Page 1

r

FACTORY CONTROLS SYSTEM

MODGAS II Controlle

Installation &

Operations Manual

Page 2

r

FACTORY CONTROLS SYSTEM

MODGAS II Controlle

For Modulating Gas Heating Applications

Installation &

Operations Manual

This document is subject to change without notice.

WattMaster Controls, Inc. or AAON Inc. do not assume responsibility

for errors or omissions herein.

AAON MODGAS Controller

Installation & Operations Manual - Form WM-MG2-IOM-01C

AAON is a registered trademark of AAON, Inc.

Copyright 2010 WattMaster Controls, Inc.

All rights reserved.

Page 3

Section 1

Table of Contents

Component Overview....................................................... 1

MODGAS II Controller............................................................................................................... 1

Blink Codes for Status LED ........................................................................................................ 2

Supply Air Temperature Sensor .................................................................................................. 4

Component Wiring............................................................ 5

MODGAS II Controller............................................................................................................... 5

Board Inputs & Outputs ................................................... 7

Analog Inputs .............................................................................................................................. 7

Relay Outputs .............................................................................................................................. 7

Setting DIP Switches .......................................................8

Discharge Air Temperature ......................................................................................................... 8

Discharge Air Temperature Reset Limit...................................................................................... 8

Table of Figures

Figure 1-1: MODGAS II Controller Component Locations.................................................... 2

Table 1-1: Diagnostic LED Blink Codes ................................................................................. 2

Figure 1-2: MODGAS II Controller Dimensions.................................................................... 3

Figure 1-3: Supply Air Sensor Installation.............................................................................. 4

Figure 1-4: MODGAS II Controller Wiring............................................................................ 5

Figure 1-5: MODGAS II Controller DIP Switch Settings...................................................9

