Page 1

www.orioncontrols.com

OE256-05 Wall Mounted

E-BUS CO

Technical Guide

Sensor

2

Page 2

TABLE OF CONTENTS

SENSOR OVERVIEW ......................................................................................................................................... 3

Features .......................................................................................................................................................................................3

Environmental Requirements ....................................................................................................................................................... 3

WALL MOUNTED E-BUS CO

SENSOR WIRING TO HVAC UNIT CONTROLLER ............................................... 4

2

TROUBLESHOOTING ........................................................................................................................................ 5

Setting The Sensor Address Switch .............................................................................................................................................5

Using LEDs to Troubleshoot ........................................................................................................................................................6

Altitude Correction ........................................................................................................................................................................6

TB1 Terminal Block (CO2 Reading) ..............................................................................................................................................6

APPENDIX ........................................................................................................................................................ 7

Mounting Plate Dimensions..........................................................................................................................................................7

PART NUMBER CROSS REFERENCE TABLE

PART DESCRIPTION PART NUMBER

Wall Mounted E-BUS CO

Duct Mounted E-BUS CO2 Sensor OE256-07

E-BUS LCD Digital Room Sensor Temp Only OE217-02

E-BUS LCD Digital Room Sensor Temp & RH OE217-03

E-BUS Digital Room Sensor Temp & RH OE217-04

Mounting Plate BK000081

EBC E-BUS Cables - varying lengths EBC-XXXF

VCB-X Controller OE335-26B-VCBX

VCC-X Controller OE338-26B-VCCX

Sensor OE256-05

2

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

www.orioncontrols.com

Form: OR-WM-EBUS-CO2-TGD-01B

Copyright December 2014 WattMaster Controls, Inc.

®

is a registered trademark of AAON, Inc., Tulsa, OK.

AAON

WattMaster Controls, Inc. assumes no responsibility for errors or

omissions.

This document is subject to change without notice.

Page 3

WALL MOUNTED E-BUS CO

Sensor Overview

SENSOR

2

Overview

The OE256-05 Wall Mounted E-BUS CO2 Sensor is used for monitoring

space CO

conditioned space. It connects to the VCB-X Controller (OE335-23-

VCBX) and VCC-X Controller (OE338-26B-VCCX) using an EBC

E-BUS Expansion Cable. It can be daisy-chained with the E-BUS

Digital Room Sensor (OE217-02, OE217-03, OE217-04) for applications requiring both a space CO2 sensor and space temperature sensor.

