Page 1

www.orioncontrols.com

OE256-07 Duct Mounted

E-BUS CO

Technical Guide

Sensor

2

Page 2

Table of Contents

SENSOR OVERVIEW ......................................................................................................................................... 3

Features .......................................................................................................................................................................................3

Environmental Requirements .......................................................................................................................................................3

DUCT MOUNTED CO2 SENSOR INSTALLATION ............................................................................................... 4

DUCT MOUNTED E-BUS CO2 SENSOR MOUNTING & WIRING TO VCB-X CONTROLLER ................................ 6

TROUBLESHOOTING ........................................................................................................................................ 7

Using LEDs to Troubleshoot ........................................................................................................................................................7

Altitude Correction ........................................................................................................................................................................7

TB1 Terminal Block (CO2 Reading) ..............................................................................................................................................7

PART NUMBER CROSS REFERENCE TABLE

PART DESCRIPTION

PART NUMBER

Duct Mounted E-BUS CO2 Sensor with Remote Pickup Tube OE256-07

Wall Mounted E-BUS CO2 Sensor OE256-05

E-BUS LCD Digital Room Sensor Temp Only OE217-02

E-BUS LCD Digital Room Sensor Temp & RH OE217-03

E-BUS Digital Room Sensor Temp & RH OE217-04

EBC E-BUS Cables - varying lengths EBC-XXXF

VCB-X Controller OE335-23-VCBX

www.orioncontrols.com

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-DM-EBUS-CO2-TGD-01A

Copyright May 2012 WattMaster Controls, Inc.

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

WattMaster Controls, Inc. assumes no responsibility for errors or omissions.

This document is subject to change without notice.