Overview & Wiring

Page 4

Page 5

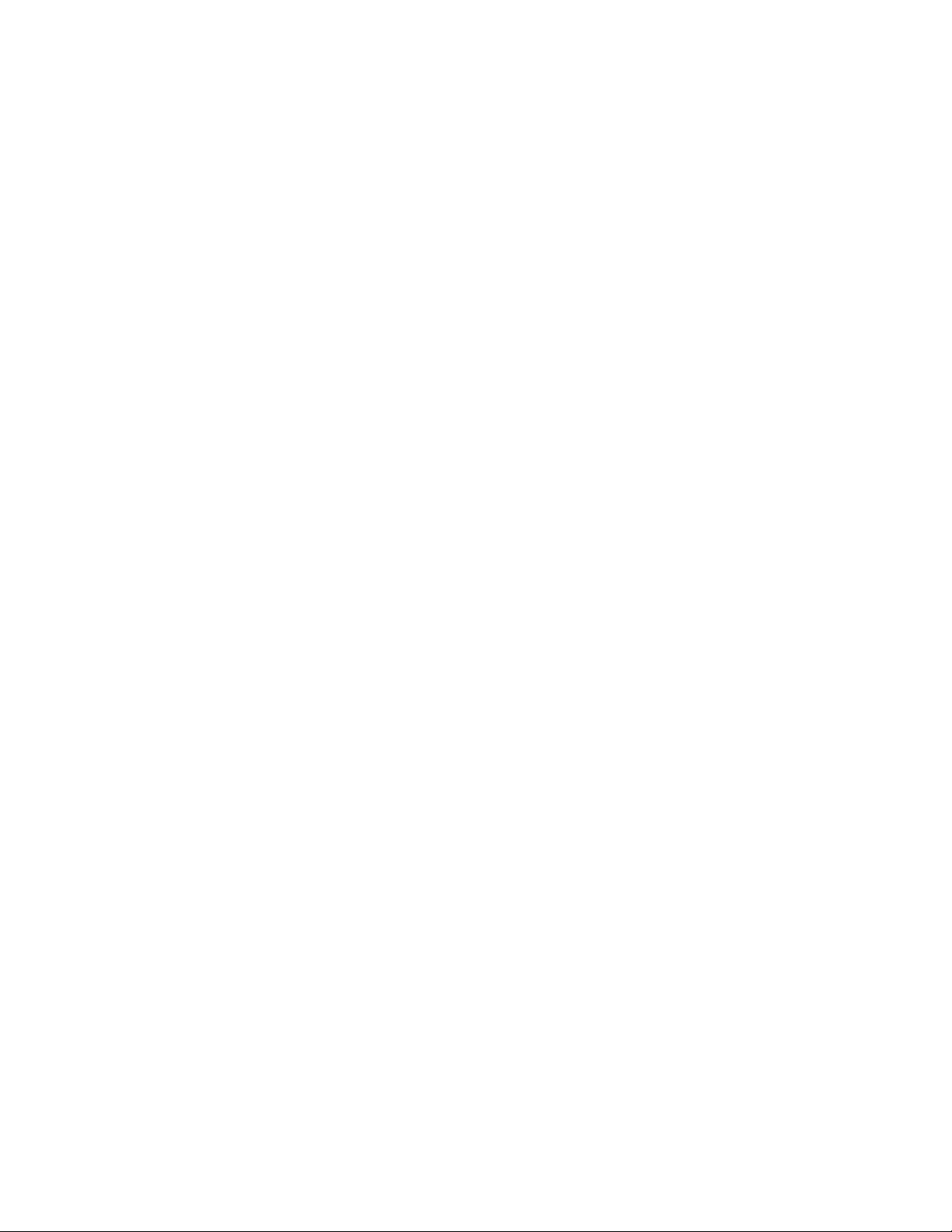

MODGAS II Controller Section 1

Component Overview

MODGAS II Controller

The MODGAS II Controller is designed to modulate a gas valve to maintain a desired Discharge

Air Temperature. It also controls the speed of the induced draft fan to maintain proper

combustion in the heat exchanger. The controller can be used as a stand-alone unit or be

connected to the AAON HVAC unit controller as an expansion board.

The MODGAS II Controller has the following inputs and outputs:

4 Inputs:

• Supply Air Temperature Sensor • HEAT EN Input (24VAC)

• Discharge Air Temperature Reset Signal from a

control automation system (0-10VDC)

• AUX Input (not used)

4 Outputs:

• Fan Enable (relay) • LO SPEED fan control (relay)

• AUX Output (relay / not used*) • Gas Valve Analog Output (0-20VDC)

* If using EPROM SS0056 V 2.20 or higher, the AUX Output Relay is functional. Once the MODGAS II

Controller brings on heat, if the Supply Air Temperature rises 5˚F and the valve output has reached 90%,

then the AUX Relay will activate to bring on a 2

modulate as needed to maintain the Heating Supply Air Setpoint. If the modulating valve falls below 30%,

the AUX Relay will disable.

When used in a stand-alone application (not connected to an AAON HVAC unit controller

board), the MODGAS II Controller will modulate the gas valve to maintain the DISCHARGE

setpoint set by the DIP switch on the board. The MODGAS II Controller is activated by a 24VAC

signal to the HEAT EN input.

When the MODGAS II Controller is connected to an AAON HVAC unit controller via the

modular cable, the following information will be passed between the MODGAS II and the

AAON HVAC unit controller.

nd

stage of fixed heat. The modulating valve is then able to

• Heat activation command • The offset for the Supply Air

Temperature Sensor.

• Hi Limit Temperature Setpoint. • Heating Discharge Setpoint. This replaces the

setpoint that is set with the Discharge Air

Temperature DIP switch on the MODGAS II

Controller.

• If the communication is interrupted

between the MODGAS II Controller

and the AAON HVAC unit controller,

the MODGAS II Controller will

revert to stand-alone operation.

Overview and Wiring 1-1

Page 6

Section 1 MODGAS II Controller

Status LED

Modulating Gas

Controller Board

These Terminals

Not Used For

This Application

24 VAC Power

Input Terminals

(See Note 1 & 2)

Max. Power

Consumption

1 Gas Valve =15VA

2 Gas Valves = 30VA

C6

I2C IN

POWER

TB3

TB2

R26

R26

R25

Analog Input

Terminals

YS101826PREV 1

MODULATING

GAS BOARD

PJ1

R15

R

SHLD

POWER

T

C7

U5

D8

V4

24VAC

GND

P1

RV1

+VDC

VR1

R7

D1

P

WDOG

CX6

U6

U1

C4

552 Processor Board

Notes:

1.)24 VAC Must Be Connected So That All Ground

Wires Remain Common.

