Page 1

MHGRV III Controller

Technical Guide

Page 2

Table of Contents

Controller Overview ......................................................................................................................................... 3

General.........................................................................................................................................................................................3

Features .......................................................................................................................................................................................3

Operation......................................................................................................................................................................................3

Inputs and Outputs .......................................................................................................................................... 4

General.........................................................................................................................................................................................4

Analog Inputs ............................................................................................................................................................................... 4

24 VAC Contact Closure Inputs ....................................................................................................................................................4

Analog Outputs.............................................................................................................................................................................4

Relay Outputs...............................................................................................................................................................................4

Modulating HGR Valve Outputs ...................................................................................................................................................4

Installation & Wiring ........................................................................................................................................ 5

Controller Mounting ...................................................................................................................................................................... 5

Important Wiring Considerations .................................................................................................................................................. 5

Additional Modulating Hot Gas Valve Control ..............................................................................................................................5

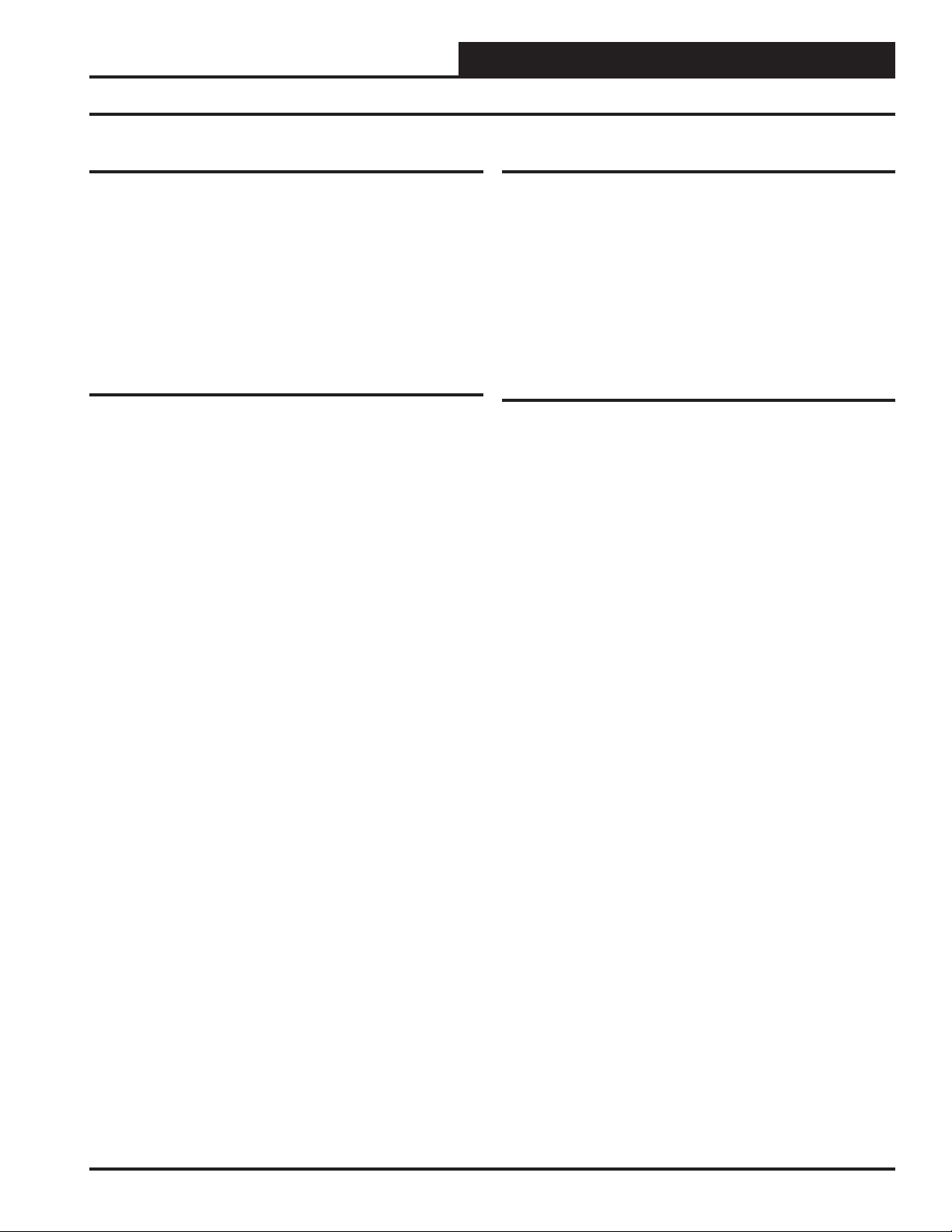

MGHRV III Controller Master To Slave Wiring when Used with VCM Controller .........................................................................6

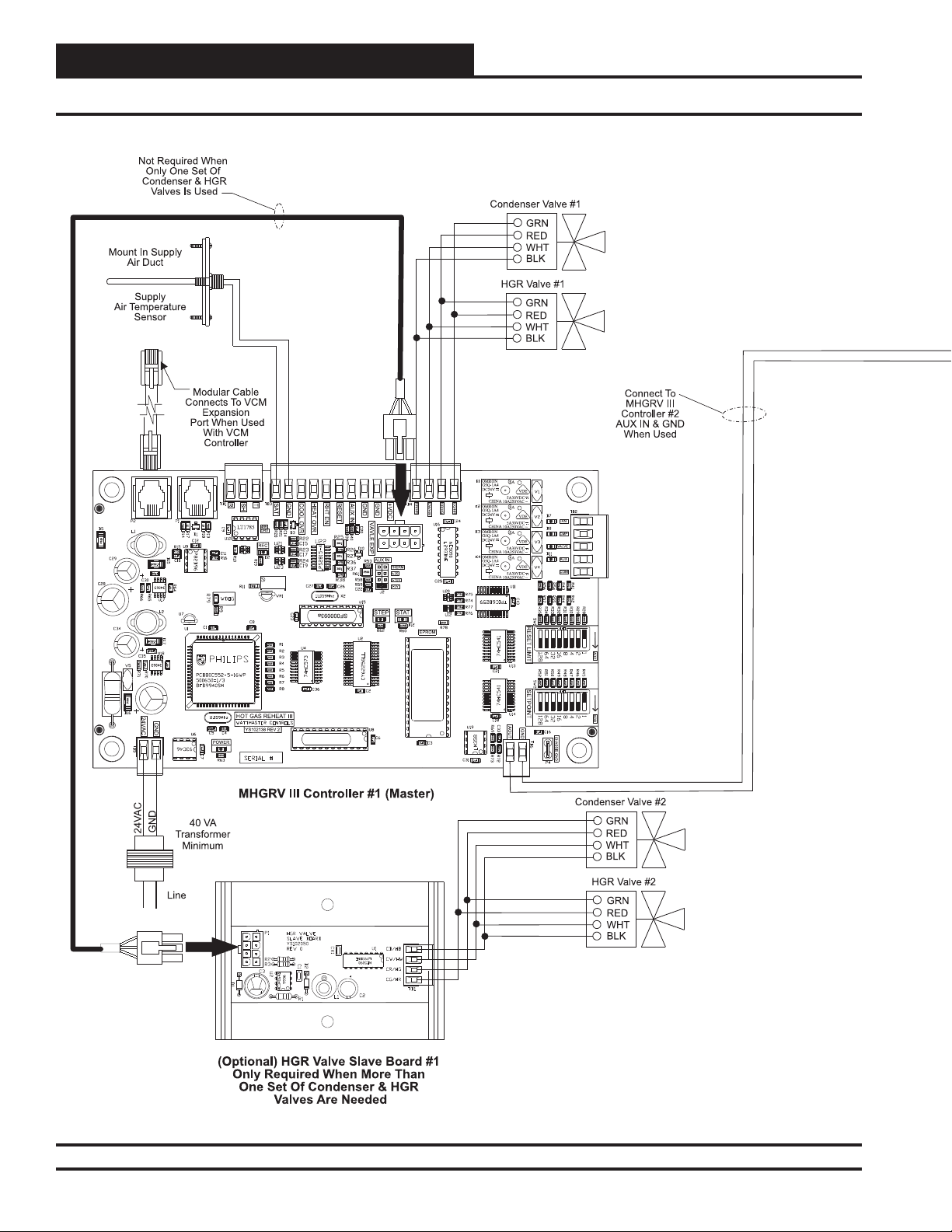

MGHRV III Controller Master To Slave Wiring when Used with VCM-X Controller ...................................................................... 8