Page 3

Duct Mounted E-BUS CO2 Sensor Technical Guide

Sensor Overview

Overview

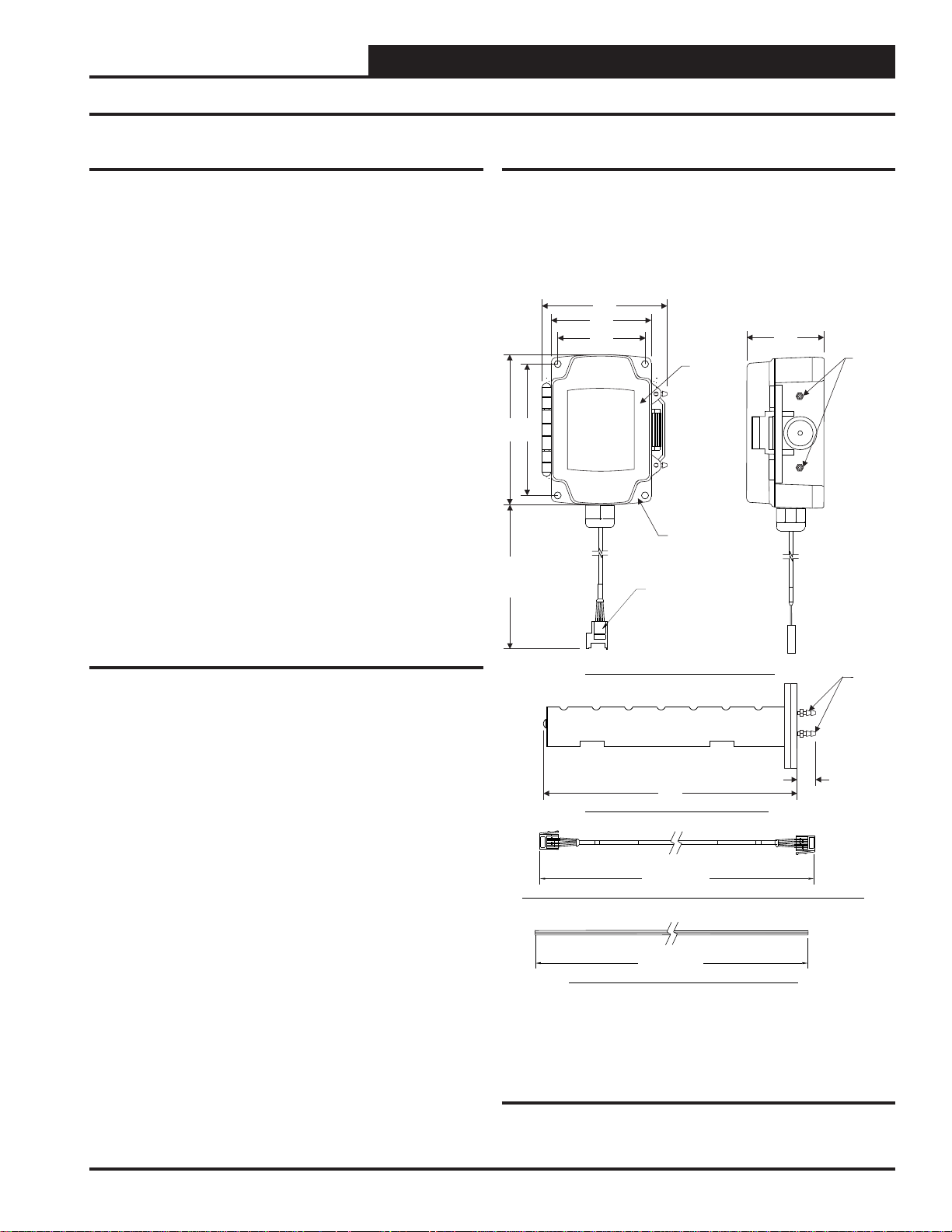

The OE256-07 Duct Mounted E-BUS CO2 Sensor with Remote Pickup

Tube

is used for monitoring duct CO2 levels and is designed for permanent mounting in the Return Air duct. It utilizes an aspiration box

to accurately capture CO2 levels in the duct. It connects to the VCB-X

Controller (OE335-23-VCBX) by using an E-BUS cable with E-BUS

connectors. See Figure 1 for dimensions.

The W all Mounted E-BUS CO2 Sensor (OE256-05) is used for monitoring space CO2 levels and is designed for permanent wall mounting in

the conditioned space. It connects to the VCB-X Controller using an

EBC E-BUS Expansion Cable. It can be daisy-chained with the E-BUS

Digital Room Sensor (OE217-02, OE217-03, OE217-04) for applications requiring both a space CO2 sensor and space temperature sensor.

For more information, refer to the OE256-05 W all Mounted CO2 Sensor

Technical Guide.

Some typical applications are:

Controlling ventilation in a building where the occupancy

varies frequently

Controlling ventilation to ensure excess outdoor air is not

causing energy waste

Ensuring good air distribution throughout building zones

Environmental Requirements

The Duct Mounted E-BUS CO2 Sensor needs to be installed in an

environment that can maintain a temperature range between 14°F and

122°F and a humidity range between 5% and 95% RH (non-condensing).

4.12"

3.31"

2.55”

BRASS

BARB

FITTINGS

FOR

0.170 I.D.

TUBING

5.00"

13.00"

APPROX.

4.06"

2.81”

HINGED

COVER

SENSOR

HOUSING

E-BUS CONNECTOR

FEMALE END

Features

The CO2 Sensor provides the following:

Uses the patented dual beam Non-Dispersive Infrared

(NDIR) technology

A very accurate and stable sensor guaranteed to maintain

its accuracy due to infrared self-calibration feature of sensor

Sensor accuracy of +/- 50 ppm @ 1000 ppm or 2% of the

measured value

Annual drift of +/- 2 ppm per year

Measurement range of 0 to 2000 ppm

HB LED under front cover shows active CO

sensing

2

™

4321

3M

CO2 SENSOR, HOUSING AND CABLE ASSEMBLY

CO2 PICKUP TUBE (PROVIDED WITH SENSOR)

3M

4321

E-BUS CONNECTOR EXTENSION CABLE WITH MALE ENDS (PROVIDED WITH SENSOR)

EBC-10F

0.170 I.D. TUBING (PROVIDED WITH SENSOR)FIRE RATED

8.25"

"WATTMASTER EBUS" "WATTMASTER EBUS"

120.00” APPROX.

