Page 1

35

INSTRUCTION MANUAL

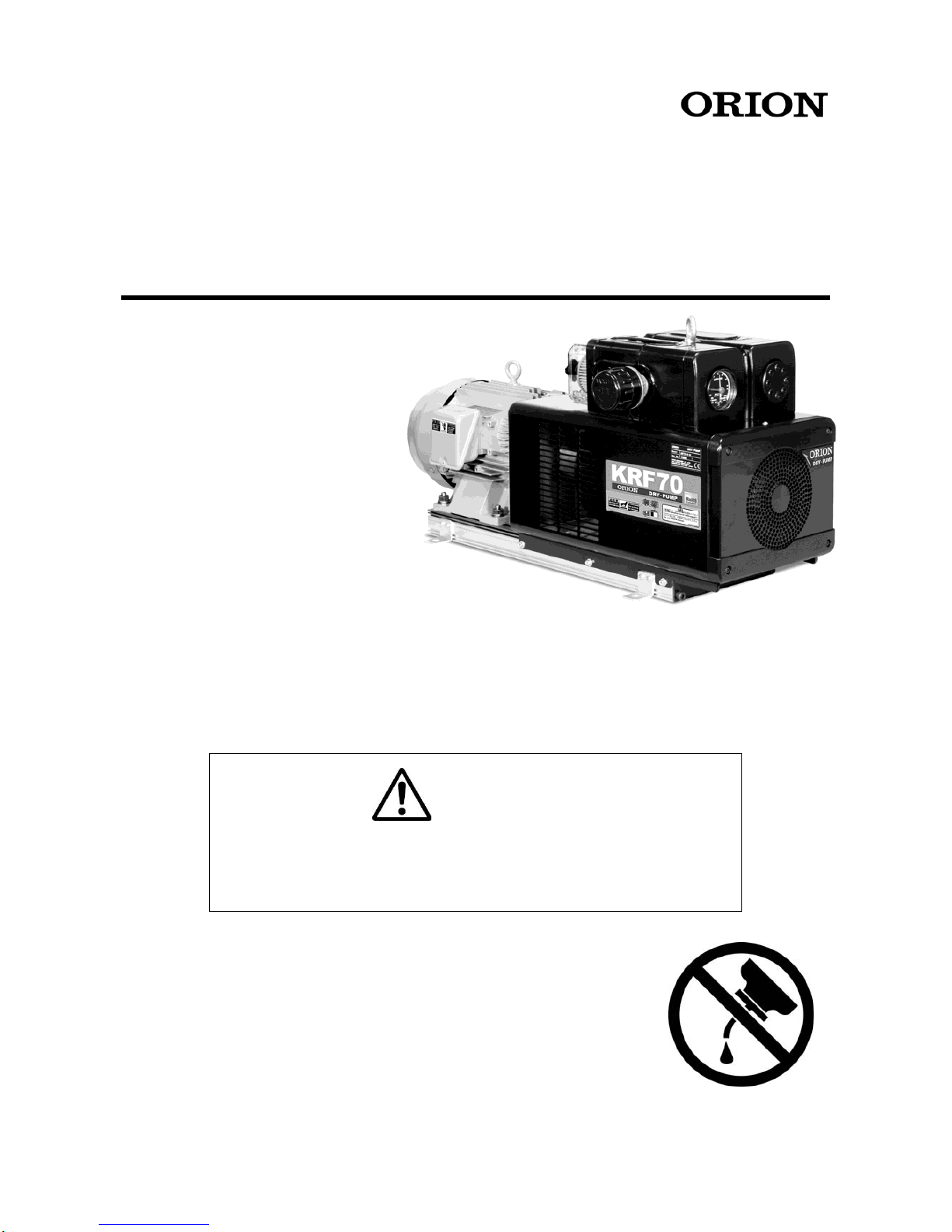

OILLESS ROTARY VACUUM PUMP & BLOWER

ORION DRY PUMP

CAUTION

●This product is intended only for industrial use. Use with caution.

●Read this Instruction Manual and follow the instructions described herein.

●Please keep this Instruction Manual for future reference.

No lubrication!

KRF70

KRF110

KRF70

Page 2

Thank you very much for your purchase of the Orion pump. Read this instruction manual in advance to

use this pump safely and to ensure continuing good performance. The product mechanism and

specifications are subject to change without notice. If mechanism or specifications are changed,

contents of this manual may not match the actual product.

Safety Information

Read "Precautions for Safety" before operation to ensure safe operation. Safety instructions in this

manual are intended to ensure safe and correct pump operation and to prevent damage or personal

injury. Safety instructions in this manual are classified into

Danger, Warning, and

Caution.

Danger

Indicates an imminently hazardous situation that, if the product is

misused, may bring about death or serious injury to the operator.

Warning

Indicates a potentially hazardous situation that, if the product is

misused, may bring about death or serious injury to the operator.

Caution

Indicates a critical situation that, if the product is misused, may bring

about injury to the operator or damage to the product.

Additionally, the situation that is explained in Caution column may cause serious accident. All

safety information must be followed for safe operation.

・

After reading this manual, keep it where an operator can refer to it anytime.

・

When transferring or renting this product, attach this manual to the product where a new owner can

easily refer to it for proper operation.

■Symbols

The symbol represents warning or caution. What is sho wn inside or des cribed near i nforms

of an actual hazard. The example on the left means caution for electric sh ock.

The symbol represents prohibition. What is shown inside or described near informs of an

actual action which is prohibited. The example on the left means prohibition of disassembly.

The symbol represents essential action or instruction. What is shown inside or described

near informs of an actual instruction about ope rati on. The ex am ple on the lef t m eans d iscon nect

the power plug from the outlet.

The symbol represents important information other than warning or caution.

Although model KRF70 is used as description pictures and figures in the manual, the oth er models in the

KRF-series are operated the same way as KRF70 if there is no note.

Be sure to read through the

safety information.

Page 3

1

Contents

Precautions for Safety ···················································· 2

Precautions for Proper Operation ····································· 6

Names of Components ··················································· 7

Preparation and Confirmation ·········································· 9

Operation Procedure ··················································· 13

Maintenance and Inspection ·········································· 16

Troubleshooting ·························································· 18

Consumable Parts ······················································· 20

Storage(Not in Use for a Long Time) ··························· 23

Disposal ···································································· 23

Specifications ····························································· 24

Dimensional Outline Drawing ········································· 26

Page 4

2

Precautions For Safety

Precautions for Use (Danger / Warning)

Danger

Indicates an imminently hazardous situation that, if the product is misused, may bring about death or

serious injury to the operator.

Keep flammable or explosive gas out.

Keep the pump from inhaling flammable or explosive gases. Do not use the unit in

the place where flammable or explosive gas exists. It may cause explosion or

fire.

Warning

Indicates a potentially hazardous situation that, if the product is misused, may bring about death or

serious injury to the operator.

Do not block the exhaust piping. (B type and V・B type)

Do not operate the pump while the pressure controller is totally closed or the exhaust

piping is blocked. Blocking the exhaust air may increase the pressure and

temperature in exhaust piping, and result in injury and malfunction due to burst

of the piping and pump parts.

Do not wash filter element with organic solvents.

When cleaning the filter element, do not use organic solvents such as thinner,

alcohol, benzine, gasoline, and kerosene. It may result in explosion or fire.

Do not remove the cover during operation.

Do not operate this product while the main cover is removed. Otherwise, your

hand(s) may be cut off or be seriously hurt because the cooling fan and the coupling

rotate at high speeds.

Prevent the power cord from any damage.

Do not damage, bend, pull, or bind the power cord. Do not place heavy object on it

or let it get caught or pinched. It may damage the cord, and may cause electric

shock or fire.

Keep this product away from water.

Do not pour water over the pump and the motor, and do not use water for cleaning

this product. Also, do not use this product where it may touch water or other liquid.

It may cause electric shock or fire.

Be alert to electric shock.

