Page 1

www.wattmaster.com

Lead/Lag Controller

Technical Guide

Page 2

Table of Contents

OVERVIEW ................................................................................................................................................. 3

Features ........................................................................................................................................................... 3

Step-By-Step Guide ......................................................................................................................................... 4

SECTION 1: LEAD/LAG WIRING & SETUP................................................................................................ 5

Environmental Requirements ........................................................................................................................... 5

Mounting .......................................................................................................................................................... 5

Power Supply ................................................................................................................................................... 5

Lead/Lag Controller Dimensions ...................................................................................................................... 5

Lead/Lag Wiring ............................................................................................................................................... 6

Communication Settings .................................................................................................................................. 7

Addressing and Baud Rate Selection .............................................................................................................. 8

SECTION 2: INSTALLING PRISM 2........................................................................................................... 9

SECTION 3: LEAD/LAG NAVIGATION AND STATUS ............................................................................... 10

SECTION 4: CONFIGURING ANALOG INPUTS ....................................................................................... 13

SECTION 5: CONFIGURING BINARY INPUTS ........................................................................................ 17

SECTION 6: CONFIGURING RELAYS...................................................................................................... 20

SECTION 7: CONFIGURING ANALOG OUTPUTS ................................................................................... 25

SECTION 8: OUTDOOR STATUS & LEAD/LAG ENABLE ......................................................................... 31

SECTION 9: SETTING SCHEDULES ....................................................................................................... 32

SECTION 10: CONFIGURING ALARMS .................................................................................................. 36

SECTION 11: SAVING AND RESTORING SETPOINTS ............................................................................ 37

SECTION 12: PRINTING STATUS REPORTS .......................................................................................... 39

APPENDIX A: SAMPLE CONFIGURATIONS ............................................................................................ 41

APPENDIX B: USB DRIVER INSTALLATION ........................................................................................... 48

INDEX ...................................................................................................................................................... 50

2

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

www.wattmaster.com

WattMaster Controls, Inc. assumes no responsibility for errors

or omissions.

This document is subject to change without notice.

Form: WM-LEADLAG-TGD-01A

Copyright December 2013 WattMaster Controls, Inc.

Lead/Lag Controller Technical Guide

Page 3

Overview

Lead/Lag Controller Overview

Overview

The OE338-23-LL Lead/Lag Controller is used for controlling

multiple pumps or HVAC units that require equal run time. The fi rst

application—Lead/Lag—is for controlling up to (4) sets of devices,

and the second application—2 Lead/1 Lag—is for controlling (3)

devices where (2) of the devices will be running at a time.

The Lead/Lag Controller has an on-board CommLink that provides

for stand-alone programming and monitoring via a direct USB

connection to a computer running Prism 2 software. If used on a

networked system that has an external CommLink, this on-board

CommLink would not be used.

The Lead/Lag Controller has (8) confi gurable analog inputs which

will accept signals from thermistor temperature sensors or from

4-20mA or 0-5VDC transmitters. The inputs are set for the desired

scaling by means of a jumper bar.

An additional modular input is available for WattMaster communicating sensors. The Lead/Lag Controller has (8) wet contact binary

inputs that can be confi gured for either normally open or normally

closed operation. Also available are (8) relay outputs for on/off

control and (4) analog outputs (0-10VDC) for modulating control.

There are (4) separate two events per day schedules which can be

assigned to any input or output for operational control or for alarm

recognition based on time of day.

NOTE: The Lead/Lag Controller contains no user-serviceable

parts. Contact qualifi ed technical personnel if your

Controller is not operating correctly.

Schedules can be confi gured to broadcast to other

WattMaster HVAC equipment installed on the same

communications loop as the Lead/Lag Controller

Can be confi gured using a computer with Prism 2

software installed

Can be operated Stand-Alone or connected to a

networked system

On-board CommLink for Stand-Alone programming

using a USB connection to a computer running Prism 2

software

Lead Lag Operation

The fi rst application option is the Lead/Lag operation. With the Lead/

Lag application, you can confi gure one “Lead” device and one or

more ”Lag” devices.

For example, if you have three pumps, but only one runs at a time

(Lead/Lag/Lag), the Lead/Lag Controller will run the fi rst pump for

a specifi ed period of time, then run the second for that amount of

time, and then fi nally run the third for that amount of time.

If any of the pumps fail, the Controller will switch to the next one

and generate an alarm. You can have multiple Lead/Lag functions

on the controller. For example, since the Controller has 8 relay

outputs, you could have up to 4 Lead/Lag combinations. Relays 1

and 2 could Lead/Lag the fi rst 2 pumps, relays 3 and 4 could Lead/

Lag the second set of pumps, etc. Or, you could have two sets of

Lead/Lag/Lag/Lag.

Features

The Lead/Lag Controller provides the following:

8 confi gurable analog inputs

8 wet contact binary inputs confi gured for normally open

or normally closed operation

8 relay outputs for on/off control

4 analog outputs (0-10VDC) for modulating control

E-BUS port for WattMaster communicating sensors

4 separate 2 events per day schedules which can be

assigned to any output for operational control or

alarm recognition based on time of day

Lead/Lag Controller Technical Guide

2 Lead / 1 Lag Operation

The second application option is the 2 Lead/1 Lag operation. The

2 Lead/1 Lag operation is used to control three devices to maintain

equal run times, where two of them are running at the same time.

The run time and failure operation would be the same as described

above. Only one “2 Lead/1 Lag” function can be confi gured on the

controller.

3

Page 4

Step-By-Step Guide

Step-By-Step Guide

Zone

Zone

Step-By-Step Guide

This guide will lead you through each step in confi guring your Lead/

Lag Controller. Below is a quick overview of each step.

Section 1: Lead/Lag Controller Wiring & Setup—This sec-

tion explains how to mount and wire your Lead/Lag Controller

properly. It also explains how to set the address and baud rate for

your particular system.

Section 2: Prism 2 Installation—This section explains how to

install Prism 2 software required to program your Lead/Lag Controller. If you are not familiar with the Prism 2 software program,

please refer to the Prism 2 Technical Guide which can be down-

loaded from the Orion Controls website: www.orioncontrols.com/

literature-new.html.

Section 3: Lead/Lag Controller Personalization & Status—

This section explains how to individualize and access Lead/Lag

Controllers when more than one is installed and also provides an

overview of the Lead/Lag Controller Status Screens.

Section 4: Confi guring Analog Inputs—This section explains

how to confi gure analog inputs, individualize analog input descrip-

tions, and calibrate thermistor sensors, and override and clear other

analog input values.

Section 5: Confi guring Binary Inputs—This section explains

how to confi gure binary inputs, individualize binary input descrip-

tions, and override binary inputs.

Section 7: Confi guring Analog Outputs—This section explains

how to confi gure analog outputs, individualize analog output descrip-

tions, override voltages, and cancel overrides.

Section 8: Outdoor Status and Lead Lag Enable—This section

explains the Override Status and Lead/Lag Enable Status.

Section 9: Setting Schedules—This section describes how

to confi gure daily and holiday schedules, perform schedule force

modes, and other scheduling functions.

Section 10: Confi guring Alarms—This section explains how to

confi gure and view alarms.

Section 11: Saving and Copying Setpoints—This section

explains how to save Lead/Lag setpoints to a fi le on your computer

and how to restore Lead/Lag setpoints once you have saved them

to a fi le. It also describes how to Load the Factory Default Settings.

Section 12: Printing Daily Status Reports—This section ex-

plains how to view and print Daily Status Reports.

Appendix A—This appendix provides Sample Confi gurations.

Appendix B—This appendix explains USB Driver Installation.

Index—The index provides page numbers for easy reference to

quickly fi nd the information you need.

Section 6: Confi guring Relays—This section explains how to

confi gure relay outputs and individualize relay descriptions.

4

Lead/Lag Controller Technical Guide

Page 5

Section 1: Lead/Lag Wiring & Setup

Dimensions and Mounting

Environmental Requirements

The Lead/Lag Controller needs to be installed in an environment that

can maintain a temperature range between -30°F and 150°F and not

exceed 90% RH levels (non-condensing).

Mounting

The Lead/Lag Controller is housed in a plastic enclosure. It is designed to be mounted by using the 3 mounting holes in the enclosure

base. It is important to mount the module in a location that is free

from extreme high or low temperatures, moisture, dust, and dirt. Be

careful not to damage the electronic components when mounting

the module.

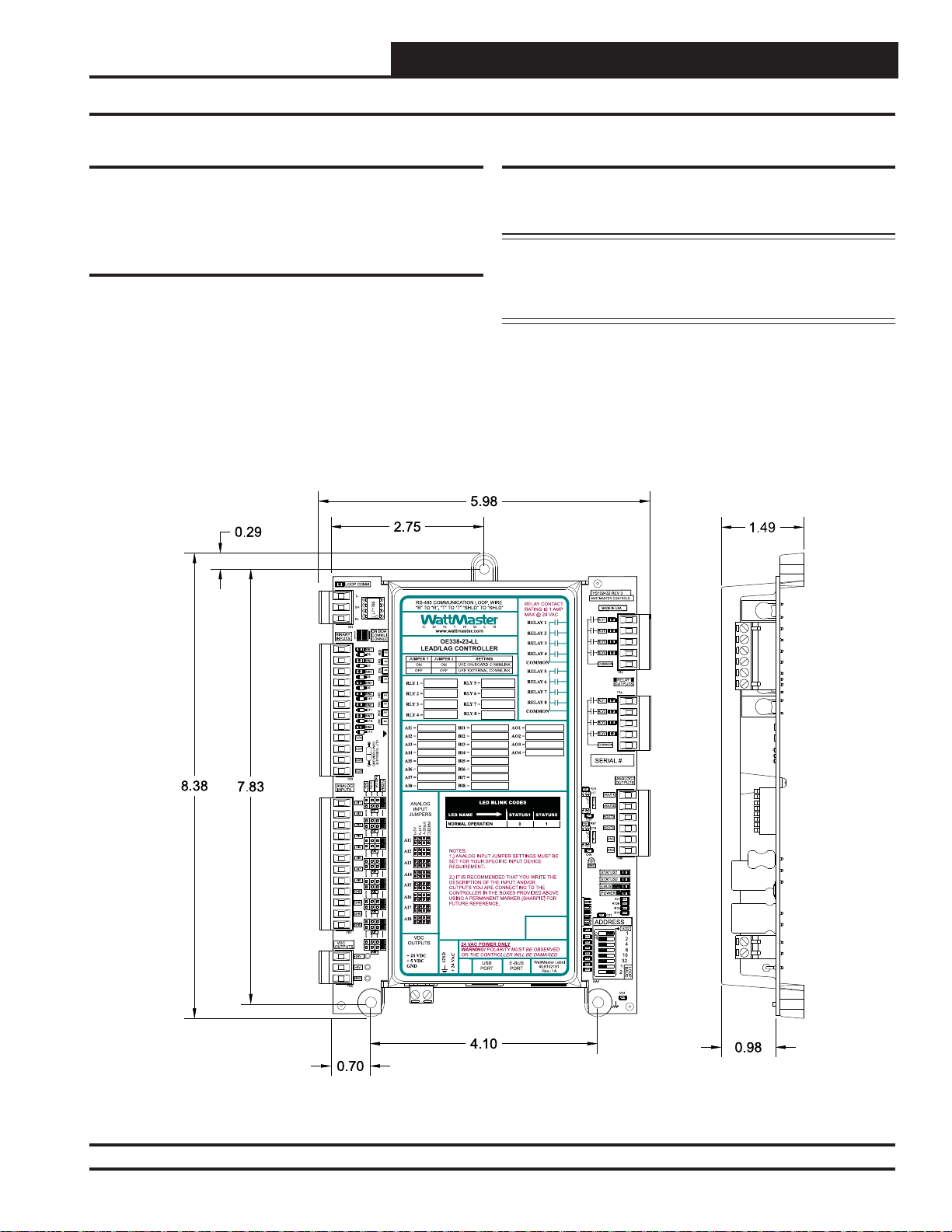

See Figure 1 for Controller dimensions (in inches).

Power Supply

The Lead/Lag Controller requires a 24 VAC power connection with

a minimum rating of 8 VA.

WARNING: Observe polarity! All boards must be wired

GND-to-GND and 24 VAC-to-VAC. Failure to

observe polarity could result in damage to the

boards.

