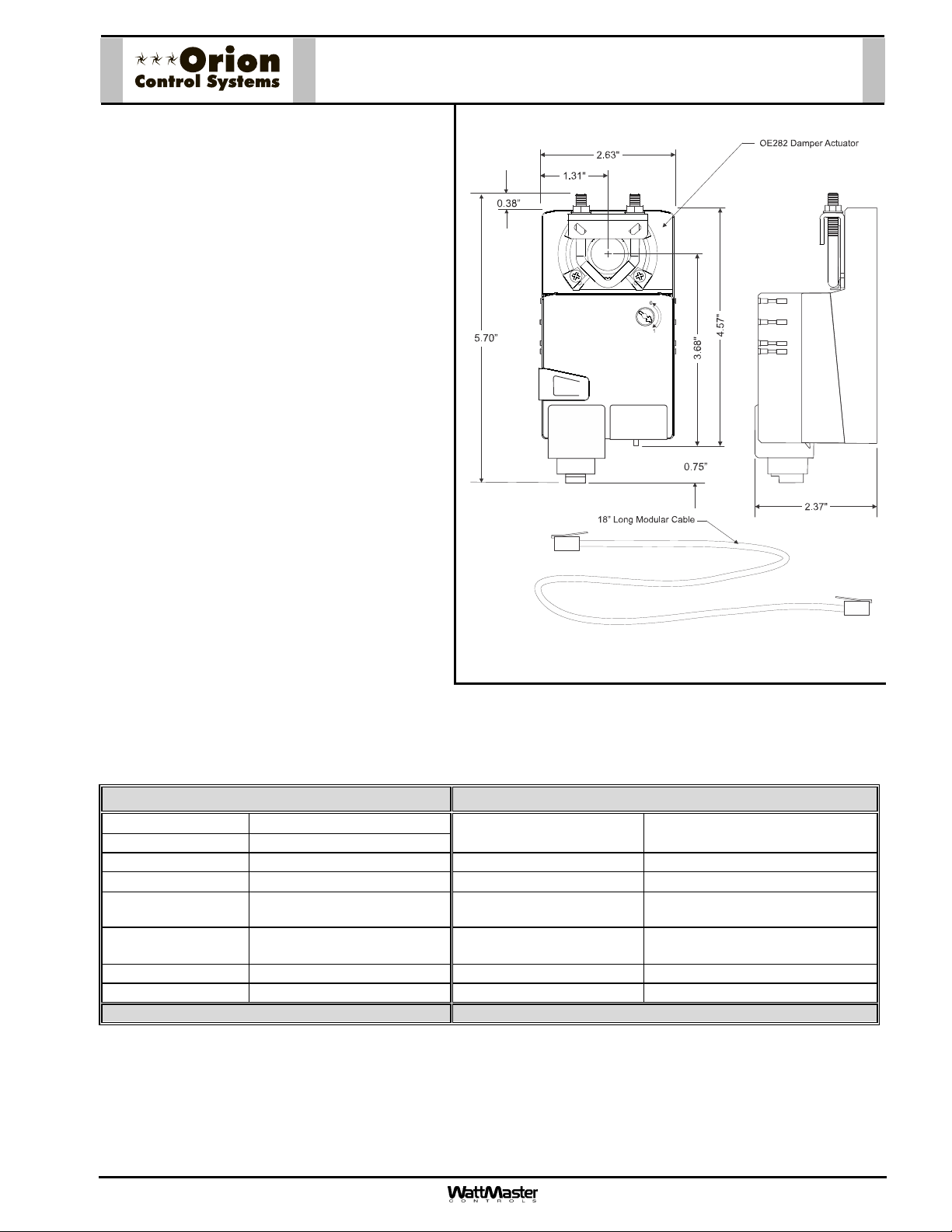

Description

The OE282 Damper Actuator is a shaft mounted,

floating point control actuator. Actuators are

24VAC/24VDC with a 10K ohm feedback signal

for position monitoring. Wiring connection to the

actuator is by means of a modular phone cable

connector located on the actuator cover. The

actuator is rated for 45 in-lb of torque. All

actuators are electronically protected against

overload. The angle of rotation is mechanically

limited to 95. When the end position of the

actuator or damper is reached, the actuator

automatically stops. For adjustment purposes,

the gears can be manually disengaged by

pushing the manual override button on the

actuator cover.

Zone Damper Actuator

OE282-01

Applications

The OE282 Damper Actuator is used to provide

control of air volume dampers in an VAV or

Zoning system.

When used in VAV and Zoning applications it is

normally factory mounted in the OE742-31VAVZ, OE742-32-VAVZ. P.D. VAV/Zone

Controller Actuator Packages or the OE744-31VAVZ, OE744-32-VAVZ. P.I. VAV/Zone

Controller Actuator Packages.

It is also a component of the OE282-03 Slaved

VAV/Zone Damper Kit. This kit allows multiple

dampers (up to 2 total besides the master) to be

connected to a master OE742-31-vVAVZ, OE742-32-VAVZ P.D. Zone/VAV Controller Actuator Package or

OE744-31-VAVZ, OE744-32-VAVZ P.I. Zone/VAV Controller Actuator Packages. The OE282-03 Kit is typically

used when larger CFM requirements dictate multiple dampers be used.

Technical Data OE282-01 Damper Actuator

Power Supply

Life Cycle Rating 2.5 Million Cycles with Mechanical Stops

Power Consumption 3 VA Maximum Power Connection RJ-11 Modular Jack

Operating Temp

Operating Humidity 5 to 95% RH Non-

Overload Protection Electronic Throughout 0 to

Feedback Signal 10K ohm 1W Potentiometer Torque Minimum 45 in-lb

Running Time 80-110 Seconds. Weight 1.2 lb.

Three Year Warranty

Form: ORION-OE282-01ZoneDmprAct-Sub-01A.doc Page 1 of 1

24VAC 20% 50/60HZ

-22F to 122F

Condensing

95 Rotation

Angle of Rotation

Servicing Maintenance Free

Quality Standard ISO 9001

Agency Listings UL873 listed

WattMaster reserves the right to change specifications without notice

Max. 95, Adjustable

CSA 4813 02 Certified

Page 8

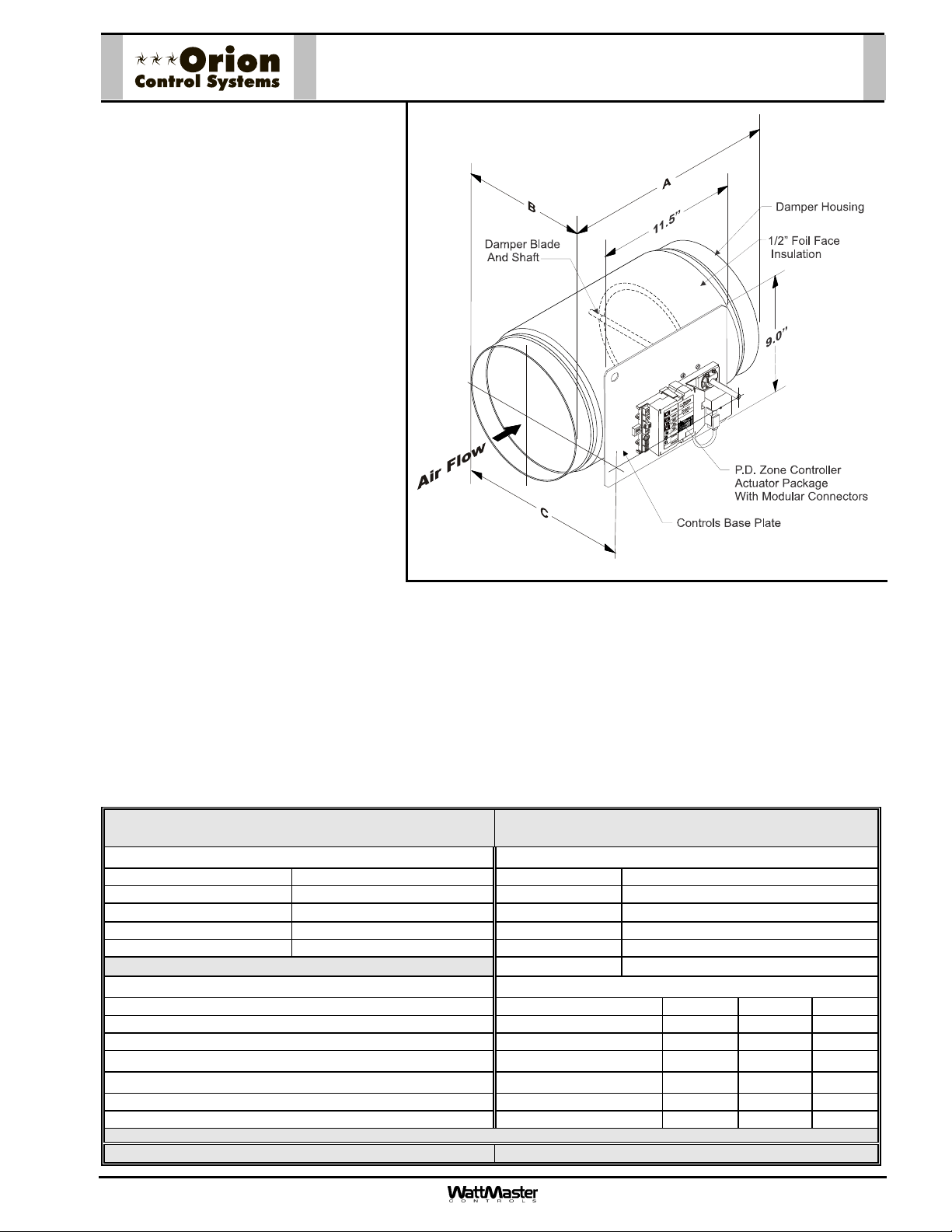

Description

The OE520-XX-M Round Pressure

Dependent Zone Damper Assembly with

modular connectors consists of a round

air damper and Zone Controller Actuator

Package with modular wiring connectors.

