Page 1

SERVICE MANUAL

MODEL NAME : MIS – 4201

Designed by Checked by Approved by

ORION PDP CO.,LTD

Page 2

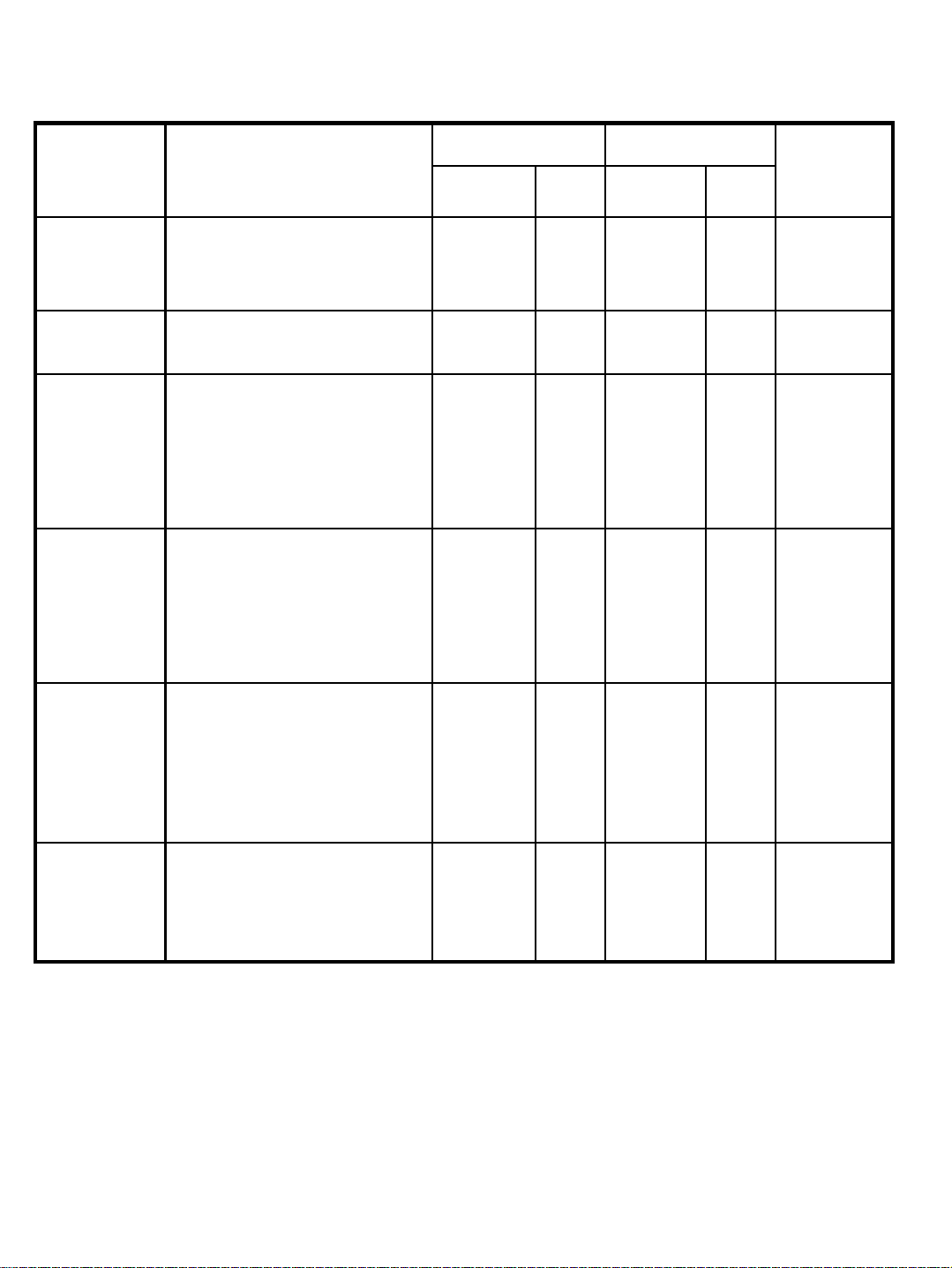

*Revision History

Revision

No.

0 SEPTEMBER.

Revision Date Page Particulars of Revision

01 2005

Causes of

Revision

61 Service manual Establishment

2

ORION PDP CO.,LTD

Page 3

* Table of Contents

1. For Safe Service

2. Tools and Measuring

3. Service Procedure

4. Product Specification

5. Board Description

6. Wiring Diagram

7. Dismantling Procedure

8. Adjustment Method

9. How to Upgrade

10. Trouble Shooting

11. Parts Replacement and Related Details

12. Spare Parts List

13. Option List(Cables)

14. Explode View for MIS-4201

3

ORION PDP CO.,LTD

Page 4

1. For Safe Service

1-1. SAFETY PRECAUTIONS

MIS-4201 is a display device to be divided into a Panel part , a Drive part and a

mechanical part. The Panel part consists of Electrodes, Phosphor, various dielectrics and

gas, the Drive part includes electronic circuitry and Board and The mechanical part

includes mask assembly, back cover and other parts.

When using / handling this monitor, Please pay attention to the below warning and cautions.

Indicates a hazard that may lead to death or injury if the warning is ignored and the

product is handled incorrectly.

Indicates a hazard that can lead to injury or damage to property if the caution is ignored

and the product is handled incorrectly.

1-2. WARNING

1) Do not supply a voltage higher than that specified to this product.

This may damage the product and may cause fire.

2) Do not use this product in locations where the humidity is extremely high,

where it may be splashed with water, or where flammable materials surround it.

Do not install or use the product in a location that does no satisfy the specified

environmental conditions.This may damage the product and may cause a fire.

3) If a foreign substance (such as water, metal, or liquid) gets inside the product,

immediately turn off the power. Continuing to use the product, it may cause fire or

electric shock.

4) If the product emits smoke, and abnormal smell, or makes an abnormal sound,

immediately turn off the power. Continuing to use the product, it may cause fire or

electric shock.

5) Do not disconnect or connect the connector while power to the product is on.

It takes some time for the voltage to drop to a sufficiently low level after the power has

been turned off.Confirm that the voltage has dropped to a safe level before

disconnecting or connecting the connector.

6) Do not pull out or insert the power cable from/to an outlet with wet hands.

It may cause electric shock.

7) Do not damage or modify the power cable. It may cause fire or electric shock.

8) If the power cable is damaged, or if the connector is loose, do not use the product:

otherwise, this can lead to fire or electric shock.

9) If the power connector or the connector of the power cable becomes dirty or dusty,

wipe it with a dry cloth. Otherwise, this can lead to fire.

10) MIS-4201 set uses a high voltage (Max.450V DC). Keep the cautions concerning

electric shock and do not touch the Device circuitry when handling the PDP Unit.

And because the capacitor of the Device circuitry may remain charged at the

moment of Power OFF, standing by for 1 minute is required in order to touch the

Device circuitry

4

ORION PDP CO.,LTD

Page 5

.

11) In order to protect static electricity due to C-MOS circuitry of the Drive part, wear a

wrist band to protect static electricity when handling.

12) When cleaning the Panel, wipe it with a soft cloth moistened with water or neutral

detergent, be careful not to touch the connector part of the Panel. And don’t use

chemical materials like thinner or benzene.

13) If this product is used as a display board to display a static image, “image sticking”

occurs. This means that the luminance of areas of the display that remain lit for a

long time drops compared with luminance of areas that are lit for a shorter time,

causing uneven luminance across the display.

The degree to which this occurs is in proportion to the luminance at which the

display is used. To prevent this phenomenon, therefore, avoid static images as

much as possible and design your system so that it is used at a low luminance, by

reducing signal level difference between bright area and less bright area through

signal processing.

14) Because PDP Module(set) emits heat from the Glass Panel part and the Drive

circuitry, the environmental te mperature must not be over 40°C. the temperature of

the Glass Panel part is especially high owing to heat from internal Drive circuitry.

And because the PDP Module(set) is driven by high voltage, it must avoid

conductive materials.

15) When inserting components or circuit board in order to repair, be sure to fix a lead

line to the connector before soldering.

16) When inserting high-power resistor(metal-oxide film resistor or metal film resistor)

in order to repair, insert it as 10mm away as from a board.

17) During repairs, high voltage or high temperature components must be put away

from a lead line

18) This is a Cold Chassis but you had better use a cold transformer for safety during

repairs. When repairing electricity source part, you must use the cold transformer.

19) Do not place an object on the glass surface of the display. The glass may be broken

or be scratched.

20) This product may be damaged if it is subject to excessive stresses

(such as excessive voltage, current, or temperature).

The absolute maximum ratings specify the limits of these stresses.

21) The recommended operating conditions are conditions in which the normal

operation of this product is guaranteed. All the rated values of the electrical

specifications are guaranteed within these conditions.

Always use the product within the range of the recommended operating conditions.

Otherwise, the reliability of the product may be degraded

22) This product has a glass display surface. Design your system so that excessive

shock and load are not applied to the glass. Exercise care that the vent at the

corner of the glass panel is not damaged.

If the glass panel or vent is damaged, t he product is inoperable.

5

ORION PDP CO.,LTD

Page 6

.

23) Do not cover or wrap the product with a cloth or other covering while power is

supplied to the product.

24) Before turning on the power to the product, check the wiring of the product and

confirm that the supply voltage is within the rated voltage range. If the wiring is

wrong or if a voltage outside the rated range is applied, the product may

malfunction or be damaged.

25) Do not store this product in a location where temperature and humidity are high.

This may cause the product to malfunction. Because this product uses a discharge

phenomenon, it may take time to light (Operation may be delayed) when the

product is used after it has been stored for a long time. In this case, it is

recommended to light all cells for about 2 hours (aging).

26) This product is made from various materials such as glass, metal, and plastic.

When discarding it, be sure to contact a professional waste disposal operator.

27) If faults occur due to arbitrary modification or disassembly, Orion PDP Co. ,Ltd..is

not responsible for function, quality or other items.

28) Use of the product with a combination of parameters, conditions, or logic not

specified in the specifications of this product is not guaranteed. If intending to use

the product in such a way, be sure to consult Orion PDP Co.,Ltd. in advance.

29) Within the warranty period, general faults that occur due to defects in components

such as ICs will be rectified by Orion PDP Co Ltd. However,

IMAGE STICKING due to misapplying the above (12) provision is not included in

the warranty. Repairs due to the other faults may be charged depending on

responsibility for the faults.

6

ORION PDP CO.,LTD

Page 7

2. Tools and Measuring

1) Portable Oscilloscope

2) Digital Multi-Meter (DMM)

3) (+) type adjustment bar

4) (+) type screw driver and tip

5) Hexagonal screw driver

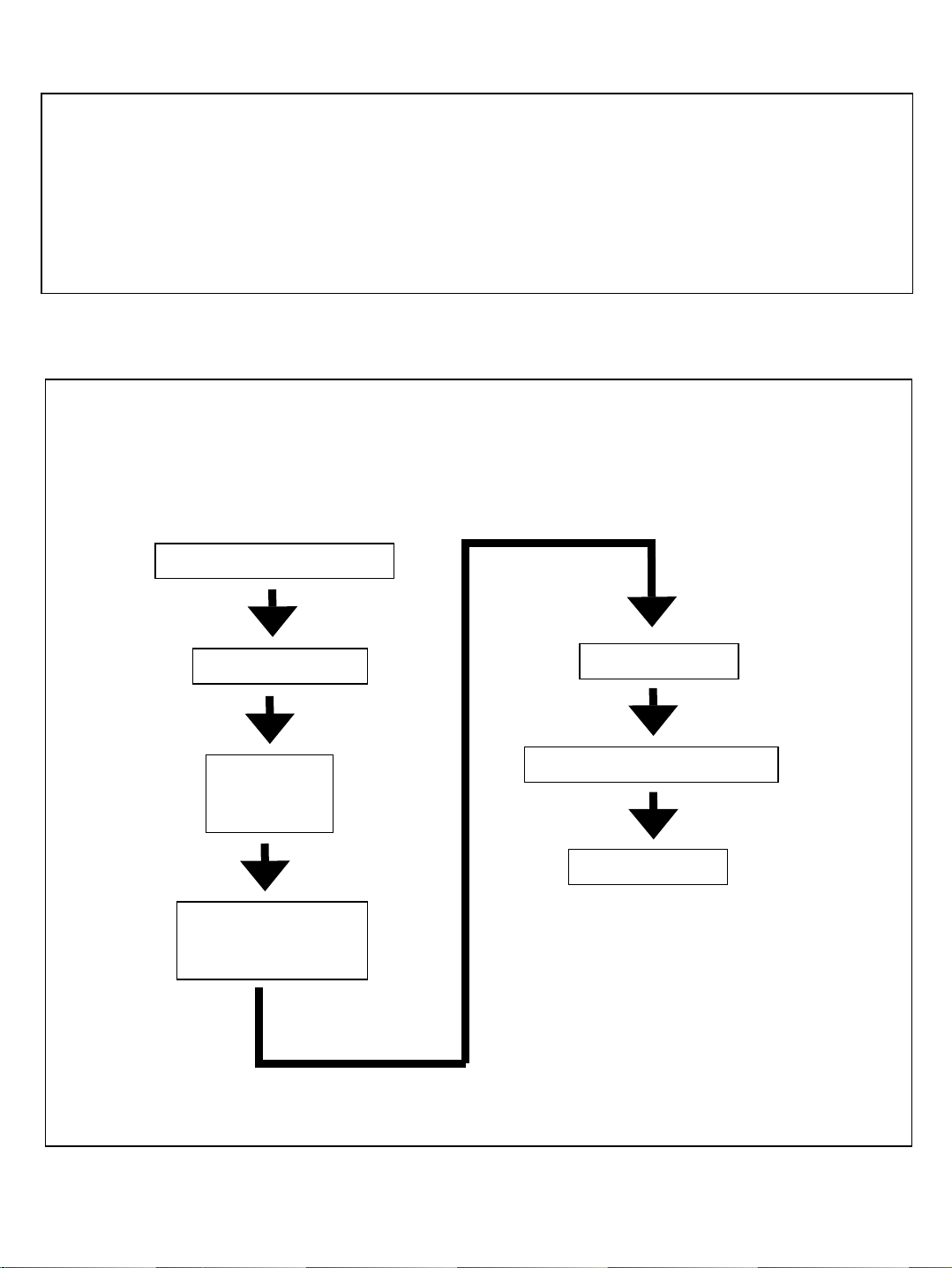

3. Service Procedure

MIS-4201 service is carried out in the following order.

