Page 1

www.orioncontrols.com

Digital Room Sensor

Technical Guide

Page 2

TABLE OF CONTENTS

OVERVIEW ....................................................................................................................................... 3

BASIC OPERATION .......................................................................................................................... 4

Sensor Operation .....................................................................................................................................................4

LED Operation .........................................................................................................................................................4

MOUNTING AND WIRING ................................................................................................................ 5

Environmental Requirements ...................................................................................................................................5

Indoor Reading Range ........................................................................................................................................5

Outdoor Reading Range .....................................................................................................................................5

Important Wiring Considerations ..............................................................................................................................5

Mounting ..................................................................................................................................................................5

SENSOR OPERATION ...................................................................................................................... 6

Main Sensor Display Screens....................................................................................................6

Temperature and Humidity Status Screen ..........................................................................................................6

Outside Air Temperature Humidity Status Screen...............................................................................................6

Unit Information Screen ......................................................................................................................................6

Setpoint Adjust Screen ........................................................................................................ ...............................6

TROUBLESHOOTING ....................................................................................................................... 7

Temperature Sensor Testing for OE217-00 .............................................................................................................7

APPENDIX ....................................................................................................................................... 8

Sensor Confi guration and Test Screens ..................................................................................................................8

Sensor Confi guration & Test Screen ...................................................................................................................8

Pixel Test Screen ................................................................................................................................................8

Sensor Info & LED Test Screen ..........................................................................................................................8

LCD Backlight Test Screens ...............................................................................................................................9

Thermistor Averaging Screen .............................................................................................................................9

Display Options - Temperature/Setpoint .............................................................................................................9

Connecting to VAV/Zone Controller & HVAC Unit Controller .................................................................................10

Connecting a Remote Sensor ................................................................................................................................ 11

Mounting Plate Dimensions ...................................................................................................................................12

PART NUMBER CROSS REFERENCE TABLE

PART DESCRIPTION ORION

Digital Room Sensor Temp Only OE217-00

Digital Room Sensor Temp & Humidity OE217-01

Mounting Plate BK000081

Space CO

Duct Mounted CO

Return Air Temperature Sensor OE231

VCM-X E-BUS Controller OE332-23E-VCMX

Sensor OE256-01

2

Sensor OE256-02

2

www.orioncontrols.com

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

®

is a registered trademark of AAON, Inc., Tulsa, OK.

AAON

WattMaster Controls, Inc. assumes no responsibility for errors

or omissions.

This document is subject to change without notice.

Form: OR-DRS-TGD-01K

Copyright May 2015 WattMaster Controls, Inc.