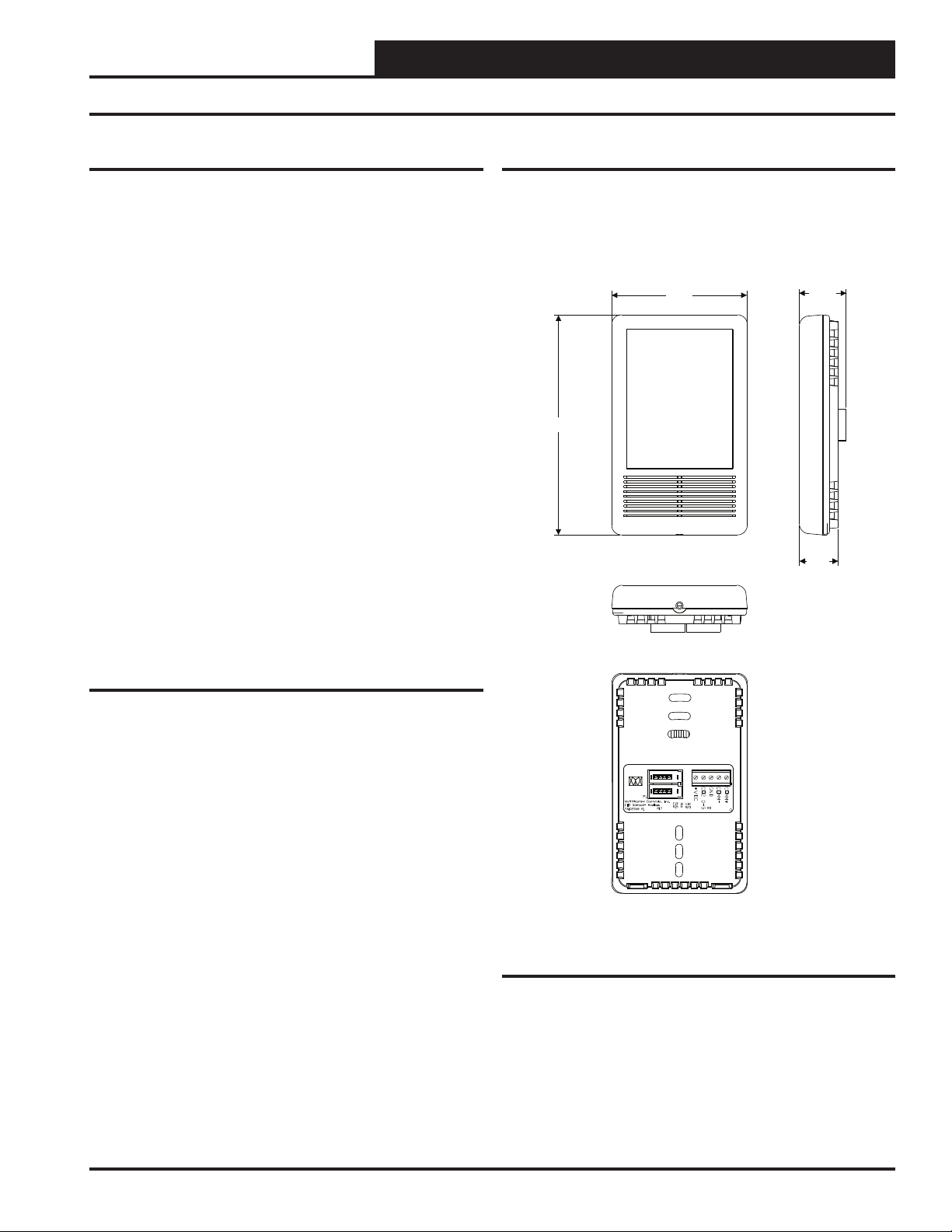

See Figure 1 for dimensions.

The OE256-07 E-BUS Duct Mounted CO2 Sensor with Remote Pickup

utilizes an aspiration box. It is used for sensing the current CO2 level in

the HVAC unit’s return air stream. It is designed to be mounted in the

return air duct of the HVAC unit and uses its integral aspiration box to

sample the CO2 level in the duct.

This technical guide provides information for the Wall Mounted E-BUS

CO2 Sensor only, for more information regarding the Duct Mounted EBUS CO2 Sensor, please see the OE256-07 Duct Mounted E-BUS CO2

Sensor Technical Guide.

Some typical applications are:

levels and is designed for permanent wall mounting in the

2

Controlling ventilation in a building where the occupancy

varies frequently

Controlling ventilation to ensure excess outdoor air is not

causing energy waste

Ensuring good air distribution throughout building zones

Environmental Requirements

The E-BUS CO2 Sensor needs to be installed in an environment that can

maintain a temperature range between 14°F and 122°F and a humidity

range between 5% and 95% RH (non-condensing).

2.80

4.54

0.96

0.80

Features

The CO2 Sensor provides the following:

Uses the patented dual beam Non-Dispersive Infrared

(NDIR) technology

A very accurate and stable sensor guaranteed to maintain

its accuracy due to infrared self-calibration feature of sensor

Sensor accuracy of +/- 50 ppm @ 1000 ppm or 2% of the

measured value

Annual drift of +/- 2 ppm per year

Measurement range of 0 to 2000 ppm

LED under front cover shows active CO

sensing

2

Addressable based on function within the system

™

Figure 1: Wall Mounted E-BUS CO2 Sensor

Dimensions

Technical Guide

3

Page 4

WALL MOUNTED E-BUS CO2 SENSOR

Wall Mounted Space CO2 Sensor Wiring to VCB-X Controller

Wall Mounting

The OE256-05 Wall Mounted E-BUS CO2 Sensor utilizes a sub-base

mounting plate with a modular phone jack providing quick and easy

mounting and wiring. The wall-mounted sensor’s sub-base is compatible with standard junction boxes. A locking screw secures the assembly

to the wall.