For service procedures and methods of each part,

refer to the corresponding section in this manual.

Preliminary Inspection

Set Dismantling

Diagnosis,

Repair,

Upgrade

Adjustment and

Operation Status

Check

Set Assembly

Operation Status Check

Completion

7

ORION PDP CO.,LTD

Page 8

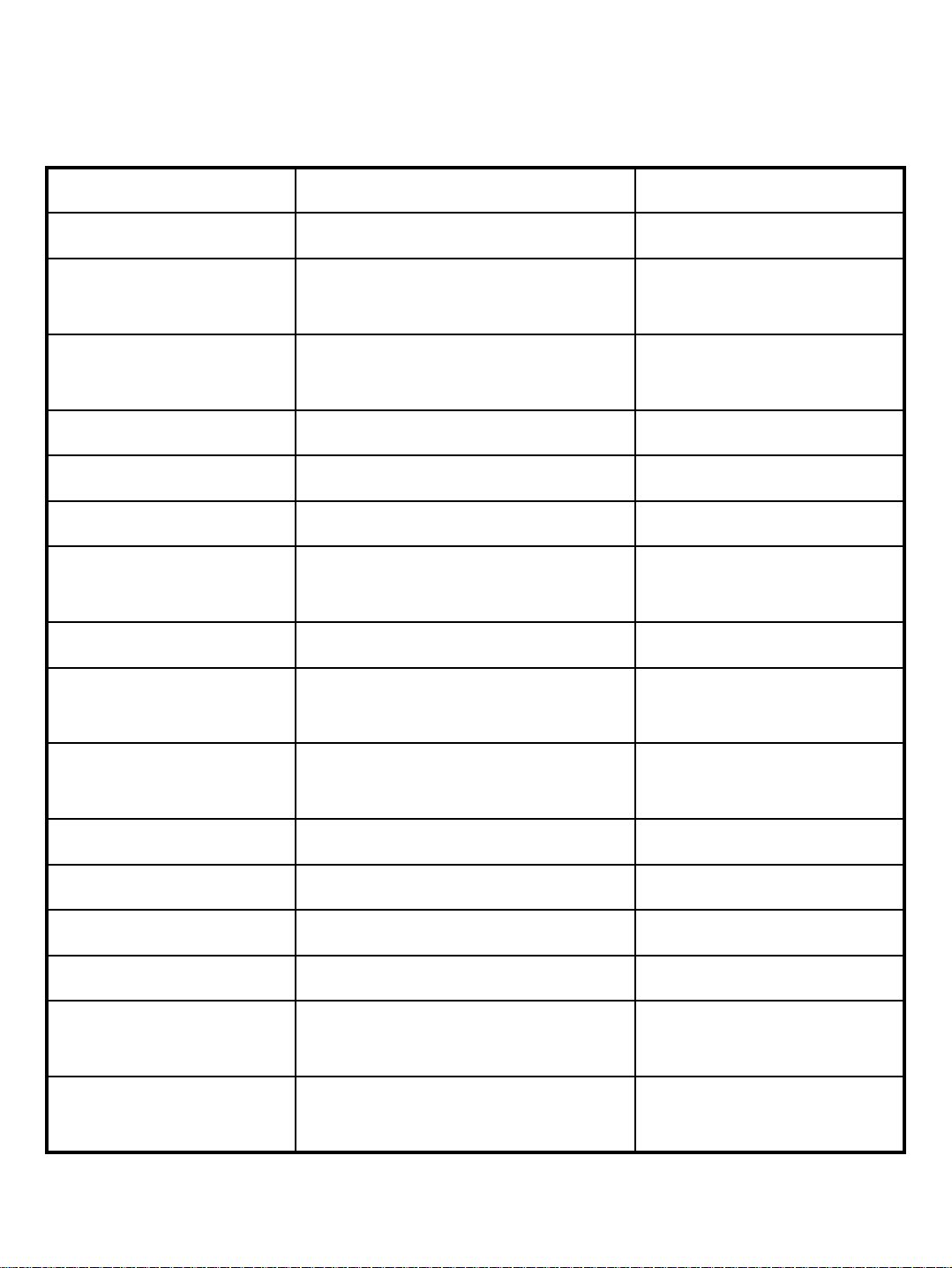

4. Product Specification

4-1. General Specification

FEATURE SPECIFICATION REMARK

POWER INPUT AC 100V ~ 240V , 50/60 Hz

POWER

CONSUMPTION

DIMENSIONS

WEIGHT 27Kg MONITOR BODY ONLY

SCREEN SIZE 921mm[H]×518mm[V] DIAGONAL IS 42 INCH

ASPECT RATIO 16 : 9

RESOLUTION 853[H]×480[V]

PIXEL PITCH 1.08 mm × 1.08 mm

COLOR

ARRAGEMENT

NUMBER OF

GRADATION

400W [MAX]

925mm[W]×523mm[H]×76.5m

m[D]

RGB VERTICAL STRIPE TYPE

256 STEPS FOR VIDEO,RGB

FULL WHITE 100%

LEVEL

WIDE VGA[1pixel=3 RGB

cells]

PEAK BRIGHTNESS Min.≥ 200 cd/㎡ 1 % WINDOWS

CONTRAST RATIO Min.≥ 400 : 1 DRCR

SEAM ≤ 6mm Monitor to Monitor

VIEWING ANGLE 160 deg.

CONTROL TIME

INTERVAL

FRONT FILTER

8

≥ 10 SECOND MSCS CONTROL

LOW REFLECTION COATING

FILM

ORION PDP CO.,LTD

Page 9

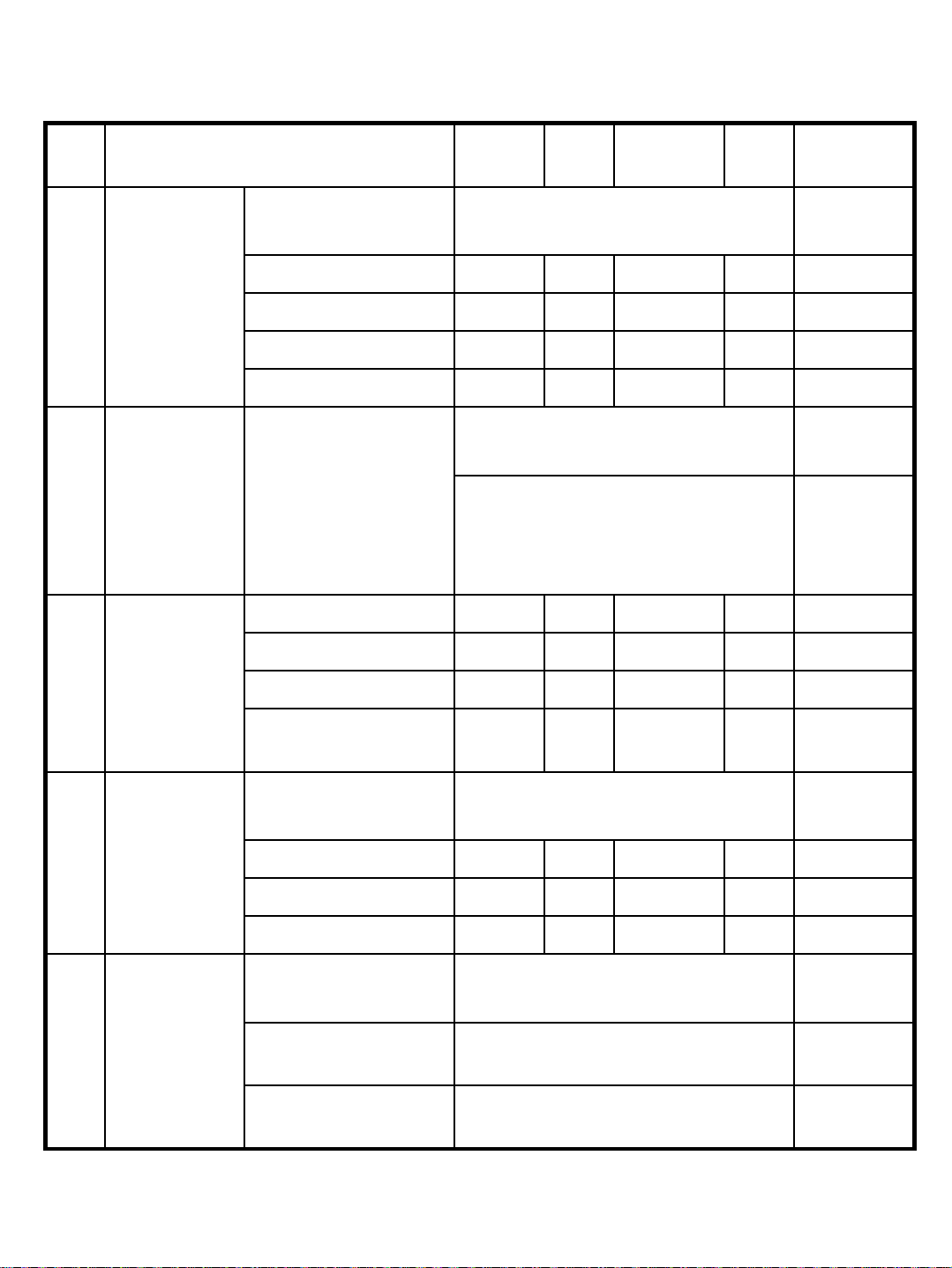

4-2. Input & Output Terminal

PORT

NAME

COMPOSI

TE

[VIDEO]

S-VIDEO NTSC/PAL/SECAM

COMPON

ENT

[DVD/DTV]

PC ANALOG RGB

NTSC/PAL/SECAM BNC 1

Y,Pb/Cb,Pr/Cr

720P[50/60Hz]

1080i[50/60Hz]

*VGA

*SVGA

*XGA

*UXGA[1600*1200,60Hz]

PORT SPEC.

* DVD : 480i,576i

* DTV : 480P,576P

INPUT PORT OUTPUT PORT

PORT

TYPE

PIN

DIN 4

PIN

BNC 3

PIN

D-SUB

15 PIN

Q’ty

1

1

1

1

PORT

TYPE

BNC 1

PIN

DIN 4

PIN

BNC 3

PIN

D-SUB

15 PIN

Q’ty

REMARK

1

1

1

1

DVI DIGITAL RGB [TMDS]

*VGA

*SVGA

*XGA

*UXGA[1600*1200,60Hz

REMOTE

CONTROL

RS-232C

*FEMALE : INPUT

*MALE : OUTPUT

9

DVI-D

24 PIN

D-SUB

9 PIN

1 *

1STRAIG

DVI-D

24 PIN

D-SUB

9 PIN

1

OPTION

HDCP

1

HT TYPE

[NOT

TWIST]

ORION PDP CO.,LTD

Page 10

4-3. Input Signal Specification

No Item Min

Component

(DVD /

D-TV)

1

DVI DVI Input

2

PC

(ANALOG

RGB)

3

Component

Input Terminal

Y Input Level

Sync Level 0.24 0.3 0.36 Vpp

Pb Input Level ± 350 mV

Pr Input Level ± 350 mV

Terminal

RGB Input Level 0.5 0.7 1.0 Vpp

Sync Separate 2.5 5.0 Vdc

Sync Composite 2.5 5.0 Vdc

Component Input

Y, Pb, Pr (Green, Blue, Red)

0.6 0.8 0.8 Vpp

DVI-D Terminal

Digital R,G,B(TMDS)

Vcc(Termination Supply Vol.)