Page 3

DIGITAL ROOM SENSOR

Overview

Overview

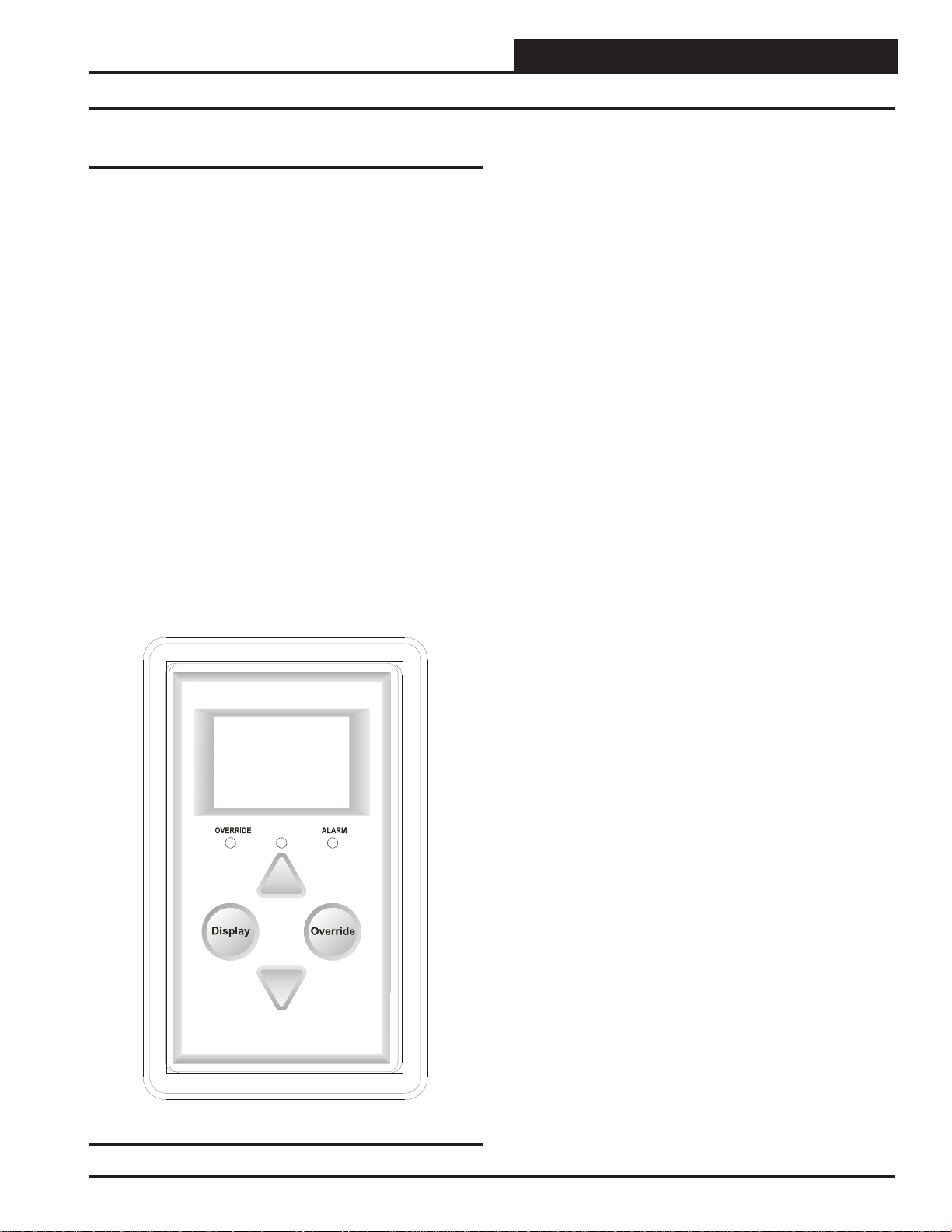

The OE217 series of Digital Room Sensors are used to sense Space T emperature only or Space Temperature & Space Humidity. See Figure 1.

The OE217-00 model is the Space T emperature Sensor only model and

can be used with the VCM-X E-BUS Controller (OE332-23E-VCMX),

RNE Controller (OE332-23E-RNE), SA E-BUS Controller (OE332-23EVCMX-SA), and VAV/Zone Controller (OE324-02). The OE217-01 is

a combination Space Temperature & Space Humidity Sensor model

and can only be used with the VCM-X E-BUS, RNE, and SA-EBUS

Controllers.

The sensor provides the following useful functions:

• Provides 112 x 64 monochrome Graphical LCD display with

LED backlight

• Displays the Current Space Temperature or Cooling/Heating

Setpoint on the Main Display Screen

• Displays Outdoor Air Temperature (if controller is confi gured

with OA Temperature Sensor)

• Displays the Current Space Humidity (OE217-01 Model

Only)

• Displays Outdoor Air Relative Humidity (OE217-01 Model if

controller is confi gured with OA Humidity Sensor)

• Displays the Current Zone Setpoint Temperature

• Equipped with Push Buttons for changing the Zone Setpoint

Temperature

• Equipped with an Override Button for forcing the VAV/Zone

Controller or VCM-X / RNE / SA Controller into Occupied

Operation from Unoccupied Operation

• Provides graphics to indicate the Mode of Operation

• Provides LEDs to indicate Schedule Override, Button Push,

and Alarms

• Can display Temperature reading from a Remote Sensor (see

Figure 19, page 11 for instructions)

• Can be used with the OE256-01 or OE256-02 CO2 Sensor (see

notes in Figures 17 & 18, page 10 for instructions)

Both sensors connect to the controllers using various lengths of

TSDRSC modular cables connected between the controller and the

sensor. The TSDRSC modular cables should not run in conduit with

other AC line voltage wiring or with any conductors carrying highly

inductive loads.

Figure 1: Digital Room Sensor

Operator Interface 3

Page 4

DIGITAL ROOM SENSOR

Basic Operation

Sensor Operation

When power is fi rst applied to the OE217-00 Digital Room Sensor, the

sensor will display the Current Room T emperature or the Cooling/Heating Setpoint and the current setting of the slide offset. The OE217-01

model will also display Relative Humidity.

NOTE: The sensor readings are not accurate until the controller

that the sensor is connected to is done calibrating.