Do not touch electrical parts such as power plug with wet hands. Also, do not

operate switch with wet hands.

It may cause electric shock.

Never fail to put the terminal box cover on.

In the case of a motor with the terminal box, do not operate it with the terminal box

cover removed. It may cause electric shock.

Do not modify the product.

Do not modify the product.

It may cause abnormal operation and may result in injury, electric shock or

fire.

Be sure to ground this product.

Be sure to ground the product with the screw for grounding inside the terminal box or

at the lower part of the frame of the motor.

Failure to do so may cause electric shock.

Page 5

3

Precautions For Safety

Precautions for Use (Warning / Caution)

Warning

Indicates a potentially hazardous situation that, if the product is misused, may bring about death or

serious injury to the operator.

Installation must be done by specialized personnel.

The product may fall down or drop if it is improperly installed. It may result in

personal injury, electric shock or fire.

Do not operate this product under abnormal conditions.

Stop the operation when it is abnormal. Then, pull out the power plug or shut off the

main power supply, and consult with our dealer or a specialized company. If the

operation is continued under such conditions, it may cause electric shock or fire.

Shut off the main power supply before cleaning, maintenance and

inspection.

Shut off the main power supply before cleaning, maintenance, and inspection, and

clearly post a sign on the power supply switch to indicate it is under cleaning,

maintenance, and inspection. Failure to do so may result in electric shock or

personal injury.

※Consult with a specialized company for maintenance and inspection.

Inspect the power plug periodically.

If the product is operated with the power plug, periodically inspect the power plug

and confirm it is not covered with dust. The power plug must be fully inserted to the

root of pins. If the power plug is covered with dust or not fully inserted, it may cause

electric shock or fire.

Be sure to install the protective device.

Consult with a specialized company to install an earth leakage breaker. Failure to

do so may cause electric shock or fire. Also, install an overload protection

device (thermal relay). Operation without such a device may cause

malfunction due to overload or fire.

Contact with a specialized company when the earth leakage breaker is

activated.

When the earth leakage breaker is activated, contact with a specialized company. If

you force to turn on the power supply, it may cause electric shock or fire.

Do not use this product outdoors.

This product is intended for indoor use. If the product is used outside and is

exposed to wind or rain, the motor may suffer from incomplete insulation and may

cause electric shock or fire.

Caution

Indicates a critical situation that, if the product is misused, may bring about injury to the operator or

damage to the product.

Do not use the machine over the specified pressure.

If using the machine over the specified pressure, it may shorten the life of product

and may cause failure, abnormal generation of heat or trouble.

Prohibition of operation with the vacuum pipe closed (V type and V・B type)

Do not operate the pump with the vacuum controller closed completely to close the

vacuum pipe. Negligence may cause an abnormal pump temperature rise resulting

in a product failure, protective cover deformation or burn injury.

Do not sit on, lean on, or place objects on this product.

Do not place heavy objects or object containing water on the product, and do not get

on it. If you get on the product, you may fall and be injured. If water spills, it may

cause rust inside or poor insulation and may cause leakage or electric shock.

Page 6

4

Precautions For Safety

Precautions for Use (Caution)

Caution

Indicates a critical situation that, if the product is misused, may bring about injury to the operator or

damage to the product.

Do not operate this product with any voltage other than the rated one

specified for the motor.

Operation with any voltage other than the rated voltage specified for the motor

may

result in failure or accident.

Prevention of melting of distribution cable covering due to contact.

Install the motor so that wiring cables do not touch the motor frame.

Contacting

with cables may result in melting covering or ignition.

Be alert to burn.

Do not touch areas around the dry pump, and the exhaust port and the piping

surface of exhaust side. They are heated to high temperature, and it may result

in burn.

Inspect the earth leakage breaker periodically.

Periodically check performance of the earth leakage breaker. If using the product

with failure of the earth leakage breaker, it may cause electric shock in case of

short circuit.

Installation of check valve

Residual pressure may reverse the rotation when the pump is stopped. Be sure to

install the check valve horizontally within 50cm from the inlet port (or the exhaust

port) of pump. No installation of check valve may cause malfunction.

Turn off the main power supply in case of not using the pump for a long

time.

When you do not use the product for a long time, shut off the main power supply.

Otherwise, it may cause electric shock or short circuit ignition due to

degenerated insulation.

Be sure to wear personal protective equipment for cleaning and

maintenance.

When you carry out cleaning or maintenance, be sure to wear gloves. Failure to

do so may result in injury or burn.

When you transfer the product, be sure to wear nonslip gloves and safety shoes.

Failure to do so may result in injury.

Continuous operation is recommended.

If the start and stop frequency is high, start and stop cycle in 5 minutes or less, it

may cause significant lifetime deterioration or malfunction of the product.

Product Use Limitations

(1) If the unit is to be used as part of critical installations, safety devices and backup

systems which can be switched to should be put into place to insure that serious

accidents or losses do not occur in the event that the unit should break down or

malfunction.

(2) This product was designed and produced as a general purpose device for use in

ordinary manufacturing. Accordingly, this warranty does not apply to nor cover

the following applications. However, in cases where the customer/user takes full

responsibility and confirms the performance of the equipment in advance, and

takes necessary safety precautions, please consult with ORION and we will

consider if use of the unit in the desired application is appropriate.

①Atomic energy, aviation, aerospace, railway works, shipping, vehicles (cars and

trucks), medical applications, transportation applications, and/or any

applications where it might have a great effect on human life or property.

②Electricity, gas, or water supply systems, etc. where high levels of reliability and

safety are demanded.

Page 7

5

Precautions For Safety

Precautions for Use (Caution)

Pull out the power plug to disconnect it.

When the product is used with power plug, pull the power plug to disconnect it.

Pulling the power cord may result in disconnection of part of the core wire, and may

cause generation of heat or deterioration.