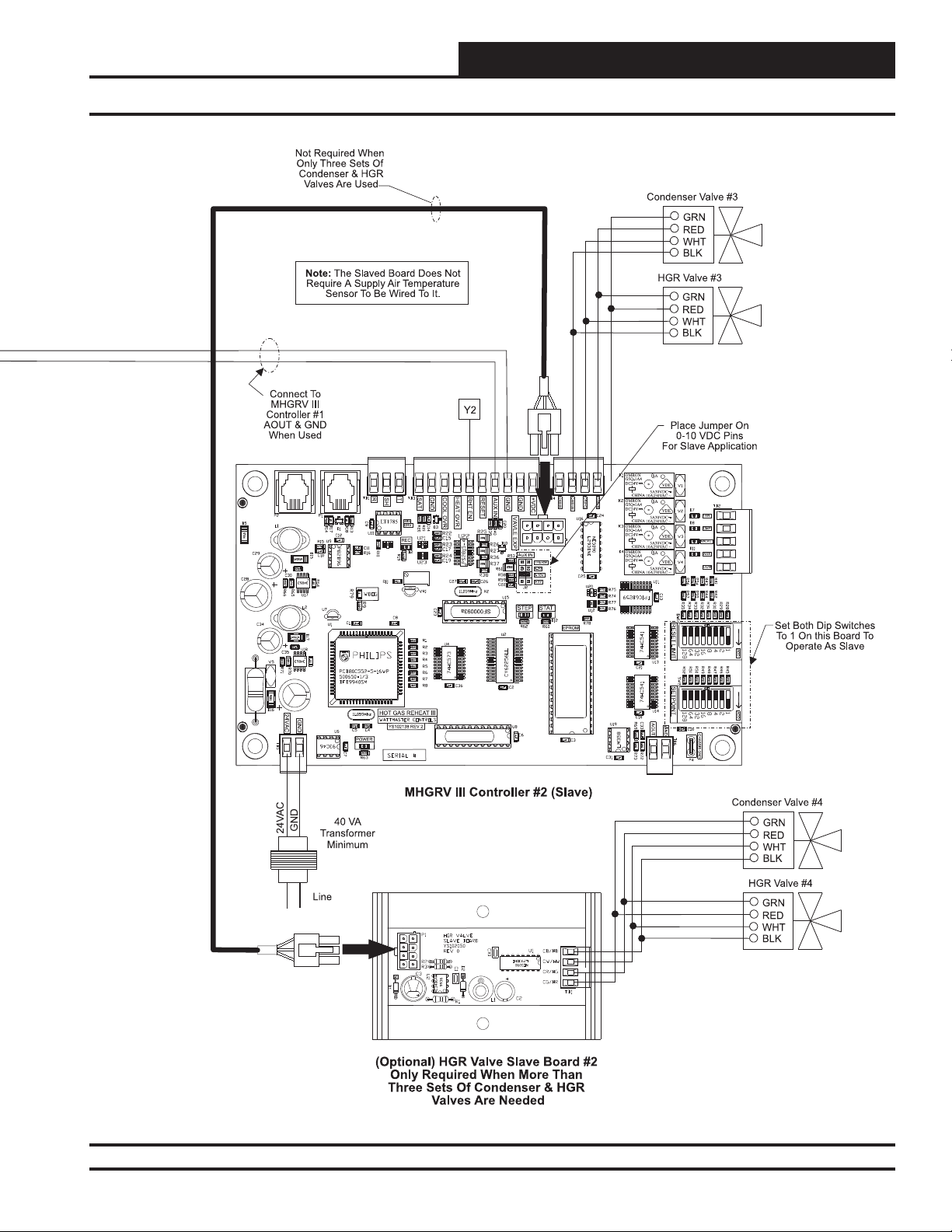

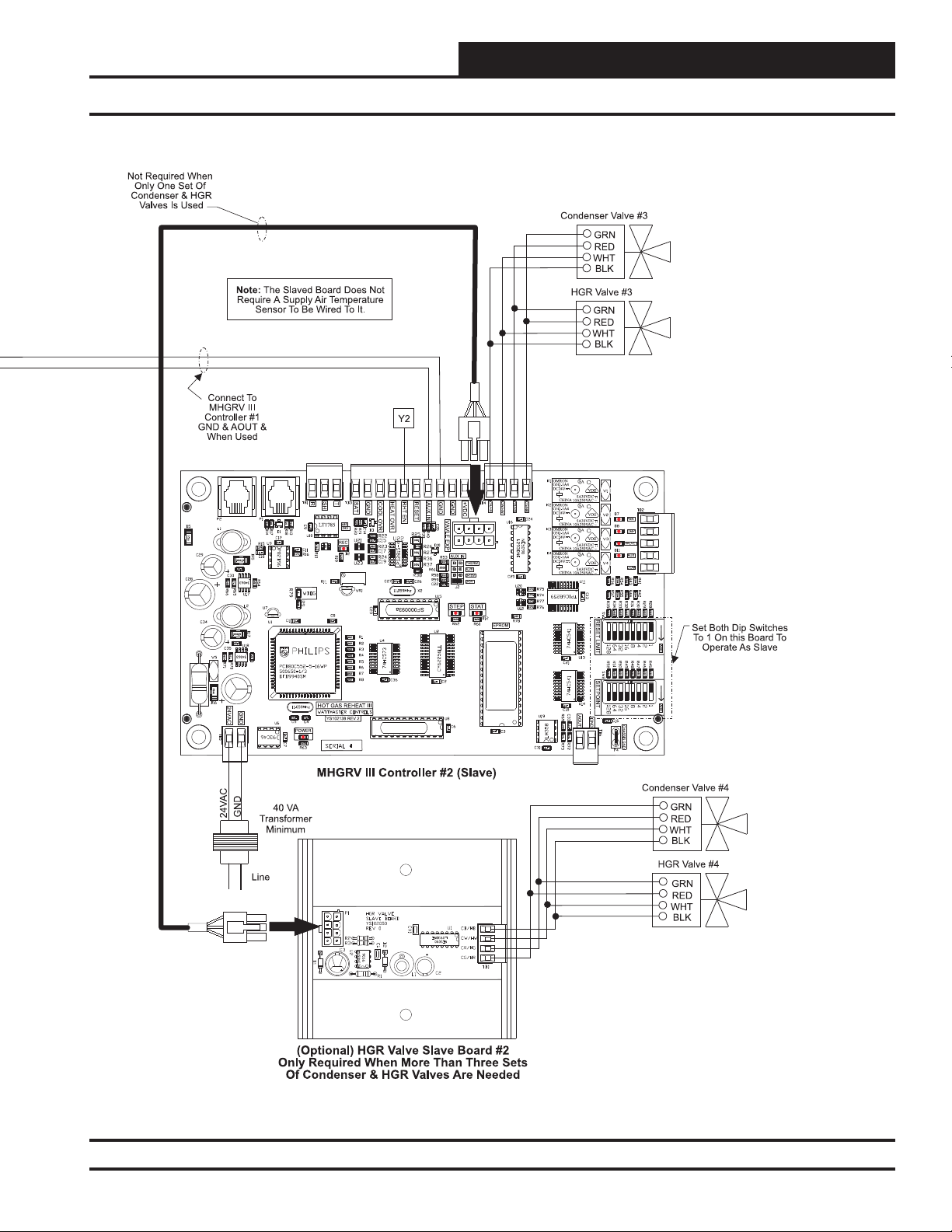

MGHRV III Controller Master To Slave Stand Alone Wiring .......................................................................................................10

DIP Switch Settings ....................................................................................................................................... 12

Supply Air Temperature .............................................................................................................................................................. 12

Supply Air Temperature Reset Limit ..........................................................................................................................................12

Field Testing ...............................................................................................................................................................................13

Start-up & Commissioning............................................................................................................................. 14

General.......................................................................................................................................................................................14

Power Wiring ............................................................................................................................................................................. 14

Power Up and Operation ............................................................................................................................................................14

Programming the Controller .......................................................................................................................................................14

Sequence of Operation .................................................................................................................................. 15

Initialization.................................................................................................................................................................................15

Modulating Hot Gas Valves ........................................................................................................................................................15

Modes of Operation ....................................................................................................................................................................15

Additional Features .................................................................................................................................................................... 15

Troubleshooting ............................................................................................................................................. 16

Using LEDs to Verify Operation..................................................................................................................................................16

Other Checks ............................................................................................................................................................................. 16

2425 So. Yukon Ave • Tulsa, OK • 74107-2728

Ph: (918) 583-2266 • Fax: (918) 583-6094

WM Form: AA-MHGRVIII-TGD-01D

Printed in the USA • Copyright 2010 • All Rights Reserved • March 2011Watt-

Master Controls, Inc. • 8500 NW River Park Drive • Parkville, MO 64152

AAON® Part No.: R76540

WattMaster Controls, Inc. assumes no responsibility for errors or omissions.