=3.3V, ±5%

Termination Resistance :

50Ohms, ±10%

Typ

e

Max Unit Remark

4

5

Composite

Video

S-Video

10

Sync On Green 0.2 0.3 0.4 Vpp Negative

Sync

Video Input

Terminal

Video Input Level 0.85 1.0 1.15 Vpp

Video Sync Input 0.25 0.30 0.35 Vpp

Video burst Input 0.25 0.30 0.35 Vpp

S-Video Input

Terminal

NTSC Y=1Vp-p/75ohm, C=0.286Vp-

PAL Y=1Vp-p/75ohm, C=0.299Vp-

BNC Jack

4 PIN DIN Jack

p/75ohm

p/75ohm

ORION PDP CO.,LTD

Page 11

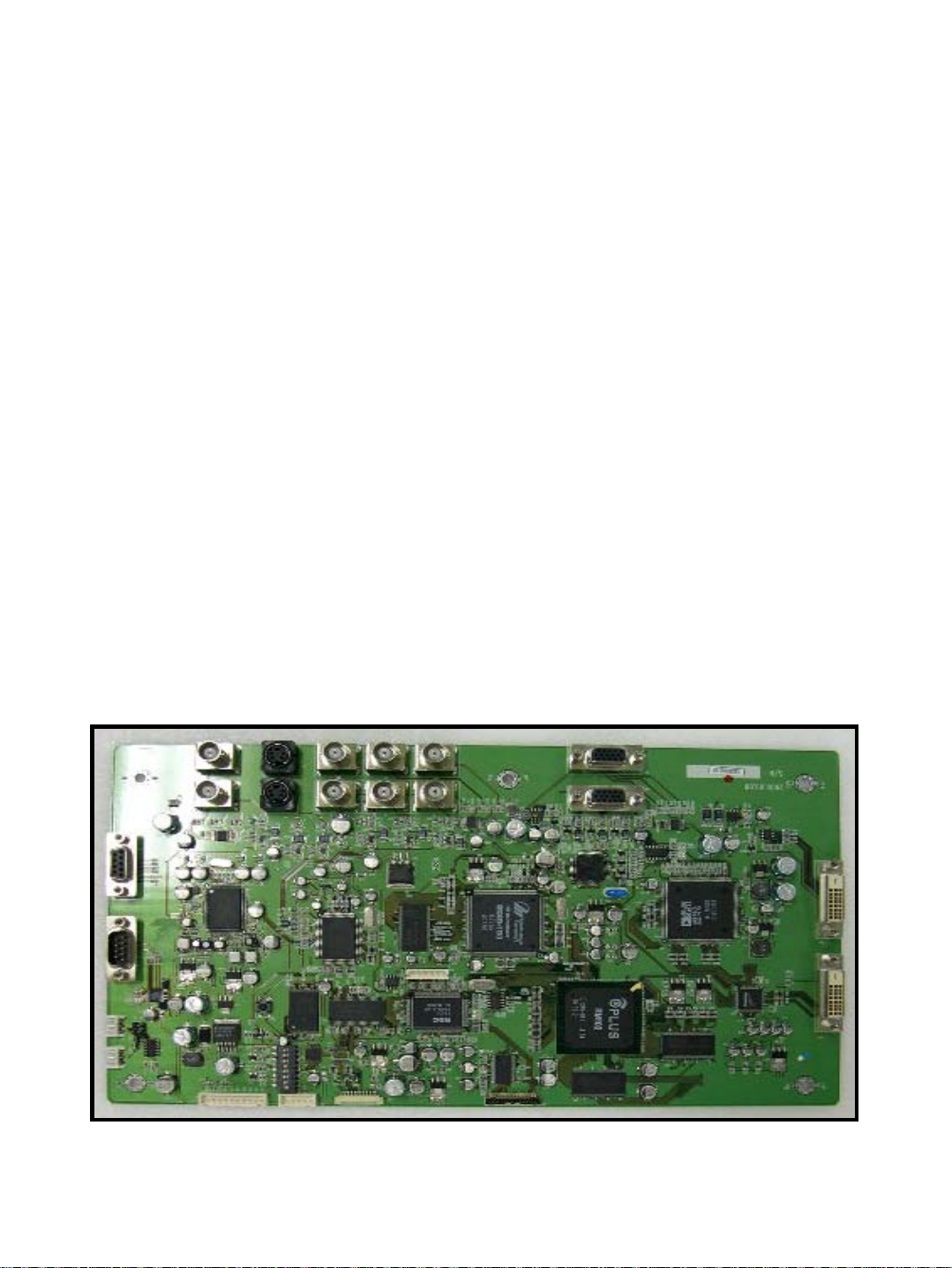

5. Board Description

5-1. I/P PCB

For input signal, S-video signal to separately enter luminance and color

signals, Y/C composite video signal, DVD signal, DTV signal and the

graphic signals of analog RGB and digital RGB can be used. In case of

graphic signals, both analog and digital versions use AD9887 ADC.

Each of 3CH even/ odd signals are converted into 8bit signals and

entered to scaler. Similarly, DTV signals are also entered to scaler

through the same route. Video signals are converted to the digital format

of BT601 through the video processor of VPC3230D. Among input

signals, CVBS (only NTSC) is entered to VPC3230D as Y/C is

separated through 3D-comb filter. VPC3230D converts the format of

input signals into 16-bit BT601, thus enters them to the deinterlacer of

MDIN-150. MDIN-150 converts interface signal into progressive to send

signal output to scaler. The output signal format is BT601, that is, Y:U:V

4:2:2 16bit. Scaler receives the input of MDIN-150 from control of

CPU[RDC R2021] and graphic signal from AD9887, thus administers

scaling to the resolution of multi-panel [853*480] and produces signal

output in LVDS format.

11

ORION PDP CO.,LTD

Page 12

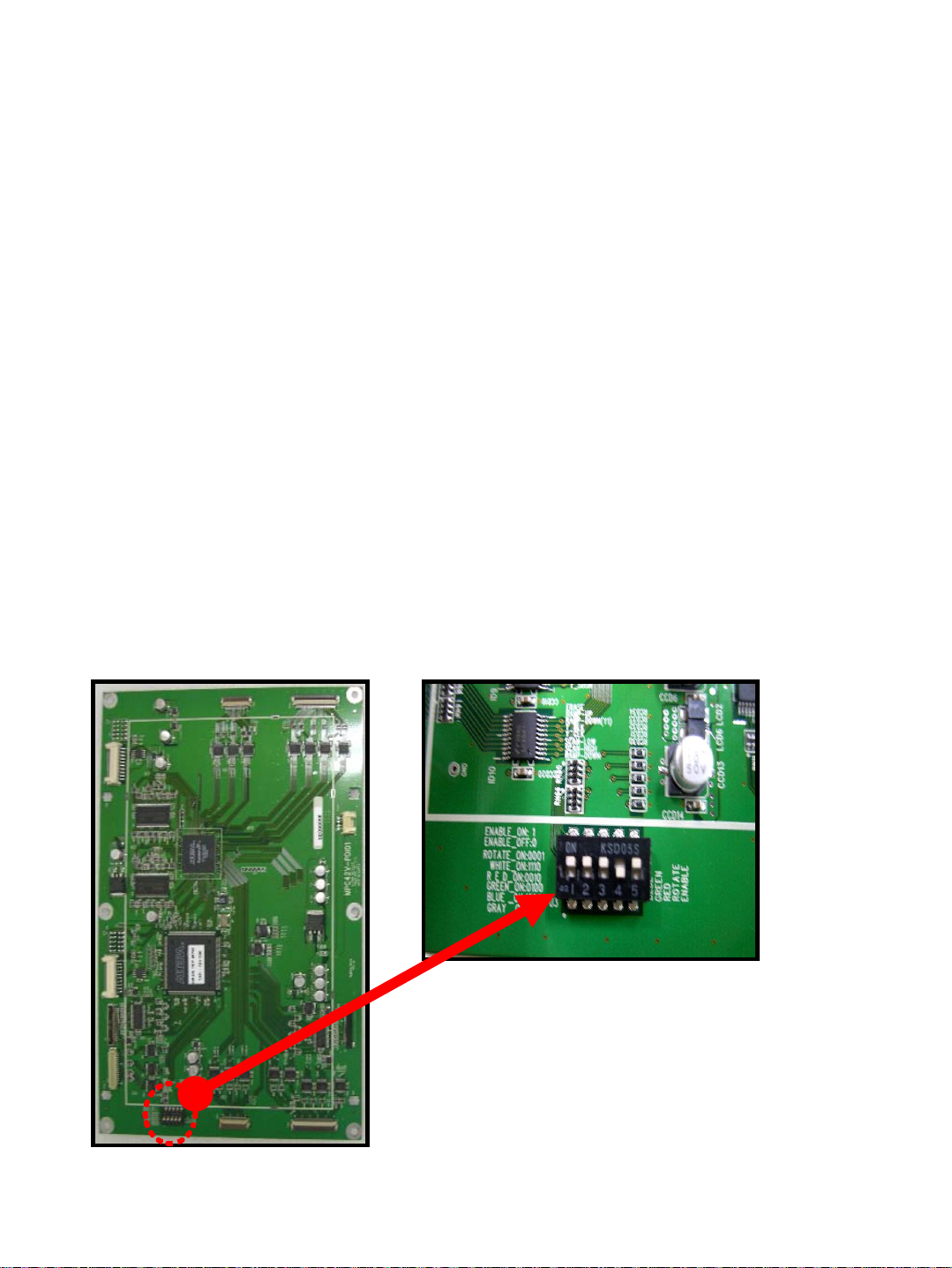

5-2. DIGITAL PCB

DIGITAL PCB receives the following signals and data from IP Board.

*LVDS FORMAT

- R, G, B data - DCLK

- Enable - H Sync.

- V Sync. - etc.

The data of R, G, B received from IP PCB is processed and adjusted to be

displayed in PDP through CON PCB and COF (Data drive circuit. )

DIGITAL PCB also has APL(Automatic Power Limit) circuit which controls

the power consumption and the heat in the PDP.

The data of H Sync, V Sync and DCLK is converted to X, Y & Z Timing pulse

data for PDP.

It is also working to reduce the Dynamic false contour and to maximize the

256 Gray level.

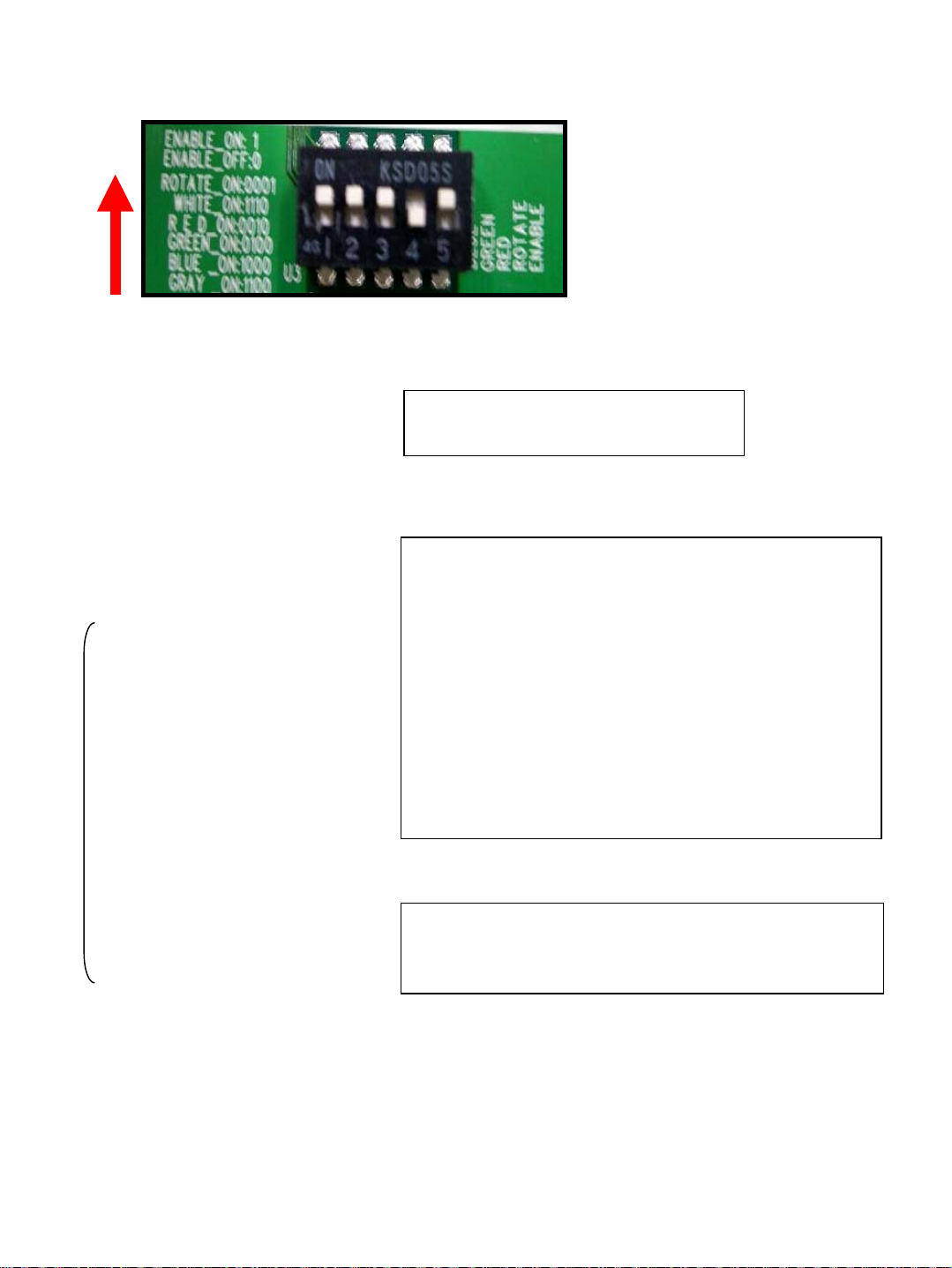

Test Pattern Switch for Module Inspection

[High : ON]