Precautions For Safety

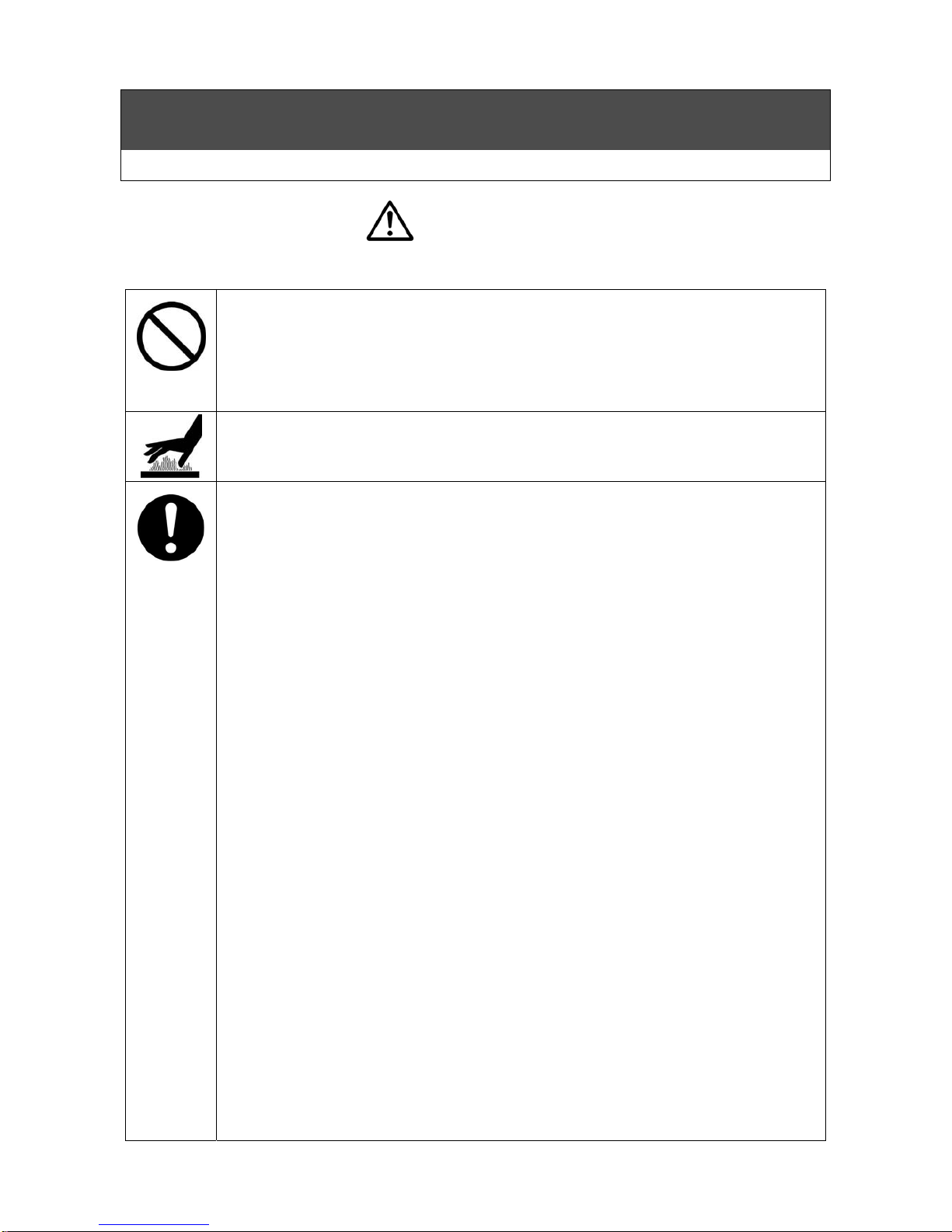

Warning Label Position on the Product

Warning Label Position on the Product

The following warning labels are selected as most important ones out of Safety Information and are

placed on the product. Read the labels before operating the product. When the labels become

unreadable due to scratch or dirt, contact with your dealer to get new ones for replacement.

■Burn

■Electric shock

Page 8

6

Precautions for Proper Operation

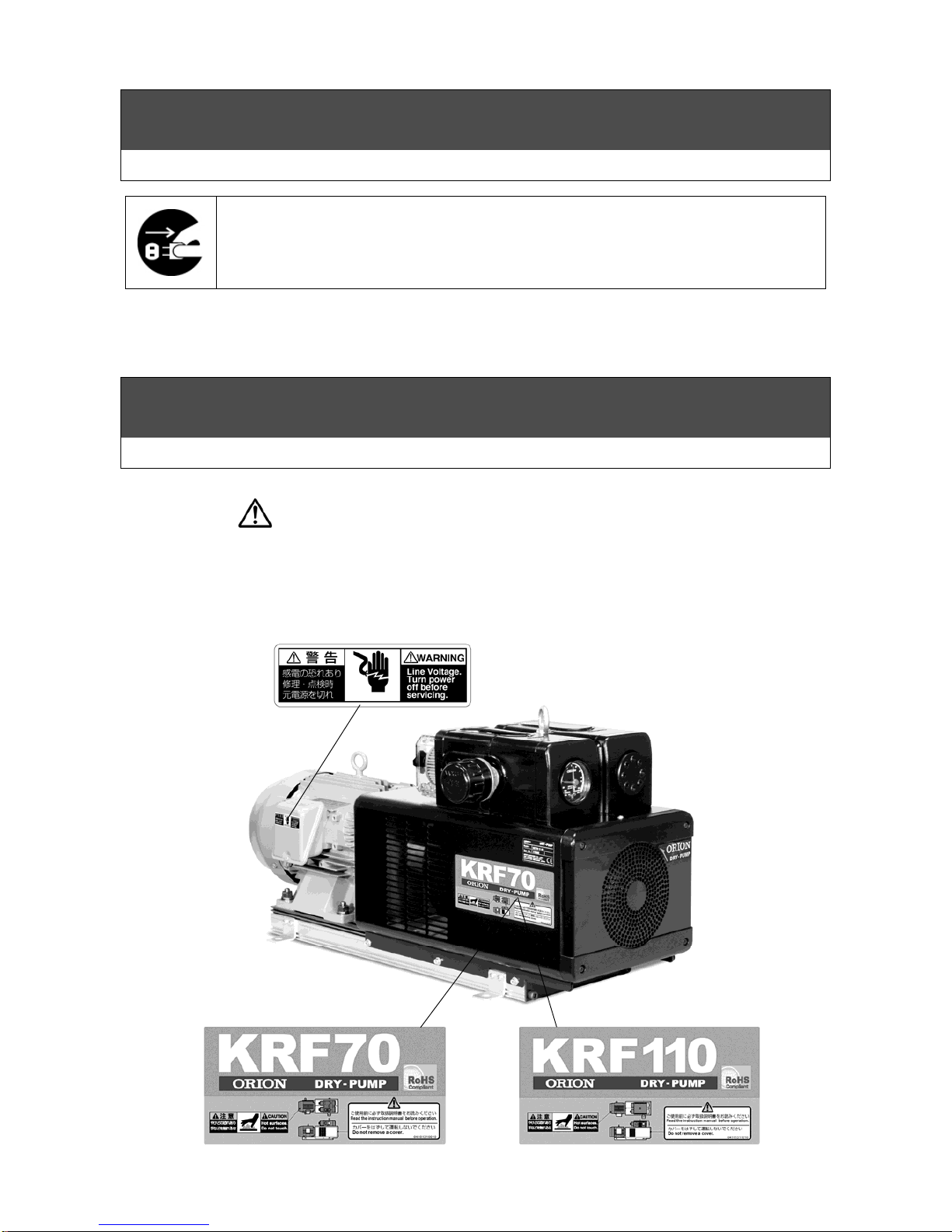

■For inlet air, aim at normal temperature and normal

humidity clean air with little dust but free from

corrosive and explosive gases.

※Normal temperature: 0 to 40 deg. C

※Normal humidity: 65% +/- 20% (JIS Z 8703)

■Prohibition of operation in reverse rotation.

■Set the ambient temperature of the dry pump to the

range of 0 to 40 degrees C.

Try not to cause condensation inside the pump.

■Keep the pump away from oil, water, dust, rain, etc. Also, never lubricate the product.

■Be sure to use under specified pressure or less.

■Do not remove the main cover , and top and bottom partition plates. Removing these cover and plates

may result in shortening the life of product severely due to the temperature rise.

■Install the product on a flat surface..

■Periodically replace consumable parts (see pages 20) and replacement parts (see page 21).

■Be sure to Install the product on the level while whole base is touching on the level surface like in

figure A.

※do not Install the product like in figure B.