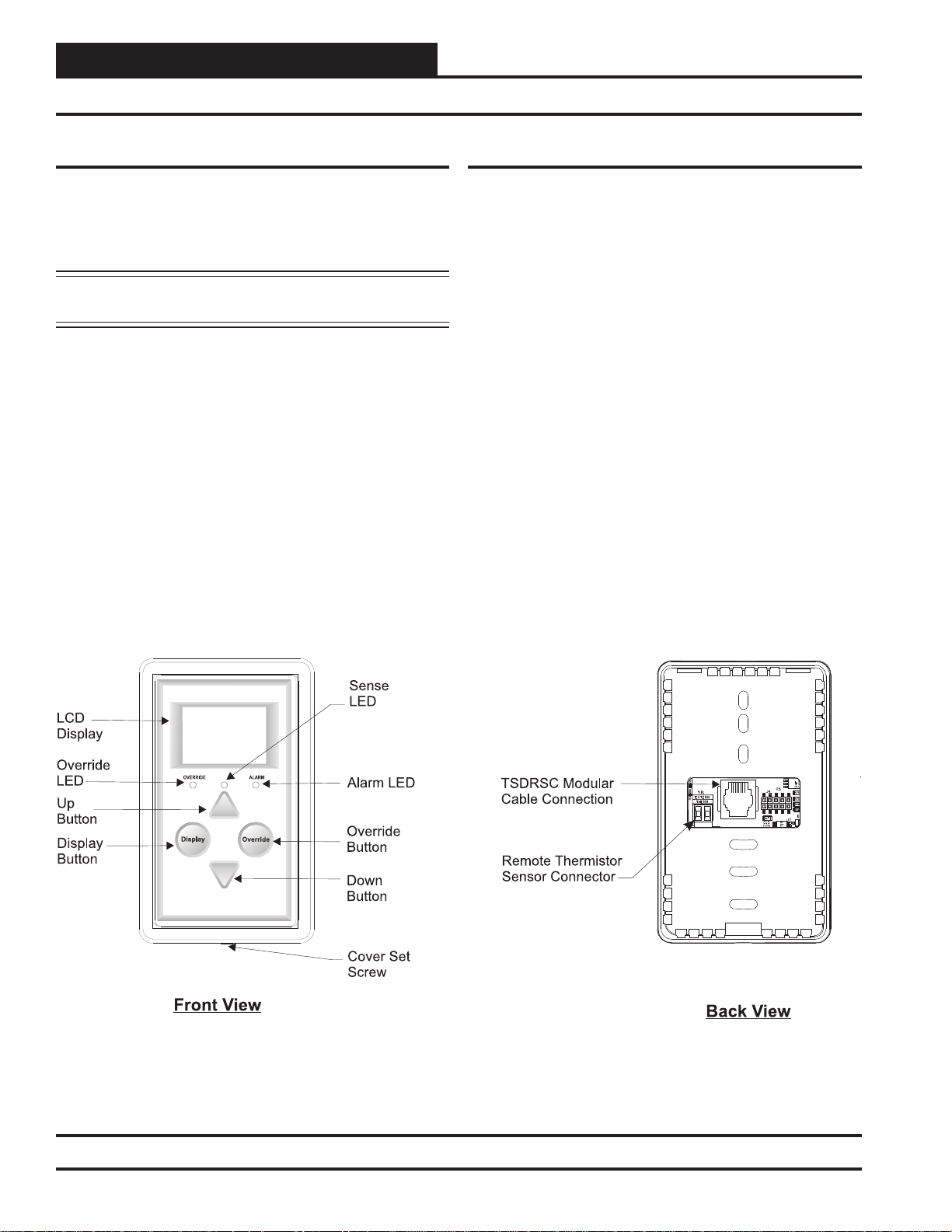

The sensor has 4 buttons—

<Down>. You can also access certain functions by touching the area

below the <Display> and <Override> buttons. The sensor has 3

LEDs—one to indicate an Override, one to indicate an Alarm, and one

to indicate that a button has been pressed. See Figure 2 for LED and

Button Descriptions.

An icon for the current mode of operation will appear in the sensor

display. The operation mode icons are a Snowfl ake for Cooling Mode,

a Flame for Heating Mode, a Fan in motion for Vent Mode, and a Moon

for Unoccupied Mode. When the unit is in Unoccupied Mode, the

screen’s background will turn dark. See Figur e 8, page 6 for examples

of operation modes.

<Display>, <Override>, <Up>, and

LED Operation

Refer to Figure 2 below for LED locations.

Alarm LED: The Alarm LED will blink when there is an alarm from

the Controller.

Sense LED: The Sense LED will blink when the sensor gets a valid

touch.

Override LED: The Override LED is inoperable when in Occupied

Mode. In Unoccupied Mode, if you touch the

Override LED will blink, indicating an override request. The Controller will respond by sending the unit into override. The Override LED

will then stay on for the duration of the Override. Any time the Unit

is in Override, you can request to cancel the override by touching the

<Override> button, and the Override LED will blink. The Unit will

then cancel the override. The Override LED will then turn off.

<Override> button, the

Figure 2: Digital Room Sensor Components

4

Operator Interface

Page 5

DIGITAL ROOM SENSOR

Mounting and Wiring

Environmental Requirements

The Digital Room Sensor needs to be installed in an environment that

does not exceed a temperature greater than 150°F or less than -30°F and

does not exceed 90% relative humidity levels (non-condensing).

Indoor Reading Range

The Digital Room Sensor’s Indoor Reading Range is 40°F to 120°F and

0-100% RH (RH is available on the OE217-01 Model). Its temperature

reading accuracy is +/- .5°F, and its RH reading accuracy is +/-2%. Its

sensor element is the integral communicating digital sensing device or

external Type III Thermistor 10K Ohm @ 77°F.