12

ORION PDP CO.,LTD

Page 13

5-2-1. How to use Inner Pattern Switch on DIGITAL PCB

ON

1

[Inner Pattern Switch on DIGITAL PCB

0

※ SET NO : 1 2 3 4

- WHITE : 1 1 1 0

- RED : 0 0 1 0

- GREEN : 0 1 0 0

- BLUE : 1 0 0 0

- GRAY : 1 1 0 0

- ROTATE : 0 0 0 1

WHITE

↓

As an example,

white pattern

5 : Enable ON - 1

Enable OFF - 0

*If you want to use this inner pattern switch on

DIGITAL PCB, the switch of CN801 on POWER

PCB should be set as shown next page.

RED

↓

YELLOW

↓

GREEN

↓

CYAN

↓

BLUE

↓

MAGENTA

13

If the switch [CN801] on POWER PCB is

connected, you can turn the power on & off

ORION PDP CO.,LTD

Page 14

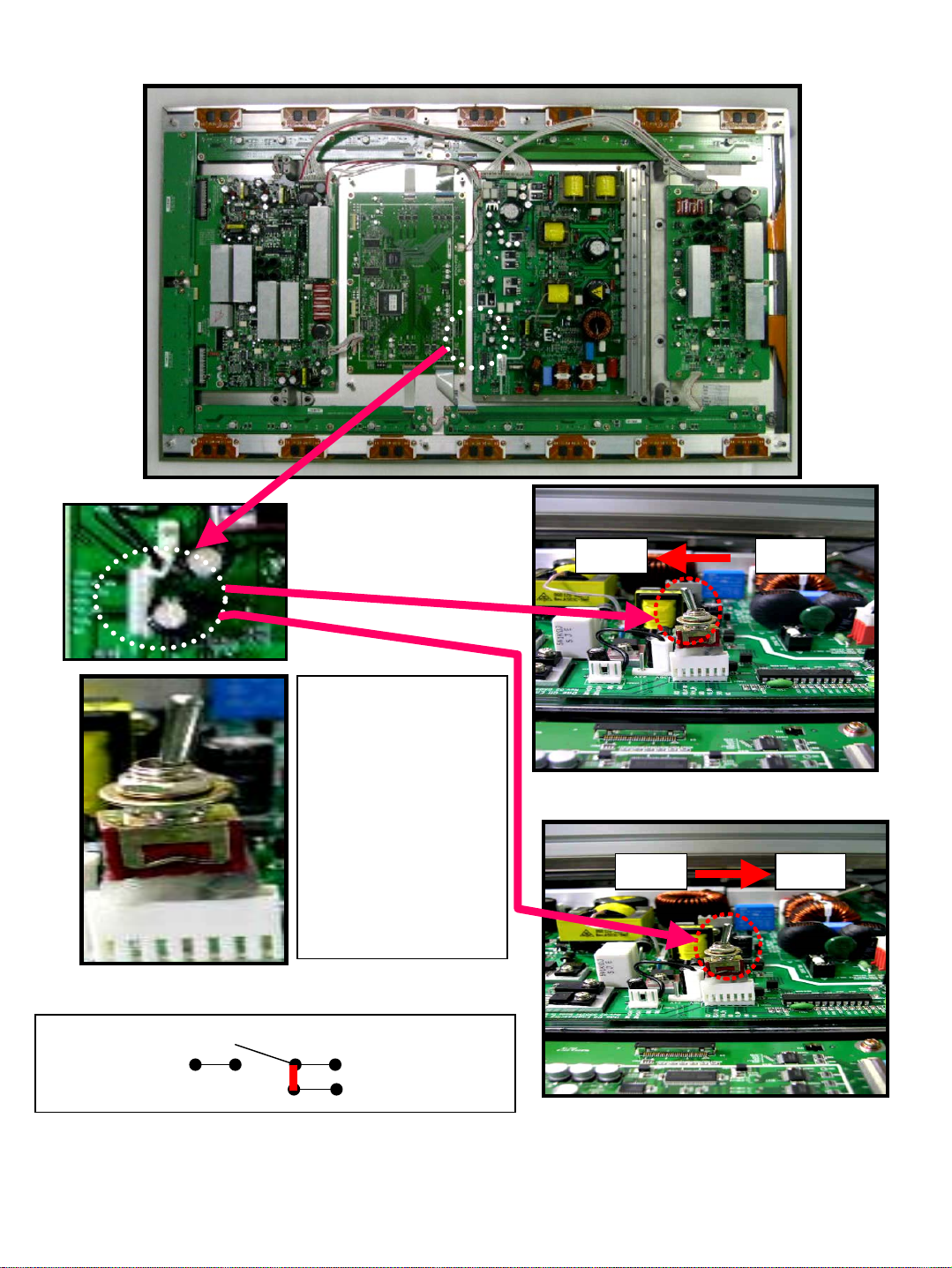

5-2-2. How to use switch on POWER PCB

[PLANK TYPE]

1 2 3 4 5 6 7

5Vst_by

CN801

1:ACD

2:RELAY_ON

3:5Vst_by

4:GND

5:Vs_ON

6:5VD

7:NC

RELAY_ON

Vs_ON

SWITCH DIAGRAM

HIGH LOW

[Turn Off]

HIGH LOW

[Turn On]

14

ORION PDP CO.,LTD

Page 15

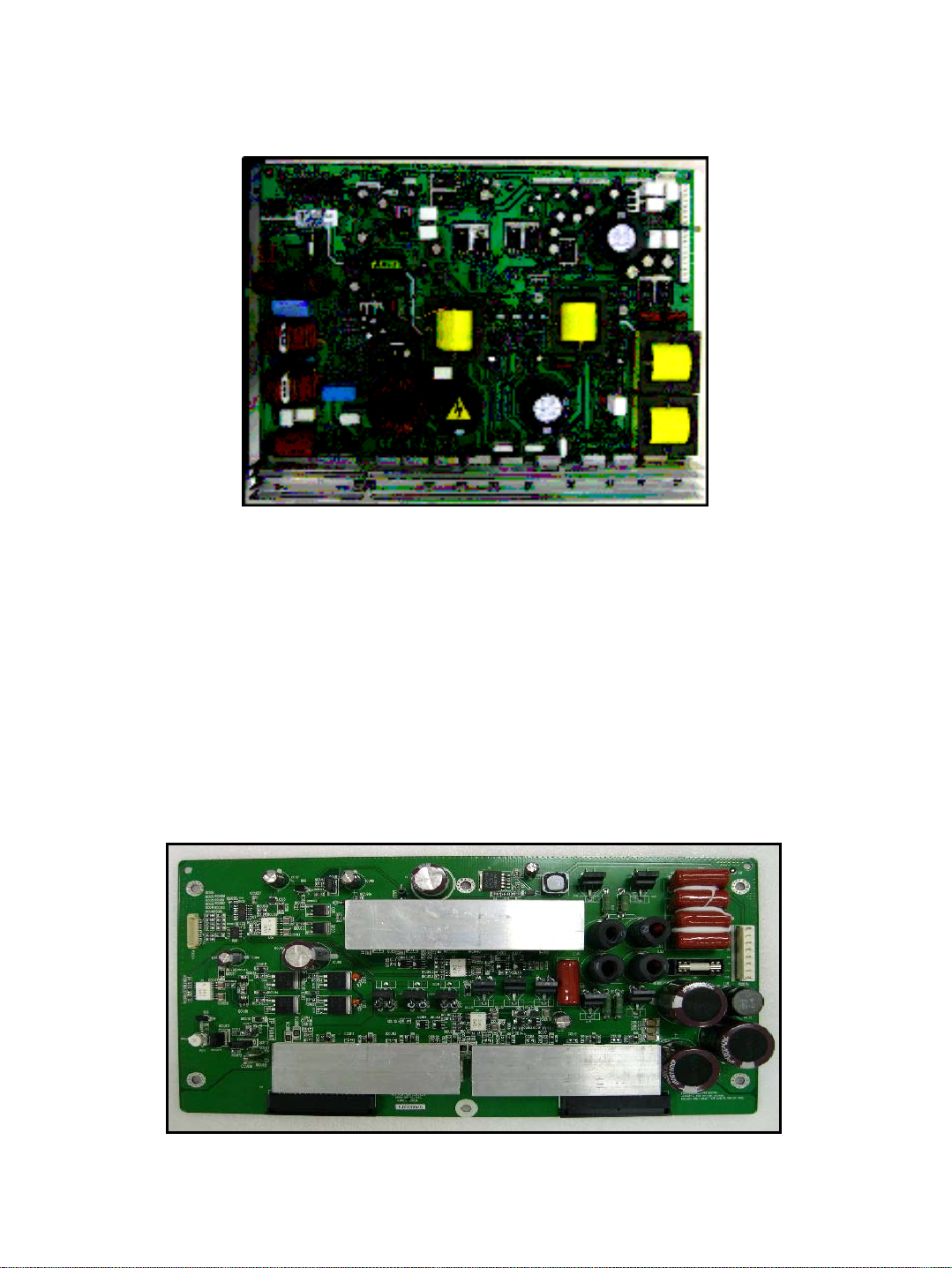

5-3. POWR PCB

POWER PCB is to receive the AC power outside and to send the power each

PCB in MIS-4201. AC 100 ~ 240 V ± 10% & 50/60 Hz ± 1 Hz is available.