Fig.A

Fig.B

Cushion rubber etc

Page 9

7

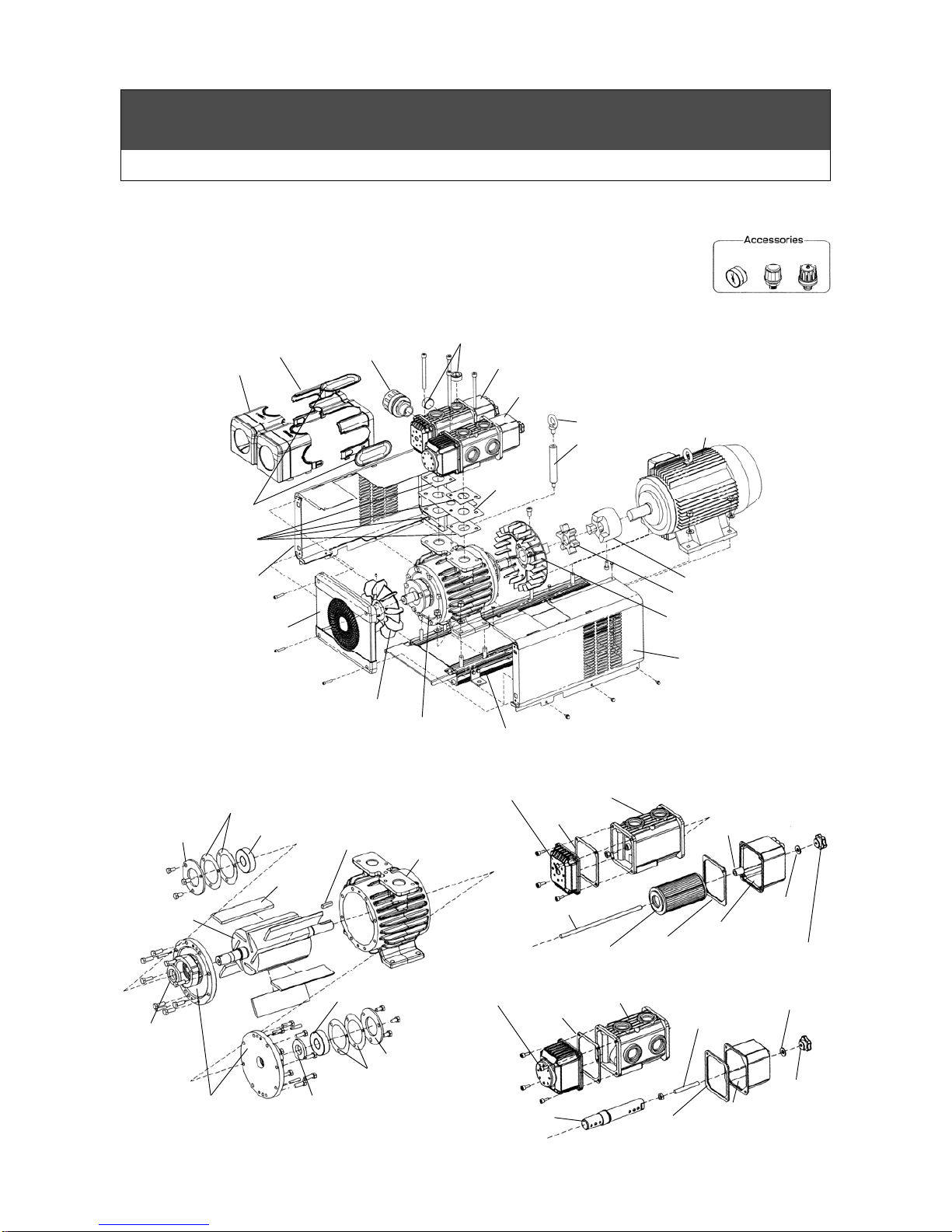

Name of Components

KRF70

※●mark indicates consumable parts that is replaced depending on wear condition when checking.

(Refer to page 20.)

※△mark indicates replacement parts that is replaced

periodically at the specified period.

(Refer to page 21.)

Parallel key

△Bearing

Side Plate(B)

△Blade

Spacer

Roto

r

Spacer

△Bearing

●Liner

Beari

Bearing

Retainer

●Liner

Cylinder

Cap

●Filte

r

Element

●Gasket

Suction case

●Rubber

packing

●Spring tube

Filter Case

●Packing

Knob nut

Long cap 70

●Gasket

Delivery case

Squeezing tube

Muffler

case

Stay bolt

●Rubber

packing

●Packing

Knob nut

Stay bolt

Dry pump deal drawing

Exploded view of filter body

Pump deal drawing

Motor

Main cover 70

No.1

Gauge cover 70

Fan

Base

Attachment

Eyebolt

VC81

●Gasket (B)

Supplementary

bolt

SD case cover

Partition

plate top

VFF-70

Hexagon socket head plug

MFF70

Fan cover 70

Pump

Fan coupling

●Spider

Processing chart of coupling

Main cover 70

No.2

①

②

③

① Compound gauge

●② Vacuum controller VC81

③ Pressure controller PCA8

Page 10

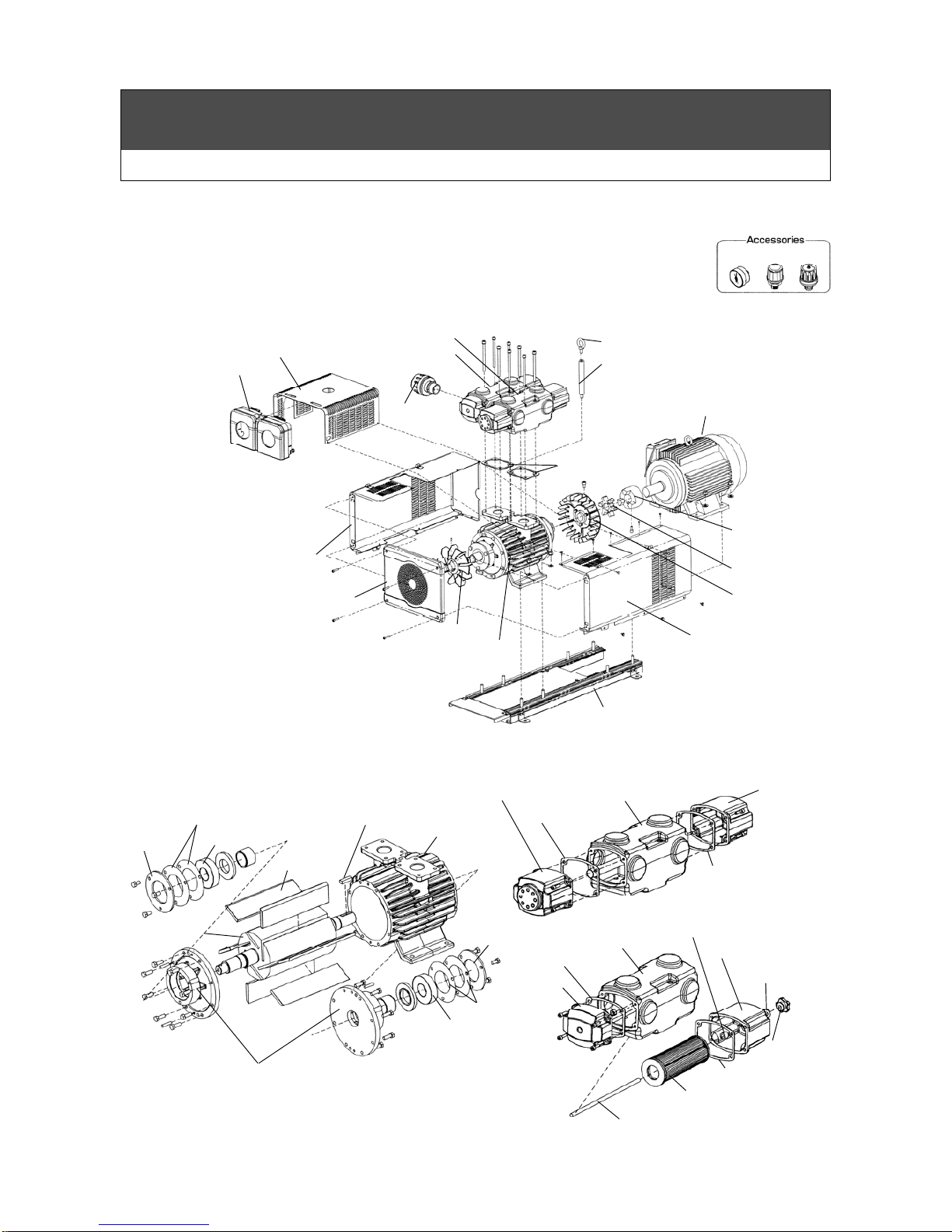

8

Name of Components

KRF110

※●mark indicates consumable parts that is replaced depending on wear condition when checking.

(Refer to page 20.)

※△mark indicates replacement parts that is replaced

periodically at the specified period.

(Refer to page 21.)