2.)All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

Discharge Setpoint

Reset Limit

DIP Switch

RST IN

SAT

AUX IN

GND

HEAT EN

C1

C2

R8

D2

R9

R2

CX1

PHILIPS

PHILIPS

C2

YS101818

P1

552 PROCESSOR

BOARD

DIP Switch

STATUS

RESET

LIMIT

F

F

J01

ADD

R1R3R1

P

U2

C3

R1

1

CX5

C1

PAL Chip

Pin 1

Relay Output

LEDs

Relay Output

Terminals

DISCHARGE

SETPOINT

TB1

O

O

F

F

1

1

2

4

8

16

32

64

128

R4

CX2

U5

2

4

8

16

32

64

128

ADD

RAM

CX4

RAM Chip

Pin 1

LO SPD

FAN

LOSPD

FAN

U4

CX3

V1 V3K3V2

K1

AUX

COM

AUX

EPROM

U3

C13

EPROM Chip

Pin 1

K2

FT

SER.#:

GAS

VALVE

GND

TB4

VOUT

V5

Gas Valve

Output

Terminals

Heat Sink

Must Be Fastened

With Sheet Metal

Screws

To A Sheet Metal

Surface

D9

Figure 1-1: MODGAS II Controller Component Locations

Blink Codes for Status LED

The MODGAS II Controller uses an on-board LED to indicate various diagnostic conditions

during power-up and operation. The LED is labeled “STATUS”. Starting with power up, the LED

blink codes are as follows:

• One Blink

• Off for five seconds

• Blinks 30 times

• Blinks 3 times rapidly

• Status code repeatedly blinks every ten seconds to indicate controller status:

Priority No. of Blinks Status

Lowest 1 Normal Operation

- 2 SAT Over High Limit

Highest 3 Bad SAT Sensor

Table 1-1: Diagnostic LED Blink Codes

Only the highest priority failure code will be shown. You must correct the highest priority alarm

before other problems will be indicated.