Optional Mounting Plate

Included with the Digital Room Sensor is a mounting plate that

can be used, if necessary, to cover the sensor sheet rock opening.

This mounting plate screws onto the back of the housing base.

The mounting plate is then mounted and covers the recessed space

in the wall. A locking screw secures the sensor to the wall. See

Figure 6, page 7 for dimensions.

OE256-05

Wall Mounted E-BUS

CO Sensor

2

NOTE: Mount Both

Sensors At Least

5 Feet Above Floor.

The Digital Room

Sensor Connects To

The Sensor.CO

2

Wiring to the VCB-X Controller

The OE256-05 Wall Mounted E-BUS CO2 Sensor connects to the

VCB-X or VCC-X Controller with an EBC E-BUS expansion cable. It

can be daisy-chained with the Digital Room Sensor (OE217-02, OE217-

03, OE217-04) for applications requiring both a space CO2 sensor and

space temperature sensor. Refer to Figure 2 for instructions (VCB-X

Controller shown).

VCB-X Controller

RS-485 COMMUNICATION LOOP. WIRE

RS-485 COMMUNICATION LOOP. WIRE

“R” TO “R”, “T” TO “T” “SHLD”TO “SHLD”

“R” TO “R”, “T” TO “T” “SHLD”TO “SHLD”

www.aaon.com

www.aaon.com

www.orioncontrols.com

www.orioncontrols.com

VCB-X CONTROLLER

VCX CONTROLLER

Orion No.:OE335-23-VCBX-A

Orion No.:OE335-23-VCX

ANALOG INPUTS

ANALOG INPUTS

AI1 = SPC (SPACETEMPERATURE SENSOR)

AI1 = SPC (SPACETEMPERATURE SENSOR)

= SAT(SUPPLY AIR TEMPERATURE SENSOR)

AI2

= SAT(SUPPLY AIR TEMPERATURE SENSOR)

AI2

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI3

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI3

= DCT (DIGITALCOMP. DISCHARGE TEMPERATURE SENSOR)

AI4

= DCT (DIGITALCOMP. DISCHARGE TEMPERATURE SENSOR)

AI4

= SPACETEMPERATURE SLIDE OFFSET

AI5

= SPACETEMPERATURE SLIDE OFFSET

AI5

BINARY INPUTS

BINARY INPUTS

= EMERGENCY SHUTDOWN

BI1

= EMERGENCY SHUTDOWN

BI1

= PROOF OF FLOW

BI2

= PROOF OF FLOW

BI2

= DIRTY FILTER

BI3

= DIRTY FILTER

BI3

= COIL TEMPERATURE SWITCH

Bi4

I

= REMOTE OCCUPIED OR COIL TEMPERATURE SWITCH

B4

G OUTPUTS

ANALO

ANALOG OUTPUTS

= FAN VFD

AO1

= FAN VFD

AO1

= ECONOMIZER

AO2

= ECONOMIZER

AO2

= SCR OR MODULATING HW HEATING

AO3

= SCR OR MODULATING HW HEATING

AO3

TRIAC OUTPUT

TRIAC OUTPUT

= DIGITALCOMP. UNLOADER

TR1

= DIGITALCOMP. UNLOADER (24 VAC & UNLOAD TERMINALS)

TR1

(24 VAC & UNLOADTERMINALS)

WattMaster Label

WattMaster Label

#LB102093-01-A

#LB102093-01-A

Rev.: 1A

Rev.: 1C

24 VAC POWER

ONLY

24 VAC POWER

WARNING!

