Page 1

A

A

A

A

A

A

A

A

Description

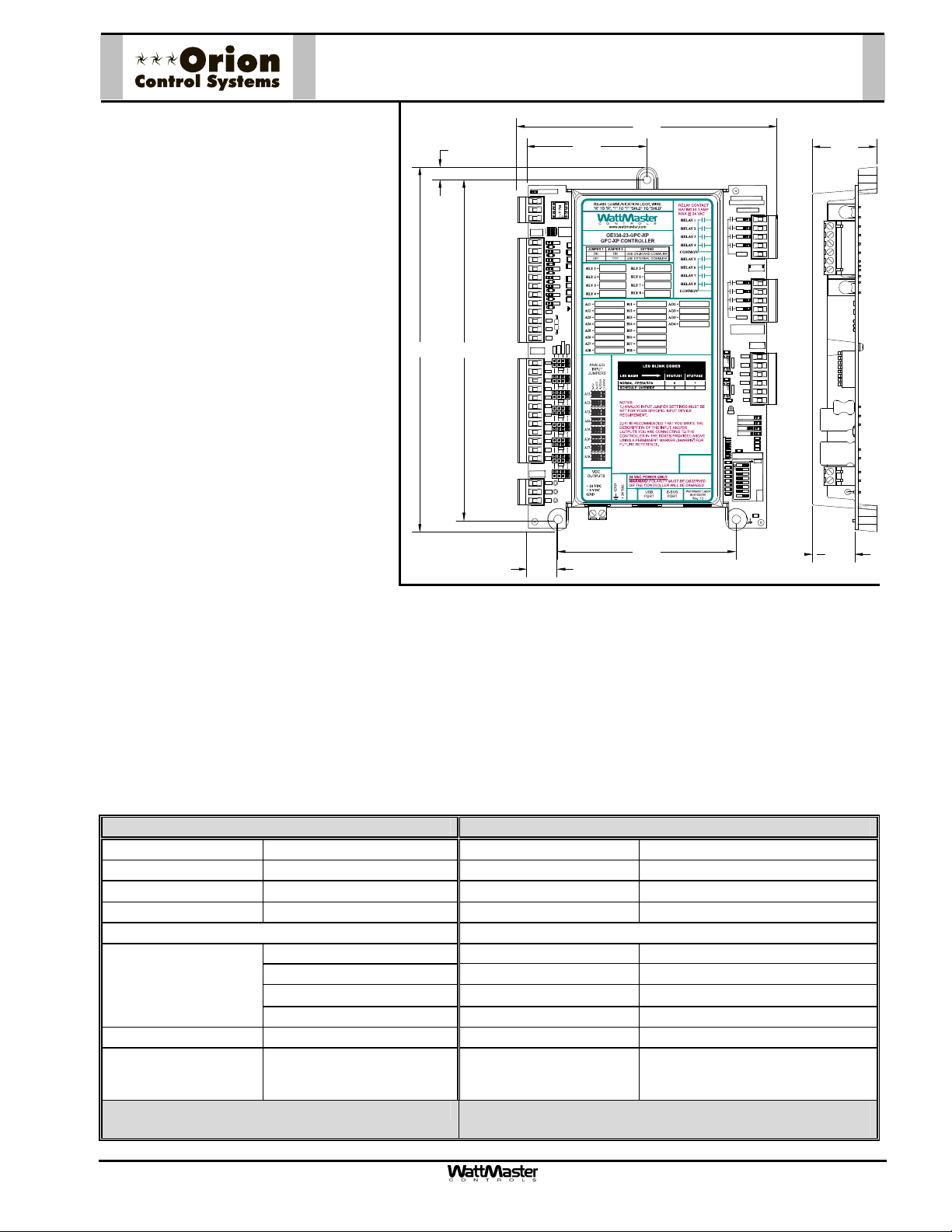

The OE338-23-GPCXP GPC-XP Controller is

used for controlling equipment or processes

0.290.29

that cannot be controlled using a standard

HVAC controller.

The GPC-XP provides the flexibility to control, schedule and/or monitor equipment such

as unit heaters, exhaust fans, motorized

dampers, pumps, and other mechanical

equipment. It can also be used for simple

boiler, chiller, or refrigeration applications as

well as to provide lead/lag start function.

The GPC-XP has an on-board CommLink

that provides for stand-alone programming

and monitoring via a direct USB connection

to a computer running Prism II software. If

used on a networked system that has an external CommLink, this on-board CommLink

would not be used.