120.00” APPROX.

EBC-10F

BRASS

BARB

FITTINGS

FOR

0.170 I.D.

TUBING

0.55”

3M

4321

Figure 1: Duct Mounted E-BUS CO2 Sensor with

Remote Pickup Tube Dimensions

Technical Guide

3

Page 4

Duct Mounted E-BUS CO2 Sensor Technical Guide

Duct Mounted E-BUS CO2 Sensor Installation

Duct Mounted CO2 Sensor Installation

To install the Duct Mounted E-BUS CO2 Sensor, please follow the instructions below. See Figure 2 for detailed illustrations of the Duct

Mounted E-BUS CO

STEP 1: Find the general location on the side of the Return Air

Duct where you want to mount the CO2 Sensor. Be sure to locate

the box with the airfl ow in the proper direction per the airfl ow

label. A conduit clamp is provided to help seal the opening where

the sensor cabling penetrates the aspiration box housing.

STEP 2: Connect the sensor’s attached cable which has a Jack

E-BUS connector to the provided EBC E-BUS Cable. Then connect the EBC E-BUS Cable to the VCB-X Controller or EBC Hub

or Adapter Board and to the VCB-X Controller.

STEP 3: Secure the sensor in its aspiration box assembly to the

ductwork with the (2) supplied sheet metal screws.

Sensor and its components.

2

STEP 4: Mount the remote pickup tube assembly separately to

the ductwork by fi rst cutting a 1

wall. Then insert the remote pickup tube into the hole. Secure

the remote pickup tube to the ductwork by inserting (2) supplied

sheet metal screws through the (2) mounting holes in the remote

pickup tube mounting plate and securing the remote pickup tube

assembly by screwing it to the ductwork using a manual or powered screw driver to tighten the screws.

STEP 5: Using the supplied 10 ft. long tubing, connect the

remote pickup tube to the aspiration box assembly, cutting the

tubing to fi t.

1

/4” diameter hole in the ductwork

4

Technical Guide

Page 5

Duct Mounted E-BUS CO2 Sensor Technical Guide

SECURE CO2 SENSOR

ASSEMBLY TO DUCT OR

UNIT HOUSING WITH

SHEET METAL SCREWS

(BY OTHERS)

Duct Mounted E-BUS CO2 Sensor Installation

CO2 SENSOR

ASSEMBLY

ROUTE

FIRE RATED 0.170 I.D.