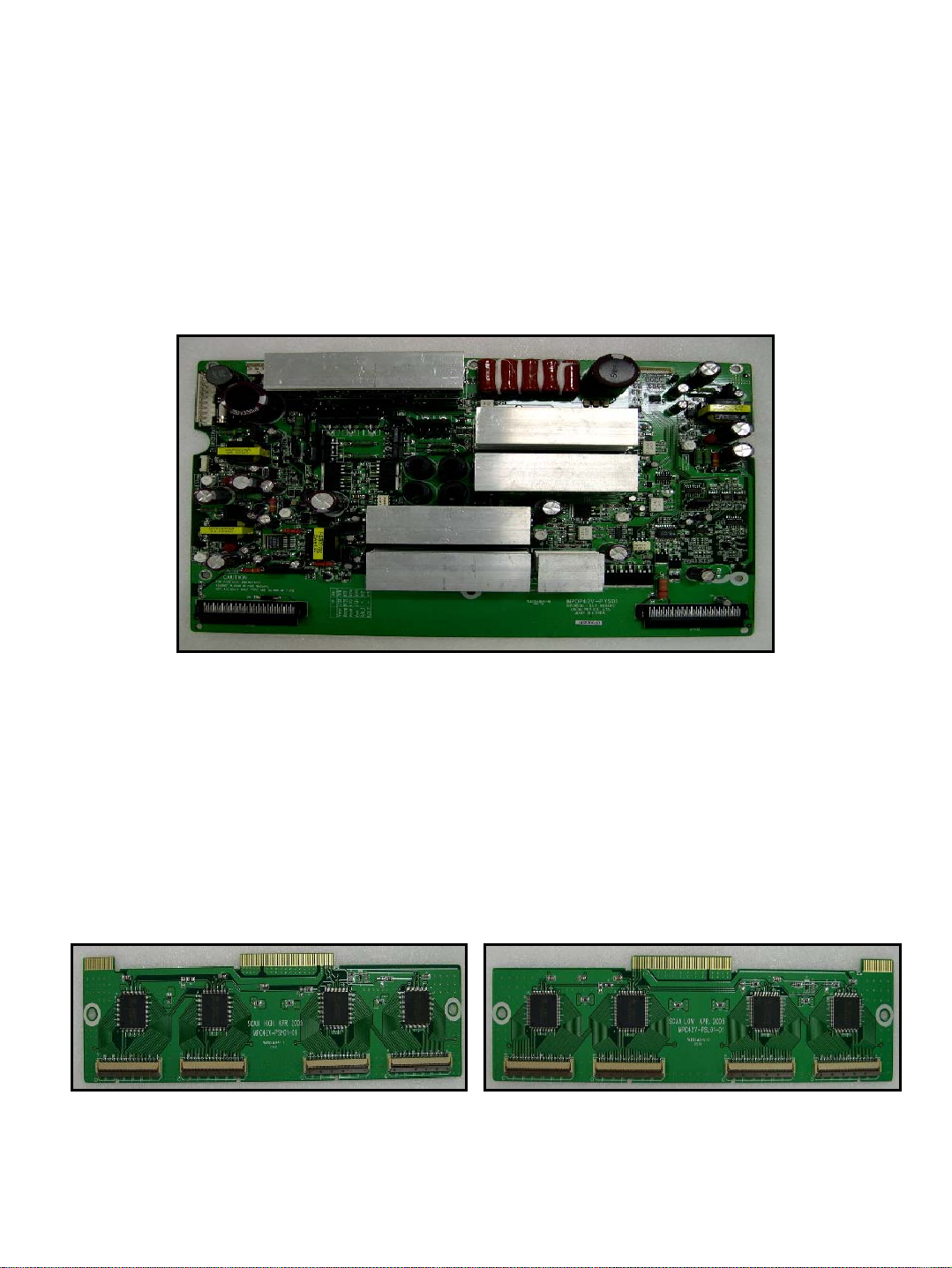

5-4. SUS X PCB

SUS X PCB consists of the following.

- SUSTAIN : It includes the circuits of Energy recovery and discharge.

- V_SHELF power REGULATOR : It works for adjusting and keeping the

Voltage in the panel.

- 15V REGULATOR : It is changing from the 5V received from POWER PCB

to the 15V and supplying it to Drive IC and SUS Y PCB.

15

ORION PDP CO.,LTD

Page 16

5-5. SUS Y PCB

SUS Y PCB consists of the following.

-SUSTAIN -RAMP-DOWN

-Y-SHELF -Y-ERASE

-SCAN -RAMP-UP REGULATOR

-SCAN REGULATOR -15V REGULATOR

SUSTAIN includes the circuits of Energy recovery and discharge.

The others work for adjusting and keeping the voltage sending to Panel.

5-6. SCAN HIGH / LOW PCB

The SCAN HIGH and LOW PCB consist of 4 PDP Scan Driver IC.

Driver IC controls 65 of high current and high voltage of output by using the

65 bit cascadable 8MHz shift register. Additionally, 64 or 65 bit of output

may be used depending on input values into the SEL port. Driver IC is

supplied with the 150V power output and the 5V logic power separately.

Command inputs are compatible with CMOS.

16

ORION PDP CO.,LTD

Page 17

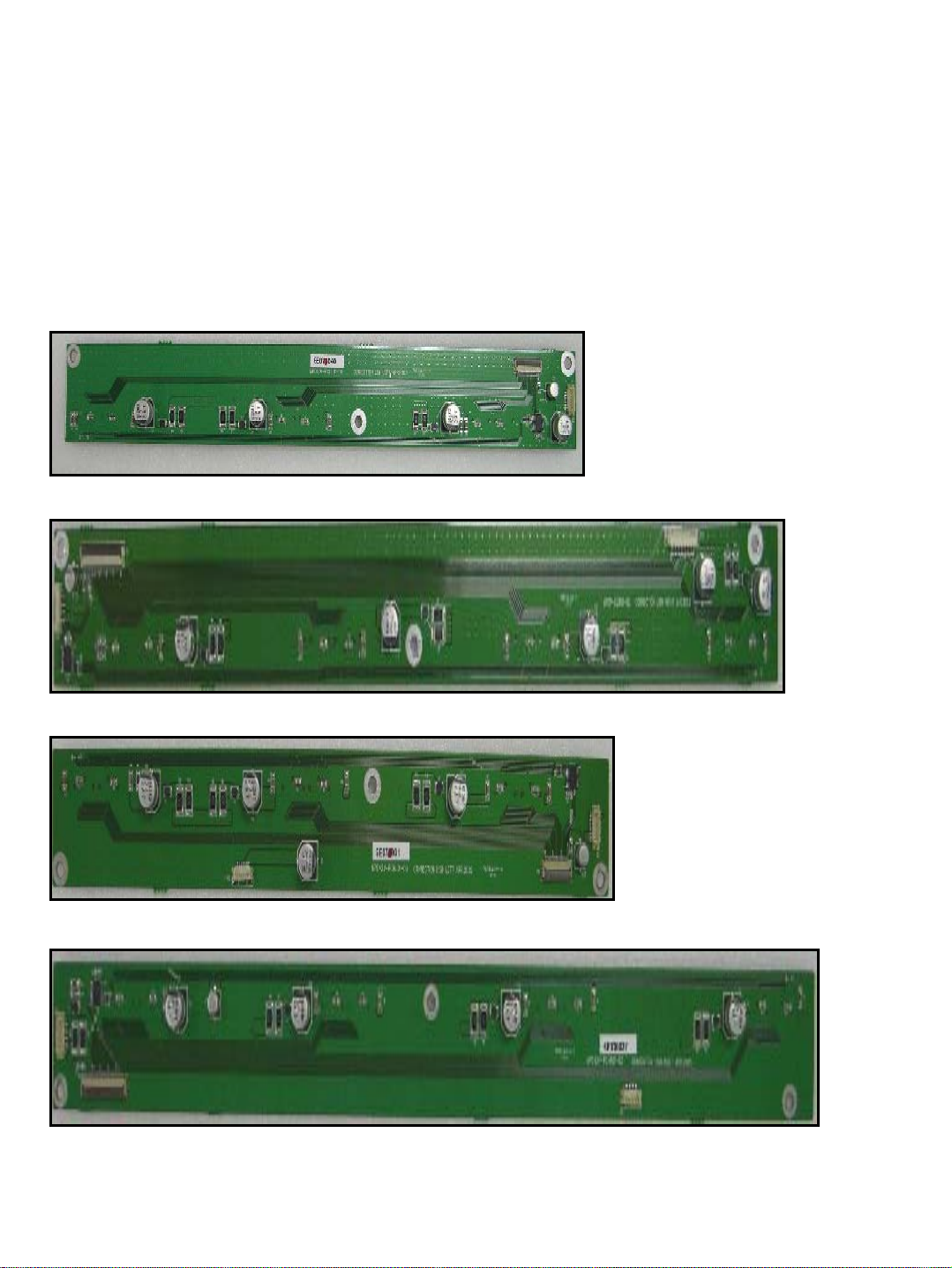

5-7. CON HIGH LEFT & RIGHT / CON LOW LEFT & RIGHT PCB

The CON HIGH LEFT & RIGHT / CON LOW LEFT & RIGHT PCB are

connecting the data signal from SUS Y PCB with Z(data) Driver IC which is

attached to the Panel.

The CON HIGH LEFT & RIGHT / CON LOW LEFT & RIGHT PCB are

connected to totally 7 COF(Chip On Film).

COF consists of the DATA Driver IC.

Those 7 COF having 2559 lines are connected with Panel.

CON LOW LEFT(LL) PCB

CON LOW RIGHT(LR) PCB

CON HIGH LEFT(HL) PCB

CON HIGH RIGHT(HR) PCB

17

ORION PDP CO.,LTD

Page 18

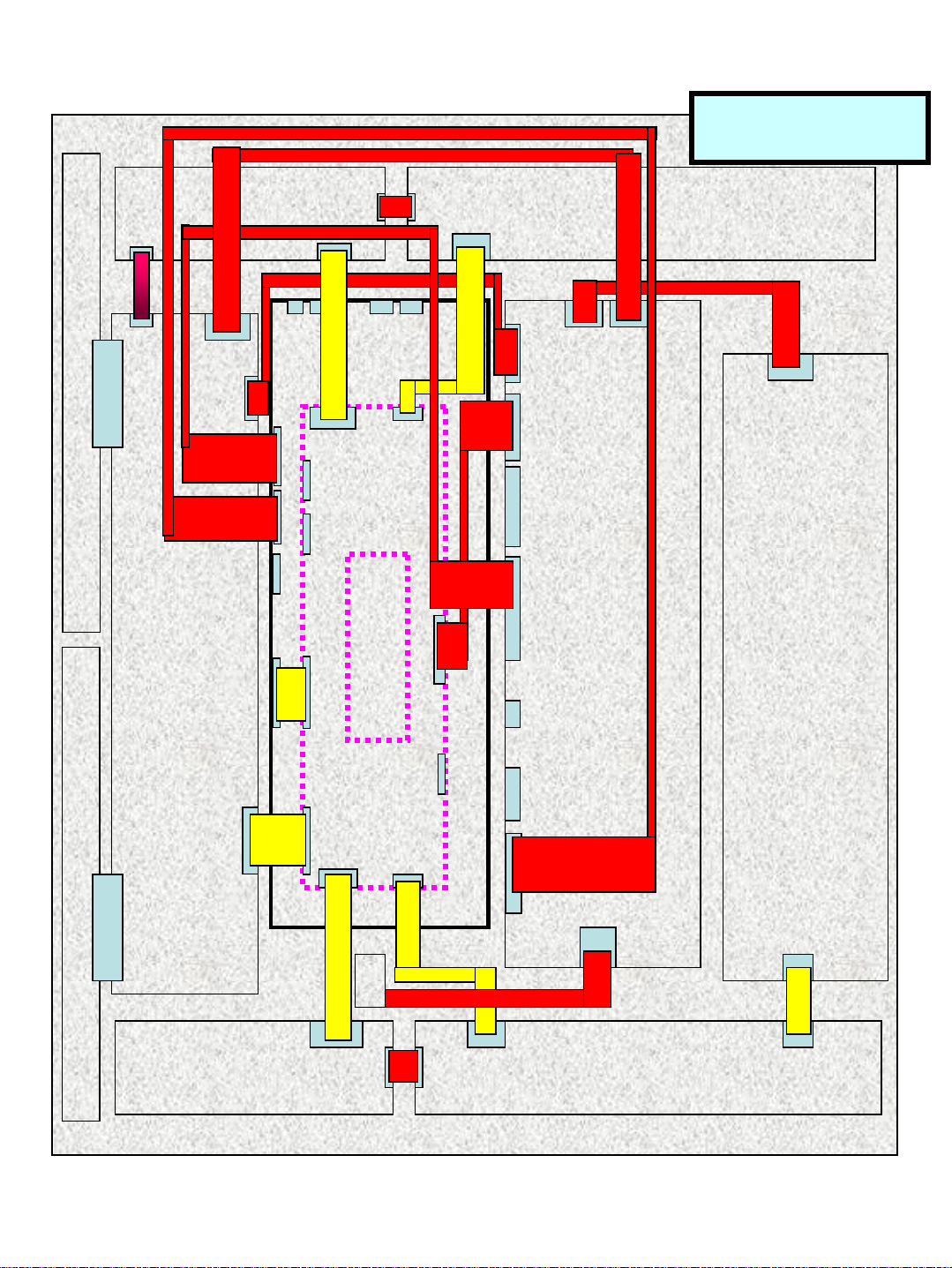

6. Wiring Diagram [Signal Line & Power Line]

*Yellow : signal line

*Red : power line

CON HIGH LEFT

CON HIGH RIGHT

④

P201A

P6

SCAN HIGH

①

P2

⑤

P1

P6

⑧

⑨

⑥

P4

J6

J3

JJ2

JL1

JN1

P5 P6

⑫

IP

BOAR

D

H1

52

ID

7

ID2

7

①

JC1JC

2

P302

P7

⑪

⑦

⑥

④

CN808

CN805

CN807

CN804

⑤

CN806

POWER

SUS Y

P1O2A

SCAN LOW

CON LOW LEFT CON LOW RIGHT

⑩

JP1

③

DIGITAL

U2

H141

H151 P304

⑫

AC

P4

P5

①

PA301A

U4

⑪

P6

⑦

⑧

P7

SUS X

CN803

CN809

CN802

CN80

1

⑨

CN101

P2021A

⑬

②

P5

18

ORION PDP CO.,LTD

Page 19

*A]The specification of connection

No.