Outdoor Reading Range

If your Digital Room Sensor is set up to read an Outdoor Air T emperature

Sensor, any outdoor air temperature below -40°F will not appear on the

Digital Room Sensor’s display.

Important Wiring Considerations

The OE217-00 and OE217-01 Space Sensors connect to the VCM-X

Controller, RNE, SA-E-BUS, or VA V/Zone Controller (OE217-00 only)

using various lengths of TSDRSC modular cables connected between

the controller and the sensor. The TSDRSC modular cables should not

run in conduit with other AC line voltage wiring or with any conductors

carrying highly inductive loads. See Figures 17 & 18, page 10 for wiring.

Mounting

CAUTION: Do not touch the front face of the sensor while you

are plugging in the modular sensor cable. Touching the front face

of the sensor while plugging in the cable may prevent proper initialization and keep the buttons on the sensor from working properly.

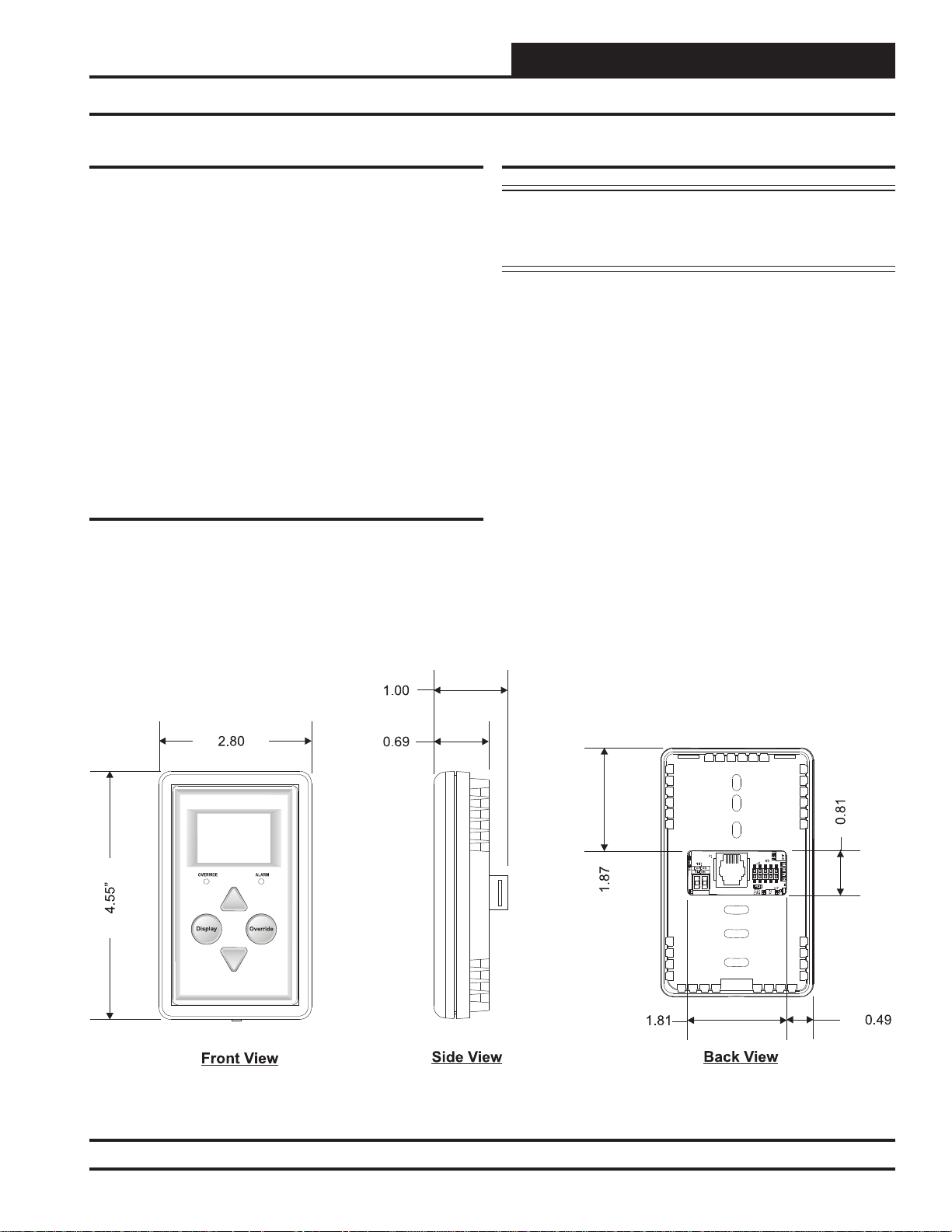

The Digital Room Sensor is designed to be mounted to a vertical 2” x

4” electrical box recessed in the wall. If the wall cannot be penetrated,

a plastic surface mount box such as those made by Wiremold

used to mount the sensor to the wall surface.