Dry pump deal drawing

Exploded view of filter body

Pump deal drawing

Parallel key

△Bearing

Side Plate(B)

△Blade

Roto

r

△Bearing

●Liner

Bearing

Retainer

●Liner

Cylinder

Bearing

Retainer

●Filter

Element F

●Gasket (B)

Suction case

●Spring tube

Filter Case (B)

●Packing

Cap

Delivery case

Muffler

case

Stay bolt

●Rubbe

r

packing

Knob nut

Long cap 100

●Gasket (B)

●Gasket (B)

Motor

Main cover 110

No.1

Gauge cover 110

Fan

Base

Eyebolt

VC100B

●Gasket (A)

Supplementary

bolt

SD case cover

VFF110

MFF110

Fan cover 110

Pump

Fan coupling

●Spider

Processing chart

of coupling

Main cover 110

No.2

①

②

③

① Compound gauge

●② Vacuum controller VC100B

③ Pressure controller PCA10

Page 11

9

Name

plate

Preparation and Confirmation

Before Installation/ Installation

Danger

●Do not use the product where flammable gas or explosive gas may exist.

Warning

●Set up the product where it is protected from water, oil and dust.

●Please use the product indoors.

●Do not set up the product where corrosive gas (chlorine or sulfur dioxide gas) exists.

●Do not set up the product under direct sunlight.

●Use the product where the ambient temperature ranges 0 to 40 degrees in Celsius.

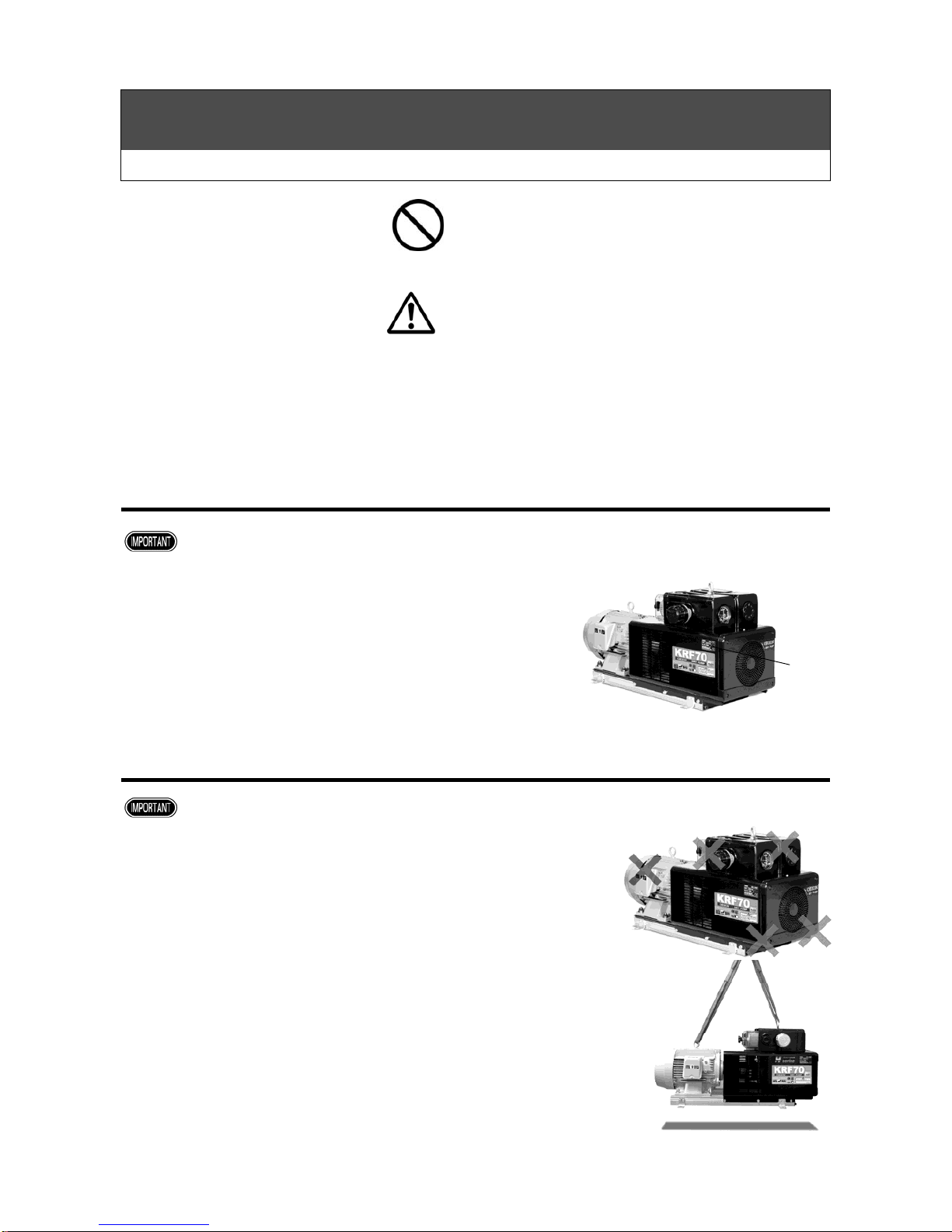

●When you transport the product, lift up with slings.

Before Installation

●The product is heavy. Be careful enough when moving the product.

●Upon receiving the product, check it carefully for signs of

shipping-related damage like scratches, deformation, etc. If

you notice a problem, contact with your dealer.

●Be sure to check the name plate whether purchased product

is

right model as you ordered.

●When the product is delivered with accessories, be sure to

check the accessories whether there are all the parts or not.

Installation

●

When the product is 25kg or over,

hold the product with two

persons.

Also,

do not hold the terminal box of motor, filter

case, and controller

when holding with two persons.

Holding the

terminal box and filter case of the motor may result in injury,

damage or malfunction if product or parts of it are dropped.

●

In case of using a hanging belt, be sure to belt as shown in the

photo.

Photo

Do not hang a sling fo

r

these parts.

Page 12

10

Preparation and Confirmation

Installation Site/ Gauge & Controller

Installation Site

Warning

●Installation should be carried out by your dealer or special service company. Improper installation

may result in vibration, electric shock, or fire.

●Set up the product in a wide space where you can easily maintain, inspect and overhaul the product.

●Ambient temperature of the pump is 40 deg. C or less. If there is any heat source near the pump, be

sure to check the ambient temperature does not exceed 40 deg. C.

●Using the product in the enclosed space may result in malfunction due to the generation of heat of the

pump. Ventilate adequately around the pump, and be careful not to exceed the permissible ambient

temperature.

●Be sure to install the product horizontally while the whole base plate is touching the level

surface.

Warning

Residual pressure may reverse rotation when the pump is stopped. Be sure to install the check valve

within 50cm from the inlet or outlet port of the pump. No installation of check valve may cause

malfunction.

Gauge & controller

KRF70

Be sure to install the gauge according to following procedure.

※For the controller installation position, refer to the outer dimension drawing provided on P26-28.

※Do not apply a sealing tape when installing the pressure gauge. (Do not overtighten.)

※Do not apply a sealing tape on the threads. After tightening the controller hand-tight, give an

additional quarter to half turn using a tool. Smooth surface due to application of a sealing tape

may result in excessively tightening the controller. This may damage or deform the thread part and

cause malfunction. (There is no need of securing high airtightness using a sealing tape or adhesive

agent because the pump is designed for low pressure/vacuum.)

※Compound gauge is a part that is weak against impacts. Do not hit or drop the product with

compound gauge.

●Installation of check valve

Remove the cover.

Install the gauge.

Push the check point, remove the claw and pull the case foward.

Claw

Press it back in place until

the cover claw is locked.

Page 13

11

Preparation and Confirmation

Gauge & Controller / Piping

KRF110

Be sure to install the gauge according to following procedure.

※For the controller installation position, refer to the outer dimension drawing provided on P29-31.

※Do not apply a sealing tape when installing the pressure gauge. (Do not overtighten.)

※Do not apply a sealing tape on the threads. After tightening the controller hand-tight, give an

additional quarter to half turn using a tool. Smooth surface due to application of a sealing tape

may result in excessively tightening the controller. This may damage or deform the thread part and

cause malfunction. (There is no need of securing high airtightness using a sealing tape or adhesive

agent because the pump is designed for low pressure/vacuum.)