An optional Zone Controller Expansion

Module (OE325-01) is available for

control of reheat, heat and/or control of

series or parallel flow fan terminal units.

The Zone Controller board is

microprocessor based and communicates

with the HVAC unit controller on the Orion

network communications loop. The Zone

Controller monitors the space

temperature and allocates the proper

airflow into its assigned space to achieve

the desired comfort and ventilation levels.

Pressure Dependent Zone Dampers are

used in air conditioning systems that do

not require pressure independent airflow

control. If your system requires pressure

independent control of the airflow, see the

“OE521-XX-M Round Pressure

Independent Zone Damper” submittal sheet for the correct specifications. All dampers are tested for performance

in accordance with AMCA 500D standards.

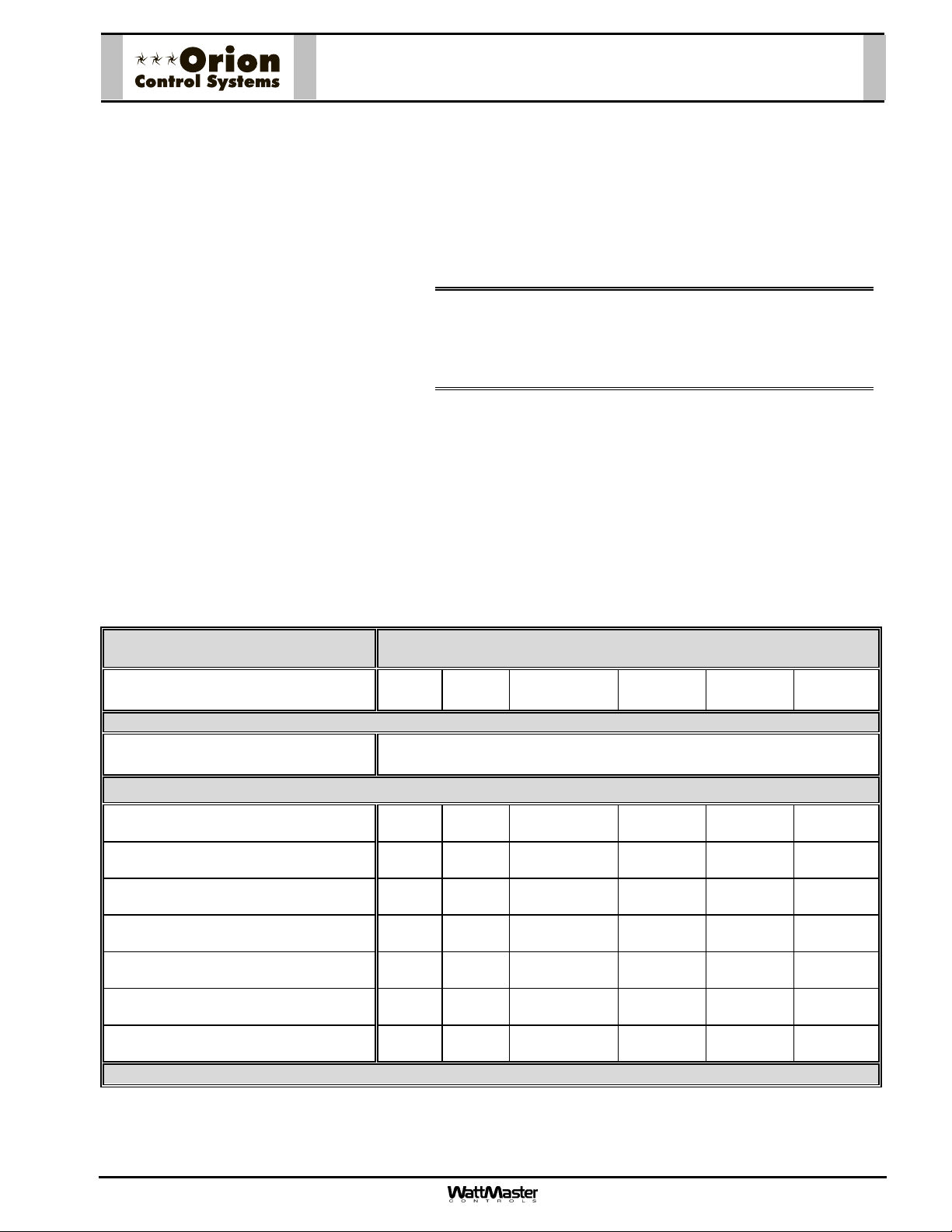

OE520-XX-M Round P.D. Zone Damper

Assembly W/ Modular Connectors

Mounting

The Zone Damper Assembly should be mounted according to standard duct installation practices with airflow

direction as shown in the illustration above. After installation of the Zone Damper in the ductwork, insulation

should be applied around any remaining un-insulated surface on the damper inlet and outlet. The Zone Damper

should be mounted so the control enclosure is positioned to the left or right side of the ductwork with the control

enclosure in a vertical plane. Do not mount the Zone Damper Assembly with the control enclosure on the top or

bottom of the ductwork. Adequate clearance should be maintained between the control panel and any

obstruction to allow for removal of the control panel cover and access to the controls.

Technical Data

Zone Damper Assembly W/ Modular Connectors

OE520-XX-M Round Pressure Dependent

Zone Controller: Air Damper Construction:

Supply Power 24 Volt AC Damper Body 20 Ga. Galv. Steel

Power Consumption 6 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

Operating Humidity 90% RH Non-Condensing Damper Seal EPDM Rubber Gasket

Communications RS-485 - 9600 Baud Leakage < 20 CFM Per Sq. Ft. @ 4” SP

35F to 125F

Damper Bearings Stainless Steel

Insulation ½” Foil Faced Fiberglass

Inputs: Dimensions:

Room Temperature Sensor

Setpoint Adjustment OE510-06 (6”) 23.00 5.88 9.88

Actuator Position Feedback OE510-08 (8”) 23.00 7.88 12.13

Communication Connectors: Modular In & Out

Outputs:

Expansion Port for Auxiliary Relay Board OE510-14 (14”) 23.00 13.88 18.50

Actuator Port for Connection to Damper Actuator OE510-16 (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

Air Damper Model “A” “B” “C”

OE510-10 (10”) 23.00 9.88 14.31

OE510-12 (12”) 23.00 11.88 16.43

Form: Orion-OE520XX-M-RndDmpr-Sub-01G Page 1 of 2

Page 9

OE520-XX-M Round P.D. Zone Damper

Assembly W/ Modular Connectors

Zone Damper Sizing

Use a load program to determine the peak

load for each zone. These calculations will be

used to select VAV/Zone Damper sizes.

The Orion Systems utilize a typical low

pressure duct design. To reduce noise

problems, duct pressures should not exceed

1” W.C.

Primary trunk ducts used with Orion systems

should not be “undersized”. This is especially

true of “pressure dependent” systems. With

larger trunk ducts, it is easier to assure

relatively constant pressure to each Zone

Damper. Runs should be as short as

possible, and the trunk duct system kept as

symmetrical as possible to facilitate system

balancing. Wherever possible, run the trunk

ducts above corridors and locate the Zone

Dampers above corridors to reduce the noise

in the space and facilitate service of the

valves. Trunk ducts should be sized for no

more than 0.1” W.C. drop per 100 ft. of duct,

and a maximum duct velocity of 2000 FPM.