The Sensor is mounted by removing the front cover and fastening the

housing base to the electrical box using the supplied (2) 6/32” x 1” machine

screws. The modular cable is then plugged into the phone jack located

on the circuit board that is mounted on the cover. The cover is then

placed onto the housing base, and the Allen Screw on the bottom of the

base is adjusted to hold the cover in place. A locking screw secures the

sensor to the wall. See Figure 3 for Digital Room Sensor dimensions.

Optional Mounting Plate

Included with the Digital Room Sensor is a mounting plate that

can be used, if necessary, to cover the sensor sheet rock opening.

This mounting plate screws onto the back of the housing base.

The mounting plate is then mounted and covers the recessed space

in the wall. A locking screw secures the sensor to the wall. See

Figure 20, page 12 for dimensions.

TM

may be

Figure 3: Digital Room Sensor Dimensions

Operator Interface

5

Page 6

DIGITAL ROOM SENSOR

Sensor Operation

Main Sensor Display Screens

There are 3 Main Sensor Display Screens. The fi rst screen displays

the Current Room Temperature or Cooling/Heating Setpoint, Operation Mode, Slide Offset, and RH (RH is available on the OE217-01

Model). The second screen displays the Outside Air Temperature and/

or Humidity if Outdoor Air Temperature and/or Outdoor Air Humidity

is being monitored. The third screen displays the unit information for

the controller that the Digital Room Sensor is connected to.

Temperature and Humidity Status

Screen

The Main Display Screen dis-

plays the current room temperature or Cooling/Heating

Setpoint, the humidity in the

room (RH is available on the

OE217-01 Model), the current

setting of the slide offset, and

an icon for the current mode of

Figure 4: Main Display

Screen

The different icons shown are a Snowfl ake for cooling mode, a Flame for

heating mode, a Fan in motion for vent mode, and a Moon for unoccupied

mode. When the unit is in unoccupied mode, the screen’s background

will turn dark. Refer to Figure 8 for operation mode screen examples.

operation once the controller it is

connected to is done calibrating.

Setpoint Adjust Screen

Touching <> or <> will dis-

play the Setpoint Adjust Screen.

You can adjust the cooling and

heating setpoints from this screen

based on the VCM-X controller

or VAV/Zone controller slide offset setpoint. For example, if the

connected controller’s Max Slide

Figure 7: Setpoint Adjust

Screen

NOTE: If the VCM-X Controller or VAV/Zone Controller’s slide

offset setpoint is set to Zero, this screen will not appear

when you touch <> or <>.

Offset Setpoint is set for fi ve, you

can adjust the setpoint up fi ve

degrees and down fi ve degrees.

Cooling Mode

with Snowfl ake Icon

Outside Air Temperature Humidity

Status Screen

If the connected controller is

receiving an outdoor air temperature and/or humidity broadcast,

touching <Display> will fi rst

bring up the Outdoor Status

Screen.

Figure 5: Outdoor Status

Screen

Unit Information Screen

Touching <Display> again will

bring up the Unit Information

Screen which contains the controller’s address or ID number,

screen ID, and software version

of the controller connected to

the sensor.

Figure 6: Unit

Information Screen

Heating Mode

with Flame Icon

Vent Mode

with Fan in Motion Icon

Unoccupied Mode

with Moon Icon

Figure 8: Operation Mode Screens

6

Operator Interface

Page 7

DIGITAL ROOM SENSOR

Troubleshooting

Temperature – Resistance – Voltage for

Type III 10K Ohm Thermistor Sensors

Temp

(ºF)

-10 93333

-5 80531

0 69822

5 60552

10 52500

15 45902

20 40147

25 35165

30 30805

35 27140

40 23874

45 21094

50 18655

52 17799

54 16956

56 16164

58 15385

60 14681

62 14014

64 13382

66 12758

68 12191

69 11906

70 11652

Resistance

(Ohms)

Temperature – Resistance – Voltage for

Type III 10K Ohm Thermistor Sensors

Temp

(ºF)

71 11379

72 11136

73 10878

74 10625

75 10398

76 10158

78 9711

80 9302

82 8893

84 8514

86 8153

88 7805

90 7472

95 6716

100 6047

105 5453

110 4923

115 4449

120 4030

125 3656

130 3317

135 3015

140 2743

145 2502

150 2288

Table 1: Temperature/Resistance for Type III 10K Ohm Thermistor Sensors

Resistance

(Ohms)

T

9302

+

-

TSDRSC Cable

Disconnected

Sensor To The

VAV/Zone or VCM-X

Controller Modular

Sensor Port

Figure 9: Temperature/Resistance Testing

Operator Interface

-

From

+

Digital Room Sensor

Back View

NOTE: ,

For This Test The Sensor Must Be Disconnected From

Its TSDRSC Cable As Shown. The Meter Must Be Set To

Measure Resistance in Ohms. Use To Determine If The

Sensor Is Reading The Correct Resistance Value For The

Ambient Temperature. This Resistance Value Should Match The

Temperature Value Listed Next To The Resistance Value In The

Table. The Temperature Should Be Measured With A Separate

Accurate Temperature Measuring Device Located In The Area

Where The Sensor Is Currently Located.