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

This document is subject to change without notice.

Page 3

MHGRV III Controller Technical Guide

Controller Overview

General

The MHGRV III Controller is designed to control a Modulating Hot

Gas Reheat Valve to maintain a desired Supply Air Temperature and

Humidifi cation setpoint. The controller can be used as a stand-alone con-

troller or it can be connected to and used in conjunction with the AAON

Factory Packaged HVAC unit controller. The MHGRV III controller is

connected to the HVAC unit controller via a modular expansion cable

and corresponding connectors on the controllers.

Features

The MHGRV III provides the following:

Can be operated as a stand-alone controller or

integrated with the HVAC Unit Controller

Provides for Supply Air Temperature Setpoint

reset when required

Second stage reheat capability when using

2 Hot Gas Reheat Valves

Control of reheat solenoid valve to provide coil

fl ushing for positive refrigerant oil return

Expansion capabilities for controlling additional

modulating hotgas values

Operation

When used in a stand-alone application (not connected to an HVAC unit

controller board), the MHGRV III controller will control the Modulating

Hot Gas Valve to maintain the Supply Air Setpoint based on the Supply

Air Temperature Sensor connected to the MHGRV III controller. The

MHGRV III controller is activated by a 24 VAC wet contact closure

signal connected to the H1 (RHT EN) input terminal on the controller.

Heating Override and Cooling Override are also controlled by 24 VAC

wet contact closure signals connected to the HEAT OVR and COOL

OVR input terminals on the controller. The Supply Air Setpoint is set

by confi guring a DIP switch on the MHGRV III controller board. Sup-

ply Air Temperature Reset is also available and is set by confi guring

a DIP switch on the controller board. When Supply Air Temperature

Reset is used, it is reset by a 0-10 VDC signal supplied to the RESET

IN terminal on the MHGRV III controller.

When the MHGRV III controller is connected to an HVAC unit controller board via its modular cable, it will operate exactly as the stand-alone

controller except that the following information will be passed between

the MHGRV III controller and the HVAC unit controller:

Reheat Enable command

Supply Air Temperature Setpoint. This replaces the

setpoint that is set with the Supply Air Temperature DIP

switch on the MHGRV III controller.

The Reset Supply Air Temperature Setpoint. This replaces

the setpoint that is set with the Supply Air Temperature

Reset DIP switch on the MHGRV III controller. The Supply

Air Temperature Reset Signal is also supplied from the

HVAC unit controller.

If the communication is interrupted between the MHGRV

III controller and the HVAC unit controller, the

MHGRV III controller will revert to stand-alone operation.

