Page 1

Factory Packaged Controls

Coil Products

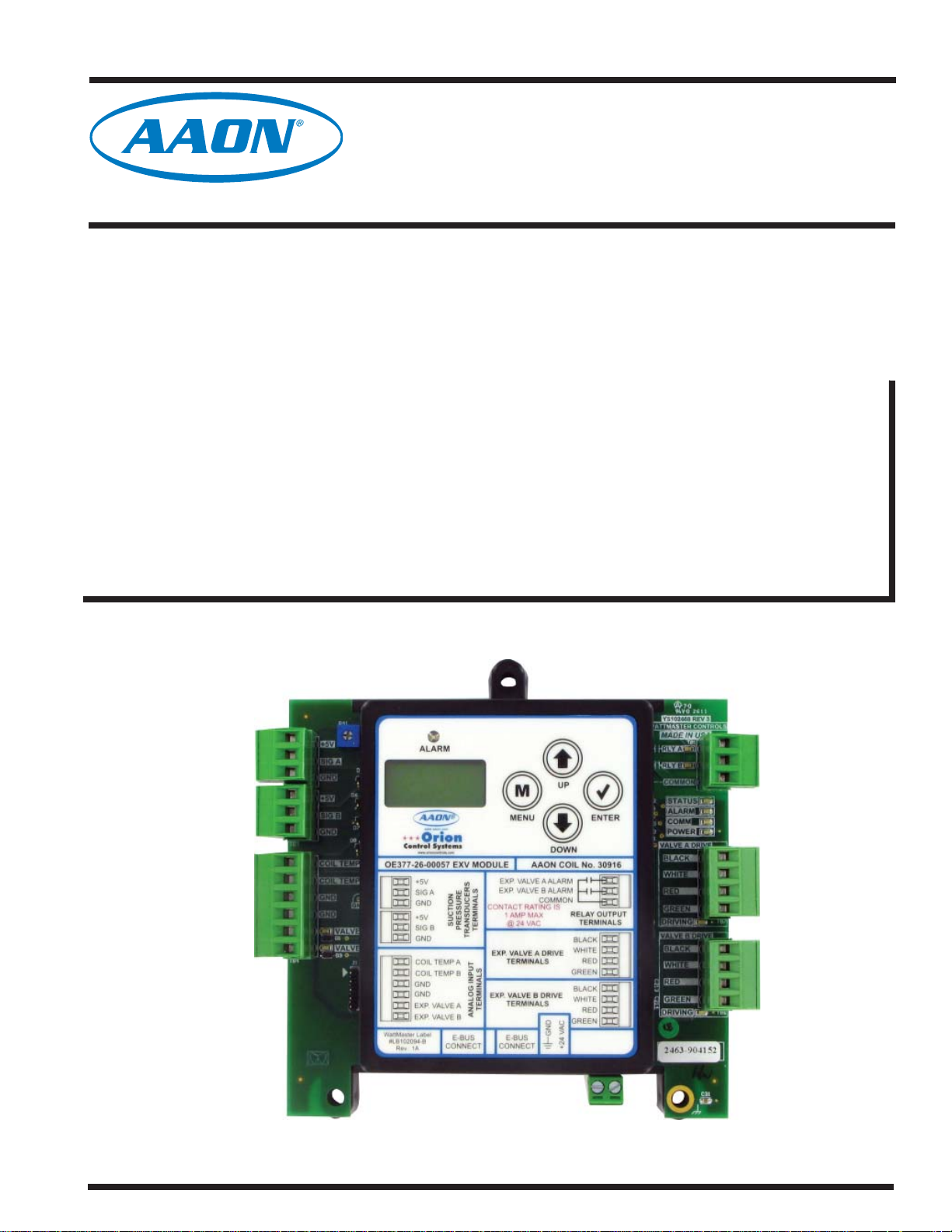

OE377-26-00057

(AAON Part #30916)

Dual Electronic Expansion

Valve Module Technical Guide

Page 2

Table of Contents

GENERAL INFORMATION ................................................................................................................................. 3

Overview ......................................................................................................................................................................................3

Features .......................................................................................................................................................................................4

Adjustable Setpoints.....................................................................................................................................................................4

Confi gurations ..............................................................................................................................................................................4

UNIT START-UP PROCEDURES ........................................................................................................................ 5

DIMENSIONS AND MOUNTING ........................................................................................................................ 6

INSTALLATION & WIRING ................................................................................................................................7

INPUTS/OUTPUTS ............................................................................................................................................ 8

I/O Map.........................................................................................................................................................................................8

Stand Alone Input Commands......................................................................................................................................................8

SEQUENCE OF OPERATION ............................................................................................................................. 9

Initialization...................................................................................................................................................................................9

Normal Operation .........................................................................................................................................................................9

Modulation Routine ......................................................................................................................................................................9

DIAGNOSTICS ................................................................................................................................................ 10

Alarms ........................................................................................................................................................................................10

LED Descriptions........................................................................................................................................................................10

LED SCREENS ................................................................................................................................................ 12

Navigation and Main Screens Map ............................................................................................................................................12

Protected Screens Map and Main Menu Screens ......................................................................................................................13

Status V-A/B and V-A/B Alarm Screens .....................................................................................................................................14

Force Valves Screens ................................................................................................................................................................15

Setpoint Screens ........................................................................................................................................................................16

Confi guration Screens ................................................................................................................................................................17

Diagnostic Screens ....................................................................................................................................................................18

TROUBLESHOOTING ...................................................................................................................................... 19

OE275-01 Suction Pressure Transducer Testing for R410A Refrigerant ........................................................................................ 20

Coil Temperature Sensor T esting ...............................................................................................................................................21

www.aaon.com

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

WattMaster Form : AA-EXV-TGD-01A

Copyright January 2012 WattMaster Controls, Inc.

®

is a registered trademark of AAON, Inc., Tulsa, OK.

AAON

Neither WattMaster Controls, Inc. nor AAON

responsibility for errors or omissions in this document.

This document is subject to change without notice.

®

assumes any

Page 3

Dual Electronic Expansion Valve Module

Overview

The OE377-26-00057 Dual Electronic Expansion V alve (EXV) Module

(AAON Part #30916) provides control of two electronic expansion

valves to maintain the superheat in the cooling circuits of the HVAC

unit. The module is designed only for R410-A refrigerant.

The EXV Module is used in stand-alone applications only.

General Information

YS102468 REV 3

R41

TB2

TB2

TB3

TB3

TB4

TB4

R41

+5V

+5V

SIG A

SIG A

GND

GND

+5V

+5V

SIG B

SIG B

GND

GND

COILTEMPA

COILTEMPA

COILTEMP B

COILTEMP B

GND

GND

GND

GND

VALVEA

VALVEA

D1

D1

VALVEB

VALVEB

D3

D3

D5

D5

D6

D6

D7

D7

D8

D8

GND

GND

J1

J1

YS102468 REV 3

WATTMASTER CONTROLS

WATTMASTER CONTROLS

MADE IN USA

MADE IN USA

TB1

TB1

RLYA

RLYA

RLYB

RLYB

COMMON

COMMON

STATUS

STATUS

ALARM

ALARM

COMM

COMM

POWER

POWER

VALVEADRIVE

VALVEADRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

GREEN

GREEN

DRIVING

DRIVING

VALVE B DRIVE

VALVE B DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

C214

C214

.1uF

.1uF

GREEN

GREEN

DRIVING

DRIVING

SERIAL #

SERIAL #

C31

C31

.1uF

.1uF

TB7

TB7

TB6

TB6

Figure 1: OE377-26-00057 Dual Electronic Expansion Valve Module

Technical Guide

3

Page 4

Dual Electronic Expansion Valve Module

Features and Applications

Features

The Dual Electronic Expansion Valve Module provides the following:

• Contains a 2x8 LCD character display and 4 buttons

that allow for status display, setpoint changes, and

confi guration changes.

• Can control two electronic expansion valves independently.

• Monitors suction pressure and coil temperature and

modulates electronic expansion valves to maintain

superheat.

• Provides active relays to monitor valve alarms.