Test Points Labeled

“Extern Therm” On

Sensor Circuit Board

256GP206

PIC24HJ

MICROCHIP

Table 1

7

Page 8

DIGITAL ROOM SENSOR

Appendix

Sensor Confi guration and Test

Screens

To access the Sensor Confi guration & Test Screens, you fi rst need to

access the Unit Information Screen by touching <Display> while at

the Main Display Screen.

NOTE: While in the Sensor Confi guration & Test Screens, the

<Display> button functions as an exit key to return to the

previous screen or menu. After a few seconds, however ,

the sensor will automatically revert to the Main Display

Screen. Refer to Figure 10 when reading the instructions

that follow.

Figure 10: Digital Room Sensor Buttons

Pixel Test Screen

To select the first option—

Pixels—touch <> while at

the Sensor Configuration &

Test Screen (Figure 11). The

Pixel T est Screen tests the pixels

of the LCD display, allowing

you to make the screen white

with black characters, black

Figure 12: Sensor Info &

LED Test Screen

with white characters, or a

black or white screen. To exit

this screen, touch

Sensor Info & LED Test Screen

To select the second option—

Info & LEDS—touch < >

while at the Sensor Confi gura-

tion & Test Screen (Figure 11).

The Sensor Info & LED Test

Screen shows the version of

software that the sensor is run-

Figure 13: Sensor Info &

LED Test Screen

ning and allows you to test the

LEDs that are used on the controller. Touching <> will turn

the LEDs on and touching <>

will turn the LEDs off. To exit

this screen, touch <Display>.

<Display>.

Sensor Confi guration & Test Screen

While the Unit Information

Screen is being displayed, you

can enter the Sensor Confi gura-

tion & Test Screen options by

touching simultaneously below

the <Display> and <Over-

ride> buttons. (See Figure 10

Figure 11: Sensor

which shows where to touch to

access this option.)

Confi guration & Test

Screen

8

Operator Interface

Page 9

DIGITAL ROOM SENSOR

Appendix

LCD Backlight Test Screens

Figure 14: Backlight Test

& Confi guration Screen

Thermistor Averaging Screen

Figure 15: Temperature

Averaging Screen

To select the third option—

BACKLT—touch <Override>

while at the Sensor Confi guration

& Test Screen (Figure 11). This

option allows you to control

when the LCD backlight turns

on and off. You can confi gure the

backlight to stay on at all times,

remain off at all times, or to come

on when any button is touched on

the sensor.

To exit this screen, touch

play>

.

To select the fourth and fi nal op-

tion—THRM AVG—, while at

the Sensor Confi guration & Test

Screen (Figure 1 1), touch simul-

taneously below the

and <Override> buttons. (See

Figure 10 which shows where to

touch to access this option.)

This option allows you to set the

rate—from 1-15 seconds—at

which the sensor takes a new

temperature reading. Touch <>

to increase the number of seconds

and touch <> to decrease the

number of seconds.

<Dis-

<Display>

Display Options - Temperature/Setpoint

To access the Display Options

DSPLY OPTIONS

UP = SETPOINT

DOWN = TEMP

TEMPERATURE

Figure 16: Address

Screen

Screen, while at the Thermistor

Averaging Screen, (Figure 15),

touch the <Override> button.

This option allows you to set the

main screen display. Touch <>

to display the Cooling/Heating

Setpoint on the Main Display

Screen. Touch <> to display

the current room temperature on

the Main Display Screen. The

default is temperature.

If the Setpoint option is chosen,

when the unit is in the Cooling

Mode, the Cooling Setpoint

will appear on the Main Display

Screen. When the unit is in the

Heating Mode, the Heating Setpoint will appear on the Main

Display Screen. When the unit

is in Unoccupied Mode or Vent

Mode, the setpoint that appears

on the Main Display Screen will

be half way between the Cooling

and Heating Setpoint.

To exit this screen, touch

<Display>.

To exit this screen, touch <Dis-

.

play>

NOTE: The sensor takes the average of the last 10 readings based

on the number that is entered in this screen. For example,

if you want a 3-second sample, the sensor will take the

average of the last 10 readings every 3 seconds over a

30-second span. Therefore, if you have your sensor next

to an outside doorway, you would want to enter a higher

number for your sample to give a more accurate reading for the room temperature in case the outside door is

opened often.