0.30

7.40

1248163264

1002

R45

1

ADD ADD

1002

R28

P4

CHASSISGND

C16

128

OFF

1002

1002

1002

1002

1002

1002

1002

R52

R51

R50

R49

R48

R47

R46

128643216842

OFF

1002

1002

1002

1002

1002

1002

1002

R34

R33

R32

R31

R35

R30

R29

2211

2211

2211

2211

R44R43

R42R41

R57R56

R55R54

2211

2211

2211

2211

COM

AUX

D11

VALVE

CMP

D8

FAN

D7

TB2

.1uF

C31

R73

R72

LM358

1001

1001

TB6

1002

10uF

.01uF

GND

AOUT

C33

C18

.1uF

U14

74HC541

SW2

C21

.1uF

U13

74HC541

RESET LIMIT SETPOINT

SW1

TPIC6B259

.1uF

C13

U11

10A250VAC~

5A30VDC

V4

VDE

SA

10A250VAC~

5A30VDC

V3

VDE

SA

10A250VAC~

5A30VDC

V2

VDE

SA

10A250VAC~

5A30VDC

V1

VDE

SA

C3

.1uF

C6

.1uF

SF000140

U19

R69

R78

1002

U12

R76

4751

R77

4751

R74

4751

0404

R75

4751

U20

.1uF

CHINA

DC24V

G5Q-1A4

OMRON

K4

CHINA

L293DNE

NE5090

DC24V

G5Q-1A4

OMRON

K3

CHINA

C24

.1uF

DC24V

G5Q-1A4

OMRON

K2

CG/HR

CR/HG

CHINA

DC24V

G5Q-1A4

OMRON

K1

U8

C2

.1uF

C36

.1uF

CY62256LL

74HC573

U4

U2

EPROM

R60

R62

36503650

D13

D12

STATSTEP

J2

10uF

0-5V

C25

U16

1002

0-10V

1002

4-20

2500

THERM

1002

R53

AUXIN

VAVLE EXP

TB4

GND

GND

+VDC

CW/HW

CB/HB

SF000093a

U15

X2VR1

C22

C26

R59

R38

R58

4751

R61

R37

3001

R36

4751

R27

3001

R26

4751

D10

3001

R25

R40

R39

10uF

C20

1002

1002

AUX IN

RHT EN

RESET IN

.1uF

C23

VREF

11.059Mhz

C27

22pF 22pF

R12

PS2815-4

C19

10uF

R24

1002

C17

10uF

R23

1002

C15

10uF

U22

R22

1002

D3

C14

.1uF

COOL OVR

GND

HEAT OVR

R63

SERIAL#

D14

YS102138REV 3

WATTMASTERCONTROLS

HOT GAS REHEATIII

R8

1002

R7

1002

R6

1002

R5

1002

R4

1002

R3

1002

R2

1002

R1

1002

10uF10uF

C8

R11

3011

U23

04 04

R19

D2

3650

R10

04

4751

REC

U5

U21

DRV

R21

R20

LT1785

485

.1uF

1002

1002

TB3

T

SAT

SH

R

U10

3650

C4

R9

WDOG

R16

C11

C9

TB1

POWER

C5

22pF 22pF

11.059Mhz

PHILIPS

C1

10020

R79

4751

.1uF

R13

7500

C7

93C46

.1uF

U6

DFD9940SM

500650=1/3

PCB80C552-5-16WP

PHILIPS

U1

P82B96

U9

.1uF

C12

D1

R18

R17

R14

10

10

7500

WARNING

OBSERVE

TB5

POLARITY

GND

D16

24VAC

R70

R71

V5

34063

1211

3831

.22

C35

U18

100pF

1N5819

D17

U7

C34

L2

U17

R66

R65

34063

.22

1741

1502

R64

C30

100pF

1N5819

C10

C29

D15

.1uF

4751

R15

L1

P2 P1

0.30

4.10

C28

RS1G

D5

4.70

4.92

8.00

8.15

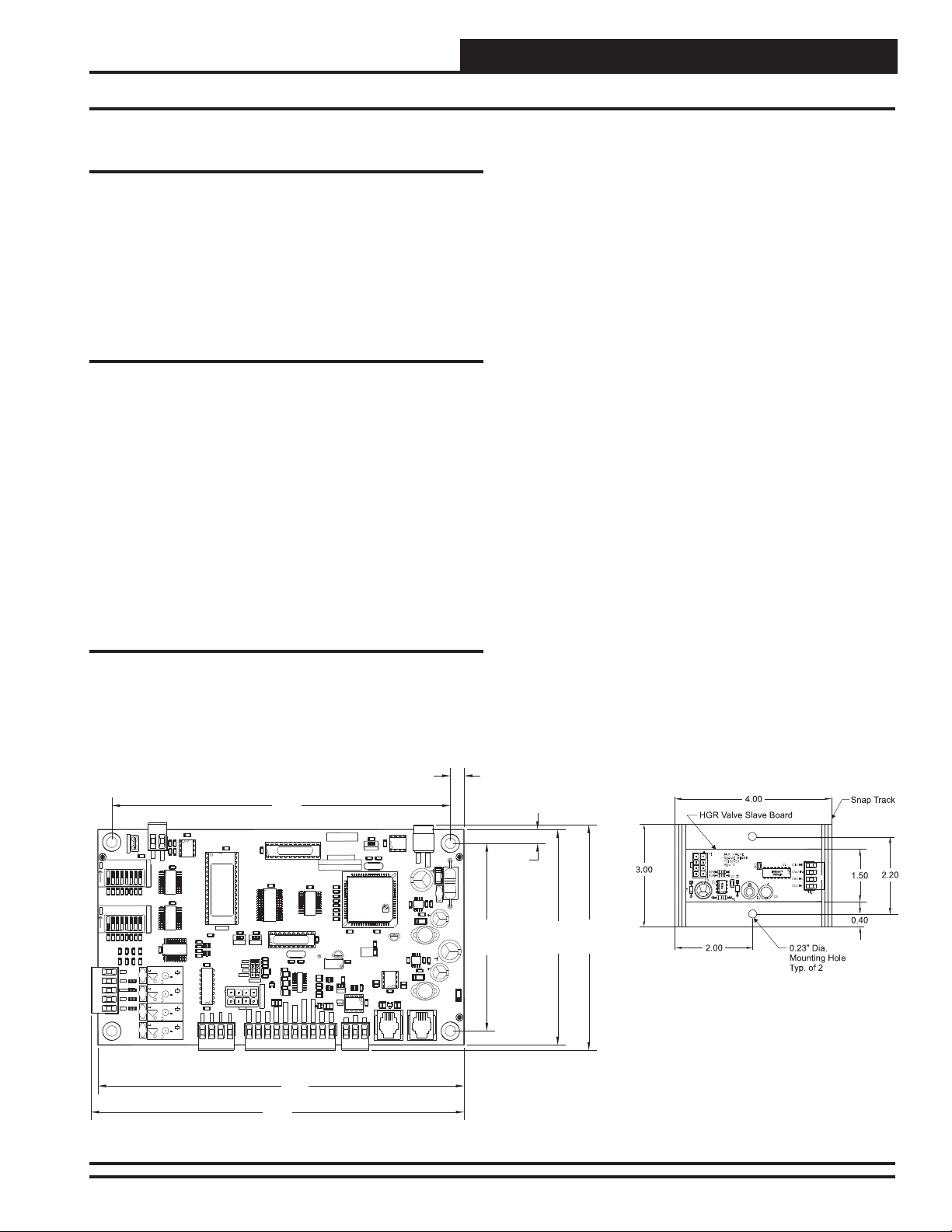

Figure 1: MHGRV III Controller Dimensions

Operator Interface 3

Page 4

MHGRV III Controller Technical Guide

Inputs and Outputs

General

The following inputs and outputs are available on the MHGRV III

controller For component locations of the inputs, outputs and wiring,

see Figures 2 and 3.

Analog Inputs

SAT: Supply Air Temperature Sensor

The Supply Air Temperature Sensor is the main control input. This sensor

has to be installed for the unit to operate. The Supply Air Temperature

Sensor is located in the discharge air stream and monitors the HVAC

unit’s Supply Air Temperature to maintain the Supply Air Temperature

Setpoint.

RESET IN: Reset Signal

The Discharge Temperature Setpoint can be reset by supplying a 0-10

VDC signal to the RESET IN low voltage terminal block. This reset

signal is optional and need only be used if you require resetting of the

discharge air temperature.

AUX IN: Valve Force Position Signal

The modulating HGR valves can be forced to a fi xed position by supply-

ing a 0-10 VDC signal to the AUX IN input. The setpoint and reset limit

switches must both be set to 1 to enable the valve force to work.

24 VAC Contact Closure Inputs

RHT EN: Dehumidifi cation

When a call for dehumidifi cation is initiated by another controller, this

interlocked 24 VAC wet contact closure is used to enable the MHGRV

III controller.

HEAT OVR: Heating Override

When a call for heating is initiated by the HVAC unit, this interlocked 24

VAC wet contact closure is used to override the MHGRV III controller

dehumidifi cation mode.

COOL OVR: Cooling Override

When a call for cooling is initiated by the HVAC unit, this interlocked 24

VAC wet contact closure is used to override the MHGRV III controller

dehumidifi cation mode.

Analog Outputs

AOUT 1: Valve Position Signal

The valve position signal is a 0-10 VDC signal that matches the position

of the valve. 0V = 0%, 10V = 100%.

Relay Outputs

COM: Relay Common

Requires 24 VAC from transformer.

FAN: Fan Enable

When a call for Dehumidifi cation, Cooling Override, or Heating Over-

ride is received, this relay output will be closed to energize the HVAC

unit Supply Fan.

CMP: Compressor Enable

When a call for Dehumidifi cation or Cooling Override is received, this

relay output will be closed to energize the Compressor(s).

VALVE: Reheat Solenoid Valve

When a call for Dehumidifi cation is active for 30 seconds, this relay

output will be closed to energize the Hot Gas Solenoid Valve.

AUX: 2 Position HGR Valve

Used on larger capacity systems that have an optional 2 Position HGR

Valve in addition to the Modulating HGR Valve. When a call for Dehumidifi cation is received and the modulating HGR valve is at 100%, this

relay output will be closed to energize the 2 Position HGR Valve. The

relay will open when the modulating HGR valve is at 0%.

Modulating HGR Valve Outputs

CG/HR:

This output is connected to the Condenser HGR Valve Green Wire

Termination and to the Reheat HGR Valve Red Wire Termination to

control their modulation.

CR/HG:

This output is connected to the Condenser HGR Valve Red Wire Termination and to the Reheat HGR Valve Green Wire Termination to control

their modulation.

CW/HW:

This output is connected to the Condenser HGR Valve White Wire

Termination and to the Reheat HGR Valve White Wire Termination to

control their modulation.

CB/HB:

This output is connected to the Condenser HGR Valve Black Wire

Termination and to the Reheat HGR Valve Black Wire Termination to

control their modulation.

4

Operator Interface

Page 5

MHGRV III Controller Technical Guide

Installation & Wiring

Controller Mounting

It is important to mount the controller in a location that is free from

extreme high or low temperatures, moisture, dust, and dirt.

Be careful not to damage the electronic components when mounting

the controller. Remove the controller from its snap track mount. Mark

the control enclosure base using the snap track as a template. Drill pilot

holes in the enclosure base and secure the snap track to it using sheet

metal screws. Do not allow metal shavings to fall onto the circuit board.

Reattach the controller to the snap track.

General Wiring Information

Please carefully read and apply the following information when wiring

the MHGRV III controller.

1. All 24 VAC wiring must be connected so that all ground

wires remain common. Failure to follow this procedure

can result in damage to the controller and connected

devices.

2. All wiring is to be in accordance with local and national

electrical codes and specifi cations.

3. Minimum wire size for 24 VAC wiring should be 18 gauge.

4. Minimum wire size for all sensors should be 24 gauge.

5. Be sure that all wiring connections are properly inserted and

tightened into the terminal blocks. Do not allow wire

strands to stick out and touch adjoining terminals which

could potentially cause a short circuit.

Important Wiring Considerations

Depending on if the MHGRV III controller is to be connected to the

HVAC controller or is to be used as a stand-alone controller determines

how the MHGRV III should be wired. For the wiring diagram to use

when the MHGRV III controller is connected to a VCM controller, see

Figure 2. For the wiring diagram to use when the MHGRV III controller

is connected to a VCM-X controller, see Figure 3. For the stand-alone

wiring diagram, see Figure 4. Please carefully read and apply the following information when wiring the MHGRV III controller.

Additional Modulating Hot Gas Valve

Control

HGR Valve Slave Board

This board is connected to the MHGRV III board with a cable that plugs

into the connector labeled Valve Exp. This board provides control to an

additional set of modulating valves. The position of the valves will be

the same as the board they are plugged into.

MHGRV III Slave Board Confi guration

Whenever the MHGRV III has both its setpoint switches set to 1, it will

work as a slave board. The board is active when it has a 24 VAC signal

on the RHT EN input. When the board is active, it looks for a 0-10

VDC on the AUX IN input and moves the HGR valves accordingly.

For example, if the input is at 10 VDC, then the reheat valve would be

100% open. If the voltage is at 5 VDC, the reheat valve would be 50%

open. See Figures 3 and 4.