NOTE: The Dual Electronic Expansion Valve Module contains

no user-serviceable parts. Contact qualifi ed technical per-

sonnel if your Dual Electronic Expansion Valve Module

is not operating correctly.

Adjustable Setpoints

The following describes some of the setpoints available for adjustment

using the LCD display on the Dual Electronic Expansion V alve Module:

• Superheat Setpoint - One setpoint is used for

both valves.

• Modulation Rate - This setpoint (in seconds) will

adjust how often the modulation routine will make a

valve adjustment.

• Proportional Window - This setpoint (in degrees)

will adjust how much of an adjustment will be made

according to how far away it is from setpoint.

Confi guration Settings

• Board Address – Can be addressed from 1 to 4.

Used as stand-alone, the default address is 1.

• Valve B Enable – When using the module for only

one valve, valve B can be disabled so false information

is not displayed such as alarms and sensor readings.

• Valve Steps – Confi gurable for what valve is being

used (1596, 2500, 3193, 6386)

• Max Valve Position – The maximum position each

valve will modulate (%).

• Min Valve Position – The minimum position each

valve will modulate (%).

• Suction Pressure A Calibration Offset –

Adjustable between -10 and 10 PSI.

• Suction Pressure B Calibration Offset –

Adjustable between -10 and 10 PSI.

4

Technical Guide

Page 5

Dual Electronic Expansion Valve Module

AAON® Unit Start-Up Procedures

AAON® Unit Start-Up Procedures

NOTE: The following instructions were provided by AAON to set

up the unit. If you have any questions about this start-up

procedure, please contact AAON Technical Support.

Refrigeration Charging Sequence:

1. Determine valve size utilized on equipment part number from the

physical valve. There are currently 4 models used:

• SER-C (5-Ton Maximum Nominal Capacity)

• SER-D (13-Ton Maximum Nominal Capacity)

• SER-G (26-Ton Maximum Nominal Capacity)

• SER-J (48-Ton Maximum Nominal Capacity)

2. Determine circuit capacity and divide by valve Maximum

Nominal Capacity to determine average full refrigerant mass fl ow

Example: CC-B-045 Condensing unit; (2) 22.5 Ton Circuits,

Evaporator contains (2) SER-G EEV (Electronic Expansion Valve)

22.5/26 = 0.865 = 86.5%, Rounded to 87%

Fine-Tuning the EEV Module’s Setpoints for Best

Reaction Time and Effi ciency:

1. Ballpark the modulation rate based on line set length using the

following table as a guide:

Line Set Length Modulation Rate

15 15

30 20

45 30

60 35

75 40

90 45

120 50

Table 1: Modulation Rate Table

2. Ensure the outside air temperature, return air temperature, and

control setpoints do not change during calibration and fi ne-tuning

procedures.

NOTE: Consult with System Specifi cation and Unit Rating, as

lower or higher evaporator temperatures and other factors

play a role in the actual capacity the compressors may

deliver.

3. Ensure system is charged to a reasonable point to enable

compressor start and ensure that all other procedures dictated for

installation and startup have been followed from the unit IOM.

4. Set the EEV Module’s Valve to manual override position of 87%.

5. Ensure the space is fully loaded at design conditions to allow for

maximum capacity operation and lock the compressor to fullyloaded capacity.

6. Energize the compressor and ensure a solid column of liquid to the

EEV via verifi cation at the sight glass.

7. From the point of a full sight glass, follow standard charging

procedures to maximize effi ciency via sub cooling, and delta T at

the evaporator.

8. Disable the manual override position on the EEV Module and

allow automatic operation at the desired set point.

3. Power off the EEV Module completely to ensure the smart-start

routine does not skew the initial position of future tests.

4. Power on the EEV Module and initialize the unit to enable

compressor operation.

5. Monitor superheat on the EEV Module and mark the time system

started until superheat is maintained at a steady state within an

acceptable dead band for more than 60 seconds.

6. Note the time from startup to stable superheat as well as the

current modulation rate set point (this process should not take longer than 20 minutes. If it does, then check unit charge or unstable

operating conditions).

7. Adjust the modulation rate set point by 2-3 seconds in either

direction and repeat test from Step 4.

8. Compare and adjust change until the best modulation rate is

obtained for the fi nal setting.

9. Verify superheat operation and consistent solid column of liquid at

the sight glass. This may take up to 15 minutes.