①

②

③

④

⑤

⑥

MATERIAL

NUMBER

M7506149

M7506150

M7506151

M7506148

M7506146

M7506147

MATERIAL NAME SPECIFICATION

CONNECTOR CABLE 6P12505HS-

06+12505TS+ULW=50

CONNECTOR CABLE

12P

CONNECTOR CABLE

15P

CONNECTOR CABLE

8P

CONNECTOR CABLE

10P

CONNECTOR CABLE

4P

12505HS-

12+12505TS+ULW=90

12505HS-

15+12505TS+ULW=90

YH396-08V+YT396J+ULW=400 1 EA X_SUS

YH396-10V+YT396J+ULW=400 1 EA Y_SUS

YH396-04V+YT396J+ULW=300 1 EA Y_5V

Q’

TY

UNIT

3EA

1EAX~CON

1EAY~DIG.

REMAR

K

CON~

CON,Y

M7506155

⑦

M7506143

⑧

M7506154

⑨

M7506145

⑩

M7519752 FFC 50P 100L 0.5pt SINGLE SIDE 2 EA

⑪

M7519753 FFC 30P 80L 0.5pt SINGLE SIDE 2 EA

⑫

M7519247 NOISE FILTER 02P-210M(TDK)-INLET(D)

⑬

CONNECTOR CABLE

4P

CONNECTOR CABLE

10P

CONNECTOR CABLE

6P

CONNECTOR CABLE

31P

171822-08+170262-1=100 1 EA DIG._5V

SMH250-10+LH01-250-12=460 1 EA AV-POW

SMH250-06+LH01-250-07=590 1 EA AV-POW

GT121-31S-CD+GT121-C-

15000=120

19

1EAAV-DIG

1EA

ORION PDP CO.,LTD

Page 20

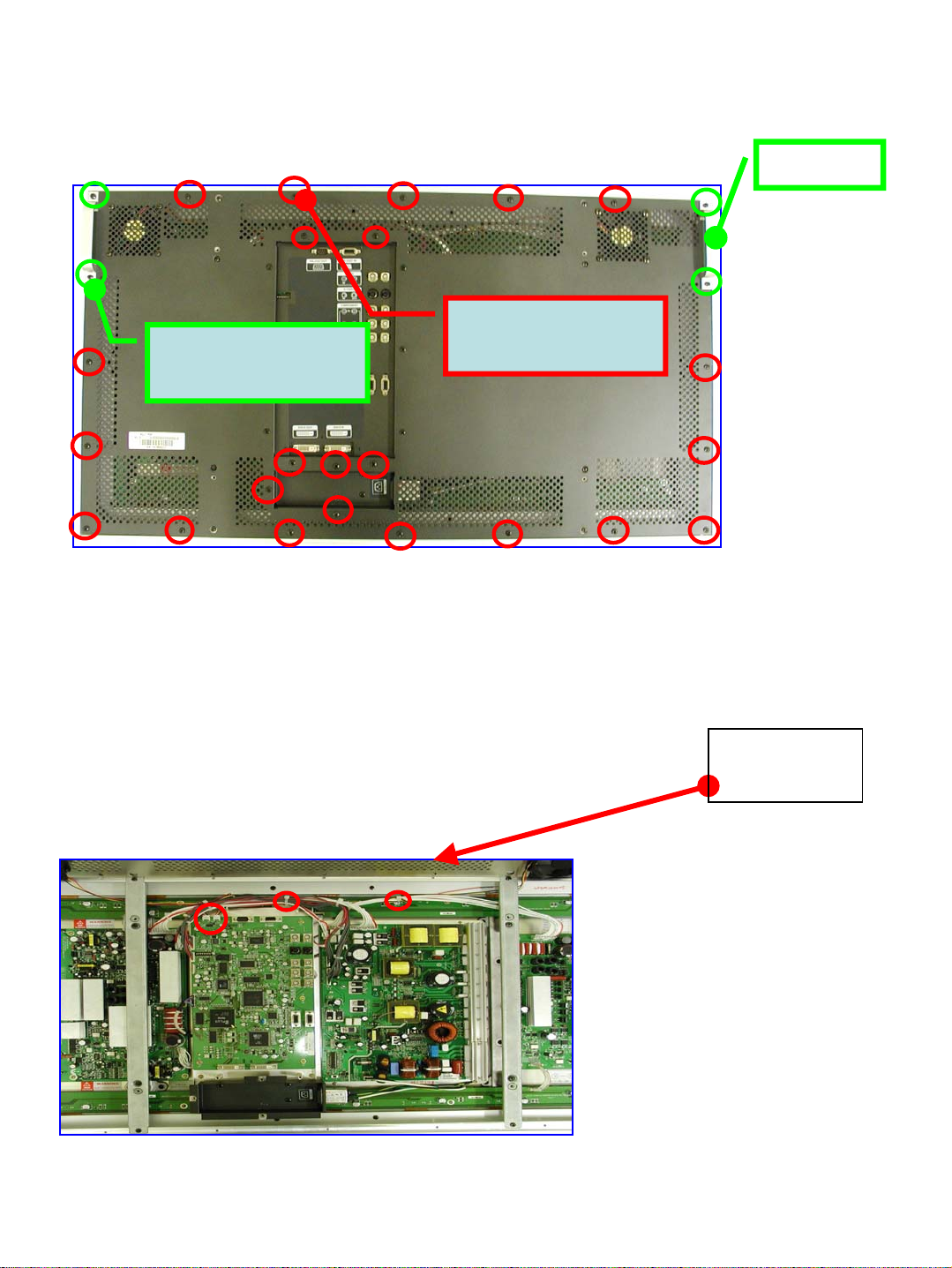

7.Dismantling Procedure

7-1. Dismantling of Back Cover

GREEN CIRCLE

M4×8 : 4EA

Handle

RED CIRCLE

M4×5 : 32EA

1) Materials Used

M7543053 SCREW MACHINE M4×8 BIND MFZN 4EA

M7543073 SCREW MACHINE M4×5 BIND MFZN 23EA

2) Dismantling Procedure

① Remove 4 screws to fasten handle.

② Remove edge screws first, then continue on

to remove other screws.

③ Lift up back cover as

shown in the picture to

the left. Then, remove

J3 and J6 connectors.

④ After removing the cable

tie, remove fan cable.

Back

Cover

20

ORION PDP CO.,LTD

Page 21

7-2. Dismantling of I/P Plate Assembly

ⓐConnector

Dismantling Position

CN01

FIG22]Before I/P PCB

Dismantling

IP

Assembly

Screw

CN01

GN

D

GND

FIG23] I/P ASSEMBLY

FIG24] After I/P PCB Dismantling

FIG24]I/P Plate+Noise

1) Materials Used

M7543061 SCREW MACHINE PSW M3×8 MFZN 9 EA

2) Dismantling Procedure

① Dismantle connector in magenta circle of ⓐ in Fig. 22].

② Remove 4 screws in yellow circle of ⓑ in Fig. 22].

③ Dismantle CN01 connector of ⓒ in Fig. 22].

④ Remove 2 screws of GND of ⓓ in Fig. 22].

⑤ Remove I/P PCB from the dismantled IP assembly[Fig. 23].

Remove 5 screws in red circle.

⑥ Dismantled up to the status indicated in Fig. 24].

21

Filter Ass’y

ORION PDP CO.,LTD

Page 22

7-3. Dismantling of Support Bracket

Support Bracket

1) Materials Used

M7543053 SCREW MACHINE BIND M4×8 MFZN(BLACK) 8 EA

2) Dismantling Procedure

① Remove 4 fixing screws on the right.

② Remove 4 fixing screws on the left.

22

ORION PDP CO.,LTD

Page 23

7-4. Dismantling of Master Frame

1) Materials Used:

M7543053 SCREW MACHINE BIND M4×8 MFZN(BLACK) 10 EA

2) Dismantling Procedure (Refer to the above picture indicating the screws to

be removed.)

There is no particular order of dismantling. However, make sure to remove

all 10 screws. The below picture indicates the pure module status after

dismantling master frame.

23

ORION PDP CO.,LTD

Page 24

7-5. Dismantling of Wires

1) Dismantling Procedure:

When dismantling wires, make sure to dismantle all of the 13 varieties

without any specific order.

During assembly, take caution not to cause damage to connectors. Refer

to 6. Wiring Diagram (Signal & Power line) for wire connection.

2) The below picture shows wires dismantled from the above picture.

24

ORION PDP CO.,LTD

Page 25

7-6. Dismantling of SCAN PCB

1) Materials Used:

M7543061 SCREW MACHINE PSW M3×8 MFZN 4 EA

2) Dismantling Procedure (Refer to above picture for screwed to be removed.)

Remove all 4 screws without any specific order. The picture below shows

the process of FPC dismantling after removing screws.

25

ORION PDP CO.,LTD

Page 26

7-6-1. Tips for disassembling

1) SCAN LOW & HIGH PCB

FPC

Picture 1. Not recommended

2) CON LOW/LEFT & RIGHT PCB

Picture 2. Recommended

COF

Picture 1. Not recommended Picture 2. Recommended

<Attention> As Picture 1, it is not recommended taking out FPC and COF from PCB

Connector horizontally. As Picture 2, hold Scan PCB Connector as pictured and pull

down the PCB and take out FPC and COF.

3) CON_HIGH/LEFT & RIGHT PCB

: The same is recommended as CON LOW/LEFT & RIGHT PCB

26

ORION PDP CO.,LTD

Page 27

7-7. Dismantling of SUS Y PCB

1) Materials Used:

M7543051 SCREW MACHINE PSW M3×8 MFZN 7EA

2) Dismantling Procedure(Refer to above picture for screws to be removed.)

Remove all 7 screws without any specific order.

27

ORION PDP CO.,LTD

Page 28

7-8. Dismantling of SUS X PCB

1) Materials Used:

M7543061 SCREW MACHINE PSW M3×8 MFZN 6EA

2) Dismantling Procedure (Refer to above picture for screws to be removed.)

Remove all 6 screws without any specific order.

The below picture shows the process of FPC dismantling after removing

screws.

28

ORION PDP CO.,LTD

Page 29

7-9. Dismantling of DIGITAL / POWER PCB

1) Materials Used:

M7543061 SCREW MACHINE PSW M3×8 MFZN 12EA

2) Dismantling Procedure (Refer to above picture for screws to be removed.)

Remove all 12 screws without any specific order.

29

ORION PDP CO.,LTD

Page 30

7-10. Dismantling of CON PCB

1) Materials Used:

M7543061 SCREW MACHINE PSW M3×8 MFZN 20EA

2) Dismantling Procedure (Refer to above picture for screws to be removed.)

Remove all 12 screws without any specific order.

The below picture shows the process of COF dismantling. The process is

the same as of SUS Y PCB FPC dismantling.

30

ORION PDP CO.,LTD

Page 31

8. Adjustment Method

8-1. Voltage Adjustment

1) Measurement instruments

① Multi test signal such as BSG-360A and BSG-265L or equivalent

② Color Analyzer such as CA-100 or equivalent

③ Millimeter (acceptable tolerance is 0.5%)

④ Computer: The following is recommended.

SXGA(Resolution: 1024 * 768,60Hz) True color 16 Bit

2) Power Board Adjustment

1) Factors for adjustment

TP

CN 808/CN806

VR301

For Vsus Adjustment

VR :Variable Resistor

TP : Test Point

For Vadd Adjustment

2) Voltage adjustment

-Turn on the SET by MSCS Control.

-Select the Input of Your Using Signal

-Set the voltage as written on the

back-plate, refer to Fig1].

Min Type Max Preset TP

Vsus 180V 190V

Vadd 65V 70V

195V 190V

VR401

70V75V

Fig1]The voltage label

On the back plate

CN808 #1 PIN

CN806 #1 PIN

31

ORION PDP CO.,LTD

Page 32

3. Y Board Adjustment

1) Factors of Adjustment

ΔRamp-Down : To be indicated as ΔRamp-Dn

2) Voltage adjustment

After Power board voltage adjustment, Y Board voltage is to be

adjusted.Adjust the voltage as written on the back plate refer to fig1].

Ramp Up & Ramp Down should not be adjusted because it is possible

with Oscilloscope .But You Set a Center of Each VR’s Variable Range.

RY9

Adj-Vramp

RY33

TP_Vramp

LY28

TP_Vscan

RY16

Adj-Vshelf

LY31

TP_Vyer

LY10

TP_Vshelf

RY8

Adj-Vscan

32

RY18

Adj-Vyer

RY2

Adj-ramp_up_T

RY10

Adj-ramp_down_T

ORION PDP CO.,LTD

Page 33

Vyer Vy_shelf Vy_scan Vramp_up

ΔRamp-

Up

ΔRamp-Dn

Min 170V 80V 210V 40usec

Type 175V 85V 215V 145usec

115V

Max 180V 90V 230V 230usec

Preset 175V 85V CENTER

VR RY18 RY8 RY9 RY2 RY10

TP LY31 LY28 -

~

120V

Fixed

Voltage

215V

RY33

70usec

80usec

CENTER

-

110usec

4. X Board adjustment

1) Factors of adjustment.