※Compound gauge is a part that is weak against impacts. Do not hit or drop the product with

compound gauge.

Piping

1.Avoid direct connection with steel pipe.

・

Use hose for inlet and exhaust piping. In case of direct connection with steel pipe, resonance with

the piping system

may cause noise or vibration.

For exhaust piping, use heat resistant and

pressure resistant (100kPa or over) hose.

・

Completely remove dirt and dust inside the hose before piping.

2.When intake air contains a big amount of dust, or if dust grains are very fine (10μm or less), use

an appropriate filter in addition to the accessory filter.

3.Install the hose of the exhaust piping system properly in order to prevent condensed water

inside the system from entering the pump, and from discharging from the piping end.

If condensed water in the piping system enters the pump, the pump inside may be locked by rust or the

blades may not come out. To avoid this situation, take the following measures:

①

Install the valve or drain in the exhaust piping system

so that the condensation of water occurred inside the

system can drain out. Also, drain out the collected

condensation of water periodically. (See Figure 1.)

・

Provide valve or drain hose on the pump side in order

to prevent condensed water from entering into the pump.

・

In case of a long piping system, provide valve or drain

hose in the halfway of the system.

・

When condensed water discharges from the piping

end, install a valve or drain hose at the piping end.

②If the pump is not frequently used, idle the pump for 10 to 15 minutes after finishing

operation.

Remove the cover.

Install the gauge.

Push the check point, remove the claw and pull the case foward.

Claw

Press it back in place until

the cover claw is locked.

(Figure 1)

Piping end side Piping end side

Drain or valve

Page 14

12

Preparation and Confirmation

Piping / Electrical Wiring

4.If reverse rotation is caused by residual pressure upon stopping the

pump, blade damage is likely to be incurred. Please install a check

valve within 50 cm from the pump's inlet port (or exhaust port) to

prevent this from happening. In installing a check valve, install it

levelly to the floor. Negligence may cause pulsation or abnormal

noises. (Figure 2)

(Recommended check valve: manufacturer's product name: JIS

compliant KITZ bronze swing check valve)

5.Do not apply a sealing tape when connecting pipes. Pieces of torn

sealing tape may cause controller malfunction or abnormal operation sound.

6.Do

not overtighten pipes. Overtightening pipes may damage the SD case.

Electrical Wiring

Warning

●Contact with a specialized company to install an earth leakage breaker. Failure to do so may cause

electric shock or fire. Also, install an overload protection device (thermal relay). Failure to do

so may cause failure to the product due to overload or fire.

1.Install the earth leakage breaker.

Set the breaking capacity to 1.5 times the current value shown on the motor name plate as a rough

guiding value. Select a sensed current of 30mA.

※

Consult with a specialized company for electrical installation.

2.Be sure to install the grounding.

・Location of grounding screws:

The grounding is attached on the terminal box.

(You can find the mark "E" or mark "

" near the screw.)

・Select a copper wire, with a nominal cross section bigger than the cross section shown in the

example, as grounding wire.

Motor rated output (kW) Nominal cross section(mm

2

)

2.2 2

3.7 3.5

・When the grounding screw becomes loose due to vibration during operation, sparks will occur at the

grounding section. Wire the grounding cable so that the grounding screw does not loose due to

vibration during operation, and tighten the screw with locking.

3.Install the overload protection device (e.g. thermal relay). Make the V specification 100%, and

B and VB specifications 110% against the rated current value written on the motor name plate

for the set value.

4.Operate the pump with the rated power supply written on the motor name plate.

5. A special characteristic of the dry pump is that during initial operation, the rated current value

may be exceeded at the start, but will drop over time.(Note that depending on the specifications

and/or operating conditions, there are cases it may not drop to the rated current value or

below.) Consult with your dealer if the overload protector (thermal relay) activates during initial

operation or during normal operation.

6.Select a power cord referring to the current value shown on the pump name plate.

7.Be sure to keep the power supply cable with holding assembly in order not to get stressed to

the internal power supply connection terminal at the time of pulling the cable.

(Recommended holding assembly: Maker; UI Lapp GMBH/ Product name: Skintop/ Model: ST-M,

STR-M)

(Figure 2) Example of chec

k

valve installation

Check valve

Page 15

13

Preparation and Confirmation

Electrical Wiring

7.Motor name plate (V, B, or VB enters into the □.)

・Matsushita-made motor is mounted for three-phase specification. Mitsubishi-made motor is

mounted as standard for single-phase specification.

Operation Procedure

Check before Operation/ Operation

Check before Operation

■Install the earth leakage breaker.

※Consult with a specialized company for electrical installation.

■Install the overload protection device (e.g. thermal relay). Make the V specification 100%, and B and

VB specifications 110% against the rated current value written on the motor name plate for the set

value.

■Before using a machine that has not been used for a long period of time, be sure to check that the

power is off, and then rotate the rotor (fan, motor fan etc.) gently to confirm that it can be rotated

smoothly.

■Compound gauge is a part that is weak against impacts. Do not hit or drop a product with compound

gauge.

■When storage temperature and operation temperature are differing more than 10 degrees in Celsius,

leave the pump at the operation site for more than 2 hours in order to eliminate the temperature

difference before using.

If condensation water occurred, and the condensation water enters into the pump, it may result in rust,

lock, and vanes might block.

■KRF70-□-04, KRF70-□H-04

■KRF110-□-04

■KRF70-□-01, KRF70-□H-01 ■KRF110-□-01

Page 16

14

Operation Procedure

Operation

Operation

1.Turn the control screw in the direction of (-) .

2.Be sure to check by inching that the rotating direction is the

same as the one shown on the "rotating direction arrow"

when it is viewed from the motor fan side.

3. Turn on the power switch.

4. Use the controller to adjust

vacuum level and exhaust pressure.

Check: Be sure to check the rotating direction.

Adjustment of vacuum level and exhaust pressure

■Adjustment of vacuum level

(Vacuum controller)

1.Turn the locking nut clockwise to unlock the control screw.

2.Turn the control screw until the desired vacuum level is obtained on the gauge.

3.Turn the locking nut counterclockwise to lock th e control screw.

■Adjustment of exhaust pressure

(Pressure controller)

1.Turn the control screw until the desired exhaust pressure is obtained on the gauge.

「Rotating direction arrow」

Adjustment of vacuum level

- vacuum +

Adjustment of exhaust pressure

- pressure +

Control screw

Locking nut

Control screw

Vacuum controller

Pressure controller

Page 17

15

Operation Procedure

Pressure range during operation / How to Correct Vacuum Level (Gauge Pressure) /Stop

Pressure range during operation

kPa KRF70・110(Standard) KRF70(High-pressure)

■

Use as vacuum

pump

(V type)

Continuous

operative

vacuum

60 or lower 80 or lower

■

Use as blower

pump(B type)

Continuous

exhaust

pressure

60 or lower 70 or lower

■

Use as vacuum

pump and

blower pump

(V, B type)

Continuous

operative

pressure

Total of continuous operative

vacuum and continuous exhaust

pressure 60 or lower

Total of continuous operative

vacuum and continuous exhaust

pressure 80 or lower

※1 Recommended range: The pump operating under 1 atmospheric pressure can exert its optimal

performance (life, operation noise, etc.) at a vacuum/pressure within this range.

Use the pump within the recommended range unless the higher vacuum/pressure is required.

※Contact with Orion or Orion dealer for other usage.

How to Correct Vacuum Level (Gauge Pressure)

Correction formula: A = C +(101.3- B)

A : Vacuum level at 1 atmosphere kpa

B : Atmospheric pressure at vacuum level measuring position kpa

C: Reading on compound gauge kpa

Ex) When the reading on the compound gauge is 76kPa and the atmospheric pressure is 973hPa

(97.3kPa), the vacuum level at 1 atmosphere is calculated as follow:76 + (101.3 – 97.3) = 80kPa

To read the accurate vacuum level, use a mercury manometer or an equivalent meter based on

absolute pressure.