The GPC-XP has (8) configurable analog

inputs which will accept signals from thermistor temperature sensors or from 4-20mA, 0-

8.388.38

7.837.83

BINARY

INPUTS

ANALOG

INPUTS

VDC

OUTPUTS

LOOP COMM

TB1

TB3

TB7

TB8

T-

SH

R+

ON BOA

COMMLI

CONNEC

R38

BIN1

300

D6

R41

BIN2

300

D7

R43

300

BIN3

R47

D8

300

BIN4

D9

BIN5

300

D10

300

BIN6

D11

300

BIN7

R61R59R55R51

D12

300

BIN8

D13

COM

CUTTO ISOL

COMFROM GND

COM

COM

TE

COM

4-20mA

THERM

0-10v

0-5v

AI1

AI1

AI2

AI3

AI2

AI4

AI5

AI3

AI6

AI7

AI4

AI8

GND

AI5

GND

AI6

GND

GND

I7

AI8

+24V

+5V

GND

5VDC, or 0-10VDC transmitters. The inputs

are set for the desired scaling by means of a

jumper bar. Custom formulas created by

available math functions and operators can

0.700.70

be used in conjunction with the analog inputs

to create a calculated value to be used and displayed for a specific analog input. An additional modular input is available for

WattMaster communicating sensors. The GPC-XP has (8) wet contact binary inputs that can be configured for either normally

open or normally closed operation. Also available are (8) relay outputs for on/off control and (4) analog outputs (0-10VDC) for

modulating control. Highest/lowest/average of the analog input values can be used in the GPC-XP logic or broadcast to other

controllers on the control system loop. There are (8) separate two events per day schedules which can be assigned to any

input or output for operational control or for alarm recognition based on time of day. These schedules can also be configured

to broadcast to other WattMaster

controllers on the control system loop.

OE338-23-GPC-XP

GPC-XP Controller

5.985.98

2.752.75

YS102432 REV 3

WATTMASTER CONTROLS

MADE IN USA

RLY1

RLY2

RLY3

RLY4

COMMON

TB2

RELAY

OUTPUTS

TB4

RLY1

RLY2

RLY3

RLY4

COMMON

SERIAL #

ANALOG

OUTPUTS

1002

R74

U17

OUT1

AOUT1-2

OUT2

.1uF

OUT3

C36

1002

R97

OUT4

U19

OUT3-4

GND

GND

.1uF

C46

TB6

GND

STATUS1

STATUS2

EBUS

POWER

1002

R21

1002

R109

1002

R16

1002

R14

.1uF

C21

ADDRESS

ADD

1002

1

1002

2

1002

4

1002

8

1002

16

1002

32

1002

LOOP

B

1

1002

UD

2

SW1

C14

.01uF

4.104.10

1.49

0.980.98

Mounting

The GPC-XP is provided with an integral plastic enclosure which provides mounting points for mounting inside of a

control enclosure. It is recommended that the GPC-XP be mounted in a control enclosure in the building equipment

room. An optional factory control enclosure for the GPC-XP is also available.

Technical Data OE338-23-GPCXP GPC-XP Controller

Power 24 Volt AC Weight 1 lb.

Power Consumption 8 VA Maximum Network Connection RS-485 – 9600 or 57,600 Baud

Operating Temp

-30F to 150F

Protocol HSI Open Protocol Token Passing

Operating Humidity 90% RH Non-Condensing Communications E-BUS

Inputs: Outputs:

Types of Allowed

Inputs

Type III-10K Ohm Sensors Total Relay Qty. On Board 8

4-20mA Relay Power Rating (2 Amp @ 24 VAC)

0-5VDC & 0-10VDC Analog Output Qty. 4

N.O. or N.C. Contact Analog Output Signal 0-10 VDC

Total Inputs Available 16 Configurable Lead Lag Scheduling (1) Output can be Configured

Additional

1 (Modular)