10. Repeat instruction for Valve 2 starting with Step 3.

Technical Guide

5

Page 6

Dual Electronic Expansion Valve Module

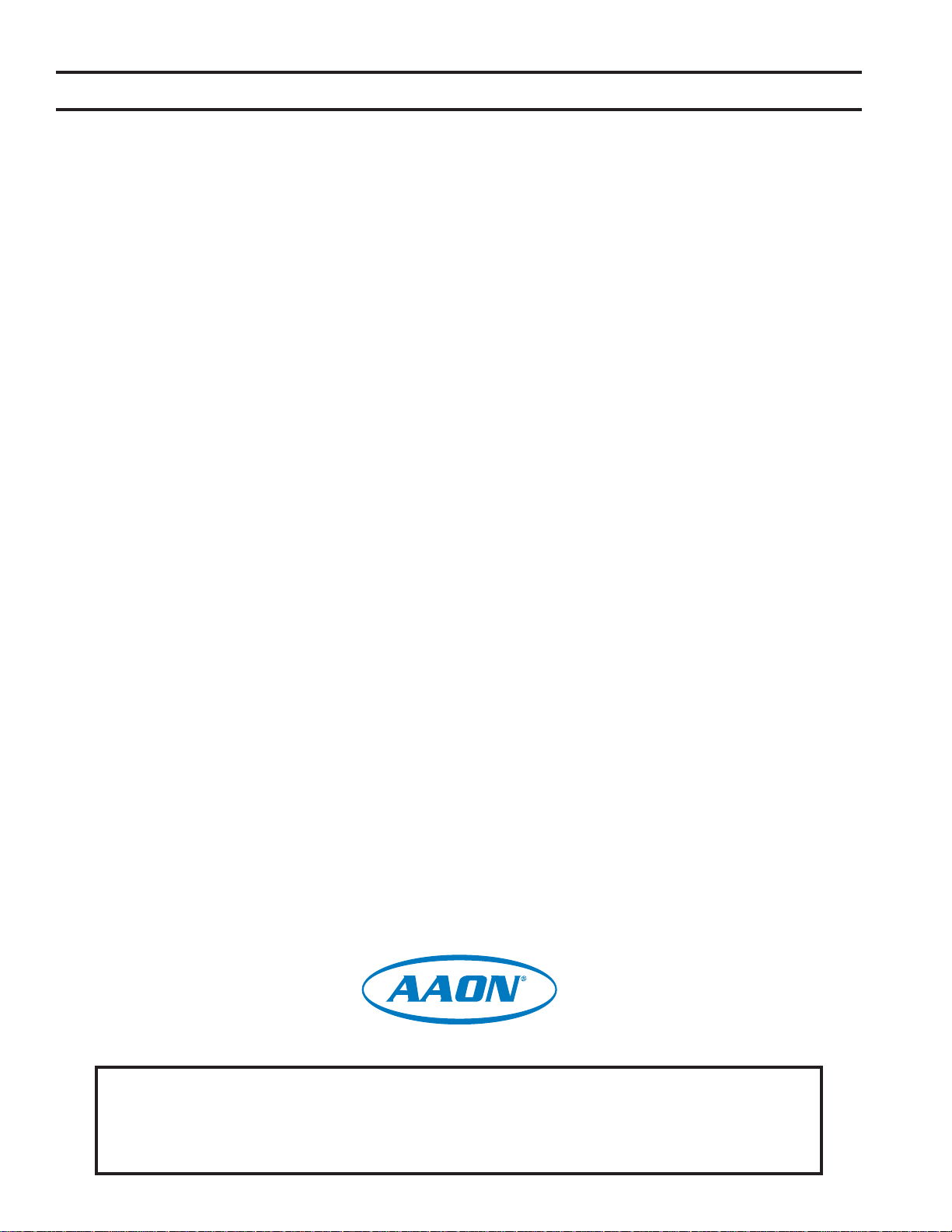

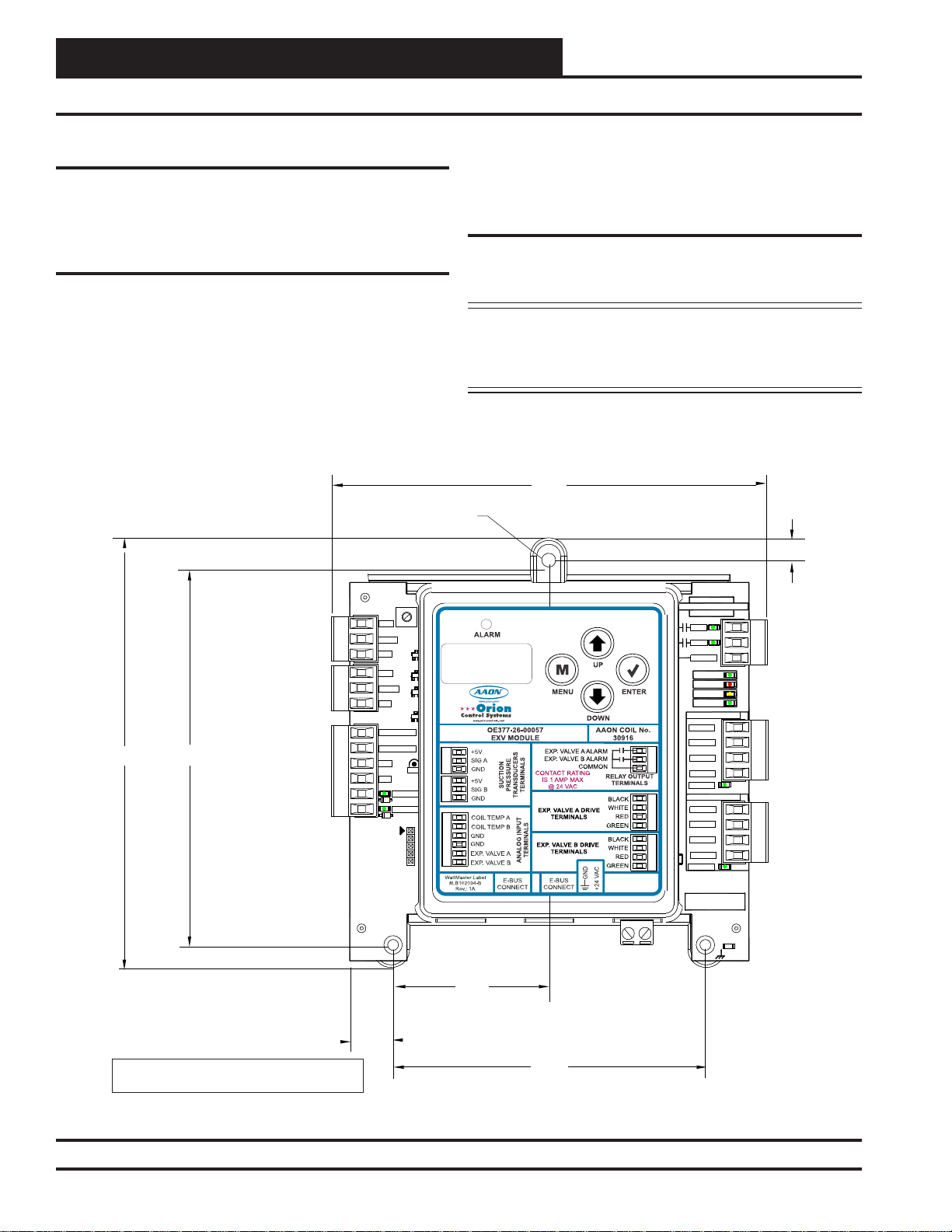

Dimensions and Mounting

Environmental Requirements

The Dual Electronic Expansion Valve Module needs to be installed in

an environment that can maintain a temperature range between -30°F

and 150°F and not exceed 90% RH levels (non-condensing).

Mounting

The Dual Electronic Expansion Valve Module is housed in a plastic

enclosure. It is designed to be mounted by using the 3 mounting holes

in the enclosure base. It is important to mount the module in a location

that is free from extreme high or low temperatures, moisture, dust, and

dirt. Be careful not to damage the electronic components when mounting the module.

See Figure 2 for Module dimensions (in inches).

0.18 DIA. TYP.

R41

R41

TB2

TB2

+5V

+5V

SIG A

SIG A

D5

D5

GND

GND

D6

D6

+5V

+5V

D7

D7

SIG B

SIG B

GND

GND

D8

COILTEMPA

COILTEMPA

COILTEMPB

COILTEMPB

GND

GND

GND

GND

VALVEA

VALVEA

D1

D1

VALVEB

VALVEB

D3

D3

D8

GND

GND

J1

J1

5.64

5.04

TB3

TB3

TB4

TB4

It is important to keep the module in a location that is free from extreme

high or low temperatures, moisture, dust, and dirt. Be careful not to

damage the electronic components.

Power Supply

The Dual Electronic Expansion V alve Module requires a 24 VAC power

connection with a minimum power rating of 1 VA.

WARNING: Observe polarity! All boards must be wired

GND-to-GND and 24 VAC-to-VAC. Failure to

observe polarity could result in damage to the

boards.

5.71

0.29

YS102468 REV 3

YS102468 REV 3

WATTMASTER CONTROLS

WATTMASTER CONTROLS

MADE IN USA

MADE IN USA

TB1

TB1

RLYA

RLYA

RLYB

RLYB

COMMON

COMMON

STATUS

STATUS

ALARM

ALARM

COMM

COMM

POWER

POWER

VALVEA DRIVE

VALVEA DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

GREEN

GREEN

DRIVING

DRIVING

VALVE B DRIVE

VALVE B DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

C214

C214

.1uF

.1uF

GREEN

GREEN

DRIVING

DRIVING

TB7

TB7

TB6

TB6

2.07

0.55

Note: Height is 1.49 inches.