Atmospheric pressure conversion formula (hPa → kPa)

B(kPa)=B(hPa)÷10

Stop

Shut off the power switch.

Page 18

16

Spring T ube

Filter case/ Muffler case

Filter Element

Delivery element

Knob Nut Assy

Paking

Rubber Paking

Maintenance and Inspection

Cleaning of filter element

Warning

Turn off the main power supply before cleaning, maintenance and inspection.

Turn off the main power supply before cleaning, maintenance and inspection, and clearly post a sign on

the power supply switch to indicate it is under maintenance. Failure to do so may result in electric

shock or personal injury.

※Consult with a specialized company for maintenance and inspection.

Do not wash filter element with organic solvents.

When cleaning the filter element, do not use organic solvents such as thinner, alcohol, benzine,

gasoline, and kerosene. It may result in explosion or fire.

Caution

Be sure to wear protective wear.

When you carry out cleaning or maintenance, be sure to wear gloves. Failure to do so may result in

injury or burn.

When you transfer the product, be sure to wear nonslip gloves and safety shoes. Failure to do so may

result in injury.

1. Cleaning of Filter Element and Delivery element

When debris deposits on the filter element, remove

the filter case and muffler case, and then remove

the filter element and the delivery element to get rid

of the debris with an air blow. If a fouled filter

element cannot be cleaned with air blows, replace

it with a new one.

Inspection period Contents

Once a week Remove dust or dirt

Page 19

17

Maintenance and Inspection

Cleaning of Filter Element

2. Cleaning of Controller

(Vacuum controller, pressure controller)

If the sheet surface of the controller is very dirty, the

function may deteriorate. Disassemble the

controller periodically, and remove the dirt of each

part.

3. Inspection of Piping

Be sure to tighten the knob nut of filter case surely

and ckeck that there is no air leakage, clogging, or

loosening in the piping.

Inspection period Contents

Once a month

Disassembly

cleaning

Inspection period Contents

Once a month

Air leak, clogging,

looseness of

tightened parts

(Vacuum controller) (Pressure controlle r)

VC81(KRF70) VC100B(KRF110) PCA8(KRF70) PCA10(KRF110)

Sheet surface

Sheet surface

Sheet surface

Sheet surface

Page 20

18

Troubleshooting

Warning

Turn off the main power supply before cleaning, maintenance and inspection.

Turn off the main power supply before cleaning, maintenance and inspection, and clearly post a sign on

the power supply switch to indicate it is under maintenance. Failure to do so may result in electric

shock or personal injury.

※Consult with a specialized company for maintenance and inspection.

Caution

Be sure to wear protective wear.

When you carry out cleaning or maintenance, be sure to wear gloves. Failure to do so may result in

injury or burn.

When you transfer the product, be sure to wear non-slip gloves and safety shoes. Failure to do so

may result in injury.

Check abnormal factors.

Page 21

19

Troubleshooting

Condition Cause Corrective action

Vacuum level

does not

increase.

Filter element is clogged with dust, and air cannot

be taken in.

Remove the element and blow off

dust from the element with

compressed air.

If the element becomes dirty,

replace it with a new one.

Oil entered into the pump, and the vane cannot

come out.

Consult with our dealer or service

personnel.

Foreign object entered into the pump and the

vane cannot come out.

Due to rust inside of the pump by intaking water,

the vane cannot come out.

Due to condensation inside of the pump, the vane

cannot come out.

Damage to meter Replace the meter.

Tightening of filter case, piping, air tank are not

tightened well, and air leaks.

Consult with our dealer or service

personnel.

The coupling fixing bolt is loose.

Decreased pump rotating speed due to motor

malfunction.

Damaged vane.

Worn vane.

When an

abnormal

noise is heard

or when the

meter shows

pulsations.

An abnormal noise is occurred because the

pressure is out of allowable range.

Return the pressure to the

applicable pressure range.

Excessive exhaust pressure causes an abnormal

noise.

Adjust the exhaust resistance to

return the exhaust pressure to

normal.

The abnormal noise occurs due to misfitting of the

coupling.

Consult with our dealer or service

personnel.

The abnormal noise occurs due to burning of the

motor.

The abnormal noise occurs because mounting

bolts became loose.

Damage to meter. Replace the meter.

Filter element is clogged with dust, and air cannot

be taken in.

Remove the element and blow off

dust from the element with

compressed air.

If the element becomes dirty,

replace it with a new one.

Oil entered into the pump, and the vanes cannot

come out.

Consult with our dealer or service

personnel.

Due to condensation inside of the pump, the

vanes cannot come out.

The vanes were broken because foreign object(s)

entered into the pump.

When pump

is stopped.

The vanes were broken because foreign object(s)

entered into the pump.

The rotor was touched because the pressure was

out of applicable pressure range.

Defective electromechanical system

Page 22

20

Consumable parts

List of Consumable Parts

List of Consumable Parts

(Parts to be replaced depending on wear condition when checking.)

Name of Parts Model KRF70 KRF110

Filter element

(Inlet side)

Parts Number 04000451010 04041878010

Quantity /unit 1

Inspection period Every week

Replacement criterion

When it was damaged, or when dirt cannot be removed by blowing air.

Delivery element

(exhaust side) ※3

Parts Number 04044336010 04101351010

Quantity /unit 1

Inspection period Every week

Replacement criterion

When it was damaged, or when dirt cannot be removed by blowing air.

Gasket

(Cylinder side)

Parts Number 04010287010 04002846010

Quantity /unit 4 2

Inspection period At the time of removal of Suction case to Delivery case

Replacement criterion

When it was damaged or crushed.

Packing

Parts Number 04001458010

Quantity /unit 2 1

Inspection period At the time of removal of Suction case to Delivery case

Replacement criterion

When it was damaged or crushed.

Rubber packing

Parts Number 03042560010 04006914010

Quantity /unit 2 1

Inspection period At the time of check and replacement of element

Replacement criterion

When it was damaged or crushed.

Gasket

(Suction side)

(Delivery side)

Parts Number 03042561010 04000020010

Quantity /unit 2

Inspection period At the time of removal of Suction case to Delivery case

Replacement criterion

When it was damaged or crushed.

Liner

※1

Parts Number 040000410□0 040028390□0

Quantity /unit To be decided by actual positioning.

Inspection period At the time of replacement of vane.

Replacement criterion

When it was damaged.

Spring tube

Parts Number 04042925010 04042925020

Quantity /unit ※2

Inspection period At the time of check and replacement of element

Replacement criterion

When it was damaged or crushed.

Spider

Parts Number 04101313010

Quantity /unit 1

Inspection period Six months

Replacement criterion

When it was damaged or crushed.

VC81

Parts Number 03000205020 ―

Quantity /unit 1 ―

Inspection period Once a month ―

Replacement criterion

When surface of control screw and

valve were abrade away.

―

VC100B

Parts Number ― 03044148020

Quantity /unit ― 1

Inspection period ― Once a month

Replacement criterion ―

When surface of control screw and valve

were abrade away.

※1 Parts number of second digits from the right side differs depending on thickness.

0.2t (white) becomes 1, 0.1t (black) becomes 2, 0.05t (yellow) becomes 3, 0.03t (red) becomes 4.

※

2 (1) 1 pc for vacuum models.

( KRF70-V-01・04) ( KRF70-VH-01・04)

( KRF110-V-01・04)

(2) 2 pcs for blower, and vacuum & blower models.

( KRF70-B-01・04) ( KRF70-VB-01・04)

( KRF70-BH-01・04) ( KRF70-VBH-01・04)

( KRF110-B-01・04) ( KRF110-VB-01・04)

※

3 (1) B lower, and vacuum & blower models only.

( KRF70-B-01・04) ( KRF70-VB-01・04)

( KRF70-BH-01・04) ( KRF70-VBH-01・04)

( KRF110-B-01・04) ( KRF110-VB-01・04)

Saction ・Delivery side gasket

Cylinder side

g

asket

Page 23

21

Consumable parts

List of Motor Maintenance Cycle / List of Replacement Parts

List of Motor Maintenance Cycle

Name of parts Model

KRF70 KRF110

Motor

Three-phase

200V spec.