Zone Damper Selection Data

Zone Damper Round Duct Size

(Area Ft

Velocity Through VAV/Zone Damper

FPM

500

750

1000

1250

1500

1750

2000

2

)

WattMaster reserves the right to change specifications without notice

6”

(0.196)

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

Using the maximum acceptable velocity for a branch duct

(typically 1000-1500 FPM for minimal noise), find the smallest

Zone Damper that will deliver the required CFM as determined

by the load program. Locate the branch velocity used in the duct

design program in the left hand column of the Zone Damper

Selection Data table. Move across the table and find the Zone

Damper, which will provide the acceptable CFM to meet the zone

airflow requirements.

Note: Compare the Zone Damper size selected against the

duct size to determine if the next size up or down will

provide acceptable performance without requiring a

transition fitting.

Up to a maximum of two Slaved Zone Dampers may be slaved

together with the main Zone Damper for large zones. This design

should be reserved only for situations when it is not practical to

use a single Zone Damper. See the AZ-300-RS Round Slaved

Zone Damper submittal sheet for information regarding

application and selection of Round Slaved Zone Dampers.

OE520-XX-M Round Pressure Dependent

Zone Damper Assembly W/ Modular Connectors

8”

(0.349)

Airflow Through VAV/Zone Damper - CFM

(P

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

10”

(0.545)

inches W.C. w/ Damper Full Open)

S

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

12”

(0.785)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

(1.069)

(< 0.01)

(< 0.01)

(< 0.01)

(0.015)

(0.030)

(0.040)

14”

535

802

1069

1336

1604

0.020)

1871

2138

16”

(1.396)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

Form: Orion-OE520XX-M-RndDmpr-Sub-01G Page 2 of 2

Page 10

Description

The OE520-XX-T Round Pressure Dependent

Zone Damper Assembly with terminal

connectors consists of a round air damper

and Zone Controller Actuator Package with

terminal wiring connectors. An optional Zone

Controller Expansion Module (OE325-01) is

available for control of reheat, heat and/or

control of series or parallel flow fan terminal

units.

The Zone Controller board is microprocessor

based and communicates with the HVAC unit

controller on the Orion network

communications loop. The Zone Controller

monitors the space temperature and allocates

the proper airflow into its assigned space to

achieve the desired comfort and ventilation

levels.

Pressure Dependent Zone Dampers are used

in air conditioning systems that do not require

pressure independent airflow control. If your

system requires pressure independent control

of the airflow, see the “OE521-XX-T Round

Pressure Independent Zone Damper”

submittal sheet for the correct specifications. All dampers are tested for performance in accordance with AMCA

500D standards.

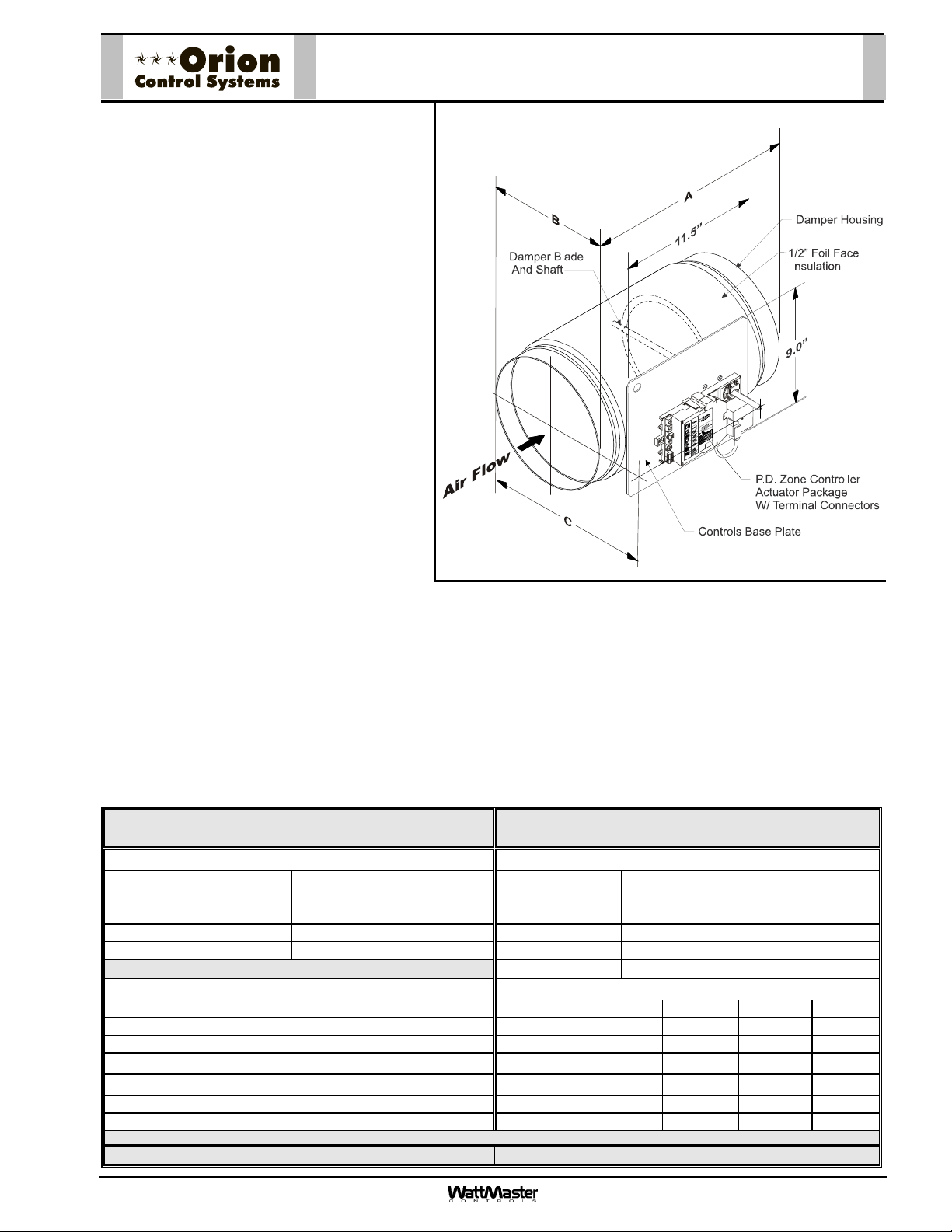

OE520-XX-T Round P.D. Zone Damper

Assembly W/ Terminal Connectors

Mounting

The Zone Damper Assembly should be mounted according to standard duct installation practices with airflow

direction as shown in the illustration above. After installation of the Zone Damper in the ductwork, insulation

should be applied around any remaining un-insulated surface on the damper inlet and outlet. The Zone Damper

should be mounted so the control enclosure is positioned to the left or right side of the ductwork with the control

enclosure in a vertical plane. Do not mount the Zone Damper Assembly with the control enclosure on the top or

bottom of the ductwork. Adequate clearance should be maintained between the control panel and any

obstruction to allow for removal of the control panel cover and access to the controls.

Technical Data

Zone Damper Assembly W/ Terminal Connectors

OE520-XX-T Round Pressure Dependent

Zone Controller: Air Damper Construction:

Supply Power 24 Volt AC Damper Body 20 Ga. Galv. Steel

Power Consumption 6 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

Operating Humidity 90% RH Non-Condensing Damper Seal EPDM Rubber Gasket

Communications RS-485 - 9600 Baud Leakage < 20 CFM Per Sq. Ft. @ 4” SP

35F to 125F

Damper Bearings Stainless Steel

Insulation ½” Foil Faced Fiberglass

Inputs: Dimensions:

Room Temperature Sensor

Setpoint Adjustment OE510-06 (6”) 23.00 5.88 9.88

Actuator Position Feedback OE510-08 (8”) 23.00 7.88 12.13

Communication Connectors: Terminals In & Out

Outputs:

Expansion Port for Auxiliary Relay Board OE510-14 (14”) 23.00 13.88 18.50

Actuator Port for Connection to Damper Actuator OE510-16 (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

Air Damper Model “A” “B” “C”

OE510-10 (10”) 23.00 9.88 14.31

OE510-12 (12”) 23.00 11.88 16.43

Form: Orion-OE520XX-T-RndDmpr-Sub-01G Page 1 of 2

Page 11

OE520-XX-T Round P.D. Zone Damper

Assembly W/ Terminal Connectors

VAV/Zone Damper Sizing

Use a load program to determine the peak

load for each zone. These calculations will be

used to select Zone Damper sizes.

The Orion Systems utilize a typical low

pressure duct design. To reduce noise

problems, duct pressures should not exceed

1” W.C.

Primary trunk ducts used with Orion systems

should not be “undersized”. This is especially

true of “pressure dependent” systems. With

larger trunk ducts, it is easier to assure

relatively constant pressure to each Zone

Damper. Runs should be as short as

possible, and the trunk duct system kept as

symmetrical as possible to facilitate system

balancing. Wherever possible, run the trunk

ducts above corridors and locate the Zone

Dampers above corridors to reduce the noise

in the space and facilitate service of the

valves. Trunk ducts should be sized for no

more than 0.1” W.C. drop per 100 ft. of duct,

and a maximum duct velocity of 2000 FPM.