Operator Interface

5

Page 6

MHGRV III Controller Technical Guide

Installation & Wiring

Figure 2: MHGRV III Controller Master To Slave Wiring When Used With VCM Controller (R46170)

6

Operator Interface

Page 7

MHGRV III Controller Technical Guide

Installation & Wiring

Figure 2, cont.: MHGRV III Controller Master To Slave Wiring When Used With VCM Controller (R46170)

Operator Interface

7

Page 8

MHGRV III Controller Technical Guide

Installation & Wiring

Figure 3: MHGRV III Controller Master To Slave Wiring When Used With VCM-X Controller (R69170)

8

Operator Interface

Page 9

MHGRV III Controller Technical Guide

Installation & Wiring

Figure 3, cont.: MHGRV III Controller Master To Slave Wiring When Used With VCM-X Controller (R69170)

Operator Interface

9

Page 10

MHGRV III Controller Technical Guide

Installation & Wiring

Figure 4: MHGRV III Controller Master to Slave Wiring - Stand Alone

10

Operator Interface

Page 11

MHGRV III Controller Technical Guide

Installation & Wiring

Figure 4, cont.: MHGRV III Controller Master To Slave Wiring - Stand Alone

Operator Interface

11

Page 12

MHGRV III Controller Technical Guide

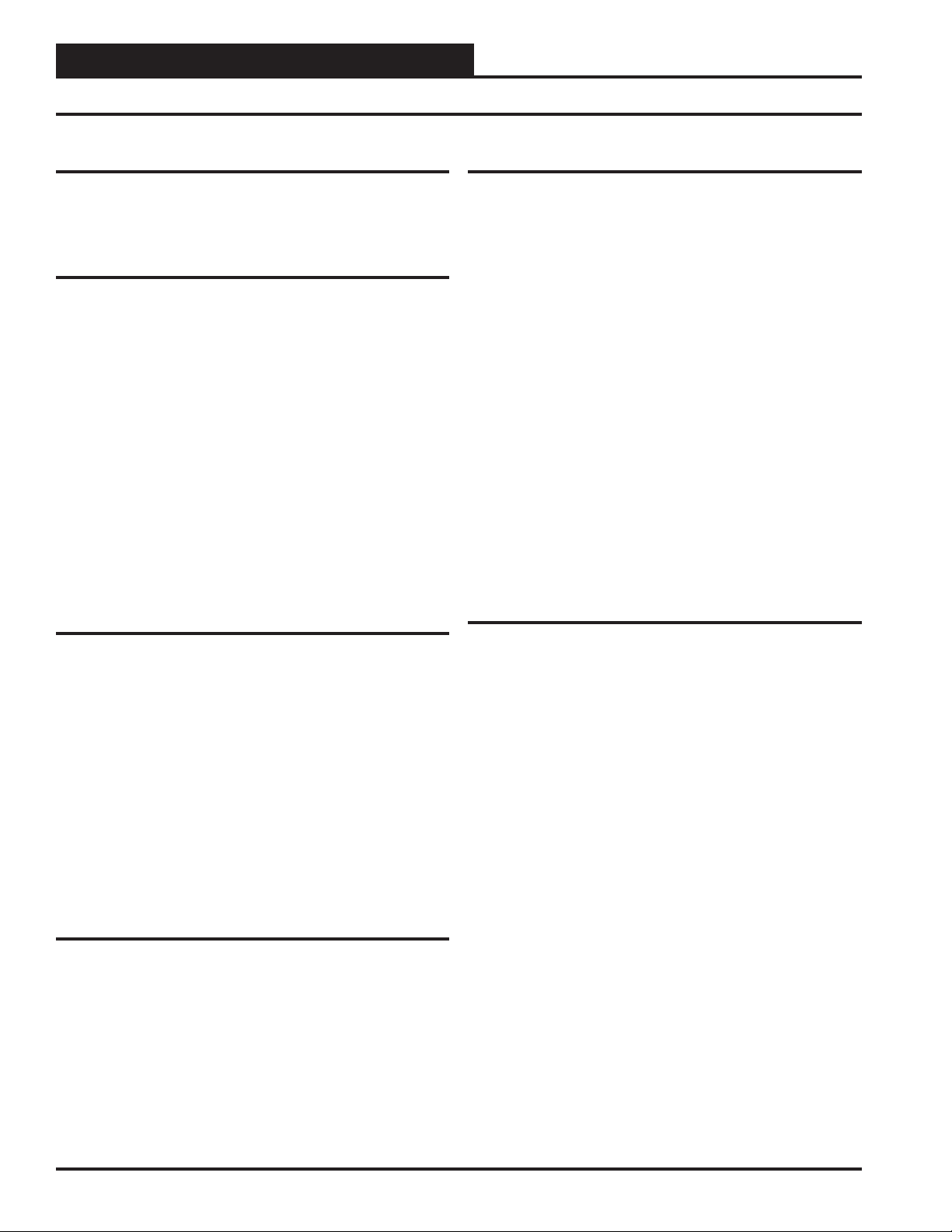

DIP Switch Setting Shown

Is For A Setpoint Of 57

DIP Switch Setting Shown

Is For A Setpoint Of 94

ADD

ADD

32+16+8+1=57

64+16+8+4+2=94

All Rocker Switches Depressed

In the Direction Of The ADD Arrow

Are Added Together To Total The Setpoint

Typical DIP Switch

Detail View

F

1

O

F

ADD

4

2

16

8

64

32

128

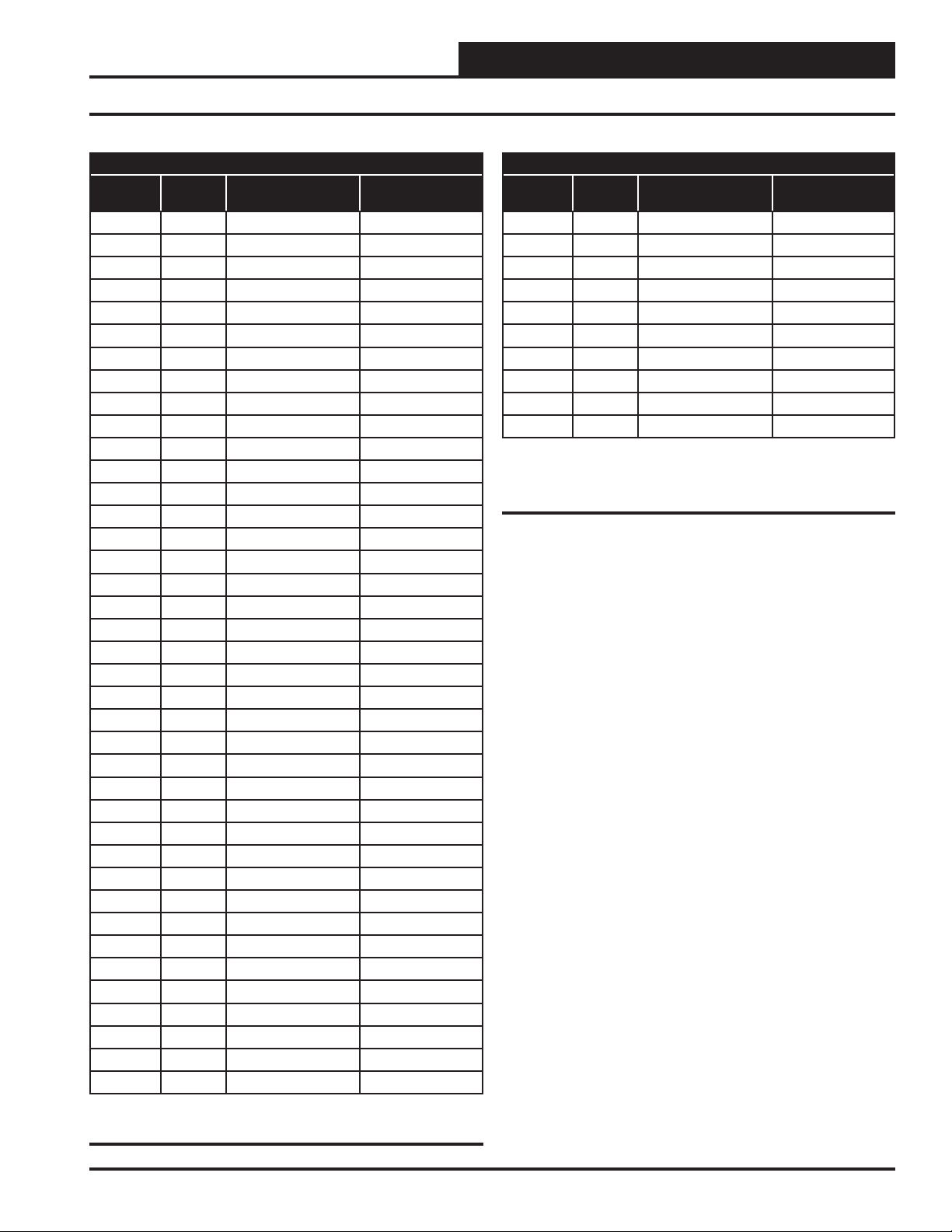

DIP Switch Settings

Supply Air Temperature

The DIP switches are only used when the controller is installed as a

stand-alone controller. The main unit controller will set the Supply Air

Temperature Setpoint and Reset Limit when the MHGRV III is used as

an expansion device.