Figure 1: Lead/Lag Controller Dimensions

Lead/Lag Controller Technical Guide

5

Page 6

Section 1: Lead/Lag Wiring & Setup

Installation & Wiring

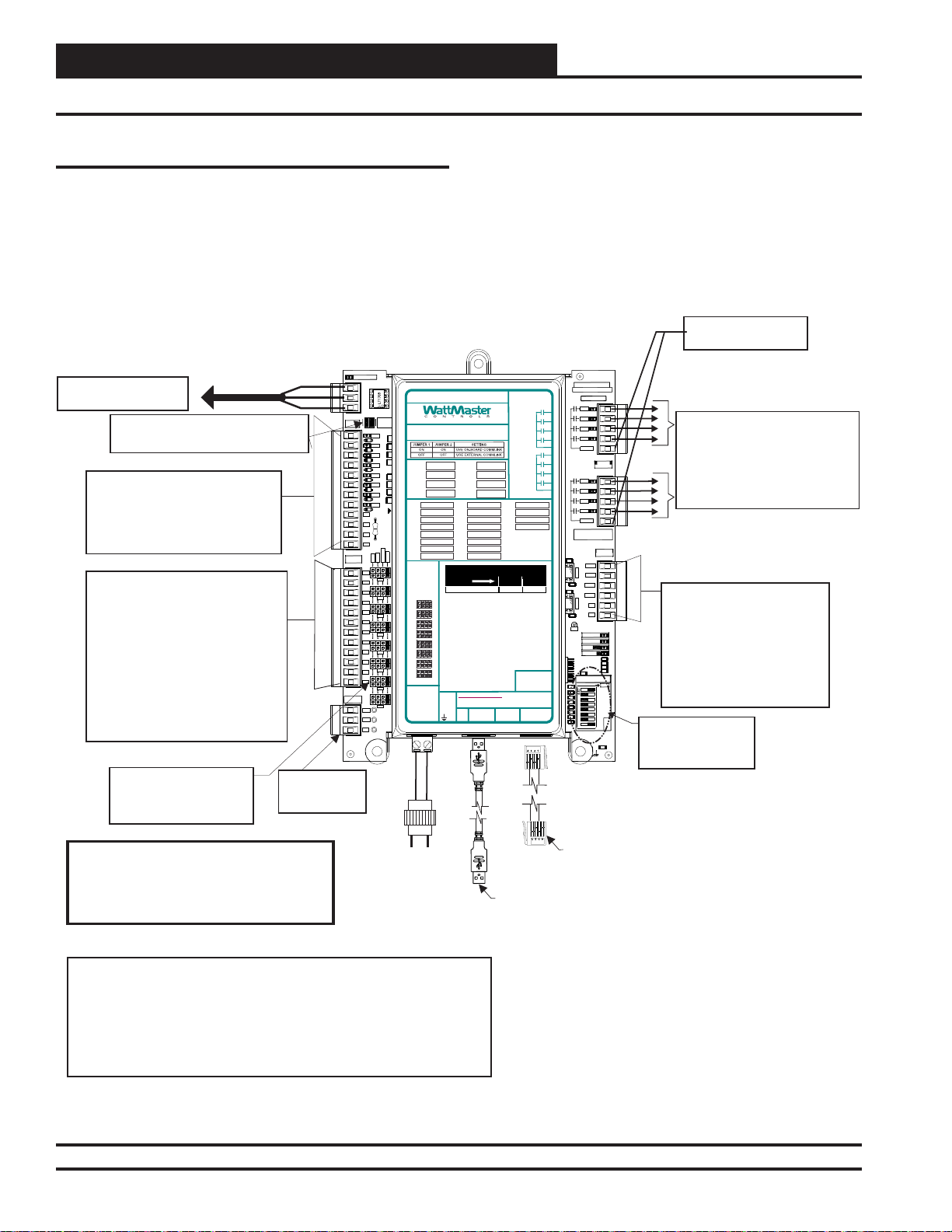

Important Wiring Considerations

Please read carefully and apply the following information when

wiring the Lead/Lag Controller:

1. To operate the Lead/Lag Controller, you must connect power

to the 24 VAC input terminal block.

All Communication Loop Wiring Is

Straight Through

T To T, R To R, SHLD To SHLD

Local Loop RS-485

Connect To Next Device

On The Local Loop

CommLink Jumpers

Both On = Use On Board CommLink

Both Off - Use External CommLink

Binary Inputs BIN1Through BIN8

Configured for The Following:

1. Not Used

2. Normally Closed Operation

3. Normally Open Operation

4. Read Global Binary

Analog Inputs AI1Through AI8

Configured For the Following:

1. Thermistor 10K Ohm Type III

Temperature Sensors (Fahrenheit)

2. Thermistor 10K Ohm Type III

Temperature Sensors (Celsius)

3. 4 - 20mA User Scaled

4. 0 - 5 vdc User Scaled

5. Read Global Analog Broadcast from

another Controller

6. Communicating Temperature Sensor

7. Communicating Humidity Sensor

8. Communicating Carbon Dioxide

Jumpers - Typical

Jumpers Must Be Set

Correctly For The Type Of

Input You Require.

9600 Baud

BINARY

INPUTS

ANALOG

INPUTS

VDC

OUTPUTS

5 VDC & 24VDC

Power For

Sensors

LOOPCOMM

T-

SH

R+

TB1

COM

COM

COM

COM

TB3

GND

GND

GND

GND

TB7

+24V

+5V

GND

TB8

ON BOA

COMMLI

CONNEC

R38

BIN1

300

D6

R41

BIN2

300

D7

R43

300

BIN3

R47

D8

300

BIN4

D9

BIN5

300

D10

300

BIN6

D11

300

BIN7

R61R59R55R51

D12

300

BIN8

D13

CUTTO ISOLATE

COMFROM GND

4-20mA

THERM

0-10v

0-5v

AI1

AI1

AI2

AI3

AI2

AI4

AI5

AI3

AI6

AI7

AI4

AI8

AI5

AI6

AI7

AI8

OE338-23-LL

Lead Lag Controller

RS-485 COMMUNICATION LOOP. WIRE

“R” TO“R”, “T” TO “T” “SHLD” TO “SHLD”

www.wattmaster.com

OE338-23-LL

LEAD/LAG CONTROLLER

RLY1 =

RLY2 =

RLY3 =

RLY4 =

AI1 =

AI2 = BI2 = AO2 =

AI3 = BI3 = AO3 =

AI4 = BI4 = AO4 =

AI5 = BI5 =

AI6 = BI6 =

AI7 = BI7 =

AI8 = BI8 =

ANALOG

INPUT

JUMPERS

4-20mA

0-10V

0-5V

THERM

AI1

AI2

AI3

AI4

AI5

AI6

AI7

AI8

VDC

OUTPUTS

+ 24VDC

+ 5VDC

GND

24 VAC

GND

2. Check all wiring leads at the terminal block for tightness.

Be sure that wire strands do not stick out and touch adjacent

terminals. Confi rm that all sensors required for your system are

mounted in the appropriate location and wired into the correct

terminals. See Figure 2 for wiring.

24VAC Power

For Relay Outputs

YS102432 REV 3

®

#LB102191

Rev.: 1A

WATTMASTER CONTROLS

RLY1

RLY2

RLY3

RLY4

COMMON

RLY1

RLY2

RLY3

RLY4

COMMON

SERIAL #

1002

R74

U17

AOUT1-2

.1uF

C36

R97

1002

U19

AOUT3-4

.1uF

C46

GND

.1uF

ADDRESS

1002

1002

1002

1002

1002

1002

1002

1002

SW1

MADE IN USA

AOUT1

AOUT2

AOUT3

AOUT4

GND

GND

STATUS1

STATUS2

EBUS

POWER

C21

R109

TB2

RELAY

OUTPUTS

TB4

ANALOG

OUTPUTS

TB6

R21

R16

R14

8 Relay Outputs Are Available For

On/Off Control Of Equipment

Configured For the Following:

1. Lead Relay for Lead/Lag Control

2. Lag Relay for Lead/Lag Control

Analog Outputs AOUT1 through

AOUT4 Provide (4) 0-10 VDC

Outputs Configured For The

Following:

1. Not Configured

1002

1002

1002

1002

ADD

1

2

4

8

16

32

LOOP

BAUD

1

2

C14

.01uF

2. Direct Acting Floating Point

3. Reverse Acting Floating Point

4. Direct Acting PID

5. Reverse Acting PID

ADDRESS Dipswitch

is Used for Setting

the Address and

Baud Rate.

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY1

RELAY2

RELAY3

RELAY4

COMMON

RELAY5

LED BLINK CODES

USB

E-BUS

PORT

PORT

RELAY6

RELAY7

RELAY8

COMMON

WattMaster Label

RLY5 =

RLY6 =

RLY7 =

RLY8 =

BI1 = AO1 =

LED NAME STATUS1 STATUS2

NORMAL OPERATION 0 1

NOTES:

1.)ANALOG INPUT JUMPER SETTINGS MUST BE

SET FORYOUR SPECIFIC INPUT DEVICE

REQUIREMENT.

2.) IT IS RECOMMENDEDTHAT YOU WRITE THE

DESCRIPTION OF THE INPUT,AND/OR

OUTPUTS YOUARE CONNECTING TO THE

CONTROLLER IN THE BOXES PROVIDEDABOVE

USINGA PERMANENT MARKER (SHARPIE) FOR

FUTURE REFERENCE.

24 VAC POWER ONLY

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILL BE DAMAGED

GND

+24VAC

Line Voltage

Warning:

24 VAC Must Be Connected So That All

Ground Wires Remain Common. Failure To

Do So Will Result In Damage To The

Controller

NOTES:

1.)24 VAC Must Be Connected So

That All Ground Wires Remain

Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

4.)It Is Recommended That The

Address Switch Is Set Before

Installation.

Figure 2: Lead/Lag Controller Wiring Diagram

6

24 VAC

Transformer

8 VA

Minimum

EBC E-BUS Cable

Connect to

Communicating Sensor

USB Cable

Connect to Computer with

Prism 2 Software Installed For

Stand-Alone Programming

Lead/Lag Controller Technical Guide

Page 7

Section 1: Lead/Lag Wiring & Setup

Communication Settings

Before Applying Power

In order to have a trouble free start-up, it is important to follow a

few simple procedures. Before applying power for the fi rst time, it

is very important to correctly address the controller and run through

a few simple checks.

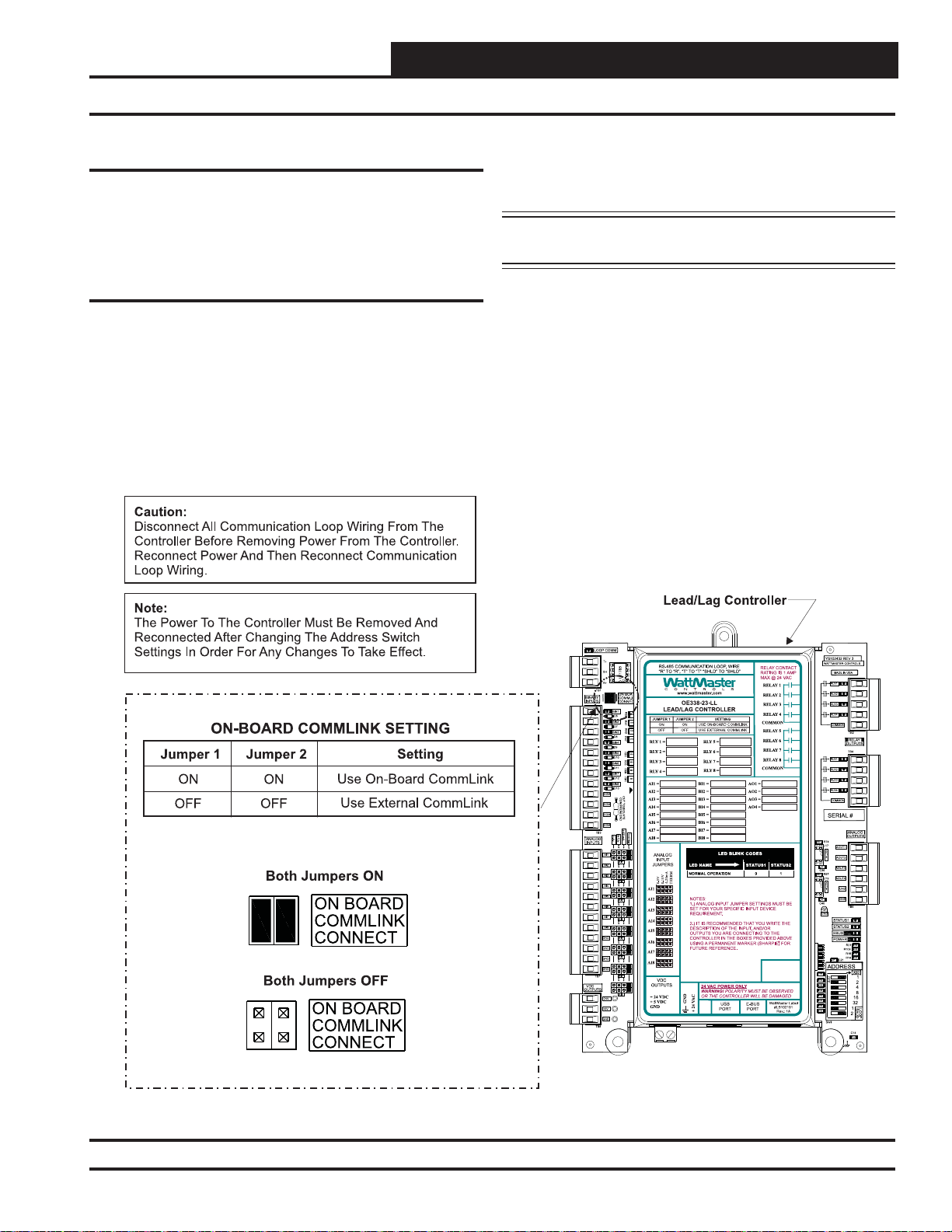

Communication Settings

Stand Alone Operation

The Lead/Lag Controller has an on-board CommLink that is used

during Stand-Alone Operation. When confi gured for Stand-Alone

operation, a computer running Prism 2 software can be connected

directly to the USB port located at the bottom of the Lead/Lag

Controller for programming and monitoring. In order to operate in

Stand-Alone Mode, two things need to be set. First, both CommLink

Jumpers found on the upper left hand side of the board need to be set

to ON. See Figure 3 for details. Second, the Baud Rate determined

by setting ADDRESS Dipswitches 7 and 8 needs to be set to OFF/

ON. See Figure 4, page 8 for details.

NOTE: If using the Internal CommLink, you must set up

the USB drivers. See Appendix B, page 48.

Network Operation

The Lead/Lag Controller can be confi gured for connection to a

networked system that has an external CommLink. In this case, the

on-board CommLink would not be used. For this confi guration,

two things need to be set. First, both CommLink Jumpers found on

the upper left found on the upper left hand side of the board need

to be set to OFF. See Figure 3 for details. Second, the Baud Rate

determined by setting ADDRESS Dipswitches 7 and 8 needs to be

set to OFF/OFF if using a CommLink IV and to OFF/ON if using a

CommLink 5. See Figure 4, page 8 for details.