Zone Damper Selection Data

Zone Damper Round Duct Size

(Area Ft

Velocity Through VAV/Zone Damper

FPM

500

750

1000

1250

1500

1750

2000

2

)

WattMaster reserves the right to change specifications without notice

6”

(0.196)

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

Using the maximum acceptable velocity for a branch duct

(typically 1000-1500 FPM for minimal noise), find the smallest

Zone Damper that will deliver the required CFM as determined

by the load program. Locate the branch velocity used in the

duct design program in the left hand column of the Zone

Damper Selection Data table. Move across the table and find

the Zone Damper, which will provide the acceptable CFM to

meet the zone airflow requirements.

Note: Compare the Zone Damper size selected against

the duct size to determine if the next size up or

down will provide acceptable performance without

requiring a transition fitting.

Up to a maximum of two Slaved Zone Dampers may be slaved

together with the main Zone Damper for large zones. This

design should be reserved only for situations when it is not

practical to use a single Zone Damper. See the AZ-300-RS

Round Slaved Zone Damper submittal sheet for information

regarding application and selection of Round Slaved Zone

Dampers.

OE520-XX-T Round Pressure Dependent

Zone Damper Assembly W/ Terminal Connectors

8”

(0.349)

Airflow Through VAV/Zone Damper - CFM

(P

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

10”

(0.545)

inches W.C. w/ Damper Full Open)

S

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

12”

(0.785)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

(1.069)

(< 0.01)

(< 0.01)

(< 0.01)

(0.015)

0.020)

(0.030)

(0.040)

14”

535

802

1069

1336

1604

1871

2138

16”

(1.396)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

Form: Orion-OE520XX-T-RndDmpr-Sub-01G Page 2 of 2

Page 12

Description

The OE521-XX-M Round Pressure

Independent Zone Damper Assembly with

modular connectors consists of a round

air damper with air flow pickup cross and

a Zone Controller Actuator Package

(including air flow sensor) with modular

connectors. An optional Zone Controller

Expansion Module (OE325-01) is

available for control of reheat, heat and/or

control of series or parallel flow fan

terminal units.

The Zone Controller board is

microprocessor based and communicates

with the HVAC unit controller on the Orion

network communications loop. The Zone

Controller monitors the space

temperature and allocates the proper

airflow into its assigned space to achieve

the desired comfort and ventilation levels.

Pressure Independent Zone Dampers are

used in air conditioning systems require

pressure independent airflow control. If

your system requires pressure dependent

control of the airflow, see the “OE520-XX-M Round Pressure Dependent Zone Damper” submittal sheet for the

correct specifications. All dampers are tested for performance in accordance with AMCA 500D standards.

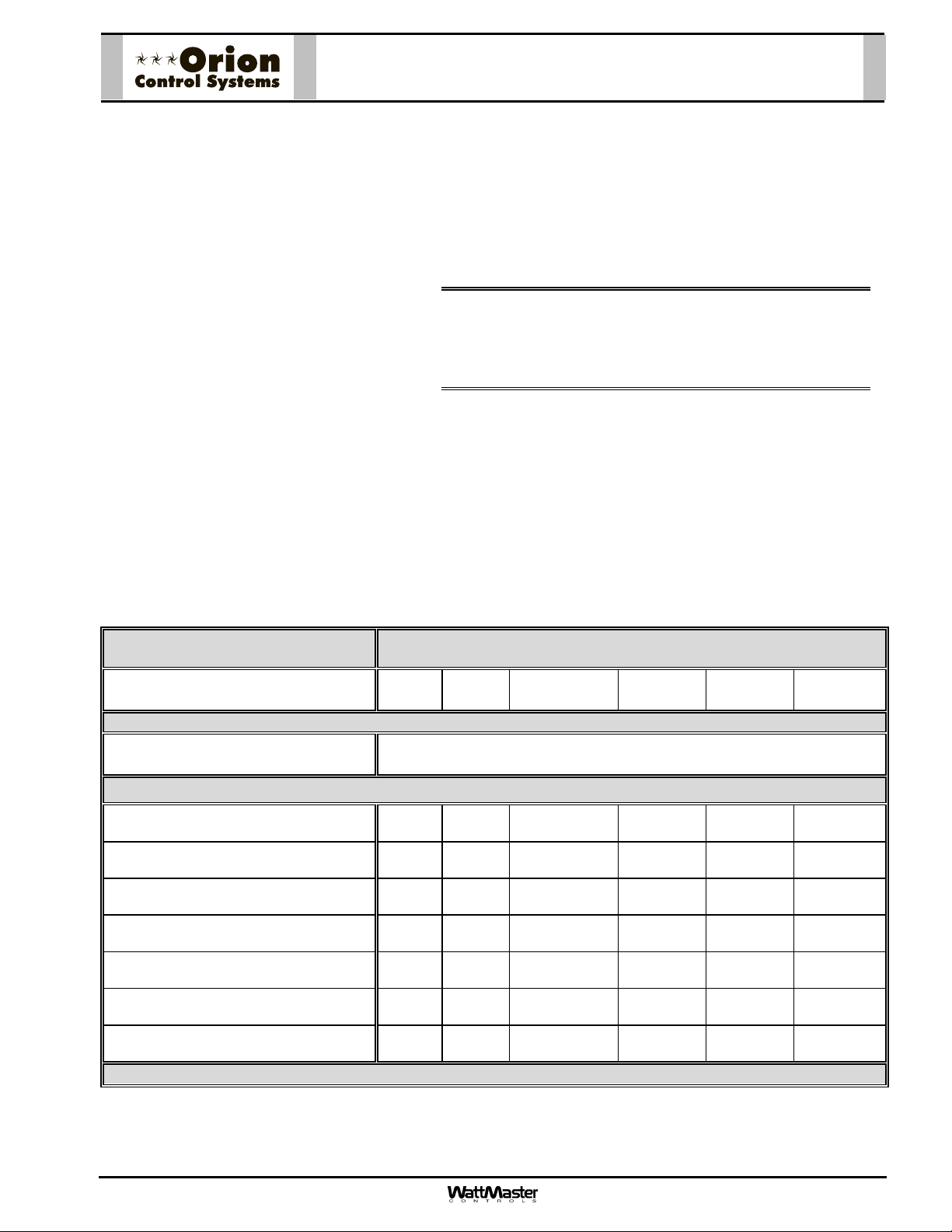

OE521-XX-M Round P.I. Zone Damper

Assembly W/ Modular Connectors

Mounting

The Zone Damper Assembly should be mounted according to standard duct installation practices with airflow

direction as shown in the illustration above. After installation of the Zone Damper in the ductwork, insulation

should be applied around any remaining un-insulated surface on the damper inlet and outlet. The Zone Damper

should be mounted so the control enclosure is positioned to the left or right side of the ductwork with the control

enclosure in a vertical plane. Do not mount the Zone Damper Assembly with the control enclosure on the top or

bottom of the ductwork. Adequate clearance should be maintained between the control panel and any

obstruction to allow for removal of the control panel cover and access to the controls.

Technical Data

OE521-XX-M Round Pressure Independent

Zone Damper Assembly W/ Modular Connectors

Zone Controller: Air Damper Construction:

Supply Power 24 Volt AC Damper Body 20 Ga. Galv. Steel

Power Consumption 6 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

Operating Humidity 90% RH Non-Condensing Damper Seal EPDM Rubber Gasket

Communications RS-485 - 9600 Baud Leakage < 20 CFM Per Sq. Ft. @ 4” SP

35F to 125F

Inputs:

Air Flow Sensor

Room Temperature Sensor

Setpoint Adjustment OE510-06 (6”) 23.00 5.88 9.88

Actuator Position Feedback OE510-08 (8”) 23.00 7.88 12.13

Communication Connectors: Modular In & Out

Outputs:

Expansion Port for Auxiliary Relay Board OE510-14 (14”) 23.00 13.88 18.50

Actuator Port for Connection to Damper Actuator OE510-16 (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

Damper Bearings Stainless Steel

Insulation ½” Foil Faced Fiberglass

Dimensions:

Air Damper Model “A” “B” “C”

OE510-10 (10”) 23.00 9.88 14.31

OE510-12 (12”) 23.00 11.88 16.43

FormOrion-OE521XX-M-RndDmpr-Sub-01G Page 1 of 2

Page 13

A

OE521-XX-M Round P.I. Zone Damper

Assembly W/ Modular Connectors

Zone Damper Sizing

Use a load program to determine the peak

load for each zone. These calculations will be

used to select Zone Damper sizes.