Operator Interface

9

Page 10

DIGITAL ROOM SENSOR

Appendix

OE742/OE744 VAV/Zone Controller Actuator Package

NOTE: If Also Using An OE256-01

Or OE256-02 C Sensor,T

Sensor

Controller First Using A TSDRSC

Cable Of The Length. The

Digital Room Sensor Then Connects

To The CO Sensor With Another

TSDRSC Cable.

Cable For Either One Or Both Cables

Combined Cannot Exceed 160 Feet.

See The

O

2

Connects To The VAV/Zone

Required

2

The Total Length Of

CO2Sensor Technical Guide

he CO

2

For Further Wiring Details.

OVERRIDE ALARM

Display

Override

OE217-00

Digital Room Sensor

Figure 17: Digital Room Sensor to VAV/Zone Controller Wiring

OE332-23E-VCMX

VCM-X E-BUS Controller

93C66

ACTUATOR

EEPROM

(-)LO

PAL

EPROM

EXPANSION D'STAT SPACE SENSOR

TSDRSC Cable

ADDRESS

OFF ON

AIR FLOW

SENSOR

485

VELOCITY

HI(VAV)

LOW(VVT)

WDOG

AIRFLOW

IN

GND

MADEINUSA

OUT

WATTMASTERCONTROLSINC

DRV

STAT

POWER / COMM

REC

NOTE: If Also Using An OE256-01

Or OE256-02 CO Sensor, The CO

Sensor Always Connects To The

VCM-X Controller First Using A

TSDRSC Cable Of The Required

Length. The Digital Room Sensor

Then Connects To The CO Sensor

With Another TSDRSC Cable.

The Total Length Of Cable For Either

One Or Both Cables Combined

Cannot Exceed 160 Feet. See The

CO2Sensor Technical Guide

Further Wiring Details.

22

2

For

OVERRIDE ALARM

Display

Override

OE217-00 Or OE217-01

Digital Room Sensor

RS-485 COMMUNICATION LOOP. WIRE

“R”TO “R”, “T” TO “T” “SHLD” TO “SHLD”

RS-485 COMMUNICATION LOOP. WIRE

“R”TO “R”, “T” TO “T” “SHLD” TO “SHLD”

www.aaon.com

www.orioncontrols.com

www.orioncontrols.com

VCM-X MODULAR E-BUS CONTROLLER

Orion No.:OE332-23E-VCMX-MOD-A

OE332-23-VCMX-AVCM-X CONTROLLER

AI1= SPC (SPACE TEMPERATURE SENSOR)

AI1= SPC (SPACE TEMPERATURE SENSOR)

= SAT(SUPPLY AIRTEMPERATURE SENSOR)

AI2

AI2

= SAT(SUPPLY AIRTEMPERATURE SENSOR)

= RAT(RETURN AIR TEMPERATURE SENSOR)

AI3

AI3

= RAT(RETURN AIR TEMPERATURE SENSOR)

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI4

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI4

= SUCTION PRESSURE SENSOR (FROM EXP. MODULE)

AI5

= SUCTION PRESSURE SENSOR

AI5

= SPACETEMPERATURE SENSOR SLIDE ADJUST

AI7

= SPACETEMPERATURE SENSOR SLIDE ADJUST

AI7

OR VOLTAGE RESETSOURCE

OR VOLTAGE RESETSOURCE

= ECONOMIZER (2-10 VDC OUTPUT)

A01

= ECONOMIZER (2-10 VDC OUTPUT)

A01

= SUPPLYFAN VFD (0-10 VDC OUTPUT)

A02

= SUPPLYFAN VFD (0-10 VDC OUTPUT)