Figure 3: Lead/Lag Controller Address Switch Setting

Lead/Lag Controller Technical Guide

7

Page 8

Section 1: Lead/Lag Wiring & Setup

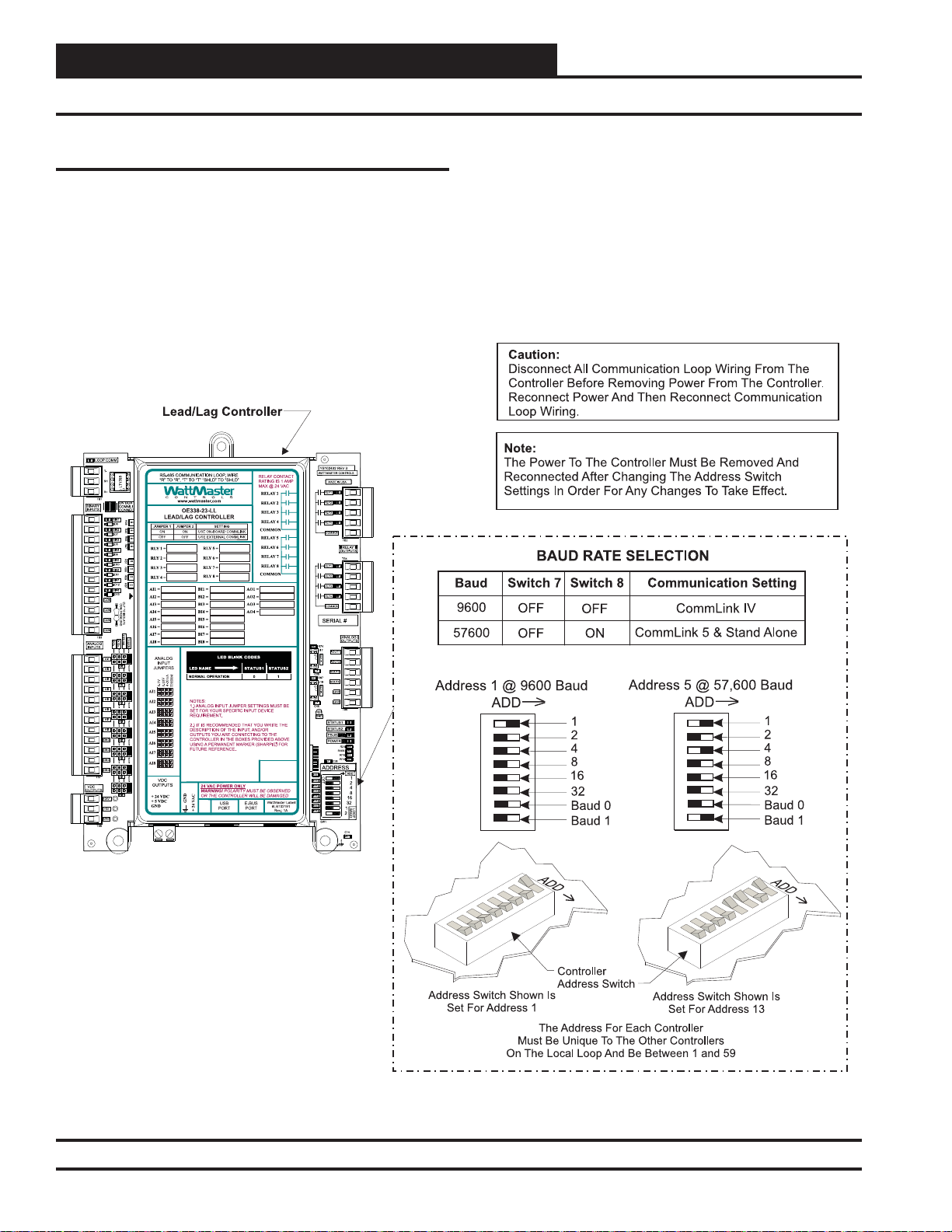

Addressing and Baud Rate Settings

Zone

Zone

Controller Addressing and Baud Rate

The Lead/Lag Controller is equipped with address switches. When

using Prism 2 to program and confi gure the Lead/Lag Controller,

you would enter this address to communicate with the controller.

When the system is to be connected to other HVAC unit controllers

on a communication loop, each controller’s address switch must be

set with a unique address between 1 and 59.

Address switches 7 and 8 are used for the baud rate selection. See

Figure 4 below for baud rate setting information.

Figure 4: Lead/Lag Controller Address Switch Setting

8

Lead/Lag Controller Technical Guide

Page 9

Section 2: Installing Prism 2

Initialization and Prism 2 Software

Initialization

On system power up, there is an approximately 30-second startup

delay where all default setpoints are initialized, LED’s are initialized,

and all outputs are turned off.

When power is fi rst applied, the STATUS1 LED will fl ash intermit-

tently for about 10 seconds. After a short pause, STATUS1 LED

and STATUS2 LED will fl ash out the controller address. STATUS1

LED will fl ash to represent the tens position. STATUS2 LED will

fl ash to represent the ones position. After the controller address is

complete, there will be a short pause while the initialization process

is completed. There will be no controller operation or communications during initialization. After initialization, STATUS2 LED will

continuously fl ash the status code—(1) blink indicates Normal

Operation; (2) blinks indicates a Push-Button Schedule Override

is in effect.

Example of a controller address of 25:

STATUS1 LED will fl ash 2 times. STATUS2 LED will fl ash 5 times.

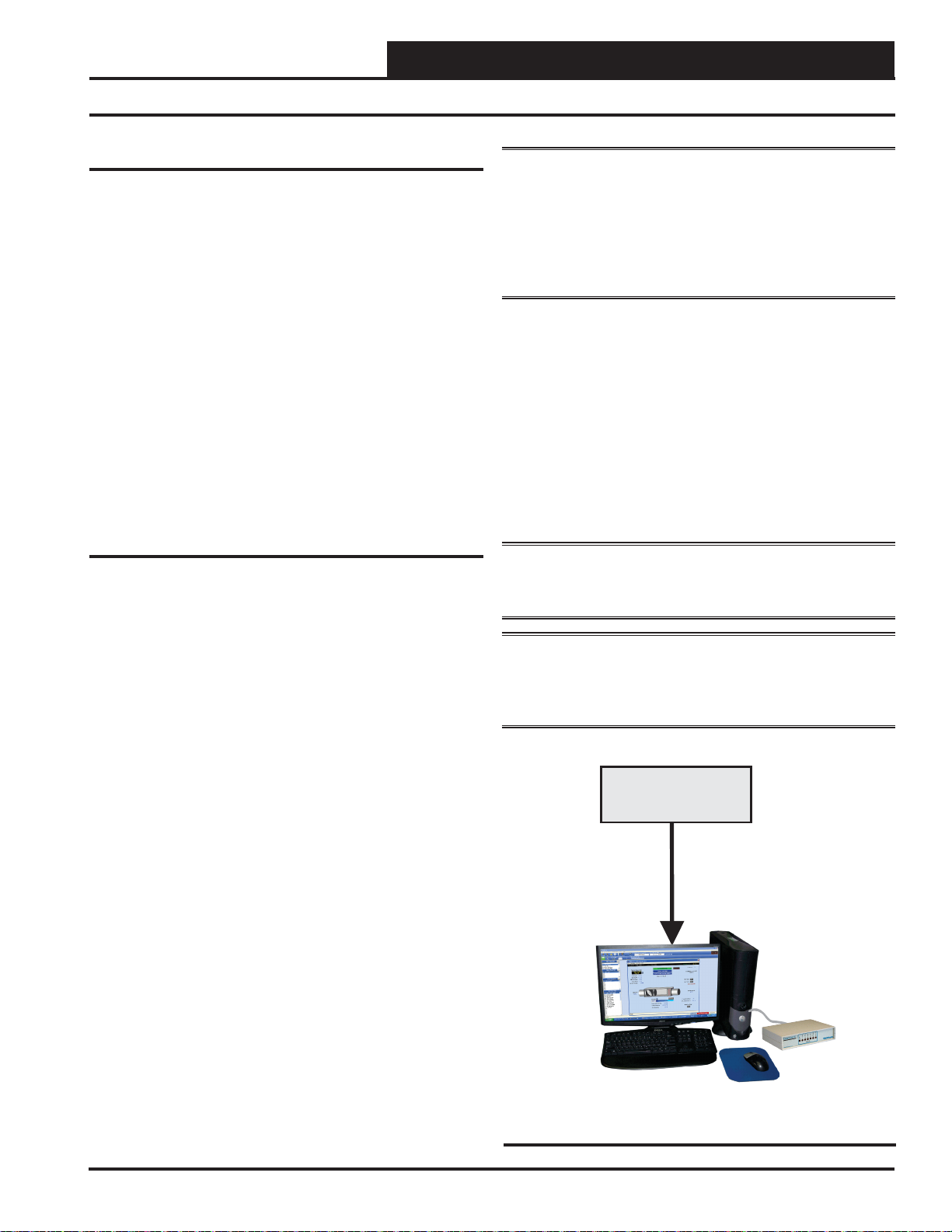

Prism 2 Software

The next step is programming the controller for your specifi c require-

ments. In order to confi gure and program the Lead/Lag Controller,

you must use Prism 2 software. This gives you access to the status,

confi guration, and setpoint screens of the Lead/Lag Controller. The

software is distributed on CD or can be downloaded for free from

our website: www.wattmaster.com/techsupport.

If you are unfamiliar with Prism 2, we recommend that you reference

the Prism 2 Technical Guide to familiarize yourself with the program.

* NOTE: The Lead/Lag Controller has a built-in CommLink

that can be utilized in Stand-Alone Mode. See page 7 for

sett i ng up St and -A lone a nd Net work operations. In Net-

work Mode, you must have a CommLink IV or CommLink

5 installed in order to communicate between your computer and

the system. If remote communication is required, a WattMaster IPModule (Ethernet) must also be installed in the CommLink.

Software License

Prism 2 does not require any license agreement and may be freely

copied and distributed.

Support Information

WattMaster Controls provides Prism 2 installation and confi guration

support. Call (866) 918-1100 for free, direct telephone support or

(816) 505-1100 to talk to a Technical Support Representative. Support for all telephone services is available Monday through Friday,

7:00 AM to 5:00 PM central standard time.

NOTE: WattMaster Controls Technical Support can-

not troubleshoot internal PC and/or Windows®-based

operating system problems.

NOTE: WattMaster Controls Technical Support can-

not troubleshoot fi rewalls, r oute rs, a nd/o r p robl ems

on a customer’s internal or external network. An IT

professional may need to be consulted.

System Requirements

To use Prism 2 you must have a computer that meets or exceeds the

following requirements:

Operating System

• Microsoft

Windows

NOTE: Prism 2 is not intended for a server/client

environment.

Minimum Hardware

• Windows

®

Windows® 2000/ Windows® Vista,

®

7 or Windows® 8

®

compatible computer

• Pentium 2 GHz Processor (Pentium 4 2 GHz or

greater, Recommended)

• 1 GB RAM (or greater)

• 120 MB hard drive space

• XVGA (1024 x 768) adapter and monitor

(1280 x 1024, Recommended)

• Network card for TCP/IP connection when IP

Module is used.

• CommLink*

Lead/Lag Controller Technical Guide

Operator

Interface

Figure 5: Computer with Prism 2 Software Installed

and CommLink

9

Page 10

Section 3: Lead/Lag & 2 Lead/1 Lag Navigation & Status

Unit Selection

Selecting and Naming Lead/Lag Controllers

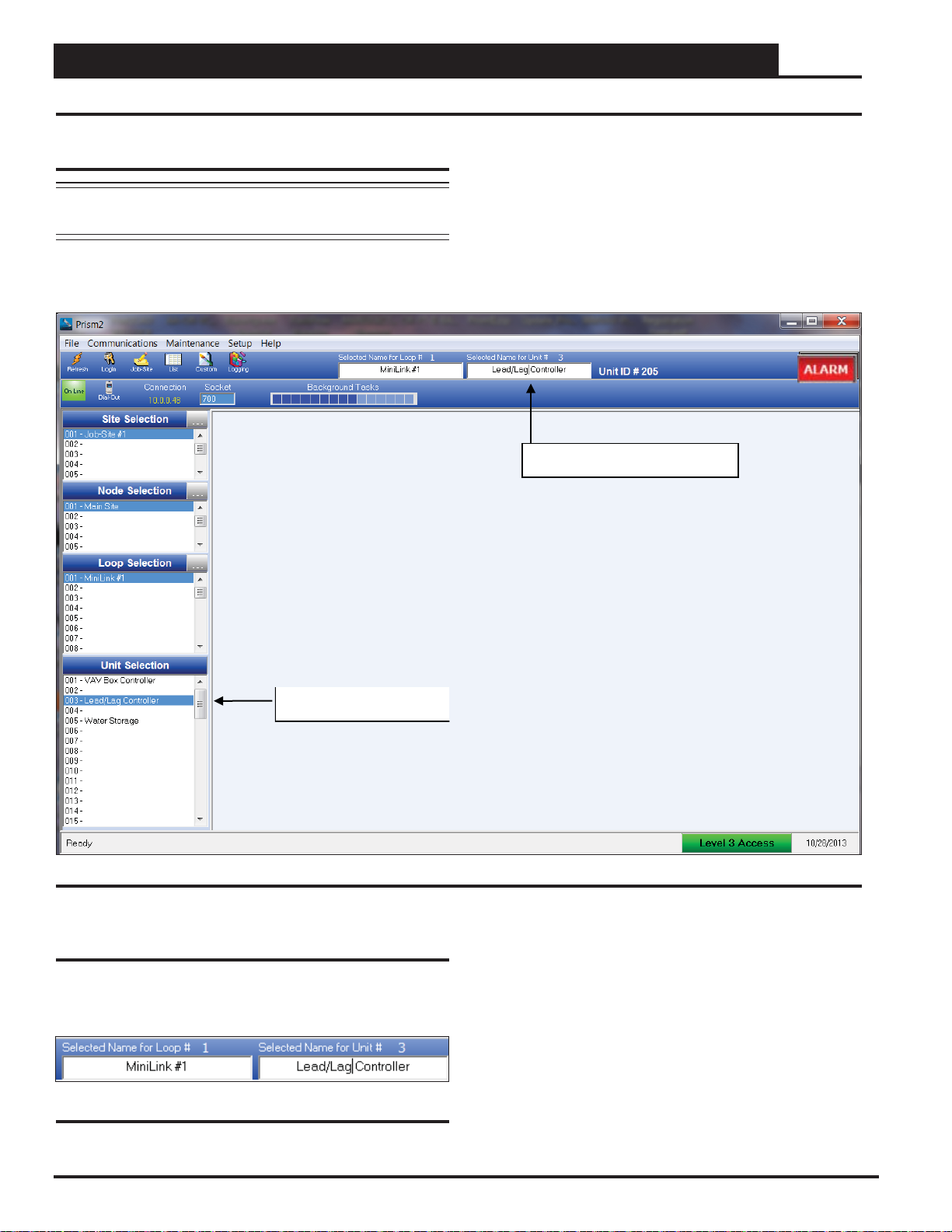

Selecting Lead/Lag Controllers

NOTE: See the Prism 2 Technical Guide for instructions on

setting up the job site and doing a search for units.