The Orion Systems utilize a typical low

pressure duct design. To reduce noise

problems, duct pressures should not exceed

1” W.C.

Primary trunk ducts used with Orion systems

should not be “undersized”. This is especially

true of “pressure dependent” systems. With

larger trunk ducts, it is easier to assure

relatively constant pressure to each Zone

Damper. Runs should be as short as

possible, and the trunk duct system kept as

symmetrical as possible to facilitate system

balancing. Wherever possible, run the trunk

ducts above corridors and locate the Zone

Dampers above corridors to reduce the noise

in the space and facilitate service of the

dampers. Trunk ducts should be sized for no

more than 0.1” W.C. drop per 100 ft. of duct,

and a maximum duct velocity of 2000 FPM.

Using the maximum acceptable velocity for a branch duct

(typically 1000-1500 FPM for minimal noise), find the smallest

Zone Damper that will deliver the required CFM as determined

by the load program. Locate the branch velocity used in the

duct design program in the left hand column of the Zone

Damper Selection Data table. Move across the table and find

the Zone Damper, which will provide the acceptable CFM to

meet the zone airflow requirements.

Note: Compare the Zone Damper size selected against

the duct size to determine if the next size up or

down will provide acceptable performance without

requiring a transition fitting.

Pressure Independent Zone Dampers may not be slaved

together with Slaved-Zone Damper Assemblies. If more than

one damper is required for a zone, all dampers must be

selected as pressure dependent. See the Pressure Dependent

Zone Damper submittal sheet and Slaved-Zone Damper

submittal sheets for selection of master/slave damper

configurations.

Zone Damper Selection Data

Zone Damper Round Duct Size

(Area Ft

CFM @ 1” Velocity Pressure

(Air Flow Probe “K” Factor)

Velocity Through VAV/Zone Damper

FPM

500

750

1000

1250

1500

1750

2000

2

)

WattMaster reserves the right to change specifications without notice

OE521-XX-M Round Pressure Independent Zone Damper

ssembly W/ Modular Connectors

6”

(0.196)

448 904 1436 1891 3015 3839

8”

(0.349)

Airflow Through VAV/Zone Damper - CFM

(P

10”

(0.545)

inches W.C. w/ Damper Full Open)

S

12”

(0.785)

14”

(1.069)

16”

(1.396)

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

535

(< 0.01)

802

(< 0.01)

1069

(< 0.01)

1336

(0.015)

1604

0.020)

1871

(0.030)

2138

(0.040)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

FormOrion-OE521XX-M-RndDmpr-Sub-01G Page 2 of 2

Page 14

Description

The OE521-XX-T Round Pressure

Independent Zone Damper Assembly with

terminal connectors consists of a round

air damper with air flow pickup cross and

a Zone Controller Actuator Package

(including air flow sensor) with terminal

connectors. An optional Zone Controller

Expansion Module (OE325-01) is

available for control of reheat, heat and/or

control of series or parallel flow fan

terminal units.

The Zone Controller board is

microprocessor based and communicates

with the HVAC unit controller on the Orion

network communications loop. The Zone

Controller monitors the space

temperature and allocates the proper

airflow into its assigned space to achieve

the desired comfort and ventilation levels.

Pressure Independent Zone Dampers are

used in air conditioning systems require

pressure independent airflow control. If

your system requires pressure dependent

control of the airflow, see the “OE520-XX-T Round Pressure Dependent Zone Damper” submittal sheet for the

correct specifications. All dampers are tested for performance in accordance with AMCA 500D standards.

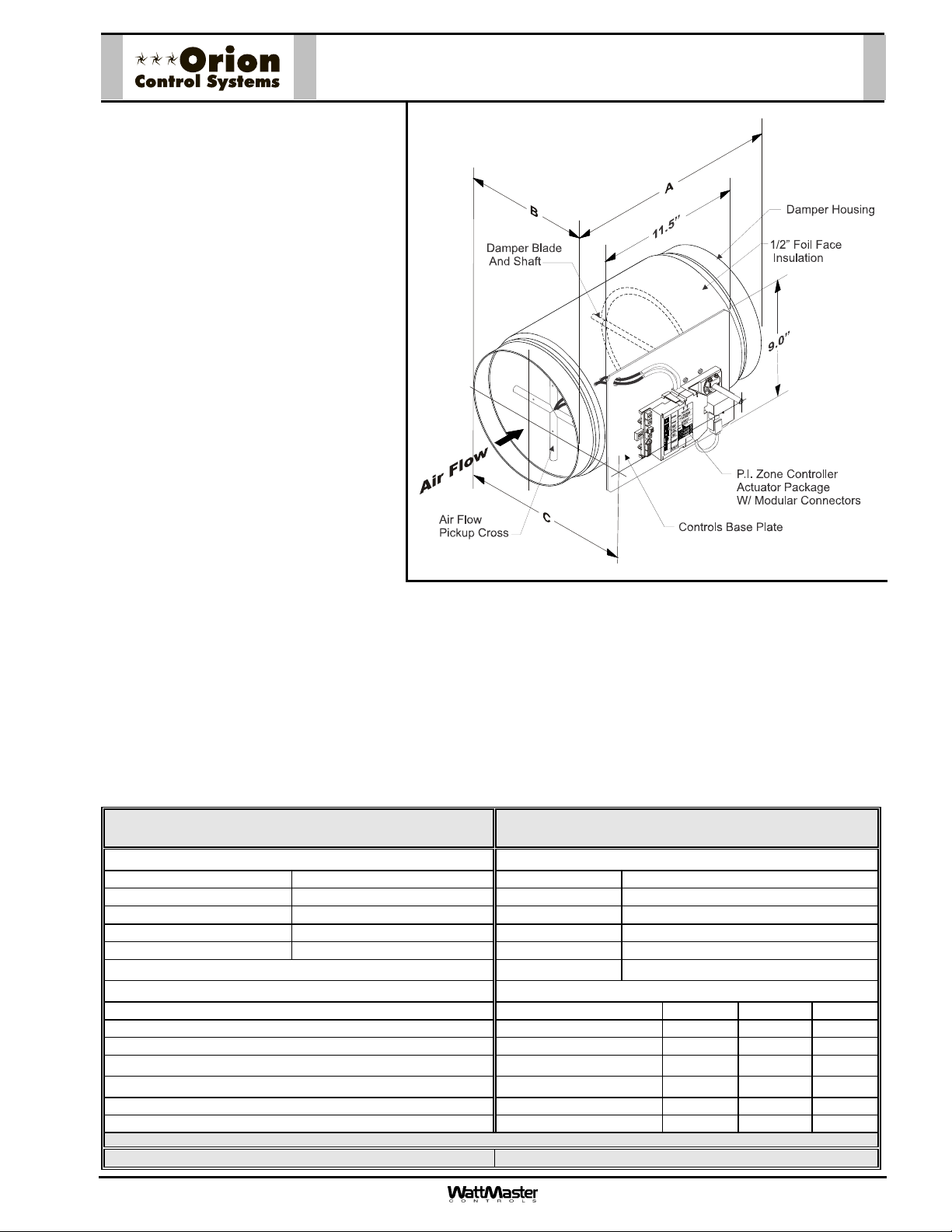

OE521-XX-T Round P.I. Zone Damper

Assembly W/ Terminal Connectors

Mounting

The Zone Damper Assembly should be mounted according to standard duct installation practices with airflow

direction as shown in the illustration above. After installation of the Zone Damper in the ductwork, insulation

should be applied around any remaining un-insulated surface on the damper inlet and outlet. The Zone Damper

should be mounted so the control enclosure is positioned to the left or right side of the ductwork with the control

enclosure in a vertical plane. Do not mount the Zone Damper Assembly with the control enclosure on the top or

bottom of the ductwork. Adequate clearance should be maintained between the control panel and any

obstruction to allow for removal of the control panel cover and access to the controls.

Technical Data

Zone Damper Assembly W/ Terminal Connectors

OE521-XX-T Round Pressure Independent

Zone Controller: Air Damper Construction:

Supply Power 24 Volt AC Damper Body 20 Ga. Galv. Steel

Power Consumption 6 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

Operating Humidity 90% RH Non-Condensing Damper Seal EPDM Rubber Gasket

Communications RS-485 - 9600 Baud Leakage < 20 CFM Per Sq. Ft. @ 4” SP

35F to 125F

Inputs:

Air Flow Sensor

Room Temperature Sensor

Setpoint Adjustment OE510-06 (6”) 23.00 5.88 9.88

Actuator Position Feedback OE510-08 (8”) 23.00 7.88 12.13

Communication Connectors: Terminals In & Out

Outputs:

Expansion Port for Auxiliary Relay Board OE510-14 (14”) 23.00 13.88 18.50

Actuator Port for Connection to Damper Actuator OE510-16 (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

Damper Bearings Stainless Steel

Insulation ½” Foil Faced Fiberglass

Dimensions:

Air Damper Model “A” “B” “C”

OE510-10 (10”) 23.00 9.88 14.31

OE510-12 (12”) 23.00 11.88 16.43

Form: Orion-OE521XX-T-RndDmpr-Sub-01G Page 1 of 2

Page 15

OE521-XX-T Round P.I. Zone Damper

Assembly W/ Terminal Connectors

Zone Damper Sizing

Use a load program to determine the peak

load for each zone. These calculations will be

used to select Zone Damper sizes.