RCU70

Adj_Vxshelf

LCU 1

TP_Vxshelf

2) Voltage adjustment

After Y board voltage adjustment, X Board voltage is to

be adjusted.Adjust the voltage as written on the back plate’s

label

33

ORION PDP CO.,LTD

Page 34

8-2. White Balance Adjustment

1. Preparation

1) Connect all signal lines and power cables required for set adjustment.

2) Set and check the set ID.

3) Run MSCS.EXE program to prepare for adjustment on the basis of details

specified in operation manual.

A] Setting and Connection of Com Port

B] Setting Multi Screen for the Installed Set

C] Setting Select Input

4) Check all M-PDP columns in PDP Control and click ‘power on’ button to

turn on multi screen.

* Set values in overall mode as of the set values indicated in Appendix 1].

5) Signal Device and Measuring Instruments Used

A] Luminance and Chromaticity Meter

------ CA-100 or other devices of equivalent or higher capacities

B] Signal Device [All Input Display]

---- BSG-360A or other devices of equivalent or higher capacities

C] Digital Voltage Meter [DVM,A-level Device]

6) Prior to adjusting white balance, let multi screen age for 20minutes or

more in full white 70% level.

7) Change to individual mode to administer adjustment.

*Take caution to prevent image retention caused by long-term fixed pattern

during adjustment.

[Refrain from using of the same pattern for 2 minutes or longer.]

34

ORION PDP CO.,LTD

Page 35

2. White Balance Adjustment

1) Adjustment Procedure [as of Input Mode]

*DVI ⇒ PC ⇒ DTV-YUV ⇒ DVD ⇒ VIDEO ⇒ S-VIDEO ⇒END

2) Adjustment of DVI Mode

A] Authorization Pattern: Vertical 8

gray pattern in Fig. 3]

B] Timing: 1024 × 768 ,60Hz

C] Adjustment Procedure

① Attach measuring probe of luminance meter in position 2) of Fig. 3].

Refer to Fig. 3].

② In MSCS, Click “Picture Control” of “Control” menu bar in order to run

“Picture Control” window

③ Input the password [ password : jglee ] .

Then will be displayed the below picture (Fig. 2).

if the values of active window are ‘0’, click the PDP SET Image to load

Fig 1] Full White

Luminance

Meter

Probe

the saved values.

*Set values as indicated in Appendix 1].

Fig 2] White Balance Adjustment Screen

35

ORION PDP CO.,LTD

Page 36

④ Adjust gain values (R.G.B.) in white balance of Fig 2] to adjust color

coordinates and luminance.

*Color Coordinates :

x : 0.285±0.001, y : 0.300±0.001, Y : 98 cd/㎡±1 cd/㎡

A] Set B as 100 and adjust G to adjust luminance. Then, adjust R to adjust

coordinates.

B] In case the conditions of luminance are satisfied, but coordinates are not

suitable, adjust R and G after adjusting B.

C] When adjustment is not satisfactory, reduce luminance by 3 cd/㎡ and

administer adjustment as in clause 1] and 2].

⇒Luminance is classified into 3 levels: 98,95,92 cd/㎡

D] When adjustment is completed, click ‘exit’ button in Fig. 2].

3) Adjustment of PC Mode

A] Authorization Pattern: Cross match

B] Timing: 1024 × 768 ,60Hz

C] Adjustment Procedure

① Click ‘auto tracking’ button. (all M-PDPs must be checked.)

② Authorize vertical 8 gray pattern as in Fig. 3].

③ In MSCS, Click “Picture Control” of “Control” menu bar in order to run

“Picture Control” window

④ Input the password [ password : jglee ]. Then will be displayed the below

picture (Fig. 2). if the values of active window are ‘0’, click the PDP SET

Image to load the saved values.

⑤ Administer setting so the values are as indicated in Appendix 1]. Then,

administer adjustment.

⑥ Attach probe of luminance meter in position A) of Fig. 3] to adjust graphic

data values of Fig. 4] so that W/B coordinates can be adjusted as of A) in

the following page.

⑦ Attach probe of luminance meter in position B) of Fig. 3] and administer

adjustment as of B) in the following page.

⑧ After completing adjustment, attach probe in position A) of Fig. 3] again to

check coordinates. If the coordinates do not correspond, repeat the above

processes of 6) and 7).

⑨ After authorizing pattern as indicated in Fig. 1], check if conditions of

luminance and coordinates are satisfied.

x : 0.285±0.005, y : 0.300

⑩ When adjustment is completed, click ‘exit’ button in Fig. 2].

±0.005, Y : 140cd/㎡ or more

36

ORION PDP CO.,LTD

Page 37

*Adjustment Values

*Adjustment Values

A) B)

x : 0.285±0.001

y : 0.300±0.001

Y : 15 cd/㎡±1 cd/㎡

Fig. 6] Low Gradation

Adjustment Coordinates

[Caution] Adjust No. 1 with offset R/G/B.

Adjust No. 2 with gain R/G/B.

Readjustment required if differences are found between

No. 1 and 2 after adjustment

A)

B)

x : 0.285±0.001

y : 0.300±0.001

Y : 98 cd/㎡±1cd/㎡

Adjust DVI with luminance.

Fig. 7] High Gradation

Adjustment Coordinates

Fig. 3] Vertical 8 Gray Pattern

Fig. 4] PC/DTV-YUV Adjustment Screen

37

ORION PDP CO.,LTD

Page 38

4) Adjustment of DTV-YUV Mode

A] Authorization Pattern: Fig. 3] Vertical 8 Gray Pattern

B] Timing: PAL region ⇒ 576P

NTSC region ⇒ 720P[60Hz]

C] Adjustment Procedure

① In MSCS, Click “Picture Control” of “Control” menu bar in order to run

“Picture Control” window

② Input the password [ password : jglee ]. Then will be displayed the below

picture (Fig. 2). if the values of active window are ‘0’, click the PDP SET

Image to load the saved values.

③ Set values as indicated in Appendix 1] and administer adjustment.

④ Attach probe of luminance meter in position 1) of Fig. 3).

Then, use offset R/G/B to administer adjustment so that to achieve the

status as indicated in Fig. 6].

⑤ Attach probe of luminance meter in position 2) of Fig 3].

Then, use gain R/G/B to administer adjustment so that to achieve the

statue as indicated in Fig. 7].

⑥ Attach probe of luminance meter in position 2) of Fig 3] to adjust gain G

so that the luminance requirements of Fig. 7] are satisfied. Then, adjust

gain R&B to adjust coordinated.

⑦ After authorizing pattern as in Fig 1], check if the conditions of luminance

and coordinates are satisfied.

x : 0.285±0.005

y : 0.300±0.005

Y : 140 cd/㎡ or more

⑧ When adjustment is completed, click ‘exit’ button in Fig. 2).

38

ORION PDP CO.,LTD

Page 39

5) Adjustment of DVD Mode

A] Authorization Pattern: Authorizing Fig.1] Full White Pattern/ Vertical 8

Gray

B] Timing: PAL region ⇒ 576i

NTSC region ⇒ 480i

C] Set values as indicated in Appendix 1].

D] Check for abnormalities in screen when changing mode. Also, set

probe as

indicated in Fig. 1] and check if the following conditions are satisfied.

x : 0.285±0.005

y : 0.295±0.005

Y : 140 cd/㎡ or more

6) Adjustment of Video Mode

A] Authorization Pattern: Authorizing Fig. 1] Full White Pattern/ Vertical

8 Gray

B] Timing: PAL region ⇒ PAL-B

NTSC region ⇒ NTSC

Set values as indicated in Appendix 1].

hen changing mode. Also, set probe as

en changing mode. Also, set probe as

set probe as

ndicated in Fig. 1] and check if the following condition are satisfied.

if the following condition are satisfied.

if the following condition are satisfied.

ed.

) Adjustment of S-Video Mode

A] Authorization Pattern: Authorizing Fig. 1] Full White Pattern/ Vertical 8 Gray

ull White Pattern/ Vertical 8 Gray

NG : PAL region ⇒ PAL-B

SECAM region ⇒ SECAM

n changing mode. Also, set probe as

changing mode. Also, set probe as

et probe as

dicated in Fig. 1] and check if the following conditions are satisfied.

the following conditions are satisfied.

llowing conditions are satisfied.

ing conditions are satisfied.

39

ORION PDP CO.,LTD

Page 40

Appendix1]”White Balance” Default Values

*White Balance Default Values per Initial Input Mode [DVI,PC,DTV]

ITEM DEFAULT[DVI] ITEM DEFAULT[PC]DEFAULT[DTV]

Gain R 49 Gain R 63 79

Gain G 83 Gain G 67 69

Gain R 100 Gain R 59 77

Gamma

R

Gamma

G

Gamma

B

CSC R 98 *RED letters changed when adjusting white

CSC G 98

CSC B 98

Bias 50

*User Mode Set Values[Only brightness differing per graphic/ video mode]

Value

50 Offset R 61 90

50 Offset G 68 77

50 Offset B 63 91

balance

*Black letters fixed

BRIGHTNESSITEM

EO]

CONTRA

ST

SHARPN

ESS

TINTCOLO

R

1515152015[20:DVD.VIDEO,SVID

*Video Data[Component: Fixed]

BRIGHT

NESS

E

M

lue

CrIT

C

40

TI

NT

b

CONTR

AST

30200204040Va

*Video Data[Composite: Fixed]

ITE

M

ue

BRIGHT

NESS

ORION PDP CO.,LTD

CON

TRAS

T

COL

OR

12545145Val

Page 41

9.How To Upgrade

9-1.PC System Requirements

Use the following PC-system to run the Flash Loader efficiently

- Standard PC.

- operating system : Windows 9x, Windows ME, Windows 2000,

Windows NT or Windows XP

- Serial port.

9-2. Program Down_Load

1.Connect the serial port of the PC to the RS-232C port of MPDP.

2.Invoke the Flash Loader, click Star and select Programs /

Oplus/ FLASH Loader. And Then The Flash Loader main window

is displayed such as FIG1]

Title Bar

Fig 1) Flash Loader Main Window (No Communication)

41

Status Bar

ORION PDP CO.,LTD

Page 42

*Explain to buttons on the FIG1]

1) Title Bar Commands

The title bar command icons are used to invoke on-line help ?),

minimize the dialog box (-) or to close the Flash Loader application (x)

2) Status Bar Information

The status bar provide important information about the status of the

Flash Loader as described below.

The Connected icon is shown when the Flash Loader has allocated the

Com port " of the PC during search for a target,

programming or verification of the Flash.When the Flash Loader has

finished the search for a target, programming or“ verification it will

release the Com port and display the Disconnected icon.

The Search Target icon is shown when the Flash Loader is trying to

start the communication with the MPDP.

The icon will vanish after the communication has been successfully

established.

3. Click the “COM” button to configure and

initiate the serial communication between the PC and MPDP.

42

ORION PDP CO.,LTD

Page 43

The COM Settings dialog box is displayed.

Select the "COM Port" on the PC that is connected to the MPDP and

choose the "Baud Rate" 115200.“

Fig 2) COM Port Setting

Click the “OK” button to close the dialog box and to return to the Flash

Loader main window. It will now display the current information about

the Flash.

*Note: If the selected Com port is already allocated by some other

application (e.g. HyperTerminal) the error message will be displayed

such as FIG3].

You should close the application that has allocated the port

Fig 3) Error Message

43

ORION PDP CO.,LTD

Page 44

4. Connect the POWER Cord to invoke the Boot Loader.

*Note: The Boot Loader will during 2 seconds check if the Flash

Loader is running. If this is the case, the Boot Loader

will initiate the communication with the Flash Loader.

Fig 4) Flash Loader Main Window

Click the “Init” button to initiate the communication with the board.

*Explain to character on Fig 4)

1) Flash Manufacturer

The manufacturer of the Flash.

2) Flash Product ID

The product Id of the Flash.

44

ORION PDP CO.,LTD

Page 45

5.Click the “Browse” button to select the files to program

6. Click the “Start” button to start the selected action program.

The status bar at the bottom of the dialog box will show the programming.

A message will show the result of the programming.

Tip: The Start button will change function to Stop during the action.

Fig 5) Flash Loader Main Window (Programming)

45

ORION PDP CO.,LTD

Page 46

Fig 6) Flash Loader Message Program OK

7. Click the “OK” Button

8. Disconnect the POWER Cord.

46

ORION PDP CO.,LTD

Page 47

10. Trouble Shooting (Measures per Symptom)

10-1. Power Not Turned On

Check AC Inlet Power

Yes

POWER Cord connected?

Yes

RS-232 cable

correctly

connected?