From the Prism 2 Main Screen, click on the Lead/Lag Controller

address in the Unit Selection W indow. In this example, it is address

3. See Figure 6.

Selected Name Dialog Box

Figure 6: Prism 2 Main Screen Lead/Lag Controller Selection

Naming Lead/Lag Controllers

If you have more than one Lead/Lag Controller, you can rename it in

the Selected Name Dialog Box. See Figur e 7. Many users name their

Lead/Lag Controller according to the application that it performs.

Figure 7: Naming the Lead/Lag Controller

10

Lead/Lag Controller Technical Guide

Page 11

Section 3: Lead/Lag & 2 Lead/1 Lag Navigation & Status

Lead/Lag Status Screen

Lead/Lag Status Screen

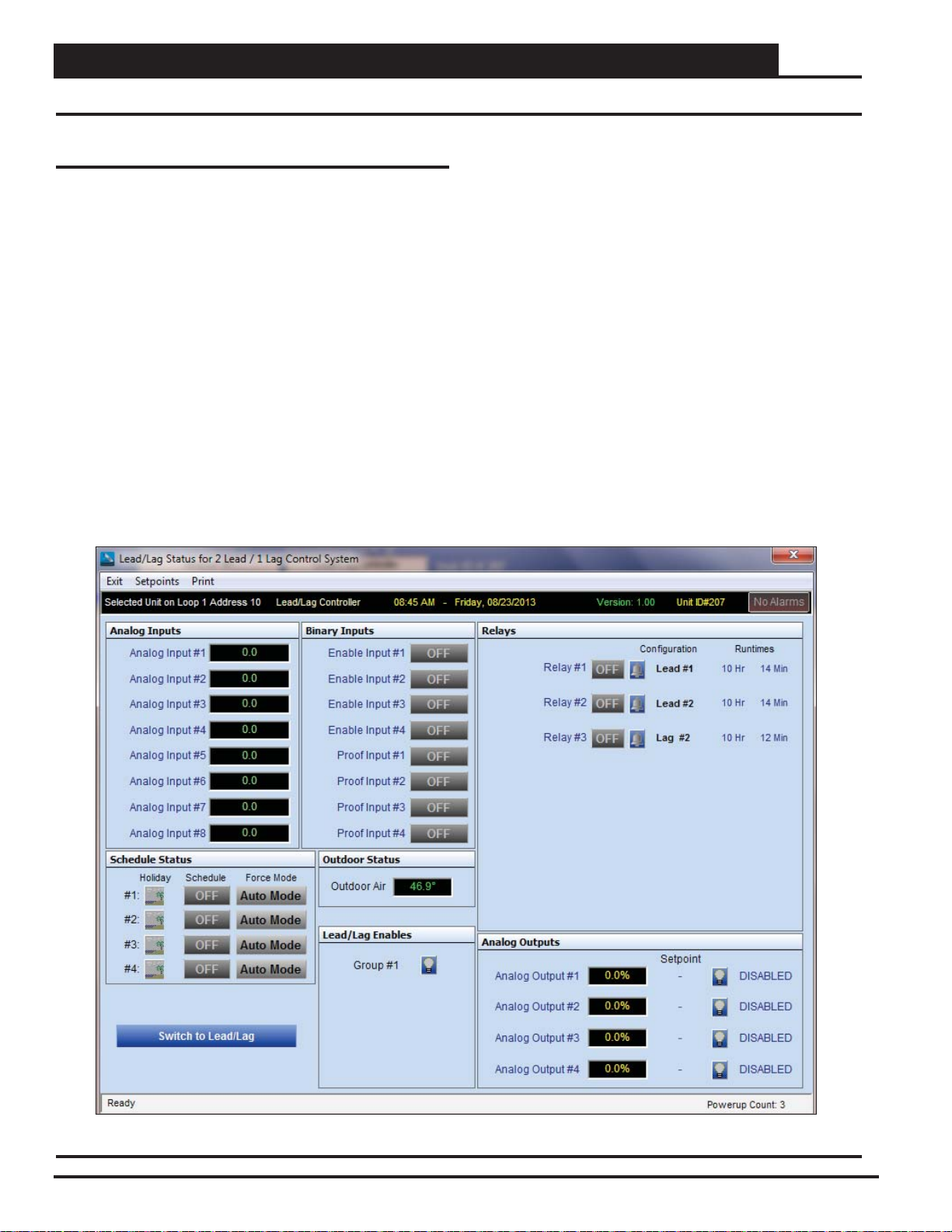

Figure 8 depicts the Lead/Lag Status Screen. To access the Lead/

Lag Status Screen, you might need to click the <Switch to Lead/

Lag> button found on the lower left of the 2 Lead/1 Lag Status

Screen (Figure 9, page 12).

The screen is divided into separate windows as follows: Analog In-

puts, Binary Inputs, Relays, Analog Outputs, Outdoor Status, Lead/

Lag Enables, Schedule Status, and Alarms.

The Lead/Lag Status Screen Toolbar also gives you the options to

access Reset Factory Defaults, Save and Restore Setpoints, and Print

a Status Report for the current day.

The Lead/Lag Status Screen provides real-time live updates of the

current operating conditions and is used to access the various setpoint

and confi guration options.

No control takes place until you confi gure the operation of the Lead/

Lag application.

Once you confi gure your inputs, outputs, and operating schedules,

everything you need to monitor the Lead/Lag application is found

on this Lead/Lag Status Screen.

The rest of this technical guide explains each component on this

screen and provides detailed instructions for confi guring the data.

The following is a list of topics and their page numbers:

Analog Inputs, page 13

Binary Inputs, page 17

Relays, page 20

Analog Outputs, page 25

Outdoor Status, page 31

Lead/Lag Enables, page 31

Schedules, page 32

Confi guring Alarms, page 36

From the Top Toolbar:

Setpoints, Restore Defaults, page 37

Setpoints, Save and Restore, pages 37 & 38

Print Status Report, page 39

Figure 8: Lead/Lag Status Screen

Lead/Lag Controller Technical Guide

11

Page 12

Section 3: Lead/Lag & 2 Lead/1 Lag Navigation & Status

2 Lead / 1 Lag Status Screen

2 Lead / 1 Lag Status Screen

Figure 9 depicts the 2 Lead/1 Lag Status Screen. To access the 2

Lead/1 Lag Status Screen, you might need to click the

Lead/1 Lag>

Screen (Figure 8, page 11).

The screen is divided into separate windows as follows: Analog In-

puts, Binary Inputs, Relays, Analog Outputs, Outdoor Status, Lead/

Lag Enables, Schedule Status, and Alarms.

The 2 Lead/1 Lag Status Screen Toolbar also gives you the options

to access Reset Factory Defaults, Save and Restore Setpoints, and

Print a Status Report for the current day.

The 2 Lead/1 Lag Status Screen provides real-time live updates of

the current operating conditions and is used to access the various

setpoint and confi guration options.

No control takes place until you confi gure the operation of the 2

Lead/1 Lag application.

button found on the lower left of the Lead/Lag Status

<Switch to 2

Once you confi gure your inputs, outputs, and operating schedules,

everything you need to monitor the 2 Lead/1 Lag application is found

on this 2 Lead/1 Lag Status Screen.

The rest of this technical guide explains each component on this

screen and provides detailed instructions for confi guring the data.

The following is a list of topics and their page numbers:

Analog Inputs, page 13

Binary Inputs, page 17

Relays, page 20

Analog Outputs, page 25

Outdoor Status, page 31

Lead/Lag Enables, page 31

Schedules, page 32

Confi guring Alarms, page 36

From the Top Toolbar:

Setpoints, Restore Defaults, page 37

Setpoints, Save and Restore, pages 37 & 38

Print Status Report, page 39

Figure 9: 2 Lead/1 Lag Status Screen

12

Lead/Lag Controller Technical Guide

Page 13

Section 4: Confi guring Analog Inputs

Analog Inputs

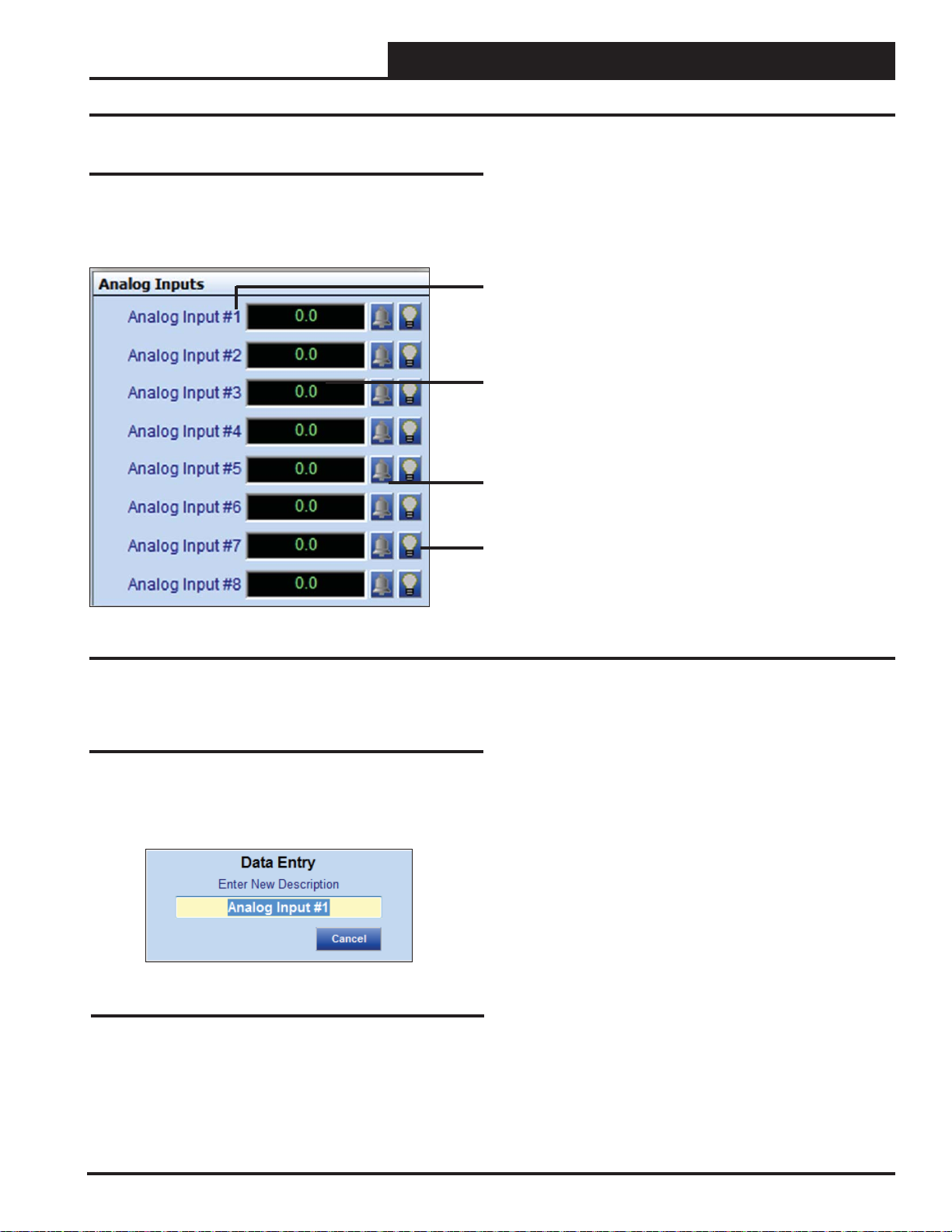

The Analog Inputs W indow is located in the upper left-hand side of

the Lead/Lag Status Scr eens (Figures 8 & 9, pages 11 & 12). There

are 8 Analog Inputs. See Figure 10 for the Analog Inputs Window

component summary and the pages that follow for details.

Analog Inputs

Right or Left-click on any of the Analog Input name

fi elds to access the description entry box to add or

change the name of the Analog Input.

Left-Click in the data entry fi eld to confi gure the Analog

Input.