1-2 Overview and Wiring

Page 7

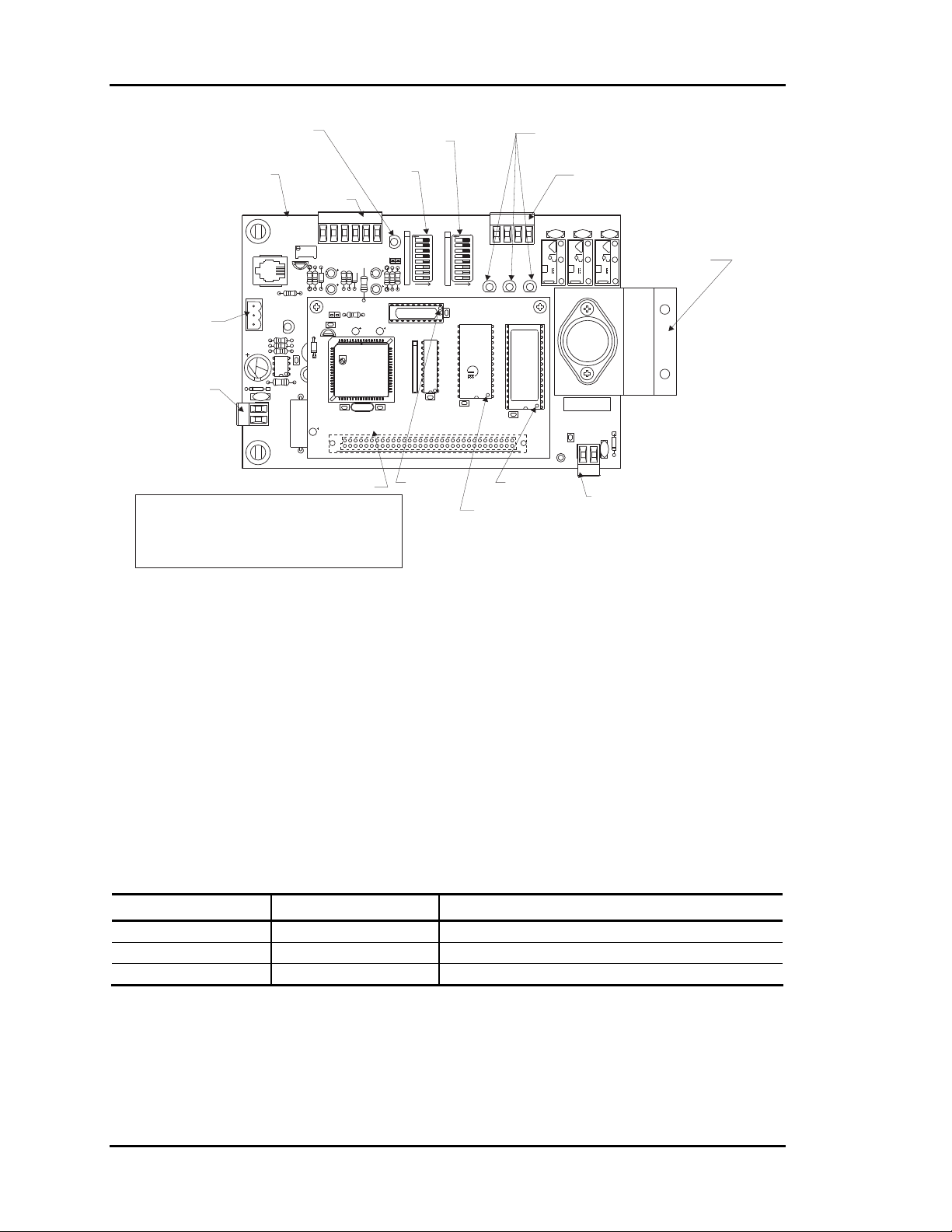

MODGAS II Controller Section 1

Figure 1-2: MODGAS II Controller Dimensions

Overview and Wiring 1-3

Page 8

Section 1 MODGAS II Controller

Supply Air Temperature Sensor

The supply air temperature sensor should be located in the ductwork downstream of the unit

supply air connection. Locate the sensor in the center of the widest part of the duct. Use the

supplied template and a

and mount securely to the duct using the supplied sheet metal screws. Be sure the gasket is

compressed to provide an air tight seal. For best accuracy, apply insulation on the outside of the

duct, over the sensor. This will help prevent thermal gradients from affecting the sensor.

5

/16" drill to make a hole for the sensor. Install the gasket over the probe

Figure 1-3: Supply Air Sensor Installation

1-4 Overview and Wiring

Page 9

MODGAS II Controller Section 1

Component Wiring

MODGAS II Controller

Figure 1-4: MODGAS II Controller Wiring

The MODGAS II Controller wiring is straightforward but allows for flexibility to set the system

up exactly as required for the specific application. All wiring should follow the minimum wire

sizing information that follows.

Overview and Wiring 1-5

Page 10

Section 1 MODGAS II Controller

Warning: Use extreme care not to damage any of the electronic components while

mounting the controller. Mark the holes and then remove the MODGAS II

Controller before drilling. Do not allow metal shavings to fall

onto the circuit boards.

The MODGAS II Controller requires the following electrical connections:

18 Gauge minimum unless otherwise noted.

-24VAC Supply Voltage.......................................................................................2 Conductors

-Supply Air Temperature Sensor ...................................................(24 Ga. Min.) 2 Conductors

-Heat Enable................................................................................... (24 Ga. Min.) 2 Conductors

Tip: After making all electrical connections, it is advised that you unplug all terminal blocks

on the MODGAS II Controller until you are ready to begin the checkout procedure.

This may help to prevent damage if wiring errors occur elsewhere in the system during

installation or start-up.

1-6 Overview and Wiring

Page 11

MODGAS II Controller Section 1

Board Inputs & Outputs

Analog Inputs

Input #1 - Heat Enable Contact (HEAT EN)

This input is only required when the controller is used in stand-alone operation; it is not

required when used as an expansion board to other unit controllers.The Heat Enable input

is activated by a 24 VAC signal supplied from a building automation system to enable the

MODGAS II Controller. The controller will not operate without 24 VAC being applied to

this input terminal when used in a stand-alone configuration.

Input #2 - Supply Air Temperature Sensor (SAT)

The Supply Air Temperature Sensor is the control source. This sensor has to be installed

for the unit to operate. The Supply Air Sensor is located in the discharge air stream and

monitors discharge air temperature to maintain the discharge air temperature setpoint.