You can set the desired Discharge Air Temperature Setpoint using the DIP

Switch labeled SETPOINT. See Figure 5 for location and DIP Switch

setting instructions. The MHGRV III controller will allow you to set a

Supply Air Temperature Setpoint between 50°F and 100°F. If a value

of less than 50°F is set, the controller will default to a 50°F Supply Air

Temperature Setpoint. A value greater than 100°F will cause the unit to

default to a 100°F Supply Air Temperature Setpoint.

Supply Air Temperature Reset Limit

You can reset the Supply Air Temperature Setpoint by supplying a 0-10

VDC control signal to the Reset Input (RST IN) terminal on the MHGRV III controller board. The reset range is determined by the RESET

LIMIT DIP Switch. See Figure 5 for location and setting instructions.

The controller will reset the Supply Air Temperature Setpoint from the

value set on the SETPOINT DIP Switch to the value set on the RESET

LIMIT DIP Switch as the Reset Input (RST IN) signal is increased from

0 Volts to 10 Volts..

Example:

You want the Discharge Air Temperature Setpoint to increase from 55°F

when the Reset Input signal is at 0 Volts and to 75°F when the Reset

Input signal is at 10 Volts.

Set the SETPOINT DIP Switch to 55°F

Set the RESET LIMIT DIP Switch to 75°F

The discharge air temperature will now increase from 55°F to 75°F as

the Reset Input voltage signal ramps from 0 Volts to 10 Volts.

NOTE: It is possible to create a “reverse acting” control sequence.

Using the temperatures from the example above by setting the SETPOINT DIP Switch to 75F and the RESET

LIMIT DIP Switch to 55F, the reset would be reverse

acting. In this case, the controller will maintain a 75F

discharge temperature when the Reset Input signal is at

0 Volts and will reduce it to 55F when the Reset Input

signal is at 10 Volts.

Figure 5: DIP Switch Setting Instructions

12

Operator Interface

Page 13

MHGRV III Controller Technical Guide

DIP Switch Settings

Field Testing

For fi eld testing purposes, the modulating hot-gas valves can be forced

to full Cooling or full Reheat via DIP switch settings on the MHGRV

III controller. See Table 1 for mode of operation and valve positioning

during force modes.

MHGR Valve - Position & Operation

Setpoint Value Reset Limit

Value

1 3 Full Cooling 100% Closed

3 1 Full Reheat 100% Open

33

Table 1: MHGR Valve Position & Operation

Mode of

Operation

Half Reheat/

Cool

HGR Valve

Position

50% Open/

Close

NOTE: For a value of 1, only turn on DIP switch labeled 1. For a

value of 3, turn on DIP switches 1 and 2. The DIP switches

are added together to complete a specifi c value.

WARNING: When force mode testing is complete, reset the DIP

switch settings to a valid temperature setting.

Do not leave the MHGRV DIP switches set in force

mode when leaving the job site.

Operator Interface

13

Page 14

MHGRV III Controller Technical Guide

Start-up & Commissioning

General

In order to have a trouble free start-up, it is important to follow a few

simple procedures. Before applying power for the fi rst time, it is very

important to run through a few simple checks.

Power Wiring

One of the most important checks to make before powering up the

system for the fi rst time is to confi rm proper voltage and transformer

sizing for the controller. Each MHGRV III controller requires 40 VA of

power delivered to it at 24 VAC.

Check all wiring leads at the terminal block for tightness. Be sure that

wire strands do not stick out and touch adjacent terminals. Confi rm

that all sensors required for your system are mounted in the appropriate location and wired into the correct terminals on the MHGRV III

controller.

After all the above wiring checks are complete, apply power to the

MHGRV III controller.

Power Up and Operation

The MHGRV III Controller uses on-board LEDs to indicate various

diagnostic conditions during power-up and operation. The LEDs are

labeled, “STAT”. Starting with power up, the LED blink codes are as

follows:

STAT on for 10 seconds

STEP on for 10 seconds

STAT blinks 30 times

STEP on for 45 seconds

STAT blinks 3 times rapidly

Status code is repeatedly blinked every ten seconds to

indicate controller status

STEP LED will be on any time modulating valves move

See the Troubleshooting section of this manual for LED diagnostic

code information.

Programming the Controller

Stand-Alone

If the MHGRV III is used as a stand-alone controller, it does not require

programming. It does require the Supply Air Temperature SETPOINT

DIP Switch and the RESET LIMIT DIP Switch (if required) be correctly

set for the required Supply Air Temperature and the Supply Air Reset

Temperature.

When Used with an HVAC Unit Controller

When the MHGRV III controller is connected to an HVAC Unit controller, the HVAC unit controller must be programmed with the desired

Supply Air Temperature Setpoint and Supply Air Temperature Reset

Setpoint and other confi guration information. In order to confi gure and

program the HVAC unit controller, you must have a central operator’s

interface or a personal computer with the Prism II computer front-end

software installed.

Two different operator interfaces are available for programming of the

HVAC unit controller to access the status and setpoints of the HVAC

unit controller—the Modular Service Tool or the Modular System Man-

ager. See the Modular Service Tool and System Manager Programming

Guide for programming information. If you are going to use a personal

computer and the Prism computer front-end software, please refer to the

Prism II Technical Guide. No matter which operator interface you use,

it is recommended that you proceed with the programming and setup

of the controller in the order that follows:

1. Confi gure the controller for your application

2. Program the controller setpoints

3. Review controller status screens to verify system

operation and correct controller confi guration

Modular Service Tool

The modular service tool can be used to check the status of the MHGRV

III board. You can do this if the board is stand-alone or being used with

an HVAC unit controller.

NOTE: Modular Service Tool must have software version 3.30

or later.

After you press the Status button on the handheld, the following screens

will appear:

Enter 56 for the MHGRV III

board.

If unit has Reheat Active, this

screen will appear:

If Reheat isn’t active, you will

see this screen:

Unit Selection

Enter Unit ID#

Selected ID#: 56

Unit Active

Supply Air: X.XF

Setpoint: X.XF

Valve Pos: X.X%

Unit Off

Supply Air: X.XF

Setpoint: X.XF

Valve Pos: X.X%

14

Operator Interface

Page 15

MHGRV III Controller Technical Guide

Sequence of Operation

Initialization

As described on the previous page under the heading, “Power Up and

Operation,” the MHGRV III Controller uses on-board LEDs to indicate

various diagnostic conditions during power-up and operation. Please

review this information for a complete description of the controller

initialization sequence.

Modulating Hot Gas Valves

The MHGRV III Controller utilizes two modulating Hot Gas Reheat

Valves to control the fl ow of Hot Gas through the Hot Gas Reheat Coil.

One of these valves is the Condenser Hot Gas Valve and the other is

the Reheat Hot Gas Valve. The valves are wired to the MHGRV III

Controller Modulating Hot Gas Valve Output terminals on the controller. These valves work in concert with each other to create a “three-way

valve” confi guration. As one closes, the other opens, etc. All modes of

operation that follow referring to the Hot Gas Reheat Valve are actually a combination of these two valves working together to achieve the

specifi ed sequence of operation.

Modes of Operation

The MHGRV III Controller can be used in two different modes of operation. These modes behave in a similar manner; the main difference is the

way they receive information to control the dehumidifi cation process.

The following is a description of these modes:

Stand-Alone Operation

As the name implies, in this mode the controller behaves as an independent unit. The controller begins the dehumidifi cation process when

the Dehumidifi cation Input “H1” receives a 24 VAC signal from an

outside source. When the signal is received, the controller will activate

the “FAN” output to energize the HVAC unit fan. At the same time, the

controller will initiate Cooling Mode by energizing the “CMP” output

starting the HVAC unit compressor. In addition, the controller will open

the Hot Gas Reheat Coil by activating the “VALVE” output. At this time,

the MHGRV III Controller will start to modulate the Modulating Hot Gas

Reheat valve. The controller will modulate the MHGR valve to maintain

the Supply Air Temperature Setpoint by activating the stepper motor

outputs on the MHGR valve. The Supply Air Setpoint is confi gured

by setting the SETPOINT DIP Switch on the MHGRV III Controller. If

Supply Air Temperature Reset is used, it will initiate when a 0-10 VDC

signal is supplied to the “RESET IN” input. As the voltage increases

from 0 to 10 Volts at the “RESET IN” input, the Supply Air Temperature

will be reset towards the Supply Air Reset Temperature Setpoint. This

setpoint is confi gured by setting the RESET DIP Switch on the MHGRV

III Controller. When a 10 Volt input signal is received at the “RESET

IN” input, it will be controlling at the Supply Air Temperature Reset

Setpoint. The controller will conclude the Dehumidifi cation process

when input “H1” is deactivated, the input “Cool Override” is activated,

or the input “Heat Override” is activated.