Right-Click on these fi elds to access the Calibration,

Override, and Clear Override.

The bell will light up to indicate that an alarm is on.

The Light bulb will light up when the Input is in the

Occupied Mode.

Figure 10: Analog Input Window Components and Navigation

Renaming Analog Inputs

To give an Analog Input a new name, click on the blue highlighted

Analog Input # fi eld and the Analog Input Data Entry Dialog Box

will open (Figure 11). Once you have typed in a new description,

<ENTER> to save. The maximum number of characters is 17.

press

Figure 11: Analog Input Data Entry Dialog Box

Lead/Lag Controller Technical Guide

13

Page 14

Section 4: Confi guring Analog Inputs

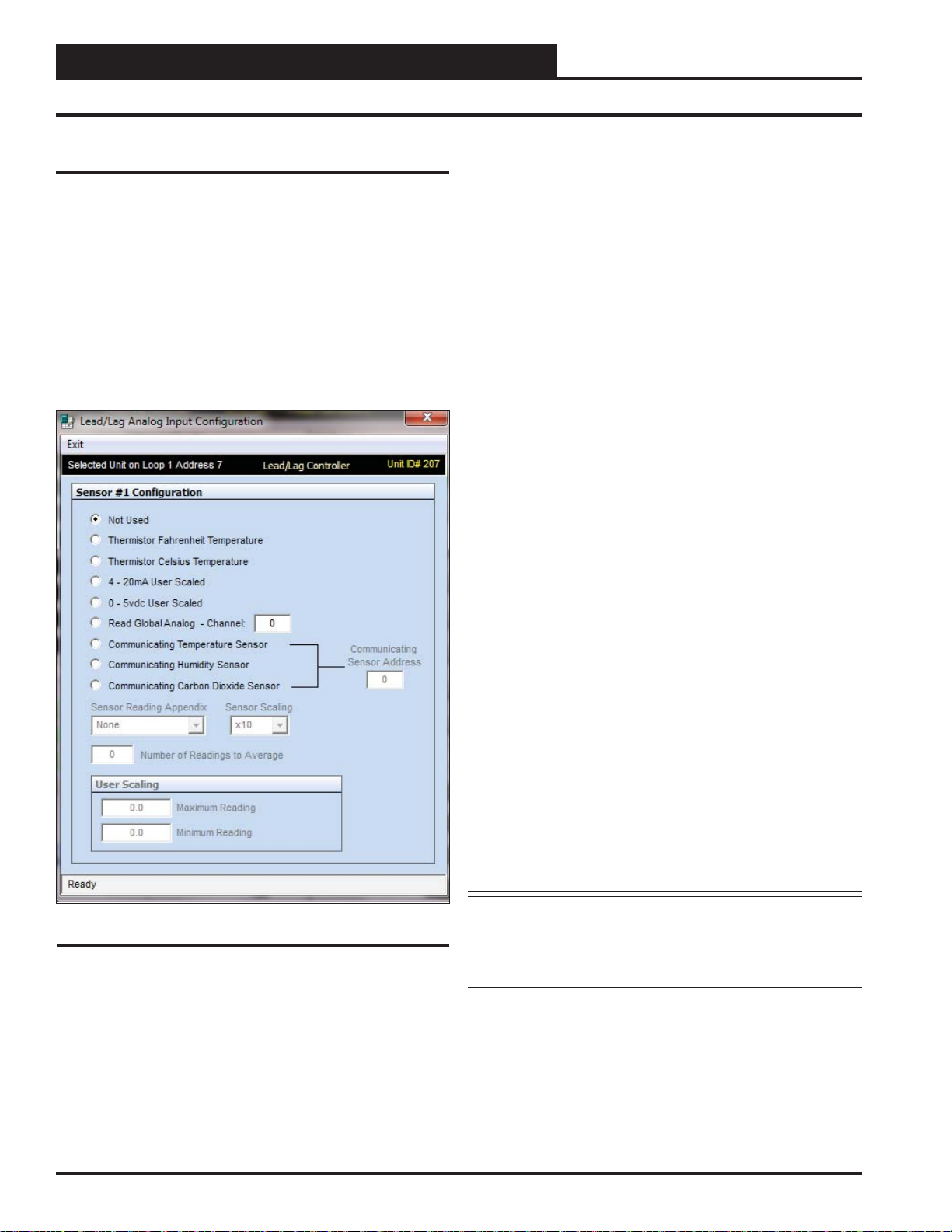

Analog Input Confi guration Screen

Confi guring Analog Inputs

Left-click in the data entry fi eld in the Analog Inputs Window to open

the Analog Input Confi guration Window (Figure 12).

The eight analog inputs can be confi gured in several different ways.

Generally, the fi rst four inputs are the only ones used for Lead/Lag

control. These inputs can be used to generate an alarm and switch

from one device to another if the fi rst cannot maintain a temperature

or PSI setpoint. The others can be used to monitor various inputs.

The controlling devices can be set up to look at one sensor or each

device can have its own sensor.

The following confi gurations are available for each Analog Input:

Not Used

●

Thermistor Fahrenheit Temperature: 10K Ohm Type III

●

Scaled for Fahrenheit. Set jumper to the appropriate setting

(see Figure 2, page 6).

Thermistor Celsius Temperature: 10K Ohm Type III

●

Scaled for Celsius. Set jumper to the appropriate setting (see

Figure 2, page 6).

4 - 20mA User Scaled: 4-20mA User-Scaled Sensor. Set

●

jumper to the appropriate setting (see Figure 2, page 6).

0 - 5vdc User Scaled: Select this option if using a 0-5vdc

●

scaled sensor. Set jumper associated with this input to the

appropriate 0-5v setting (see Figure 2, page 6.)

●

Read Global Analog Broadcast Channel from Another

Controller

● Communicating Temperature Sensor ( OE217-02):

If using a WattMaster Communicating Temperature

Sensor with a modular cable, confi gure this input to read

the appropriate Communicating Sensor Address. Enter

an address from 1-8 in the < Communicating Sensor

Address>

fi eld and press <ENTER>.

Figure 12: Analog Input Confi guration Window

Communicating Humidity Sensor ( OE217-03): If using

●

a combination Temperature and Humidity Communicating

Sensor with a modular cable, confi gure one input to read

the temperature and another input to read the humidity,

both using the same Communicating Sensor address. Enter

an address from 1-8 in the <Communicating Sensor

Address>

●

Communicating Carbon Dioxide Sensor ( OE256-05

or OE256-07)

Sensor with a modular cable, confi gure this input to read

the appropriate Communicating Sensor Address. Enter

an address from 1-8 in the <Communicating Sensor

Address>

*NOTE: See the E-BUS Digital Room Sensor Technical Guide,

fi eld and press <ENTER>.*

: If using a WattMaster Communicating CO2

fi eld and press <ENTER>.*

E-BUS Wall-Mounted CO

or E-BUS Duct-Mounted CO

for information on how to address the communicating sensors.

Sensor Technical Guide,

2

Sensor T echnical Guide

2

14

Lead/Lag Controller Technical Guide

Page 15

Section 4: Confi guring Analog Inputs

Sensor Reading, Scaling, and Override Duration

Sensor Reading Appendix

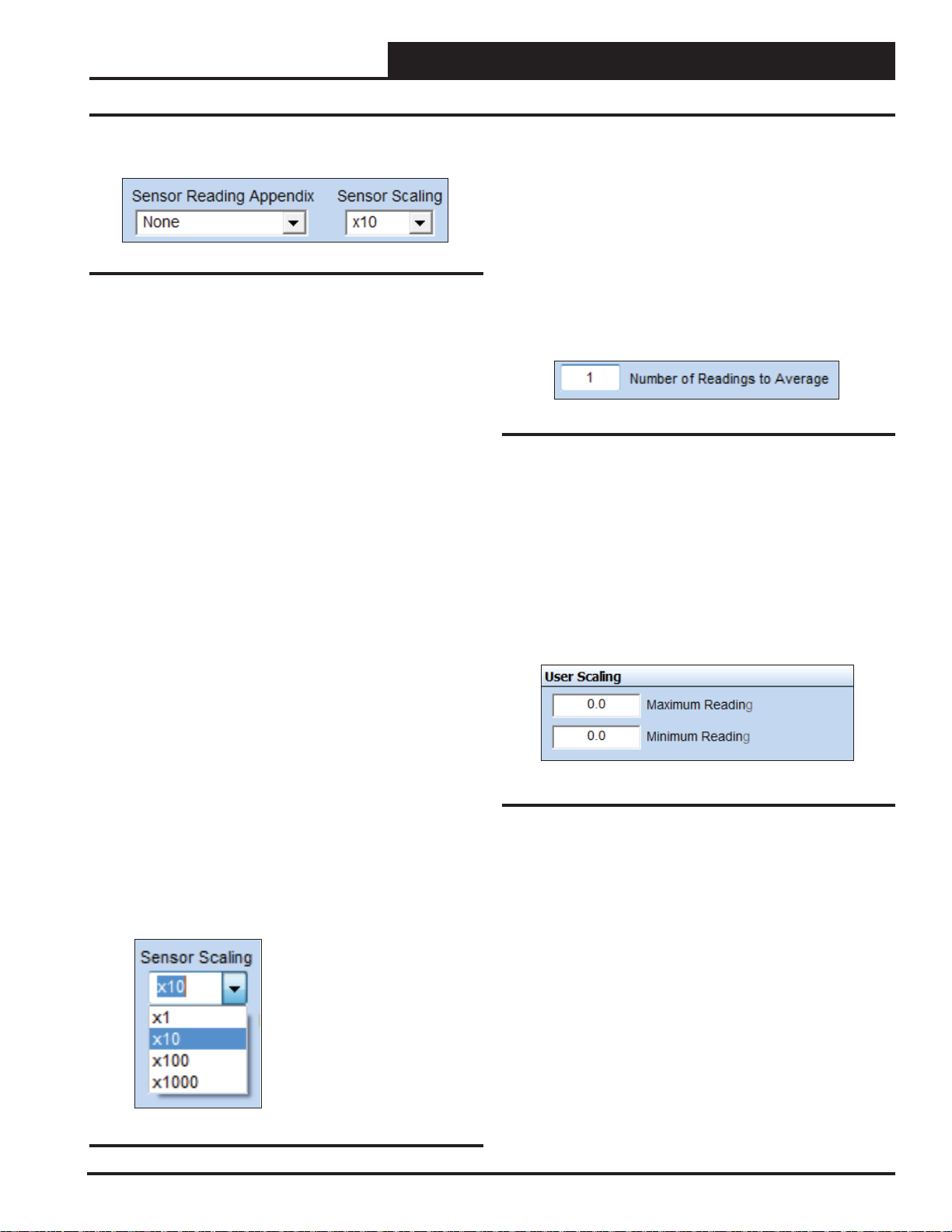

Figure 13: Sensor Reading Appendix Field

Select from the drop down list in the <Sensor Reading Appendix>

fi eld (Figure 13) to give the sensor reading a qualifi er.

●

None: No Appendix Required

● RH%: Humidity Percentage

%: Percentage

●

°F: Fahrenheit

●

°C: Celsius

●

PPM: Parts per Million

●

PSI: Pound per Square Inch

●

“WG: Inches of Water Gauge

●

“: Inches

●

Ft.: Feet

●

RPM: Revolutions per Minute

●

VDC: Volts D.C.

●

Number of Readings to Average

This function has the capability of averaging up to 25 sensor readings

before it displays a new value on one of the Lead/Lag Controller

Status Screens. Sensor values are read once per second.

Type the number of readings from this sensor you want to aver-

age in the <Number of Readings to Average> fi eld and press

<ENTER> to save. See Figure 15. Valid entries are from 1-25.

If you want the input sensor to only show its most current reading,

enter <1>.

Figure 15: Number of Readings to Average Field

User Scaling

The User Scaling Box allows you to set a Maximum and Minimum

Reading for the specifi c 4-20 mA or 0-5 vdc sensor you are using.

This means you can display values with ± 1, ± 0.1, ± 0.1± 0.01 or

higher resolutions. Just keep in mind that the maximum value that

can be sent from the controller is ±30,000, so if you have scaled your

reading to ± 0.001, then the maximum value you can send is ± 30

with the 3 additional decimal values (30.000). See Figure 16. Type

in the values and press <ENTER> to save.

BTU: British Thermal Unit

●

CFM: Cubic Feet per Minute

●

Hr: Hours

●

Min: Minutes

●

GPM: Gallons per Minute

●

kPa: Kilopascals

●

Sensor Scaling

All readings are user-scalable according to the number of digits

to the right of the decimal point. See Figure 14 and values and

examples below.