4.14

Figure 2: OE377-26-00057 Dual Electronic Expansion Valve Module Dimensions

6

SERIAL #

SERIAL #

C31

C31

.1uF

.1uF

Technical Guide

Page 7

Dual Electronic Expansion Valve Module

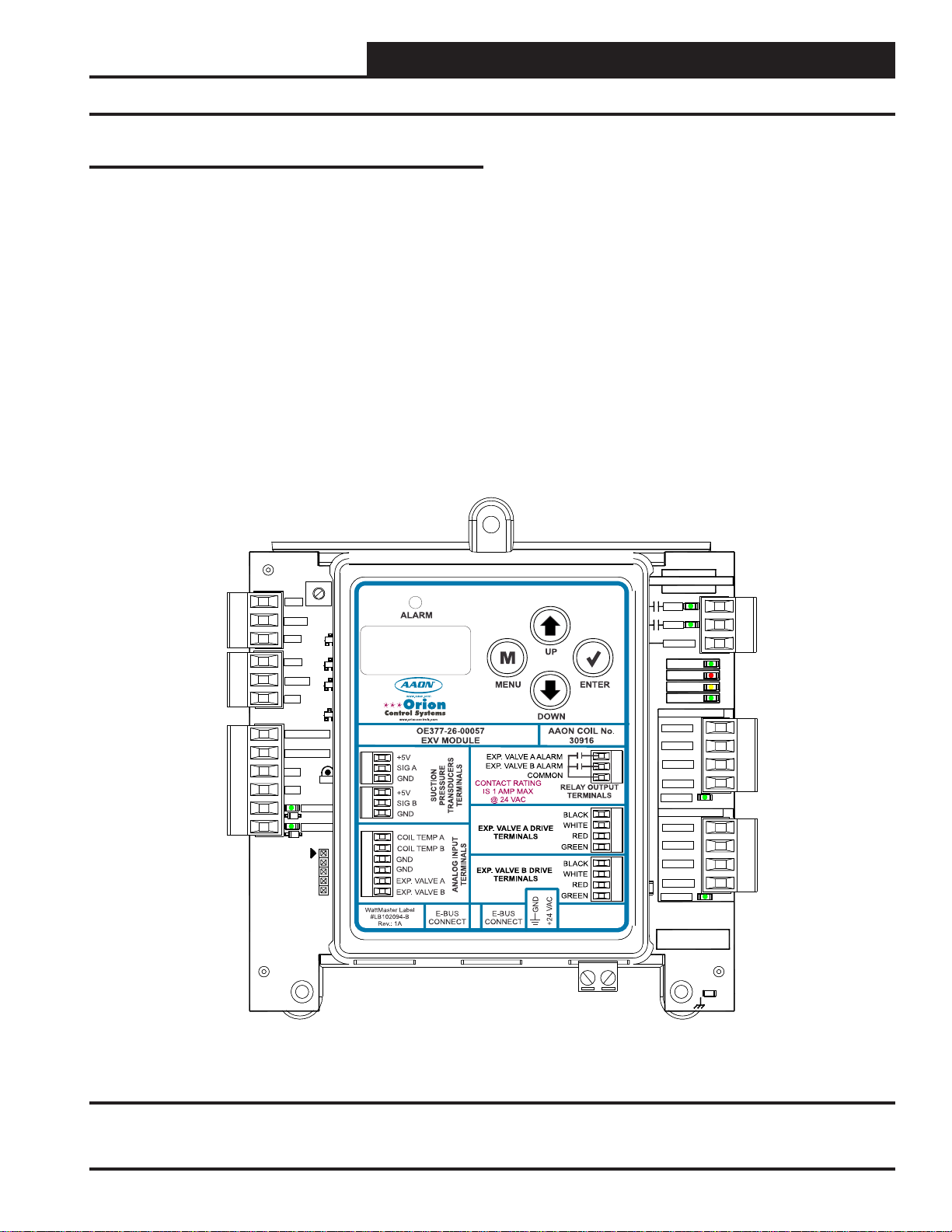

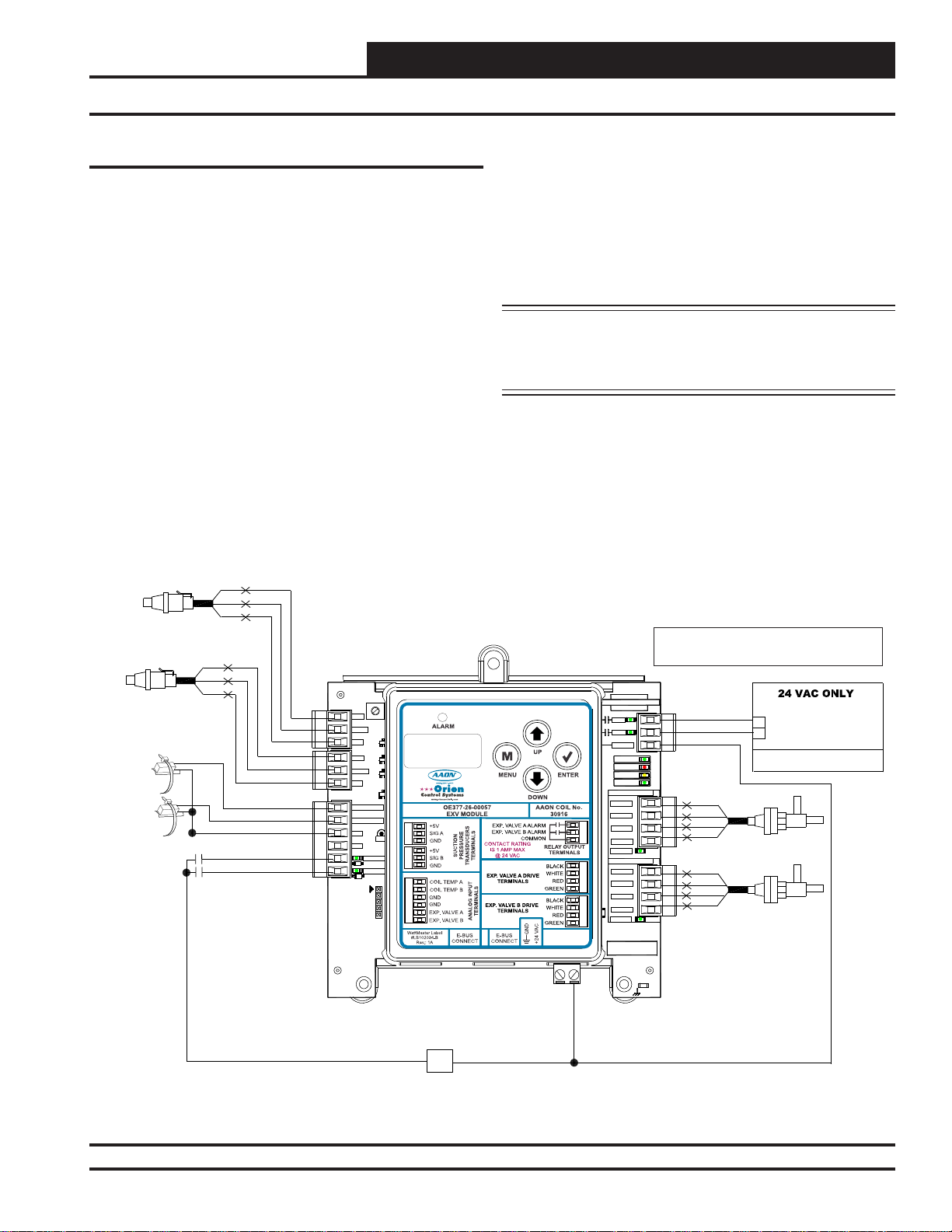

Installation & Wiring

Important Wiring Considerations

Please read carefully and apply the following information when wiring

the

Dual Electronic Expansion Valve Module Controller:

1. The Dual Electronic Expansion Valve Module requires a 24

VAC power connection with an appropriate VA rating.

2. Each Pressure Transducer must have its own 18-gauge

shielded twisted pair cable. The Drain Wire must be the “Gnd”

signal for the transducer.

3. All 24 VAC wiring must be connected so that all ground wires

remain common. Failure to follow this procedure can result in

damage to the module and connected devices.

COIL A - SUCTION

PRESSURE TRANSDUCER

COIL B - SUCTION

PRESSURE TRANSDUCER

COIL TEMP A

SENSOR

COIL TEMP B

SENSOR

RD

WH

BK

RD

WH

BK

Expansion Valve A

Expansion Valve B

GND

OE377-26-00057

Dual Electronic Expansion Valve

Module

R41

R41

TB2

TB2

+5V

+5V

SIGA

SIGA

D5

D5

GND

GND

D6

D6

+5V

+5V

D7

D7

SIG B

SIG B

GND

GND

D8

D8

TB3

TB3

COILTEMPA

COILTEMPA

COILTEMPB

COILTEMPB

GND

GND

GND

GND

GND

GND

VALVEA

VALVEA

D1

D1

VALVEB

VALVEB

D3

D3

TB4

TB4

J1

J1

4. All wiring is to be in accordance with local and

national electrical codes and specifi cations.

5. Check all wiring leads at the terminal block for tightness.

Be sure that wire strands do not stick out and touch adjacent

terminals. Confi rm that all transducers required for your

system are mounted in the appropriate location and wired into

the correct terminals.

WARNING: Observe polarity! All boards must be wired

GND-to-GND and 24 VAC-to-VAC. Failure to

observe polarity could result in damage to the

boards.