TUBING FROM C02

PICKUP TUBE PORTS TO

SENSOR HOUSING PORTS

SUPPLIED

CO2 PICKUP

TUBE ASSEMBLY

CUT 1-1/4” DIAMETER

HOLE IN DUCT FOR CO2

PICKUP TUBE INSERTION

RETURN AIR

DUCT SIDE WALL

SECURE CO2 PICKUP TUBE

ASSEMBLY TO DUCT WITH

4321

3M

3M

4321

VCB-X CONTROLLER

SUPPLIED E-BUS

EXTENSION CABLE

CONNECTED BETWEEN

CO2 SENSOR E-BUS

CONNECTOR AND E-BUS

CONNECTOR ON VCB-X,

E-BUS HUB OR ADAPTER

BOARD

SUPPLIED SHEET METAL SCREWS

LOOPCOMM

485 DRV

T-

SH

LT1785

U

.1uF

R+

TB1

BINARY

INPUTS

P5

BIN1

D6

BIN2

D7

BIN3

D8

BIN4

R38

D9

30

COM

R41

30

R43

COM

30

R47

TB3

30

CUTTO ISOLATE

COM FROM GND

R1

R63

+3.3V

J1

+5V

GND

3650

R68

BACNET

485 DRV

T-

SH

4751

LT1785

R+

U2

.1uF

C81

TB7

ANALOG

INPUTS

AI1

AI2

AI3

AI4

AI5

GND

+12V

GND

TB4

GND

3650

R17

APPHB

3650

R20

OS HB

3650

R22

WDOG

SERIAL #

SERIAL #

4321

YS102442 REV 1

WATTMASTER CONTROLS

MADE IN USA

RLY1

RLY2

RLY3

RLY4

RLY5

RLY6

COMMON

TB2

RELAY

OUTPUTS

ALERT

R82

3650

24VAC

P2

DIGITAL

COMP

P3

UNLOAD

C30

ANALOG

1002

R51

OUTPUTS

2201

R59

U17

AOUT1

AOUT2

.1uF

AOUT3

C36

2201

R73

U19

GND

AOUT3AOUT1-2

GND

TB6

.1uF

STATUS 1

C46

STATUS 2

EBUS

POWER

3650

R21

3650

R109

R16

3650

R14

3650

.1uF

C21

ADDRESS

ADD

1002

1

1002

2

1002

4

1002

OFF

8

1002

16

1002

32

1002

BAUD

LOOP

1

1002

2

SW1

3M

C14

.01uF

Figure 2: Mounting and Cable Installation for Duct Mounted E-BUS CO2 Sensor

Technical Guide

5

Page 6

Duct Mounted E-BUS CO2 Sensor Technical Guide

Duct Mounted E-BUS CO2 Sensor Wiring to VCB-X Controller

Duct Mounted E-BUS CO2 Sensor

The OE256-07 Duct Mounted E-BUS CO2 Sensor with Remote Pickup

Tube is used for sensing the current CO2 level in the HV AC unit’ s return

air stream. This is useful when you want an average CO2 reading in the

area served by the HVAC unit or when you don’t want a wall mounted

E-BUS CO2 Sensor due to sensor tampering concerns in the space.

The OE256-07 Duct Mounted Return Air CO2 Sensor is comprised of

the CO2 Sensor, the W attMaster Aspiration Box Assembly , and a Remote

Pickup Tube. See the dimensional and installation information in Figur es

2 & 3 for mounting, wiring, and installation details.

Note:

1.) The Duct Mounted E-BUS CO Sensor

Connects To The Controller Using An

VCB-X

EBC E-BUS Cable Of The Required Length

Or The Provided 10 Foot EBC Cable.

OE256-07 Duct Mounted

E-BUS CO Sensor

2

2

The Duct Mounted Return Air E-BUS CO2 Sensor with Remote Pickup

Tube is designed to be mounted in the return air duct of the HVAC unit

and uses its integral aspiration box to sample the CO2 level in the duct.

See Figure 3 below for wiring and installation details.

NOTE: If using multiple E-BUS Sensors or Modules, the

E-BUS Hub or Adapter Board may be required.

RS-485 COMMUNICATION LOOP. WIRE

“R” TO “R”, “T” TO “T” “SHLD”TO “SHLD”

www.aaon.com

www.orioncontrols.com

VCB-X CONTROLLER

Orion No.:OE335-23-VCBX-A

ANALOG INPUTS

AI1 = SPC (SPACETEMPERATURE SENSOR)

= SAT(SUPPLY AIR TEMPERATURE SENSOR)

AI2

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI3

= DCT (DIGITALCOMP. DISCHARGE TEMPERATURE SENSOR)

AI4

AI5

= SPACETEMPERATURE SLIDE OFFSET

BINARY INPUTS

BI1

= EMERGENCY SHUTDOWN

BI2

= PROOF OF FLOW

BI3

= DIRTY FILTER

Bi4

= COIL TEMPERATURE SWITCH

G OUTPUTS

ANALO

AO1

= FAN VFD

AO2

= ECONOMIZER

AO3

= MOD. HEATING

TRIAC OUTPUT

TR1

= DIGITALCOMP.