Input #3 - Reset Input (RST IN)

The Discharge Temperature Setpoint can be reset by supplying a 0-10 VDC

signal to the RST IN low voltage terminal block. This reset signal is optional and need

only be used if you require resetting of the discharge air temperature.

Relay Outputs

Relay #1 - Fan Enable (FAN)

This relay works in conjunction with the LO SPEED relay to control the speed of the

induced draft blower motor. When the MODGAS II Controller has heat enabled, this

relay closes to bring the induced draft blower on at high speed. The controller will

activate the LO SPEED relay to reduce the induced draft blower speed as the gas valve

modulates closed.

Relay #2 - Fan Low Speed (LO SPD)

Depending on the gas valve position, this relay will close to switch the induced draft

blower to low speed. The controller automatically switches the blower to low speed as

the gas valve modulates closed in order to maintain proper fuel to air ratios.

Relay #3 - AUX Output (AUX)

If using EPROM SS0056 V 2.20 or higher, the AUX Output Relay is functional. Once

the MODGAS II Controller brings on heat, if the Supply Air Temperature rises 5˚F and

the valve output has reached 90%, then the AUX Relay will activate to bring on a 2

stage of fixed heat. The modulating valve is then able to modulate as needed to maintain

the Heating Supply Air Setpoint. If the modulating valve falls below 30%, the AUX

Relay will disable.

Gas Valve Output (VOUT)

This output is designed to supply a 0-20 VDC output signal for control of the modulating

gas valve. Up to two gas valves may be connected to this output if required by the

application. Do Not Connect More Than Two Gas Valves.