●

X 1 65°F

● X 10 65.5°F

● X 100 65.54°F

● X 1000 65.543°F

Figure 16: User Scaling Box

Figure 14: Sensor Scaling Field

Lead/Lag Controller Technical Guide

15

Page 16

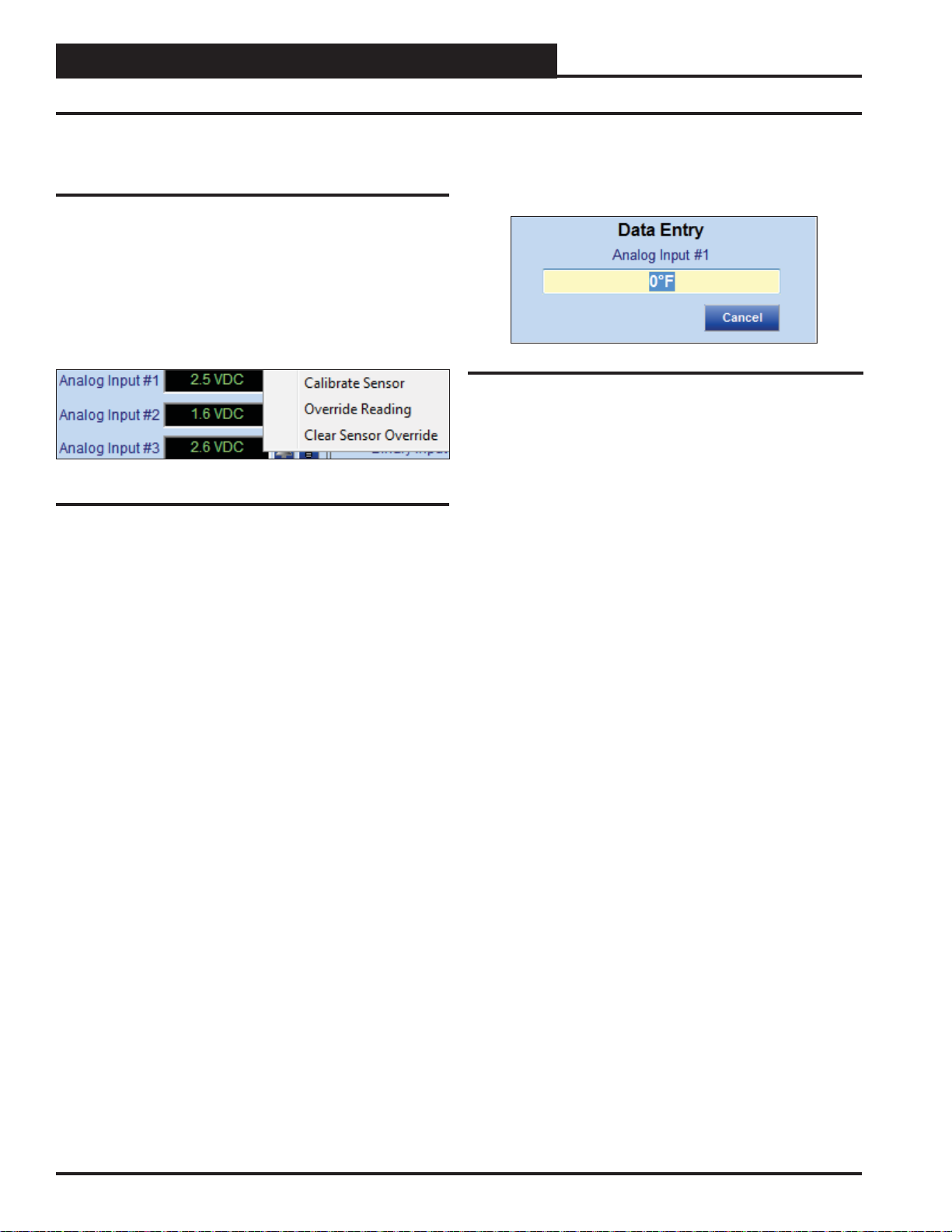

Section 4: Confi guring Analog Inputs

Calibrate, Override, and Clear Sensor Override

Calibrate, Override, and Clear Sensor

Override

Once confi gured, all readings can be overridden to specifi c values

for test purposes. Additionally, all thermistor sensors can also be

calibrated by entering positive or negative offsets to be applied to

the current readings.

Right-click in the data entry fi eld in the Analog Inputs Window to

open the Calibrate, Override, and Clear Sensor Override Pop-Up

Menu shown in Figure 17 and select the desired function.

Figure 17: Calibrate and Override Sensor

If you select Calibrate Sensor or Override Reading, the data entry

window as shown by Figure 18 will open. Left-click in the yellow

text fi eld, type in the desired value, and press <ENTER> to save.

Figure 18: Data Entry Field

Calibrate Sensor: Type a positive or negative offset that

●

will be applied to the current reading and press

to save. NOTE: The reading Offset can be from -100° to +

100°. This function only applies to Thermistor Temperature

Sensors.

Override Reading: Type a value that will override the

●

actual sensor reading and press <ENTER> to save.

Clear Sensor Override: Select to clear a sensor override

●

that was entered.

<ENTER>

16

Lead/Lag Controller Technical Guide

Page 17

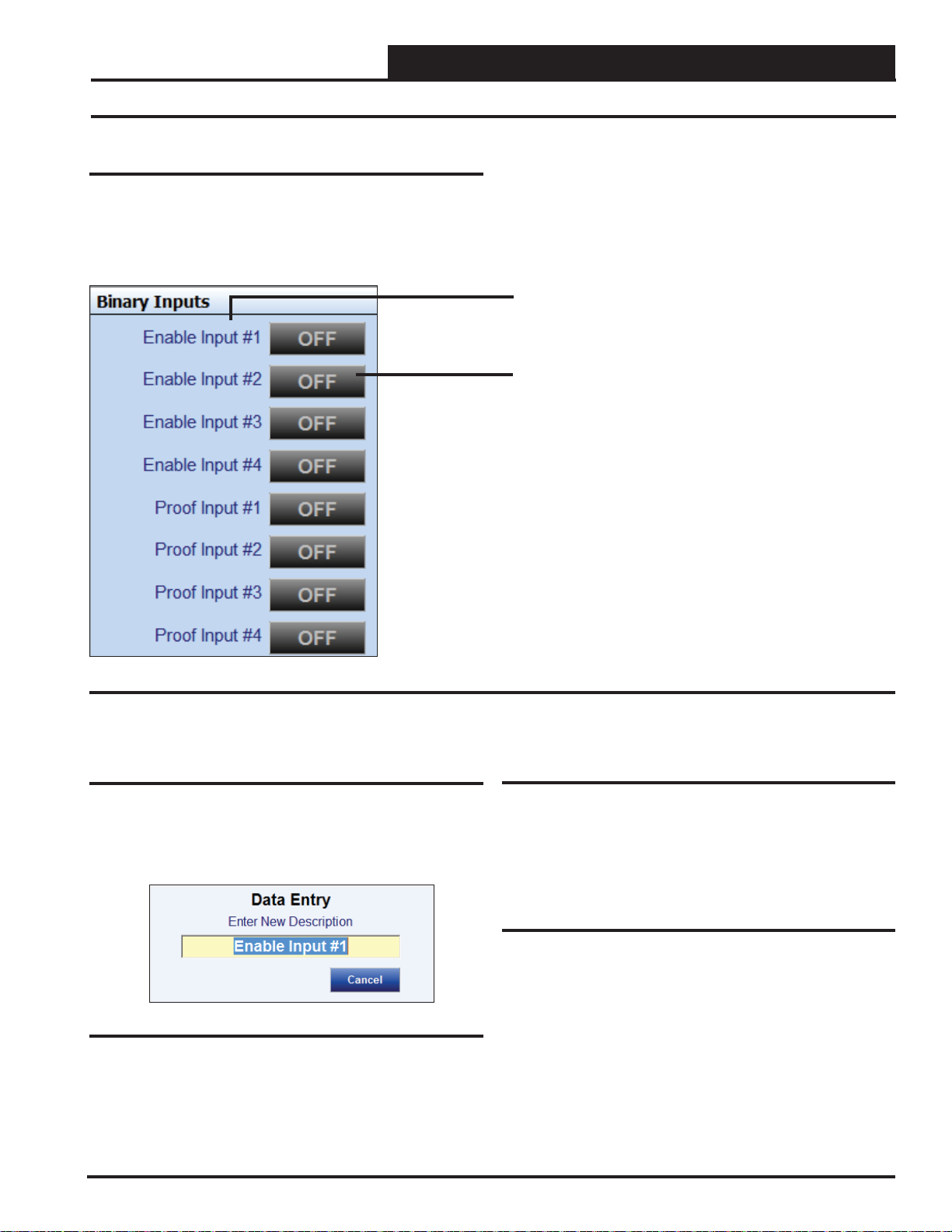

Section 5: Confi guring Binary Inputs

Binary Inputs

The Binary Inputs W indow is located in the upper center of the Lead/

Lag Controller Status Scr eens (Figures 8 & 9, pages 1 1 & 12). There

are 8 Binary Inputs. Binary Inputs are used as either Enable Inputs

or Proof Inputs. These Binary Inputs are 24 VAC wet contacts. See

Figure 19 for the Binary Inputs Window component details.

Components and Navigation

Right or Left-click on any of the Binary Input name

fi elds to access the description entry box to add or

change the name of the Binary Input.

Left-click on the Status box to confi gure the Binary

Input.

Right-click to override the Binary Input.

Figure 19: Binary Input Window Components and Navigation

Renaming Binary Inputs

To give the Binary Input a new name, click on the blue highlighted

Binary Input # fi eld and the Binary Input Data Entry Dialog Box

will open (Figure 20). Once you have typed in a new description

(max 17 characters), press <ENTER> to save.

Enable Inputs

The fi rst 4 Binary Inputs are Enable Inputs—Inputs #1-#4. Enable

Inputs can be used to activate the Lead/Lag devices. Confi guring

the Lead/Lag devices to use the Enable (Activation) Inputs is done

in the Relay Confi guration Screens.

Proof Inputs

The last 4 Binary Inputs are Proof Inputs—Inputs #5-#8. Proof Inputs

are used to prove that the devices are operating correctly. They can

be such things as air fl ow switches, water fl ow switches, or pressure

differential switches. Confi guring the Lead/Lag devices to use the

Figure 20: Binary Input Data Entry Dialog Box

Proof Inputs is done in the Relay Confi guration Screens.

Lead/Lag Controller Technical Guide

17

Page 18

Section 5: Confi guring Binary Inputs

Binary Input Type and Override

Confi guring Binary Inputs

Left-click on the “ON” or “OFF” button to the right of Binary Input

#1 in the Binary Input Window (Figure 19, page 17) to open the

Binary Input Confi guration Window (Figure 21). Each Binary Input

is separately confi gured, so 8 binary input combinations are possible

for one controller.

Figure 21: Binary Input Confi guration Window

Binary Confi guration

The following confi gurations are available for each Binary Input:

Override

Once configured, Binary Inputs can be overridden to specific

conditions.

Right-click on the Status box in the Binary Inputs Window (Figure

19, page 17) to open the Override Binary Input Dialog Box shown

in Figure 22, and select the desired function.

Figure 22: Override Binary Input

●

AUTO: Select to have a Binary Input turn ON and OFF on

its own.

ON: Select to override and turn a Binary Input ON.

●

OFF: Select to override and turn a Binary Input OFF.

●

Not Used

●

N/O Contact (Closes for Active) - This normally open

●

(N/O) input will become active when 24 VAC is applied.

N/C Contact (Opens for Active) - This normally closed

●

(N/C) input will become active when 24 VAC is removed.

Read Global Binary - This input will read the Global

●

Binary on the selected channel.

18

Lead/Lag Controller Technical Guide

Page 19

Section 6: Confi guring Relays

Lead/Lag Relays

The Relays Window is located in the upper right of the Lead/Lag

Controller Status Screens (Figures 8 & 9, pages 11 & 12). There

are 8 Relays. See Figure 23 for the Lead/Lag Relays W indow component summary and the pages that follow for details. See Figure

24 for the 2 Lead/1 Lag Relays Window component summary and

the pages that follow for details.

Components and Navigation

Right or left-click on any of the Relay fi elds

to access the description entry box to add or

change the name of the Relay.

Left-click on this Status box to confi gure the

Relays.

Right-click to override the Relay.

The bell will light up to indicate that an alarm

is on.

Figure 23: Lead/Lag Relays Window

Amount of time in hours and minutes that the

relay has been energized.

Renaming Relays

To give the Relay a new name, click on the blue highlighted Relay

# fi eld and the Relay Data Entry Dialog Box will open (Figur e 25).

Once you have typed in a new description, press <ENTER> to save.

Figure 24: 2 Lead/1 Lag Relays Window

Lead/Lag Controller Technical Guide

Figure 25: Relay Data Entry Dialog Box

19

Page 20

Section 6: Confi guring Relays

Lead/Lag Relay Confi guration Window

Confi guring Lead/Lag Relays

Left-click on the “ON” or “OFF” button to the right of the Relay #

in the Relays Window (Figure 23, page 19) to open the Lead/Lag

Relay Confi guration Screen. (Figure 26).

One relay can be confi gured as the lead and up to 7 relays can be lag.

There are (8) relays that can be confi gured.

The Relay Confi guration Screen contains (4) windows which are

described on the pages that follow:

● Main Control Method

● Timers

● Relay Output Type

● Lead/Lag Proof Setpoint Help

Figure 26: Lead/Lag Relay Confi guration Screen

20

Lead/Lag Controller Technical Guide

Page 21

Section 6: Confi guring Relays

Lead/Lag Relay Confi guration Window

Confi guring 2 Lead/1 Lag Relays

Left-click on the “ON” or “OFF” button to the right of the Relay #

in the Relays Window (Figure 24, page 19) to open the 2 Lead/1

Lag Relay Confi guration Screen. (Figure 27).

Only three relays are used. Two of them are confi gured as Lead

and 1 is Lag.

The 2 Lead/1 Lag Relay Confi guration Screen contains (4) windows

which are described on the pages that follow:

● Main Control Method & Control Source

● Timers

● Relay Output Type

● Lead/Lag Proof Setpoint Help

Figure 27: 2 Lead/1 Lag Relay Confi guration Screen

Lead/Lag Controller Technical Guide

21

Page 22

Section 6: Confi guring Relays

Control Method and Control Source

Control Method

The Control Method Drop Down Menu (Figure 28) is located on

the top left of the Relay Confi guration Screens (Figure 26 & 27,

page 20 & 21). As you select items, the corresponding fi elds that

you need to fi ll out will become available. Fields that do not pertain

to the confi guration at hand will be greyed out.