NOTE: NORMALLY

ALL RELAY OUTPUTS ARE

OPEN AND RATED FOR 24 VAC POWER ONLY

- 1 AMP MAXIMUM LOAD

YS102468 REV 3

YS102468 REV 3

WATTMASTER CONTROLS

WATTMASTER CONTROLS

MADE IN USA

MADE IN USA

TB1

RLYA

RLYA

RLYB

RLYB

COMMON

COMMON

VALVEA DRIVE

VALVEA DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

GREEN

GREEN

DRIVING

DRIVING

VALVE B DRIVE

VALVE B DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

C214

C214

.1uF

.1uF

GREEN

GREEN

DRIVING

DRIVING

SERIAL #

SERIAL #

STATUS

STATUS

ALARM

ALARM

COMM

COMM

POWER

POWER

TB1

RLYA

RLYB

COMM

VALVE A ALARM ENABLE

VALVE B ALARM ENABLE

HVAC UNIT CONNECTIONS

BK

WH

RD

GRN

TB7

TB7

TB6

TB6

EXPANSION VALVE A

BK

WH

RD

GRN

EXPANSION VALVE B

C31

C31

.1uF

.1uF

24 VAC

R

Figure 3: OE377-26-00057 Dual Electrical Expansion Valve Module Wiring Diagram

Technical Guide

7

Page 8

Dual Electronic Expansion Valve Module

Inputs and Outputs

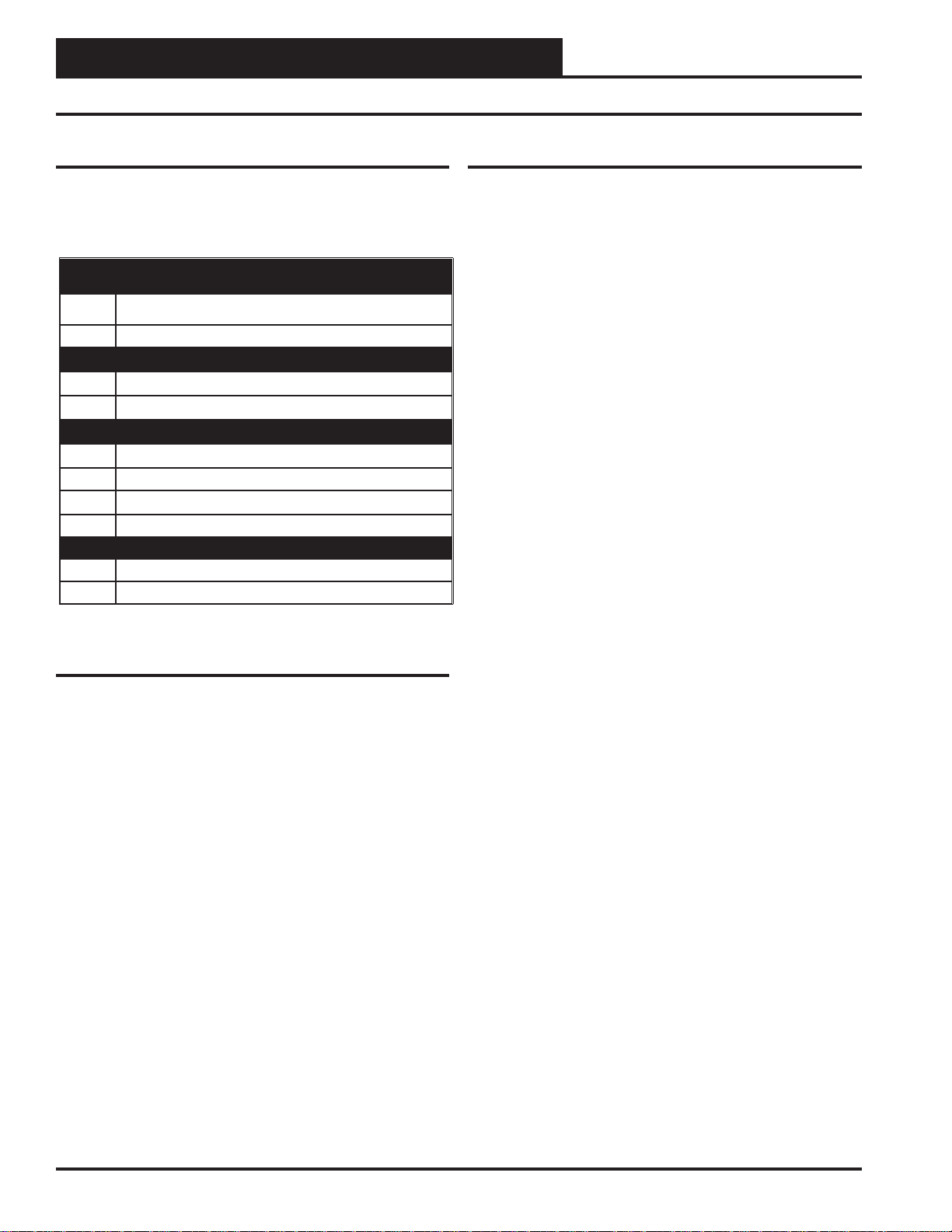

I/O Map

The following inputs and outputs are available on the Dual Electronic

Expansion Valve Module. See Table 2 below to reference the Input/

Output Map.

Binary Inputs

1 V alve A Enable

2 Valve B Enable

Binary Outputs

1 V alve A Alarm Relay

2 Valve B Alarm Relay

Analog Inputs

1 Coil A T emperature

2 Coil A Suction Pressure

3 Coil B Temperature

4 Coil B Suction Pressure

Stepper Motor Outputs

1 Expansion Valve A

2 Expansion Valve B

Stand-Alone Input Commands

Valve A Enable On/Off

A 24 volt signal to Binary Input #1 initiates the Valve A Enable

function. Once Valve A is enabled, it tries to maintain the desired

Superheat Setpoint. Valve A maintains the Superheat Setpoint until it loses the enable signal which then puts Valve A in Off mode.

Valve B Enable On/Off

A 24 volt signal to Binary Input #2 initiates the Valve B Enable

function. Once Valve B is enabled, it tries to maintain the desired

Superheat Setpoint. Valve B maintains the Superheat Setpoint until it loses the enable signal which then puts Valve B in Off mode.

Table 2: Dual Electronic Expansion Valve Module

Inputs & Outputs

8

Technical Guide

Page 9

Dual Electronic Expansion Valve Module

Sequence of Operation

Initialization

At power up, the Dual Electronic Expansion Valve Module will send

both expansion valves 110% of total steps in the closed position. This is

done to make sure that the valves always start from a valid 0% position.

For example, if the module is confi gured for a 6386 expansion valve,

the controller will step 7025 steps.

Normal Operation

The Dual Electronic Expansion Valve Module will continuously calculate the superheat for the different cooling circuits. The superheat will

be calculated by subtracting the saturated suction pressure from the

measured coil temperature at the suction line. The module is designed

for R410-A refrigerant.

The expansion valve signals will be maintained at the Smart Start position until the enable signal is activated. Anytime power is cycled, the

Smart Start will be 50%. After that, the Smart Start is based on the

history of the valve position.

The module will then modulate the expansion valve signals to maintain

the desired superheat.

The Superheat Setpoint and Time Constant are user-adjustable.

Force Mode

The electronic expansion valve is designed with the ability to manually

adjust the valve position by turning the Force Mode on for each valve.

The valve will reinitialize to zero when the Force Mode is turned back

off or after 1 hour. Each valve works independently.

• Force Mode Valve A – Ability to enable Valve A

Force Mode. Force Mode for Valve A will timeout

after 1 hour if not manually turned off.

• Force Valve A % - If Force Valve A mode is enabled,

you can manually adjust the valve position.

• Force Mode Valve B – Ability to enable Valve B

Force Mode. Force Mode for Valve B will timeout

after 1 hour if not manually turned off.

• Force Valve B % - If Force Valve B mode is

enabled, you can manually adjust the valve position.

Modulation Routine

The electronic expansion valve is designed with a modulation routine

that is used to try to maintain superheat as quickly and effi ciently as

possible. Currently, there are user adjustable setpoints that can be set

to adjust the modulation sequence to function better on a particular unit.

1. Modulation Rate (in seconds) – This setpoint will adjust how

often the modulation routine will make a valve adjustment. Some

systems are slower reacting than others, so setting this setpoint to

a higher value will slow down the response.

2. Proportional Window (in degrees) – This setpoint will adjust

how much of an adjustment will be made according to how far

away it is from setpoint. A smaller value will make larger changes

while a larger value will make smaller changes.

Technical Guide

9

Page 10

Dual Electronic Expansion Valve Module

Diagnostics

Alarms

The controller may have the following alarms for each refrigerant circuit:

• Low Suction Pressure

This alarm will be activated when the suction pressure

drops below 70 PSIG for longer than 10 seconds.Valve

will modulate by 10% one time when alarm occurs to

try to get suction pressure back up. This alarm will

cease when Suction Pressure is above 70 PSIG.