UNLOADER

(24 VAC & UNLOAD

TERMINALS)

WattMaster Label

#LB102093-01-A

Rev.: 1B

24 VAC POWER

ONLY

WARNING!

POLARITY MUST

BE OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

GND

+24 VAC

STATUS LED BLINK CODES

LED NAME STATUS1 STATUS2

NORMAL OPERATION 0 1

SAT FAIL 1 2

OAT FAIL 2 2

SPC FAIL 3 2

MISSING EXP MODULE 4 2

CO2 SENSOR FAIL 6 2

AIRFLOW SENSORFAIL 7 2

MECH COOL FAIL 1 3

MECH HEATFAIL 2 3

FAN PROOF FAIL 3 3

DIRTY FILTER 4 3

EMERGENCY SHUTDOWN 5 3

LOW SAT 1 4

HIGH SAT 2 4

CONT. TEMPHI ALARM 3 4

CONT. TEMP LOALARM 4 4

HIGH HEAD PRESSURE 5 4

WATER PROOF FAILURE 6 4

SUCTION PRESSURE ALARM 7 4

LOW LEAVING WATER TEMP 8 4

E-BUS

EXPANSION

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

FAN

RELAY2

RELAY3

RELAY4

RELAY5

RELAY6

RELAY

COMMON

AAON No.:

V04740

ALERT LED BLINKCODES BLINKS

NORMAL OPERATION 0

MISSINGOR SHORTED

DISCHARGE TEMP. SENSOR

IN 30 MIN. CUTOFF PERIOD 3

IN HIGH TEMP. CUTOFF 4

COMPRESSOR LOCKEDO UT 6

E-BUS

EXPANSION

MADE IN USA

1

VCB-X Controller

4 3 2 1

1.2

37X04

3M

<PC>

1.6

EBC E-BUS

Cable

with Jack

Connection

10 Foot EBC

E-BUS Cable

(Provided)

Figure 3: Duct Mounted E-BUS CO2 Sensor & Digital Room Sensor Wiring for VCB-X Controller

6

Technical Guide

Page 7

Duct Mounted E-BUS CO2 Sensor Technical Guide

Using LEDs to Troubleshoot

LEDs are available for troubleshooting the CO2 Sensor. There are two

LEDs that are visible at an angle through the plastic cover. See Figure

4 for locations.

COMM LED

The COMM LED blinks on whenever communications are sensed.

HB LED

Initially, the HB LED blinks fast for 30 seconds. It will then blink every

30 seconds. A CO2 sample is taken once every 30 seconds.

HB

LED

COMM

LED

Troubleshooting

R+

G

+12

T -

Altitude Correction

Altitude correction can be confi gured using Prism II software installed

on a computer. The altitude can be confi gured at a value of 0-15,000

feet. The default is 500 feet.

TB1 Terminal Block (CO2 Reading)

The TB1 terminal block should only be used to test the sensor when the

sensor cable is plugged into the controller and the sensor and controller

are powered up. Directions: Set the meter for DC volts and connect

the GND probe to the GND terminal and the + probe to the CO2 0-5

terminal. Look at the output voltage and record it. Multiply the voltage

times 400. The value should match the CO2 as read on the System Manager TS, Modular System Manager, Modular Service Tool, or Prism. If

the signal doesn’t match the sensor reading, call WattMaster Controls

for a replacement.

J1

Figure 4: OE256-07 Board LEDs

Technical Guide

7

Page 8

Form: OR-DM-EBUS-CO2-TGD-01A Printed in the USA May 2012

All rights reserved. Copyright 2012

WattMaster Controls Inc. 8500 NW River Park Drive Parkville, MO 64152

Phone: 866-918-1100 www.orioncontrols.com Fax (816) 505-1101

Loading...

Loading...