nd

Overview and Wiring 1-7

Page 12

Section 1 MODGAS II Controller

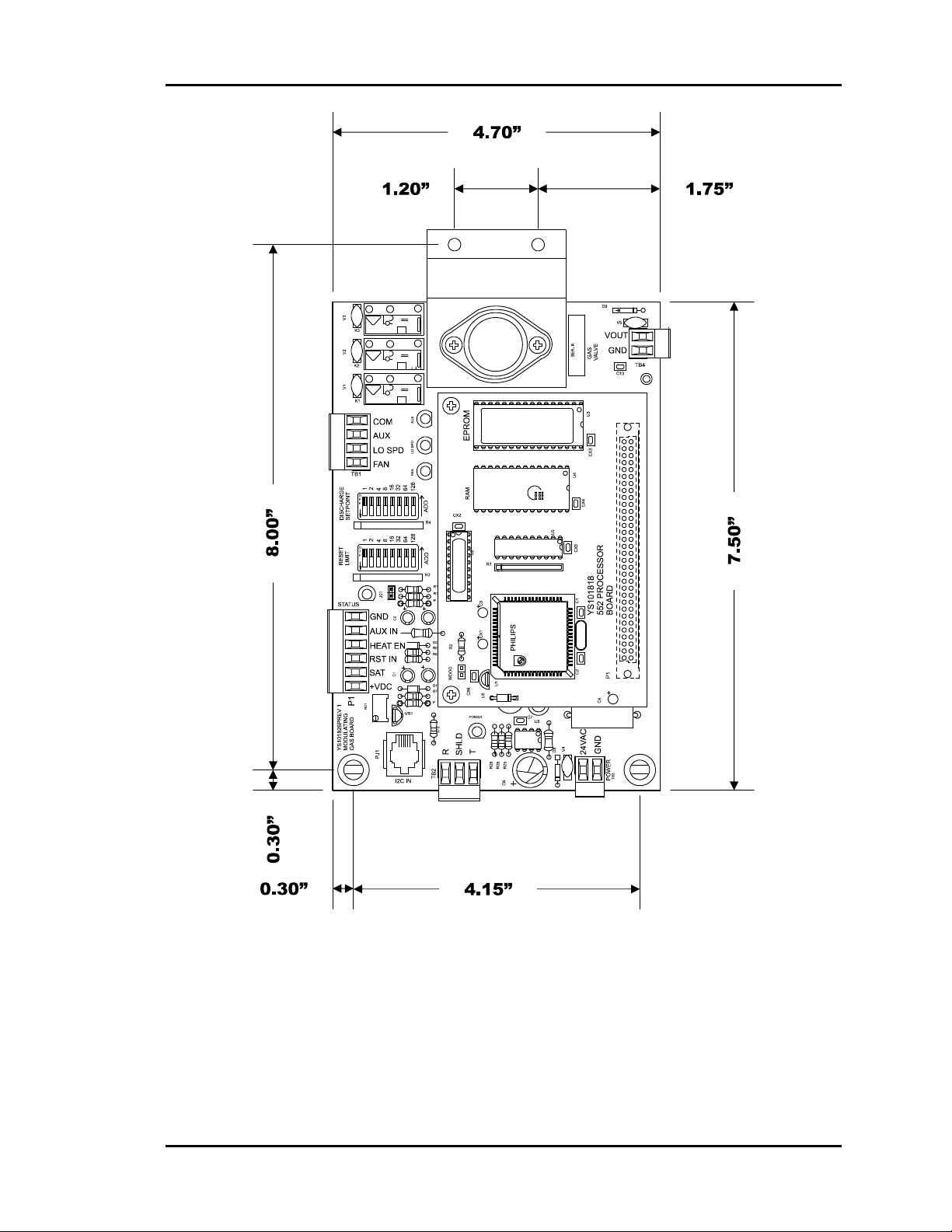

Setting DIP Switches

Discharge Air Temperature

This switch is only used when the controller is operated in stand-alone mode. The main unit

controller will set the discharge setpoint when the MODGAS II is used as an expansion device.

The user can set the desired Discharge Air Temperature Setpoint using the DIP Switch

labeled DISCHARGE SETPOINT. See Figure 1-5 for location and DIP Switch setting

instructions. The MODGAS II Controller will allow the user to set a Discharge Air

Temperature Setpoint between 40°F and 200°F. If a value of less than 40°F is set, the

controller will default to a 40°F Discharge Air Temperature Setpoint, a value greater

than 200°F will cause the unit to default to a 140°F Discharge Air Temperature

Setpoint.

Discharge Air Temperature Reset Limit

The user can reset the Discharge Air Temperature Setpoint by supplying a 0-10VDC

control signal to the Reset Input (RST IN) terminal on the MODGAS II Controller

board. The reset range is determined by the RESET LIMIT DIP Switch. See Figure 1-5 for

location and setting instructions. The controller will reset the Discharge Air Temperature

Setpoint from the value set on the DISCHARGE SETPOINT DIP Switch to the value set on the

RESET LIMIT DIP Switch, as the Reset Input (RST IN)

signal is increased from 0Volts to 10Volts.

Example:

We want the Discharge Air Temperature Setpoint to increase from 70°F when the Reset Input

signal is at 0 Volts to 130°F when the Reset Input signal is at 10 Volts.

• Set the DISCHARGE SETPOINT DIP Switch to 70°F

• Set the RESET LIMIT DIP Switch to 130°F

The discharge air temperature will now increase from 70°F to 130°F as the Reset Input voltage

signal ramps from 0 Volts to 10 Volts.

1-8 Overview and Wiring

Page 13

MODGAS II Controller Section 1

NOTE: It is possible to create a “reverse acting” control sequence by setting the

DISCHARGE SETPOINT DIP Switch to 130°F and the RESET LIMIT DIP

Switch to 70°F. In this case the controller will maintain a 130°F discharge

temperature when the Reset Input signal is at 0 Volts and will reduce it to 70°F

when the Reset Input signal is at 10 Volts.

Reset Limit DIP Switch

YS101826PREV 1

MODULATING

GAS BOARD

P1

RV1

RST IN

SAT

+VDC

PJ1

I2C IN

TB2

C6

POWER

TB3

VR1

R15

R

SHLD

POWER

T

R26

R26

R25

C7

U5

D8

V4

24VAC

GND

HEAT EN

C1

R8

R9

R7

D1

P

WDOG

R2

CX6

U6

U1

PHILIPS

PHILIPS

C2

C4

P1

MODGAS II Controller Board

64+32+16+8=120

Discharge Setpoint DIP Switch

AUX IN

GND

C2

D2

CX1

STATUS

J01

P

C3

C1

YS101818

552 PROCESSOR

BOARD

DISCHARGE

RESET

LIMIT

O

F

F

1

2

4

8

16

32

64

128

ADD

R1R3R1

U2

R1

1

CX5

SETPOINT

R4

CX2

U5

TB1

O

F

F

1

LO SPD

FAN

2

4

8

16

32

64

LOSPD

FAN

128

ADD

RAM

U4

CX4

CX3

AUX

EPROM

COM

AUX

V1 V3K3V2

K1

U3

All Rocker Switches Depressed

In the Direction Of The ADD Arrow

Are Added Together To Total The Setpoint

K2

FT

SER.#:

GAS

VALVE

GND

C13

TB4

D9

VOUT

V5

128+2=130

O

F

F

1

2

4

8

16

32

64

128

ADD

Typical DIP Switch

Detail View

ADD

DIP Switch Setting Shown

Is For A Setpoint Of 120

ADD

DIP Switch Setting Shown

Is For A Setpoint Of 130

Figure 1-5: MODGAS II Controller DIP Switch Settings

Overview and Wiring 1-9

Page 14

Section 1 MODGAS II Controller

1-10 Overview and Wiring

Page 15

Section 2

Table of Contents

Hand Held Service Tool LCD/Keypad Operations............ 1

Data Entry Functions................................................................................................................... 1

Menu Screens ..................................................................2

Main Menu Screen #1 ................................................................................................................. 2

View Status......................................................................2

MODGAS II Controller Status .................................................................................................... 2

Change Setpoints............................................................. 3

MODGAS II Controller Setpoints............................................................................................... 3

Summary Screen.............................................................. 5

MODGAS II Controller Summary .............................................................................................. 5

Programming

Page 16

Page 17

MODGAS II Controller Section 2

Hand Held Service Tool

LCD/Keypad Operations

Initialization Screen

Initializing

Service Tool v1.22

Mod Heat Controller

Wattmaster Controls

The screen shown above is displayed for a few seconds after the service tool is powered up. This

screen displays the current version of the software installed in your service tool.

The remainder of this section will lead the user through the system menus and keypad operations.

Data Entry Functions

A - Abort

B - Backup

C - Clear

D - Negative

* - Decimal

# - Enter

Used to exit from screens or from data entry.

Use this key to return to the Main Menu from

any screen in the system.

The user can step backwards to previous

screens or setpoints by pressing this key.

If a data entry mistake is made, press this

key to clear the data entry field and start

over.

If the user is entering a setpoint that is

negative in value, press this key for the

minus sign.

Use this key as the decimal point when

entering decimal values.

This key is used to close a data entry field

and advance to the next item or screen.

Programming 2-1

Page 18

Section 2 MODGAS II Controller

Menu Screens

After initialization, you will be advanced to the Main Menu screen. All status and setpoint

screens are accessed from this screen and additional menu screens are also accessed from this

Main Menu screen.

Main Menu Screen #1

1) View Status

2) Change Setpoints

3) Summary Screen

View Status

MODGAS II Controller Status

Accessed from Main Menu Screen #1 – Menu Item #1

The following status screens will appear when this menu item is selected and the selected unit is a

Modulating Gas Heat Controller. Step to each additional screen by pressing the “#” key. Press the

“A” key to exit before all status screens have been viewed. If the unit doesn’t respond, the data on

the screen will not be valid, although you can still step through the screens to get an idea of what

is displayed on each status screen. Use the “B” key to step backwards through the Status Screens.

Note: The top line of every status screen displays the same message that identifies the type

of unit you accessed. (Mod-Heat Controller)

Status Screen #1

Mod-Heat Controller

No Signal To Run

Supply Air: xxx.x°F

Line 2 -

Line 3 -

No Signal To Run = A signal has not initiated

controller operation.

W1 Signal Active = A signal has initiated controller

operation.

Supply Air xxx.x°F = Supply Air Temperature in

degrees Farenheit

2-2 Programming

Page 19

MODGAS II Controller Section 2

Status Screen #2

Mod-Heat Controller

MAX Setpoint: xxx°F

MIN Setpoint: xxx°F

Line 2 -

Line 3 -

Max Setpoint = This is the value from the RESET

LIMIT DIP switch on the MODGAS II Controller.