Figure 28: Control Method Drop Down Menu

For Lead/Lag confi guration, one relay will be the Lead and up to

seven can be the Lag, and they are confi gured from their own Relay

Confi guration Screens. For 2 Lead / 1 Lag, two relays are Lead and

one is Lag and all three relays are confi gured from Relay #1 screen.

The choices are one of the following methods of control listed below:

●

Not Confi gured

● Lead Relay

● Lag Relay

Lead Relay – If this option is selected, you can also select a Control

Source input in the next fi eld to be used as a Proof of Operation to

allow switching to the Lag Relay upon a failure. This proof can

either be a binary contact activation or an analog input level. If

your Proof is an analog input level, you can then confi gure either

an Increasing or Decreasing Proof Setpoint (Figure 30, page 23).

Control Source

Figure 29: Control Source Field

The Control Source Options in the Control Sour ce Drop Down Menu

(Figure 29) are shown below:

●

Not Confi gured

● Analog Input #1

● Analog Input #2

● Analog Input #3

● Analog Input #4

● Analog Input #5

● Analog Input #6

● Analog Input #7

● Analog Input #8

● Proof Input #1

● Proof Input #2

● Proof Input #3

● Proof Input #4

● Outdoor Air

If your Proof is a Binary Input, the Proof Failure is initiated when

the selected Binary Input is “Active” (See Binary Input Activation

Window, Figure 35, page 24.)

In the Timers Window (Figure 36, page 24) found at bottom left of

the Lead/Lag Relay Confi guration Screen ( Figur e 26, page 20), you

can confi gure a Lead/Lag Changeover Interval and a Proof Failure

Timeout Delay.

Lag Relay – This Lag Relay will follow the same confi gurations

as the Lead Relay.

22

Lead/Lag Controller Technical Guide

Page 23

Section 6: Confi guring Relays

Increasing and Decreasing Proof Setpoints

Increasing Proof Setpoint

Figure 30: Increasing Proof Setpoint

Use this option if you want to use a temperature as proof that the

device is operating correctly and to determine if the unit has failed

if it cannot maintain a temperature that is above this setpoint. For

example, if the unit is trying to maintain a 80° supply air temperature

and drops below this setpoint for the “ Proof Failure Timeout Delay”,

then the Lead/Lag controller will shut off the device that is running,

start the backup device, and generate an alarm.

Decreasing Proof Setpoint

Figure 31: Decreasing Proof Setpoint

Use this option if you want to use a temperature as proof that the

device is operating correctly and to determine if the unit has failed

if it cannot maintain a temperature that is below this setpoint. For

example, if the unit is trying to maintain a 55° supply air temperature

and it rises above this setpoint for the “Proof Failure Timeout Delay”,

then the Lead/Lag controller will shut off the device that is running,

start the backup device, and generate an alarm.

Relay Override

Figure 33: Relay Override

In order to override the relays on, off, or put them back in auto mode,

right-click on the relay’s On/Off box in the Relay Confi guration

Window. See Figures 23 & 24, page 19.

Activation Schedule

Control of the Lead/Lag devices must be initiated based on a

Schedule and/or a Binary Input Activation. If only an Activation

Schedule is selected the Lead/Lag operation will be active whenever

the Schedule is Occupied. The schedule can be set with a 7-day

schedule with 2 start/stops per day, or it can be confi gured for con-

tinuous 24/7 operation. If both an Activation Schedule and a Binary

Input Activation are selected, the Lead/Lag operation will be active

when the Binary Input is active and the Schedule is Occupied. If no

Activation Schedule is selected, the Lead/Lag operation will activate

solely on the basis of a Binary Input Activation.

The controller only uses Schedule #1 for control of 2 Lead/ 1 Lag

functions. For Lead/Lag operation, 4 schedules are available. Schedule #1 would correspond to Lead/Lag #1 operation, Schedule #2 for

Lead/Lag #2 operation, etc. See Section 9: Setting Schedules, page

32 for more information.

Relay Output Type

Figure 32: Relay Output Type

Some control methods require the relay contacts to be closed when

the output is activated; others require the contacts to be open. You

can select which method of control to use with this option.

Lead/Lag Controller Technical Guide

Figure 34: Activation Schedule

23

Page 24

Section 6: Confi guring Relays

Binary Input Activation and Timers

Binary Input Activation (Enable)

Control of the Lead/Lag devices must be initiated based on a Binary

Input Activation (Enable) and/or an Activation Schedule. Binary

Inputs #1 - #4 are used as Activation Binary Inputs. If no Activation

Schedule is confi gured, the Lead/Lag operation will be initiated

solely on the basis of a Binary Input Activation. If both a Binary

Input Activation and an Activation Schedule and are selected, the

Lead/Lag operation will be active when the Binary Input is active

and the Schedule is Occupied.

Figure 35: Binary Input Activation Window

Timers

The Changeover Interval is the amount of time the fi rst device will

run before it switches to a backup device. See Figure 36. It can be

set up to a maximum of 1488 hours.

The Proof Failure Timeout Delay establishes the time the controller

will wait to prove that the Lead device is running correctly before

switching to Lag device and generating an alarm. If it is a pump, it

could be proof of water fl ow or pressure, and if it is an air handling

unit, it might be temperature or proof of air fl ow. See Figure 36.

Figure 36: Timers Window

24

Lead/Lag Controller Technical Guide

Page 25

Section 7: Confi guring Analog Outputs

Analog Outputs

The Analog Outputs W indow is located in the lower right-hand side

of the Lead/Lag Controller Status Scr eens (Figures 8 & 9, pages 1 1

& 12). There are 4 Analog Outputs. See Figure 37 for the Analog

Outputs Window component summary. See the pages that follow

for details.

Components and Navigation

Right or Left-click on any of the Analog Output

name fi elds to access the description entry box

and change the name of the Analog Output.

Left-Click in the data entry fi eld to confi gure the

Analog Output.

Right-Click on these fi elds to access the

Override and Cancel Override options.

Enabled or Disabled indicates whether the output is active

or inactive.

The Light bulb will light up when the Output is in the

Occupied Mode.

Current Analog Output Setpoint

Figure 37: Analog Outputs Window Components and Navigation

Renaming Analog Outputs

To give the Analog Output a new name, click on the blue highlighted

Analog Output # fi eld and the Analog Output Data Entry Dialog Box

will open (Figure 38). Once you have typed in a new description,

press <ENTER> to save.

Figure 38: Analog Output Data Entry Dialog Box

Lead/Lag Controller Technical Guide

25

Page 26

Section 7: Confi guring Analog Outputs

Analog Output Confi guration Window

Confi guring Analog Outputs

Left-click in the data entry fi eld in the Analog Outputs Window

(Figure 37, page 25) to open the Analog Output Confi guration

Window (Figure 39).

Figure 39: Analog Output Confi guration Window

Control Type Field

The following are the control options available (Figure 40):

Figure 40: Control Type Field

26

Not Confi gured

●

● Direct Acting Floating Point

● Reverse Acting Floating Point

● Direct Acting PID

● Reverse Acting PID

Lead/Lag Controller Technical Guide

Page 27

Section 7: Confi guring Analog Outputs

Floating Point Control and PID Control

Floating Point Control

Floating Point Control works best on slow changing applications

where the amount of time it would take to drive full on or full off

is not as critical. For faster response, the PID Control method is

recommended.

With Direct Acting Floating Point Control, as the selected Control

Source rises above Setpoint, the Analog Output voltage signal increases to try to maintain the Setpoint. As the Control Source falls

below Setpoint, the Analog Output voltage signal decreases.

With Reverse Acting Floating Point Control, as the selected Control

Source rises above Setpoint, the Analog Output voltage signal decreases to try to maintain the Setpoint. As the Control Source falls

below Setpoint, the Analog Output voltage signal increases.

A Deadband above and below the Setpoint can be confi gured in

which no control signal change is made.

With Floating Point Control, you can confi gure a Calculation Interval

and a Proportional Control Window. See Figure 41.

Figure 41: Calculation Settings for Floating Point

Control

Calculation Interval - Determines how often the control signal

calculation is made to try to reach setpoint. Setting this too fast can

cause over-shooting.

Proportional Control Window - Determines how large of a signal change will occur at each Calculation Interval. The larger the

Proportional Window, the smaller the signal change will be at each

Calculation Interval.

PID Control

PID Control allows Proportional, Integral, and Derivative Rate of

Change Control. With this option, you can confi gure the Proportional

Control Window, an Integral Constant, and a Derivative Constant

as well as the Calculation Interval and PID Derivative Filter. See

Figure 42.

With Direct Acting PID Control, as the selected Control Source rises

above Setpoint, the Analog Output voltage signal increases to try to

maintain the Setpoint. As the Control Source falls below Setpoint,

the Analog Output voltage signal decreases.

With Reverse Acting PID Control, as the selected Control Source

rises above Setpoint, the Analog Output voltage signal decreases

to try to maintain the Setpoint. As the Control Source falls below

Setpoint, the Analog Output voltage signal increases.

Figure 42: Calculation Settings for PID Control

Calculation Interval - Determines how often the control signal

calculation is made to try to reach setpoint. Setting this too fast can

cause over-shooting.

Proportional Control Window { Kp} - Determines how large of

a signal change will occur at each Calculation Interval. The larger

the Proportional Window, the smaller the signal change will be at

each Calculation Interval.

Integral Constant { Ki} - Accelerates the movement of the process

towards setpoint and eliminates the residual steady-state error that

occurs with a pure proportional controller. However, since the integral term responds to accumulated errors from the past, it can cause

the present value to overshoot the setpoint value. We recommend to

start with a small Ki and increase it until a small overshoot occurs

and then dial it back.

Derivative Constant { Kd} - The derivative term slows the rate of

change of the controller output. Derivative control is used to reduce

the magnitude of the overshoot produced by the integral component

and improve the combined controller-process stability. However,

the derivative term slows the transient response of the controller.

Also, differentiation of a signal amplifi es noise and thus this term in

the controller is highly sensitive to noise in the error term, and can

cause a process to become unstable if the noise and the derivative

gain are suffi ciently large. We recommend to start with a small Kd

and increase it until overshoot is reduced to desired point.

PID Derivative Filter - The controller will average this number of

input changes in order to smooth out a fast changing value.

If the Derivative Constant (Kd) is set to “0,” then control will be

the Proportional/Integral (PI). If both the Derivative Constant (Kd)

and the Integral Constant (Ki) are set to “0,” then the control will

only be Proportional.

Lead/Lag Controller Technical Guide

27

Page 28

Section 7: Confi guring Analog Outputs

Control Source, Control Setpoints, Setpoint Reset Source

Control Source

The Control Source Options are as follows (Figure 43):

●

Analog Inputs #1 - 8

Figure 43: Control Source

Control Setpoints & Reset Limits

For most applications, only the Max Setpoint and the Deadband will

be used. See Figure 44. Unless a Setpoint Reset Source is selected,

the other values in this section will be grayed-out and not used. In

this situation, the Max Setpoint will be the setpoint you are trying to

maintain. The Deadband is the range above and below the Setpoint

in which no control signal change is made.

Setpoint Reset Source

You can confi gure a Setpoint Reset Source that will allow reset of the

Control Setpoints (Figure 45). Once a Reset Source is selected, you

will be able to confi gure both a “Max Setpoint” and a “Min Setpoint”

as well as a Max Reset value and a Min Reset value (Figure 46).

As the Reset Source value varies between the Max and Min Reset

values, the Control Setpoint will be proportionally reset between

the Max and Min Control Setpoints. At the Max Reset value, the

Control Source will be at the Max Setpoint, regardless if it is an

inverse relationship.

Figure 45: Setpoint Reset Source

Figure 44: Control Setpoints & Reset Limits

Disabled Mode Offsets

The Disabled Mode Offsets (Figure 46) can be used if you are

using an Enabling Relay, an Enabling Binary Input, or a Controlling Schedule. Anytime this output is not enabled by the Enabling

Relay or the Enabling Binary, or is in the Unoccupied Mode (per the

Schedule), these offsets will be applied to the Max/Min Setpoints

to initiate the control operation of this analog output. These would

then act as “Night Setback” type offsets. If these offset values are

‘0’, there will be no Disabled Mode operation.

Figure 46: Disabled Mode Offsets

28

Lead/Lag Controller Technical Guide

Page 29

Section 7: Confi guring Analog Outputs

Outdoor Air Enable, Controlling Schedule, Enabling Relay

Outdoor Air Enable

If this option is used, the Outdoor Air Temperature must be between

these setpoints for this Analog Output to function. See Figure 47.

Figure 47: Outdoor Air Enable Setpoints

Controlling Schedule

No matter what Control Method or Control Source has been selected,

each analog output can be confi gured to follow a schedule. See

Figure 48. Actual Schedules are set in the Schedules Window. See

instructions on page 33 for setting Schedules.

Enabling Binary Input

An Enabling Binary Input can also be selected (Figure 50). The

operation of this Analog Output will only occur once the selected

Binary Input is Active.

For example, if the Binary Input selected is confi gured as “N/O Con-

tact (Closes for Active),” then this Analog Output is enabled when

24 VAC is applied and the N/O Binary Input contact closes (Active).

If the Binary Input selected is confi gured as “N/C (Opens for Ac-

tive),” then this Analog Output will be enabled when 24 VAC is

removed and the N/C Binary Input contact opens (Active).

Figure 50: Enabling Relay Binary Input

Figure 48: Controlling Schedule

Enabling Relay

An Enabling Relay can also be selected. The operation of this Analog

Output will only occur once the Enabling Relay (based on its logic)

has energized. See Figure 49.

Figure 49: Enabling Relay

Output Voltage Limits

This output normally operates with a range of 0-10 VDC. If you need

it to operate with a different Min and/or Max voltage, those voltages

can be entered in the Output Voltage Limits Box (Figure 51).