ONLY

POLARITY MUST

WARNING!

BE OBSERVED

POLARITY MUST

OR THE

BE OBSERVED

CONTROLLER

OR THE

WILL BE

CONTROLLER

DAMAGED

WILL BE

DAMAGED

GND

24 VAC

INPUT

+24 VAC

STATUS LEDBLINK CODES

LED NAME STATUS1 STATUS2

LED NAME STATUS1 STATUS2

NORMAL OPERATION 0 1

NORMAL OPERATI ON 0 1

SAT FAIL 1 2

SATFAIL 1 2

OAT FAIL 2 2

OATFAIL 2 2

SPC FAIL 3 2

SPC FAIL 3 2

AIRFLOW SENSORFAIL 7 2

MECHCOOL FAIL 1 3

MECH COOL FAIL 1 3

MECHHEAT FAIL 2 3

MECH HEAT FAIL 2 3

FANPROOF FAIL 3 3

FAN PROOFFAIL 3 3

DIRTY FILTER 4 3

DIRTY FILTER 4 3

EMERGENCY SHUTDOWN 5 3

EMERGENCYSHUTDOWN 5 3

LOW SAT 1 4

LOW SAT 1 4

HIGH SAT 2 4

HIGHSAT 2 4

CONT. TEMPC OOLFAIL 3 4

CONT. TEMP COOL FAIL 3 4

CONT.TEMP HEAT FAIL 4 4

CONT. TEMP HEAT FAIL 4 4

PUSH BUTTONOVR 1 5

PUSH BUTTON OVR 1 5

OUTPUT FORCE ACTIVE 0 6

OUTPUTFORCE ACTIVE 0 6

E-BUS

E-BUS

EXPANSION

EXPANSION

RELAYCONTACT

RELAYCONTACT

RATING IS 1AMP

RATING IS 1AMP

MAX @ 24 VAC

MAX @ 24 VAC

RELAY

COMMON

RELAY2

RELAY3

RELAY2

RELAY3

RELAY4

RELAY4

RELAY5

RELAY5

RELAY6

RELAY

RELAY6

COMMON

AAON No.:

V04740

ALERT LEDBLINK CODES BLINKS

NORMAL OPERATION 0

MISSING OR SHORTED

DISCHARGE TEMP. SENSOR

IN 30 MIN. CUTOFF PERIOD 3

IN HIGH TEMP. CUTOFF 4

COMPRESSOR LOCKED OUT 6

LED BLINKCODES

EXPANSION

EXPANSION

E-BUS

E-BUS

FAN

FAN

MADE IN USA

1

OVERRIDE ALARM

Display

Override

EBC E-BUS Cable

EBC E-BUS Cable

OE217-02, OE217-03, OE217-04

E-BUS Digital Room Sensor

Figure 2: Wall Mounted Space E-BUS CO2 Sensor & Digital Room Sensor Wiring for VCB-X Controller

4

Technical Guide

Page 5

WALL MOUNTED E-BUS CO

Setting the Address Switch

SENSOR

2

Addressing & LEDs On/Off

The Wall Mounted E-BUS CO2 Sensor is equipped with binary dipswitches. The Address Switch is located on the Sensor’s board and is

only visible by taking the device off the wall and removing the back

cover. See location in Figure 3. The default addresses are as follows:

• Space or Return CO2 Sensor = Address 1

• Supply CO2 Sensor = Address 2 (Future)

• Open addresses for Custom Applications = 3-15

• LEDs On = Dipswitch 8 ON

NOTE:

Power Up The VCB-X or VCC-X Controller That The C Sensor Is

Connected To Before Setting the C Sensor’s Address Switch In

Order For Any Changes To Take Effect. Default Is Address 1. If Using

Only One C Sensor, There Is No Reason To Change The Address.

O

2

O

2

ADD

O

2

NOTE: If you forget to set the address, and all dipswitches are

off, the address will default to address 1.

To set the address, follow these instructions:

1. Power up the VCB-X or VCC-X Controller that the Sensor

is plugged into.