Operation as an Expansion Board

In this mode, the MHGRV III Controller behaves as an expansion board

for a VCM controller. The controller begins the dehumidifi cation pro-

cess when the HVAC Unit controller makes a request to the MHGRV

III Controller for dehumidifi cation. At that time, the controller will

activate the “FAN” output to energize the HVAC unit fan. At the same

time, the controller will initiate Cooling Mode by energizing the “CMP”

output starting the HVAC unit compressor. In addition, the controller

will open the Hot Gas Reheat Coil by activating the “VALVE” output

which opens the Reheat Solenoid Valve. At this time, the MHGRV III

Controller will start to modulate the Modulating Hot Gas Reheat valve.

The controller will modulate the MHGR valve to maintain the Supply

Air Temperature Setpoint by activating the stepper motor outputs on

the MHGR valve. The Supply Air Setpoint is set by programming the

HVAC unit controller. If Supply Air Temperature Reset is used, it will

initiate when the HVAC sends a request to reset the Supply Air Temperature. The Supply Air Temperature will be reset towards the Supply Air

Reset Temperature Setpoint stored in the HVAC controller. It will send

a request to move towards the Supply Air Temperature Reset Setpoint

based on its setpoints and confi guration. The controller will conclude

the Dehumidifi cation process when the HVAC control sends a request to

terminate Dehumidifi cation or a Cooling or Heating Override request is

made by the HVAC unit controller. Any DIP switch settings or signals

at the inputs to the MHGRV III Controller will be ignored.

Additional Features

The following are features which are also designed into the MHGRV

III Controller:

Reheat Coil Flush

To assure positive oil return to the compressor, the Hot Gas Reheat

Coil will be fl ushed of liquid refrigerant by moving the Modulating

Gas Reheat Valve to its maximum position for a short interval. If the

unit is in cooling mode, a fl ush will occur every hour. If the unit is in

dehumidifi cation mode and the valve is below 70% for 20 minutes, a

fl ush will occur.

Optional Second Stage Reheat

On larger systems, where more hot gas reheat capacity may be required,

a 2 Position Hot Gas Reheat valve can be connected to the MHGRV III

Controller to be used in conjunction with the Modulating Hot Gas Reheat

valve. Any time the reheat demand moves above the Modulating Hot Gas

Reheat valve capacity, this 2 position valve would be energized to supply

additional hot gas to the Hot Gas Reheat coil. As the reheat demand is

satisfi ed, the MHGRV III Controller will de-energize the 2 position valve

and control reheat with the Modulating Hot Gas Reheat valve.

Reheat Solenoid Valve Control

The Hot Gas Reheat Solenoid valve for the Reheat Coil is activated when

there is a call for Dehumidifi cation. In this mode, the Hot Gas Reheat

Solenoid will be deactivated 2 minutes after the reheat demand ceases.

The Hot Gas Reheat Solenoid valve will be reactivated when a request

for reheat is received by the MHGRV III Controller.

Operator Interface

15

Page 16

MHGRV III Controller Technical Guide

Troubleshooting

Using LEDs to Verify Operation

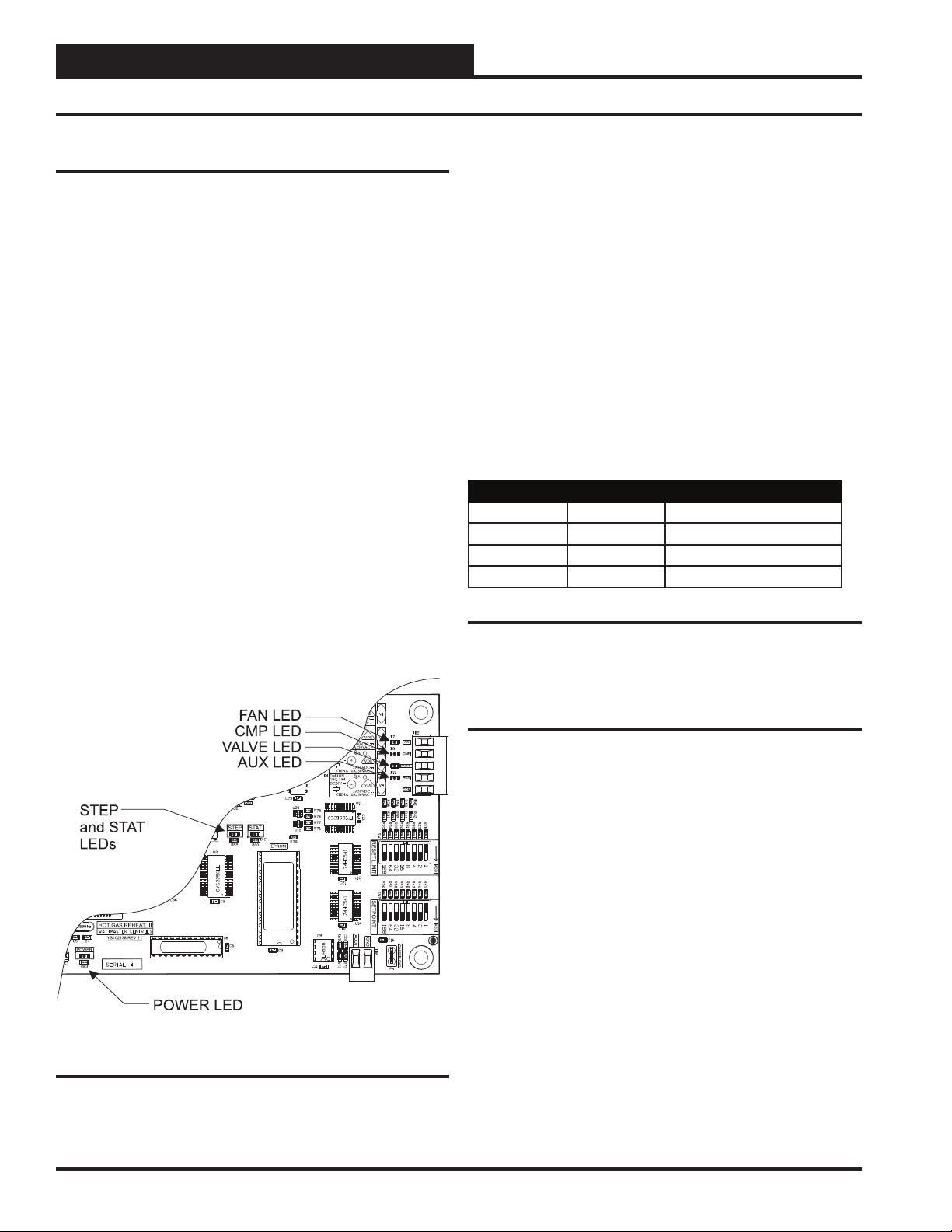

The MHGRV III controller is equipped with LEDs that can be used as

very powerful troubleshooting tools. The MHGRV III controller board

has six LEDs. Two of these LEDs are used in troubleshooting. See Figure

6 for the LED locations. The LEDs and their uses are as follows:

LED Descriptions

“STAT ” - This is the diagnostic blink code LED. It will light up and

blink out diagnostic codes. See Table 2 for blink codes.

“STEP” - This LED is on any time the modulating hot gas reheat valve

is moving.

“POWER” - This LED will light up to indicate that 24 VAC power has

been applied to the controller.

“FAN” - This light indicates that the relay for the “FAN” output is

energized and its Normally Open Contact is closed.

“CMP” - This light indicates that the relay for the “CMP” output is

energized and its Normally Open Contact is closed.

“VALVE” - This light indicates that the relay for the “VALVE” output

is energized and its Normally Open Contact is closed.

LED Diagnostics

“POWER” LED: When the MHGRV III Controller is powered up,

the POWER LED should light up and stay on continuously. If it does

not light up, check to be sure that the power wiring is connected to the

board, the connections are tight, and the transformer is powered. If after

making all these checks, the POWER LED does not light up, the board

is probably defective.