The Orion Systems utilize a typical low

pressure duct design. To reduce noise

problems, duct pressures should not exceed

1” W.C.

Primary trunk ducts used with Orion systems

should not be “undersized”. This is especially

true of “pressure dependent” systems. With

larger trunk ducts, it is easier to assure

relatively constant pressure to each Zone

Damper. Runs should be as short as

possible, and the trunk duct system kept as

symmetrical as possible to facilitate system

balancing. Wherever possible, run the trunk

ducts above corridors and locate the Zone

Dampers above corridors to reduce the noise

in the space and facilitate service of the

valves. Trunk ducts should be sized for no

more than 0.1” W.C. drop per 100 ft. of duct,

and a maximum duct velocity of 2000 FPM.

Zone Damper Selection Data

Zone Damper Round Duct Size

(Area Ft

2

)

6”

(0.196)

Using the maximum acceptable velocity for a branch duct

(typically 1000-1500 FPM for minimal noise), find the smallest

Zone Damper that will deliver the required CFM as determined

by the load program. Locate the branch velocity used in the

duct design program in the left hand column of the Zone

Damper Selection Data table. Move across the table and find

the Zone Damper, which will provide the acceptable CFM to

meet the zone airflow requirements.

Note: Compare the Zone Damper size selected against

the duct size to determine if the next size up or

down will provide acceptable performance without

requiring a transition fitting.

Pressure Independent Zone Dampers may not be slaved

together with Slaved-Zone Damper Assemblies. If more than

one damper is required for a zone, all dampers must be

selected as pressure dependent. See the Pressure Dependent

Zone Damper submittal sheet and Slaved-Zone Damper

submittal sheets for selection of master/slave damper

configurations.

OE521-XX-T Round Pressure Independent

Zone Damper Assembly W/ Terminal Connectors

8”

(0.349)

10”

(0.545)

12”

(0.785)

14”

(1.069)

16”

(1.396)

CFM @ 1” Velocity Pressure

(Air Flow Probe “K” Factor)

Velocity Through VAV/Zone Damper

FPM

500

750

1000

1250

1500

1750

2000

WattMaster reserves the right to change specifications without notice

448 904 1436 1891 3015 3839

Airflow Through VAV/Zone Damper - CFM

(P

inches W.C. w/ Damper Full Open)

S

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

535

(< 0.01)

802

(< 0.01)

1069

(< 0.01)

1336

(0.015)

1604

0.020)

1871

(0.030)

2138

(0.040)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

Form: Orion-OE521XX-T-RndDmpr-Sub-01G Page 2 of 2

Page 16

Description

The OE522-XX Round Bypass Damper

Assembly, consists of a round air damper

with a bypass actuator and bypass wiring

interface card mounted in a control

enclosure.

The Bypass Damper controls duct static

pressure to insure proper system airflow.

The Bypass Damper is controlled by the

Orion HVAC Unit Controller. The Unit

Controller modulates the Bypass Damper in

response to the duct static pressure, based

on a signal received from a static pressure

sensor located in the main system ductwork.

All dampers are tested for performance in

accordance with AMCA 500D standards.

OE522-XX Round Bypass

Damper Assembly

Mounting

The Round Bypass Damper Assembly

should be mounted according to standard

duct installation practices with airflow

direction as shown in the illustration above.

After installation of the Bypass Damper in

the ductwork, insulation should be applied

around any remaining un-insulated surface

on the damper inlet and outlet. The Bypass Damper should be mounted so the control enclosure is positioned to

the left or right side of the ductwork with the control enclosure in a vertical plane. Do not mount the Bypass

Damper Assembly with the control enclosure on the top or bottom of the ductwork. Adequate clearance should

be maintained between the control panel and any obstruction to allow for removal of the control panel cover and

access to the controls.

Technical Data OE522-XX Round Bypass Damper Assembly

Actuator Air Damper Construction:

Supply Power 24 Volt AC Damper Body 20 Ga. Galv. Steel

Power Consumption 3.4 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

Operating Humidity 90% RH Non-Condensing Damper Seal EPDM Rubber Gasket

Inputs: Dimensions:

Actuator Position Feedback

OE522-10 (10”) 23.00 9.88 14.31

OE522-12 (12”) 23.00 11.88 16.43

OE522-14 (14”) 23.00 13.88 18.50

OE522-16 (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

35°F to 125°F

Damper Bearings Stainless Steel

Leakage < 20 CFM Per Sq. Ft. @ 4” SP

Insulation ½” Foil Faced Fiberglass

Air Damper Model “A” “B” “C”

Form: Orion-OE522-RDBypDmpr-Sub-01F Page 1 of 2

Page 17

OE522-XX Round Bypass

Damper Assembly

Bypass Damper Sizing

Because the zones in an Orion System are

controlled using variable air volume, it is

unlikely that all zones will be at design load

at the same time. This zoning allows for

load diversity to be taken into account when

sizing the central HVAC unit. This typically

will provide better comfort with a smaller

HVAC unit than with the use of a constant

volume system. Use a load program to

determine the individual zone loads.

Because of zone diversity the HVAC unit

should be sized for the correct

instantaneous peak load, not the sum of the

peak loads as would be the case when

sizing a normal constant volume unit

system. The Bypass Damper should be

sized to provide for the maximum amount

of air to be bypassed in the system. This is

typically 60 to 70% of the HVAC units rated

capacity. These calculations will be used in

selecting the appropriate Bypass Damper

Size(s).

The Orion Systems utilize a typical low

pressure duct design. To reduce noise

problems, duct pressures should not

exceed 1” W.C..

Using the maximum acceptable velocity for a bypass duct

(typically 1750-2250 FPM for minimal noise), find the smallest

damper that will deliver the required CFM as determined by the

load program.

When determining the bypass duct size, be sure to take into

account any transition fittings and their associated pressure

drops. Locate the bypass duct velocity used in the duct design

program in the left hand column of the Bypass Damper Selection

Data table. Move across the table and find the Bypass Damper

size which will provide the acceptable CFM to meet the bypass

airflow requirements.

Note: Compare the Bypass Air Damper size selected

against the bypass duct size to determine if the next

size up or down will provide acceptable performance

without requiring a transition fitting.

Up to a maximum of two additional Bypass Dampers may be

slaved together with the main Bypass Damper for large bypass

airflow requirements. This design should be reserved only for

situations when it is not practical to use a single large Bypass

Damper. The slaved valves should all be of the same size for

proper control. Divide the total CFM by two or three depending on

how many bypass and slave dampers you will be using and size

accordingly.

Bypass Damper Selection Data OE522-XX Round Bypass Damper Assembly

Bypass Air Damper Round Duct Size

(Area Ft

Velocity Through Bypass Air Damper

2

)

FPM

750

1000

1250

1500

1750

2000

2250

WattMaster reserves the right to change specifications without notice

10”

(0.545)

Airflow Through Bypass Air Damper - CFM

(ΔP

inches W.C. w/ Air Damper Full Open)

S

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

1226

(0.07)

12”

(0.785)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

1766

(0.05)

14”

(1.069)

802

(< 0.01)

1069

(< 0.01)

1336

(0.015)

1604

0.020)

1871

(0.030)

2138

(0.040)

2405

(0.05)

16”

(1.396)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

3141

(0.04)

Form: Orion-OE522-RDBypDmpr-Sub-01F Page 2 of 2

Page 18

p

y

OE523-XX Round Slaved Zone

Dam

Description

The OE523-XX Round Slaved Zone

Damper Assembly, consists of a round air

damper, actuator, (1) slave wiring interface

card mounted in the enclosure and also

includes (1) slave wiring interface card kit

shipped loose for field mounting to the

master zone damper assembly. This kit

contains a slave wiring interface card and a

cable.

The Round Slaved Zone Damper

Assembly is used in systems when it is not

possible or practical to use a single large

Zone Damper to satisfy the zone's CFM

requirements.