2. Set the Dipswitch to the proper setting.

3. The address range can be set from 1 to 15.

4. To verify that the correct address has been entered,

refer to the STATUS LED information on page 6.

The board address is stored in nonvolatile memory. Once the address is

set, the address will be saved after loss of power. See Figure 3 below

for address switch setting information.

1

2

4

8

Not Used

Not Used

Not Used

LEDs ON

ADD

O

2

O

2

Address Switch Shown Is

Set For Address 1

C SensorO

2

If Using More Than One C Sensor,

The Address For Each C Sensor

Must Be Unique From The Others.

This Feature Is For Future Use.

Address Switch

Figure 3: Setting the Address and LEDs On/Off Option

E-BUS C Sensor with Back Cover RemovedO

PIC32MX440F

MICROCHIP

512H-80I/PT

2

Technical Guide

5

Page 6

WALL MOUNTED E-BUS CO2 SENSOR

Troubleshooting

Using LEDs to Troubleshoot

LEDs are available for troubleshooting the CO2 Sensor. The LEDs are

ON when Dipswitch 8 is on. The LEDs are off when Dipswitch 8 is off.

The Front LED is visible through the front cover of the CO2 Sensor. See

Figure 5 for location. The other LEDs are located on the Sensor’s board

and are only visible by taking the device off the wall and removing the

back cover. See Figure 4 for locations.

Front LED

When the LEDs are turned on, a green LED will be visible through the

front plastic cover of the CO2 sensor. See Figure 5. The Front LED

will blink whenever a CO2 sample is taken. A sample is taken every

30 seconds.

STATUS LED

Initially, the STATUS LED blinks fast for 30 seconds. It then stays on

and blinks the board address whenever a CO2 sample is taken. A CO2

sample is taken once every 30 seconds.

COMM LED

The COMM LED blinks on whenever communications are sensed.

ADDRESS SWITCH

STATUS LED

COMM LED

512H-80I/PT

PIC32MX440F

MICROCHIP

Altitude Correction

Altitude correction can be confi gured using Prism 2 software installed

on a computer. The altitude can be confi gured at a value of 0-15,000

feet. The default is 500 feet.

TB1 Terminal Block (CO2 Reading)

The TB1 terminal block should only be used to test the sensor when the

sensor cable is plugged into the controller and the sensor and controller

are powered up. Directions: Set the meter for DC volts and connect

the GND probe to the GND terminal and the + probe to the CO2 0-5

terminal. Look at the output voltage and record it. Multiply the voltage

times 400. The value should match the CO2 as read on the System Manager TS, Modular System Manager, Modular Service Tool, or Prism. If

the signal doesn’t match the sensor reading, call WattMaster Controls

for a replacement.

Figure 4: Address Switch and Board LEDs

Figure 5: Wall Mounted E-BUS CO2 Sensor’s Front

LED

6

Technical Guide

Page 7

WALL MOUNTED E-BUS CO

1.638

1.810

0.882

1.407

1.842

0.733

2.110

2.920

0.810

R0.220

3.275

0.060

0.160

5.037

3.278

3.766

4.153

Appendix - Mounting Plate Dimensions

Optional Mounting Plate

Included with the Digital Room Sensor is a mounting plate that

can be used, if necessary, to cover the sensor sheet rock opening.

This mounting plate screws onto the back of the housing base.

The mounting plate is then mounted and covers the recessed space

in the wall. A locking screw secures the sensor to the wall. See

Figure 6, below for dimensions.

SENSOR

2

Figure 6: BK000081 Mounting Plate Dimensions

Technical Guide

7

Page 8

Form: OR-WM-EBUS-CO2-TGD-01B Printed in the USA December 2014

All rights reserved. Copyright 2014

WattMaster Controls Inc. 8500 NW River Park Drive Parkville, MO 64152

Phone: 866-918-1100 www.orioncontrols.com Fax (816) 505-1101

Loading...

Loading...