Parts no. 0A001675000 0A001676000

Model

Toshi ba IK-FCKA21

2.2kW 6P

Toshi ba IK-FCKA21

3.7kW 6P

Qty. 1

※

Maintenance cycle 20,000Hr

Motor

Three-phase

400V spec.

Parts no. 0A001677000 0A001678000

Model

Toshi ba IK-FCKA21

2.2kW 6P

Toshi ba IK-FCKA21

3.7kW 6P

Qty. 1

※

Maintenance cycle 20,000Hr

※Time on the list is the time that possibility to reaching the friction damage range becomes high. It is

not necessary to replace the motor on time because it differs depending on the installation site.

However, be sure to replace and repair the motor whenever troubles happen.

List of Replacement Parts

(Parts to be replaced periodically at specified period.)

(V,B, or VB enters into the □)

Name of parts Model KRF70-□ KRF-□H KRF110-□

Vane

Parts Number

04101504010 04101504010 04100653010

Quantity /unit 6 6 6

Replace-ment time

10,000 6,000 5,500

Bearing

Parts Number 0A000332000 0A000332000 0A000333000

Quantity /unit 2 2 2

Replace-ment time

10,000 6,000 5,500

※Consider the replacement time as a guide, and carry out the periodic replacement.

※Advanced technologies are required to replace vanes and bearings, so contact with our dealer or

service personnel.

※Exchange bearings at the same time when you exchange vanes.

※The indicated blade replacement period is recommended in order to help prevent breakdown due to

blade wear, and assumes average blade wear at 60Hz operation; specific performance is not

guaranteed. The blade might not last as long as the above specified replacement time due to higher

than normal wear from operating environments with low humidity or high temperatures, etc.

The blade should be replaced soon if performance decreases or noise levels increase.

※If the blade is not replaced periodically, progressive wearing down of the the blade height and

thickness can result in the blade being damaged which could lead to the pump becoming inoperable.

Page 24

22

Consumable parts

List of Replacement Parts / Maintenance of plastic parts affecting operation safety

Use the maintenance kit for replacement parts.

Name of Parts Unit

Maintenance kit

Assembly 70

Maintenance kit

Assembly 110

Model KRF70 KRF110

Parts no. 04101347010 04101348010

Items

Vane

Pcs/Unit

6

Bearing 2

Liner (white) 2

Liner (black) 2

Liner (yellow) 4

Liner (red) 6

Maintenance of plastic parts affecting operation safety

Caution

Replace the following plastic parts affecting operation safety promptly upon detection of breakage or

deformation. Failure to do so may cause personal injury.

Name of Parts Model

KRF70

KRF110

Front cover 70

Parts Number

03101467010 ―

Quantity /unit

1 ―

Fan cover

Parts Number

― 03101469010

Quantity /unit

― 1

Front cover 70

Front cover 110

KRF70 KRF110

Page 25

23

Storage(Not in Use for a Long Time)

Storing method / Storage location

St oring method

Pay attention to formation of rust if the pump is not used immediately after received or if the regularly

used pump has not been used for a long time.

St orage location

1.Store the product indoors and place the cover on the pump to protect it from water and dust.

2.Store the product where it is protected from water, oil and dust.

3.Store the product in a dry and clean place.

4.Store the product in an airy place where the ambient temperature is 40 degrees in Celsius or less.

5.Do not store the product where toxic gas such as chlorine gas or sulfur dioxide gas, which corrodes

the pump, is generated.

6.Store the product in a low humidity place to prevent the pump from rusting.

Disposal

Be sure to entrust the disposal of the Product to the specialists in the trade of disposal of industrial

wastes, observing Law about Disposal of Wastes and the Cleaning.

Page 26

24

Specifications

Specification list

Specification list

(V,B, or VB enters into the □)

Model ※1 KRF70-□ KRF70-□H KRF110-□

Designed capacity L/min 1130 / 1350 1850 / 2200

Speed ※2 rpm 930 / 1110 940 / 1120

Ultimate vacuum kPa 90 or more

Continuous operative (V) kPa 60 or less 80 or less 60 or less

Continuous exhaust (B) kPa 60 or less 70 or less 60 or less

Continuous operative (VB) kPa

Total of vacuum level

and exhaust pressure:

60kPa or lower

Total of vacuum level

and exhaust pressure:

80kPa or lower

Total of vacuum level and

exhaust pressure:

60kPa or lower

Diameter of piping connection Rc1 Rc1-1/4

Power supply

※2, ※3, ※4

Three-phase

200V spec

Hz

200V-50/60, 220V-60

Three-phase

400V spec

380V-50, 400V-50/60, 415V-50, 440V-60, 460V-60

Motor

Three-phase

200V spec

kW 2.2(6P) 3.7(6P)

Three-phase

400V spec

Rated current

※2

Three-phase

200V spec

A

10.4/9.6 (200V-50/60Hz)

9.2 (220V-60Hz)

16.2/15.6 (200V-50/60Hz)

14.6 (220V- 60Hz)

Three-phase

400V spec

5.4 (380V-50Hz)

5.2/4.8 (400V-50/60Hz)

5.2 (415V-50Hz)

4.6 (440V-60Hz)

4.5 (460V-50Hz)

8.2 (380V-50Hz)

8.1/7.8 (400V-50/60Hz)

7.9 (415V-50Hz)

7.3 (440V-60Hz)

7.1 (460V-50Hz)

Mass ※2

Three-phase

200V spec

kg 75 120

Three-phase

400V spec

Operation noise

Three-phase ※2

(V)

dB

67/68 73/74 74/75

(B) 74/76 76/77

Applicable

environment

Installation site Indoor

Permissible ambient

temperature

0 to 40 deg.C

Suction air ※5

"Normal temperature:0 to 40 deg.C , Normal humidity:65±20% (JIS Z 8703)

Conditions where there is no corrosive and explosive gas exist.

Clean air without vapor and dew condensation, and less dirt and dust."

Altitude of installation

1000m or less

Pollution Degree Pollution Degree 3 (Worse environment than normal environment)

Overvoltage classification ※6 Classification 3 (supply from the fixed wiring facility)

※1 Only three-phase specification is complied with CE ma rking.

※2 V al ues sh own are with ou r st and ard moto r.

※3 Allowable intermittent power supply voltage fluctuation range is ±10% of the specified voltage; allo wable

sustained supply voltage fluctuatio n range is ±5% of the specified voltage.

※4 Voltage specifications for motors other than our standard ones are according to power supply

specifications specifications shown on the motor name plates.

※5 Consult with your dealer if the product is used in extremely low humidity for adjustment. It may cause the

malfunction of pump.

※6 Refer to IEC664-1.

Page 27

25

Specifications

EC Declaration of Conformity

EC Declaration of Conformity

■This EC declaration of conformity applies only to models that are equipped

with ORION specified 3 phase motors. Models with single phase motors,

models without motors, and those models where the CE marking is not

printed on the machine name plate are not CE approved.

Page 28

26

Dimensional Outline Drawing

KRF70-V-01,04 / KRF70-VH-01,04

(unit : mm)

Page 29

27

Dimensional Outline Drawing

KRF70-B-01,04 / KRF70-BH-01,04

(unit : mm)

Page 30

28

Dimensional Outline Drawing

KRF70-VB-01,04 / KRF70-VBH-01,04

(unit : mm)

Page 31

29

Dimensional Outline Drawing

KRF110-V-01,04

(unit : mm)

Page 32

30

Dimensional Outline Drawing

KRF110-B-01,04

(unit : mm)

Page 33

31

Dimensional Outline Drawing

KRF110-VB-01,04

(unit : mm)

Page 34

37

memo

Page 35

37

memo

Page 36

K No.0322 ’12.2.1 C DG TY

Loading...

Loading...