Schedules Available (8) 2 Events per day

Communicating

Sensor Input

Three Year Warranty WattMaster reserves the right to

change specifications without notice

Form: ORION-OE338-23-GPCXP-Controller-01B.doc Page 1 of 1

Page 2

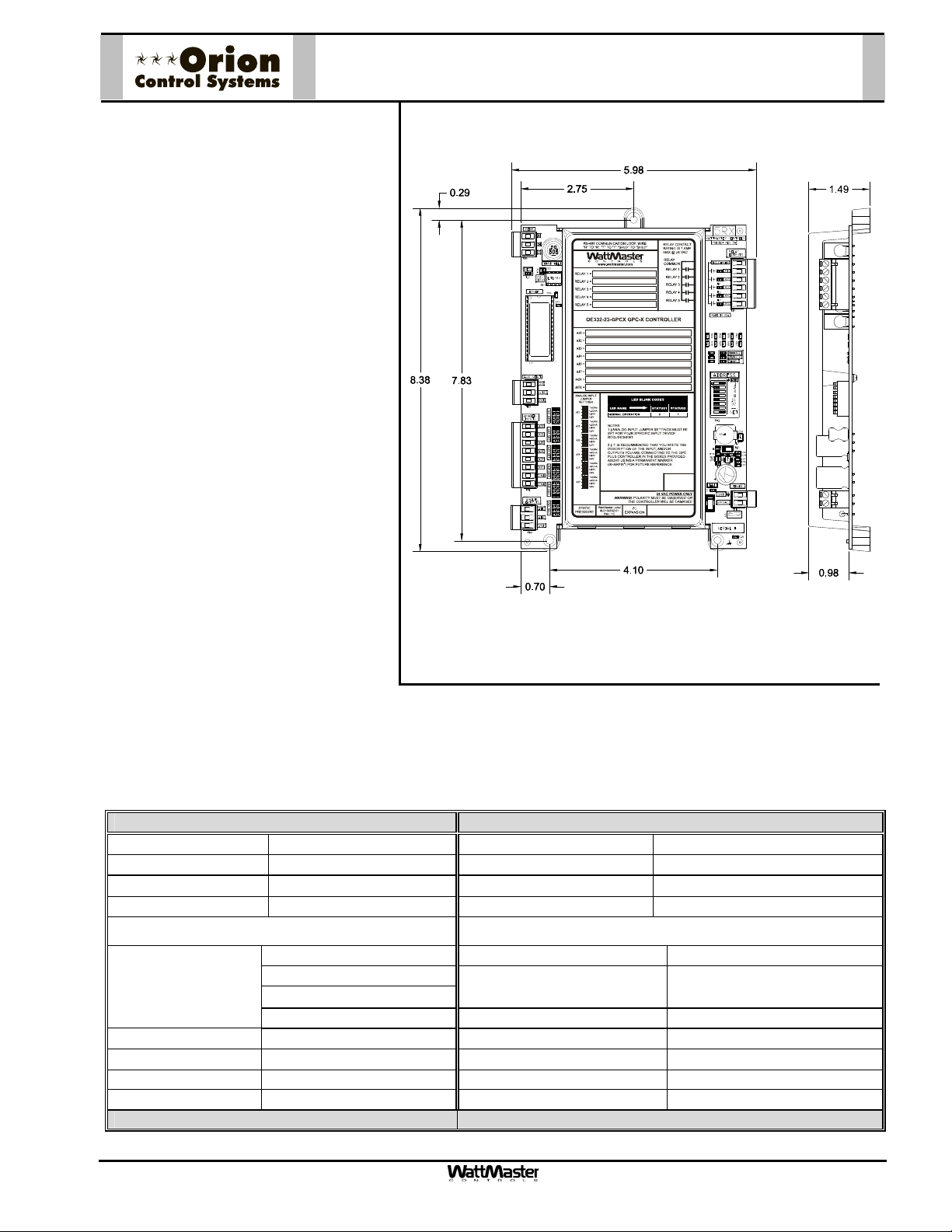

Description

The OE332-23-GPCX GPC-X Controller

is used for controlling equipment or

processes that cannot be controlled using a standard HVAC controller. The

Prism computer front end software is

used to interface with the GPC-X controller functions. The GPC-X Controller provides the flexibility to control, schedule

and/or monitor equipment such as unit

heaters, exhaust fans, motorized louvers, and other mechanical equipment.

The GPC-X has (6) configurable inputs

which will accept signals from thermistor

temperature sensors, 4-20mA or 05VDC or 0-10VDC transmitters or dry

contact closures. The inputs are set for

the desired input by means of a jumper

bar. An additional modular input is provided for connection of an OE271 static

pressure sensor. The GPC-X has (5)

relay outputs for on/off control and (2)

analog outputs. With the addition of the

OE358-23-12R, 12 Relay Expansion

Module, (4) additional relay outputs (of

the 12 total relays on the module) are

available for use with the GPC-X, providing for a maximum of (9) usable relay

outputs total. The GPC-X also has (5)

separate 2 event per day schedules,

each with its own optimal start functions

built in. In addition the GPC-X provides

lead/lag start capabilities.