“STAT” LED: As previously described, when the board is fi rst powered

up, the STAT LED will do the following:

On for 10 seconds

Blinks 30 times

Blinks 3 times rapidly (after STEP LED is on

for 45 seconds)

Status code is repeatedly blinked every ten seconds to

indicate controller status

Priority No. of Blinks Status

Lowest 1 Normal Operation

- 2 SAT Over High Limit (170º)

- 3 Bad SAT Sensor

Highest 4 Force Mode Active

“AUX” - This light indicates that the relay for the “AUX” output is

energized and its Normally Open Contact is closed.

Table 2: STAT LED Blink Codes

Only the highest priority failure code will be shown. You must correct

the highest priority alarm before other problems will be indicated.

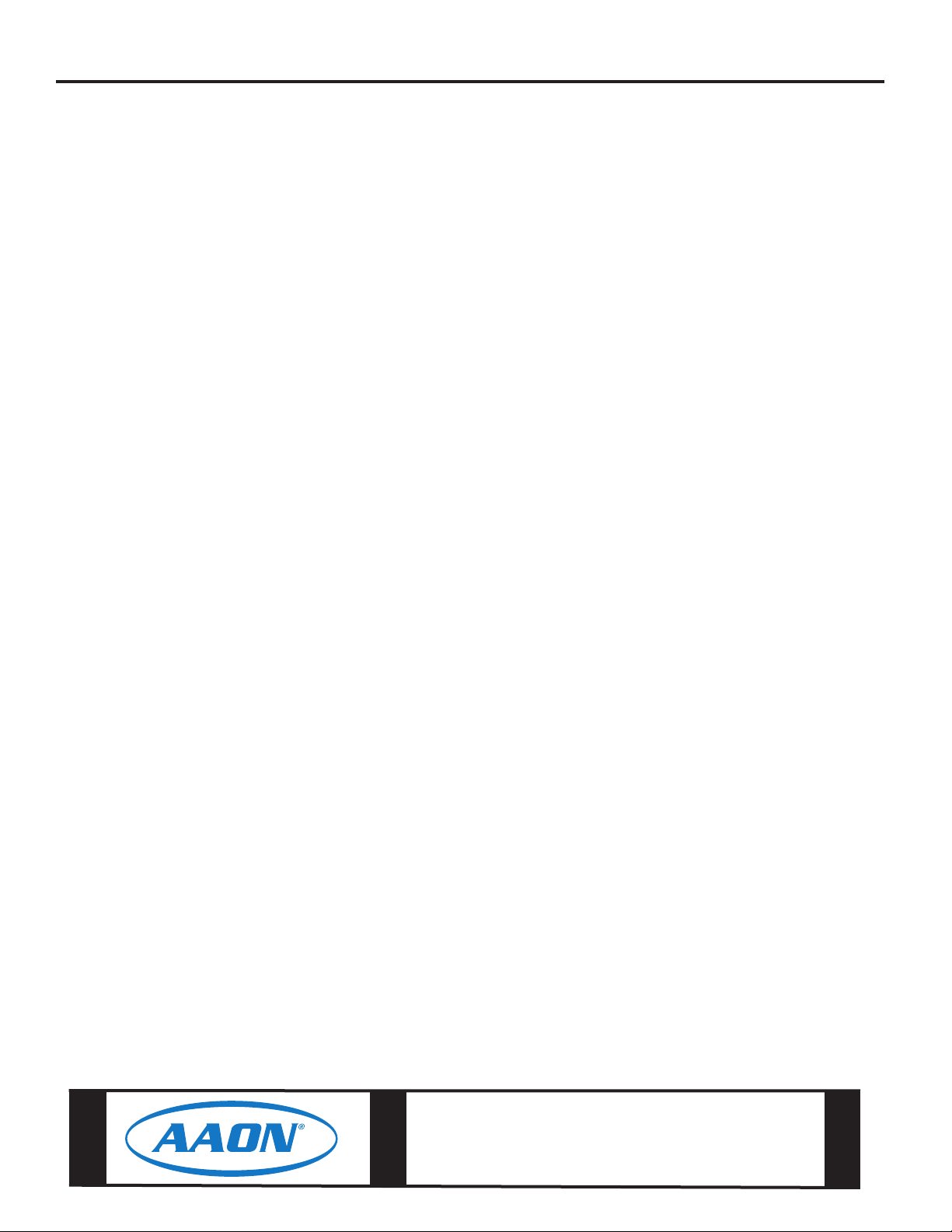

Other Checks

Supply Air Temperature Sensor

If you suspect the Supply Air Temperature Sensor is not reading correctly, make sure the wiring terminal connections are tight and that any

wiring splices are properly connected. You can check the operation of the

Supply Air Temperature Sensor by measuring the resistance or voltage

using a digital multimeter. Set the meter to DC Volts. Place the positive

probe on the AIN terminal and the negative probe on the GND terminal.

Read the DC Volts and fi nd that voltage in Table 3.

Read the temperature corresponding with that voltage and determine

if this is close to the actual temperature the sensor is exposed to. If the

temperature from the chart is different by more than a few degrees, you

probably have a defective or damaged sensor. You can also check the

sensor resistance to determine correct operation. To read the resistance,

set the meter to Ohms. Unplug the sensor connector from the board and

measure the resistance across the disconnected wires. This resistance

should match the corresponding temperature from Table 3.

Figure 6: LED Locations

16

Operator Interface

Page 17

MHGRV III Controller Technical Guide

Troubleshooting

Temperature to Resistance/Voltage Chart

Temp

(°F)

-10 -23.3 93333 4.620

-5 -20.6 80531 4.550

0 -17.8 69822 4.474

5 -15.0 60552 4.390

10 -12.2 52500 4.297

15 -9.4 45902 4.200

20 -6.7 40147 4.095

25 -3.9 35165 3.982

30 -1.1 30805 3.862

35 1.6 27140 3.737

40 4.4 23874 3.605

45 7.2 21094 3.470

50 10.0 18655 3.330

52 11.1 17799 3.275

54 12.2 16956 3.217

56 13.3 16164 3.160

58 14.4 15385 3.100

60 15.6 14681 3.042

62 16.7 14014 2.985

64 17.8 13382 2.927

66 18.9 12758 2.867

68 20.0 12191 2.810

69 20.6 11906 2.780

70 21.1 11652 2.752

71 21.7 11379 2.722

72 22.2 11136 2.695

73 22.7 10878 2.665

74 23.3 10625 2.635

75 23.9 10398 2.607

76 24.4 10158 2.577

78 25.6 9711 2.520

80 27.8 9302 2.465

82 27.8 8893 2.407

84 28.9 8514 2.352

86 30.0 8153 2.297

88 31.1 7805 2.242

90 32.2 7472 2.187

95 35.0 6716 2.055

100 37.8 6047 1.927

Temp

(°C)

Resistance (Ohms) Voltage @

Input (VDC)

Temperature to Resistance/Voltage Chart

Temp

(°F)

105 40.6 5453 1.805

110 43.3 4923 1.687

115 46.1 4449 1.575

120 48.9 4030 1.469

125 51.7 3656 1.369

130 54.4 3317 1.274

135 57.2 3015 1.185

140 60.0 2743 1.101

145 62.8 2502 1.024

150 65.6 2288 0.952

Temp

(°C)

Resistance (Ohms) Voltage @

Input (VDC)

Table 3, cont.: Temperature Sensor - Voltage &

Resistance for Type III Sensors

Thermistor Sensor Testing Instructions

1.) Use the resistance column to check the thermistor sensor while

disconnected from the controllers (not powered).

2.) Use the voltage column to check sensors while connected to powered controllers. Read voltage with meter set on DC volts. Place the “-”

(minus) lead on GND terminal and the “+” (plus) lead on the sensor

input terminal being investigated.

If the voltage is above 5.08 VDC, the sensor or wiring is “open.” If the

voltage is less than 0.05 VDC, the sensor or wiring is shorted.

Table 3: Temperature Sensor - Voltage &

Resistance for Type III Sensors

Operator Interface

17

Page 18

MHGRV III Controller Technical Guide

Notes

18

Operator Interface

Page 19

MHGRV III Controller Technical Guide

Notes

Operator Interface

19

Page 20

2425 So. Yukon Ave • Tulsa, OK • 74107-2728

Ph: (918) 583-2266 • Fax: (918) 583-6094

WM Form: AA-MHGRVIII-TGD-01D

Printed in the USA • Copyright 2011 • All Rights Reserved • August 2011

WattMaster Controls, Inc. • 8500 NW River Park Drive • Parkville, MO • 64152

AAON® Part No.: R76540

Loading...

Loading...