A total of two Slaved Zone Dampers may

be used in conjunction with a master Zone

Damper. The Slave Damper(s) are wired in

parallel with the master Zone Damper and

track the movement of the master Zone

Damper. Connection of the master Zone

Damper requires a slave wiring interface

kit, which is shipped loose for field

mounting to the master Zone Damper and

is supplied with each Slaved Zone

Damper. The kit connects the Zone

controller on the master to the master

actuator and provides wiring terminals for

wiring to the Slaved Zone Dampers. Only (1) of these kits is required for each master/slave installation. All

dampers are tested for performance in accordance with AMCA 500D standards.

er Assembl

Mounting

The Slaved Zone Damper Assembly should be mounted according to standard duct installation practices with air

flow direction as shown in the illustration above. After installation of the Air Damper in the ductwork, insulation

should be applied around any remaining un-insulated surface on the air valve inlet and outlet. The Air Damper

should be mounted so the control enclosure is positioned to the left or right side of the ductwork with the control

enclosure in a vertical plane. Do not mount the Air Damper Assembly with the control enclosure on the top or

bottom of the ductwork. Adequate clearance should be maintained between the control panel and any

obstruction to allow for removal of the control panel cover and access to the controls.

Technical Data

Actuator: Air Damper Construction:

Supply Power 24 Volt AC Damper Body 20 Ga. Galv. Steel

Power Consumption 3.4 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

Operating Humidity 90% RH Non-Condensing Damper Seal EPDM Rubber Gasket

Position Feedback (Bypass) 10Kohm, 1 W Potentiometer Leakage < 20 CFM Per Sq. Ft. @ 4” SP

Dimensions:

Air Damper Model “A” “B” “C” Air Damper Model “A” “B” “C”

OE513-06 (6”) 23.00 5.88 9.88 OE513-12 (12”) 23.00 11.88 16.43

OE513-08 (8”) 23.00 7.88 12.13 OE513-14 (14”) 23.00 13.88 18.50

OE513-10 (10”) 23.00 9.88 14.31 OE513-16 (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

OE523-XX Round Slaved

Zone Damper Assembly

35°F to 125°F

Damper Bearings Stainless Steel

Insulation ½” Foil Faced Fiberglass

Form: Orion-OE523-RdSlaveDmpr-Sub-01F Page 1 of 2

Page 19

OE523-XX Round Slaved Zone

Damper Assembly

Slaved Zone Damper Sizing

Use a load program to determine the peak load for

each zone. These calculations will be used in

selecting the appropriate Zone and Slaved Zone

Damper sizes. Only pressure dependent Zone

Dampers may be slaved.

The Orion Systems utilize a typical low pressure

duct design. To reduce noise problems, duct

pressures should not exceed 1” W.C.

Primary trunk ducts used with Orion systems

should not be “undersized”. With larger trunk

ducts, it is easier to assure relatively constant

pressure to each Zone Damper. Runs should be

air flow requirements. This design should be reserved only

for situations when it is not practical to use a single large

Zone Air Damper.

It is recommended that the Slaved Zone Damper(s) should

be of the same size as the master Zone Damper. This

insures that adequate air flow and minimum noise will

occur at all damper positions.

Divide the total zone CFM required by the total number of

air valves to be used.

Using the maximum acceptable velocity for a branch duct

(typically 1000-1500 FPM for minimal noise), go to the Air

Damper Selection Data Chart below and find the quantity

and size of Air Dampers that will deliver the required CFM

as determined by the load program

as short as possible, and the trunk duct system

kept as symmetrical as possible to facilitate

system balancing. Wherever possible, run the

trunk ducts above corridors and locate the master

Zone and Slaved Zone Dampers above corridors

to reduce the noise in the space and facilitate

service of the valves. Trunk ducts should be sized

Note: Compare the Zone and Slaved Zone Damper

sizes selected against the branch duct sizes to

determine if the next size up or down will

provide acceptable performance without

requiring a transition fitting.

for no more than 0.1” W.C. drop per 100 ft. of

duct, and a maximum duct velocity of 2000 FPM.

Up to a maximum of two additional Slaved Zone

Dampers may be connected together with the

main Zone Damper(s) for large zone

Order one OE520-XX Round Pressure Dependent Zone

Damper of the size selected previously. Order one or two

OE523-XX Round Slaved Zone Dampers as required, of

the same size as the Zone Damper just selected. The

Round Slaved Zone Dampers will track and maintain the

same damper position as the master Zone Damper.

Slaved Damper Selection Data OE523-XX Slaved Zone Damper Assembly

(Pressure Dependent Only)

Zone Air Damper Round Duct Size

(Area Ft

Velocity Through Zone Air Damper

FPM

500

750

1000

1250

1500

1750

2000

2

)

WattMaster reserves the right to change specifications without notice

6”

(0.196)

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

8”

(0.349)

10”

(0.545)

12”

(0.785)

Airflow Through Zone Air Damper – CFM

(ΔP

inches W.C. w/ Air Damper Full Open)

S

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

14”

(1.069)

535

(< 0.01)

802

(< 0.01)

1069

(< 0.01)

1336

(0.015)

1604

0.020)

1871

(0.030)

2138

(0.040)

16”

(1.396)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

Form: Orion-OE523-RdSlaveDmpr-Sub-01F Page 2 of 2

Page 20

OE524-XX-PD Round Pressure

Dependent Zone Damper

Description

The OE524-XX-PD Round Pressure Dependent

Zone Damper consists of a Round Air Damper with

a control mounting plate on the side of the damper

housing. This plate is designed for mounting of the

OE742-31-VAVZ and OE742-32-VAVZ VAVZ

Pressure Dependent Zone Controller Actuator

Packages which are field mounted on the OE524XX-PD Round Pressure Dependent Zone Damper.

The Round Air Damper is constructed of 20 gauge

galvanized steel with a 14 gauge galvanized steel

blade. The damper has a full circumference EPDM

rubber gasket seal providing a Class 2 leakage

rating. The ½” damper shaft rotates in a stainless

steel bushing. A slot is cut into the end of the

damper shaft for damper position indication.

All Round Dampers are tested for performance in

accordance with AMCA 500-D standards.

When selecting Round Dampers for use as a

Pressure Dependent Zone Dampers, select from

the Zone Damper Airflow Chart and follow the

Zone Damper Guidelines on page 2 of this document.

Mounting

The Pressure Dependent Round Zone Damper assembly should be mounted according to standard duct installation practices with airflow direction as shown in the illustration above. After installation of the Round Zone Damper in the ductwork, insulation should be applied around any remaining uninsulated surface on the air valve inlet

and outlet. The Round Zone Damper should be mounted so the control enclosure is positioned to the left or right

side of the ductwork with the control enclosure in a vertical plane. Do not mount the Round Zone Damper Assembly with the control enclosure on the top or bottom of the ductwork. Adequate clearance should be maintained between the control panel and any obstruction to allow for removal of the control panel cover and access

to the controls.

Technical Data

OE524-XX-PD Pressure Dependent Round Zone

Damper

Air Damper Construction: Dimensions:

Damper Body 20 Ga. Galv. Steel

Damper Blade Round -14 Ga. Galv. Steel OE524-06-PD (6”) 23.00 5.88 9.88

Damper Bushings Stainless Steel OE524-08-PD (8”) 23.00 7.88 12.13

Damper Seal EPDM Rubber Gasket OE524-10-PD (10”) 23.00 9.88 14.31

Leakage < 20 CFM Per Sq. Ft. @ 4” SP OE524-12-PD (12”) 23.00 11.88 16.43

Insulation ½” Foil Faced Fiberglass OE524-14-PD (14”) 23.00 13.88 18.50

OE524-16-PD (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

Form: Orion-OE524-XX-PD-RndPDDmpr-Sub-01A Page 1 of 2

Air Damper Model “A” “B” “C”

One Year Warranty

Page 21

Round Pressure Dependent

Zone Damper Sizing

Use a load program to determine the peak load

for each zone. These calculations will be used

to select Round Pressure Dependent Zone

Damper sizes.

The Orion Systems utilize a typical low pressure duct design. To reduce noise problems,

pressures should not exceed 1” W.C. in the

duct.

Primary trunk ducts used with Orion systems

should not be “undersized”. This is especially

true of “pressure dependent” systems. With

larger trunk ducts, it is easier to assure relatively constant pressure to each Round Zone

Damper. Runs should be as short as possible,

and the trunk duct system kept as symmetrical

as possible to facilitate system balancing.

Wherever possible, run the trunk ducts above

corridors and locate the Round Zone Dampers

above corridors to reduce the noise in the

space and facilitate service of the valves. Trunk

ducts should be sized for no more than 0.1”

W.C. drop per 100 ft. of duct, and a maximum

duct velocity of 2000 FPM.

OE524-XX-PD Round Pressure

Dependent Zone Damper

Using the maximum acceptable velocity for a branch duct (typically 1000-1500 FPM for minimal noise), find the smallest

Round Zone Damper that will deliver the required CFM as determined by the load program. Locate the branch velocity used

in the duct design program in the left hand column of the Round

Zone Damper Selection Data table. Move across the table and

find the Round Zone Damper, which will provide the acceptable

CFM to meet the zone airflow requirements.