OE332-23-GPCX

GPC-X Controller

Mounting

The GPC-X is provided with an integral plastic enclosure which provides mounting points for mounting inside of a

control enclosure. It is recommended that the GPC-X be mounted in a control enclosure in the building equipment room. An optional factory control enclosure for the GPC-X is also available.

Technical Data OE332-23-GPCX GPC-X Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

10°F to 149°F

Inputs: Outputs:

Types of Allowed

Inputs

Total Inputs Available 7 Analog Output Qty. 2

Static Pressure Inputs 1 (Modular ) Analog Output Signal 0-10 VDC

Configurable Inputs 6 Optimal Start Schedules (5) Total - (1) for Each Schedule

Schedules Available (5) 2 Event per day Lead Lag Scheduling (1) Output can be Configured

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: ORION-OE332-23-GPCX-Controller-01A.doc Page 1 of 1

Type III-10kohm sensors Total Relay Qty. On Board 5

4-20ma

0-5VDC & 0-10VDC

N.O. or N.C. Binary Contact Relay Power Rating (2 Amp @ 24 VAC)

Protocol HSI Open Protocol Token Passing

Total Relay Qty. Available With

Optional Expansion Board

9

Page 3

Description

The OE332-23-GBDX General Broadcast Device

Controller provides a method of connecting up to

a maximum of (6) Thermistor 10 K Ohm Room

Temperature Sensors (OE210, OE211, OE212,

and OE213) so that they can then be averaged

and globally broadcast to one VCM-X controller

on a local loop. The GBD-X also includes the

ability to read up to (6) CO

(OE255 and OE256) and/or 0-5VDC (by others)— and average or find the highest reading

and then broadcast the reading to one VCM-X

controller on a local loop. It also provides a 0-10

VDC proportional voltage output signal on Analog Output #1 of the GBD-X. The GBD-X calculates and varies this signal depending on the

level of CO

justable minimum setting to an adjustable maximum level. Also, if desired, Analog Output #2

can provide a 10.0 VDC fixed output signal

whenever the CO

point. In addition, Relay Output #1 activates

whenever the CO

point and deactivates when it falls 5 PPM below

the minimum setpoint. Relay Output #2 activates

whenever the CO

setpoint and deactivates when it falls 5 PPM

below the maximum setpoint.

When more than (6) CO

sors are to be used, a second GBD-X controller

can be connected to the VCM-X and would then

allow the use of from (7) to (12) Room Temperature Sensors or CO

either temperature averaging or CO

(2) GBD-X controllers, one configured for CO

to a combined (16) additional GBD-X controllers can be daisy-chained together for a total of (18) GBD-X controllers on one

loop. Either a CommLink or MiniLink PD must always be installed on the controls system when using the GBD-X Controller

due to its broadcast requirements. A personal computer with Prism software installed or the System Manager Touch Screen is

also required to program the GBD-X controller.

in the space as it rises from an ad-

2

is above the minimum set-

2

rises above the minimum set-

2

rises above the maximum

2

Sensors—4-20 ma

2

or Temperature Sen-

2

averaging, but not both on the same GBD-X controller. When both are required at least

2

Sensor inputs. Each GBD-X controller can be used for

2

control and the other configured for Temperature averaging must be used. Up

2

OE332-23-GBDX

GBD-X Controller

Mounting

The GBD-X is provided with an integral plastic enclosure which provides mounting points for mounting inside of a control enclosure. It is recommended that the GBD-X be mounted in a control enclosure in the building equipment room.

Technical Data OE332-23-GBDX GBD-X Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

10F to 149F

Protocol HSI Open Protocol Token Passing

Inputs Available Outputs Available:

Types and Quantity of

User Selectable

Inputs (one of the 3

options at right)

Three Year Warranty WattMaster reserves the right to change specifications without noti ce

Form: ORION-OE332-23-GBDX-Controller-01B.doc Page 1 of 1

Type III-10kohm input (6) AO1 Output 0-10 VDC Variable Signal

4-20ma input (6) AO2 Output 10 VDC Fixed Signal

0-5 VDC (6) R1 Output Contact Closure

R2 Output Contact Closure

Page 4

Description

The OE268 Over-voltage Module is designed to protect against higher than normal

incoming control voltages that exceed the

normal 24VAC +/-10%. WattMaster recommends the use of the OE268 Over-voltage

Module anytime the measured voltage to the

controller is above 27 VAC. The circuitry

contained on the OE268 Over-voltage Module will safely limit the AC control voltages

being supplied to the devices connected to it.