• High Superheat

This alarm will be activated when the Superheat

reaches 25 degrees for longer than 60 seconds. This

alarm will not affect valve operation. This alarm will

cease when the Superheat drops below 25 degrees.

• Low Superheat

This alarm will be activated when the Superheat

is 0 degrees for longer than 60 seconds. This alarm

will not affect valve operation. This alarm will cease

when the Superheat rises above 0 degrees.

Alarm LED’s will blink and the specifi c alarm can be accessed on the

LCD display. Also, the Relay will activate for the specifi c valve that

has the alarm.

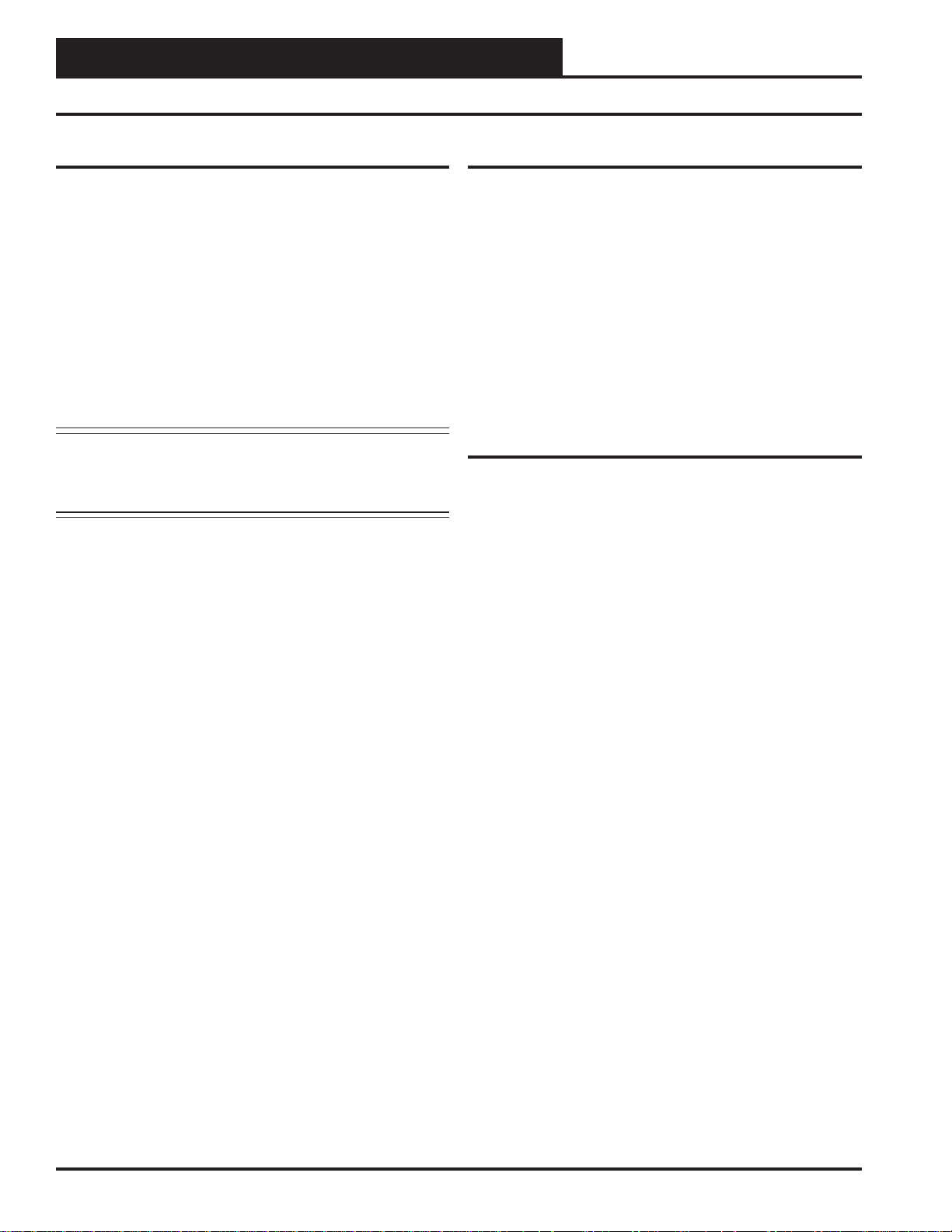

LED Descriptions

The Dual Electronic Expansion Valve Module is equipped with LEDs

that can be used to verify operation and perform troubleshooting. There

are LEDs for communication, operation modes, and diagnostic codes.

The module has 11 LEDs—1 used for E-BUS communications, 8 used

for operation & status, and 2 used for alarms.

See Figure 4 for the LED locations. The LEDs associated with these

inputs and outputs allow you to see what is active without using a voltmeter. The LEDs and their uses are as follows:

Operation LEDs

POWER - This green LED will light up to indicate that 24 VAC power

has been applied to the module.

STATUS - This green LED will light up and blink the board address

at startup.

Diagnostic LEDs

ALARM - This red LED will light up to indicate an alarm. The type of

alarm will display on the LCD display. The ALARM LED also blinks

when the expansion valve is initializing at startup.

10

Technical Guide

Page 11

Dual Electronic Expansion Valve Module

Diagnostics

Communication LEDs

COMM - This yellow LED will light up and blink when E-BUS communications are detected.

Expansion Valve LEDs

DRIVING VALVE A - This green LED will light up when Expansion

Valve A is being driven open or closed.

DRIVING VALVE B - This green LED will light up when Expansion

Valve B is being driven open or closed.

ALARM LED

R41

R41

+5V

+5V

SIG A

SIG A

GND

GND

+5V

+5V

SIG B

SIG B

GND

GND

COILTEMPA

COILTEMPA

COILTEMP B

COILTEMP B

GND

GND

GND

GND

VALVEA

VALVEA

D1

D1

VALVEB

VALVEB

D3

D3

D6

D6

D7

D7

D8

D8

GND

GND

J1

J1

D5

D5

VALVE A & B

LEDs

TB2

TB2

TB3

TB3

TB4

TB4

Relay LEDs

RLYA - This green LED will light up when Valve A has an alarm and

will stay lit as long as Valve A relay is active.

RLYB - This green LED will light up when Valve B has an alarm and

will stay lit as long as Valve B relay is active.

Binary Input LEDs

V ALVE A - This green LED will light up when Valve A is enabled.

VALVE B - This green LED will light up when Valve B is enabled.

YS102468 REV 3

YS102468 REV 3

WATTMASTER CONTROLS

WATTMASTER CONTROLS

MADE IN USA

MADE IN USA

TB1

TB1

RLYA

RLYA

RLYB

RLYB

COMMON

COMMON

STATUS

STATUS

ALARM

ALARM

COMM

COMM

POWER

POWER

VALVEA DRIVE

VALVEA DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

GREEN

GREEN

DRIVING

DRIVING

VALVE B DRIVE

VALVE B DRIVE

BLACK

BLACK

WHITE

WHITE

RED

RED

C214

C214

.1uF

.1uF

GREEN

GREEN

DRIVING

DRIVING

TB7

TB7

TB6

TB6

RELAY

LEDs

STATUS LED

ALARM LED

COMM LED

POWER LED

VALVE A

DRIVING LED

VALVE B

DRIVING LED

Figure 4: Dual Electrical Expansion Valve Module LED Locations and Descriptions

Technical Guide

SERIAL #

SERIAL #

C31

C31

.1uF

.1uF

11

Page 12

Dual Electronic Expansion Valve Module

Navigation Keys and Main Screens Map

LCD Display Screen & Navigation

Keys

The Dual Electronic Expansion Valve Module allows you to make confi guration changes, view status, change setpoints, create force modes,

and perform diagnostics using the keypad next to the LCD display. See

Figure 5 and refer to Table 3 for descriptions.

Figure 5: LCD Display and Navigation Keys

Navigation Key Key Function

MENU

Use the MENU key to navigate through the

Main Menu Screens

Main Screens Map

Refer to the following map when navigating through the LCD Main

Screens. The fi rst two screens are initialization screens. To scroll through

the rest of the screens, press the <MENU> button.