Note: Compare the Round Zone Damper size selected

against the duct size to determine if the next size

up or down will provide acceptable performance

without requiring a transition fitting.

Up to a maximum of two Slaved Round Zone Dampers may be

slaved together with the main Round Zone Damper for large

zones. This design should be reserved only for situations when

it is not practical to use a single Round Zone Damper. See the

Round Slaved Zone Damper specification sheet for information

regarding application and selection of Round Slaved Zone

Dampers.

Round Zone Damper Selection Data

VAV/Zone Damper Round Duct Size

(Area Ft

Velocity Through VAV/Zone Damper

FPM

500

750

1000

1250

1500

1750

2000

2

)

WattMaster reserves the right to change specifications without notice

6”

(0.196)

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

OE524-XX-PD Pressure Dependent

8”

(0.349)

10”

(0.545)

12”

(0.785)

Airflow Through VAV/Zone Damper - CFM

(P

inches W.C. w/ Air Damper Full Open)

S

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

Round Zone Damper

14”

(1.069)

535

(< 0.01)

802

(< 0.01)

1069

(< 0.01)

1336

(0.015)

1604

0.020)

1871

(0.030)

2138

(0.040)

16”

(1.396)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

Form: Orion-OE524-XX-PD-RndPDDmpr-Sub-01A Page 2 of 2

Page 22

OE524-XX-PI Round Pressure

Independent Zone Damper

Description

The OE524 Round Pressure Independent Zone

Damper consists of a Round Air Damper with a

control mounting plate on the side of the damper

housing. This plate is designed for mounting of

the OE744-31-VAVZ and OE744-32-VAVZ VAVZ

Pressure Independent Zone Controller Actuator

Packages which are field mounted on the OE524

Round Pressure Independent Zone Damper. The

Round Pressure Independent Zone Damper also

has a patented Tri Averaging Flow Sensor

in to provide accurate airflow measurement when

connected to the flow sensor provided with the

Pressure Independent Zone Controller Actuator

Packages.

The Round Air Damper is constructed of 20

gauge galvanized steel with a 14 gauge

galvanized steel blade. The damper has a full

circumference EPDM rubber gasket seal

providing a Class 2 leakage rating. The ½”

damper shaft rotates in a stainless steel

bushing. A slot is cut into the end of the damper

shaft for damper position indication.

All Round Dampers are tested for performance in

accordance with AMCA 500-D standards.

When selecting Round Dampers for use as a Pressure Independent Zone Dampers, select from the Zone

Damper Airflow Chart and follow the Zone Damper Guidelines on page 2 of this document.

® built

Mounting

The Pressure Independent Round Zone Damper assembly should be mounted according to standard duct installation practices with airflow direction as shown in the illustration above. After installation of the Round Zone

Damper in the ductwork, insulation should be applied around any remaining uninsulated surface on the air valve

inlet and outlet. The Round Zone Damper should be mounted so the control enclosure is positioned to the left or

right side of the ductwork with the control enclosure in a vertical plane. Do not mount the Round Zone Damper

Assembly with the control enclosure on the top or bottom of the ductwork. Adequate clearance should be maintained between the control panel and any obstruction to allow for removal of the control panel cover and access

to the controls.

Technical Data

Air Damper Construction: Dimensions:

Damper Body 20 Ga. Galv. Steel

Damper Blade Round -14 Ga. Galv. Steel OE524-06-PI (6”) 23.00 5.88 9.88

Damper Bushings Stainless Steel OE524-08-PI (8”) 23.00 7.88 12.13

Damper Seal EPDM Rubber Gasket OE524-10-PI (10”) 23.00 9.88 14.31

Leakage < 20 CFM Per Sq. Ft. @ 4” SP OE524-12-PI (12”) 23.00 11.88 16.43

Insulation ½” Foil Faced Fiberglass OE524-14-PI (14”) 23.00 13.88 18.50

OE524-16-PI (16”) 23.00 15.88 20.56

WattMaster reserves the right to change specifications without notice

OE524-XX-PI Pressure Independent Round Zone

Damper

Air Damper Model “A” “B” “C”

One Year Warranty

Form: Orion-OE524-XX-PI-RndPIDmpr-Sub-01A Page 1 of 2

Page 23

Round Pressure Independent

Zone Damper Sizing

Use a load program to determine the peak load

for each zone. These calculations will be used

in selecting the appropriate zone damper sizes.

The Orion Systems utilize a typical low pressure duct design. To reduce noise problems,

pressures should not exceed 1” W.C. in the

duct.

Primary trunk ducts used with Orion systems

should not be “undersized”. This is especially

true of “pressure dependent” systems. With

pressure independent systems this is not as

critical. With larger trunk ducts, it is easier to

assure relatively constant pressure to each

Round Zone Damper. Runs should be as short

as possible, and the trunk duct system kept as

symmetrical as possible to facilitate system

balancing. Wherever possible, run the trunk

ducts above corridors and locate the Round

Zone Dampers above corridors to reduce the

noise in the space and facilitate service of the

valves. Trunk ducts should be sized for no

more than 0.1” W.C. drop per 100 ft. of duct,

and a maximum duct velocity of 2000 FPM.

OE524-XX-PI Round Pressure

Independent Zone Damper

With pressure independent systems it is possible to exceed this

rule by up to 50%. However it is advised that unless you are

experienced with VAV duct design the 2000 FPM rule should

be used. Using the maximum acceptable velocity for a branch

duct (typically 1000-1500 FPM for minimal noise), find the

smallest damper that will deliver the required CFM as determined by the load program.

Locate the branch velocity used in the duct design program in

the left hand column of the Round Zone Damper Selection Data

table. Move across the table and find the damper, which will

provide the acceptable CFM to meet the zone airflow requirements.

Note: Compare the Round Zone Damper size selected

against the duct size to determine if the next size

up or down will provide acceptable performance

without requiring a transition fitting.

Pressure Independent Round Zone Dampers may not be

slaved together with Round Slaved Zone Damper Assemblies.

If more than one damper is required for a zone, all dampers

must be selected as pressure dependent. See the Round Pressure Dependent Zone Damper submittal sheet and Round

Slaved Zone Damper submittal sheets for selection of master/slave damper configurations.

Round Zone Damper Selection Data

VAV/Zone Damper Round Duct Size

(Area Ft

CFM @ 1” Velocity Pressure

(Air Flow Probe “K” Factor)

Velocity Through VAV/Zone Damper

FPM

500

750

1000

1250

1500

1750

2000

2

)

WattMaster reserves the right to change specifications without notice

6”

(0.196)

448 904 1436 1891 3015 3839

98

(< 0.01)

147

(0.01)

196

(0.015)

245

(0.025)

294

(0.035)

343

(0.045)

392

(0.065)

OE524-XX-PI Pressure Independent

8”

(0.349)

10”

(0.545)

12”

(0.785)

Airflow Through VAV/Zone Damper - CFM

(P

inches W.C. w/ Air Damper Full Open)

S

175

(< 0.01)

262

(0.01)

349

(0.015)

436

(0.02)

523

(0.035)

611

(0.035)

698

(0.043)

273

(< 0.01)

409

(0.01)

545

(0.01)

681

(0.015)

818

(0.022)

954

(0.034)

1090

(0.040)

393

(< 0.01)

589

(< 0.01)

785

(< 0.01)

981

(0.015)

1178

(0.020)

1374

(0.030)

1570

(0.040)

Round Zone Damper

14”

(1.069)

535

(< 0.01)

802

(< 0.01)

1069

(< 0.01)

1336

(0.015)

1604

0.020)

1871

(0.030)

2138

(0.040)

16”

(1.396)

698

(< 0.01)

1047

(< 0.01)

1396

(< 0.01)

1745

(0.015)

2094

(0.020)

2443

(0.025)

2792

(0.030)

Form: Orion-OE524-XX-PI-RndPIDmpr-Sub-01A Page 2 of 2

Page 24

Description

r

The OE519 Rectangular Damper is used

in applications where rectangular duct is

specified or required because of space

limitations or job requirem ents. The Rectangular Damper utilizes opposed blades

of airfoil design for im proved air flow control. The Rectangular Damper frame is

made of .080 thick extruded aluminum.

The blades are also made of extruded

aluminum. Blade pins are 7/16” hexagon

shaped aluminum f ixed to a Celcon inner

bearing rotating within a polycarbonate

outer bearing inserted in the damper

frame. The Damper linkage is mechanically assembled and located in the

damper frame. The linkage components

are constructed of aluminum, zinc and

nickel plated steel. Blade gaskets are

made of extruded EPDM mater ial and are

secured within an integral slot on the

blade. Jamb seals are of extruded TPE

material for low leakage through the