Figure 51: Output Voltage Limits

Lead/Lag Controller Technical Guide

29

Page 30

Section 7: Confi guring Analog Outputs

Alternate Override and Override

Alternate Override

An Alternate Override Source can be selected to override the output

signal of this Analog Output to a fi xed value when a certain condi-

tion occurs (Figure 52).

Figure 52: Alternate Override

First select which Override Source to use:

Override & Cancel Override

You can manually override the logic of an Analog Output and force

it to a specifi c voltage. The Override Voltage fi eld defaults to “-1.0”

which means no override.

Right-click in the data entry fi eld in the Analog Outputs Window

(Figure 37, page 25) to open the Override Voltage Box shown in

Figure 55 and enter an override value. Click the <Enter> button to

save the value. If you enter an incorrect value, click the <Clear> button to start over. If there is any value in the fi eld, including “0” when

you click <Enter>, the voltage from this output will be forced to that

value. Canceling the Override will cause the voltage to go back to its

original reading, and the Override Voltage fi eld will display “-1.0”.

●

Analog Inputs # 1 – 8

● Outdoor Air

Next select the logic, setpoint, and deadband that will determine

the Override (Figure 53). Right or left-click in the Logic Field to

select < , >, or =.

Figure 53: Logic, Setpoint, and Deadband

Finally, select the voltage you want to hold this output to based on

the above logic (Figure 54).

Figure 54: Voltage

Figure 55: Calibrate and Override Sensor

30

Lead/Lag Controller Technical Guide

Page 31

Section 8: Outdoor Status & Lead/Lag Enable

Outdoor Status and Lead/Lag Enables Windows

Outdoor Status

The Outdoor Status W indow is located in the center of the Lead/Lag

Controller Status Screens (Figure 8-9, pages 11-12) and displays

the Outdoor Air (OA) Temperature. See Figur e 56. In order for the

Outdoor Air Temperature to display, you must have another controller

set up to broadcast the Outdoor Air Temperature.

Figure 56: Outdoor Status Window

Lead/Lag Enables for Lead/Lag

The Lead/Lag Enables W indow is located in the center of the Lead/

Lag Controller Status Screen (Figure 8, page 11). See Figure 57.

Each Group corresponds to a schedule. So Group #1 corresponds

to Schedule #1, Group #2 corresponds to Schedule #2, and so on.

The lightbulb lights up when the Schedule is activated in the Relay

Confi guration Window (Figure 34, page 23).

Lead/Lag Enables for 2 Lead/1 Lag

The Lead Lag Enables W indow is located in the center of the 2 Lead/1

Lag Controller Status Screen (Figure 9, page 12). See Figure 58.

Group #1 corresponds to Schedule #1. The lightbulb lights up when

Schedule #1 is activated in the Relay Confi guration Window (Figure

34, page 23).

Figure 58: 2 Lead/1 Lag Enables Window

Figure 57: Lead/Lag Enables Window

Lead/Lag Controller Technical Guide

31

Page 32

Section 9: Setting Schedules

Schedules Window Components and Navigation

Schedule Status Window

The Schedule Status W indow is located in the bottom left of the Lead/

Lag Controller Status Scr eens (Figures 8 & 9, pages 11 & 12) and

allows (4) Schedules with (4) associated Holiday Schedules and

Overrides (Force Mode). See Figure 59 for the Schedule Status W in-

dow components and summary and the pages that follow for details.

Click on the Holiday button to program the Holidays

for each schedule.

Click on the Schedules button (ON/OFF button) to

program each schedule.

Click on this button to Override the Schedule.

Figure 59: Schedule Status Window

32

Lead/Lag Controller Technical Guide

Page 33

Section 9: Setting Schedules

Setting Schedules

Left click the <Sc hedules> button (ON/OFF button) in the Schedules

Status Window (Figur e 59, page 32) to open the Schedule Confi gu-

ration Window (Figure 60). You can confi gure up to (4) separate

schedules for various uses on the Lead/Lag Controller, but can

only confi gure (1) schedule on the 2 Lead/1 Lag Controller. These

Schedules are (7) day, (2) event per day Schedules.

Schedules Window

Figure 60: Schedule #1 Confi guration #1 Window

The Schedule Confi guration Window in the example shows a 7:30

AM to 5:30 PM operating schedule for Monday through Friday. You

can also use 24 hour military format if you wish. The bars on the right

side of the screen give a visual indication of the selected time periods.

When you enter a time in any fi eld, you must designate AM or PM

press <ENTER> to save.

and

NOTE: Yo u M UST press <ENTER> to have the system accept

your entr y. If you do not press

will either not display or will not change.

The holiday start and stop times will override the standard operating hours. The holidays themselves are scheduled in the

<ENTER> , the bar graph to the right

Holiday

Schedule Window described on page 35.

To eliminate a schedule from any event, simply type a zero and press

<ENTER> for the Start and Stop time for that day. The screen will

display 12:00 AM for both the Start and Stop times, indicating that

the equipment will not activate for that day.

If you want the controller to run the full 24 hours, type 11:59 AM

for the Start time and type 11:59 PM and

Stop time. This ensures the full 24-hour period will remain in the

occupied mode without interruption.

press <ENTER> for the

Select <Save> to save your schedule. Select <R estore> to restore

a previously saved schedule.

schedule to all like controllers,

to all schedules in this window for continuous operation, and select

<Erase Schedules> to completely erase the schedule appearing

in the window. See page 34 for an explanation of each of these

functions.

WARNING: < Erase Schedules> will clear ALL entered

Select <Copy to All> to copy the

select < Set 24 Hour Operation>

stop/start times, so use with caution.

Lead/Lag Controller Technical Guide

33

Page 34

Section 9: Setting Schedules

Saving, Restoring, Copying Schedules

Saving Schedules

To save the weekly time schedule, click <Sa v e>. The File Save W in-

dow will appear (Figure 61). Give the fi le a name in the “Selected

File” fi eld and click <Save> or press <ENTER> to save.

Figure 62: Copy Setpoints Window

Set 24 Hour Operation

NOTE: Make sure to save any schedules you desire before

selecting this option.

Figure 61: File Save Window

A message will pop up if the schedule is saved successfully. Click

<OK> to make it disappear.

Restoring Schedules

Click <Restore> to restore any previously saved schedule from a

previously saved fi le. Once you have located the fi le, click <Open>.

A message will pop up if the schedule is restored successfully.

<OK> to make it disappear.

If you try to load a schedule from one type of controller to a different

type of controller, Prism 2 will display an error message and prevent

you from making this mistake.

Click

Copying Schedules

Click <Copy To All> to copy a schedule to other controllers. The

Copy Setpoints Window will appear (Figure 62).

Select a range to copy to in the Range Box or type unit number(s)

in the

Selected Units Box and then click <Send> to start the copy

process. When the copying is complete, the message

will appear in the bottom status bar of the window.

close the window.

Copy Completed

Click <Exit> to

To set all schedules for continuous operation, click

Operation>. The Schedules Window will display constant operation

for weekends and weekdays (Figure 63). In order to return to the

normal schedule, you will need to restore the schedule.

<Set 24 Hour

Figure 63: Set 24 Hour Schedule Operation

Erase Schedules

WARNING: <Erase Schedules> will clear ALL entered

stop/start times, so use with caution.

To erase all schedules, click <Erase Schedules>. The schedules

will be completely cleared. In order to return to a schedule, you will

need to restore the schedule.

34

Lead/Lag Controller Technical Guide

Page 35

Section 9: Setting Schedules

Setting Holidays and Schedule Override

Setting Holidays

If your job-site has days during the year when you need

to override the standard operating hours to accommodate holidays or other special events, you can use this

window to select the holidays.

To access the controller’s Holiday scheduling,

button in the Schedules Status Window (Figure 59, page 32). The

Holiday Schedule Window will appear. See Figure 64.

click the <Holidays>

Every defi ned holiday uses the same Holiday operating schedule

programmed in the

As in the case with Week Schedules, you can select the <Erase>

button to clear all selected holidays at one time. Refer to Week

Schedules for directions on <Save>, <Restore>, and <Copy to All>.

Holidays can only be pr ogra mmed for the curr ent year. You c annot program

holidays before the next year occurs. Holidays do not automatically

adjust for the new year, so you will need to access this screen after

the new year and make necessary adjustments to the days that fl oat,

such as Memorial Day.

Schedules Window.

Schedule Override

To override a schedule, click on the <Force Mode> button next to

the Schedule you wish to override from the Schedules Status Window

(Figure 59, page 32). See Figure 65.

Figure 64: Holiday Schedule Window

Click on the date to highlight it and tag it as a holiday.

Days selected as holidays are indicated with a green background

and white text.

There are 14 holiday periods available for each year. These holiday

periods can be a single day or they can span multiple days, weeks,

or even months. The key to extended holiday periods is to make sure

you select every single day, including weekends, between the start

of the holiday and the end of the holiday.

For example, if you want to schedule a summer break, you need only

schedule one holiday period to defi ne a two or three month break

from operating in the occupied mode. Of course, the equipment will

still operate with its unoccupied settings.

Figure 65: Override Schedule

AUTO - Click AUTO to have the schedule run under its

●

normal schedule.

ON - Click ON to override the schedule and have the

●

schedule be continuously occupied.

●

OFF - Click OFF to override the schedule and have the

schedule be continuously unoccupied.

Lead/Lag Controller Technical Guide

35

Page 36

Section 10: Confi guring Alarms

Confi guring Alarms

Alarm Notifi cation

The controller can generate alarms for remote alarm notifi cation if

alarms have been enabled and if Prism 2 is connected and running

24 hours a day. If an alarm condition occurs, the <ALARM> button in

the upper right hand corner of the Lead/Lag Controller Status Scr een

will light up. See Figure 66. If no alarm(s) exists, the button will be

gray and display the words, No Alarms. See

Figure 66: ALARM Button

Figure 67: No Alarms Button

Individual alarms will also be indicated with a bright red alarm bell

icon in the Relays Status Window. See Figure 68.

Figure 67.

Confi guring and Enabling Alarms

Alarms are enabled in the Lead/Lag Alarms Window. To confi g-

ure alarms, click on the <ALARM> or <No Alarms> button in the

upper right hand corner of the Lead/Lag Controller Status Screens

(Figures 8 & 9 , pages 11 & 12). The Lead/Lag Alarms Window

will open. See Figure 69.

Due to the quantity of Inputs and Outputs on the Lead/Lag controller,

alarms have been grouped into 4 Groups. Each group corresponds

to a Schedule. So Group #1 is linked to Schedule #1, Group #2 to

Schedule #2, and so on.

Alarm

Indicator

Figure 68: Relay Status Alarm Icon

Figure 69: Lead/Lag Alarms Window

Click the Enabled box beside any Alarm you wish to enable. When

that alarm condition occurs, the <ALARM> button in the upper right

corner of the Main Prism 2 Screen will turn bright red (Figure 6,

page 10 & Figures 8 & 9, pages 11-12). This selection will also

allow that Alarm to send out an e-mail notifi cation if your system

is set up for that function. See the Prism 2 Technical Guide for

instructions on setting up e-mail alarm notifi cations.

If the proof source doesn’t meet the requirements in the programmed

amount of time, the system switches to the standby output and generates the proof alarm and either the Lead or Standby alarm, depending

on which relay caused the condition.

If only one Group generates an alarm, normal operation can be

restored by clicking the

<Reset Lead/Lag> button will restart the system using the relay

with the least amount of accumulated run time. Both do not have

to be in an alarm state for you to reset the lead/lag operation. If the

system has switched to the standby output, it can be restored to the

lead output if you want to test it again or repairs have been made

and you just want to restore normal operations.

If more than one Group generates an alarm, they will not attempt to

activate again until the

This is to protect the equipment from possible severe damage if an

output is attempting to operate damaged equipment.

< Reset Lead/Lag> button. Clicking the

<Reset Lead/Lag> button has been clicked.

36

Lead/Lag Controller Technical Guide

Page 37

Section 11: Saving and Restoring Setpoints

Reset Factory Defaults & Save to File

Reset Factory Defaults

WARNING: <Reset Defaults> resets ALL settings and

confi gurations back to the original defaults. Use this option

with extreme caution!

From the top toolbar of the Lead/Lag Controller Status Screens

(Figure 8 & 9, pages 11 & 12), click on <Setpoints>, and then

click on <Reset Defaults>. See Figure 70.

Figure 70: Setpoints Menu

The following warning will appear (Figure 71). Click

do not want to reset the defaults. Click <Yes> if you want to reset

to the defaults.

<No> if you

Saving Lead/Lag Setpoints

You can save all setpoints to a fi le on your computer for use in restor-

ing or for copying to another specifi c controller.

From the top toolbar of the Lead/Lag Controller Status Scr een, click

<Setpoints> and then click <Save To File>. See Figure 72.

Figure 72: Setpoints Menu - Save To File

In the File Save Window (Figure 73), give the setpoint fi le a name

and then click <Save>.

Figure 71: Reset Defaults Warning

Lead/Lag Controller Technical Guide

Figure 73: File Save Window

37

Page 38

Section 11: Saving and Restoring Setpoints

Restore From File

Restoring / Copying Lead/Lag

Setpoints

Once you save the Lead/Lag setpoints to a fi le on your computer,

you can restore or copy the setpoints to another controller.

From the top toolbar of the Lead/Lag Controller Status Scr een, click

<Setpoints> and then click <Restore From File>. See Figure 74.

Figure 74: Setpoints Menu - Restore From File

In the File Open Window (Figure 75), click on the desired fi le from

the list of folders and click

Figure 75: File Open Window

<Open>.

38

Lead/Lag Controller Technical Guide

Page 39

Section 12: Printing Status Reports