ADDRESS

#

DUAL EXV

STARTUP!

DUAL EXV

CONTROL

Press to scroll through DUAL EXV Screens.

Press to go to STATUS V-A Screens.

STATUS

V-A

Press to scroll through STATUS V-A Screens.

Press to go to STATUS V-B Screens.

STATUS

V-B

UP

DOWN

ENTER

Use this key to adjust setpoints and change

confi gurations. This key is also used to turn

Valve Force Mode on.

Use this key to adjust setpoints and change

confi gurations. This key is also used to turn

Valve Force Mode off.

Use the Enter key to move through screens

within Main Menu categories. Also, use this

key to save setpoints and confi guration

changes.

Table 3: Navigation Key Functions

Press to scroll through STATUS V-B Screens.

Press to go to V-A ALARM Screens.

NO V-A

ALARMS

Press to scroll through V-A ALARM Screens.

Press to go to V-B ALARM Screens.

NO V-B

ALARMS

Press to scroll through V-B ALARM Screens.

Press to go to FORCE VALVE Screens.

FORCE

VALVES

Press to scroll through FORCE VALVE Screens.

12

Technical Guide

Page 13

Dual Electronic Expansion Valve Module

Protected Screens Map and Main Menu Screens

Protected Screens Map

Refer to the following map when navigating through the LCD Protected

Screens. From the DUAL EXV CONTROL Screen, press <ENTER>

twice to get to the Software Screen. Then hold the <UP> button for 5

seconds. T o scroll through the rest of the screens, press the <MENU>

button.

DUAL EXV

CONTROL

S/A MODE

SOFTWARE

TESTv108

Hold for 5 seconds.

Main (Dual EXV Control) Screens

Refer to the following map when navigating through the Main Screens.

From the DUAL EXV CONTROL Screen, press <ENTER> to scroll

through the screens.

DUAL EXV

CONTROL

S/A MODE

STAND ALONE MODE

SOFTWARE

TESTv108

CURRENT SOFTWARE VERSION

You can access the protected

screens from this screen by holding

the <UP> button for 5 seconds.

SETPOINT

CONFIG

DIAGNSTC

ENTER TO

EXIT

ADDRESS

#

CURRENT BOARD ADDRESS

VLVSTEPS

2500

CURRENT VALVE CONFIGURATION

(STEP SIZE)

Technical Guide

13

Page 14

Dual Electronic Expansion Valve Module

Status V-A/B and V-A/B Alarm Screens

Status V-A & V-B Screens

Refer to the following map when navigating through the Status Valve

A Screens. From the STATUS V-A or STATUS V-B Screen, press

<ENTER> to scroll through the screens.

STATUS

V-A/B

V-A/B MODE

ON/OFF/FORCE

VALVE A/B MODES: ON ,OFF, FORCE

ON: Valve is modulating to maintain Superheat.

OFF: System is off.

FORCE: Valve is set to a forced position.

COIL TMP

XX.X

COIL TEMPERATURE READING FROM

TEMPERATURE SENSOR INPUT

CALC TMP

XX.X

CALCULATED COIL TEMPERATURE

FROM SUCTION PRESSURE INPUT

SUC PRESS

XXX

SUCTION PRESSURE READING

FROM INPUT

V-A/B POS

0 TO 100%

VALVE POSITION

0 to 100 percent

SUPRHEAT

XX.X

CURRENT SUPERHEAT CALCULATION

SUPRHEAT SP

O TO 25

SUPERHEAT SETPOINT SETTING

0 to 25

V-A & V-B Alarm Screens

Refer to the following map when viewing Valve A and Valve B Alarm

Screens. These screens will display automatically when alarms are

present.

V-A/B

ALARMS

ALARMS

The alarms are as follows:

NO V-A/B ALARMS: This will be shown if there are no current alarms.

LO SPRESS: This indicates a Low Suction Pressure Alarm condition

which is activated when the Suction Pressure drops below 70 PSIG for

longer than 10 seconds. The valve will modulate by 10% one time when

alarm occurs to try to increase the suction pressure. This alarm will disable when Suction Pressure is above 70 PSIG.

HI SHEAT: This alarm will be activated when the Superheat reaches

25 degrees for longer than 60 seconds. This alarm will not affect valve

operation. This alarm will disable when the Superheat drops below 25

degrees.

LO SHEAT: This alarm will be activated when the Superheat is 0

degrees for longer than 60 seconds. This alarm will not affect valve

operation. This alarm will disable when the Superheat rises above 0 degrees

14

Technical Guide

Page 15

Dual Electronic Expansion Valve Module

Force Valves Screens

Force Valves Screens

Refer to the following map when navigating through the Force Valves

Screens. From the FORCE VALVE Screen, press <ENTER>. At the

FORCE MODE ON/OFF screens, press the <UP> arrow key to turn

the valve on and press the <DOWN> arrow key to turn the valve off.

Use the <UP> and <DOWN> arrow keys to increase and decrease

the percentage.

FORCE

VALVES

FRC V-A

MODE ON/OFF

Press the <UP> button to turn the valve on.

Press the <DOWN> button to turn the valve off

Force Valve will timeout after 1 hour

if not manually turned off.

FRC V-B

MODE ON/OFF

Press the <UP> button to turn the valve

on. Press the <DOWN> button to turn

the valve off.

Force Valve will timeout after 1 hour

if not manually turned off.

FRC V-B

%

FORCE VALVE PERCENTAGE

If Force Valve B is enabled, you can manually

adjust the valve position.

Press the <UP> button to increase the

percentage. Press the <DOWN> button to

decrease the percentage.

FRC V-A

%

FORCE VALVE PERCENTAGE

If Force Valve A is enabled, you can manually

adjust the valve position.

Press the <UP> button to increase the

percentage. Press the <DOWN> button to

decrease the percentage.

NOTE: When you turn the Force Valve back

off or after 1 hour has elapsed, the valve will

reinitialize to zero.

NOTE: When you turn the Force Valve back

off or after 1 hour has elapsed, the valve will

reinitialize to zero.

FORCE

TIMEOUT

FORCE MODE TIME OUT

This screen will appear when the

Force Mode times out after 1 hour.

Technical Guide

15

Page 16

Dual Electronic Expansion Valve Module

Setpoints Screens

Setpoints Screens

Refer to the following map when navigating through the Setpoints

Screens. From the SETPOINTS Screen, press <ENTER> to

scroll through the screens and change setpoints. Use the <UP>

and <DOWN> arrow keys to change your selections. Then press

<ENTER> to save the new setpoint.

SETPOINTS

SHEAT SP

0 TO 25

SUPERHEAT SETPOINT

One setpoint is used for both valves

Default = 9

MODRATE

O TO 180

MODULATION RATE (in seconds)

This setpoint will adjust how often the modulation routine

will make a valve adjustment. Some systems are

slower reacting than others, so setting this setpoint to a

higher value will slow down the response.

PROPORTIONAL WINDOW (in degrees)

This setpoint will adjust how much of an adjustment will be

made according to how far away it is from setpoint. A

smaller value will make larger changes while a larger

value will make smaller changes.

Default = 30

PROP WIN

0 TO 30

Default = 30

16

Technical Guide

Page 17

Dual Electronic Expansion Valve Module

Confi guration Screens

Confi guration Screens

Refer to the following map when navigating through the Confi guration

Screens. From the CONFIG Screen, press <ENTER> to scroll through

the screens and change setpoints. Use the <UP> and <DOWN> arrow

keys to change your selections. Press <ENTER> to save any changes.

CONFIG

ADDRESS

1 TO 4

CURRENT ADDRESS OF THE BOARD

The address confi guration is not used in Stand

Alone Mode. Stand Alone Mode Default is 1.

MAX VLV%

0 TO 100

MAXIMUM VALVE POSITION

The maximum position each valve will modulate (%).

Default =100

MIN VLV%

0 TO 100

MINIMUM VALVE POSITION

The maximum position each valve will modulate (%).