The OE268 Over-voltage Module is specifically designed to work with and protect the

following products. The groups or items

listed below on each line, require that you

use (1) OE268 Over-voltage Module to

power that group or item.

• VCM Controller and a 2 or 4 Slot Ex-

pansion Base Board

• GPC Plus Controller and a 2 Slot Ex-

pansion Base Board

• GBD Controller

• MODGAS or MODGASII Controller

• MHGRV, MHGRVII or MHGRVIII Con-

troller

OE268 Over-voltage Module

Mounting

The OE268 Over-voltage Module is supplied mounted in a plastic Snap Track channel. Carefully remove the

module from the Snap Track by sliding it out of the Snap Track channel. Mount the Snap Track to the control

panel or enclosure base using one of the supplied sheet metal screws to secure it through the pre-drilled hole in

the Snap Track channel. If desired, the second supplied screw can be used to further secure the Snap Track by

drilling a second hole and using it to fasten the Snap Track. Carefully slide the Over-voltage Module back into the

Snap Track Channel to complete the mounting procedure.

Wiring

Warning: Correct Polarity must be observed on all wiring connections or damage to the controller and/or the

OE268 may result. Wire sizes, types and wiring practices used should conform to all applicable national & local electric code requirements.

• First remove the power from the 24 VAC control transformer supplying the controller’s low voltage power.

• Connect the TB2 “Power Input” terminal labeled “AC IN” to the 24VAC control supply voltage

• Connect the TB2 “Power Input” terminal labeled “GND” to the 24VAC “common or GND”

• Connect the TB1 “Power Output” terminal “+V” to the controller’s “24 VAC” power input terminal

• Connect the TB1 “Power Output” terminal “GND” to the controller’s “GND” power input terminal

• Reconnect the power to the control transformer and observe controller for correct operation.

Technical Data OE268 Over-voltage Module

Input Voltage 22 to 32 VAC Power Consumption Less Than 2 Watts

Output Voltage 30 VDC Nominal Wiring Connections Terminal Blocks

Operating Temperature

One Year Warranty WattMaster reserves the right to change specifications without notice

-30°F to +150° F

Operating Humidity 5-95% RH Non-Condensing

Form: ORION-OE268-OvervoltageModule-1A.doc Page 1 of 1

Page 5

A

Description

The OE331-21-KWH (Kilowatt Hour)

OE331-21-KWH

KWH Module

Module provides the ability to record and

display KW usage and to limit demand

on your control system. Using the Prism

Graphical Computer Front End, a status

screen displays current demand, yesterday’s demand, and the peak demand

values and times for both. Historical logs

from the previous month and the current

month are also available and can be

downloaded for archiving via the PRISM

software interface. A running total of

power consumption is also displayed on

the status screen. This value can be

manually reset at any time allowing the

user to monitor overall power consumption over long periods of time.

Analog Input #2 on the KWH Module

monitors all incoming contact closures

from a KW pulse meter (usually provided

by the utility company) and times them to

generate the current KW Demand. A

user adjustable setpoint is provided to

.20 Dia.

Typ. o f 4

7.3”

TB1

COMM

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

INPUTS

TB3

PRESSURE

SENSOR

C21

T

SHLD

R

CX5

TEST POINT

U7

RV1

VREF ADJ

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

EXPANSION

6.2“

CX1

RN1

1

U1

U5

RS-485

COMM

1

HH

RN3

C1

P1

+VREF

5.11V

EWDOG

R28

RN5

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

C10

PU7

D14

C12

D15

C17

C20

R26

PJ2

U3

CX2

U2

EPROM

RAM

TUC-5R PLUS

(1 MEG)

YS101816 REV. 2

U6

C2

PHILIPS

C3

ADD

DDRESS

1

2

4

8

16

CX10

32

TOKEN

NETWORK

U10

SW1

C11

X2

0-5

0-1

VDC

VDC

JP1

U13

R15

U12

CX14

C14

R19

U14

CX13

U15

C15

R22

R24

R25

CX15

D17

PJ3

T'STAT

6.7”