No

No

No

Take a step so that the

power can be supplied

normally.

Reconnect

POWER Cord.

Reconnect

RS-232 cable.

Yes

Check the input

signal source.

Yes

47

No

Take a step so that

the signal is

displayed correctly.

ORION PDP CO.,LTD

Page 48

MSCS connection correct?

Yes

Click ‘power on’

button

repeatedly.

Does it operate

correctly?

Yes

No

No

Re-click ‘Connect’

button of MSCS.

Dismantle POWER

Cord and reconnect

it after 1 minute.

Connect MSCS and

turn the power on.

Replace

I/P PCB.

Complete

No

Power

turned

on ?

Yes

48

ORION PDP CO.,LTD

Page 49

10-2. Power turned On But color Defected or the set is not worked.

Check signal

output of

selected signal

source.

Yes

LVDS cable

connected

correctly?

Yes

Replace

I/P PCB.

No

Change signal

device or fix.

No

Reconnect

LVDS cable.

49

Yes

Operate

normally?

Yes

Complete

No

Replace

DIGITAL PCB.

ORION PDP CO.,LTD

Page 50

10-3. Power Turned Off After Few Seconds of Being Turned On

Dismantle power

cord for 1 minute

and reconnect it.

Operate

correctly?

No

Dismantle I/P PCB

and operate plank

state.

Operate

normally?

Yes

Replace

I/P PCB.

Yes

No

Complete

Dismantle wires

connected to SUS Y

and POWR PCB.

Operate

normally?

Yes

Replace

SUS Y PCB.

50

Complete

No

Dismantle wires

connected SUS X and

POWER PCB.

Complete

ORION PDP CO.,LTD

Page 51

Operate

normally?

No

Dismantle wires

connected to DIGITAL

and POWER PCB.

Operate

normally?

No

Yes

Replace

SUS X PCB.

Complete

Yes

Replace

DIGITAL PCB.

Replace

POWER PCB.

Complete

Complete

51

ORION PDP CO.,LTD

Page 52

10-4. Vertical Blankness on Screen (Block Type)

CON PCB and

FFC connected

correctly?

Yes

CON PCB and

COF

Connected

correctly?

Yes

No

No

No

Reconnect

FFC.

Operate

correctly?

Reconnect COF.

Yes

Complete

Replace

CON PCB.

Operate

normally?

Yes

Complete

52

No

No

Operate

normally?

Replace

DIGITAL PCB.

Yes

Complete

ORION PDP CO.,LTD

Page 53

10-5. Vertical Blankness on Screen (Irregular Lines Missing)

Replace

DIGITAL PCB.

Operate

normally?

Yes

No

Replace

PANEL.

Complete

53

ORION PDP CO.,LTD

Page 54

10-6. Dark Screen or Flickering

Check output voltage

of SUS X, SUS Y and

POWER PCB.

Output

voltage

normal?

Yes

Dismantle

SCAN HIGH PCB.

Yes

Display in the

lower section

normal?

Yes

Replace

SCAN HIGH PCB.

Yes

No

No

Readjust output

voltage.

Voltage

successfully

adjusted?

Dismantle SCAN

LOW PCB and

connect SCAN

HIGH PCB.

Operate

normally?

No

Yes

Replace the PCB,

If The Voltage. is

not adjusted.

Complete

Replace

SCAN LOW PCB.

54

Yes

Operate

normally?

Yes

Complete

No

No

Replace

SUS Y PCB.

Complete

ORION PDP CO.,LTD

Page 55

Operate

normally?

No

Replace

SUS X PCB.

Complete

Yes

Complete

55

ORION PDP CO.,LTD

Page 56

10-7. Horizontal Noise Formed on Screen

Check connection

between I/P PCB

and display device.

GND

correctly

connected?

Yes

Replace

I/P PCB.

No

Reconnect or

replace signal line.

No

Operate

normally?

Yes

56

Complete

ORION PDP CO.,LTD

Page 57

10-8. Black or White Horizontal Lines Formed on Screen

Reconnect FPC

connected to SCAN

PCB corresponding

to the part of line

formation.

No

Operate

normally?

Replace

SCAN PCB.

Yes

Complete

Yes

Operate

normally?

Replace PANEL.

Complete

57

ORION PDP CO.,LTD

Page 58

11. Part Replacement and Related Details

※ When reparing set, make sure to locate set on a smooth and thick

material placed on flat surface.

11-1. Replacement of I/P PCB

1. Save the white balance value of the defected IP PCB.

2. Dismantle back cover.

3. Dismantle 3 wires connected.

4. Replace defected I/P PCB.

5. Set white balance with the existing value by through control program.

6. Adjust PC and DTV-YUV mode in accordance with the white balance

adjustment method in Chapter 5.

7. When adjustment is completed, compare set with other sets so that the

colors can be adjusted to be similar to the colors of other sets.

11-2. Replacement of SUS Y PCB

1. Dismantle back cover.

2. In order to conveniently dismantle SUS Y PCB, loosen bolts

fastening SCAN PCB so that the depth of fastening is about half the

original.

3. Dismantle 3 wires connected.

4. Replace defected SUS Y PCB.

5. Set Vyer, Vscan and Vramp-up by referring to the adjustment voltages of

voltage label attached to back plate.

11-3. Replacement of SUS X PCB

1. Dismantle back cover.

2. Dismantle FPC connected to SUS X PCB.

3. Dismantle 2 wires connected.

4. Replace defected SUS X PCB.

5. Set Vx-shelf as the adjustment voltage of voltage label attached to back

plate.

58

ORION PDP CO.,LTD

Page 59

11-4. Replacement of Power Board

1. Dismantle back cover.

2. Dismantle 7 wires connected.

3. Replace defected POWER PCB.

4. Set Vsys and Vadd by referring to the adjustment voltages of voltage

label attached to back plate.

11-5. Replacement of DIGITAL PCB

1. Dismantle back cover.

2. Dismantle I/P PCB and I/P plate.

3. Dismantle 1 wire and 4 FFCs connected.

4. Replace defected DIGITAL PCB.

11-6. Replacement of SCAN PCB

1. Dismantle back cover.

2. Dismantle master frame.

※ In order to prevent damages on COF in the course of dismantling,

make sure dismantling should be done by a team two persons.

3. Replace defected SCAN PCB.

11-7. Replacement of CON PCB

1. Dismantle back cover.

2. Dismantle master frame.

※ In order to prevent damages on COF in the course of dismantling, make

sure dismantling should be done by a team two persons.

3. Replace defected CON PCB.

59

ORION PDP CO.,LTD

Page 60

12.Spare Parts List

No

1 P70100A00C CARTON BOX MPDP 1 set BOX Ass’y

2 P70300A003 PACKING PAD MPDP-EPP 1 set

3 G7740145 ASSEMBLED MOD WSBAMIS4201 1 EA PLANK

4 G7714004 B/P ASSEMBLED PNL MSPA4201 1 EA BACK+PANEL

5 G7814020

6 M7570556 GUIDE PIN PM42M-GUI00-00 4 EA

7 M7570549 SUPPORT BRACKET PM42V-SUB00-00 2 EA

8 G7814021 COVER BACK ASS'Y MPDP(3P) 1 EA

9 M7570586 COVER BACK PM42M-CBA000-00 1 EA Back Cover

10 M7543066 SCREW TAPTITE

Material

Number

MASTER FRAME

Material

Name

ASS'Y

Material Specification

MPDP-01 1 EA

TT2 PAN 5*12

MFZN(BLACK)

Q’

ty

8EA

Un

it

Remark

EPP PAD

Ass’y

ATTACHED

FAN

FOR FAN

ASSEMBLY

11 M7543070 SCREW MACHINE

12 M7543053 SCREW MACHINE

13 M7572082 DC-FAN AD0812DB-A72GL-550 1 EA

14 M7572083 DC-FAN AD0812DB-A72GL-250 1 EA

15 M7570557 HANDLE PM42M-HAN00-00 2 EA

16 M7572950

17 M7572931 BACK LABEL(EU) MPDP-4201-00 1 EA

BACK LABEL

(CHINA)

BIND M4*5

MFZN(BLACK)

M4×8 BIND

MFZN(BLACK)

MPDP-4201-01 1 EA

32 EA

22 EA

COVER

BACK+

I/P COVER+

NOISEFILTER

COVER

SUPPORT

BRACKET+

HANDLE+

MASTER

FRAMR ASS'Y

CHINA CCC

LABEL

Others

Country

60

ORION PDP CO.,LTD

Page 61

No

Material

Number

Material

Name

Material Specification

Q’tyUn

it

Remark

18 M7572932 AV BACK LABEL MPDP-4201-POWER

19 M7570587 NOISE FILTER COVER PM42M-NFC00-00

20 M7519247 NOISE FILTER 02P-210M(TDK)-INLET(D)

21 M7543069 SCREW MACHINE

22 M7543061 SCREW MACHINE PSW M3*8 MFZN 74 EA

23 G7800004 SCAN-H ASS'Y MPA42V-PSH01 1 EA

24 G7802003 SCAN-L ASS'Y MPA42V-PSL01 1 EA

25

G7806005 CONN-HR-ASS'Y MPA42V-PCHR01 1 EA

26 G7804005 CONN-HL-ASS'Y MPA42V-PCHL01 1 EA

BIND M3*8 PW

MFZN(BLACK)

EA

EA

EA

EA

Board

ASS'Y

+BACKPLATE

27 G7806006 CONN-LR-ASS'Y MPA42V-PCLR01 1 EA

28 G7804006 CONN-LL-ASS'Y MPA42V-PCLL01 1 EA

29

G7808004 SUS-X-ASS'Y MPA42V-PXS01 1 EA

30 G7810002 SUS-Y-ASS'Y MPA42V-PYS01 1 EA

31

G7812005 DIGITAL ASS 'Y MPA42V-PDI01 1 EA

32 M7512011 POWER DGO-120S1 1 EA

33 G7840000 IP ASS'Y MIS4201-IP-00 1 EA

34 M7570552 I/P COVER PM42M-IPC00-00 1 EA

35 M7570551 I/P PLATE PM42M-IPP00-00 1 EA

36 M7506149

61

CONNECTOR CABLE

6P

12505HS06+12505TS+ULW=50

3EA

ORION PDP CO.,LTD

CON~C

ON,Y

Page 62

No

Material

Number

Material

Name

Material Specification

Q’tyUn

it

Remark

37 M7506150

38 M7506151

39 M7506148 CONNECTOR CABLE 8P YH396-08V+YT396J+ULW=400 1 EA X_SUS

40 M7506146

41 M7506147 CONNECTOR CABLE 4P YH396-04V+YT396J+ULW=300 1 EA Y_5V

42 M7506155 CONNECTOR CABLE 4P 171822-08+170262-1=100 1 EA DIG._5V

43 M7506143

44 M7506154 CONNECTOR CABLE 6P

CONNECTOR CABLE

12P

CONNECTOR CABLE

15P

CONNECTOR CABLE

10P

CONNECTOR CABLE

10P

12505HS12+12505TS+ULW=90

12505HS15+12505TS+ULW=90

YH396-10V+YT396J+ULW=400 1 EA Y_SUS

SMH250-10+LH01-25012=460

SMH250-06+LH01-25007=590

1EAX~CON

1EAY~DIG.

1 EA AV-POW

1 EA AV-POW

45 M7506145

46 M7519752 FFC

47 M7519753 FFC

CONNECTOR CABLE

62

31P

GT121-31S-CD+GT121-C15000=120

50P 100L 0.5pt SINGLE

SIDE

30P 80L 0.5pt SINGLE

SIDE

1EAAV-DIG

2EA

2EA

ORION PDP CO.,LTD

Page 63

13.Option List[Cables]

No

1 M7565704 PC CABLE D-SUB 15M/M 1M 7.5 1EA

2 M7565706 DVI-D CABLE SY-150M 1M 1EA

3 M7565708 VIDEO CABLE BNC 1P 1M 1EA

4 M7565710 DVD CABLE BNC 3P 1M 1EA

5 M7565751 RS-232C CABLE D-SUB 9M/F 1M 1EA

6 M7565712 S-VIDEO CABLE MINI DIN 4P 1M 1EA

7 M7565705 PC CABLE D-SUB 15M/M 5M 7.5 1EA

8 M7565707 DVI-D CABLE SY-150M 5M 1EA

9 M7565709 VIDEO CABLE BNC 1P 5M 1EA

10 M7565711 DVD CABLE BNC 3P 5M 1EA

Material

Number

Material

Name

Material specification Q’ty Unit Remark

11 M7565752 RS-232C CABLE D-SUB 9M/F 5M 1EA

12 M7565713 S-VIDEO CABLE MINI DIN 4P 5M 1EA

63

ORION PDP CO.,LTD

Page 64

14.Exploded View For MIS-4201

64

ORION PDP CO.,LTD

Loading...

Loading...