Default = 0

SP-A CAL

-10 TO 10

VALVE B

ENABLED/

DISABLED

VALVE B ENABLED/DISABLED

When using the module for only one valve, valve

B can be disabled so false information is not dis-

played such as alarms and sensor readings.

VLVSTEPS

1596,2500,

3193,6386

VALVE STEPS

Confi gurable for what valve is being used

(1596, 2500, 3193, 6386)

Default = 2500

SUCTION PRESSURE VALVE A

CALIBRATION OFFSET

If the Suction Pressure Sensor is reading incorrectly,

you can use this offset to adjust its reading.

Default = 0

SP-B CAL

-10 TO 10

SUCTION PRESSURE VALVE B

CALIBRATION OFFSET

If the Suction Pressure Sensor is reading incorrectly,

you can use this offset to adjust its reading.

Default = 0

Technical Guide

17

Page 18

Dual Electronic Expansion Valve Module

Diagnostic Screens

Diagnostic Screens

Refer to the following map when navigating through the Diagnostic

Screens. From the DIAGNSTC Screen, press <ENTER> to scroll

through the screens.

DIAGNSTC

WDOG CNT

#

WATCH DOG TIMER

Displays the number of times the board has been reset due

to watchdog timer overfl ow .

PWER CNT

#

POWER LOSS COUNT

Displays the number of times the board has been reset due

to power loss.

18

Technical Guide

Page 19

Dual Electronic Expansion Valve Module

Dual Electronic Expansion Valve

Module Troubleshooting

Valve Enable Outputs Not Working

Make sure 24 VAC is applied and the LEDs are lit.

Electronic Expansion Valve Outputs

Not Working

• Make sure the valves are wired correctly according to

the colored wires shown on the module.

• Make sure the correct valve size is confi gured.

• Monitor the LEDs to see if the valve is modulating.

• Valve may not modulate if Superheat is at the Superheat

Setpoint.

Troubleshooting

Technical Guide

19

Page 20

Dual Electronic Expansion Valve Module

Troubleshooting

OE275-01 Suction Pressure Transducer

T esting for R410A Refrigerant

The Evaporator Coil Temperature is calculated by converting the Suction Pressure to T emperature. The Suction Pressure is obtained by using

the OE275-01 Suction Pressure Transducer , which is connected into the

Suction Line of the Compressor.

The Suction Pressure and Calculated Temperature is displayed in the

Module’s Status Screens. A voltage measurement can also be taken on

input for verifi cation.

The Suction Pressure Transducer must have a 5 volt supply voltage to

work properly. A measurement can be taken on the +5V terminal for

verifi cation.

Use the voltage column to check the Suction Pressure Transducer while

connected to the Dual Electronic Expansion V alve Module. Read voltage

with a meter set on DC volts. If the temperature/voltage or pressure/voltage readings do not align closely with the chart, your Suction Pressure

Transducer is probably defective and will need to be replaced.

See the OE275-01 Suction Pressure Transducer , Pressure, T emperature,

and Voltage Chart for R410A Refrigerant testing (Table 4). The chart

shows a temperature range from 20°F to 80°F . For troubleshooting purposes, the DC Voltage readings are also listed with their corresponding

temperatures and pressures.

OE275-01 Suction Pressure Transducer Coil Pressure

– Temperature – Voltage Chart for R410A Refrigerant

°F

Temperature

21.19 80.94 1.8 59.03 168.10 3.2

24.49 87.16 1.9 61.17 174.32 3.3

27.80 93.39 2.0 63.19 180.55 3.4

30.99 99.62 2.1 65.21 186.78 3.5

33.89 105.84 2.2 67.23 193.00 3.6

36.80 112.07 2.3 69.24 199.23 3.7

39.71 118.29 2.4 71.15 205.46 3.8

42.30 124.52 2.5 72.95 211.68 3.9

44.85 130.75 2.6 74.76 217.91 4.0

47.39 136.97 2.7 76.57 224.14 4.1

49.94 143.2 2.8 78.37 230.36 4.2

52.23 149.42 2.9 80.18 236.59 4.3

54.50 155.65 3.0

56.76 161.88 3.1

PSI

Pressure

Signal

DC Volts

°F

Temperature

PSI

Pressure

Signal

DC Volts

Table 4: Coil Pressure/Voltage/Temp for OE275-01

Suction Pressure Transducers - R410A Refrigerant

20

Technical Guide

Page 21

Dual Electronic Expansion Valve Module

Troubleshooting

Coil Temperature Sensor Testing

The following sensor voltage and resistance table is provided to aid in

checking a coil temperature sensor that appears to be operating incorrectly. Many system operating problems can be traced to incorrect sensor

wiring. Be sure the sensor is wired per the wiring diagrams in this manual.

The Suction Pressure and Calculated Temperature is displayed in the

Module’s Status Screens. A voltage measurement can also be taken on

input for verifi cation.

If the sensors still do not appear to be operating or reading correctly,

check voltage and/or resistance to confi rm that the sensor is operating

correctly per the tables. Please follow the notes and instructions that

appear after the chart when checking sensors.

Temperature – Resistance – Voltage for Type III

10 K Ohm Thermistor Sensors

Temp

(ºF)

-10 -23.33 93333 4.51

-5 -20.55 80531 4.45

0 -17.77 69822 4.37

5 -15 60552 4.29

10 -12.22 52500 4.2

15 -9.44 45902 4.1

20 -6.66 40147 4.002

25 -3.88 35165 3.891

30 -1.11 30805 3.773

35 1.66 27140 3.651

40 4.44 23874 3.522

45 7.22 21094 3.39

50 10 18655 3.252

52 11.11 17799 3.199

54 12.22 16956 3.143

56 13.33 16164 3.087

58 14.44 15385 3.029

60 15.55 14681 2.972

62 16.66 14014 2.916

64 17.77 13382 2.861

66 18.88 12758 2.802

68 20 12191 2.746

69 20.55 11906 2.717

70 21.11 11652 2.691

71 21.66 11379 2.661

Table 5: Temperature/Resistance for Type III 10K

Ohm Thermistor Sensors

Temp

(ºC)

Resistance

(Ohms)

Voltage @

Input (VDC)

Temperature – Resistance – Voltage for Type III

10 K Ohm Thermistor Sensors

Temp

(ºF)

72 22.22 11136 2.635

73 22.77 10878 2.605

74 23.33 10625 2.576

75 23.88 10398 2.549

76 24.44 10158 2.52

77 25 10000 2.5

78 25.55 9711 2.464

80 26.66 9302 2.41

82 27.77 8893 2.354

84 28.88 8514 2.3

86 30 8153 2.246

88 31.11 7805 2.192

90 32.22 7472 2.139

95 35 6716 2.009

100 37.77 6047 1.884

105 40.55 5453 1.765

110 43.33 4923 1.65

115 46.11 4449 1.54

120 48.88 4030 1.436

125 51.66 3656 1.339

130 54.44 3317 1.246

135 57.22 3015 1.159

140 60 2743 1.077

145 62.77 2502 1.001

150 65.55 2288 0.931

Temp

(ºC)

Resistance

(Ohms)

Voltage @

Input (VDC)

Table 5, cont.: Temperature/Resistance for Type III

10K Ohm Thermistor Sensors

Thermistor Sensor Testing Instructions

Use the resistance column to check the thermistor sensor while disconnected from the controllers (not powered).

Use the voltage column to check sensors while connected to powered

controllers. Read voltage with meter set on DC volts. Place the “-”

(minus) lead on GND terminal and the “+” (plus) lead on the sensor

input terminal being investigated.

If the voltage is above 4.88 VDC, then the sensor or wiring is “open.” If

the voltage is less than 0.05 VDC, then the sensor or wiring is shorted.

Technical Guide

21

Page 22

Dual Electronic Expansion Valve Module

Notes

22

Technical Guide

Page 23

Dual Electronic Expansion Valve Module

Notes

Technical Guide

23

Page 24

www.aaon.com

AAON Coil Products

203 Gum Springs Road • Longview, TX 75602-1721

Ph: (903) 236-4403 • Fax: (903) 236-4463

WattMaster Manual Form No: AA-EXV-TGD-01A

Loading...

Loading...