This is the value that the controller will use as the

Discharge Temperature Setpoint when the RESET

INPUT voltage signal is at 10 VDC.

NOTE: It is acceptable for this value to be less than

the MIN Setpoint for reverse acting control schemes.

Min Setpoint = This is the value from the

DISCHARGE SETPOINT Dip switch on the

MODGAS II Controller. This is the value that the

controller will use as the Discharge Temperature

Setpoint when the RESET INPUT voltage signal is at

0 VDC or when the no reset signal is connected.

Change Setpoints

MODGAS II Controller Setpoints

Accessed from Main Menu Screen #1 – Menu Item #2

Setpoint Screen #1

Controller Setpoints

Proportional. Kp: xx

Integral......Ki: xx

Setpoint Screen #2

Controller Setpoints

Derivative Kd.: xxx

Unwind Signal..:xxx

Kp = the proportional constant value for the PID loop. This

value affects the process stability of the PID loop.

Ki = the Integral constant value of the PID loop. This value is

used to eliminate positioning error on the PID loop.

Proportional Kp 1 20 70

Integral Ki 0 5 90

Kd = The derivative constant value of the PID loop. This value is

used to change the anticipation function on the PID loop.

The Integral Unwind value accounts for non-linear effects and

limitations in the valve.

Minimum Default Maximum

Derivative Kd 0 5 90

Unwind Signal 0 5 30

Programming 2-3

Minimum Default Maximum

Page 20

Section 2 MODGAS II Controller

Setpoint Screen #3

Controller Setpoints

PID LOOP PERIOD

Seconds......: xxx s

This value represents the sampling interval of the PID loop. It

indicates the time in seconds between calculations.

Minimum Default Maximum

PID LOOP Period 0 sec. 15 sec. 100 sec.

Setpoint Screens #4

Controller Setpoints

Switch To HI Speed

Fan Above Sig: xxx%

This is the percentage open of the modulating gas valve where the

Hi-Speed fan is required for proper induced airflow in the heat

exchanger.

Switch To HI Speed

Minimum Default Maximum

0% 40% 100%

Fan Above Sig

Setpoint Screens #5

Controller Setpoints

SUPPLY CUT-OFF

Temp. Above..: xxx°F

If the Supply Air Temperature ever exceeds this value, the

MODGAS II Controller will immediately be disabled. In order

for the MODGAS controller to be re-enabled (resume normal

operation), the temperature must drop 10°F below this setpoint.

Temp Above

Setpoint Screens #6

Controller Setpoints

Sensor Calibration

SAT: xx.x° xx.x°

The Thermistor Type III sensor readings can be calibrated. Enter

a Positive value to increase a reading and a Negative value to

decrease a reading.

Supply Sensor SAT

Minimum Default Maximum

50°F 150°F

300°F

Minimum Default Maximum

-100.0° 0.0°F +100.0°F

2-4 Programming

Page 21

MODGAS II Controller Section 2

Summary Screen

MODGAS II Controller Summary

Accessed from Main Menu Screen #1 – Menu Item #3

OFF SAT xxx SP xxx

VLV xxx % Fan OFF

BRN1 OFF

O xx.x N xx.x D xx.x

Line 1 -

Line 2-

Line 3 -

Line 4 -

OFF – ON = Indicates if unit is off or on.

SAT = Supply Air Temperature at unit discharge in

degrees Fahrenheit.

SP = Setpoint Temperature currently being used by the

controller in degrees Fahrenheit.

VLV xxx % = Percentage that valve is open.

FAN – Off – Lo Speed – High Speed = Indication of fan

condition and speed.

BRN1 = Indicates the status of the burner. This value is

either ON or OFF.

O = Old Error – The previous error calculation.

N = New Error – Difference between the setpoint and the

current temperature.

D = Desired Position – The position the valve is driving

towards.

Programming 2-5

Page 22

Form: WM-MG2-IOM-01C Printed in the USA March 2010

All rights reserved

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville MO • 64152

Phone (816) 505-1100

Copyright 2010

E-mail: mail@wattmaster.com

2425 So. Yukon Ave • Tulsa, OK 74107-2728

Ph: (918) 583-2266 • Fax: (918) 583-6094

Fax (816) 505-1101

AAON Part No. R02950

Loading...

Loading...