A02

E-BUS

CONNECTOR

ANALOG INPUT

ANALOG INPUT

JUMPER

JUMPER

SETTINGS

SETTINGS

THERM

LEDNAME STATUS1 STATUS2

THERM

4-20mA

4-20mA

AI1

AI1

0-10V

NORMALOPERATION 0 1

0-10V

0-5V

0-5V

SATFAIL 1 2

THERM

THERM

OATFAIL 2 2

4-20mA

4-20mA

AI2

AI2

SPCFAIL 3 2

0-10V

0-10V

0-5V

0-5V

MODULEALARM 4 2

THERM

THERM

MECHCOOL FAIL 1 3

4-20mA

4-20mA

AI3

AI3

MECHHEAT FAIL 2 3

0-10V

0-10V

0-5V

0-5V

FANPROOF FAIL 3 3

THERM

THERM

DIRTYFILTER 4 3

4-20mA

4-20mA

AI4

EMERGENCYSHUTDOWN 5 3

AI4

0-10V

0-10V

0-5V

0-5V

LOWSAT 1 4

THERM

THERM

HIGHSAT 2 4

4-20mA

4-20mA

AI5

AI5

CONT.TEMP COOL FAIL 3 4

0-10V

0-10V

0-5V

CONT.TEMP HEAT FAIL 4 4

0-5V

THERM

PUSHBUTTON OVR 1 5

THERM

4-20mA

4-20mA

AI7

ZONEOVR 2 5

AI7

0-10V

0-10V

OUTPUTFORCE ACTIVE 0 6

0-5V

0-5V

ANALOG INPUTJUMPER SETTINGS

ANALOG INPUTJUMPER SETTINGS

MUSTBE SET AS SHOWN FOR

MUSTBE SET AS SHOWN FOR

PROPER OPERATION

PROPER OPERATION

STATIC

WattMaster Label

WattMaster Label

STATIC

#LB102073-01-A

PRESSURE

#LB102033-01

PRESSURE

Rev.: 1A

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

LEDBL INKCODES

24 VAC POWER ONLY

WARNING!POLARITY MUST BE OBSERVED

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILLBE DAMAGED

OR THE CONTROLLER WILLBE DAMAGED

2

2

IC

IC

EXPANSION

EXPANSION

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY

COMMON

RELAY

COMMON

RELAY2

RELAY2

RELAY3

RELAY3

RELAY4

RELAY4

RELAY5

RELAY5

AAON No.:

24 VAC POWER ONLY

TSDRSC Cable

FAN

FAN

V07150

2

2

IC DIGITAL

IC DIGITAL

SENSOR

SENSOR

POLARITY

OBSERVE

WARNING

Figure 18: Digital Room Sensor to VCM-X E-BUS Controller Wiring

10

Operator Interface

Page 11

DIGITAL ROOM SENSOR

Appendix

Connecting a Remote Sensor

NOTE: The following directions are for the OE217-00 Space

Temperature Only E-BUS Digital Room Sensor. If you

are using an OE217-01 Space T emperature and Humidity

Model, please contact WattMaster T echnical Support for

instructions.

Sometimes due to the requirements of a job, the sensor must be located

outside the conditioned space due to special requirements such as

hospital surgical room codes, security, or tampering considerations.

In these cases, the Digital Room Sensor can be mounted in a different

room and have a remote sensor connected to it. T ypically , this would be

a Return Air Duct Temperature Sensor. Usually, you will be using the

OE231 Return Air Temperature Sensor , but you can also use any T ype III

10K Ohm Thermistor Sensor.

To connect a remote sensor to the Digital Room Sensor, you must fi rst

remove the Digital Sensor’s back cover. Y ou will see a loop of wire hanging off of the sensor circuit board. See Figure 19. This is the external

thermistor loop wire. Clip the external thermistor loop wire so that the

sensor will read the remote temperature input. Be sure to cut the ends

of the wire close to the circuit board so that the sensor loop wire ends

won’t short between each other. The remote sensor then wires to the

remote sensor terminal block on the back of the Digital Room Sensor.

If using the W attMaster OE210 type Space Sensor as the remote sensor ,

you must clip off the yellow C1 capacitor from the back of the OE210.

Be sure to cycle power to begin reading the remote sensor.

MICROCHIP

256GP206

PIC24HJ

Cut Wire Loop As Shown.

Make Sure That The Wires

Are Cut Close Enough To

The Circuit Board So They

Can’t Touch Each Other.

OE231 Return Air

Temperature Sensor

Return

Air Duct

OE217-00 Digital Room Sensor Back View

Mount Sensor In Return Air

Duct As Shown. Route Wires

To Digital Room Sensor

Location And Connect To

Terminal Block.

OE217-00 Digital Room Sensor Back View

Sensor Shown With

Back Cover Removed

MICROCHIP

256GP206

PIC24HJ

Sensor Shown With

Back Cover Removed

Figure 19: Attaching a Remote Sensor

Operator Interface

11

Page 12

DIGITAL ROOM SENSOR

1.638

1.810

0.882

1.407

1.842

0.733

2.110

2.920

0.810

R0.220

3.275

0.060

0.160

5.037

3.278

3.766

4.153

Mounting Plate Dimensions

Optional Mounting Plate

Included with the Digital Room Sensor is a mounting plate that

can be used, if necessary, to cover the sensor sheet rock opening.

This mounting plate screws onto the back of the housing base.

The mounting plate is then mounted and covers the recessed space

in the wall. A locking screw secures the sensor to the wall. See

Figure 20, below for dimensions.

Figure 20: BK000081 Mounting Plate Dimensions

12

Operator Interface

Page 13

DIGITAL ROOM SENSOR

Notes

Operator Interface

13

Page 14

DIGITAL ROOM SENSOR

Notes

14

Operator Interface

Page 15

DIGITAL ROOM SENSOR

Notes

Operator Interface

15

Page 16

Form: OR-DRS-TGD-01K Printed in the USA May 2015

All rights reserved. Copyright 2015

WattMaster Controls Inc. 8500 NW River Park Drive Parkville, MO 64152

Phone: 866-918-1100 www.orioncontrols.com Fax (816) 505-1101

Loading...

Loading...