D1

CX3

CX4

U4

RLY1

RLY2RLY3RLY4RLY5

PAL

1

RN2

CX6

X1

1

RN4

U9

C7

R7

D10

L1

CX12

D12

R13

SC1

D19

D18

C19

C18

VR1

VR2

V1

D2D3D4D5

V2

V3

COM1-3

R1

R2

R3

R4

R5

COM4-5

TB2

V4

V5

U8

NE5090NPB3192

0PS

CX8

R6

C9

R10

D13

9936

R11

U11

MC34064A

C13

C16

TB4

GND

R27

D16

V6

POWER

7824CT

24VAC

M

6.6”

1.1”

define what each pulse represents in

Kilowatts Per Hour. A Demand Factoring

Constant is also provided if it appears that contact bounce may be affecting the operation. The Demand Factor is

simply the number of times to average the current demand reading to create the final Demand Reading. It is normally left at a value of '1' unless a problem is encountered.

Two additional setpoints are provided for the EMS Demand Limiting Broadcast. A Limit Setpoint and a Proportional Reset Range are provided so that the user can adjust when to begin shedding demand and how rapidly

this occurs. Any controllers equipped to "hear" this broadcast begin spreading their heating and cooling setpoints

proportionally until the maximum EMS Adjustment limit is reached. This value is also user adjustable for each

individual controller so that the rate at which demand is shed can be optimally configured for special cases where

not all zones can tolerate a large change in temperature.

Mounting

The KWH Module is provided with an integral backplate for mounting inside of a control enclosure. It is recommended that the KWH Module be mounted in a control enclosure in the building equipment room. An optional

factory control enclosure for the KWH Module is available.

Technical Data OE331-21-KWH

KWH Module

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Protocol HSI Open Protocol Token Passing

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Input Output

Location Type Location Type

AIN2 Dry Contact Closure KW

Pulse Meter (By Others)

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: ORION-OE331-21-KWH-Module-01A.doc Page 1 of 1

RS-485 Communications Loop EMS Demand Limiting

Broadcast

Page 6

OE310-21-LP

Lighting Controller

Description

The OE310-21-LP Lighting Controller

allows an Orion Control System to also

control the building lighting systems

along with the HVAC system. The

Lighting Controller is provided with 7

schedules, each providing 2 start/stop

events per day and 14 start/ stop holiday events. Lighting Controller schedules are designed to operate from a

starting time, a contact closure or a percentage light level as sensed by a (0-

1.5kohm, 0-100%) light level sensor,

thus providing maximum lighting control

flexibility. As an example, a lighting

schedule could be programmed to allow

the lighting circuit to come on at dusk,

based on a light sensor and then turned

off at a given time during the night

based on a time schedule. With the

Lighting Controller, lighting schedules

may be overridden to “on” with a user

provided pushbutton. This pushbutton is

wired to the analog input that corresponds to the schedule number, on the

Lighting Controller. Schedule override

time periods are programmed from the

Orion Prism program. Lighting Controller output relays may be configured for

continuous ON mode during the occupied schedule or a short pulse when the

schedule starts and another short pulse

when the schedule ends. Pulsed output requires an optional Expansion Relay Board and a GE RR-7 or RR-9 or

equivalent lighting relay. The Lighting Controller may be connected to any local loop at any point on the Orion

system. Orion Prism computer front end software is used to interface with the Lighting Panel Controller functions.

The Lighting Controller cannot be programmed through the System Manager operator interface.

Mounting

The Lighting Controller is provided with an integral backplate for mounting inside of a control enclosure. It is recommended that Lighting Controller be mounted in the in a control enclosure in the building equipment room. An

optional factory control enclosure for the Lighting Controller is available.

Technical Data OE310-21-GPC

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 10 VA Maximum Network Connection RS-485

Operating Temp

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Types Allowed Type Provided Continuous Contact Closure or

Total Inputs Available 1 Total Outputs Available 7

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: ORION-OE310-21-LightingController-01A.DOC Page 1 of 1

10°F to 149°F

Protocol HSI Open Protocol Token Passing

Inputs: Outputs:

Pushbutton Override

Connected to Analog Input

#8 (N.O. Binary Contact

by Others) All Schedules May

be Programmed to Follow or

Not Follow the Override

Relay Power Rating 2 Amp @ 24 VAC

GPC-17 Controller

Start Pulse and Stop Pulse

for Each of the 7 Schedules

(N.O. Binary Contact)

Loading...

Loading...